Page 1

PRECISIO

Seen at Ideal Tools.

CS 70 EB

CS 70 E

Bedienungsanleitung 6 - 11

Operating Instructions 12 - 17

Mode demploi 18 - 24

Instrucciones de servicio 25 - 30

Istruzioni duso 31 - 36

Gebruiksaanwijzing 37 - 42

Bruksanvisning 43 - 48

Käyttöohje 49 - 54

Driftsvejledning 55 - 60

Bruksanvisning 61 - 66

Instruções de uso 67 - 73

Руководство по эксплуатации 74 - 80

Návod k obsluze 81 - 85

Instrukcja obs³ugi 86 - 91

Kezelési utasítás 92 - 97

461 001_002

ПдзгЯб лейфпхсгЯбт 98 - 104

Festool GmbH Wertstr. 20 D-73240 Wendlingen ( 07024/804-0

Page 2

Seen at Ideal Tools.

Page 3

Seen at Ideal Tools.

Page 4

Seen at Ideal Tools.

Page 5

Seen at Ideal Tools.

Page 6

3.1.2 Emission values at place of work

Seen at Ideal Tools.

AP emission - idling 77 dB(A)

AP emission - at work 90 dB(A)

The sound level at the place of work can exceed

85 dB(A), in which case soundproofing measures

(hearing protection) are required for the operator.

The values quoted are emission values and thus

do not necessarily represent true work place

values. Although there is a correlation between

emission and immission levels, it is impossible

to reliably say whether additional safety measures

will be necessary or not. Factors which could

affect the immission levels actually present at the

place of work include the duration of the exposure,

the peculiarities of the work room, other sources

of noise, etc., e.g. the number of machines and

other neighbouring processes. However, this

information should allow the user to make a better

estimation of the dangers and risks.

3.2 Residual risks

Despite the observance of all relevant construction

regulations, risks may still arise from the use of the

PRECISIO, for example from:

flying workpiece parts

flying parts of damaged tools

wood dust emission

noise emission

its own.

The return speed can be adjusted by altering the

damping at the setting screw (3.5).

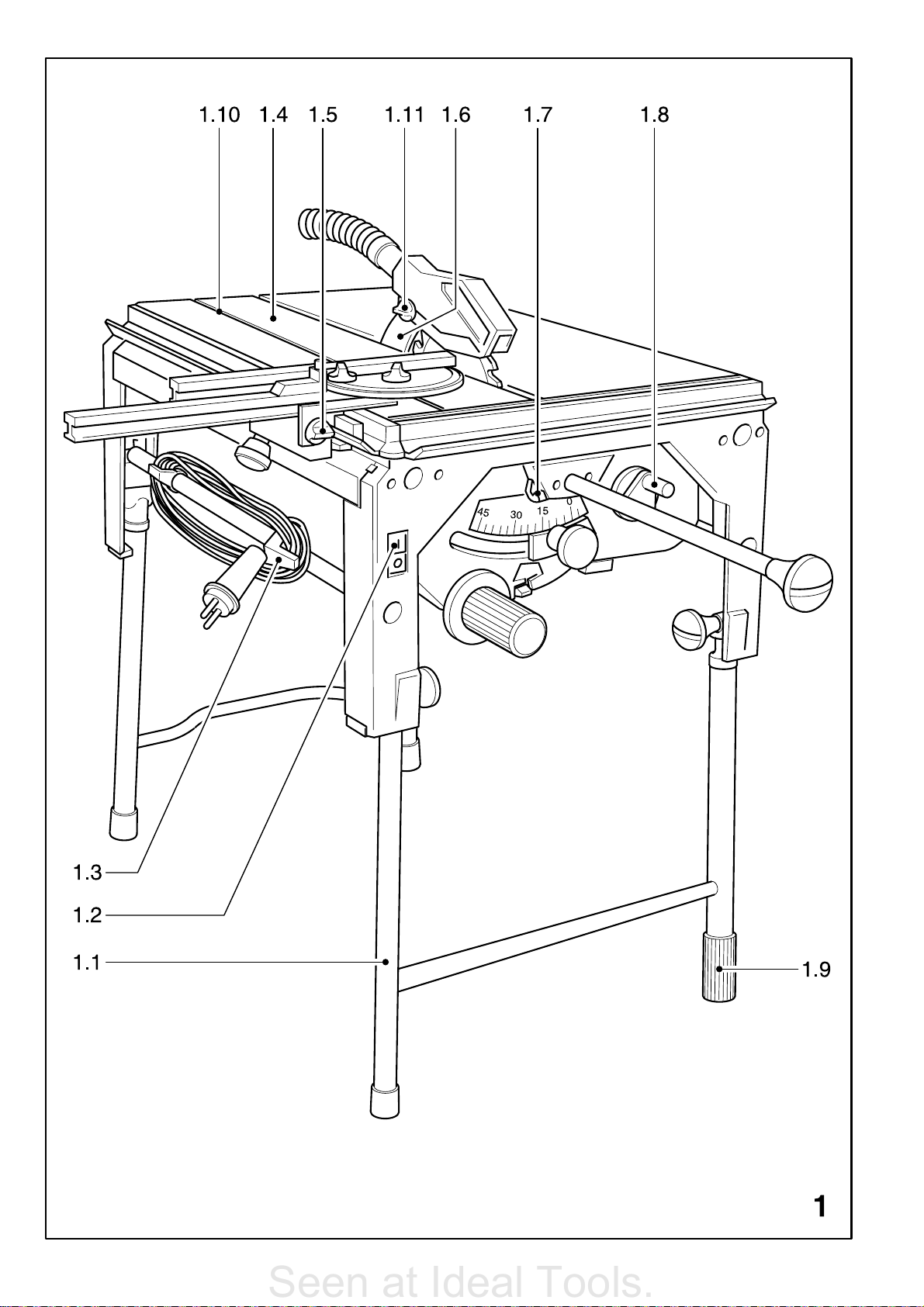

The end cap (1.9) can be rotated to adjust the

height of the front right foot to ensure that the saw

stands firmly on the ground without wobbling.

5 Basic comments on working with the

saw

The saw can be used in two different ways:

as an under-table pulling-cut saw (section 5.1),

where the workpiece is stationary and the saw is

moved during cutting.

as a bench-mounted circular saw (section 5.2),

where the saw is stationary and the workpiece is

moved.

5.1 As an under-table, pulling-cut saw

Turn the knob (2.6) to the left to release the saw

lock and pull saw forwards with this knob. The

saw can be locked in the foremost position by

pressing the catch lever (1.7) down so that the

controls to adjust the saw (depth of cut, angle

adjustment, speed) are easily accessible. Turn

the knob (2.6) to the left to release the lock again.

Fit the mitre fence accordingly (see section 9) so

that the workpiece can be held firmly on the saw

table.

4 Erecting the saw

After removing the machine from its transport

packaging unfold the foldaway legs (1.1) and

screw in place using the grip knobs at the joints.

Now place the machine on an even, firm base.

Screw the loose grip knob (2.6) enclosed with the

machine into the pull bar in an anti-clockwise

direction. Attention! left-hand thread.

On delivery the saw is locked in its idle position.

Turn the knob (2.6) to the left to release the lock

so that the saw can be pulled forwards.

The saw is now locked in its foremost position

(setting-up position) by pressing the catch lever

(1.7) down and can be adjusted to a maximum

cutting depth by turning the crank (1.8) to the right.

The height of the built-in riving knife (1.6) can be

adjusted and this has an upper and lower locked

position. The lower locked position (state on

delivery) is necessary for concealed cuts. The

riving knife must be in its upper locked position

for all other cuts. The riving knife should thus be

brought into its upper position by pulling upwards

firmly (7.2) In this position, the enclosed upper saw

cover is screwed onto the riving knife with a screw.

Turn the knob (2.6) to the left to release the saw

lock, the saw now slides into the idle position on

5.2 As a bench-mounted circular saw

First pull the saw fully forwards. Now let it slide

gently back. After a few mm press the catch lever

(1.7) down. During further backward movement

the catch lever engages in the pull bar and locks

the saw in the centre of the table (bench-mounted

saw position).

6 Electrical connection and starting

The PRECISIO is a device from protective class II.

The mains voltage must correspond to the voltage

specified on the ratings plate.

We recommend a 16 A fuse due to the high load

on the motor. The mains cable can be wound around

the clips (1.3) when the machine is not in use or for

transportation purposes.

Switch

(1.2) The red button is the OFF button.

The switch has a no-voltage circuit breaker.

After a power failure the machine does not restart

automatically when power is restored.

The green ON button has to be pressed.

A lockable switch guard is available as an

accessory as protection against unauthorised use

(order no. 488 065).

the machine on by pressing the green button

13

Page 7

7 Electronics

Seen at Ideal Tools.

The saw has an electronic system with the following

functions:

7.1 Soft start

The electronically-controlled soft start ensures that

the tool starts without jerking - no starting current

rushes.

7.2 Speed control (only CS 70 EB)

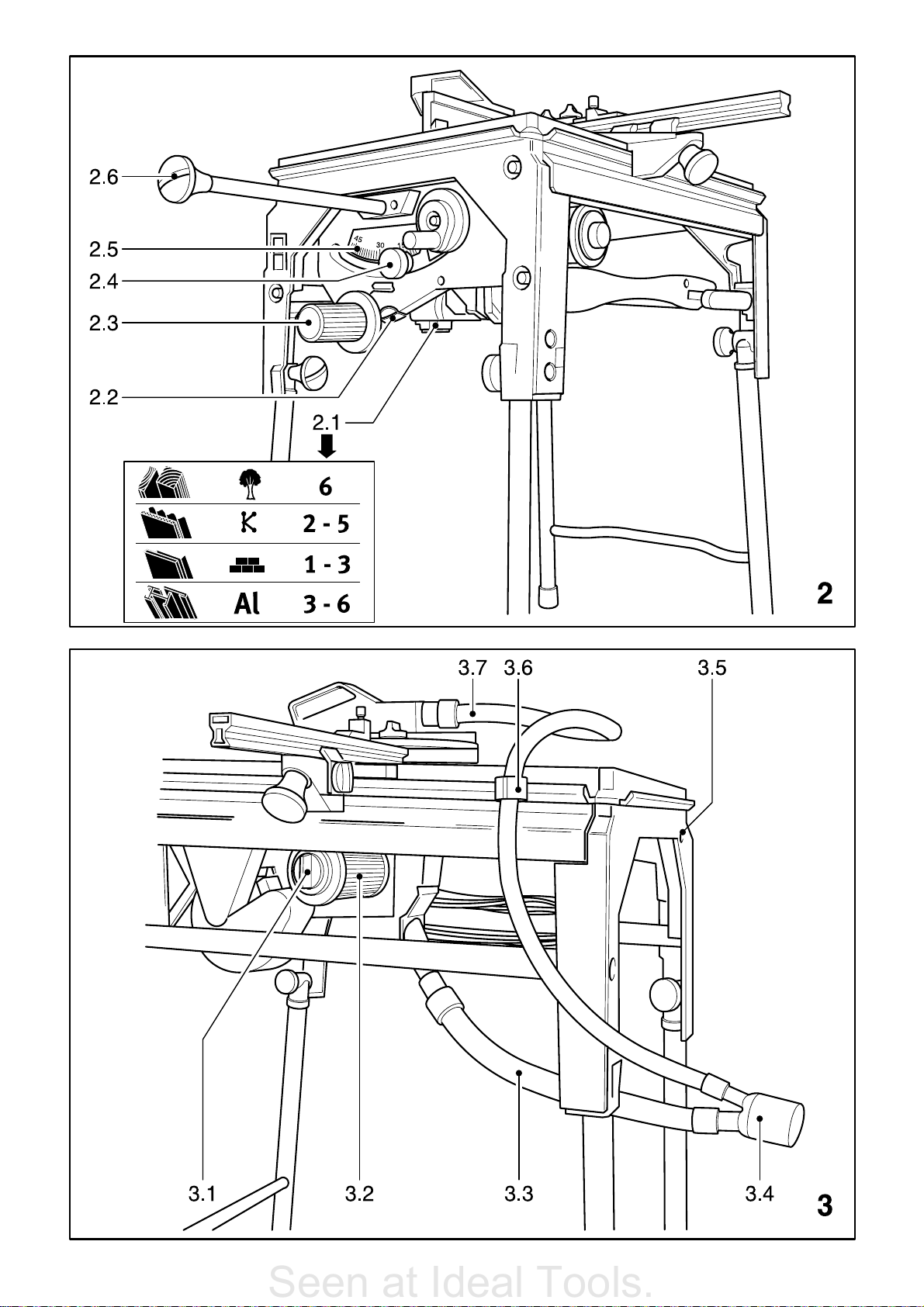

The speed of the saw blade can be infinitely

adjusted at the adjusting wheel (2.1) between 2,000

rpm (position 1) and 4,200 rpm (position 6),

corresponding to the following saw blade speeds:

Position 1 2,000 rpm Position 4 3,300 rpm

Position 2 2,400 rpm Position 5 3,800 rpm

Position 3 2,800 rpm Position 6 4,200 rpm

7.3 Overload protection (current protection)

In cases of extreme overload (rip cutting, use of blunt

saw blades) the power consumption may

considerably exceed the permissible rated value.

In this case the motor is switched of by an

electronic safety clutch and re-starts as soon as

the load is removed.

7.4 Overload protection - temperature

protection

Extreme overload in continuous operation causes

the motor to heat up. An electronic temperature

monitoring device is fitted to prevent overheating

(motor burn-out).

The electronic safety device switches the motor off

before the motor is able to reach a critical

temperature. After a cooling period of approx. 3-5

minutes the machine is once again ready for

operation and can run at full load.

The cooling period can be greatly reduced if the

machine is running (idling or recovery speed).

7.5 Quick-acting brake system (only

CS 70 EB)

When the OFF button is pressed the electronics

start a braking process which brings the saw blade

to a standstill within 3 seconds.

8.2 Adjusting angle cuts

Lock the saw in its setting-up position (foremost

position). Release the clamp (2.4) so that the saw

can be pivoted with the rotary knob (2.3) from 045° according to the scale (2.5).

Visible edges must match cleanly during exact

fitting work. These joining edges can be slightly

undercut to obtain this effect. Press button (2.2)

down to release the stops at the 0 and 45°

positions and the saw can be pivoted by a

further 2°.

The 0 and 45° stops are once again effective when

the button (2.2) is released.

Retighten the rotary knob (2.4) after setting the

desired angle.

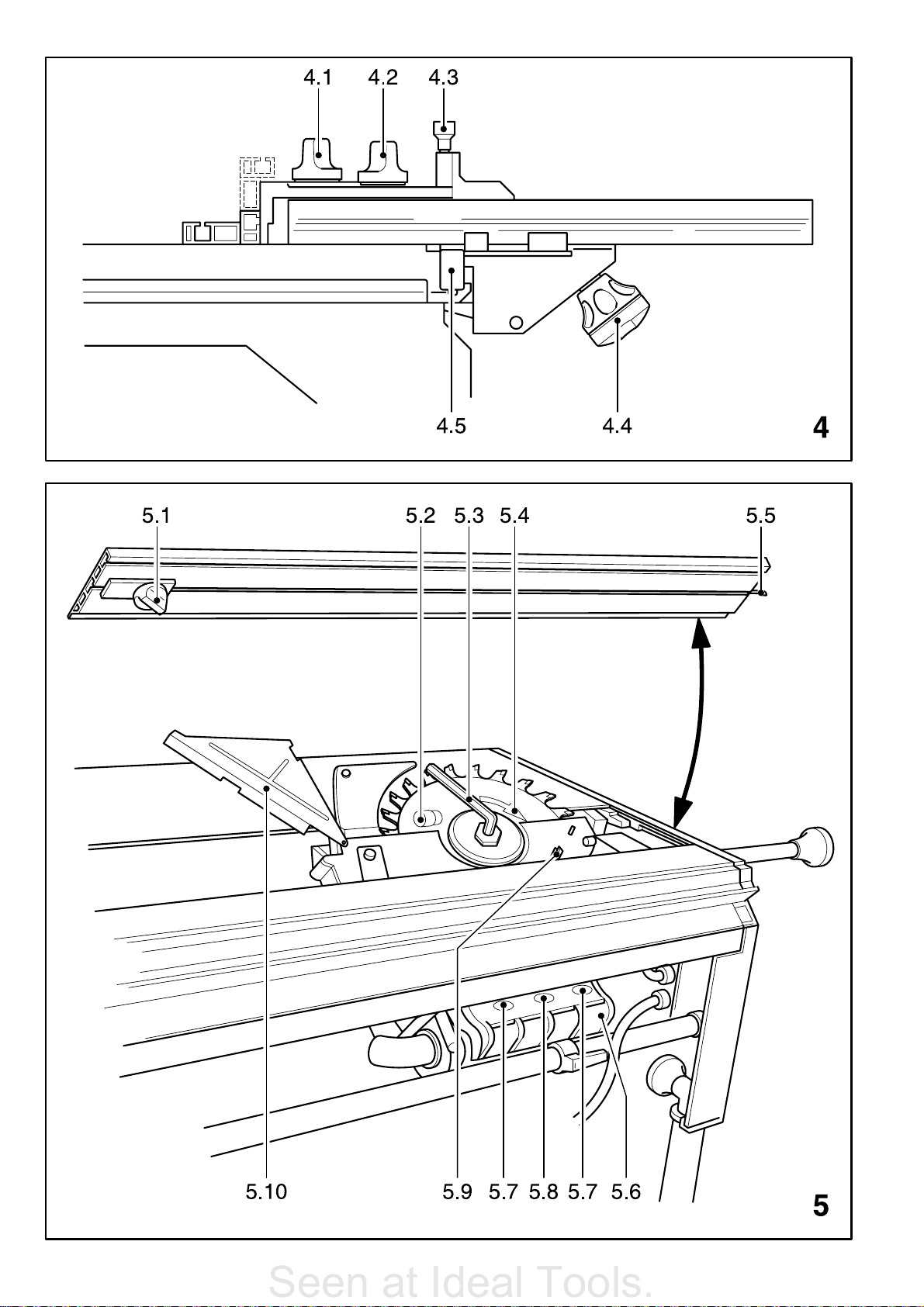

9 The mitre fence

A correctly adjusted stop is an important precondition for safe working with saws.

The enclosed mitre fence can be fitted at any

position on the peripheral clamping lip on the saw

table and can be used as a cross fence and linear

stop for all sawing work thanks to its versatility.

Make sure that the fitting surfaces are not dirty

before fitting the mitre fence since otherwise a

correct angle cannot be ensured.

Use as cross fence (fig. 1) .

Use as a linear stop (fig. 6).

The following adjustments are possible at the mitre

fence:

9.1 Fastening to the saw table

Open the clamping jaws with the grip handle (4.4)

via a system of levers.

Place the guide rail (4.5) from above on the

peripheral clamping lip.

Clamp clamping segment with grip handle.

9.2 Moving fence on clamping segment.

Release rotary knob (1.5), move fence on clamping

segment and tighten in place.

9.3 Moving the fence ruler

Release rotary knob (4.1), move fence ruler

accordingly and tighten in place.

8 Adjusting

8.1 Adjusting the depth of cut

As already described in sections 3 and 4.1, the saw

is locked in its foremost position (setting-up

position). The depth of cut can be infinitely adjusted

from 0-70 mm by turning the crank (1.6). A clean

saw cut is obtained when the pre-set depth of cut

is 2-5 mm larger than the thickness of the

workpiece.

9.4 Angle adjustment

The guide face can be pivoted by a max. of 180°

Release rotary knob (4.2) and raise locking pin

(4.3). The common angle adjustments can be

locked with the locking pin (4.3). Retighten rotary

knob (4.2) after setting the desired angle.

14

Page 8

9.5 Moving the mitre fence

Seen at Ideal Tools.

According to regulations, a higher or a lower

workpiece guide face must be available as a stop

depending on the workpiece.

Release the rotary knob (4.1) to remove the guide

ruler and replace in the guide groove after rotating

by 90° (fig. 4). The aluminium section has been

dimensioned so that both a high guide face and

the lower guide face required for flatter

workpieces is available.

9.6 Fence ruler

The fence ruleris set off on one side by 8 mm.

The cross fence can be moved up to the saw cut to

support the workpiece with this guide rail without

the upper protective hood having to be removed.

9.7 Linear stop

The fence ruler is set parallel to the saw cut for linear cuts. Use the slide stick (6.1) to push through

narrow workpieces.

To enable the fence to be aligned according to the

scale on the front edge of the table, the zeroes of

the two scales on the left and right are set to the left

and right cutting edge of the saw blade in the works

(7.1).

10 Dust extraction

The PRECISIO has a fitted dust extractor set (Order No. 488292; included with the CS70EB) and

has been tested in accordance with EN1093-8.

A wood dust concentration of 2mg/m

maintained in the proximity of the tool provided a

dust extractor with the following features is

connected:

dust extractor in accordance with EN 60335-2-

69, dust class M;

connection adapter Ø50mm;

volume flow of at least 142m

vacuum approx. 3,000 Pa.

Note: The Festool dust extractors CTM22E

CTM55E meet these requirements.

10.1 Fitting the dust extractor set

Connect suction hose Ø27mm (3.7) to the upper

protective hood. Plug the hose holder (3.6) into

the clamping rail of the saw table to guide the

suction hose.

Connect suction hose Ø36mm (3.3) to the lower

protective hood.

Join both suction hoses with a Y-piece (3.4) and

connect to a dust extractor with a Ø50mm

connection.

3

/h;

3

is reliably

10.2 General remarks

If dust chips block the suction channel of the lower

protective hood, open the flap (5.6) by a gap of

approx. 8 mm by releasing the rotary knob (5.8)

and remove the blockage.

In the event of serious blockages, or if saw sections

jam, the seals (5.7) can be released with the

enclosed hexagon key so that the flap (5.6) can be

fully opened.

The hexagon key is fastened on the saw blade cover

directly above the flap (5.6).

Attention: disconnect the plug from the mains

before unscrewing the seals.

Once the blockage has been removed reclose the

flap with the seals.

11 Concealed cuts

As already described in section 4, the height of the

riving knife can be locked in two positions without

tools.

Remove the upper protective cover for concealed

cuts and bring the riving knife into its lower locked

position by pressing down firmly (7.1).

When carrying out concealed cuts make sure of a

good workpiece guidance by pressing the

workpiece firmly onto the table.

Select the sequence of cuts so that sides of the

workpiece which have already been cut are not on

the side facing the fence.

Return the riving knife into its upper position (7.2)

and replace the protective cover on completion of

any concealed cuts.

12 Changing the saw blade

Unplug from the mains before changing the saw

blade.

Only use saw blades with the following dimensions:

Outer diameter 220 - 226 mm

Bore diameter 30 mm

Core thickness of blade 1.8 mm

Width of cut 2-2.5 mm

Lock the saw in its foremost position (setting up

position) and set to maximum slant and depth of

cut.

Release insert clamp with rotary knob (5.1), push

claw forwards.

Raise rear of table inlay (1.4) from below and

remove from table from the front.

Remove the protective hood and swing the cover

(5.10) back.

Remove hexagon key (5.3) from holder and insert

into saw blade locking screw.

15

Page 9

Press spindle stop (5.2 - behind saw blade) and

Seen at Ideal Tools.

rotate saw shaft with hexagon key until button (5.2)

catches and locks the saw shaft.

Attention: the saw blade locking screw has a lefthand thread.

Release locking screw by turning firmly to the right

and remove clamping flange and saw blade. Insert

new saw blade.

Attention: Pay attention to the direction of rotation

(cutting edge of saw teeth in direction of rotation

(5.4))! Screw saw blade and flange to saw shaft

with locking screw.

Close the cover (5.10) and replace the upper

protective hood again.

Warning: Make sure that the cover (5.10) engages

in the clips (5.9) when closing.

Return hexagon key to holder and replace table inlay

in table.

First insert the inlay into the front of the table frame

with protruding spring steel sheet (5.5).

Insert inlay and screw tight with claw and rotary

knob.

13 Maintenance and service

13.1 Removing dust accumulations

General accumulations of dust are to be sucked

off with a dust extractor from time to time.

We especially recommend:

a) cleaning the gears behind the rotary knob

(2.3)

b) leaning the two guide rods after tilting the saw

onto one side.

The specialised workshop can order repair

instructions from Festool under the order

no. 450 157 to carry out the following simple

repairs: change brushes, change the belt, replace

the electronics, clean the scraper on the guides,

change the mains cable, replace the motor, replace

the switch.

Any maintenance and repair work requiring an

opening of the drive unit and electrical system may

only be carried out by a Festool customer service

workshop or specialised workshop.

14 Range of accessories

14.1 Extension table

The CS 70 VB extension table (order no. 488 060)

can be fitted to the basic table of the PRECISIO for

safe and precise sawing to width (with stop) up to

a cutting width of 680 mm.

14.2 Extension table

The extension table CS 70 VL (order no. 488 061)

is available for fitting to the basic table for safe

sawing of longer workpieces.

14.3 Linear stop

The linear stop CS 70 LA (order no. 488 062) is

indispensable for safe and precise linear cuts.

14.4 Switch cover

If the switch cover CS 70 SA order no. 488 065) is

fitted, the machine can be protected against

unauthorised use with a padlock.

13.2 Cleaning the filter (only CS 70 EB)

If the cut-out cycles of the temperature monitoring

system in accordance with section 6.4 become

shorter with no extreme overload, the air intake filter

(3.2) should be cleaned.

Release rotary knob (3.1), remove filter insert and

remove dust by tapping on the front or vacuuming

the surface of the filter. Replace filter.

Exchange any damaged filter with a new filter

cartridge (order no. 447 995).

13.3 Inspection and servicing

The device is fitted with special motor brushes with

an automatic cut-out.

When the brushes become worn the power supply

is shut off automatically and the tool comes to a

standstill.

If this occurs, the machine should be returned to a

Festool customer service workshop or specialised

workshop to change the brushes.

14.5 Transportation rollers

Transportation rollers CS 70 TR (order no. 488 064)

can be fitted to the foldaway legs of the saw to

enable simple and easy transportation.

14.6 Sliding platform

The sliding platform CS 70 ST (order no. 488 059)

can be fitted to the PRECISIO when sawing boards

up to a cutting length of 920 mm.

The sliding platform CS 70 ST 650 (order no.

490 312) can be fitted to the PRECISIO when

sawing boards up to a cutting length of 650 mm.

14.7 Saw blades

HM Ø 225 x 2.5 x Ø 30

Universal HW / 32 Order no. 488 288

Fine-tooth HW / 48 Order no. 488 289

Panther HW / 18 Order no. 488 290

Special HW / 68 Order no. 488 291

16

Page 10

14.8 Fitting the splinterguard

Seen at Ideal Tools.

The splinterguard SP-CS 70 (Order No. 490 339,

included with the CS70EB) prevents splinters in

the lower cut edge of the workpiece during vertical

cuts (saw blade in 0° position).

Warning: bevel cuts are not possible with the

splinterguard!

The splinterguard should thus be removed

immediately after use.

Unplug the mains lead from the wall socket!

Release insert clamp with rotary knob (5.1), push

claw forwards.

Raise and remove the base runner (1.4) at the

rear.

Set saw blade to minimum cutting depth.

Push splinterguard (8.1) from the side into the

holder (8.2) up to the stop.

Replace base runner and plug mains lead into

wall socket.

Switch on tool and slowly move the saw blade up

to the maximum cutting depth this cuts the

splinterguard to shape.

For a optimum function the raised part (8.4) of the

splinterguard should protrude slightly (approx.

0.3 mm) above the surface of the base runner.

For this purpose the height of the holder (8.3) can

be adjusted after releasing both screws (8.1).

15 Miscellaneous

Warranty

Our equipment is under warranty for at least 12

months with regard to material or production faults

in accordance with national legislation.

In the EU countries, the warranty period is 24 months

(an invoice or delivery note is required as proof of

purchase).

Damage resulting from, in particular, normal wear

and tear, overloading, improper handling, or caused

by the user or other damage caused by not

following the operating instructions, or any fault

acknowledged at the time of purchase, is not

covered by the warranty.

Complaints will only be acknowledged if the

equipment has not been dismantled before being

sent back to the suppliers or to an authorised

Festool customer support workshop.

Store the operating instructions, safety notes, spare parts list and proof of purchase in a safe place.

In addition, the manufacturers current warranty

conditions apply.

14.9 Fitting a screw clamp

A screw clamp (Order no. 489570) can be inserted

into the groove (1.10). Workpieces can be clamped

in place with the screw clamp.

Note

We reserve the right to make changes to the

technical data contained in this information as a

result of ongoing research and development work.

17

Page 11

EG-Konformitätserklärung. Wir erklären in alleiniger

Seen at Ideal Tools.

Verantwortung, dass dieses Produkt mit den

folgenden Normen oder normativen Dokumenten

übereinstimmt:

EN 61 029, EN 55 014, EN 61 000 gemäß den Bestimmungen

der Richtlinien 98/37/EG, 89/336/EWG.

CE-Konformitetserklæring. Vi erklærer på eget

ansvar at dette produktet er i overensstemmelse med

følgende normer eller normative dokumenter: EN 61 029,

EN 55 014, EN 61 000 i henhold til bestemmelsene i direktivene

98/37/EF, 89/336/EØF.

EC-Declaration of Conformity: We declare at our sole

responsibility that this product is in conformity with

the following standards or standardised documents:

EN 61 029, EN 55 014, EN 61 000 in accordance with the

regulations 98/37/EC, 89/336/EEC.

CE-Déclaration de conformité communautaire. Nous

déclarons sous notre propre responsabilité que ce

produit est conforme aux normes ou documents de

normalisation suivants: EN 61 029, EN 55 014, EN 61 000

conformément aux prescriptions des directives

98/37/CE, 89/336/CEE.

CE-Declaración de conformidad. Declaramos bajo

nuestra exclusiva responsabilidad que este

producto corresponde a las siguientes normas o documentos

normalizados: EN 61 029, EN 55 014, EN 61 000 conforme a

las prescripciones estipuladas en las directrices 98/37/CE,

89/336/CEE.

CE-Dichiarazione di conformità. Dichiariamo sotto

la nostra esclusiva responsabilità che il presente

prodotto è conforme alle norme e ai documenti normativi

seguenti: EN 61 029, EN 55 014, EN 61 000 conformemente

alle normative delle direttive 98/37/CE, 89/336/CEE.

CE-Declaração de conformidade: Declaramos, sob

a nossa exclusiva responsabilidade, que este

produto corresponde às normas ou aos documentos

normativos citados a seguir: EN 61 029, EN 55 014,

EN 61 000 segundo as disposições das directivas

98/37/CE, 89/336/CEE.

Заявление о конформности СЕ. Мы заявляем в

единоличной ответственности, что данное изделие

соответствует требованиям следующих стандартов или

нормативов: EN 61 029, EN 55 014, EN 61 000 в соответствии

с постановлениями директив ЕС 98/37, ЕЭС 89/336.

Prohláení o souladu s normami CE. Prohlaujeme

na vlastní zodpovìdnost, e tento výrobek odpovídá

následujícím normám nebo normativním dokumentùm:

EN 61 029, EN 55 014, EN 61 000 v souladu s ustanoveními

smìrnic 98/37/EHS, 89/336/EHS.

Owiadczenie o zgodnoci CE. Niniejszym

owiadczamy z ca³¹ odpowiedzialnoci¹, ¿e wyrób

ten odpowiada nastêpuj¹cym normom wzglêdnie dokumentom

normatywnym: EN 61 029, EN 55 014, EN 61 000 zgodnie z

postanowieniami wytycznych 98/37/EG, 89/336/EWG.

EG-conformiteitsverklaring. Wij verklaren op eigen

verantwoordelijkheid dat dit produkt voldoet aan de

volgende normen of normatieve documenten. EN 61 029,

EN 55 014, EN 61 000 conform de richtlijnen 98/37/EG,

89/36/EEG.

EG-konformitetsförklaring. Vi förklarar i eget ansvar,

att denna produkt stämmer överens med följande

normer och normativa dokument: EN 61 029, EN 55 014,

EN 61 000 enligt bestämmelserna i direktiven 98/37/EG,

89/336/EEG.

EY-standardinmukaisuusvakuutus. Vakuutamme

yksinvastuullisina, että tuote on seuraavien

standardien ja normatiivisten ohjeiden mukainen: EN 61 029,

EN 55 014, EN 61 000 direktiivien 98/37/EY, 89/336/EY

määräysten mukaan.

EF-konformitetserklæring: Vi erklærer at have alene

ansvaret for, at dette produkt er i overensstemmelse

med de følgende normer eller normative dokumenter:

EN 61 029, EN 55 014, EN 61 000 i henhold til bestemmelserne

af direktiverne 98/37/EF, 89/336/EØF.

CE-konformitás-nyilatkozat.Kizárólagos

felelõsségvállalás mellett ezennel tanúsítjuk, hogy

a jelen termék megfelel az alábbi szabványoknak ill.

szabványdokumentációnak: EN 61 029, EN 55 014,

EN 61 000 a 98/37EG, 89/336/EWG irányvonalak

rendelkezései szerint.

Дзлщуз ухммьсцщузт ЕК. Ме бнЬлзшз фзт

ухнплйкЮт ехиэнзт дзлюнпхме, ьфй фп рбсьн рспйьн

ухмцщнеЯ ме фб рбсбкЬфщ рсьфхрб кбй ме фб

рсьфхрб рпх бнбцЭспнфбй уфб учефйкЬ Эггсбцб ЕН 61 029,

ЕН 55 014, EN 61 000 уэмцщнб ме фпхт кбнпнйумпэт

98/37ЕК, 89/336/ЕПК.

Leitung Forschung und Entwicklung

Management Research and Development

Direction de recherce et développement

Festool GmbH

Wertstr. 20

D-73240 Wendlingen

Dr. Johannes Steimel

449 699/170703

Page 12

Festool GmbH

Seen at Ideal Tools.

Postfach 1163

D-73236 Wendlingen

Wertstraße 20

D-73240 Wendlingen

) (07024) 804-0

Fax (07024) 804-608

http://www.Festool.com

Loading...

Loading...