Page 1

FESTOOL GmbH

Wertstrasse 20

D-73240 Wendlingen

Tel.: 07024/804-0

Telefax: 07024/804-608

E-Mail: info@tts-festool.com

Originalbedienungsanleitung/Ersatzteilliste 4 - 9

Original operating manual/Spare parts list 10 - 15

Notice d’utilisation d’origine/Liste de pièces de rechange 16 - 21

Manual de instrucciones original/Lista de piezas de repuesto 22 - 27

Istruzioni per l’uso originali/Elenco parti di ricambio 28 - 33

Originele gebruiksaanwijzing/Lijst met reserveonderdelen 34 - 39

Originalbruksanvisning/Reservdelslista 40 - 44

Alkuperäiset käyttöohjeet/Varaosaluettelo 45 - 49

Original brugsanvisning/Reservedelsliste 50 - 54

Originalbruksanvisning/Reservedelsliste 55 - 59

Manual de instruções original/Lista de peças sobresselentes 60 - 65

Оригинал Руководства по эксплуатации/Перечень запасных частей 66 - 71

Originál návodu k obsluze/Seznam náhradních dílù 72 - 76

Oryginalna instrukcja eksploatacji/Lista części zamiennych 77 - 82

RAS 180.03 E-HR

468094_001

Page 2

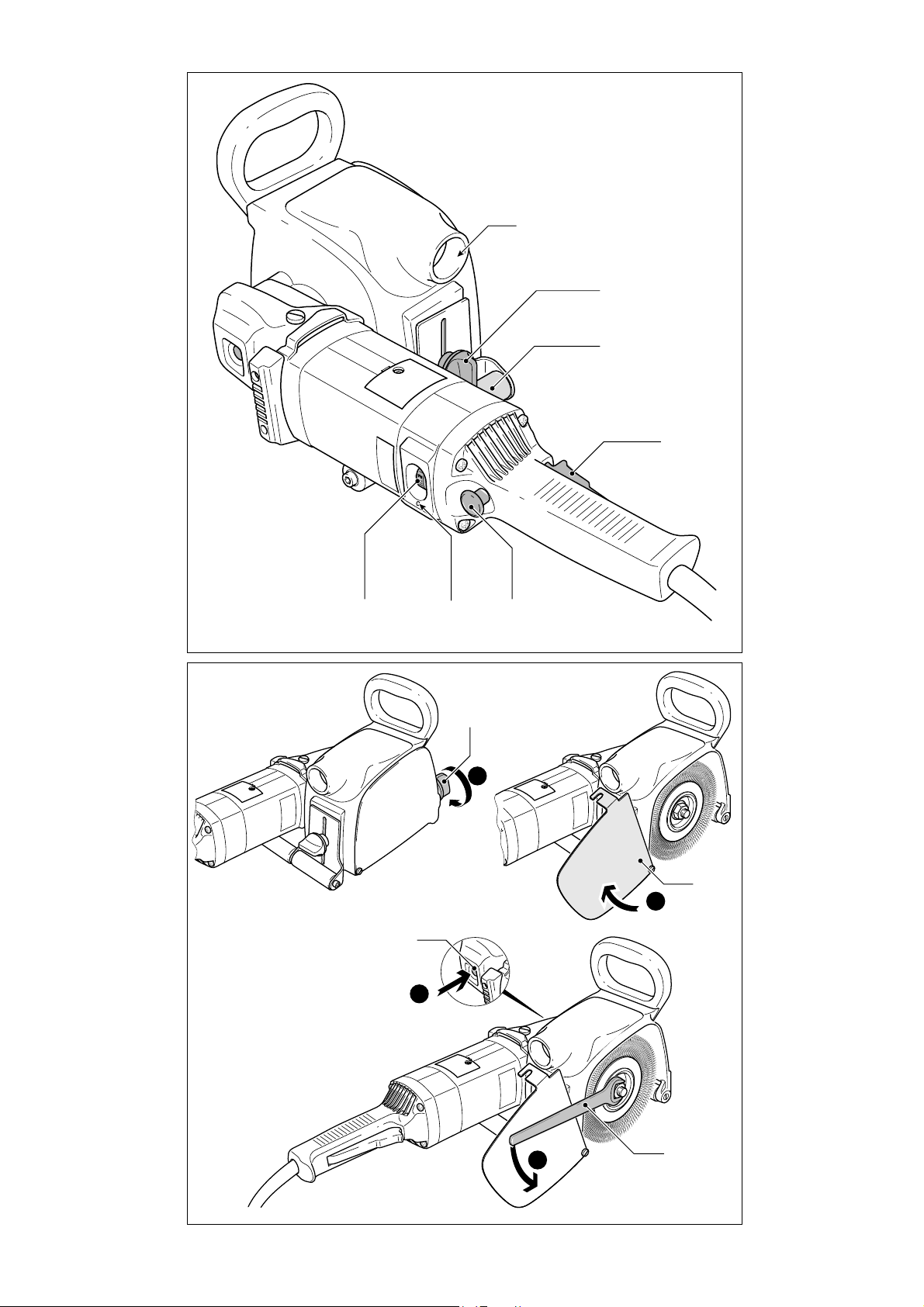

1-7

1-6

1-5

1-1

1

1-4

1-3 1-2

2-1

1

2-2

2

2-3

3

2

4

SW 24

Page 3

RUSTOFIX RAS 180.03 E-HR

Table of contents

1 Symbols

2 Technical data

3 Machine features

4 Intended use

5 Safety instructions

5.1 General safety instructions

5.2 Machine-related safety instructions

5.3 Emission levels

6 Commissioning

7 Machine settings

7.1 Electronics

7.2 Changing the brushes

7.3 Adjusting the texture depth

7.4 Dust extraction

8 Working with the machine

9 Service and maintenance

10 Disposal

11 Accessories

12 Warranty

13 Declaration of Conformity

The specifi ed illustrations are at the begin-

ning of this operating manual.

3 Machine features

[1-1] On/off switch

[1-2] Switch-on lock

[1-3] LED

[1-4] Speed control

[1-5] Support roller

[1-6] Depth adjustment wheel

[1-7] Extractor connector

4 Intended use

According to specifi cations, the machine

is designed to brush and texture wooden

surfaces.

The user bears the responsibility for damage

and accidents caused by improper use.

5 Safety instructions

5.1 General safety instructions

- Before using the machine, carefully read

all of the attached safety instructions and

the operating manual.

- Keep all of the accompanying documents

and pass on the documentation if the machine changes ownership.

- Never allow children to use the machine.

1 Symbols

Warning of general danger

Electric shock

Read the operating instructions/

notes

2 Technical data

Power consumption 1500 W

Rotational speed 800 – 4000 rpm

Tool dia. 150 mm

Spindle thread M 14

Dust extractor connection diameter 27

mm

Protection class / II

Weight 7.5 kg

5.2 Machine-related safety in-

structions

- This machine is designed for brushing.

Please read all of the safety information,

instructions, illustrations and descriptions

delivered with the machine. If the following instructions are not observed, this

can result in an electric shock, fi re and/or

serious injury.

- Work such as roughing, polishing or abrasive cutting must not be carried out with

this machine. Performing tasks for which

the machine is not designed can create

hazards and lead to injury.

- Never use accessories that were not specially developed and designed for this

machine. Just because an accessory part

can be fi tted on your machine does not

guarantee danger-free operation.

- The permissible rotational speed of the

accessory must be at least as high as the

10

Page 4

maximum speed specifi ed on the machine.

Accessories that rotate faster than the

permissible level can rupture.

- The outside diameter and the thickness of

the accessory must be within the specifi ed

size range of the machine. Accessories

with incorrect dimensions cannot be suffi ciently protected or controlled.

- The bore diameter of discs, fl anges, sup-

port plates and all other accessories must

fi t the machine spindle exactly. Accessories with an unsuitable diameter are out

of round, vibrate excessively and lead to

loss of control.

- Do not use damaged accessories. Check

accessories such as wire brushes for loose

or broken wires before using. Every time

the machine is dropped, check the machine

and accessories for damage, or install undamaged accessories. Following the check

and assembly of accessories, ensure that

all persons are beyond the rotating range

of the tool and run the machine for one

minute at maximum speed. Damage accessories usually break completely during

this test time.

- Wear personal protective equipment. Depending on the application, use a shield

or protective goggles. If practical, wear a

dust mask, ear protection, safety gloves

and a work apron suitable to protect

against impact or small sanding or workpiece parts. The protective goggles must

be capable of blocking fl ying debris caused

by the various work operations. The dust

mask or device must be capable of fi ltering

particles generated during work. Continuous exposure to loud noise can cause loss

of hearing.

- Ensure that persons standing near the

machine are at a safe distance from the

work area. All persons in the work area

must wear personal protective equipment.

Parts of the workpiece or broken accessories can fl y off and cause injury outside

the immediate work area.

- Keep the power cable away from rotating parts. If you lose control, the power

cable could be cut or become stuck and

your hand or arm could be drawn into the

rotating parts.

- Never set the machine down until the tool

has stopped completely. Turning tools can

catch on the storage area, causing you to

lose control of the machine.

- Never allow the machine to operate while

carrying it at your side. The rotating tool

can catch on your clothing by accident and

cause serious cutting injuries.

- Clean the cooling air openings on your

machine on a regular basis. The cooling

air fan sucks the dust into the machine

and excessive deposits of metal dust can

result in electrical hazards.

- Never operate the machine near combustible materials. Sparks can ignite these

materials.

- Never use tools that have to be liquidcooled. Water and other liquid coolants can

cause potentially fatal electric shocks.

Cause and prevention of kickbacks

A kickback is a sudden reaction to jamming

or catching of a rotating disc, a support

plate, a brush or other accessory. Jamming

or catching results in a rapid standstill of

the rotating accessory, whereby, as a counter-reaction, an out-of-control machine is

accelerated around the jamming point in

a direction of rotation opposed to the accessory. If, for example, a sanding disc is

jammed or caught by the workpiece, the disc

circumference can dig into the workpiece

surface at the jamming point, causing the

disc to be expelled. The disc can either fl y

towards or away from the user, depending

on the direction of rotation of the disc at the

jamming point.

This can also cause sanding discs to break.

A kickback is the result of misuse of the

machine and/or incorrect method of work

or operation and can be avoided by closely

observing the following precautionary measures.

- Always hold the machine fi rmly and po-

sition your body and arm such that you

can control any kickback force. Always

use the additional handle, if included in

the delivery, to ensure optimum control

over kickbacks or reaction torques during

start-up. The user can control reaction torques or kickbacks if suitable precautionary

measures are taken.

- Never place your hands near rotating tools.

Tools can kick back over your hand.

- Never position your body in the area in

which the machine moves in the event of

11

Page 5

a kickback. A kickback accelerates the machine in the direction of rotation opposed

to the disc at the jamming point.

- Take particular care when working in corners, on sharp edges, etc. Take care to

prevent the machine from jumping back or

getting caught. Corners, sharp edges or a

jump back tend to cause the rotating tool

to catch, thus leading to a loss of control

or a kickback.

- Never install a chainsaw or saw blades

with teeth to cut wood. Such blades often

cause kickback and loss of control.

Special safety instructions for brush-

ing

- Remember that the brush may scatter

wires in all directions during normal use.

Do not place the brush under excessive

strain and risk breaking the wires. Wires

can easily penetrate thin clothing and

skin.

- If the wire brushes require a protective

cover during use, prevent the wire brush/

disc from making any kind of contact with

the protective cover. The working and centrifugal forces that occur during operation

may increase the diameter of the wire

brushes/discs.

5.3 Emission levels

Levels determined in accordance with EN

60745 are typically:

Sound pressure level 84 dB(A)

Noise level 95 dB(A)

Measuring uncertainty allowance K = 4 dB

Measured acceleration 3 m/s

The noise produced during work

may damage your hearing.

Always use ear protection.f

WARNING

2

6 Commissioning

Risk of accident if the machine is operated using unauthorised voltages or

frequencies.

- The mains voltage and the frequency of

the power source must correspond with

the specifi cations on the machine’s name

plate.

- In North America, only Festool machines

with a voltage specifi cation of 120 V/60

Hz may be used.

The tool is fi tted with an on/off switch [1-1]

with switch-on lock [1-2]. Press the switchon lock to release the switch. Pressing and

holding the switch-on lock briefl y after the

machine starts locks the switch while the

motor is running. The motor switches off

when you press the on/off switch again.

WARNING

7 Machine settings

Risk of accident, electric shock

Always pull the plug out of the socket

f

before performing any type of work on

the machine.

7.1 Electronics

The machine features full-wave electronics

with the following features:

Smooth start-up

The electronically controlled smooth startup ensures that the machine starts up joltfree.

Speed control

You can regulate the rotational speed steplessly between 800 and 4000 rpm using the

adjusting wheel [1-4].

The following table serves as a guideline to

help you select the best electronics setting

for the working material. The transition between each speed setting is smooth.

WARNING

12

Page 6

Processed material

Working procedure

Rustic texture

on wood (LD 85) 3 - 5

Brushing

wood (KB 80) 2 - 3

Brushing

stained parts (BG 85) 2 - 3

Constant speed

The preselected motor speed remains constant through electronic control. This ensures a uniform cutting speed even when

under load.

Overload safety device

In extreme applications, the current consumption may far exceed the permitted

nominal value. A "safety coupling" integrated

in an electronic overload safety device

switches off the motor and prevents it from

burning out. Motor operation resumes immediately after the load is relieved.

Temperature cut-out

To protect against overheating (burning out

of motor), an electronic temperature monitoring system has been installed. Prior to

reaching a critical motor temperature, the

safety electronics switches off the motor.

After a cooling time of approx. 3-5 minutes,

the machine can be operated again at full

load. The machine requires less time to cool

down when idling.

Electronics

setting

7.2 Changing the brushes

Loosen the screw [2-1].

f

Swivel the silver cover [2-2] down.

f

Press and hold the spindle lock [2-3] and

f

unscrew the hexagon nut (size 24) on the

brush.

Insert a different brush.

f

Tighten the hexagon nut to secure the

f

brush and then close the silver cover.

For brushes LD 85 and BG 85, use the

L

accompanying centring disc.

7.3 Adjusting the texture depth

Set the required texture depth using the

f

thumbwheel [1-6].

7.4 Dust extraction

Breathing in dust damages the

respiratory passage.

Always connect the machine to a dust

f

extractor.

When performing work that generates

f

dust, always wear a dust mask.

You can connect a Festool extractor to the

extractor connector [1-7]. The extractor

hose in the Festool extractor is 27 mm in

diameter.

CAUTION

LED indicator

The rotary sander is fi tted with an electronic

adjusting wheel and a green and red LED [13]. A green lit LED indicates that the rotary

sander is operating in normal mode. A red

lit LED indicates that the motor is operating

at approx. 70% overload. The overload or

temperature cut-out switches off the motor

if overloaded for longer periods.

However, alternately fl ashing green and red

LEDs indicate that the brushes are completely worn (remaining working hours max.

10 hours). In this case, have an authorised

after-sales service workshop replace the

carbon brushes the next day. Always replace

these brushes with special carbon brushes

available in pairs otherwise the LED indicators will not work.

8 Working with the ma-

chine

The RUSTOFIX gives beams or wooden panelling a rustic texture.

Working method

After the fi rst working procedure with the

wire brush LD 85, protruding fi bres give the

wooden surface a rough feel. In the second

working procedure, plastic bristles KD 80

sand the textured surface to lend a smooth

fi nish.

fAlways guide the machine evenly and in

the direction of the grain.

fHold the machine with both hands to en-

sure safe guidance.

fDo not overload the machine by pressing

with excessive force! The best results are

achieved with moderate application pressure.

13

Page 7

fMaintain the speed specifi ed. (see Chapter

7.1)

Use the correct brush for the relevant

working procedure:

Working procedure

Texturing Rustilon brush LD 85

Intermediate sanding

Smoothing Rustilon brush BG 85 (si-

Note

• Do not use the KD 80 brush with plastic

bristles for texturing. The brush is not

suitable for heavy-duty texturing.

• The BG 85 is the only brush suitable for

processing stained or oiled parts. All other

brushes will be damaged.

Brush

(standard wire brush)

Rustilon brush KB 80

(plastic bristles)

sal bristles)

9 Service and mainte-

nance

EU only: European Directive 2002/96/EC

stipulate that used electric power tools must

be collected separately and disposed of at

an environmentally responsible recycling

centre.

11 Accessories

Use only original Festool accessories and

Festool consumable material intended for

this machine because these components

are designed specifi cally for the machine.

Using accessories and consumable material

from other suppliers will most likely affect

the quality of your working results and limit

any warranty claims.

Machine wear or your own personal workload

may increase depending on the application.

Protect yourself and your machine, and

preserve your warranty claims by always using original Festool accessories and Festool

consumable material!

The order numbers of the accessories and

tools can be found in the Festool catalogue or

on the Internet under "www.festool.com".

Risk of accident, electric shock

f

Always pull the plug out of the socket

before performing any type of work on

the machine.

All maintenance and repair work which

f

requires the housing to be opened must

only be carried out by an authorised

service workshop.

To ensure constant air circulation, always

keep the ventilation openings clean and free

of blockages.

The machine is equipped with self-disconnecting special carbon brushes. If they are

worn, power is interrupted automatically

and the machine comes to a standstill (see

Chapter "Electronics").

WARNING

10 Disposal

Do not throw the power tool in your household waste! Dispose of the machine, accessories and packaging at an environmentallyresponsible recycling centre! Observe the

valid national regulations.

12 Warranty

For our tools, we give warranty for material

and production defects in accordance with

the locally applicable legal provisions, but

in any case for at least 12 months. Within

the EU member states, the warranty period

is 24 months (verifi cation through invoice

or delivery note). Damage caused by the

operator, natural wear, overloading, incorrect handling or through the use of the

equipment not specifi ed in the operating

manual, or damage which was known at the

time of purchase, is not covered by the warranty. Furthermore, damage caused by the

use of non-original Festool accessories and

consumable material (e.g. sanding pads)

is also excluded. Complaints can only be

recognised if the tool is returned while still

assembled to the supplier or an authorised

Festool Customer Service workshop. Keep

the operating manual, safety instructions,

spare parts list and purchase receipt in a

safe place. Otherwise the respective, current warranty conditions of the manufacturer

shall apply.

14

Page 8

Note

Due to continuous research and development work, we reserve the right to make

changes to the technical content of this

documentation.

13 Declaration of Conform-

ity

We declare under sole responsibility that this

product complies with the following norms

or normative documents:

EN 60 745, EN 55 014, EN 61 000 in accordance with the regulations stipulated

in Directives 98/37/EC (until 28 Dec.

2009), 2006/42/EC (from 29 Dec. 2009),

2004/108/EC.

Dr. Johannes Steimel

Head of research and development

Festool GmbH, Wendlingen, Germany

15

Loading...

Loading...