Page 1

Getting the Most from Festool Sanders

Text and photos by Jerry Work

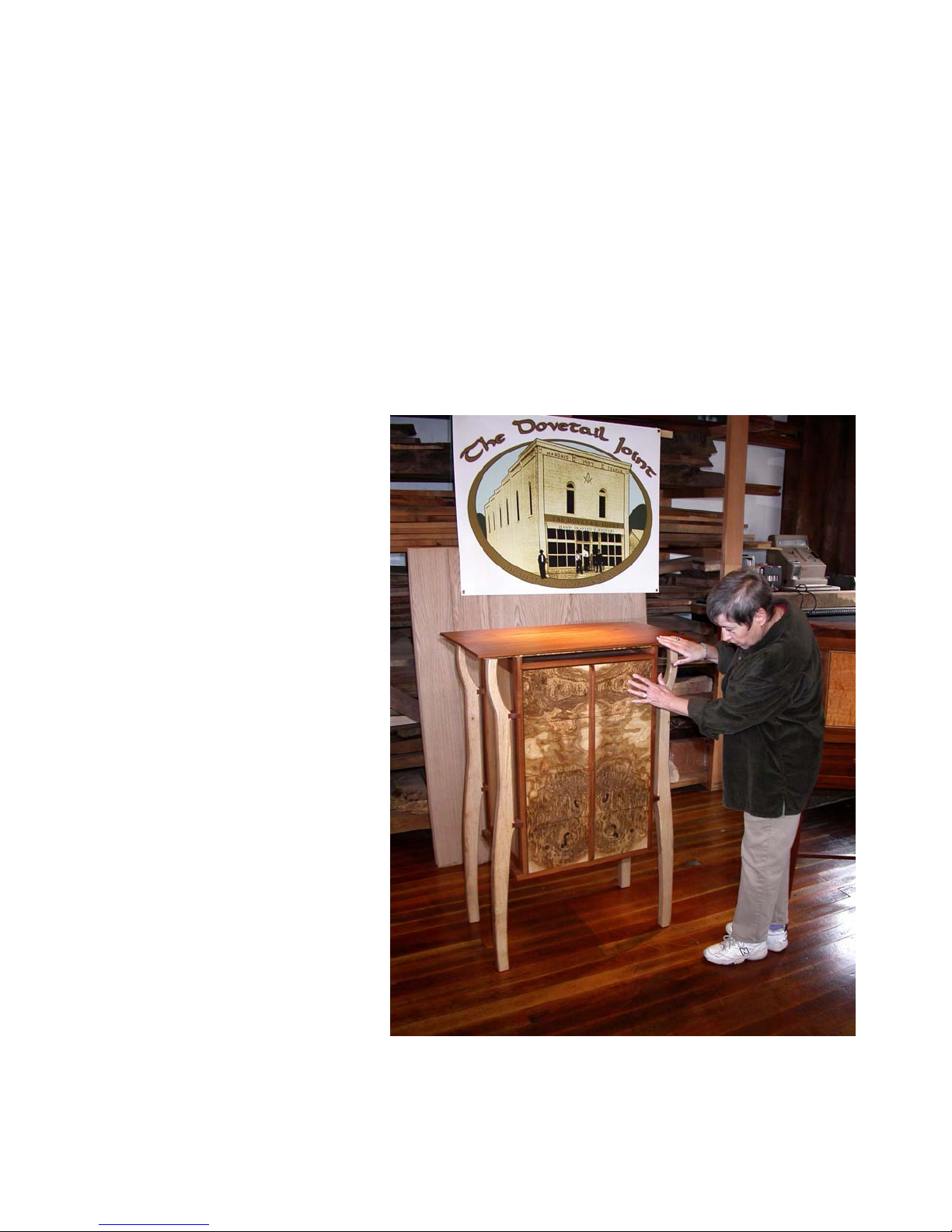

It is always fun to watch visitors who come into my small gallery and studio

as they approach the fine furniture I design and hand craft. Unlike those

who stand back to look at flat art or sculpture, when looking at furniture

most people move quickly to a piece and invariably move their hands

across the surface while they take in the piece with their eyes from up

close. They might pause

to ask if it is OK to touch

the pieces first, but once

they know they can, the

tactile urge takes over.

At some point the question

is always asked, “what

kind of finish do you use?”

It does not make any difference if it is a flat oil

based finish or a highly

polished mirror-like finish,

they seem to think the

silky tactile feel is somehow accomplished by the

application of a magic

elixir.

While the choice of finish

material is important to

achieving the desired

overall look and feel, the

far more important factor

is how the raw wood was

prepared before the application of the finish material. And, that is what this manual is all about.

Page 2

I thought long and hard about how best to organize this discussion. The sanders are

the machines which move the abrasive in a defined manner. The abrasives themselves

do all the cutting and shaping. However, in the process of cutting and shaping they also

produce a great deal of dust which can be quite harmful for the operator.

Festool wisely developed these three systems to work together: the sander, the abrasives and the dust collection components. Used together these not only make the

sanders more efficient and productive for the user but also greatly reduce the dangerous airborne particulate matter, making the work far safer and healthier and the tools

more pleasant to use day in and day out.

Finally, to make matters a bit more potentially confusing, as we come to understand

these different systems, there are at least three major standards by which the “grit” on

the sanding media are measured. So what is called 1000 grit by one standard is called

800 by another and 500 by still another “standard!”

All of these are important to getting the most from Festool sanders so I decided to organize this manual by first talking about the differences between the three grit “standards,” then talking about the dust collection systems and how they work together with

the sanders, then talking about the differences between the several different kinds of grit

media supplied by Festool, and then, finally, talking about the sanders themselves.

So, let’s go......

Page 3

Three Different Grit “Standards”

GRIT COMPARISION CHART

MICRON US CAMI

FEPA 'P'

(Festool)

JAPAN JIS

500 36 36 36

430 40

410 40

350 50 40

320 50

300 50

270 60

260 60

250 60

210 70

197 80

192 80

177 80

156 100

149 90

140 100

127 120 100

116 120

97 150 120

93 150

78 180 180 150

66 220 220 180

60 240 240

52 240 280 280

46 320 320

42 280

40 360 360

35 320 400 400

30 500

28 360 500

25 600 600

21 400 800 700

18 500 1000 800

15 600 1200 1000

13 800 1500 1200

10 1000 2000 1500

8 1200 2500 2000

7 2500

6 3000

and all.

In building fine furniture more than 50%

of one’s time goes into sanding, final assembly, buffing and polishing. The sanding part alone can take more than twice

the amount of time that it

took to machine all the

component parts of

the piece. Yet,

sanding processes,

tools and materials

are seldom as

carefully chosen as

are the machines

that cut the wood

components in the

first place.

Sanding, after all,

is just using some

kind of hard material to abrade the

surface fibers of

the wood, shearing

them off to leave a

smooth feel to the

surface. Simple to

say, but hard to do

well. As you

abrade the surface

you also scratch

the surface. If

those scratch

marks are large

enough, they will

detract from, not add to the appearance

of the final product.

So, the trick is to learn how to use smaller

and smaller particles of the hard material

to remove the larger scratches and leave

smaller and smaller scratches until they

no longer are visible and to do so in such

a way that the entire surface of the finished piece is uniformly treated, corners

Initially, this work was done laboriously by

hand by scooping up naturally occurring

small rock particles (sand) and rubbing

them over the surface with animal skins

or cloth. Later, means were found

to adhere the sand to a paper

or cloth backing and what

we today call “sandpaper”

was born. That is where it

started, but far from where

it ended.

What we call “sandpaper”

today rarely is either really

sand in the way we normally think of sand nor is it

necessarily paper. The

abrasive particles can be

anything from natural materials like garnet and

diamonds that have been

carefully processed to be

as even in particle size as

possible to manmade materials like aluminum oxide

or silicone carbide engineered with a very high

uniformity in particle size.

The backing material can

be various kinds of paper

derivatives or various

kinds of cloth materials or

manmade screens or

combinations of all three.

There may also be other materials added

to the abrasive surface like soaps and

waxes (called “stearates”) to help prevent

loading of the paper with small particles

of wood fibers and the resins that naturally occur in the wood.

Page 4

To add to the confusion surrounding

“sandpaper,” there are three different

“standards” applied to describing the size

of the abrasive particles. The US grades

are called “CAMI,” the European grades

including the Festool sanding media are

identified as “FEPA” and in Japan the

grades are identified as “JIS.”

The table on the previous page lists how

these different size grades relate one to

another with the actual size of the particles measured in microns. In coarser

grades they are quite close, but as you

move to the finer grades the differences

become greater.

It is not as important to know these differences as it is to recognize how the abrading materials you are using have been

graded. This is important because in order to achieve a desired very smooth final

finish you need to progressively “sand”

the finish with finer and finer grits before

you apply the finish and often afterwards

as well. You don’t want to be inadvertently jumping back and forth between

grading standards or you could be moving from a finer to a coarser grit without

realizing it.

Dust Control With Festool Sanders

All Festool sanders feature built-in dust

ports to which a vacuum or dust collector

can be attached. These dust ports lead

to pads which have a series of holes cut

in them. The Festool sandpapers have

matching holes cut in them so the vast

majority of the sanding dust is pulled

through the holes and out through the

dust port into the vacuum or dust collector without spilling out into the open air,

and therefore into the operator’s lungs.

Festool sanders

which use round

abrasives feature a unique

pattern of eight

smaller holes

around the outside edge of the

pad and paper

plus one larger

hole in the center of the pad

and paper.

Here is a picture of a typical Festool

round sanding material in the 150mm diameter size. The photo shows the back

of the material which has printed on it the

type (which we will discuss in a moment)

and grade (P180 in this case.) All Festool

sanders and supplied sanding media use

a hook-and-loop style of fastening which

means you can remove and reattach the

sanding material repeatedly and quickly.

For the sanders which use the round media, vacuum is drawn through the dust

collector port which is routed to the outer

eight holes. The center hole aligns with

specially designed air inlet ports in the

backing plates. This allows air to be

drawn in through the center hole and

then pulled out to outer holes bringing

with this air stream most of the sanding

particles. As a result Festool sanders are

Note the 9 hole pattern on the

pads on these two Festool

Rotex sanders

Page 5

very efficient in collecting sanding dust at

the point it is created.

Festool Dust Extractors

Festool supplied dust collectors (they

use the term “extractor”) like the CT 22

model shown below are very efficient

vacuums designed to work as a system

First, the Festool dust collectors come in

several sizes. The smallest is called the

CT Mini while the larger units are called

CT xx where xx refers to the collection

capacity of the internal bag. A CT 22 has

with all of the Festool sanders and cutting

tools. Combined with the 9 hole vent pattern in the round pad sanders, and the

variety of hole patterns in the other sanders, this potent team keeps the air around

the sanding area much cleaner and safer

for the person operating the sander.

Since human safety is such an important

topic with respect to sanding, let’s take a

few moments to look in more detail at

how the Festool sanders and dust collectors work together.

a 22 liter (5.8 gallon) capacity, A CT 33

has a 33 liter (8.7 gallon) capacity and so

on.

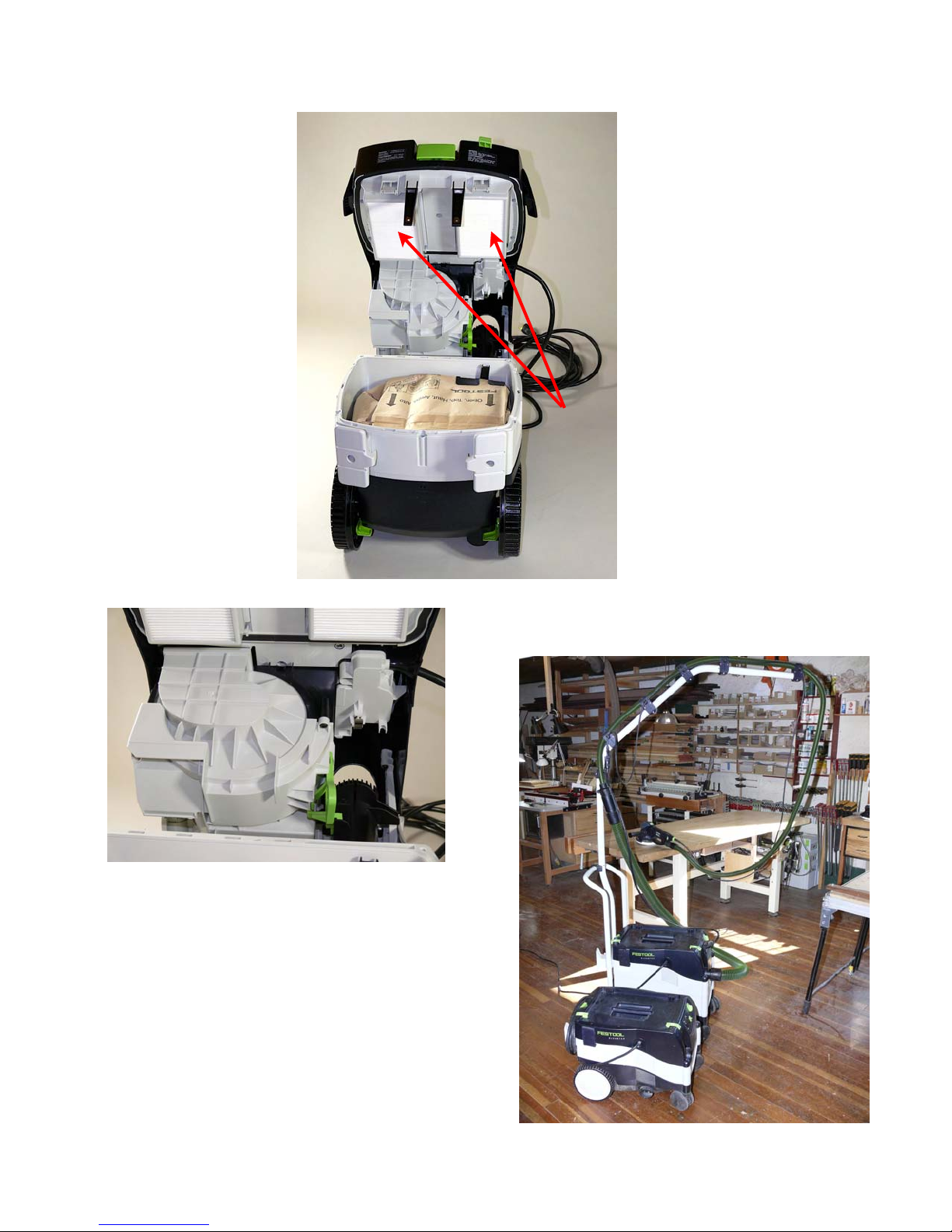

The CT Mini pictured above has a 10 liter

(2.6 gallon) capacity and hose/cord storage built into the top of the unit. As with

all the other Festool dust collectors, it can

utilize hoses of

different diameters for different

tasks. It comes

with a 27mm

(~1”) hose but

larger diameter

hoses can also

be connected if

need be.

Unlike the other

Festool dust

collectors, the

CT Mini opens

Page 6

by releasing catches on the sides of the

unit and then lifting the whole top assembly off of the base section as is shown in

the bottom photo on the previous page.

The bag snaps into the bottom assembly

and a cone shaped section in the upper

assembly engages the bag opening

(which is sealed by a soft lip running all

around the bag opening) when the two

assemblies are brought together.

Air is sucked in through the hose port and

into the bag trapping most of the airborne

particulates. The now largely cleaned air

that passes through the disposable bag is

further scrubbed by replaceable automotive type air cleaner elements (shown in

brown in the upper assembly in the bottom photo on the previous page) before

being returned to the room.

Suction is 99 CFM with up to 80” of static

water lift so performance is impressive

even for such a small unit.

Inlet air tube

Inlet air tube

CT 22 Dust Extractor

The CT 22 and larger units are different.

First, the top hinges open rather than lifting off. The disposable bags fit into a

chamber tightly connecting to the incoming air hose tube shown in the photos

above and to the left.

CT 22 Dust Extractor

An “O” ring seals the bag chamber to the

top when the top is closed. As with the

CT Mini, the air coming through the disposable bag is quite clean. But unlike the

CT Mini which uses automotive style air

cleaner elements, on the CT 22 and

larger units, before the air is returned to

the room, it passes through dual HEPA

filters shown in white in the photo on the

next page. These remove 99.97% of all

particulate down to 0.3 microns in size

so that the air coming back into the room

where you are operating the sander is

99.99% dust-free.

Page 7

This is why the designed interaction

between the dust

collection built into

each sander and

the dust extraction

system itself is so

important to discuss

before we move on

to the sanders

themselves.

HEPA (High Efficiency Particulate

Air) filters were developed by the U.S.

Atomic Energy

Commission to remove radioactive

dust from industrial

exhaust. These

type filters are now

from the room is used to

cool the motor which is

never in the path of the

incoming dirty air. That

means a longer service

life and little down time.

The green tabs shown

on the inside of the back

wheels in the picture to

the left operate wheel

locks to keep the unit

steady when you want it

fixed in position.

HEPA

Filters

The front wheels are

casters for easy rolling

around.

As the size increases on

the CT 22 and larger

units the motor assembly remains the same,

but the lower chamber holding the bag

the primary filtration systems used in the

most sensitive manufacturing and healthcare environments.

They are a most welcome addition to my

studio and will be to your studio or shop

as well!

Another important feature of the Festool

dust collectors is the sealed motor chamber shown above. Only clean air drawn

CT 33 behind

CT 22 in front

Page 8

gets taller. A CT 22 is shown in front of a

CT 33 in the photo on the previous page.

Notice how the white lower section is

taller on the CT 33 than on the CT 22.

They draw 134 CFM and pull an impressive 90” of static water lift (23000Pa)

while generating only a 72dB noise

level.

I can’t leave the discussion about the

Festool dust collectors without commenting on the boom arm shown

mounted on the CT 33 on the previous page and to the right. This highly

useful device keeps the vacuum

hose and the power cord up off the

floor and out of your way no matter

which Festool product you might be

using.

When I first heard about the boom

arm I must admit that I thought it was

just one of those ‘nice to have but

certainly not critical’ items. From the

minute I first used one, I changed that

position 180 degrees. It simply alters for

the better how well the already very good

dust collection system works in a shop or

studio setting.

As you can see, bottom left, for years I

kept a Festool dust collector under my

primary sanding station with all the various Festool sanders close at hand. Yes, I

After the boom arm

was always stumbling over the hose and

the sea of cords shown in the photo below but, it was so much better than anything I had used before, I guess I just ig-

nored the mess and instead

enjoyed the dramatic improvement in productivity brought on

by the tight integration of the

sanders and the dust extractors.

Before the boom arm

However, as soon as the boom

arm mounted on the Festool

DC moved to the far side on

one end of the sanding station,

everything changed for the better. As the photo above clearly

shows, the sanding station now

is free of the hose/cord clutter

on the floor. The power strip

into which all the sanders

Page 9

were plugged is gone, replaced by the

one power cord that is right beside

the vacuum hose. All the sanders

are still in the same place and right

at hand, it is just that now the hose

and cord are both up off the floor and

out of my way.

The boom arm mounts easily to the

back of any of the CT 22 or larger

dust collectors. It swivels through a

wide arc so there is good work surface coverage. You can mount stabilizing out-riggers (supplied) if you

wish but I don’t find them necessary

the way I use the unit. I can’t say

enough good about the boom arm.

I won’t cover here the several other

neat features of the Festool dust collectors like the 20 amp power cords, the

self-locking stacking storage for the

boxes the sanders and other Festool

products come in (called “Systainers,”)

but instead will direct you to the Festool

catalog and web site for more details.

on the tool.

Many of the sanders also come with

handy “mini bags” which attach directly to

these ports when you are working in areas not easily reached by the dust collector hose. The photos here show both the

round and the oval port configu-

rations. Notice the “O” ring seal

at the bottom of the port fitting.

A nice touch.

“O” ring seal

All the Festool products with built-in dust

collection have either round or oval ports

Festool vacuum hoses have

soft rubber ends that can easily

mold to either the round or the

oval shape, and the green versions of those hoses are antistatic so they don’t build up dust

on the outside as normal vacuum hoses do.

Ok, now we know something

about the three different grit sizing “standards” (remember Festool supplied grits all use the

European FEPA

Page 10

standard,) and we have covered the very

important topic of user health via the dust

collection ports built into every Festool

sander working in conjunction with the

HEPA filtered Festool dust collectors, so it

is now time to move to the topic of the

sanding media itself.

Page 11

Festool Supplied Sanding Media

Festool supplies an extensive line of

sanding media for each of its sanders.

These different sanders utilize seven different shapes and sizes of pads so there

are seven different shapes for the Festool

supplied sanding media as shown here.

while Brilliant media is more densely

populated. This means that for any given

grit size, there will be fewer actual granules of grit per surface area on the Cristal

paper than on the Brilliant paper. As a

result, the Cristal paper will cut more aggressively and load up less than the Brilliant, but the Brilliant will leave a finer surface at any given grit level than will the

Cristal.

For really heavy duty work where tearing

of the media could be an issue, the rec-

ommended media is called SAPHIR. For

cleaning and mild sanding a scouring pad

type material called VLIES is supplied.

For solid surface (manmade countertop

materials) and automotive work where

paper loading can be a major issue, a

stearated media called TITAN is avail-

able.

The round shapes are 150mm, 125mm or

115mm in diameter. The triangular

shapes are 100mm x 150mm or 93mm x

93mm while the rectangular shapes are

either 80mm x 133mm or 115mm x

228mm. These equate to 6”, 5”, 4 1/2”

round, 4” x 6” or 3 11/16” triangular, and 3

5/32” x 5 1/4” or 4 1/2” x 9” rectangular.

For each of these shapes several different types of media are available. Each is

given a name which can be a bit intimidating at first. In the catalog and on the

web site an icon is used to identify the

most common use for each media type.

For our purposes I think the following

simple explanation will help clear things

up.

For bare wood the recommended type is

called RUBIN. For bare wood, paint,

varnish or filler materials either CRISTAL

or BRILLIANT can be used with success.

Cristal is a much more open grit paper

PLATIN is a special purpose mesh on

foam media designed for fine sanding of

metal or surfaces to be polished.

The ones I use the most in my furniture

making are Brilliant, Rubin and Cristal

and I use them on bare wood interchangeably. On finished surfaces that I

want to flatten before applying additional

top coats or before final polishing, I use

Brilliant. I also find lots of uses for the

scouring pad type material called Vlies. It

will brighten and clean metals, clean up

plastics without burning, clean rust off my

cast iron tool tables without changing the

surface itself, and scrub sinks and floors

clean when I gunk them up with finish or

glues.

There is no right or wrong here. Any media can be used for any task, it is just that

each is optimized for the task indicated.

Let’s look at each in a bit more detail.

Page 12

Brilliant is a

paper based

material of differing weights

to which highstrength aluminum oxide has

been bonded

by a synthetic

resin compound. It uses

antistatic

agents to reduce loading of the abrasives as you

sand. It is ideal for both sanding of bare

woods and for sanding paints and varnishes (sanding the finish itself). Since

the backing is thinner than Rubin or Saphir, it will follow minor contours somewhat better. It is also less expensive

which makes it an all-around good choice

for most furniture making applications.

has been bonded, also by a synthetic

resin compound. It uses special filling

materials to prevent premature clogging

with sanding dust or wood fibers. It tends

to last longer than Brilliant and is somewhat more expensive. It is also a good

all-around choice for most furniture making applications and does an especially

good job on bare wood.

Saphir is a

cloth based

aluminum oxide

designed for

rapid stock removal on wood,

metal, or manmade materials.

It is most commonly used

with rotary action sanders.

Cristal is an open coat material similar to

Brilliant but with fewer grit particles per

unit of surface area than Brilliant or Rubin. It is especially good for rapid stock

removal and for taking off old finishes

without undue damage to the underlying

surface. It is my first choice if the wood

surface is damaged and in need of flattening before finish sanding can begin or

where I am intending to shape the wood

before final finishing. It cuts very quickly

and does not load up even on resinous

woods like Bloodwood, Jataba, Teak, Cocobolo, Rosewoods and other exotics. It

does leave a more noticeable grit marking than either Brilliant or Rubin but those

grit marks can be quickly taken out by

starting with Brilliant or Rubin several grit

levels coarser than the last Cristal grit

used.

Rubin uses a heavier weight paper to

which another form of aluminum oxide

The heavy cloth

type backing can take more heat and

abuse than the paper backed materials

used on Brilliant, Cristal and Rubin.

While it can take more heat, be careful as

it is very aggressive and can remove a lot

of stock very quickly. In the process a lot

of heat can be generated. Use a light

touch and the results are very impressive.

Titan has a water resistant backing material and is designed for smoothing solid

surface (manmade) countertop materials

or automotive finishes.

Vlies is more like a

scouring pad and is

designed for smoothing finished surfaces or

for removing rust,

paints or pollutants

from just about any

surface. It uses both

Page 13

aluminum oxide and silicon carbide particles embedded in a synthetic fiber mat

allowing it to easily follow surface contours and to reach into surface imperfections. It does a great job of cleaning most

anything and in coarser grits can be quite

aggressive.

Platin is a mesh material impregnated

with silicon carbide abrasives on a foam

layer which I use either as a final step on

polished surfaces or for the final flattening

steps just before the use of rubbing or

buffing compounds. They are available in

“grits” up to 4000 so produce a really nice

fine surface on their own.

and valleys a bit like a topographical map

rather than a flat surface.

If Platin is used as the final step you will

get a very flat surface which will refract

light well but which has less surface

sheen than is achieved by following with

rubbing or buffing compounds so the surface will reflect a bit less light.

The view above is of the working surface

of Festool’s Platin while the photo above

right shows the foam layer (this photo of

another manufacturers similar product).

When Platin is followed by rubbing or

buffing compounds an extreme high gloss

can easily be achieved. Try this on highly

figured woods like big leaf maple that

have been finished by quality clear water

based conversion varnish and people will

just have to touch the surface to make

sure it is flat. It looks so three dimensional they will swear there are peaks

For some “real” magic on bare hardwood,

especially resinous exotics like bloodwood or rosewood, sand to around 800

grit and then use Platin working up to

4000 grit. The surface of the unfinished

wood will take on a gloss and patina of its

own that simply cannot be matched by

any finish I know if. A bit of wax will maintain that patina, but it is an easily marked

surface unsuited for any wear and is not

at all water resistant.

There are a number of other abrasive

materials available from other manufacturers that can also be useful but some

may present a bit of a downside as well.

One, sold by Mirka, is called “Abranet”. It

is an open silicon carbide mesh. Without

the interface pad also sold by Mirka, the

use of Abranet may prematurely wear the

hook and loop elements on the Festool

Page 14

pads, so be careful when using abrasive

materials supplied by others.

Why so many different kinds of

sanding materials?

Offering an array of different engineered

abrasives came about naturally for Festool. While they first became known in

Germany for the development of a portable chain saw in the 1920’s (photo right),

they really made their mark shortly after

WWII with the development of the first

powered orbital hand sander (lower photo

right.)

This tool so improved the efficiency of the

German furniture makers that, according

to a story in the January 2005 issue of

“Handy” magazine, those artisans would

travel for miles by bicycle to pay their deposits knowing they would wait weeks

just to receive one.

(These photos are from the Handy magazine article which can be found on the

Festool web site, www.festoolusa.com.)

Since that time Festool has refined and

expanded the art and science of power

hand sanding. Along the way they have

introduced numerous machines for moving the abrasive particles across the surface of the wood, added all these different kinds of abrasive materials, and designed integrated dust collection creating

whole “systems” optimized for this task.

Our next task is to look at the sanders

themselves.

Page 15

Let’s start by understanding how

the different kinds of sanding

machines do their job.

We are going to look at nine different

Festool sanders covering the range of

different ways of moving the abrasive.

the “old” and the “new” Rotex as we discuss that sander. The 150mm (6”) pad

diameter Rotex (the two shown on the left

in the bottom photo) is now also joined by

a 125mm (5”) pad diameter unit (shown

right most of the trio).

To help you judge relative size, each

sander we talk

about will be

shown with the

same collection

of different sizes

and shapes of

media and they

will also be

shown with me

holding each.

Hopefully, these

two visual cues

will put the different sizes into

better perspective.

The seven shown in this photo

sitting atop two Festool Multi

Function Tables (model 1080)

joined together are from my

studio and are in use daily. I

did clean them up a bit for

these photos, but they show the

marks and scuffs from continuous use.

Festool has also introduced an

upgraded version of the dual

mode sander shown second

from the left above (called the

“Rotex” sander), also shown in

the picture to the right. We will

cover the differences between

Each different

kind of sander is

designed to

Page 16

move the abrasive in a different pattern or

to have a different abrasive form factor to

reach different shapes of surfaces.

RS 400 (not pictured), DS 400

(second from the right) and RS 2

(third from the left) use an orbital

There are basically three different ways

the abrasive can be moved by a machine

sander: linearly in a fore-aft motion, in

a circle in a rotary motion, or back

and forth in an arc. Festool uses the

first two motions but not the arc motion.

If these motions are combined or the

pivot point is also moved at the same

time, the motion becomes much more

complex. If the pivot point rotates and

the pad is free to move independently but

not forced to move in a defined path, then

the motion is called “random orbit”.

We will discuss each of the different Festool sanders in terms of how they move

the abrasive from the pure rotary sander

to the various random orbit units.

RAS 115 uses a pure rotary motion

(third from the right in the picture).

motion.

DX 93 Deltex (right most pictured)

uses a tight rotary motion.

ETS 150/3 (left most), 150/5 (not

shown), and ETS 125 (not shown)

use a random orbit motion.

RO 150 Rotex (second from the

left) and RO 125 (not pictured) can

be switched between a random orbit motion and a rotary motion with

a rotating pivot point.

LS 130 uses a pure linear back and

forth motion (center one pictured).

Page 17

Let’s start with the RAS 115.04 E

sander. It is a pure rotary sander with a

circular pad 115mm (about 4 1/2”) in diameter. Some might liken it to an angle

grinder. The abrasive material is affixed

to the pad by a hook and loop system

that allows the material to be removed

and replaced without damage.

You can see from the photo above right

(RAS 115 in foreground) that there are no

holes around the perimeter of the pad as

in the other Festool sanders like the RO

150 behind it. Instead, there

is a space between the pad

and the base of the machine

through which particles are

drawn out through the built in

vacuum port at the rear of the

machine. There is a brush

about one third of the circumference of the pad (at the bottom of the pad in the photo)

that can be rotated to any position around the outside of

the pad to help direct these

cut particles into the vacuum

port. The handle on the side

of the machine is rotated to move the position of the brush. The speed of rotation

can be varied from 1500 to 4000 RPM.

Brush can be rotated

This is a VERY aggressive machine capable of removing a lot of material in a

hurry. This much abrasive action generates a lot of heat. It takes a light touch to

prevent digging the pad too far into the

work piece and to prevent overheating of

the pad or the work piece.

I find it ideal for rough shaping wood such

as carving a chair seat for example. In

furniture designs where I want to instill an

Oriental feel, I often will curve the under

sides of top or shelf components, a process I refer to as “boating.” The curves

are more abrupt (have a smaller radius)

at the outer edges and become softer (have longer radiuses) towards the center.

Such complex curves can be

roughed out easily and

quickly with the RAS sander

and then finished with one of

the less aggressive sanders

we will discuss later on.

The RAS sander is also very

handy for removing paints,

rust or surface contaminants

as long as you keep in mind

just how much heat doing so can generate. You don’t want to burn the work

piece nor do you want to burn and ruin

the pad.

Page 18

The Vlies scouring pads shown in use

with the RAS 115 to the right are especially useful for this as they tend to dissipate the heat better than regular abrasive

sheets do and leave far fewer deep

scratch marks than coarse abrasive

sheets will.

In this photo I am cleaning the floor of my

finish room which, as you might imagine,

gets quite gunked up from time to time.

The RAS 115 with Vlies scouring pads is

just the ticket.

The small (115mm) diameter pad helps

get into nooks and crannies that larger

grinder style units cannot such as under

the toe kick on the cabinets that are present in my finish room.

My suggestion is to practice a bit with this

machine before starting in on an important work piece. Use a slower speed and

a lighter touch until you get the feel of

how aggressive it is with a given abrasive

material. Once you develop a feel for it,

you will find it in your hands often.

Dust extraction, while very good, is not as

complete as with the other Festool sanders which employ the nine hole system

we discussed earlier where air is drawn

through the center hole and out through

the eight outer holes and into the attached dust collector. As mentioned

above, the RAS 115 instead uses a

space between the sanding material and

the body of the unit to draw the sanding

grit out through the vacuum port. The

brushes that can be rotated around the

outside perimeter of this space are what

help to direct the sanding grit into the

vacuum port.

Page 19

The LS 130 EQ is a pure linear

sander. It moves the pad fore and aft in a

4mm (5/32”) stroke. There is no rotary or

side to side action. This allows the effi-

cient

sanding

of

edges

and

profiles

that

would

not be

possi-

ble by

any other means. Sanders which move

the pad in any direction other than purely

linearly will create a flat spot on any linear

curved surface like a stair handrail. With

the LS sander you can easily do rebates

(rabbets), edges, or profiles that otherwise would require laborious hand sanding.

attached vacuum through a port designed

into the machine itself.

Finally, a scraping knife (shown in the

Many different pads are available to fit

flat profiles, both concave and convex

radiuses of different sizes, and various

angles. The standard profile pads are

shown here along with the sander itself.

There even is a kit (shown to the right of

the sander) which will allow you to create

a custom profile. A block of foam with

dust extraction holes already formed into

the block is included along with glue and

a hook and loop surface. Temporarily

glue the hook and loop to the profile with

the included contact cement. Fit a piece

of sand paper to carve the backer block

to the shape of your custom profile. Now

glue on the hook and loop surface to the

profiled backer block and you are ready

to sand to exactly that shape. Slick!

Each of these pads has holes in it to allow the extraction of sanding dust via an

center of this photo) is offered as an accessory. Since the motion of the LS 130

is purely fore and aft you can use this to

scrape off wallpaper, carpet, and other

glued on materials far more easily than

you could do by hand.

Page 20

Next are the orbital sanders.

These move the pad in an orbit around a

fixed pivot point. The DS 400 EQ (pictured) is a very small and lightweight

sander that employs a triangular shaped

pad that moves in a 2mm (5/64”) orbit.

Its companion is the RS 400 EQ (not pic-

While pure orbital sanders

from other

manufacturers

often will leave

very noticeable

circular scratch

patterns, the

small diameter

orbit on these

two leaves a

nearly imperceptible scratch

pattern with all

but the largest grits. They are not in use

every day in my studio like the other Festool sanders are, but when the small size

or tight corner ability is needed, they are

really handy.

The other pure rotary sander, the RS 2 E

(pictured below) is another story. It is a

big, powerful work horse that is in my

hands virtually every day. It has a bit

tured) which has the same small size and

orbit but with a rectangular pad.

Both are so much smaller than most of

the other Festool sanders that they are

ideal for getting into corners or areas like

the inside of the box pictured above

where the RS 2 E (on the left) and the

ETS 150 3 (on the right) simply won’t fit.

Page 21

larger orbit (2.5mm), has a much larger

pad (115mm x 228mm or 4 1/2” x 9”), and

at 5.5 pounds is twice as heavy as the

DS and RS 400 sanders.

That big flat sanding pad (the right most

media pictured above) simply cannot be

beat for smoothing out large surfaces. It

is not an overly aggressive sander compared to the RAS 115 we discussed earlier or the RO 150 we will be discussing

shortly, but you can use it all day long

with no tingling of the hands. Since it

produces a really flat surface, there is no

worry about dips or gouges showing up

after the final finish is applied.

The weight works very much in your favor. All you need to do is guide it across

the surface. No downward pressure is

needed and none is desirable. Just glide

it along nearly vibration free and enjoy

how the surface begins to develop a

natural patina even before you apply any

finish at all. I often stop just to admire the

natural beauty of the wood itself once I

have worked up to the finer grits.

As pictured here you can see

how the large flat surface is

ideal for rail, style and panel

components where a tip of

the sander could well leave

an undesirable depression

along an edge.

The RS sander is also the

champion in my book for

sanding edges and breaking

sharp edges. I particularly

like the way it handles end

grain. The pure orbital action seems to me to cut the

end grain fibers more

cleanly than any of the other

sanders. You can also get

right up into corners on pan-

Page 22

els that are not raised flush with the surrounding rail and style components.

You can get either hook and loop pads or

pads with a clamp on each end to mechanically hold the abrasive material. A

hole punch is available if you prefer to

use your own abrasive sheet goods instead of buying the pre-punched sanding

materials.

stand shown both in process and completed) without it.

If you get the impression that I like this

sander a lot, you are correct. I use it

every day and can’t imagine making

fine furniture (such as the Brazilian

Cherry and Black Walnut plasma TV

Page 23

The DX 93 E “Deltex” sander is a specialty sander with a number of tricks up

its small “sleeves.” It rotates in a short

orbit to prevent the scratches that I found

common with other brands of arc swing

detail sanders. Those other brands simply move the pad in a fixed arc which exacerbates scratch marks since, unless

you constantly

move the machine, the same

sanding grit

passes the surface of the work

piece at the

same location

repeatedly

leaving often

hard to remove

deep scratches.

The DX sander

does not do this

and the results even in tight corners are

outstanding.

It is gear driven so it can drive even

coarse abrasives easily, but where I find it

really shines is in doing careful detail restoration sanding. This was required by

my son, Alex, for the fragile pieces on this

folding lap table made a half century ago

by Tubbs, the Wallingford, VT, snow shoe

company. Turn down the speed, put on a

fine abrasive, and the DX becomes a

very precise sanding tool that won’t tear

up details that you want to preserve.

While the DS 93 is featured by Festool as

“.... designed for strong abrasion through

reduction gearing ..... ideal for stripping

off old, thick and stubborn coatings,” I find

it also is one of the gentlest and most

easily controlled of all the Festool sanders when the speed is turned down. I

don’t make scale models, but, if I did, this

would be the first sander for which I’d

reach.

The pad at 93mm x 93mm (left in the

photo to the right) is quite a bit smaller

than the 100mm x 150mm pad on the DS

400 (right) we discussed earlier. Also, the

form factor is flatter so you can maneuver

the DX into even smaller areas than you

can with the DS sander.

Page 24

Both hard and soft pads are available.

Festool materials are offered in Brilliant,

Rubin or Saphir (shown right) up to 400

grit.

I often hand cut much finer grits from

other size materials and use them on the

DX 93 when I want very fine finishes in

very tight corners. With no holes in my

hand cut abrasives the dust collection is

not good so I have to be careful to frequently wipe away the residual sanding

dust. Dust collection with the Festool

supplied materials which do have the

proper holes is excellent.

The photo on the right shows the relative

sizes of the DX 93 (right) and the DX 400

(left). The tape measures may help you

visualize the absolute size of each.

Page 25

This brings us to the best known of the

Festool sanders, the random orbit machines and the highly regarded Rotex

units.

Random orbit machines rotate a pivot

point while allowing the attached but

not mechanically driven pad to move

in a random motion. This produces

very fine finishes with little or no scratching so long as you keep the pad flat on

the work surface. Tip the pad to get more

aggressive stock removal and

scratches are sure to be the result.

In the Festool lineup three random orbit sanders are offered:

two 150mm (six inch) pad size

units and a 125mm (five inch)

pad size unit. The ETS 150

EQ units are available with either

a 3mm orbit for fine sanding

(shown here on the left and below) and a 5mm orbit (not pictured) for more aggressive, but

still very fine, stock removal. The

ETS 125 (not pictured) has a

2.5mm orbit.

All three feature the Festool unique “Jetstream” system for dust removal and control. As we discussed in the

beginning of

this manual, the

machines draw

air through a

hole in the center of the abrasive material

then out

through eight

holes around

the outer perimeter of the

pad through a

port designed

into the sanders

themselves. This system is so effective

that even after a day of sanding I seldom

need to clean off my sanding center nor

do I find a need for ceiling mounted ambient air dust cleaners. I only wear a

Page 26

mask when dealing with woods that I

know cause an allergic reaction.

I can’t even begin to remember how

many random orbit sanders I wore out

and threw away before I began buying

Festool sanders when they first became

available in the US. No matter what

brand I tried, I always found myself limited in how long I could sand by vibration

induced tingling in my hands and by the

cloud of dust thrown off. I also was always irritated by having to replace the

hook and loop pads every few months.

Not so with the Festool units. The vibration is so minimal that I never even think

about the length of time I have been

sanding and seldom, if ever, feel that

dreaded tingling sensation in my hands.

In all the time I have used Festool sanders, I have only replaced pads on two of

them: once

on a Rotex

unit that I

simply wore

out since it

was in use so

much, and

the other time

on the RAS

when I first

got it and did

not realize

just how

much heat

could be

generated by

that aggressive unit (“pilot error” on

my part, not a

design issue

with the machine.)

Now let’s look at what I call the “great

synthesizer” of the Festool sanders, the

dual mode Rotex sander, buffer, pol-

isher unit shown here. The previous version is shown in the top photo and the

newer, replacement version is shown left

along side the previous version in the

lower photo.

These have the form factor of angle

grinders but that is where any comparison stops. The Rotex units, whether the

Page 27

150mm (6”) pad unit or the 125mm (5”)

unit (both shown here for size comparison), feature a switch selectable sanding

action. The green switch on the top

makes the mode change. In one mode

they act just like the ETS random orbit

units. Switch modes on the RO 150 or

the RO 125 and things get very different.

The second mode on both machines is a

hybrid between the gear driven pure rotary motion of the RAS 115 and the pure

random orbit motion of the ETS units.

the random orbit mode and smooth out

the relatively rough surface left by the rotary mode all the while gathering up all

that sanding dust through the

unit and off into the bag of the

vacuum rather than sending it

into the air and into your lungs.

Remove the sanding hook and

loop pad and put on a

polishing/buffing pad and the

RO units turn into one of the

finest variable speed polishers

I have ever used.

To buff out a build finish to a

mirror-like surface takes only

the Festool felt pads and a

couple of grits of an automotive polishing compound. With

rotary motion speed control

from 240 to 560 RPMs and eccentric motion control from 2000 to 5600

orbits per minute you don’t have to worry

about burning a sensitive finish or knocking off the edges unless you simply

“screw up.”

Practice a bit and you can replicate a guitar or piano gloss like the top of this coffee table done in highly figured Oregon

The gear driven pad turns in a rotary

motion while the pivot point orbits to

minimize burning and scratching. In

this mode (what Festool calls “rotary/

random” mode) these units are capable of removing stock at a very rapid

rate. Put on a coarse grit and I would

call it very, very rapid stock removal,

enough so that with the 150mm pad it

can be a handful to control until you

get the hang of it.

What is slick is how you can do rapid

stock removal with one grit and then

without even switching grits change to

Page 28

big leaf maple. Truly amazing results and

all from one very versatile machine.

No question about it, the Rotex machines, along with the big flat pad RS2E,

are my favorite Festool sanders, hands

down. I use the others for special purposes, but day in and day out it is either

the Rotex or the big flat pad RS2E that is

in my hands most of the time.

I use the Rotex with papers of all kinds up

to 1200 grit, with mesh backed screens

up to 4000 grit and with felt pads and

several different grits of polishing compounds. I also use it for applying waxes

when I want a soft “hand” on a piece.

all the way to the 14 foot ceiling. The

vent hood was constructed of plywood

and then covered with 5mm thick veneers

of the Bloodwood. After the final sanding

(with the RO 150 and Festool CT22 dust

collector,) wax was used as the final finish to produce the soft patina look I was

after.

Notice how easy the RO 150 is to control

even with one hand. With both hands on

the RO 150 it is really easy to manage

allowing you to balance even in difficult

locations such as on a ladder without

having to hang on for dear life.

One wax I really like is a combination of

beeswax and hard carnuba wax in a toluene base that can be somewhat difficult

to apply evenly. Put a 6” micro fiber pad

(available from surbuf.com) on the hook

and loop surface of the RO 150 polishing

pad and waxing becomes as easy and

fast as polishing.

That is what I am doing in this picture.

Here the design of this very modern

kitchen with solid wood countertops

called for a South African Bloodwood

stove vent hood over the top of the commercial gas range. The vent hood goes

Before I take a piece to a show or put it

into a gallery where I know it will be “lovingly” handled frequently, I like to put on

three coats of this wax since fingerprints

from one day can simply be wiped off before the show opens the next.

When I did this by hand on large pieces it

was a significant task. Now it is a “no

brainer” that I can do at the last minute,

thanks to the RO machines.

The RO 150 E has a 5mm stroke identical to the ETS 150/5 and, in random orbit

mode, sands just the same and hence

just as well. The smaller RO 125 uses a

3.6mm stroke and performs in random

orbit mode much the same but a bit more

aggressively than the ETS 125 with it’s

2.5mm orbit.

Page 29

Conclusion

In this manual we have looked at nine different Festool sanders which run the

gamut from pure rotary, to pure linear, to

pure orbit, to combinations of all of these.

The different kinds of sanders allow you

to select the optimum abrasive motion for

the work you are doing and the result you

want to achieve.

The question I get all the time is, “Which

should I buy”? I think the best way to

parse that question is the following:

If you are only able to buy one Festool

sander, and you do general woodworking

and furniture making, my recommenda-

tion is to start with the RO 150 or RO

125 Rotex sander. These are the allaround work horse sanders that, with the

right abrasive materials, can take you

from aggressive sanding and shaping in

the rotary mode through fine finish sanding in the random orbit mode. Switch to

felt pads and rubbing compounds to impart a mirror-like shine to your finish or to

apply waxes easily. The one I use the

most is the RO 150 as I like the 150 mm

(6”) sanding surface. The smaller 125

mm RO 125 works just as well, only covers less ground. Some like the lighter

weight of the RO 125, but I do not find the

RO 150 either heavy or clumsy.

The RO 150 uses a 5mm stroke while the

RO 125 uses a 3.6 mm stroke which can

result in a slightly smoother finish with the

same grit abrasive.

Need to sand large flat surfaces? The

choice is simple - use the RS 2. The

2.5mm stroke and pure rotary motion

coupled with the large (4.5” x 9”) rectangular pad produces an exceptionally

smooth flat surface. It is ideal for panels,

edges or any flat component. It is so

smooth you can sand all day if you need

to without the dreaded tingle in the

hands, wrists or arms. Dust collection is

really good when coupled with any of the

Festool vacuums.

If one is doing model work or trying to

reach small recesses my choice would be

the DX 93 Deltex sander. The small

triangular pad reaches where most other

pad shapes will not. At high speeds such

as the maximum 9,500 RPM its 2.5mm

sanding stroke produces very rapid stock

removal but obviously only over small

surface areas as the pad is only 93mm x

93mm. Slow it down to the low speed of

5,000 RPMs and use a fine grit to produce very smooth, very controlled sanding on small or fragile components.

Is rapid stock removal or rapid cleaning of

gunk or rust the objective? Go for the

RAS 115. Put on Saphir, Cristal or Ru-

bin abrasives and shape just about anything. Switch to Vlies pads for cleaning,

gunk and rust removal.

Do you need to sand profiles or odd edge

surfaces? If so, there is no substitute for

the LS 130 pure linear sander with all of

the available profile shape pads. Add the

profiling kit and you can easily custom

shape a backer pad to fit nearly any profile.

More and more I am asked to make solid

wood countertops like the ones shown on

the next page. To make them properly

(so they will never warp,) I like to place

sliding dovetails every 150 to 300mm

along the bottom side. This allows the

solid wood top to expand and contract

with normal seasonal changes in humidity

while holding the top from warping over

Page 30

time. A lip covers the ends of these sliding dovetail stringers. The top is attached

to the cabinet by screwing into the stringers.

Most of my customers prefer a soft

rounded edge like is shown here which I

like to cut with a Festool 491-015 roundover bearing guided router bit. To finish

sand that curved edge I use a 491-197

pad on the LS 130. While the round-over

bit has a 9.5mm radius and the pad is a

10mm radius, the results are very good

indeed.

As we discussed earlier, a really nice feature is the ability to make your own custom profile using the 490 780 kit. With it,

you are limited only by the overall size of

the pad (80 x 195mm). If the edge profile

is bigger than that, you can use two or

more kits to make custom profiles for different parts of the edge profile. I

can’t tell you how much hand sanding time this gem saves.

If furniture making is what you do and you

can bring yourself to invest in three Festool sanders, the combination of the RO

150 Rotex, ETS 150/3, and RS 2 shown

below is really hard to beat. The RO 150

(previous version pictured foreground left)

will do the fast stock removal and shaping

operations as well as the sanding up to

the middle grit range. Then switch to the

ETS (rear) for the finer grits and the RS

(right) for the flat panels and your work

will take on a whole new smoothness. If

polishing and buffing fits the look you are

after, put felt pads or a sheepskin pad on

the RO 150 and let rubbing compounds

and waxes work their magic. You will be

floored by the mirror-like surface you can

create. Then, when your needs, interests, and pocket book allow, add one or

more of the spe-

cialty sanders

shown here.

In general, random orbit sanders

will likely be the ones you use the

most often in the most different applications with the exception of the

RS 2 which will see use daily if you

build furniture which has large flat

surfaces.

If you are like

me, before long

all the great Festool sanders will

be in use in your

shop or studio

on a daily basis.

Enjoy!

Page 31

A Closing Note On Continuous

Improvement Engineering

Earlier we saw a few pictures of the

“new” and “previous” versions of the

Rotex sanders. I want to comment a bit

more on the differences as it reflects

well the Festool focus on continuous

improvement engineering.

There certainly was nothing “wrong”

with the previous Rotex sander. I can’t

even guess how many hours I used that

machine before the new version became available. It was, and the new

one remains, the best sander I have ever

while the longer body of the

older version caused it to tip

backwards.

The dust port is now removable to make tasks like polishing which don’t require the

dust port a bit easier. The

removable dust port (shown

in the photo above) also acts

as a hand guard to keep you

from banging your knuckles

on the work surface during

aggressive sanding operations.

used.

So, what did they improve?

The new version (left) is a bit shorter,

easier to control and has a more powerful

motor (720 vs 500 watts). Notice in the

photo at the top of the next column how

the new version balances flat on its pad

Pads change with a quick

quarter-turn twist lock instead

of via removal of the machine

screw fastener used on the previous

model.

Notice that the new model features the

very handy removable cord that is being

introduced across the Festool line with

each upgraded model. A quick quarterturn removes or attaches the power cord

so it is not in your way when the machine

is not in use.

Page 32

On the previous version changing from

rotary to random orbit mode required

lifting the lock and twisting a shaft, the

green mechanism shown in this photo.

Simple enough but a bit fussy. On the

thumb naturally falls. The previous

model had the on-off switch on the

side where you had to consciously

look or feel for it.

Finally, there is now a slick snap on

guard that prevents the Rotex pad

from impacting the work piece -

very much appreciated if you have

ever scarred a work piece by inad-

new version the same change is accomplished by simply moving the green rectangular button on the front top of the

unit. Faster and far handier. The other

green button shown is the on-off switch

positioned to be on top right where your

vertently hitting some part of it

with the edge of the pad. Ouch!

So this new version of the already

very good Rotex is a nice piece of

continuous improvement engineering that adds useful new features, improves power, and makes

the unit a bit smaller and easier to

handle with none of the good stuff

from the previous unit compromised. Bravo Festool!

Page 33

About the author.

Jerry Work designs and hand crafts fine

furniture in the 1907 Masonic Temple

building in historic Kerby, Oregon. Unless otherwise noted, all of the photos

used in this manual were taken in his

studio and gallery. Located on the Redwood Highway (US 199) 26 miles SE of

Grants Pass, OR, where visitors are always welcome.

He can be reached at glwork@mac.com

or via phone at 541-592-5360.

Loading...

Loading...