Page 1

RAP 80.02 E

Seen at Ideal Tools.

Bedienungsanleitung Rotationspolierer 4 - 6

Operating Instructions Rotary polisher 7 - 9

Mode demploi Polisseuse 10 - 12

Instrucciones de servicio Pulidora 13 - 15

Istruzioni duso Lucidatrice 16 - 18

Gebruiksaanwijzing Polijstmachine 19 - 21

Bruksanvisning Ploermaskin 22 - 24

Käyttöohje Kiillotuskone 25 - 27

Driftsvejledning Rotationspoleringsmaskine 28 - 30

Bruksanvisning Polérmaskin 31 - 33

Instruções de uso Polidora rotativa 34 - 36

Руководство по эксплуатации Полировал¾ная машинка 37 - 39

Návod k obsluze Rotaèní letièka 40 - 42

Instrukcja obs³ugi Polerka rotacyjna 43 - 45

Kezelési utasítás Rotációs polírozógép 46 - 48

463 304_001

ПдзгЯб лейфпхсгЯбт Ресйуфспцйкьт уфйлвщфЮт 49 - 51

Festool GmbH Wertstr. 20 D-73240 Wendlingen ( 07024/804-0

Page 2

EG-Konformitätserklärung. Wir erklären in alleiniger

Seen at Ideal Tools.

Verantwortung, dass dieses Produkt mit den

folgenden Normen oder normativen Dokumenten

übereinstimmt:

EN 50 144, EN 55 014, EN 61 000 gemäß den Bestimmungen

der Richtlinien 73/23/EWG, 98/37/EG, 89/336/EWG.

CE-Konformitetserklæring. Vi erklærer på eget

ansvar at dette produktet er i overensstemmelse med

følgende normer eller normative dokumenter: EN 50 144,

EN 55 014, EN 61 000 i henhold til bestemmelsene i direktivene

73/23/EØF, 98/37/EF, 89/336/EØF.

EC-Declaration of Conformity: We declare at our sole

responsibility that this product is in conformity with

the following standards or standardised documents:

EN 50 144, EN 55 014, EN 61 000 in accordance with the

regulations 73/23/EEC, 98/37/EC, 89/336/EEC.

CE-Déclaration de conformité communautaire. Nous

déclarons sous notre propre responsabilité que ce

produit est conforme aux normes ou documents de

normalisation suivants: EN 50 144, EN 55 014, EN 61 000

conformément aux prescriptions des directives 73/23/CEE,

98/37/CE, 89/336/CEE.

CE-Declaración de conformidad. Declaramos bajo

nuestra exclusiva responsabilidad que este

producto corresponde a las siguientes normas o documentos

normalizados: EN 50 144, EN 55 014, EN 61 000 conforme a

las prescripciones estipuladas en las directrices

73/23/CEE, 98/37/CE, 89/336/CEE.

CE-Dichiarazione di conformità. Dichiariamo sotto

la nostra esclusiva responsabilità che il presente

prodotto è conforme alle norme e ai documenti normativi

seguenti: EN 50 144, EN 55 014, EN 61 000 conformemente

alle normative delle direttive 73/23/CEE, 98/37/CE,

89/336/CEE.

CE-Declaração de conformidade: Declaramos, sob

a nossa exclusiva responsabilidade, que este

produto corresponde às normas ou aos documentos

normativos citados a seguir:

EN 50 144, EN 55 014, EN 61 000 segundo as disposições

das directivas 73/23/CEE, 98/37/CE, 89/336/CEE.

Заявление о конформности СЕ. Мы заявляем в

единоличной ответственности, что данное изделие

соответствует требованиям следующих стандартов или

нормативов: EN 50 144, EN 55 014, EN 61 000 в соответствии

с постановлениями директив ЕЭС 73/23, ЕС 98/37,

ЕЭС 89/336.

Prohláení o souladu s normami CE. Prohlaujeme

na vlastní zodpovìdnost, e tento výrobek odpovídá

následujícím normám nebo normativním dokumentùm:

EN 50 144, EN 55 014, EN 61 000 v souladu s ustanoveními

smìrnic 73/23/EHS, 98/37/EHS, 89/336/EHS.

Owiadczenie o zgodnoci CE. Niniejszym

owiadczamy z ca³¹ odpowiedzialnoci¹, ¿e wyrób

ten odpowiada nastêpuj¹cym normom wzglêdnie dokumentom

normatywnym: EN 50 144, EN 55 014, EN 61 000 zgodnie z

postanowieniami wytycznych 73/23/EWG, 98/37/EG,

89/336/EWG.

EG-conformiteitsverklaring. Wij verklaren op eigen

verantwoordelijkheid dat dit produkt voldoet aan de

volgende normen of normatieve documenten. EN 50 144,

EN 55 014, EN 61 000 conform de richtlijnen 73/23/EEG,

98/37/EG, 89/336/EEG.

EG-konformitetsförklaring. Vi förklarar i eget ansvar,

att denna produkt stämmer överens med följande

normer och normativa dokument: EN 50 144, EN 55 014,

EN 61 000 enligt bestämmelserna i direktiven 73/23/EEG,

98/37/EG, 89/336/EEG.

EY-standardinmukaisuusvakuutus. Vakuutamme

yksinvastuullisina, että tuote on seuraavien

standardien ja normatiivisten ohjeiden mukainen: EN 50 144,

EN 55 014, EN 61 000 direktiivien 73/23/EY, 98/37/EY,

89/336/EY määräysten mukaan.

EF-konformitetserklæring: Vi erklærer at have alene

ansvaret for, at dette produkt er i overensstemmelse

med de følgende normer eller normative dokumenter:

EN 50 144, EN 55 014, EN 61 000 i henhold til bestemmelserne

af direktiverne 73/23/EØF, 98/37/EF, 89/336/EØF.

CE-konformitás-nyilatkozat.Kizárólagos

felelõsségvállalás mellett ezennel tanúsítjuk, hogy

a jelen termék megfelel az alábbi szabványoknak ill.

szabványdokumentációnak: EN 50 144, EN 55 014,

EN 61 000 a 73/23/EWG, 98/37EG, 89/336/EWG irányvonalak

rendelkezései szerint.

Дзлщуз ухммьсцщузт ЕК. Ме бнЬлзшз фзт

ухнплйкЮт ехиэнзт дзлюнпхме, ьфй фп рбсьн рспйьн

ухмцщнеЯ ме фб рбсбкЬфщ рсьфхрб кбй ме фб

рсьфхрб рпх бнбцЭспнфбй уфб учефйкЬ Эггсбцб ЕН 50 144,

ЕН 55 014, EN 61 000 уэмцщнб ме фпхт кбнпнйумпэт

73/23 ЕПК, 98/37ЕК, 89/336/ЕПК

Leitung Forschung und Entwicklung

Management Research and Development

Direction de recherce et développement

Festool GmbH

Wertstr. 20

D-73240 Wendlingen

Dr. Johannes Steimel

455 789/05.02

Page 3

Seen at Ideal Tools.

Page 4

1 Technical Data RAP 80.02 E

Seen at Ideal Tools.

Power consumption 500 W

Speed adjustable from 750-2300 rpm

Tool diameter for polishing up to 80 mm

Tool diameter for sanding up to 115 mm

Connection thread M14

Degree of protection / II

Weight 1.6 kg

5 Electronics

The rotary polisher is fitted with a fullwave electronic control with the

following functions:

5.1 Smooth run-up

The electronically controlled smooth run-up

ensures that the machine starts without jolts.

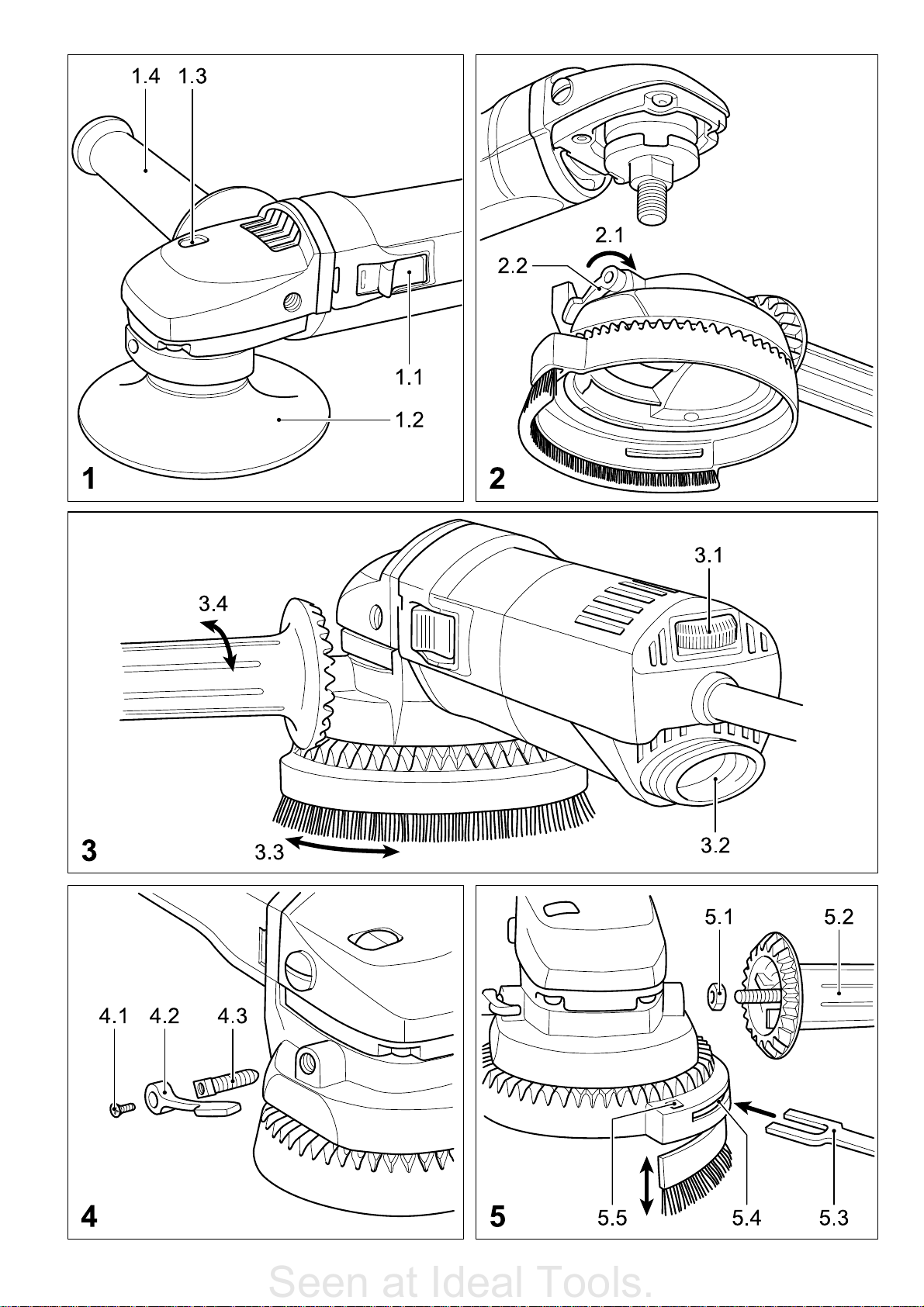

The specified illustrations can be found at the

beginning of the operating instructions.

2 Correct use

The RAP 80.02 E is designed for polishing all

types of painted and lacquered surfaces.

If the AH-RAS 115 extractor hood is fitted, it

can also be used to sand paints/varnishes,

fillers, composite materials, wood, plastics,

metal, stone and similar materials.

Should explosive or inflammable dust

be produced when sanding certain

materials, please refer to the

processing instructions supplied by the

material manufacturer.

The tool is unsuitable for wet sanding

for reasons of electrical safety.

3 Before starting

3.1 Safety instructions

Please read the safely instructions on

the enclosed sheet before starting

work.

3.2 Noise and vibration figures

The values typical for the device measured

according to EN 50 144 are:

Sound level 82 dB(A)

Rated acceleration < 2.5 m/s²

3.3 Metalworking

If the device is used primarily for

processing metals, the inside of the

drive unit may become very dirty.

In such cases, we recommend the use of a

high-power extractor, a shortening of cleaning

cycles and/or the series connection of a faulty

current safety switch.

5.2 Speed control

The speed of the working spindle can be

infinitely adjusted with the speed controller

(3.1).

The numbers on the speed controller roughly

correspond to the following idling speeds:

1 750 rpm 4 1,600 rpm

2 1,000 rpm 5 1,950 rpm

3 1,350 rpm 6 2,300 rpm

5.3 Constant speed

The preselected motor speed is kept

electronically constant. This ensures a constant

working speed even under load.

5.4 Temperature overload

Extreme overload in continuous running will

cause the motor to overheat.

An electronic temperature monitoring device

is fitted to provide protection against

overheating (burning-out of the motor).

The electronic safety device switches off the

motor before a critical motor temperature is

reached, the tool then has to be switched off

at its switch.

After a cooling period of approx. 3-5 minutes,

the machine is once again ready for use at full

load.

If the machine is kept running (idling), the

cooling period is reduced.

Never use the rotary polisher if its

electronics are faulty since this can lead

to overspeeding.

Faulty electronics are indicated by the absence

of a smooth run-up or speed control as well

as excessive idling noises.

4 Electrical connection and start-up

The mains voltage must correspond

with the voltage figure on the

ratings plate!

Push the sliding switch (1.1) forwards to switch

the tool on.

A slight pressure on the rear of the switch is

sufficient to switch the rotary polisher off.

6 Working with the RAP 80.02 E

The RAP 80.02 E is a compact, handy tool for

polishing painted or varnished surfaces.

It can also be used for sanding work if fitted

with the AH-RAS 115 extractor hood (Order

No. 485 056, description see No. 7).

7

Page 5

6.1 Rough speeds for work with diffe-

Seen at Ideal Tools.

rent materials

a) Polishing

Work Setting

Distribute polish 1-2

Polishing sensitive surfaces

(e.g. painted plastic parts) 3-4

High-gloss polishing 5-6

now be exchanged. Reassemble in reverse

order.

You can adjust the free-running of the rotating

additional handle using the counternut (5.1)

by clamping this against the hood with an openend spanner, size 13, before tightening the additional handle.

b) Sanding

Work Setting

Light sanding of thin topcoats 4-6

Sanding smearing paints / varnishes 4-6

Sanding off dry, cracked paint 6

Removing anti-fouling paint 6

Sanding out rust on varnished metal parts (6)

Sanding thermoplastics 2-4

Sanding wood 6

Smoothing stained wood with

sanding brush 2-4

Cleaning sandstone, concrete,

shuttering material 4-6

( ) Only conditionally suitable

7 AH-RAS 115 extractor hood

7.1 Fitting (Fig. 2)

Before fitting the hood, take care to

ensure that the clamping lever is in the

released position (2.2).

Press the extractor hood firmly onto the

clamping neck of the rotary polisher and fasten by pushing the clamping lever forwards

(2.1).

Do not start work if the hood extractor

hood is not safely and firmly locked

onto the clamping neck.

If the clamping force should deteriorate after

frequent use, adjust the clamping lever:

loosen screw (4.1) on clamping lever and

remove clamping lever (4.2),

tighten square-head threaded bolt (4.3) by

hand,

replace clamping lever and fasten with screw.

The optimum position can be determined by

closing the clamping lever before tightening

the screw.

7.2 Changing the position of the

rotating handle

The rotating additional handle can be also be

fastened on the right of the extractor hood

depending on the users personal preferences.

It should be exchanged with the clamping lever.

Loosen screw (4.1) on clamping lever and

remove clamping lever (4.2).

Remove square-head threaded bolt (4.3).

Loosen additional handle (5.2) with Allen key,

size 6.

The clamping lever and additional handle can

7.3 Changing the brush insert

Press the brush insert out by inserting a

screwdriver into the square hole (5.5).

Place the new brush insert into the groove,

adjust the radius by bending slightly and push

in firmly until the insert rests on the base of

the hood.

The bevel of the bristles must hereby point

outwards.

Two different brush inserts are available:

AH-RAS D 115 Poly (Order No. 484 727),

contains 2 polyamide brushes (as

replacements for worn brushes).

AH-RAS D 115 Metal (Order No. 484 728),

contains 1 metal brush (for use on materials

which produce sparks).

7.4 Changing the sanding pad

In normal cases the sanding pad (1.2) can be

unscrewed from the working spindle by hand

after the spindle stop (1.3) has been pressed.

However, should the sanding pad sit firmly

Remove brush insert

Insert special key (5.3) through slot (5.4)

into the tools key slot.

Press the spindle stop and loosen the tool by

turning the special key.

Always screw the sanding pad onto the

working spindle by hand.

This greatly facilitates a later loosening.

7.5 Sanding and dust extraction

Connect the hose (Ø 27 mm) of a

Festool dust extractor to the adapter

(3.2) on the rear of the rotary

polishers casing.

The brush (3.3) can be adjusted with the

rotating handle (3.4).

This permits an optimum adjustment to the

respective working position.

Always rotate the brush in the direction of flight

of the sanding dust.

When sanding metals and other

materials which produce sparks, a

spark trap (Order No. 484 733) must

be fitted between the dust extractor

and rotary polisher for safety reasons.

8

Page 6

8 Fitting tools

Seen at Ideal Tools.

Do not use tools whose maximum

permissible speed is lower than the

speed specified on the rotary polishers

ratings plate.

This is guaranteed with all original accessories

from Festool.

There are two types of fixtures depending on

the tools used.

The motor spindle is locked by pressing the

spindle stop (1.3). This permits a fast and easy

replacement of the tools used.

8.1 Direct fitting

The sanding pad STF D80 included with the

tool and the polishing drum available as an

accessory, together with the individual sanding

disks, all have an M14 thread.

These can be screwed directly into the working

spindle.

12 Care and maintenance

Always disconnect the machine at

its mains plug before performing

maintenance work!

Keep the ventilation slots in the motor housing

clean and free of obstructions at all times to

ensure an adequate circulation of air.

The tool is fitted with special motor brushes

with an automatic cut-out.

When the brushes become worn the power

supply is shut off automatically and the polisher

comes to a standstill.

Any maintenance and repair work

requiring an opening of the motor

housing may only be carried out by an

authorised customer service

workshop.

8.2 Fitting with locking nut

The flexible sanding pad is fastened to the drive

shaft with a locking nut and tightened with the

face spanner.

9 Additional handle

The additional handle (1.4) can be optionally

fitted on the right or left of the rotary polishers

transmission head.

10 PoliStick and Stickfix System

All PoliStick felts are mounted on the STF D80

polishing pad.

Stickfix sanding discs D115 are fastened on

the Stickfix sanding pad STF D115.

Only use polishing and sanding pads

with undamaged Stickfix adhesive

covering.

Check before use whether the hook-eye

fastening has been damaged by incorrect use

(e.g. melted).

13 Warranty

Our equipment is under warranty for at least

12 months with regard to material or

production faults in accordance with national

legislation.

In the EU countries, the warranty period is 24

months (an invoice or delivery note is required

as proof of purchase).

Damage resulting from, in particular, normal

wear and tear, overloading, improper handling,

or caused by the user or other damage caused

by not following the operating instructions, or

any fault acknowledged at the time of

purchase, is not covered by the warranty.

Complaints will only be acknowledged if the

equipment has not been dismantled before

being sent back to the suppliers or to an

authorised Festool customer support

workshop.

Store the operating instructions, safety notes,

spare parts list and proof of purchase in a safe

place.

In addition, the manufacturers current

warranty conditions apply.

11 Accessories

The accessory order number can be found in

your Festool catalogue or on the Internet under

www.festool.com".

Note

We reserve the right to make changes to the

technical data contained in this information as

a result of ongoing research and development

work.

9

Page 7

Festool GmbH

Seen at Ideal Tools.

Postfach 1163

D- 73236 Wendlingen

Wertstr. 20

D- 73240 Wendlingen

) (07024) 804-0

Fax (07024) 804-608

http://www.festool.com

Loading...

Loading...