Page 1

706246_004

Instruction manual

Page 3

IMPORTANT: Read and understand all instructions before using.

Guide d’utilisation

Page 11

IMPORTANT: Lire et comprendre toutes les instructions avant de

démarrer les travaux.

Manual de instrucciones

Pagina 20

IMPORTANTE: Lea y comprende todas las instrucciones antes de

usar.

Instruction manual

Guide d’utilisation

Manual de instrucciones

RAS 115 E

Festool GmbH

Wertstrasse 20

73240 Wendlingen

Germany

www.festoolusa.com

Page 2

Page 3

3

About this manual

Save these instructions

It is important for you to read and understand this

manual. The information it contains relates to protecting your safety and preventing problems. The

symbols below are used to help you recognize this

information.

DANGER

Description of imminent hazard

and failure to avoid hazard will

result in death.

WARNING

Description of hazard and

possible resulting injures or

death.

CAUTION

Description of hazard and

possible resulting injuries.

NOTICE

Statement including nature of

hazard and possible result.

HINT

Indicates information, notes, or

tips for improving your success

using the tool.

Safety instructions

Read all safety warnings, instructions, illustrations and specifi cations provided

with this power tool. Failure to follow all instruc-

tions listed below may result in electric shock, fi re

and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR

FUTURE REFERENCE.

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

General safety instructions

1) Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive atmo-

spheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while op-

erating a power tool. Distractions can cause you

to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets

will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase

the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the infl uence of drugs, alcohol or medi-

Contents

About this manual .............................................3

Safety instructions ...........................................3

General safety instructions .............................. 3

General safety instructions for sanding ..........4

Further safety instructions for all operations .. 5

Technical data ..................................................6

Symbols ...........................................................6

Intended use ....................................................6

Electrical connection and operation ................7

Extension cord ..................................................7

Electronic control ............................................7

Tool settings ....................................................7

Extraction hood AH-RAS D 115 ......................... 7

Fitting tool inserts ............................................ 8

Attaching the abrasive .....................................9

Working with the tool .......................................9

Maintenance and care ...................................... 9

Accessories, tools .......................................... 10

Page 4

4

cation. A moment of inattention while operating power tools may result in serious personal

injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your fi nger on the switch or energising

power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away

from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore, tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such preven-

tive safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in

the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

h) Keep handles dry, clean and free from oil and

grease. Slippery handles do not allow for safe

handling and control of the tool in unexpected

situations.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

General safety instructions for sanding

a) This power tool is intended to function as a

sander. Read all safety warnings, instructions,

illustrations and specifi cations provided with

this power tool. Failure to follow all instructions

listed below may result in electric shock, fi re

and/or serious injury.

b) Operations such as grinding, polishing, wire

brushing or cutting-off are not recommended to

be performed with this power tool. Operations

for which the power tool was not designed may

create a hazard and cause personal injury.

c) Do not use accessories which are not specifi -

cally designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safe operation.

d) The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and fl y apart.

e) The outside diameter and the thickness of ac-

cessories must be within the capacity rating of

Page 5

5

your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

f) Threaded mounting of accessories must match

the grinder spindle thread. For accessories

mounted by fl anges, the arbour hole of the

accessory must fit the locating diameter of

the fl ange. Accessories that do not match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may cause

loss of control.

g) Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install

an undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged ac-

cessories will normally break apart during this

test time.

h) Wear personal protective equipment. De-

pending on application, use face shield, safety

goggles or safety glasses. As appropriate, wear

dust mask, hearing protectors, gloves and shop

apron capable of stopping small abrasive or

workpiece fragments. The eye protection must

be capable of stopping fl ying debris generated by

various operations . The dust mask or respirator

must be capable of fi ltrating particles generated

by your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area must

wear personal protective equipment. Frag-

ments of workpiece or of a broken accessory

may fl y away and cause injury beyond immediate

area of operation.

j) Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the

operator an electric shock.

k) Position the cord clear of the spinning acces-

sory. If you lose control, the cord may be cut or

snagged and your hand or arm may be pulled

into the spinning accessory.

l) Never lay the power tool down until the acces-

sory has come to a complete stop. The spinning

accessory may grab the surface and pull the

power tool out of your control.

m) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

o) Do not operate the power tool near fl ammable

materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid cool-

ants. Using water or other liquid coolants may

result in electrocution or shock.

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation at

the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse and/

or incorrect operating procedures or conditions

and can be avoided by taking proper precautions

as given below.

a) Maintain a fi rm grip on the power tool and po-

sition your body and arm to allow you to resist

kickback forces. Always use auxiliary handle,

if provided, for maximum control over kickback

or torque reaction during start-up. The operator

can control torque reactions or kickback forces,

if proper precautions are taken.

b) Never place your hand near the rotating acces-

sory. Accessory may kickback over your hand.

c) Do not position your body in the area where

power tool will move if kickback occurs. Kick-

Page 6

6

back will propel the tool in direction opposite to

the wheel’s movement at the point of snagging.

d) Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specif-

ic for Sanding Operations

a) Do not use excessively oversized sanding disc

paper. Follow manufacturers recommendations, when selecting sanding paper. Larger

sanding paper extending beyond the sanding

pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

TO REDUCE THE RISK OF INJURY,

USER MUST READ INSTRUCTION MANUAL.

Various dust created by power sanding,

sawing, grinding, drilling and other construction

activities contains chemicals known (to the State

of California) to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products,

• Arsenic and chromium from chemically-treated

lumber.

The risk from these exposures varies, depending

on how often you do this type of work.

To reduce your exposure to these

chemicals work in a well ventilated

area and use approved safety equipment, such as dust masks that are specially designed to fi lter out microscopic

particles.

Technical data

Wattage 500 W

Speed 4000 min

-1

Max. speed* 5000 min

-1

Sanding base dia. 115 mm (4.5 in.)

Spindle thread M 14

Weight 1.6 kg (3.5 lbs.)

Safety level

/ II

*Max. possible speed with faulty electronics.

Symbols

Warning of general danger

Read the Operating Instructions/Notes!

Wear ear protection.

Wear eye protection.

Wear a dust mask!

V Volts

A Amperes

Hz Hertz

W Watt

~ Alternating current

n Speed

Class II Construction

rpm/ min

-1

Revolutions per minute

Ø Diameter

Intended use

The RAS 115 E is designed for sanding wood, plastics, stone, composite materials, paints / lacquers,

fi llers, stoppers and similar materials.

Never use the tool for grinding or cutting metal. Materials containing asbestos must not

be processed.

Never fasten grinding disks on the

tool. Work only with the provided sanding pad and

whereupon fastened abrasives.

The device is unsuitable for wet sanding for reasons of electrical safety.

Page 7

7

If explosive or self-infl ammable dusts are produced

when sanding certain materials, refer to the processing instructions of the material manufacturer.

The user bears sole responsibility for

any damage or accidents resulting from incorrect

use.

Electrical connection and operation

The mains voltage must correspond

to the voltage on the rating plate!

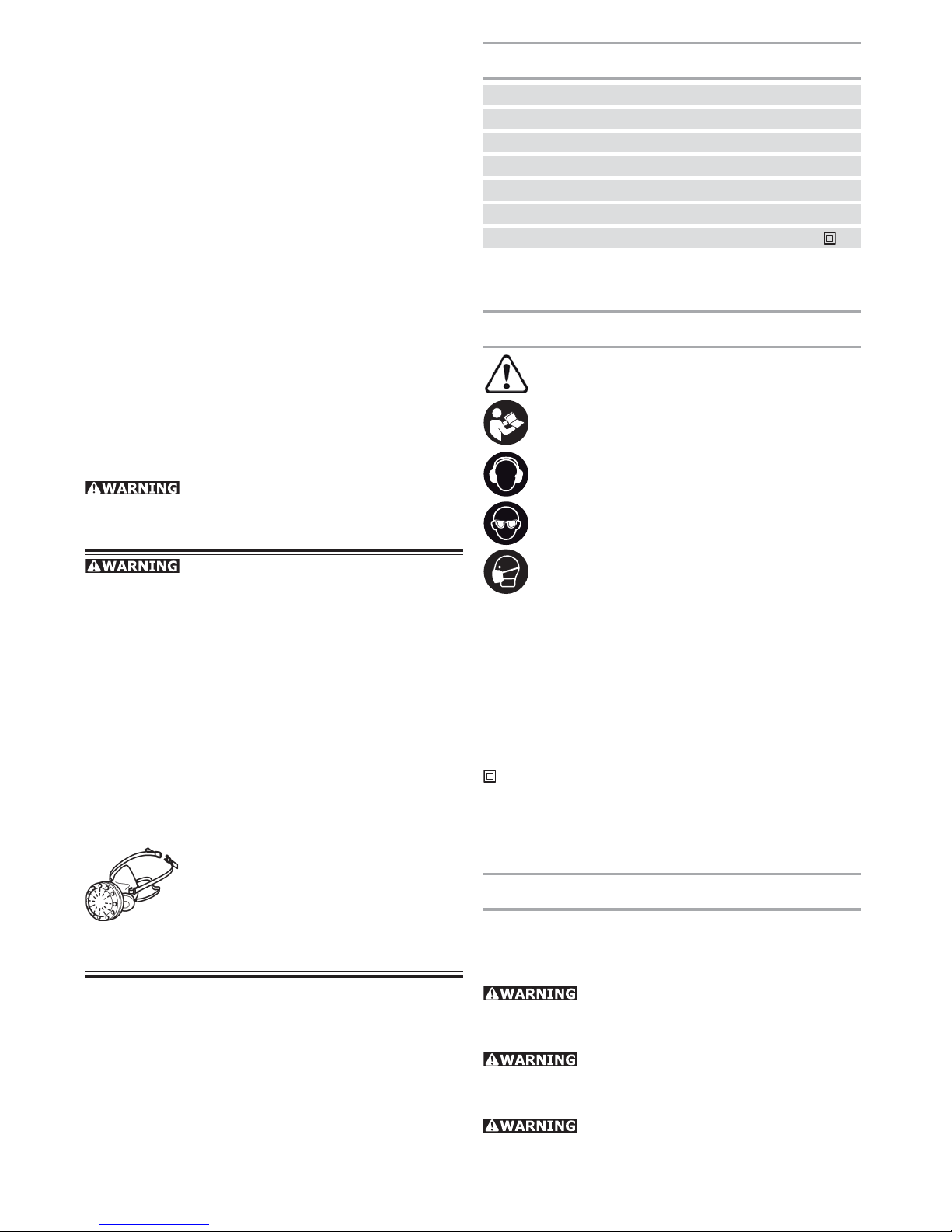

1.1

To switch the tool on, push the safety sliding switch

(1.1) forwards. The tool is switched off by gently

pressing the rear end of the switch.

Extension cord

If an extension cord is required, it must have suffi cient cross-section to prevent an excessive drop

in voltage or overheating. An excessive drop in voltage reduces the output and can lead to failure of

the motor. The table below shows you the correct

cord diameter as a function of the cord length for

the RAS 115 E.

Total Extension Cord

Lenght (feet)

25 50 100 150

Cord size (AWG) 18 16 16 14

Use only U.L. and CSA listed extension cords. Never

use two extension cords together. Instead, use one

long one.

Note: The lower the AWG number, the stronger the

cord.

Electronic control

The tool has full-wave electronics with the following features.

Do not use the rotary sander if the

electronic control is defective, since this can lead

to excessive speeds. A defect of this kind can be

recognized by the fact that the smooth run-up is

absent, the noise level under no-load conditions is

higher or the speed cannot be controlled.

Speed adjustment

2.1

You can regulate the speed steplessly between

1500 and 4000 rpm using the adjusting wheel (2.1).

This lets you optimize the sanding speed to suit the

material (see "Working with the tool").

Smooth start-up

The smooth start-up ensures jolt-free startup.

Constant speed

The pre-selected speed remains constant whether

the tool is in operation or in neutral position.

Temperature control

To prevent overheating, the safety electronics

switch the tool off when it reaches a critical motor

temperature. Let the tool cool down for approx. 3-5

minutes before using it again. The tool requires

less time to cool down if it is running, i.e. in neutral

position.

Tool settings

Always remove the power plug from

the socket before carrying out any work on the

power tool.

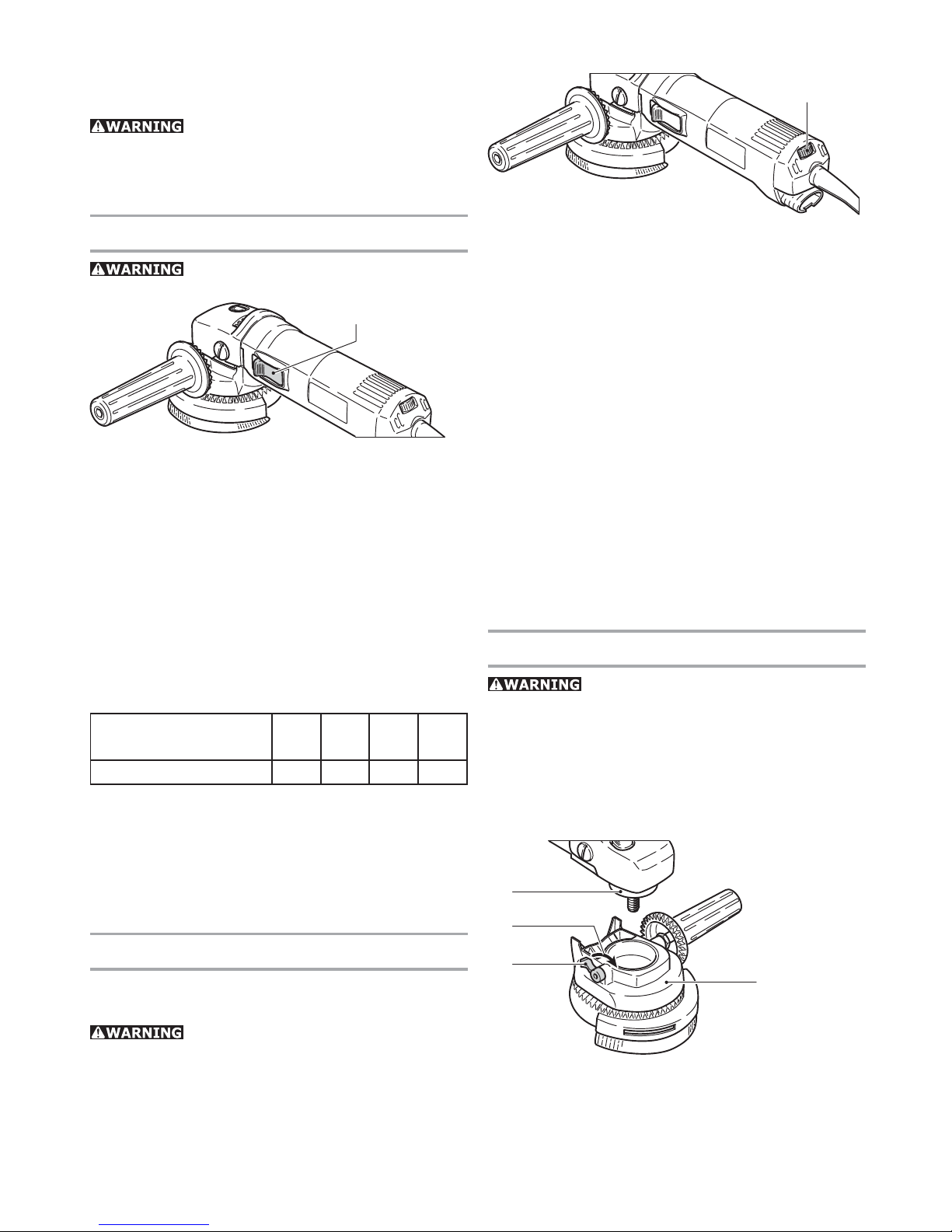

Extraction hood AH-RAS D 115

The extraction hood AH-RAS D 115 (3.1) can be used

in conjunction with the sanding pads STF D 115.

3.4

3.2

3.3

3.1

a) Fitting

Before fi tting the extractor hood, ensure that the

clamping lever is in “released” position (3.4). Press

the extractor hood onto the clamping throat (3.2) of

Page 8

8

the rotary sander and secure the hood by moving

the clamping lever forward (3.3).

4.1

4.2

4.5

4.4

4.3

Do not work with the machine unless the extractor

hood is clamped fi rmly and securely to the clamping throat. If the clamping force is reduced as the

result of frequent use, the clamping lever can be

re-adjusted.

–Release the screw (4.1) on the clamping lever and

remove the lever (4.2).

–Tighten the square-headed screw (4.3) by hand

until a tension is obtained.

–Re-fi t the clamping lever and secure it with the

screw. The optimum clamping force can be determined by closing the clamping lever before the

clamping screw is tightened.

b) Repositioning the rotatable handle

The rotatable additional handle can, if required, also

be fi tted to the right-hand side of the extractor hood.

For this purpose, the handle and the clamping lever

should be interchanged.

–Release the screw (4.1) on the clamping lever and

remove the lever (4.2).

–Remove the square-headed screw (4.3).

–Detach the additional handle (4.5), using a 6 mm

A/F Allen key.

The clamping lever and the additional handle can

now be interchanged. Fitting is carried out in the

reverse of the above sequence. The locking nut

(4.4) can be used to vary the turning resistance of

the rotatable additional handle by tightening the

nut against the housing, using a 13 mm A/F openended wrench, before fully tightening the additional

handle.

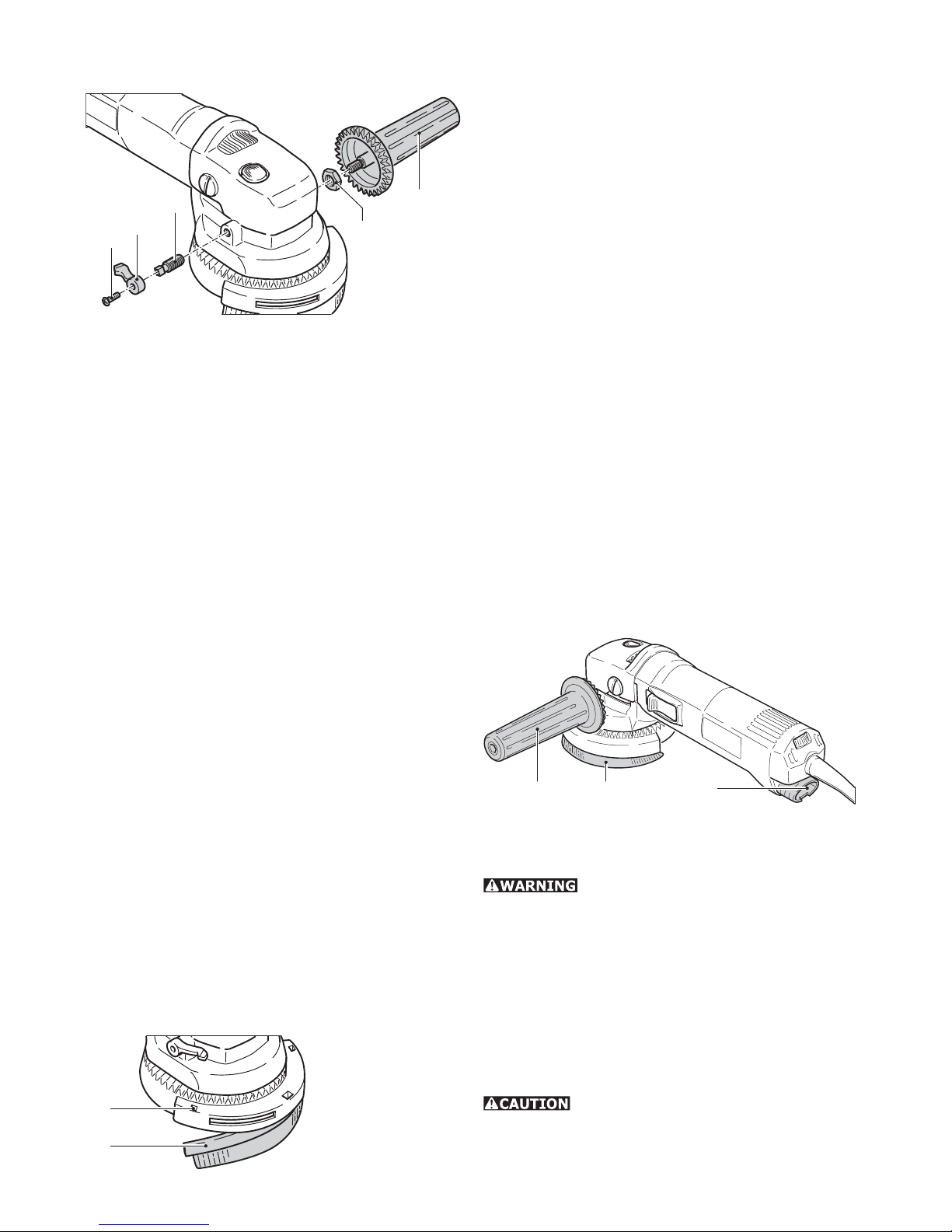

c) Replacing the brush insert

5.1

5.2

In order to replace this, press out the brush insert

by inserting a screwdriver through the square apertures (5.1). Insert the new brush strip (5.2) into

the groove, slightly bend this to obtain the correct

radius and press in fi rmly until the brush strip is in

contact with the base of the hood. The inclination of

the brush bristles must point outwards.

Two different brush inserts are available:

• AH-RAS D 115 Poly (484727): Pack of 2 polyamide

brushes (replacement for worn originals)

• AH-RAS D 115 metal (484728): Pack of 1 metal

brush (for use with spark-generating materials)

d) Sanding with dust extraction

For dust extraction, the suction hose (27 mm dia.)

of a Festool dust extractor should be inserted into

the connection socket (6.3) at the end of the rotary

sander housing.

The brush ring (6.2) can be adjusted by means of

the additional rotatable handle (6.1). This makes

it possible to achieve an optimum setting for the

working position used. Always turn the brush ring

into the direction of travel of the sanding dust.

A considerable quantity of air-borne sparks are

generated during the sanding of metals and other

spark-generating materials. For safety reasons,

therefore, a spark-trap (484733) must be fi tted

between the extractor hood and the rotary sander.

6.3 6.1 6.2

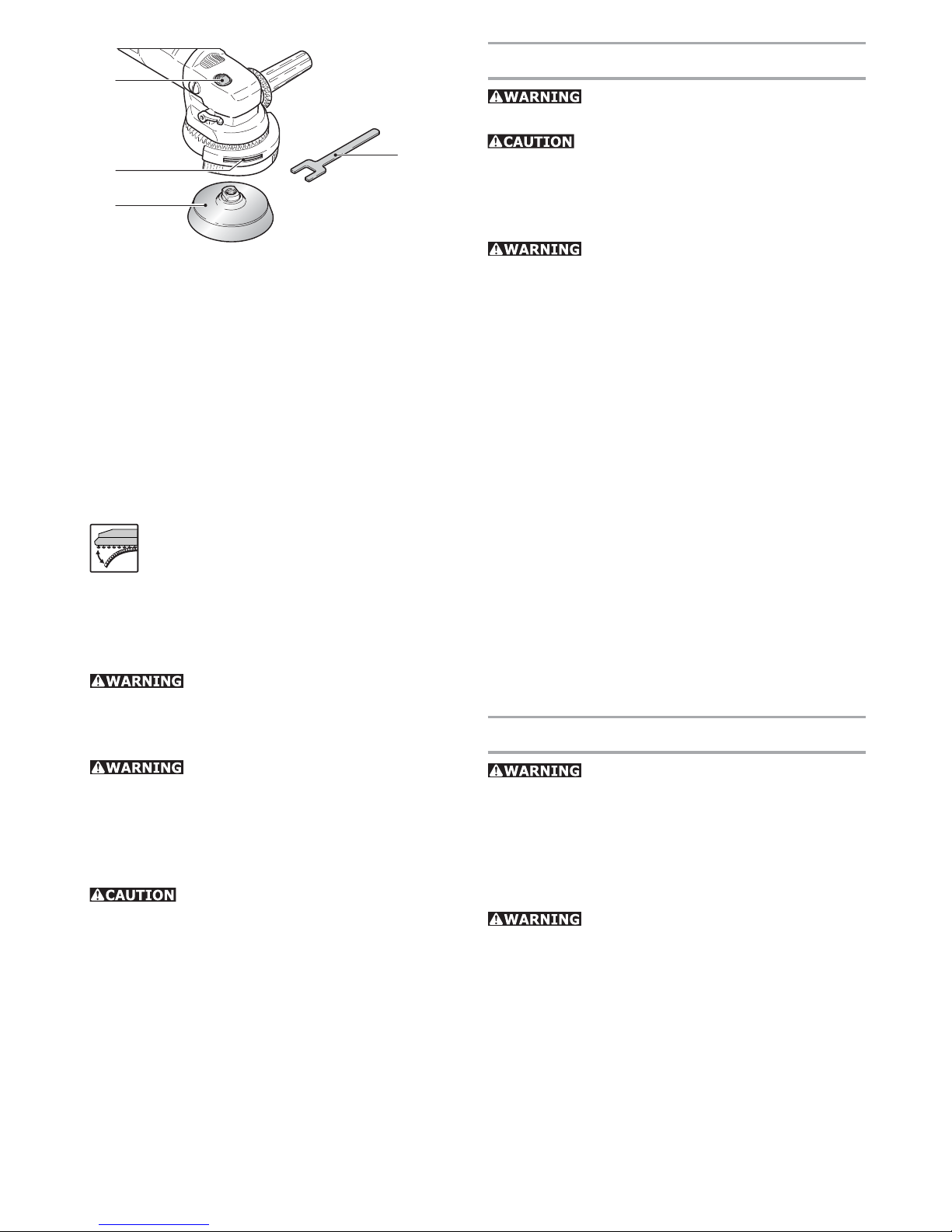

Fitting tool inserts

Use only tool inserts whose maximum

permissible speed is at least equal to the speed

given on the rating plate of the rotary sander. This

is the case with all original Festool accessories.

The Stickfi x sanding pads STF D 115 are provided

with an M 14 thread which enables these to be

screwed directly onto the drive spindle.

It is normally possible to unscrew the sanding pad

(7.3) by hand from the drive spindle after pressing

the spindle stop (7.1).

Actuate the spindle stop only when the

drive spindle is stationary. Do not switch on the motor when the spindle stop is pressed in.

Page 9

9

7.1

7.2

7.3

7.4

In case the pad should seize:

– Remove the brush insert.

– Insert the special spanner (7.4) through the slot

(7.2) and place on spanner fl ats of tool.

– Release the tool with the spindle stop pressed by

turning the special spanner.

Please note: Always screw the sanding pad onto the

drive spindle by hand. This will make it considerably

easier to remove it subsequently.

Attaching the abrasive

Stickfi x is a hook-and-loop fastening sys-

tem. Stickfi x sanding pads allow the use

of self-adhesive hook-and-loop abrasives

such as Stickfi x sandpapers and sanding

cloths.

Simply press the abrasive onto the sanding pad and

pull it off again after use.

Use only abrasives with an undamaged

Stickfi x hook-and-loop coating. Before use, check

that the coating has not been damaged by improper

use (such as over heating).

In the case of a weakening adhesive

effect of the StickFix surface, the sanding pad accessories, in particular those which are not yet

touching the workpiece, may come loose from

the sanding pad and cause injuries. Replace the

sanding pad!

The Mini-Stickfi x D 52 sanding pad was

developed for use in confi ned spaces and with small

areas. This small-diameter pad and the affi xed

abrasive will inevitably heat up in use more than

larger pads, since the same pressure is distributed

over a smaller area. Sand only with moderate pressure and do not sand continuously for too long. Lift

the sander off the workpiece at intervals to allow

friction heat to dissipate.

Working with the tool

Always secure the workpiece in such

a manner that it cannot move while being sanded.

Never overload the tool by using too

much pressure! The best sanding results are

achieved when applying moderate pressure. Sanding performance and quality depend primarily on

the choice of the right abrasive.

For safe guidance, always hold the tool

with both hands.

We recommend the following settings on the rotary

control (2.1) for electronic machines:

6

• Sanding hard GRP components (limited suit-

ability).

3 - 6

• Sanding off dry, cracked paint.

• Stripping anti-fouling paints.

• Sanding wood.

2 - 4

• Sanding paint/varnish with tendency to smear

• Light sanding of thin top coats of paint.

• Cleaning sandstone, concrete, formwork materi-

als.

1 - 2

• Sanding thermoplastic materials.

Maintenance and care

All maintenance or repair work requiring the motor housing to be opened must be carried

out only by an authorized service workshop. Maintenance or repair work carried out by an unauthorized

person can lead to the incorrect connection of the

wiring or other components, which in turn can lead

to accidents with serious consequences.

Always remove the plug from the

mains supply socket before carrying out any work

on the machine!

Always keep the tool and in particular the ventilation slots clean.

The tool is fi tted with special motor brushes with

an automatic cut-out. When the brushes become

worn the power supply is shut off automatically and

the tool comes to a standstill.

Page 10

10

Customer service and repair. Only through

manufacturer or service workshops:

Please fi nd the nearest address at:

www.festoolusa.com/Service

EKAT

1

2

3

5

4

Use only original Festool spare parts! Order

No. at: www.festoolusa.com/Service

Accessories, tools

For safety reasons, only use original

Festool accessories and tools!

The accessory and tool order number can be found

in the Festool catalog or on the Internet under www.

festoolusa.com.

Systainer

open

lock

connect

connect

T-loc

8.1

8

A

B

Many Festool products are shipped in a unique

system container, called "Systainer". This provides

protection and storage for the tool and accessories.

The Systainers are stackable and can be interlocked

together. They also can be interlocked atop Festool

CT dust extractors.

To open the Systainer:

• Turn the T-loc (8.1) to the position

.

To lock the Systainer:

• Turn the T-loc (8.1) to the position

.

To connect two Systainers:

• Place one Systainer on the top of the other (Fig.

8 A).

• Turn the T-loc (8.1) to the position

or

(Fig. 8 B).

The Systainers are connected and locked.

A new generation Systainer is connectable on

top of a previous generation Systainer by the four

latches of the previous Systainer.

Page 11

11

À propos de ce manuel

Conservez ces instructions

Il est important pour vous de lire et de comprendre

ce manuel. Les informations qu'il contient, se

rapporte à la protection de votre sécurité et de

prévention des problèmes. Les symboles suivants

sont utilisés pour vous aider à reconnaître cette

information.

DANGER

Description du risque

imminent et l'incapacité à

éviter tout risque qui peut

entraîner la mort.

AVERTISSEMENT

Description des dangers

possibles et des blessures

qui en résultent ou la mort.

ATTENTION

Description des dangers et

des éventuelles blessures

qui en résultent.

AVIS

Déclaration incluant le type

de danger et conséquences

possibles.

CONSEIL

Indique des informations,

des notes ou des conseils

pour améliorer votre

succès en utilisant l'outil.

Régles de sécurité

Lire toutes les consignes

de sécurité, des instructions, des illustrations et

des indications fournies avec cet outil électrique.

Le non-respect des instructions indiqués ci-après

peut entraîner un choc électrique, un incendie et/

ou de graves blessures.

CONSERVER TOUS LES AVERTISSEMENTS ET

TOUTES LES INSTRUCTIONS POUR POUVOIR S’Y

REPORTER ULTÉRIEUREMENT.

Le terme « outil » dans les avertissements fait reference à votre outil électrique alimenté par le secteur

(avec cordon d’alimentation) ou votre outil fonctionnant sur batterie (sans cordon d’alimentation)

Régles de sécurité générales

1) Place de travail

a) Maintenez l’endroit de travail propre et bien

éclairé. Un lieu de travail en désordre ou mal

éclairé augmente le risque d’accidents.

b) N’utilisez pas l’appareil dans un environne-

ment présentant des risques d’explosion et

où se trouvent des liquides, des gaz ou poussières infl ammables. Les outils électroportatifs

génèrent des étincelles risquant d’enfl ammer

les poussières ou les vapeurs.

c) Tenez les enfants et autres personnes éloignés

durant l’utilisation de l’outil électroportatif.

En cas d’inattention vous risquez de perdre le

contrôle sur l’appareil.

d) Ne laissez pas l‘outil électrique fonctionner

sans surveillance. Ne vous éloignez de l‘outil

électrique que lorsque l‘accessoire est complètement immobilisé.

2) Sécurité relative au système électrique

a) La fi che de secteur de l’outil électroportatif

doit être appropriée à la prise de courant. Ne

modifi ez en aucun cas la fi che. N’utilisez pas

de fi ches d’adaptateur avec des appareils avec

mise à la terre. Les fi ches non modifi ées et

les prises de courant appropriées réduisent le

risque de choc électrique.

b) Evitez le contact physique avec des surfaces

mises à la terre tels que tuyaux, radiateurs,

fours et réfrigérateurs. Il y a un risque élevé

de choc électrique au cas où votre corps serait

relié à la terre.

À propos de ce manuel ................................... 11

Régles de sécurité .........................................11

Régles de sécurité générales ......................... 11

Règle de sécurité particulière

supplémentaire ............................................... 13

Autres instructions de sécurité pour toutes les

opérations ....................................................... 14

Caractéristiques techniques ..........................15

Symbole .........................................................15

Utilisation conforme ......................................15

Raccordement électrique et mise en service . 16

Câble de rallonge ........................................... 16

Réglage électronique .....................................16

Réglages de l'outil .........................................16

Capot d‘aspiration AH-RAS D 115 .................. 16

Montage des disques ..................................... 17

Fixer l’abrasif ................................................. 18

Travailler avec l'outil ..................................... 18

Entretien et maintenance ..............................18

Accessoires et outils ...................................... 19

Table des matières

Page 12

12

c) N’exposez pas l’outil électroportatif à la pluie

ou à l’humidité. La pénétration d’eau dans un

outil électroportatif augmente le risque d’un

choc électrique.

d) N’utilisez pas le câble à d’autres fi ns que celles

prévues, n’utilisez pas le câble pour porter

l’appareil ou pour l’accrocher ou encore pour

le débrancher de la prise de courant. Maintenez le câble éloigné des sources de chaleur,

des parties grasses, des bords tranchants ou

des parties de l’appareil en rotation. Un câble

endommagé ou torsadé augmente le risque d’un

choc électrique.

e) Au cas où vous utiliseriez l’outil électroportatif

à l’extérieur, utilisez une rallonge autorisée

homologuée pour les applications extérieures.

L’utilisation d’une rallonge électrique homologuée pour les applications extérieures réduit le

risque d’un choc électrique.

f) Si l’usage d’un outil dans un emplacement

humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel résiduel (RCD). L’usage d’un RCD réduit le

risque de choc électrique.

3) Sécurité des personnes

a) Restez vigilant, surveillez ce que vous faites.

Faites preuve de bon en utilisant l’outil électroportatif. N’utilisez pas l’appareil lorsque

vous êtes fatigué ou après avoir consommé

de l’alcool, des drogues ou avoir pris des

médicaments. Un moment d’inattention lors

de l’utilisation de l’appareil peut entraîner de

graves blessures sur les personnes.

b) Portez des équipements de protection. Portez

toujours des lunettes de protection. Le fait de

porter des équipements de protection personnels tels que masque anti-poussières, chaussures de sécurité antidérapantes, casque de

protection ou protection acoustique suivant le

travail à effectuer, réduit le risque de blessures.

c) Evitez une mise en service par mégarde. Assu-

rez-vous que l’interrupteur est effectivement

en position d’arrêt avant de retirer la fi che de

la prise de courant. Le fait de porter l’appareil

avec le doigt sur l’interrupteur ou de brancher

l’appareil sur la source de courant lorsque

l’interrupteur est en position de fonctionnement,

peut entraîner des accidents.

d) Enlevez tout outil de réglage ou toute clé avant

de mettre l’appareil en fonctionnement. Une clé

ou un outil se trouvant sur une partie en rotation

peut causer des blessures.

e) Ne surestimez pas vos capacités. Veillez à gar-

der toujours une position stable et équilibrée.

Ceci vous permet de mieux contrôler l’appareil

dans des situations inattendues.

f) Portez des vêtements appropriés. Ne portez pas

de vêtements amples, ni de bijoux. Gardez les

cheveux et les vêtements à distance des pièces

mobiles. Des vêtements amples, des bijoux ou

des cheveux longs peuvent être happés par les

pièces en mouvement.

g) Si des dispositifs servant à aspirer ou à recueil-

lir les poussières doivent être utilisés, vérifi ez

que ceux-ci soient effectivement raccordés et

qu’ils sont correctement utilisés. L’utilisation

de tels dispositifs réduit les dangers dus aux

poussières.

h) Ne devenez pas trop sûr de vous, par habitude

suite à une utilisation fréquente de l'appareil,

de manière à ne pas respecter les principes

de sécurité de base de l'appareil. Une action

imprudente peut occasionner de graves blessures en l'espace d'une fraction de seconde.

4) Utilisation et emploi soi-

gneux de l’outil électroportatif

a) Ne surchargez pas l’appareil. Utilisez l’outil

électroportatif approprié au travail à effectuer. Avec l’outil électroportatif approprié, vous

travaillerez mieux et avec plus de sécurité à la

vitesse pour laquelle il est prévu.

b) N’utilisez pas un outil électroportatif dont

l’interrupteur est défectueux. Un outil électroportatif qui ne peut plus être mis en ou hors

fonctionnement est dangereux et doit être

réparé.

c) Retirer la fi che de la prise de courant avant

d’effectuer des réglages sur l’appareil, de

changer les accessoires, ou de ranger l’appareil. Cette mesure de précaution empêche une

mise en fonctionnement par mégarde.

d) Gardez les outils électroportatifs non utilisés

hors de portée des enfants. Ne permettez pas

l’utilisation de l’appareil à des personnes qui

ne se sont pas familiarisées avec celui-ci ou

qui n’ont pas lu ces instructions. Les outils

électroportatifs sont dangereux lorsqu’ils sont

utilisés par des personnes non initiées.

e) Prenez soin des outils électroportatifs. Vérifi ez

que les parties en mouvement fonctionnent

correctement et qu’elles ne soient pas coincées, et contrôlez si des parties sont cassées ou

endommagées de telle sorte que le bon fonctionnement de l’appareil s’en trouve entravé.

Page 13

13

Faites réparer les parties endommagées avant

d’utiliser l’appareil. De nombreux accidents

sont dus à des outils électroportatifs mal entretenus.

f) Maintenez les outils de coupe aiguisés et

propres. Des outils soigneusement entretenus

avec des bords tranchants bien aiguisés se

coincent moins souvent et peuvent être guidés

plus facilement.

g) Utilisez les outils électroportatifs, les acces-

soires, les outils à monter etc. conformément à

ces instructions et aux prescriptions en vigueur

pour ce type d’appareil. Tenez compte également des conditions de travail et du travail à

effectuer. L’utilisation des outils électroportatifs

à d’autres fi ns que celles prévues peut entraîner

des situations dangereuses.

h) Gardez les poignées dans un état sec, propre

et exempt d'huile et de graisse. Des poignées

glissantes ne permettent pas une prise en main

sûre et le contrôle de l'outil électrique dans des

situations inattendues.

5) Service

a) Ne faites réparer votre outil électroportatif que

par un personnel qualifi é et seulement avec

des pièces de rechange d’origine. Ceci permet

d’assurer la sécurité de l’appareil.

Règle de sécurité particu-

lière supplémentaire

Consignes de sécurité communes rela-

tives au ponçage avec papier abrasif

a) Cet outil électroportatif doit être utilisé en tant

que ponceuse à abrasif. Respectez toutes les

consignes de sécurité, instructions, représentations et données fournies avec cette machine.

Le non-respect des consignes suivantes peut

aboutir à un choc électrique, à un incendie et/

ou à des blessures graves.

b) Cet outil électroportatif ne convient pas pour

le meulage, le polissage, le tronçonnage et le

brossage métallique. Des utilisations non pré-

vues de l'outil électroportatif peuvent être à l'origine de situations dangereuses et de blessures.

c) Ne pas utiliser d’accessoires non conçus spé-

cifi quement et recommandés par le fabricant

d’outils. Le simple fait que l’accessoire puisse

être fi xé à votre outil électrique ne garantit pas

un fonctionnement en toute sécurité.

d) La vitesse assignée de l’accessoire doit être au

moins égale à la vitesse maximale indiquée sur

l’outil électrique. Les accessoires fonctionnant

plus vite que leur vitesse assignée peuvent se

rompre et voler en éclat.

e) Le diamètre extérieur et l’épaisseur de votre

accessoire doivent se situer dans le cadre des

caractéristiques de capacité de votre outil

électrique. Les accessoires dimensionnés de

façon incorrecte ne peuvent pas être protégés

ou commandés de manière appropriée.

f) Les outils amovibles avec insert fi leté doivent

être adaptés précisément au fi letage de l'arbre

de ponceuse. Pour les outils amovibles installés

au moyen d'une bride, le diamètre d'orifi ce de

l'outil doit être adapté au diamètre de montage

de la bride. Les outils amovibles mal fi xés sur

l'outil électroportatif ont une vitesse de rotation

irrégulière, génèrent des vibrations importantes

et peuvent entraîner une perte de contrôle.

g) N'utilisez pas d'outils amovibles endommagés.

Avant toute utilisation, vérifi ez l'état irréprochable des outils amovibles, à savoir que les

patins de ponçage ne sont pas effi lochés ou

fi ssurés, que le plateau de ponçage n'est pas

fi ssuré, usé ou fortement dégradé, ou que les

brosses ne présentent pas de fi ls arrachés ou

cassés. En cas de chute de l'outil électroportatif

ou de l'outil amovible, vérifi ez qu'il n'est pas

endommagé ou utilisez un outil amovible en

parfait état. Une fois que vous avez contrôlé et

mis en place l'outil amovible, tenez-vous ainsi

que toute autre personne à distance de la zone

de l'outil amovible en rotation et laissez tourner l'équipement au régime maximum pendant

une minute. La plupart du temps, cette période

d'essai provoque une rupture de l'outil amovible

s'il est endommagé.

h) Porter un équipement de protection indivi-

duelle. En fonction de l’application, utiliser un

écran facial, des lunettes de sécurité ou des

verres de sécurité. Le cas échéant, utiliser un

masque antipoussières, des protections auditives, des gants et un tablier capables d’arrêter

les petits fragments abrasifs ou des pièces à

usiner. La protection oculaire doit être capable

d’arrêter les débris volants produits par les

diverses opérations. Le masque antipoussières

ou le respirateur doit être capable de fi ltrer les

particules produites par vos travaux. L’exposi-

Page 14

14

tion prolongée aux bruits de forte intensité peut

provoquer une perte de l’audition.

i) Maintenir les personnes présentes à une

distance de sécurité par rapport à la zone de

travail. Toute personne entrant dans la zone de

travail doit porter un équipement de protection

individuelle. Des fragments de pièce à usiner ou

d’un accessoire cassé peuvent être projetés et

provoquer des blessures en dehors de la zone

immédiate d’opération.

j) Tenir l’outil uniquement par les surfaces de

préhension isolantes, pendant les opérations

au cours desquelles l’accessoire coupant peut

être en contact avec des conducteurs cachés ou

avec son propre câble. Le contact de l’accessoire

coupant avec un fi l «sous tension» peut également mettre «sous tension» les parties métalliques exposées de l’outil électrique et provoquer

un choc électrique sur l’opérateur.

k) Placer le câble éloigné de l’accessoire de rota-

tion. Si vous perdez le contrôle, le câble peut être

coupé ou subir un accroc et votre main ou votre

bras peut être tiré dans l’accessoire de rotation.

l) Ne jamais reposer l’outil électrique avant que

l’accessoire n’ait atteint un arrêt complet. L’accessoire de rotation peut agripper la surface et

arracher l’outil électrique hors de votre contrôle.

m) Ne pas faire fonctionner l’outil électrique en le

portant sur le côté. Un contact accidentel avec

l’accessoire de rotation pourrait accrocher vos

vêtements et attirer l’accessoire sur vous.

n) Nettoyer régulièrement les orifi ces d’aération

de l’outil électrique. Le ventilateur du moteur

attirera la poussière à l’intérieur du boîtier et une

accumulation excessive de poudre de métal peut

provoquer des dangers électriques.

o) Ne pas faire fonctionner l’outil électrique à

proximité de matériaux inflammables. Des

étincelles pourraient enfl ammer ces matériaux.

p) Ne pas utiliser d’accessoires qui nécessitent

des réfrigérants fl uides. L’utilisation d’eau ou

d’autres réfrigérants fl uides peut aboutir à une

électrocution ou un choc électrique.

Autres instructions de sécuri-

té pour toutes les opérations

Rebonds et mises en garde correspondantes

Le rebond est une réaction soudaine au pincement

ou à l’accrochage d’une meule rotative, d’un patin

d’appui, d’une brosse ou de tout autre accessoire.

Le pincement ou l’accrochage provoque un blocage

rapide de l’accessoire en rotation qui, à son tour,

contraint l’outil électrique hors de contrôle dans

le sens opposé de rotation de l’accessoire au point

du grippage.

Par exemple, si une meule abrasive est accrochée

ou pincée par la pièce à usiner, le bord de la meule

qui entre dans le point de pincement peut creuser

la surface du matériau, provoquant des sauts ou

l’expulsion de la meule. La meule peut sauter en

direction de l’opérateur ou encore en s’en éloignant,

selon le sens du mouvement de la meule au point

de pincement. Les meules abrasives peuvent également se rompre dans ces conditions.

Le rebond résulte d’un mauvais usage de l’outil et/

ou de procédures ou de conditions de fonctionnement incorrectes et peut être évité en prenant les

précautions appropriées spécifi ées ci-dessous.

a) Maintenir fermement l’outil électrique et placer

votre corps et vos bras pour vous permettre

de résister aux forces de rebond. Toujours

utiliser une poignée auxiliaire, le cas échéant,

pour une maîtrise maximale du rebond ou de

la réaction de couple au cours du démarrage.

L’opérateur peut maîtriser les couples de réaction ou les forces de rebond, si les précautions

qui s’imposent sont prises.

b) Ne jamais placer votre main à proximité de

l’accessoire en rotation. L’accessoire peut effectuer un rebond sur votre main.

c) Ne pas vous placer dans la zone où l’outil

électrique se déplacera en cas de rebond. Le

rebond pousse l’outil dans le sens opposé au

mouvement de la meule au point d’accrochage.

d) Apporter un soin particulier lors de travaux

dans les coins, les arêtes vives etc. Eviter les

rebondissements et les accrochages de l’accessoire. Les coins, les arêtes vives ou les rebondis-

sements ont tendance à accrocher l’accessoire

en rotation et à provoquer une perte de contrôle

ou un rebond.

e) Ne pas fi xer de chaîne coupante, de lame de

sculpture sur bois, de chaîne coupante ni de

lame de scie dentée. De telles lames provoquent

des rebonds fréquents et des pertes de contrôle.

Instructions de sécurité additionnelles

pour les opérations de ponçage

a) Ne pas utiliser de papier abrasif trop surdi-

mensionné pour les disques de ponçage. Suivre

les recommandations des fabricants, lors du

choix du papier abrasif. Un papier abrasif plus

Page 15

15

grand s’étendant au-delà du patin de ponçage

présente un danger de lacération et peut provoquer un accrochage, une déchirure du disque

ou un rebond.

POUR RÉDUIRE LE RISQUE

DE DOMMAGES, L'UTILISATEUR DOIT LIRE LE

MANUEL D'INSTRUCTION.

Certaines poussières créées

par le ponçage mécanique, le sciage, le meulage, le

perçage et autres activités reliées à la construction

contiennent des substances chimiques connues

(dans l’État de la Californie) comme pouvant causer

le cancer, des anomalies congénitales ou représenter d’autres dangers pour la reproduction. Voici

quelques exemples de telles substances:

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le

ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’œuvre traité avec un

produit chimique.

Le risque d’exposition à de tels produits varie

selon la fréquence à laquelle vous faites ce genre

de travail.

Pour réduire les risques d’exposition à

ces substances chimiques : travaillez

dans un endroit adéquatement ventilé

et utilisez un équipement de sécurité

approuvé, tel que masques antipoussières spécialement conçus pour fi ltrer

les particules microscopiques.

Caractéristiques techniques

Puissance absorbée 500 W

Vitesse nominale 4000 tr/min

Vitesse de rotation max* 5000 tr/min

Patin de ponçage, Ø 115 mm (4.5 in.)

Arbre porte outil M 14

Poids 1.6 kg (3.5 lbs.)

Sécurité

/ II

* Vitesse de rotation max. en cas d'électronique

défectueuse.

Symbole

Avertissement de danger

Lire les instructions / les remarques !

Munissez-vous de casques anti-bruit !

Portez des lunettes de protection !

Portez un masque antipoussières !

V Volt

A Ampère

Hz Hertz

W Watt

~ Tension alternative

n Vitesse nominale

Construction de classe II

tr/min Tours par minute

Ø Diamètre

Utilisation conforme

L’appareil RAS 115 E est destiné à poncer le bois,

les matières plastiques, la pierre, les matériaux

composites, la peinture et la laque, les matières

de remplissage, le mastic et des matériaux semblables.

Il ne doit pas servir à poncer

le métal. L‘usinage de l‘amiante est formellement

interdit.

Sur l‘appareil, aucun disque

abrasif ne peut être attaché. Il peut être travaillé

seulement avec le plateau de ponçage fournie et

sur quoi les abrasifs attachés.

En raison de la sécurité électrique, les appareils ne se prêtent pas à un ponçage

humide.

Si, lors du ponçage, il y a production de certaines

matières explosives ou de poussière auto-infl ammable, suivez les consignes du fabricant du matériau.

En cas d’une utilisation non

conforme, la responsabilité des dommages et

accidents incombe à l’utilisateur.

Page 16

16

Raccordement électrique

et mise en service

La tension du réseau doit correspondre à celle

indiquée sur la plaque signalétique!

1.1

Pour enclencher, poussez l‘interrupteur vers l‘avant

(1.1 ). Une pression sur l‘arrière de l‘interrupteur

suffi t pour arrêter l‘appareil.

Câble de rallonge

Si une rallonge électrique est nécessaire, elle doit

présenter une section suffi sante pour éviter une

chute de tension excessive ou une surchauffe.

Une chute de tension excessive réduit la puissance

et peut entraîner une défaillance du moteur. Le

tableau suivant vous présente la section correcte

du câble en fonction de sa longueur pour la norme

RAS 115 E.

Longueur totale

rallonge (pieds)

25 50 100 150

Section du câble (AWG) 18 16 16 14

Utilisez exclusivement des rallonges recommandées par les organismes U.L. et CSA. N'utilisez jamais deux rallonges branchées l'une après l'autre,

mais remplacez-les par une rallonge plus longue.

Remarque : plus le numéro AWG est petit, plus la

section du câble est grande.

Réglage électronique

Cet outil contient un dispositif électro nique à

double alternance présentant les caractéristiques

suivantes .

N’utilisez pas la ponceuse

rotative si la commande électronique est défectueuse car cela risquerait d‘entraîner une vitesse

de rotation trop élevée. La commande électronique

est défectueuse si le démarrage progressif ne fonctionne pas, si le bruit lors de la rotation à vide est

plus élevé que d’habitude ou si vous êtes incapable

de réguler la vitesse.

Démarrage progressif

Le démarrage progressif assure un fonctionnement

sans à-coups de l'outil.

Réglage de la vitesse

2.1

Le régime est réglé en continu au moyen de la

molette (2.1) entre 1400 et 4000 tr/min. Vous pouvez

ainsi adapter de façon optimale la vitesse de coupe

à chaque matériau (voir "Travailler avec l'outil").

Régime constant

Le régime sélectionné reste constant pendant que

l'outil est en fonctionnement ou en position neutre.

Contrôle de la température

Pour assurer une protection contre la surchauffe,

le système électronique de sécurité arrête l'outil

dès que le moteur atteint une certaine température. Après une période de refroidissement de 3

à 5 minutes environ, l'outil est à nouveau prêt à

être utilisé. Le temps de refroidissement diminue

lorsque l'outil fonctionne (marche à vide).

Réglages de l'outil

Avant de faire quelque entretien

sur l'outil, débranchez-le!

Capot d‘aspiration AH-RAS D 115

Le capot d‘aspiration AH RAS D 115 (3.1) peut être

utilisé avec les patins de ponçage STF D 115.

3.4

3.2

3.3

3.1

a) Montage

Avant de monter le capot d‘aspiration, vérifi ez que

le levier de serrage est en position «dégagé (3.4).

Serrez le capot sur la bague de fi xation (3.2) de la

machine et poussez le levier de serrage vers l‘avant

(3.3).

Page 17

17

Ne travaillez pas si le capot n‘est pas correctement

fi xé. Si la pince de serrage devait se désserrer,

après un travail intense, vous pouvez refaire le

réglage:

4.1

4.2

4.5

4.4

4.3

–Dévissez la vis (4.1) du levier de serrage et retirez

celui-ci (4.2).

–Serrez la vis (4.3) à la main.

–Remettez le levier de serrage et fi xez-le. La posi-

tion optimale est obtenue en fonction du levier de

serrage avant de serrer la vis.

b) Inversement de la poignée tournante

La poignée tournante peut également être fi xée du

côté droit de la machine. Il suffi t de l‘inverser avec

le levier de serrage.

–Dévissez la vis (4.1) du levier de serrage et retirez

celui-ci (4.2).

–Retirez la vis (4.3).

–Dévissez la poignée (4.5) à l’aide d’une clé SW 6.

Inversez le montage de la poignée et du levier. Vous

pouvez changer l‘orientation de la poignée en utilisant l‘écrou (4.4). Avant de fi xer la poignée, serrez

l‘écrou au capot à l’aide d’une clé SW 13. Le levier

de serrage peut maintenant être interchangé avec

la poignée tournante.

c) Changement du cadre brosse

5.1

5.2

Enlevez le cadre brosse avec un tournevis, introduisez ce dernier dans l‘ouverture (5.1) et poussez

sur le cadre pour le retirer. Le cadre brosse (5.2) de

remplacement doit être adapté dans la rainure, en

recouvrant le rebord du capot d‘aspiration. Les fi ls

de la brosse doivent être orientés vers l‘extérieur.

Il existe deux types de cadres brosses :

• AH-RAS D 115 Poly (484727) : 2 pièces, polyamides

(pour remplacement en cas d‘usure).

• AH-RAS D 115 métal (484728) : 1 pièce, métal

(pour les travaux entraînant des étincelles).

d) Ponçage et aspiration

6.3 6.1 6.2

Insérez un tuyau d‘aspiration de diamètre 27 mm

dans l‘embout d‘évacuation des poussières (6.3)

situé au bout du capot d‘aspiration de la ponceuse

rotative. Reliez le tout à un aspirateur Festool.

Le cadre brosse (6.2) est décalé avec la poignée (6.1).

Une adaptation optimale est ainsi obtenue pour toute

position de travail. Tournez le cadre brosse toujours

en direction de l‘éjection des copeaux. Lorsque vous

poncez des métaux, des étincelles se produisent. Installez un pare-étincelles (484733) entre la ponceuse

rotative et l‘aspirateur.

Montage des disques

Utilisez uniquement des outils

dont la vitesse de rotation maximale n‘est pas inférieure à celle prescrite sur la plaque signalétique

de la ponceuse rotative. Cette consigne s’applique

à tous les accessoires Festool.

Les patins STF D 115 sont équipés d‘un pas de vis

M 14. Les outils peuvent directement se monter

sur l‘arbre moteur.

Normalement, le changement du patin de ponçage

(7.3) se fait manuellement en dévissant le patin de

l‘arbre après avoir pressé l‘interrupteur de blocage

de l‘arbre (7.1).

Actionnez le blocage de l‘arbre

uniquement lors de l‘arrêt total de l‘arbre moteur.

N’actionnez jamais le moteur lors du blocage.

7.1

7.2

7.3

7.4

Dans le cas où cela ne serait pas possible :

–Enlevez le cadre brosse.

Page 18

18

–Introduisez la clé spéciale (7.4) dans l‘ouverture

(7.2).

–Bloquez l‘arbre et dévissez le disque avec la clé.

Remarque : Fixez toujours le disque de ponçage

manuellement. Vous pourrez ainsi retirer plus

facilement le patin.

Fixer l’abrasif

Stickfi x est un système de fi xation de type

auto-agrippant. Sur les patins de ponçage

Stickfi x, vous pouvez fi xer tous les types

d'abrasif auto-agrippants.

Posez-le simplement sur le patin et retirez-le après

utilisation.

Utilisez uniquement des patins

Stickfi x dont l'état de la surface auto-agrippante

est impeccable. Avant l'utilisation, vérifi ez si la

surface n'a pas subi de dégradation suite à un

échauffement.

Si l'adhérence du revêtement

StickFix diminue, il est possible que des accessoires

du patin de ponçage se détachent du patin de ponçage, en particulier quand il n'est pas monté, et

causent des blessures. Remplacez le plateau de

ponçage !

Les patins mini-Stickfix D 52

ont été conçus pour être utilisés dans des espaces

clos et sur de petites surfaces. Ce patin de faible

diamètre et l’abrasif s’échaufferont inévitablement

s’ils sont utilisés sur de plus grandes surfaces étant

donné que la même pression est répartie sur une

surface plus réduite. Par conséquent, appliquez une

pression modérée et ne poncez pas trop longtemps

au même endroit. Levez la ponceuse à intervalles

pour permettre à la chaleur résultant de la friction

de se dissiper.

Travailler avec l'outil

Fixez la pièce à usiner de manière à ce qu’elle ne puisse pas bouger pendant le

traitement.

Ne surchargez pas l'outil en

appuyant trop fort ! Vous obtiendrez le meilleur

résultat de ponçage avec une pression d’application

moyenne. Le rendement et la qualité du ponçage

dépendent essentiellement de la sélection de

l’abrasif adéquat.

Pour un guidage sûr, tenez

l'outil à deux mains.

Pour des machines électroniques nous pré-conisons les réglages ci-après de la molette (2.1):

6

• Ponçage de GRP (n‘utiliser que sous certains

conditions).

3 - 6

• Décapage de vieilles peintures sèches.

• Ponçage de peinture antisalissures.

• Ponçage du bois.

2 - 4

• Décapage peintures/ vernis «barbouillés».

• Ponçage de la fi ne couche de vernis de surface.

• Nettoyage de pierres fi nes, béton, matériel coffrage.

1 - 2

• Ponçage de matériaux thermoplastiques.

Entretien et maintenance

Les travaux d'entretien et de

réparation nécessitant une ouverture du carter

moteur ne doivent être effectués que par le personnel d'un atelier autorisé du service après-vente.

La maintenance ou la réparation de l'outil par des

personnes non autorisées peut entraîner un branchement incorrect de câbles électriques ou d'autres

composants, ce qui peut provoquer des accidents

avec blessures graves.

Débranchez l'outil avant tout

entretien.

L'outil et les orifi ces de ventilation doivent toujours

rester propres.

La polisseuse est équipée de charbons spécifi ques

à coupure automatique. Si ces charbons sont usés,

il y a coupure de courant automatique et arrêt du

fonctionnement de la machine.

Seuls le fabricant et un atelier homologué

sont habilités à effectuer toute réparation

ou service. Les adresses à proximité sont

disponibles sur:

www.festoolusa.com/Service

EKAT

1

2

3

5

4

Utilisez uniquement des pièces de rechange

Festool d‘origine.Référence sur www.

festoolusa.com/Service

Page 19

19

Accessoires et outils

Pour des raisons de sécurité, il

faut utiliser exclusivement des accessoires et outils

d’origine Festool!

Les références des accessoires et outils fi gurent

dans le catalogue Festool ou sur Internet sous

www.festoolusa.com.

ouvrir

fermer

connecter

connecter

T-loc

8.1

A

B

8

Systainer

De nombreux produits Festool sont fournis dans

une caisse exclusive, appelée "Systainer". Celle-ci

permet de protéger et de ranger des outils et des

appareils complémentaires. Les Systainer sont

empilables et peuvent être solidarisés. En outre, il

se fi xent sur les aspirateurs CT Festool.

Pour ouvrir le Systainer:

• Tournez le T-loc (8.1) à la position

.

Pour fermer le Systainer:

• Tournez le T-loc (8.1) à la position

.

Pour connecter deux Systainers:

• Placez un Systainer au dessus de l’autre (Fig. 8 A).

• Tournez le T-loc (8.1) à la position

ou

(Fig. 8 B).

Les Systainers sont combinés.

Un Systainer de la nouvelle génération peux être

attaché au dessus d’ un Systainer de l’ancienne

génération par les quatre loquets de l’ancien

Systainer.

Page 20

20

Sobre este manual

Guarde estas instrucciones

Es importante que usted lea y entienda este manual. La información que contiene se relaciona con

la protección de su seguridad y la prevención de

problemas. Los símbolos que siguen se utilizan

para ayudarlo a reconocer esta información.

PELIGRO

Descripción de peligro

inminente y fracaso para

evitar riesgos que podran

causar la muerte.

ADVERTENCIA

Descripción de peligro y

posibles lesiones resultantes

o la muerte.

PRECAUCIÒN

Descripción de peligro y

posibles lesiones resultantes.

AVISO

Declaración incluyendo

el tipo de riesgo y posible

resultados.

CONSEJO

Indica informaciónes, notas,

o consejos para mejorar su

éxito con la herramienta.

Normas de seguridad

Lea todas las advertencias de

seguridad, instrucciones, ilustraciones y especifi caciones que acompañan a esta herramienta eléctrica. El incumplimiento de dichas instrucciones

puede dar lugar a descargas eléctricas, incendios

o lesiones graves.

GUARDAR TODAS LAS ADVERTENCIAS DE PE

LIGRO E INSTRUCCIONES PARA FUTURAS CON

SULTAS.

El término herramienta eléctrica empleado en las

siguientes advertencias de peligro se refi ere a herramientas eléctricas de conexión a la red (con cable

de red) y a herramientas eléctricas accionadas por

acumulador (o sea, sin cable de red).

Normas generales de seguridad

1) Puesto de trabajo

a) Mantenga limpio y bien iluminado su puesto

de trabajo. El desorden y una iluminación defi -

ciente en las áreas de trabajo pueden provocar

accidentes.

b) No utilice la herramienta eléctrica en un en-

torno con peligro de explosión, en el que se

encuentren combustibles líquidos, gases o

material en polvo. Las herramientas eléctricas

producen chispas que pueden llegar a infl amar

los materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras personas

de su puesto de trabajo al emplear la herramienta eléctrica. Una distracción le puede hacer

perder el control sobre el aparato.

d) Vigile siempre la herramienta eléctrica mien-

tras esté en funcionamiento. Mantenga vigilada

la herramienta eléctrica hasta que ésta pare por

completo.

2) Seguridad eléctrica

a) El enchufe del aparato debe corresponder a

la toma de corriente utilizada. No es admisible modifi car el enchufe en forma alguna. No

emplear adaptadores en aparatos dotados con

una toma de tierra. Los enchufes sin modifi car

adecuados a las respectivas tomas de corriente

reducen el riesgo de una descarga eléctrica.

b) Evite que su cuerpo toque partes conectadas

a tierra como tuberías, radiadores, cocinas y

refrigeradores. El riesgo a quedar expuesto a

una sacudida eléctrica es mayor si su cuerpo

tiene contacto con tierra.

Contenido

Sobre este manual ..........................................20

Normas de seguridad .................................... 20

Normas generales de seguridad .................... 20

Indicaciones de seguridad comunes para el

lijado con papel de lija..................................... 22

Instrucciones de seguridad adicionales para

todas las operaciones ..................................... 23

Datos técnicos ................................................24

Símbolos ........................................................ 24

Uso conforme a su uso ...................................24

Conexión eléctrica y operación ...................... 24

Cable de extensión ......................................... 24

Regulación electrónica ..................................25

Ajustes en la máquina ....................................25

Capuchón de extracción AH-RAS D 115 ........ 25

Montaje de las herramientas de trabajo ....... 26

Fijación de la lija ............................................ 27

Trabajo con la lijadora ...................................27

Mantenimiento y cuidados .............................27

Accesorios, herramientas .............................. 27

Page 21

21

c) No exponga las herramientas eléctricas a la

lluvia y evite que penetren líquidos en su interior. Existe el peligro de recibir una descarga

eléctrica si penetran ciertos líquidos en la herramienta eléctrica.

d) No utilice el cable de red para transportar o

colgar el aparato, ni tire de él para sacar el

enchufe de la toma de corriente. Mantenga el

cable de red alejado del calor, aceite, esquinas cortantes o piezas móviles. Los cables de

red dañados o enredados pueden provocar una

descarga eléctrica.

e) Al trabajar con la herramienta eléctrica en la

intemperie utilice solamente cables de prolongación homologados para su uso en exteriores. La utilización de un cable de prolongación

adecuado para su uso en exteriores reduce el

riesgo de una descarga eléctrica.

f) Si fuese imprescindible utilizar la herramienta

eléctrica en un entorno húmedo, es necesario

conectarla a través de un fusible diferencial.

La aplicación de un fusible diferencial reduce el

riesgo a exponerse a una descarga eléctrica.

3) Seguridad de personas

a) Esté atento a lo que hace y emplee la herra-

mienta eléctrica con prudencia. No utilice la

herramienta eléctrica si estuviese cansado, ni

tampoco después de haber consumido alcohol,

drogas o medicamentos. El no estar atento du-

rante el uso de una herramienta eléctrica puede

provocarle serias lesiones.

b) Utilice un equipo de protección y en todo caso

unas gafas de protección. El riesgo a lesionarse

se reduce considerablemente si, dependiendo

del tipo y la aplicación de la herramienta eléctrica empleada, se utiliza un equipo de protección adecuado como una mascarilla antipolvo,

zapatos de seguridad con suela antideslizante,

casco, o protectores auditivos.

c) Evite una puesta en marcha fortuita del

aparato. Cerciorarse de que el aparato esté

desconectado antes conectarlo a la toma de

corriente. Si transporta el aparato sujetándolo

por el interruptor de conexión/desconexión, o

si introduce el enchufe en la toma de corriente

con el aparato conectado, ello puede dar lugar

a un accidente.

d) Retire las herramientas de ajuste o llaves fi jas

antes de conectar la herramienta eléctrica.

Una herramienta o llave colocada en una pieza

rotante puede producir lesiones al ponerse a

funcionar.

e) Sea precavido. Trabaje sobre una base fi rme y

mantenga el equilibrio en todo momento. Ello

le permitirá controlar mejor la herramienta

eléctrica en caso de presentarse una situación

inesperada.

f) Utilice ropa adecuada. No utilice ropa ancha ni

objetos de joyería o bisutería. Mantenga el pelo

y la ropa alejada de las piezas en movimiento.

La ropa suelta o el pelo largo pueden quedar

atrapados por piezas en movimiento.

g) Siempre que sea posible utilizar unos equipos

de aspiración o captación de polvo, asegúrese

que éstos estén montados y que sean utilizados correctamente. El empleo de estos equipos

reduce los riesgos derivados del polvo.

h) No debe jamás confi arse por el uso frecuente

de las máquinas e ignorar los principios de

seguridad de la herramienta. Un manejo im-

prudente puede ocasionar lesiones graves en

fracciones de segundo.

4) Trato y uso cuidadoso de herramientas eléctricas

a) No sobrecargue el aparato. Use la herramienta

prevista para el trabajo a realizar. Con la he-

rramienta adecuada podrá trabajar mejor y más

seguro dentro del margen de potencia indicado.

b) No utilice herramientas con un interruptor

defectuoso. Las herramientas que no se puedan

conectar o desconectar son peligrosas y deben

hacerse reparar.

c) Saque el enchufe de la red antes de realizar

un ajuste en el aparato, cambiar de accesorio

o al guardar el aparato. Esta medida preventiva

reduce el riesgo a conectar accidentalmente el

aparato.

d) Guarde las herramientas fuera del alcance de

los niños y de las personas que no estén familiarizadas con su uso. Las herramientas utili-

zadas por personas inexpertas son peligrosas.

e) Cuide sus aparatos con esmero. Controle si

funcionan correctamente, sin atascarse, las

partes móviles del aparato, y si existen partes

rotas o deterioradas que pudieran afectar al

funcionamiento de la herramienta. Si la herramienta eléctrica estuviese defectuosa haga

repararla antes de volver a utilizarla. Muchos

de los accidentes se deben a aparatos con un

mantenimiento defi ciente.

f) Mantenga los útiles limpios y afi lados. Los úti-

les mantenidos correctamente se dejan guiar y

controlar mejor.

g) Utilice herramientas eléctricas, accesorios,

Page 22

22

útiles, etc. de acuerdo a estas instrucciones y

en la manera indicada específi camente para

este aparato. Considere en ello las condiciones

de trabajo y la tarea a realizar. El uso de he-

rramientas eléctricas para trabajos diferentes

de aquellos para los que han sido concebidas

puede resultar peligroso.

h) Mantenga las empuñaduras secas, limpias

y libres de aceite y grasa. Las empuñaduras

resbaladizas no permiten una manipulación y

un control seguros de la herramienta eléctrica

en situaciones inesperadas.

5) Servicio

a) Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando exclusivamente piezas de repuesto originales.

Solamente así se mantiene la seguridad de la

herramienta eléctrica.

Indicaciones de seguridad comu-

nes para el lijado con papel de lija

a) Esta herramienta eléctrica debe utilizarse

como lijadora de papel de lija. Observar todas

las indicaciones de seguridad, instrucciones,

representaciones y datos entregados junto con

la herramienta. De no respetar las siguientes

instrucciones, podría producirse una descarga

eléctrica, un incendio o lesiones graves.

b) Esta herramienta eléctrica no es apta para

el lijado, el pulido, el cepillo de alambre ni el

tronzado. El uso de esta herramienta eléctrica

para aplicaciones no previstas supone riesgo de

lesiones.

c) Utilice únicamente accesorios de Festool con-

cebidos especialmente para esta máquina. El

hecho de que un accesorio pueda colocarse en

su máquina no presupone una garantía de un

funcionamiento sin riesgos.

d) El número de revoluciones admisible del acce-

sorio debe ser como máximo igual al número de

revoluciones máximo indicado en la máquina.

Las piezas que sobrepasen la velocidad permitida pueden reventar.

e) El diámetro exterior y el grosor del accesorio

deben hallarse dentro de las dimensiones

indicadas para la máquina. Un accesorio de

dimensiones incorrectas no se puede proteger

ni dominar con garantías.

f) Las herramientas con accesorio de rosca deben

ajustarse exactamente a la rosca del husillo de

lijado. En el caso de las herramientas que se

montan mediante bridas, el diámetro del agujero de la herramienta debe ajustarse al diámetro

del alojamiento de la brida. Las herramientas

que no se fi jan con precisión en la herramienta

eléctrica giran irregularmente, vibran mucho y

pueden provocar la pérdida del control.

g) No utilice herramientas dañadas. Antes de cada

uso, compruebe que las herramientas como

los discos de lijar no están fragmentadas ni

presentan grietas, que los platos lijadores no

están agrietados, desgastados o muy consumidos y que los cepillos de alambre no presentan

alambres rotos. Si la herramienta eléctrica o la

herramienta se cae, compruebe si está dañada o utilice una herramienta no dañada. Si ha

comprobado y utilizado la herramienta, sujétela,

mantenga a las personas que se encuentran

cerca fuera del área de la herramienta en rotación y deje que la herramienta funcione durante

1 minuto a la máxima velocidad. Generalmente,

las herramientas dañadas se rompen durante

esta fase de prueba.

h) Utilice equipamiento de protección. Use, de-

pendiendo de la aplicación, pantalla protectora

o gafas protectoras. Cuando sea necesario, utilice mascarilla de respiración, protección para

los oídos, guantes de seguridad y delantal de

trabajo, adecuado para la protección contra los

impactos de pequeños trozos del lijado y de las

piezas de trabajo. Las gafas de protección deben

ser apropiadas para detener los fragmentos

despedidos que se generan con los diferentes

trabajos. Las mascarillas de respiración o los

respiradores deben ser adecuados para fi ltrar

los fragmentos generados con los trabajos.

Una carga acústica prolongada e intensa puede

provocar sordera.

i) Asegúrese de que los presentes mantienen una

distancia de seguridad con respecto a la zona de

trabajo. Toda persona en el ámbito de trabajo

debe utilizar un equipamiento de protección

personal. Los trozos de la pieza de trabajo o

de un accesorio roto pueden salir despedidos

y causar daños fuera de la zona de trabajo de

radio más próximo.

j) Sujete el aparato sólo por las superfi cies de

agarre con aislamiento cuando lleve a cabo

trabajos en los que la herramienta de corte

pudiera entrar en contacto con cables eléctricos

ocultos o con el propio cable del aparato. El con-

tacto con líneas electrifi cadas también pondría

bajo tensión las piezas metálicas del aparato, lo

que causaría una descarga eléctrica.

Page 23

23

k) Mantenga el cable de la corriente alejado de las

piezas giratorias. Si pierde el control, el cable de

corriente podría separarse o quedar suspendido

y su mano o su brazo podrían verse arrastrados

hacia dichas piezas.

l) No suelte nunca la máquina hasta que la he-

rramienta no esté totalmente parada. Las herramientas giratorias se pueden enganchar en

la superfi cie de depósito y sacudir la máquina

fuera de su control.

m) No deje la máquina en funcionamiento mientras