Page 1

OF 1400 EQ

Plunge Router Instruction Manual

Important: Read and understand all

instructions before using this tool.

Page 2

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1 year + 2

years = 3 years) for your Festool power tool. Festool shall be

responsible for all shipping costs during the first year of the

warranty. During the second and third year of the warranty

Festool Limited Warranty

This warranty is valid on the pre-condition that the tool is

used and operated in compliance with the Festool operating

instructions. Festool warrants, only to the original consumer

purchaser, that the specified tool will be free from defects in

materials and workmanship for a term of one year from the

date of procurement. Festool makes no other warranty,

express or implied, for Festool portable power tools. No

agent, representative, distributor, dealer or employee of

Festool has the authority to increase or otherwise change the

obligations or limitations of this warranty. The obligations of

Festool in its sole discretion under this warranty shall be

limited to the repair or replacement of any Festool portable

power tool that is found to be defective as packaged with the

User Manual.

Excluded from coverage under this warranty are: normal

wear and tear; damages caused by misuse, abuse or neglect;

damage caused by anything other than defects in material

and workmanship. This warranty does not apply to

accessory items such as circular saw blades, drill bits, router

bits, jigsaw blades, sanding belts, and grinding wheels. Also

excluded are “wearing parts”, such as carbon brushes,

lamellas of air tools, rubber collars and seals, sanding discs

and pads, and batteries.

Festool portable power tools requiring replacement or repair

are to be returned with the receipt of purchase to Festool

(call 800-554-8741 for address details).

the customer is responsible for shipping the tool to Festool.

Festool will pay for return shipping to the customer using

UPS Ground Service. All warranty service is valid 3 years

from the date of purchase on your receipt or invoice.

IN NO EVENT SHALL FESTOOL BE LIABLE FOR ANY

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR

BREACH OF THIS OR ANY OTHER WARRANTY,

EXPRESSED OR IMPLIED WHATSOEVER. ALL

WARRANTIES IMPLIED BY STATE LAW, INCLUDING

THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE

HEREBY LIMITED TO THE DURATION OF THREE

YEARS.

Some states in the U.S. and some Canadian provinces do not

allow the limitations on how long an implied warranty lasts,

so the above limitation may not apply to you. With the

exception of any warranties implied by state or province law

as hereby limited, the foregoing express limited warranty is

exclusive and in lieu of all other warranties, guarantees,

agreements and similar obligations of Festool. This warranty

gives you specific legal rights and you may also have other

rights which vary from state to state in the U.S., and

province to province in Canada.

As hereby limited, the foregoing express limited warranty is

exclusive and in lieu of all other warranties, guarantees,

agreements and similar obligations of Festool. This warranty

gives you specific legal rights and you may also have other

rights which vary from state to state in the U.S. and province

to province in Canada.

Liability Statement

This product has been built to the high standards of Festool.

Please do not attempt to operate or repair this equipment

without adequate training. Any use, operation, or repair in

contravention of this document is at your own risk. By

acceptance of this system you hereby assume all liability

consequent to your use or misuse of this equipment. Festool

assumes no liability for incidental, special, or consequential

damage of any kind. Equipment specifications, applications,

and options are subject to change at the sole discretion of

Festool without notice.

Proprietary Notice

All drawings and information herein are the property of Festool, TTS Tooltechnic Systems AG & Co. KG. All unauthorized

use and reproduction is prohibited.

Written and Illustrated by Rick Christopherson.

© 2005 TTS Tooltechnic Systems AG & Co. KG

All rights reserved. Printed in the United States of America and Germany.

Festool is a trademark and service mark of TTS Tooltechnic Systems AG & Co. KG

www.festoolusa.com

2 OF 1400 EQ Router

Page 3

Contents

Warranty ..............................................................................2

Conditions of 1+2 Warranty .........................................2

Festool Limited Warranty .............................................2

Liability Statement .........................................................2

Proprietary Notice..........................................................2

General Safety Rules...........................................................4

Work Area Safety .......................................................4

Electrical Safety ..........................................................4

Extension Cords .........................................................4

Personal Safety ...........................................................4

Tool Use and Care......................................................4

Service..........................................................................5

Specific Safety Rules for Routers..................................5

Router Feed Direction................................................5

Respiratory Exposure Warning................................5

Tool Description..................................................................6

Power Controls ...............................................................7

Technical Specifications.................................................7

Changing Router Bits.....................................................8

Changing Collets........................................................8

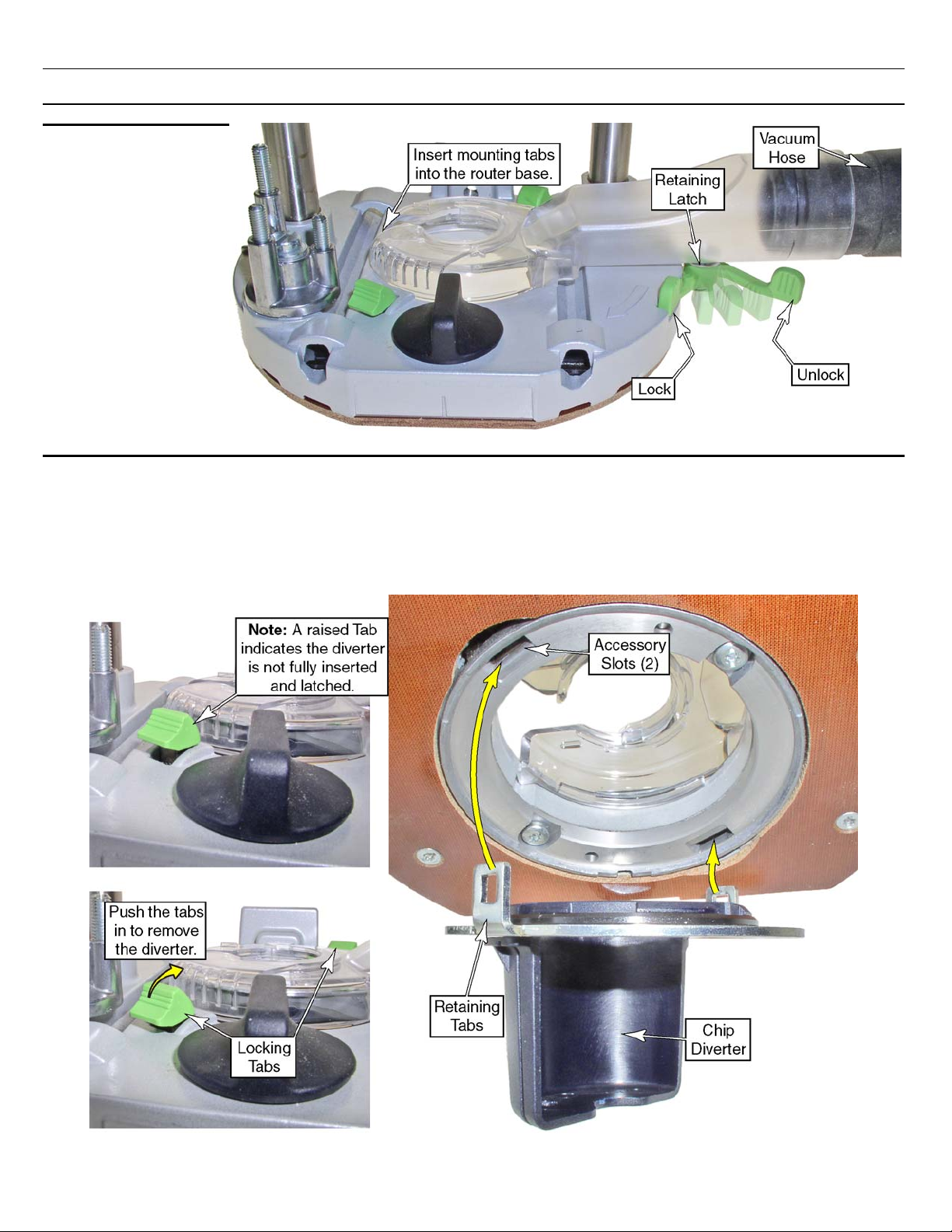

Dust Collection....................................................................9

Dust Extraction Hood................................................9

Chip Diverter ..............................................................9

Setting the Plunge Depth.................................................10

Using the Plunge Depth Gauge .............................10

Using the Depth Stop Turret.......................................11

Calibrating the Turret Posts....................................11

Using the Turret for Successive Depths................11

Using the Turret for Precision Depths ..................12

Basic Routing.....................................................................12

Fixed Depth...............................................................12

Feed Direction Rules................................................12

Plunge Routing.........................................................13

Plough Cuts...............................................................13

Router Speed and Feed Rate...................................13

Advanced Routing Techniques ......................................14

Starting a Cut Near a Corner ......................................14

Multi-pass Cuts.............................................................15

Multi-depth Ploughing............................................15

Multi-depth Profiles.................................................15

Multi-position (horizontal) Profiles.......................15

Pre-cutting Dovetails and Keyways ......................16

Tips for Successful Routing ........................................16

Chipping and Tearout .............................................16

Chatter .......................................................................16

Climb-cutting with Small Diameter Bits................... 17

Accessories.........................................................................18

Guide Rail Attachment................................................18

Assembling the Guide Rail Attachment ...............18

Using the Guide Rail Attachment..........................19

Alternative Method for Using the Guide Rail

Attachment

Edge Guide.................................................................... 21

Template Guides ..........................................................22

Systainer (System Container) .....................................23

Troubleshooting................................................................24

Maintenance ......................................................................25

Routine Maintenance...................................................25

Changing the Motor Brushes...................................... 26

..........................................................20

Instruction Manual 3

Page 4

General Safety Rules

WARNING: Read and understand all instructions listed below.

Failure to heed instructions may result in personal injury,

electrocution, or fire hazard.

Work Area Safety

► Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

► Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

Electrical Safety

► Double insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in

any way. Double insulation eliminates the need for the three wire

grounded power cord and grounded power supply system.

Extension Cords

All due care should be practiced while using extension cords with

this tool.

► When operating a power tool outside, use an outdoor extension

cord marked “W-A” or “W”. These cords are rated for outdoor

use and reduce the risk of electric shock.

► Never use an extension cord that is damaged, such as cuts,

exposed wires, or bent/missing prongs.

► Use only extension cords rated for the purpose.

Personal Safety

► Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious

personal injury.

► Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long hair can be caught

in moving parts.

► Avoid accidental starting. Be sure the switch is off before

plugging in the power cord. Carrying tools with your finger on

Tool Use and Care

► Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to loss of control.

► Do not force the tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

► Do not use the tool if the switch does not turn it on or off. Any

tool that cannot be controlled with the switch is dangerous and

must be repaired.

► Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

preventive safety measures reduce the risk of starting the tool

accidentally.

Save These Instructions

► Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

► Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

► Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

► Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

► Use only extension cords rated for the amperage of this tool

and the length of the cord. Using too small of an extension cord

can cause the router to lose power and damage the tool.

Extension Cord Ratings

Cord Length Size (AWG)

<50 Ft. 14

50-100 Ft. 12

100-150 Ft. 10

>150 Ft. Not recommended

the switch or plugging in tools that have the switch on invites

accidents.

► Remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

► Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in

unexpected situations.

► Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions. (Ordinary glasses are NOT

proper eye protection.)

► Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

► Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely

to bind and are easier to control.

► Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tool's

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

► Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool may become hazardous when used on another tool.

4 OF 1400 EQ Router

Page 5

Service

► Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

Specific Safety Rules for Routers

► Hold the tool by the insulated handles when performing an

operation in which the cutter may contact hidden wiring or its

own cord. Contact with a “live” wire will make the exposed

metal parts of the tool “live” and shock the operator.

► Use clamps or another suitable means to support and secure the

workpiece to a stable platform. Holding the workpiece by hand

or against your body is unstable and may lead to loss of control.

► Always make sure the work surface is free from nails and other

foreign objects. Cutting into a nail can cause the bit and the tool

to jump and damage the bit.

► Keep hands away from the cutting area. Keep your second hand

on the auxiliary handle. If both hands are holding the tool, they

cannot be cut by the bit.

► NEVER hold the piece being cut in your hands or across your

leg. It is important to support the work properly to minimize

body exposure or loss of control.

Router Feed Direction

For safety and control, the router should always be fed in the

direction against the rotation of the bit. This is called push-cutting

(among other names). Feeding the router in the same direction as

the bit rotation is called climb-cutting, and is extremely dangerous.

► When servicing a tool, use only identical replacement parts.

Use of unauthorized parts or failure to follow maintenance

instructions may create a risk of electric shock or injury.

► After changing the bit or making any adjustments, make sure

the collet nut and any other adjustment devices are securely

tightened. A loose adjustment device can unexpectedly shift,

causing loss of control, and loose rotating components can be

violently thrown.

► Never start the tool when the bit is engaged in the workpiece.

The cutting bit may grab and cause loss of control.

► Always feed the router against the rotation of the bit (called

push-cutting).

► Never operate the router with the cutting tool engaged in the

workpiece without locking the plunge lock knob. Unexpected

changes in cutting depth can result in a violent loss of control.

When fed in the push-cut direction, the router bit resists forward

movement and provides greater control to the operator.

If a router is fed in the climb-cut direction, the router bit tends to

self-feed, climb, or walk its way down the edge of the workpiece.

Feeding in this direction can, and will, cause the router to grab

suddenly and jerk down the workpiece, resulting in loss of control.

Special care needs to be taken when making dado cuts and plunge

cuts with a router because one side of the bit is push-cutting, and

the other side is climb-cutting. This can have unpredictable results

as each side of the bit engages the workpiece.

Refer to the "

Feed Direction Rules" section on page 12 for

additional information.

Respiratory Exposure Warning

Various dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known (to the

State of California) to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

► lead from lead-based paints,

► crystalline silica from bricks, cement, and other masonry

products,

► arsenic and chromium from chemically-treated lumber.

The risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to filter

out microscopic particles.

Instruction Manual 5

Page 6

Tool Description

This section provides a

quick overview of the

components and features

of the OF 1400 EQ router.

Additional information

about these components

and features will be

discussed later in the

manual.

Figure 1

a. Trigger (On/Off Switch). Used to turn the router On and

Off.

b. Trigger Lock. This locks the power trigger in the On

position.

c. Speed Control. This dial is used to change the motor

speed of the router. The higher the number, the faster the

motor speed.

d. Depth Stop Post Handle. The depth stop post is raised or

lowered with this handle.

e. Plunge Depth Gauge. Indicates the depth of plunge. This

is used in conjunction with the other depth setting

features to determine the depth of plunge.

f. Plunge Depth Pointer. This sliding pointer is used to set

the plunge depth relative to a basepoint setting.

g. Plunge Stop Micro-adjust Knob. The micro adjustment

knob is used to fine tune a depth setting by small

increments.

h. Plunge Lock Knob. This dual action knob acts as an

auxiliary handle for the router, and also clamps the

router in a fixed-plunge position.

i. Depth Post Lock. This lever locks the depth post in

position.

j. Depth Stop Turret. The turret allows for three rapid-

change depth settings based on a single depth stop. Each

position can be adjusted for individual depth.

k. Accessory Latches (2). The accessory latches are used to

secure optional accessories below the base of the router,

such as a template guide.

l. Outrigger Clamping Knob. The clamping knob is used

to secure outrigger accessories to the router base, such as

an edge guide accessory.

m. Dust Collection Port. The removable dust collection port

can be connected to a vacuum system for chip removal.

n. Dust Collection Port Latch. The latch secures the dust

collection port in position.

o. Ratcheting Spindle Lock. The spindle lock stops the

shaft from turning during a bit change. The dual action

lever locks the spindle in one direction and ratchets in the

opposite direction for faster bit changing. Press the lever

on the left to tighten the collet nut, and press it on the

right to loosen the collet net.

p. Collet. The collet holds router bits in place.

6 OF 1400 EQ Router

Page 7

Power Controls

To operate the router:

1. Set the motor speed by turning the variable speed

control knob to the desired speed according to the router

speed settings table on page 13.

2. Start the router by pulling up on the power switch.

3. If desired, lock the power switch in the on position by

holding in the trigger lock button, and then release the

power switch.

4. To release the trigger lock, pull up then release the

power switch.

Technical Specifications

Power Consumption 1400 Watts (12 amps @ 120 volts)

Weight 4.5 kg (9.9 lbs)

Speed Range 10,000 to 22,500 RPM (no load)

Quick Height Adjustment 70 mm (2.76")

Fine Height Adjustment 8 mm (0.31")

Maximum Bit Diameter 63 mm (2.5")

Collet Sizes 1/2-in. and 8mm Standard

Certifications IEC 745, UL745, CSA C22.2/745

The OF 1400 EQ router has a removable power cord for

added convenience. To install the power cord:

1. Insert the cord into the receptacle on the router's handle

with the keyway lined up with the key.

2. Twist the locking knob in the direction shown.

3. Reverse the procedure to remove the cord.

1/4-in. and 3/8-in. Optional

All metric dimensions are binding.

Instruction Manual 7

Page 8

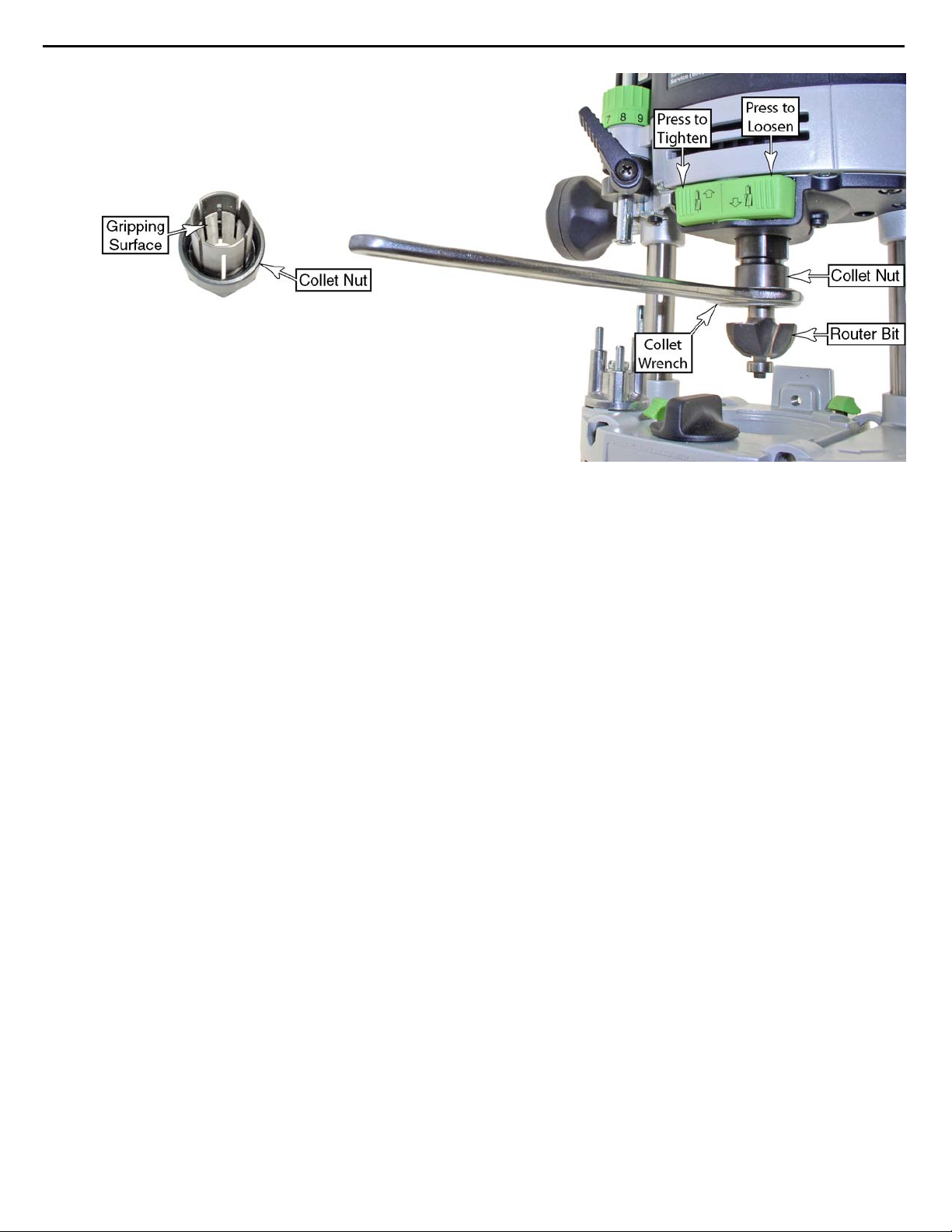

Changing Router Bits

g

y

y

The OF1400 EQ has the unique feature of a ratchetin

spindle lock. Because the spindle lock is ratcheted, you

don't need to remove the wrench to make multiple turns

of the collet nut; simply move the wrench back and

forth.

The router also has a ver

Ver

few router bits are long enough to bottom out in the

spindle. This is important, because if a router bit is

inserted so deep into the spindle that it touches the

bottom, the collet will not tighten properly and the bit

can come loose. The router bit gripping surface of the

collet is approximately 1 inch deep (shown above).

1. Unplug the router for safety.

2. Insert the router bit into the collet at least one inch. This

will vary with different bits, but most of the shank

should be within the collet. Do not exceed two inches.

deep spindle bore (2¼ inches).

6. R0 10.02 450.32224 4485d2.0009 479.33852 Tm(e)Tj10.02 0 0 10.0342.7119965 479.33852 Tmmoveen thwrenchut f

7. router bit, follow the same procedure

ollet nut before starting

3. Place the collet wrench on the collet nut.

4. Press the left-hand side of the spindle lock.

5. Tighten the colle

t nut firmly.

Page 9

Dust Collection

Dust Extraction Hood

The dust extraction

hood can be installed on

the top of the router

base and connected to a

vacuum for dust

collection.

To install the dust

extraction hood, insert

the mounting tabs into

the router base, and turn

the retaining latch to the

locked position.

Make sure the router bit

won't cut into the

extraction hood.

Chip Diverter

The chip diverter is used for edge forming to keep the

routing debris from coming back toward the operator.

This can be used with or without dust extraction. To

install the chip diverter:

1. Lay the router on its side.

2. Insert the tabs of the chip diverter into the accessory slots

and push in until you hear the locking tabs click.

3. Verify that the diverter is fully seated and latched. Note

the position of the locking tab in the upper left picture

when the diverter is not fully latched.

Instruction Manual 9

Page 10

Setting the Plunge Depth

Using Basic Plunge Features

The basic plunge features are used for the majority of

operations including both fixed depth routing and

plunge routing.

1. Unplug the router for safety.

2. Loosen the depth stop clamping lever so the depth

stop is free to move up and down.

3. Lower the router to the approximate depth desired

and lock the depth stop clamping lever.

► Note: With the depth stop clamped, the router can

be raised and lowered as needed to check the final

depth of cut.

4. Fine tune the depth stop by turning the fine

adjustment dial. Use the following guidelines:

► To increase the depth, turn the dial toward the

increasing numbers.

► To decrease the depth, turn the dial toward the

decreasing numbers. (Do not decrease the depth

setting with the plunge lock knob tightened.)

► Each index number represents 0.1 mm (0.004 inch) of depth,

and one full turn represents 1 mm (0.040 inch) of depth.

5. Operate the router as described in the “Basic Routing”

section on page 12.

Using the Plunge Depth Gauge

The depth gauge is used to set the cutting depth relative to a

basepoint setting. A typical example where this is used is when

the cutting depth needs to be relative to the surface of the

workpiece, such as a dado cut.

1. Unplug the router for safety.

2. Loosen the plunge lock knob ¼-turn and lower the router

until the router bit touches the basepoint (such as the surface

of the workpiece).

3. For convenience, you may wish to re-tighten the plunge lock

knob.

4. Set the basepoint (see the left-hand image):

a. Lower the depth stop until it touches one of the posts on

the turret.

b. Slide the index pointer down to the zero-setting.

c. Note that the depth stop lever is unlocked.

5. Set the desired depth (see the right-hand image):

a. Raise the depth stop until the index pointer is pointing

to the desired depth on the gauge (the example in the

right-hand image shows a final depth setting of 10 mm).

b. Lock the depth stop lever.

6. Release the plunge lock.

7. Operate the router as described in the “Basic Routing”

section on page 12. The depth of plunge will be the amount

set in step 5.a above.

10 OF 1400 EQ Router

Page 11

Using the Depth Stop Turret

The depth stop turret allows you to easily change between

different depths without changing the depth stop settings.

► The turret posts can be calibrated for repeatable depth

settings from a basepoint depth, such as making dado cuts.

Calibrating the Turret Posts

► One of the most common tasks for the turret is making

successively deeper cuts to achieve a final depth that

cannot be completed in a single pass.

The height of the turret posts may be left at the default settings,

but you may wish to set the heights based on frequently

performed tasks. Use this procedure if you want to set the

difference between post heights to be specific to your needs.

► The actual height of each post is not critical; the difference in

height between posts is critical.

► If all three posts are to be calibrated, begin with the lowest

two posts, and work upward from there.

1. Unplug the router for safety.

2. To ensure the router depth does not change, tighten the

plunge lock knob.

3. Set the Basepoint (see the left-hand image):

a. Rotate the turret to the lower of the two posts to be

adjusted. This lower post height is not adjusted, but

serves as the baseline for adjusting the higher post(s).

b. Release the depth stop lever and lower the depth stop

down to the post.

c. Slide the index pointer down to the zero-position.

4. Calibrate the adjacent post (see right-hand image):

a. Lift the depth stop out of the way and rotate the turret

to the higher post to be calibrated.

► To increase the difference between posts, turn the

higher post counterclockwise.

5. Verify the adjustment by lowering the depth stop

back down to the higher post and reading the result

on the depth gauge.

b. Lower the depth stop to the post.

► Do not re-zero the index pointer.

► The index pointer will be showing the difference

between the two posts heights.

c. Adjust the height of the higher post until the index

pointer is pointing to the desired difference between

post heights:

► Do not change the height of the lower post.

► Lift the depth stop out of the way (or rotate the turret)

to adjust the post height.

► To decrease the difference between posts, turn the

higher post clockwise.

Using the Turret for Successive Depths

The turret can be very useful when making deep

plunge cuts because successively deeper cuts can be

made without readjusting the router (see Multi-depth

Ploughing on page 15).

1. Unplug the router for safety.

2. Rotate the turret to the lowest post and set the

depth stop for the final desired depth as described

on page 9.

3. Rotate the turret to the highest post, and operate the router

as described in the “Basic Routing” section on page 12. This

will route the workpiece at the shallowest setting.

4. Next, rotate the turret to the middle post, and perform the

routing operation again. The depth will be slightly deeper

than the first.

5. Finally, rotate the turret to the lowest post and complete the

final pass.

Instruction Manual 11

Page 12

Using the Turret for Precision Depths

This procedure is very helpful when you have day-to-day

plunging operations that use the same depth relative to a

basepoint. You can quickly reset the depth even after

changing the router bit.

Before using this procedure, make sure you perform the

“Calibrating the Turret Posts” procedure on page 11 to set

the difference between turret posts to the precise depth you

need.

For example, using the calibration procedure, you could set

the difference between posts as follows:

st

► 1

to 2nd post to ¼ inch

nd

► 2

to 3rd post to ½ inch

st

► 1

to 3rd post to ¾ inch

Basic Routing

Fixed Depth

Fixed depth routing is typically performed with router bits

with a guide bearing that rides along the edge of a workpiece.

The depth of cut is fixed before the router is engaged.

1. Verify that the router bit is properly secured, and the

router is ready for operation.

2. Secure the workpiece to a stable surface.

3. Lower the router to the desired depth and tighten the

plunge lock knob.

1. Unplug the router for safety.

2. Decide which two posts provide the difference in height

necessary for the operation.

3. Rotate the turret to the higher of the two posts.

4. Lower the router down until the router bit touches the

surface of the workpiece.

5. Lock the depth stop at this depth.

6. Rotate the turret to the lower of the two posts.

7. Operate the router as described in the “Basic Routing”

section below.

4. Set the router speed according to the speed settings

table on page 13.

5. Place the router on the workpiece, but make sure the bit

is not touching the wood.

!CAUTION: Starting the router with the bit in contact with

the workpiece may cause a loss of control and injury.

6. Firmly grasp both handles of the router and pull up on

the power switch.

7. Advance the router through the cut according to the

feed direction rules below.

Feed Direction Rules

► Always feed the router against the rotation of the bit. This

prevents the router from grabbing the wood and selffeeding, resulting in a loss of control.

► When routing around the exterior of a shape, feed the

router counterclockwise.

► When routing around the interior of a shape (such as the

circle shown below), feed the router clockwise.

► Begin routing across the end grain first (as indicated with

"Start Here" in the figure below). This reduces tearout at

the corners.

12 OF 1400 EQ Router

Page 13

Plunge Routing

Plunge routing is any operation where the router is

lowered down into the cutting area after the router has

been started. Most often this involves router bits that do

not have a guide bearing, but can also be used for interior

cutting (such as the circular cut shown on page 12).

!WARNING: Take care while plunge routing to maintain

control of the router at all times. For many plunge

operations, one side of the router bit will be climbcutting and the other side will be push-cutting. This

can lead to a loss of control and/or poor cut quality.

1. Verify that the router bit is properly secured and the

router is ready for operation.

2. Secure the workpiece to a stable surface.

3. Set the router speed according to the speed settings

table below.

Plough Cuts

When making plough cuts, as shown to the right,

three sides of the router bit are engaging the

workpiece. This can lead to undesired changes in

the path of the router.

4. With the router turned off, place the router on the

workpiece.

5. Firmly grasp both handles of the router and pull up on the

power switch.

6. Lower the router to the desired depth, tighten the plunge

lock knob, and advance the router through the cut.

!WARNING: Failure to tighten the plunge lock knob may

result in a loss of control and injury.

► For router bits with guide bearings, advance the router

through the cut according to the feed direction rules

discussed on page 12.

► When using router bits without a guide bearing, or with an

external guide rail, follow the tips in "plough cuts" below

to keep the router tracking properly.

► One side of the router bit is climb-cutting, and

this tends to propel the router forward.

► One side of the router bit is push-cutting, and

this tends to slow the feed rate.

► The leading edge of the router bit pushes the

router sideways, opposite the rotation of the bit.

The opposing climb-cutting and push-cutting sides

will cause the router to advance with a jerking

motion.

To avoid drift from the leading edge of the router

bit, position a guide rail on the push-cutting side of

the router (toward the middle in the image to the

right).

Router Speed and Feed Rate

The optimal router speed for an operation is determined

by the diameter of the router bit and the type of material

being machined. The important factor is the speed that the

router bit tips move past the workpiece. The tip speed is

proportional to the diameter of the router bit.

If the tip speed is too high, friction causes excessive heat

and the workpiece can be scorched. Too low of a tip speed

and the bit will tear the material instead of cutting (for

aluminum, the bit will grab the workpiece).

The feed rate of the router past the workpiece is a function

of the router speed, material type, and amount of material

being removed. Too fast of a feed rate can cause chatter

and tearout. Too slow of a feed rate can burn or scorch the

workpiece.

Material

Pine

Oak

Cherry

Maple

Particleboard

and MDF

Soft Plastics

Hard Plastics

Aluminum

Router Speed Settings

Bit Diameter (inches)

≤½ ¾ 1 1¼ ≥1½

5-6 5-6 4-6 3-5 3-5 Fast

5-6 4-6 4-5 3-5 2-4 Moderate

3-5 3-5 3-4 2-4 2-3 Moderate

3-5 3-5 3-4 2-4 2-3 Slow

5-6 5-6 4-6 3-5 3-5 Fast

3-5 3-5 3-4 2-4 1-3 Slow

2-4 1-4 1-3 1-2 1-2 Slow

3-4 3-4 2-3 2-3 1-3 Slow

Feed

Rate

Instruction Manual 13

Page 14

Advanced Routing Techniques

Starting a Cut Near a Corner

When routing a profile on the edge of a board, it can be

difficult starting the cut at the corner without having the

router lurch backward and cut into the adjoining side of the

board (going past the corner). To avoid having the router

catch unexpectedly, firmly hold the auxiliary handle (plunge

lock knob) with one hand, and pivot the router with the

main handle. This method gives you more control over the

router, even if it were to unexpectedly catch.

This procedure is described and shown with right-

handed operation. For left-handed operation, revers

the hand positions describe

shown in the photograph.

1. Clamp the workpiece to a stable surface.

2. Set the router bit depth and firmly tighten the plunge

lock knob.

3. Set the speed control according to the table on page 13.

d in the procedure and

e

4. Place the router on the workpiece with the router bit

positioned slightly ahead of the corner (away from a

right-handed operator as shown) and about ½ to 1 inch

away from the workpiece.

5. Firmly place your left forearm on the workpiece and

grasp the auxiliary handle (plunge lock knob) of the

router. Your hand will serve as the pivot point for this

operation, so you want to keep it held as firmly in place

as possible.

6. Place your right hand on the main handle and start the

router.

7. Nibble away at the corner by rocking the router back

and forth taking light, controlled cuts. Gradually move

your left hand as necessary to cut deeper.

8. Finish routing the rest of the edge as normal.

14 OF 1400 EQ Router

Page 15

Multi-pass Cuts

Nearly all routing operations can be improved by making

multiple passes. In some cases the routing operation would

remove too mach material to be completed safely in a single

pass. In other cases, the finished cut is improved by making

Multi-depth Ploughing

When ploughing out large volumes

of material or making deep dados,

make the cuts using successively

deeper settings until the final depth

is reached. The three positions of the

depth stop turret are well suited for

this type of operation.

a shallow, clean-up pass. Depending on the type of cut being

made, some multi-pass cuts are made by varying the depth

and others are made by varying the position. The different

types are shown below.

Multi-depth Profiles

There are several reasons for making

multiple passes with edge forming, profile

cutters.

► For large profiles, a shallow first-pass can

be made to remove the bulk of the material.

► Several shallow passes can be made for

better control with large router bits.

► A final, shallow, clean-up pass can improve

the quality of the finished edge.

Multi-position (horizontal) Profiles

Altering the horizontal position of a router

cut for multiple passes is required whenever

the profile cuts back into the workpiece in a

way that changing the depth would destroy

the desired profile. A common example of

this is a slot cutter. A common problem with

this type of cutter is that sharp corners

between the cut profile and the uncut wood

edge will tend to tear out. This can be

reduced by making a very shallow scoring

cut before making a full profile cut.

Instruction Manual 15

Page 16

Pre-cutting Dovetails and Keyways

Dovetail and keyway cutters are inherently weak

because the upper shank of the bit is smaller than

the cutting edges. If the stress on the bit is too

great, the cutting tip can break. To reduce the

stress on the cutter, it is common practice to

plough out the majority of the material with a

straight bit. The depth of the straight bit should be

slightly shallower than the depth of the final bit so

the bottom of the profile remains square.

Tips for Successful Routing

Chipping and Tearout

One of the most common problems woodworkers will encounter

when using a router is chipping and tearout of the workpiece.

The following tips can reduce the occurrence of chipping and

tearout.

► Take shallower passes to reach your final depth. With a shallow

pass, the router bit teeth will be cutting parallel with the grain

instead of arching through the grain.

► Examine the woodgrain before routing. If possible, orient the

workpiece so the grain doesn't fracture. To identify the grain

orientation, examine the edge grain, not the surface grain. Use

the following tips:

► If the grain orientation is not in the right direction, turn the

board over. (Rotating the board to the opposite edge does not

change the orientation. You must flip the board over.)

► For tight-grained woods where the grain orientation is not

obvious, look for pre-existing signs, such as small splinters at

the corners. You can also use a knife to cleave the grain.

► For open pore woods such as oak, examine the

capillaries on the edge of the wood. Orient the

board so the router is moving away from the

capillary entrance holes.

Chatter

Router bit chatter is the presence of small curves, or

scallops, in the routed profile (refer to the image on page

17). The following items may cause chatter:

► Too fast of a feed rate for the router RPM.

► Trying to take too much material in a single pass.

► Chatter is more noticeable with smaller diameter router bits.

16 OF 1400 EQ Router

Page 17

Climb-cutting with Small Diameter Bits

Disclaimer: Even though Festool does not condone the

practice of climb-cutting with a router, the topic is

known to exist in books and other written publications

on router techniques.

This topic is presented for information only, and is

intended to warn the user of the potential dangers of

climb-cutting. The information below does not explain

how to perform climb-cutting, but instead, what not to

do. Any user attempting climb-cutting, does so at their

own risk.

Climb-cutting is feeding the router in the same direction as

the rotation of the bit. The inherent danger is that the router

bit will tend to self-feed, or "climb" its way down the

workpiece. The sole benefit for climb-cutting is that there

will be less tearout in the cut. This is because the tip of the

cutter enters the edge of the workpiece, instead of exiting the

edge of the workpiece. This shears the wood fibers in a

compressing action, and results in less tearout.

WARNING: Climb-cutting with a router is

inherently dangerous! Read, understand, and

follow all of the warning messages below.

!WARNING: There is no entirely safe method for climb-

cutting. The router bit can grab the workpiece at any

time.

!WARNING: Never attempt climb-cutting with large

diameter bits.

!WARNING: Never, under any circumstances, attempt to

climb-cut with a table-mounted router. The workpiece

will catch and will be propelled off the table.

!WARNING: Never climb-cut around an interior cutout in a

workpiece. The bit can easily catch in the corners.

!WAR place

Procedure Notes

NING: The workpiece must be fully secured in

with

clamping devices. Friction mats are not sufficient

for

securing a workpiece.

► N

ever let your guard down. Always be expecting the

router to catch, and think ahead of how you should best

react to the situation before it happens.

► A er tool, respect the danger, but do not

s with any pow

operate the tool if you are afraid of the operation. Your

reactions will be diminished if you are afraid of the tool o

th

e procedure.

► In l the

stead of relying on your reaction-time to contro

r

router feed rate, use friction. By holding your forearm

fi ut

rmly to the workpiece as shown in the "Starting a C

Near a Corner" procedure on page 14, you use friction to

assist in keeping the router under control.

► A

void climb-cutting with the router moving toward your

bo le with the router pulling

dy. More control is possib

away from your b

► Climb-cutting end

The wood fibers are torn and compressed, and the resu

a rougher finish.

► such as cherry and

For materials that are prone to burning (

maple) climb-cutting reduces burning because the prima

ody with your arms outstretched.

grain does not improve the cut quality.

lt is

ry

cut is shearing the fibers.

►

For best results, always follow a climb-cut with a clean up

pass in the push

► Climb-cutting will push the router bit away from the

-cut direction for the following reasons:

workpiece, making the cut shallower than expected.

Push-cutting pulls the bit into the workpiece.

► Climb-cutting will result in more chatter marks (shown

to the left). Push-cutting will remove these.

Instruction Manual 17

Page 18

Accessories

Guide Rail Attachment

The guide rail attachment is used to connect the router to

a Festool guide rail system for making straight cuts.

3. Place the other guide block over the free end of the micro-

adjust thumbwheel.

Assembling the Guide R

1. Before assembling the attachmen

rail gibs on both guide blocks.

a. Place the block on one of the ribs of the guide rail.

b. Tighten the two adjustment screws until the block

fits snuggly to the rib but still move

2. Thread the micro-adjust thumbwheel into either one

of the two guide blocks.

ail Attachment

t, adjust the guide

s freely.

4. Insert the two guide rods through both guide blocks. Make

18 OF 1400 EQ Router

Page 19

6. Install and adjust the leveling

g

outrigger to the back of the router.

a. Adjust the height of the outrigger

so the router is level when sitting

on the edge of the guide rail.

b. Tighten the clamping

thumbscrew.

► The router bit radius gauge is

used to indicate the location of

the edge of the router bit. This is

helpful for making stopped cuts.

Note that this gauge indicates the

radius of the bit and not the

diameter.

Make sure to raise the outrigger

out of the way when not in use.

Us g the Guide Rail Attachment in

The Festool

htedge for routing.

straig

► The zero-clearance strip does not serve a purpose for

this operation, so take care not to cut into the strip.

(Keep the router bit at least ¼-inch away from the

zero

-clearance strip.)

► ing as a

Because the guide rail is simply serv

straightedge, the router can be placed on the guide

rail in any one of several ways, depending on the

need. (Also refer to the procedure on the next page.)

► In o t feature, the

rder to utilize the micro-adjustmen

gui talled on the guide

de rail attachment must be ins

rail with the inner guide block free to move, as

sho

wn.

uide rail is used as a conven

ient

1. Clamp the guide rail to the workpiece. Note that the

cutting action of the router bit may tend to move the

guide rail if it is not properly clamped.

2. Place the router and guide rail attachment on the guide

rail with the outer guide block on the first rib of the

guide rail.

3. Verify that the leveling outrigger is at the proper height

so the router base is level (see procedure above).

4. Loosen the clamping thumbscrew on the router, and

slide the router in or out to its approximate final

position. Retighten the thumbscrew.

5. With the inner guide block clamping knob tight and the

outer guide block clamping knob loose, adjust the microadjust thumbwheel to set the final position of the router:

► Each number on the wheel represents 0.1mm, and a full

turn of the wheel represents 1.0 mm.

► After the micro-adjustment is complete, tighten the

outer guide block clamping knob.

Instruction Manual 19

Page 20

Alternative Method for Using the Guide Rail Attachment

This procedure can be used for greater stability of the

gui

de rail attachment, but does not permit the use of the

m

icro-adjustment feature. This is helpful when using

rou or

ter bits prone to deflecting the position of the router,

whe

n making precision cuts that must remain perfectly

true

to the guide rail.

The

primary basis for this procedure is that the microadjustment thumbwheel is used to adjust the inner and

out

er guide blocks to the guide rail ribs, and provide a

la

rger guide surface area than using the guide rail gibs

(ref

er to page 18 for further information on the guide rail

gibs

).

Note that the micro-adjustment feature cannot be

used with this setup. If you need to use the microadjustment feature to set the router's position, use

the procedure on page 19.

1. Clamp the guide rail to the workpiece. Note that the

cutting action of the router bit may tend to move the

guide rail if it is not properly clamped.

2. Place the router and guide rail attachment on the

guide rail with both guide blocks on the ribs of the

guide rail.

3. Use the micro-adjust thumbwheel to adjust the guide

blocks to fit the guide rail.

► The interior edges have a larger bearing surface, so moving

the two guide blocks apart makes the guide more stable.

a. Loosen the clamping knob on the inner guide block.

b. Move the two guide blocks apart by turning the micro-

adjust thumbwheel toward the increasing numbers,

until the guide blocks fit snuggly to the guide rail ribs,

but not so tight that the guide doesn't slide freely.

c. Re-tighten the clamping knob.

4. Verify that the leveling outrigger is at the proper height so

the router base is level (refer to the "Assembling the Guide

Rail Attachment" procedure on page 18).

5. Adjust the position of the router.

a. Loosen the clamping thumbscrew on the router base.

b. Slide the router in or out to its final position.

c. Retighten the thumbscrew.

20 OF 1400 EQ Router

Page 21

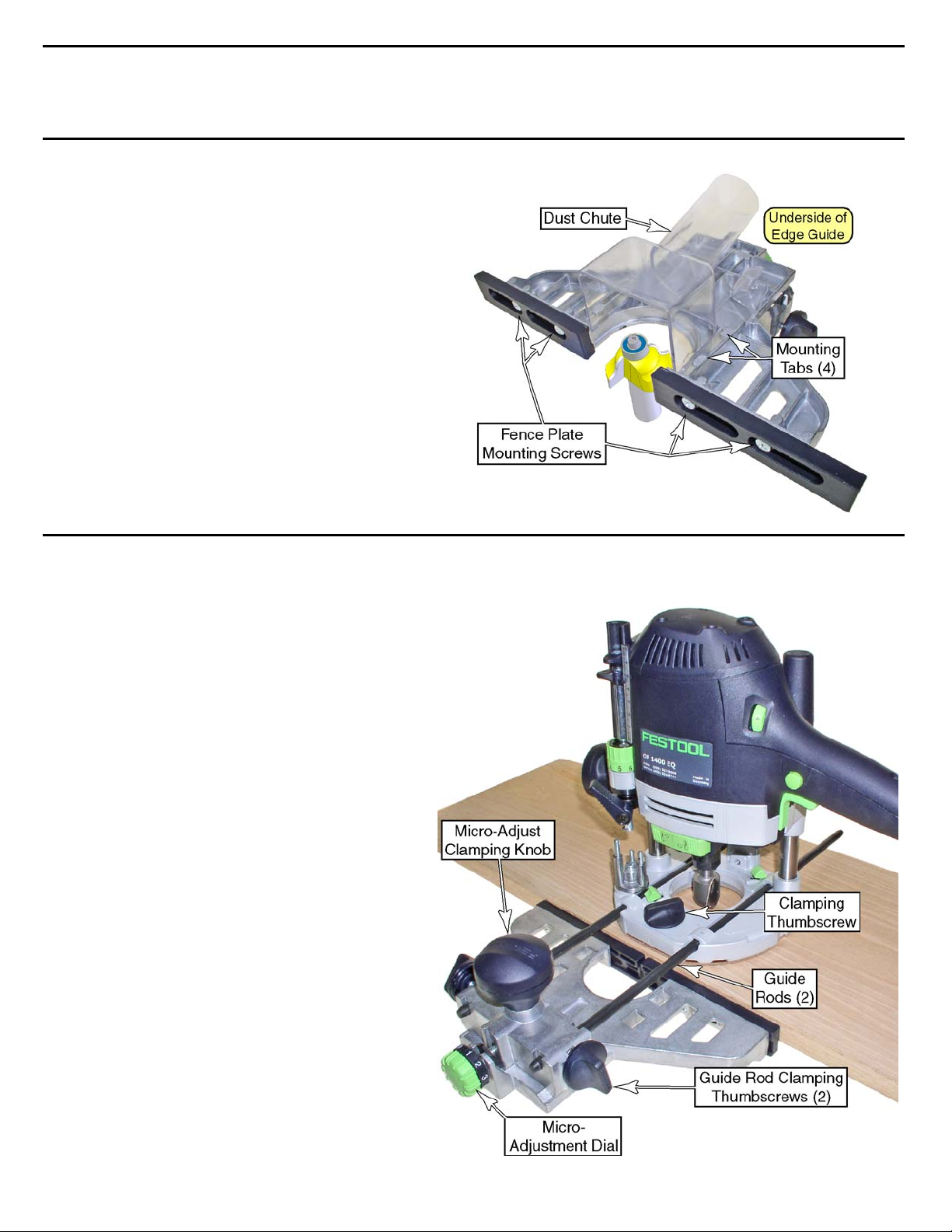

Edge Guide

The edge guide is used for guiding the router relative to the

edge of a workpiece. This can be used for interior plunge

rou ile

ting (such as fluted columns) or for edge forming. Wh

Edg

e Forming Setup

When using the edge guide for edge forming, the router

bit

will be within the cutout of the edge guide (as shown

to the ri

ght).

h

t e operations are similar, there are additional setups

n

ecessary for edge form routing.

► The tw

clear

► There are two options for dust collection. The standard

o fence plates need to be separated enough to

the router bit so the bit does not cut the fence.

dust extraction hood may be used (see page 9), or the

optional dust chute may be attached to the underside of

the edge guide. (Both dust extraction options may be

used together, but the results may not be as expected.)

1. Loosen the four mounting screws on the fence plates

and slide the plates apart enough to clear the router

bit.

2. Retighten the mounting screws.

3. If desired, slide the dust chute under the mounting

tabs until it clicks into place.

General Setup

The same general setup is used for both interior and

edge form routing. The image to the right shows an

interior routing setup.

1. Insert the guide rods through the edge guide as

shown, and tighten the clamping thumbscrews.

2. Insert the other end of the guide rods through the

eyelets in the router base.

3. Set the approximate position of the router, and

tighten the clamping thumbscrew on the router

base.

4. To set the final position of the router using the

micro-adjust feature:

a. Loosen the micro-adjust clamping knob on

the edge guide.

b. Turn the micro-adjustment dial to set the

position of the router.

► Turning the dial toward increasing numbers

moves the router away from the edge guide.

► Each number represents 0.1 mm, and a full

revolution is equal to 1.0 mm.

c. Retighten the clamping knob.

5. Make sure you operate the router from left to

right to keep the edge guide tight to the

workpiece. (Refer to the discussion on "Plough

Cuts" on page 13.)

Instruction Manual 21

Page 22

ides Template Gu

Template guides (also known as copy rings) are used to

control the position of the router relative to an external

pattern or template. This permits you to follow an external

pattern even if the router bit does not have a guide bearing.

The OF 1400 EQ router package may include either a

standard Festool copy ring, a universal template guide

adapter, or both. The template guide adapter allows you t

o

use universal guides from other manufacturers with yo

ur

Festool router.

The function of the Festool copy ring and the universal

template guide adapter are the same, except with the

universal guide adapter you provide the template bushing.

This allows you to use template guides that you already own

with your Festool router.

Using a Template Guide

► To install the template guide to the router base,

llow the same procedure for installing the fo

Chip Diverter as described on page 9.

► Template guides are available with a variety of

bushing diameters. Typically, the bushing

d

iameter should be slightly larger than the

router bit diameter, but never so close that the

o

r uter bit can contact the interior of the

bushing.

CAUTION: If the spinning router bit

tacts the interior con of the template guide, it

will damage both the router bit and the

guide.

► The routi

des

to the

► The

ng pattern needs to be larger than the

ired routed edge as shown in both images

right.

offset (shown in both images to the right)

between the pattern and the final routed edge

is ½ the difference between the template guide

bushing diameter and the router bit diameter.

22 OF 1400 EQ Router

Page 23

Container) Systainer (System

Every Festool product is shipped in its own unique syste ainer, called a "Systainer". This provides protection and

storage for the tool and accessories. All Systainers are stacka

locking atop Festool dust extractors.

m cont

ble and can be interlocked together, including stacking and

Parts of the Systainer

► Carrying Handle. The carrying handle folds flat when not

in use.

► Cover Latches. The two green latches on the front of the

Systainer secure the cover. (These are also used for

stacking Systainers, as described below.)

► Stacking Latches. The two gray latches on the sides of the

Systainer are used for stacking one or more systainers

together.

► Stacking Tabs. The stacking tabs are used to lock two

systainers together. There are four sets of tabs (two on the

front and two on the sides) of each systainer.

Stacking Systainers

F r convenience in transporting Festool tools and o

accessories, the systainers can be stacked and locked

together. The systainers are locked together using the

stacking t

1.

2. r by pulling

abs and latches.

Place one systainer on top of the other.

Release all four latches on the lower systaine

back at their top edges (step A to the right).

3. four latches upward (step B) as depicted by the

Slide all

two views.

4. (step C) so

Snap all four latches back to their flat position

they engage the stacking tabs of the upper sys

tainer.

The lower image to the right shows two accessory systainers

st

acked together.

Instruction Manual 23

Page 24

Troubleshooting

Symptom Possible Causes

Motor does not start ► Check that the cord is properly plugged into the router and into an

outlet.

► Make sure the ou e circuit breaker or try

another outlet.

► If used with a Fes

pointing to "Auto". The auxiliary outlet on the dust extractor has power

only when the se

► Inspect the power c

missing prongs.

► The motor brushes

Router does not plunge smoothly ► Make sure the plunge lock knob is loose.

► Clean the plunge

damage.

Router bits slip in the collet ► The collet and ma nd oil

in the wood. Clean the tapered surfaces:

1. Remove the collet from the router.

2. Using a plastic scrubbing pad, clean the outer taper of the collet.

3. Using a plastic scrubbing pad, clean the interior taper of the arbor.

4. Make sure there is no plastic or metal debris left over from the

cleaning, and reinsert the collet.

► If router bits have spun inside the collet, it may be damaged and need

replacement.

Routed profile burns ► The router bit is dull.

► The

router speed is too fast.

► The fee

► Some m

d speed is too slow.

aterials are prone to burning. Take a shallow clean-up pass

with a higher feed rate.

► If the burn is below the profile, then the router bit guide bearing (if

present) is wor

► Remove the bi

If the bearing spins roughly, it needs replacement.

► A good bear

with your finger. If it coasts more than one revolution, it is worn.

► Replace the b

Router vibrates excessively ► If a large diameter router bit is slightly out of balance, it will vibrate at

high speed. Re

the router bit.

► The router bit shaft may be bent. Discard the bit if the shaft is bent.

► The router bearings may be worn and need replacement. Send the

router in for service.

tlet has power. Check th

tool dust extractor, make sure the selector switch is

lector is at Auto.

ord (including extension cords) for damage or

may have worn and need replacement.

posts (columns) and inspect for scratches and

ting arbor taper can become pitted from acids a

n.

t from the router and spin the bearing with your finger.

ing should coast for about one revolution when spun

earing or bit.

duce the router speed. If the vibration is severe, discard

24 OF 1400 EQ Router

Page 25

Maintenance

Routine Maintenance

Any maint hat requires opening of

the motor housing should be carried out only

authorized Customer Service Center (whose

supplied by your dealer)! Maintenance or repa

carried out by an unauthorized person can l

connection of electrical wires or other compon

can result in injury.

To prevent injury or electrocution, always u

from the power supply outlet before performin

maintenance or repair work on the tool!

Do no oto

tool, as you could inject foreign objects into

through the ventilation openings. Compressed

used sonal safe

should be employed (hearing, vision, and resp

enance or repair work t

by an

name is

ir work

ead to improper

ents, which

nplug the tool

g any

t use compressed air to clean the m r housing of the

the motor

air may be

on other components, but per ty protection

iratory).

►

As a general rule, keep the tool clean of all dust and

debris. Even soft-wood dust can be abrasive o

► Examine all moving parts for dust and debris

►

Keep the plunge posts clean so dust does not get

ver time.

.

embedded into the bearing surfaces.

Keep the Router

Bits Sharp

Using a dull router bit can be extremely dangerous and

cause poor cut quality.

► Never attempt to sharpen a

equipment is necessary

type cutter. An improperly sharpened router

router bit ma

nually. Special

to properly sharpen any rotating-

bit can injure

the operator, destroy the tool, and damage the workpiece.

► Your router bits should be sharpened regularly, and

by a qualified sharpen

ing service.

only

Certain cleaning agents and solvents are harm

parts. Some of these include, but are not limite

Gasoline, Acetone, Methyl Ethyl Ketone (MEK

Chloride, cleaning solutions containing Chlori

and household cleaners containing Ammonia.

To ensure proper cooling of the tool and moto

vents in the motor housing must always be k

clean.

Keep the Tool Clean

Dust and debris from some materials can be

abrasive and cause components within the r

extremely

outer to wear

prematurely. It is important to keep moving p

abrasive dusts.

ful to plastic

d too:

), Carbonyl

ne, Ammonia,

r, the cooling

ept clear and

arts cleared of

Adjust and Inspect the Tool

To ensure the tool is in proper working order, period

inspect the operation of the tool and ensure it is prop

adjusted.

► Observe the function of the router during normal

operation.

Unusual sounds are indicative of pending problems.

►

A r

►

eduction in the cut quality indicates the router bit is

dull or the rout

► A reduct

er is not functioning properly.

ion in cutting power or speed may indicate a dull

cutter or a motor problem.

ically

erly

Instruction Manual 25

Page 26

r Brushes Changing the Moto

The motor brushes wear out over time and need to be replaced by an authorized service center. Festool does not condone

brush replacement by the end-user.

warranty.

Removal Procedure

CAUTION! Make sure the

power cord is unplugged

before beginning this

procedure.

1. Remove the four screws that

secure the access cover to the

motor, and remove the cover.

2. Remove the three screws that

secure the upper cover to the

main handle, and remove the

cover.

3. To access one of the two brushes,

you will need to remove the

electronics module.

Completion of this procedure by an unauthorized service center will void the tool's

a. Make note where the wires

are routed.

b. Very carefully,

copper strap unt

lift up on the

il it is free

from the retaining tab.

c. Slide the electronics module

up, but

do not remove it

completely.

4. Lift the wire connectors off the terminals on the

brushes.

5. Remove the screw that secures each brush to the

motor housing. Be careful not to drop the screws

into the motor.

6. Carefully lift the brushes straight up to remove

them.

26 OF 1400 EQ Router

Page 27

Replacement Procedure

1. Hold the carbon brush inside the brush body, and

insert the brush into the mounting slot (as shown

below)

.

2. Fully seat the brush

. Replace the two brush mounting screws.

3

into the slot.

4. Replace the two wire connectors to the terminals

o t

n he brushes.

5. Press the electronics module back

► under the copper

Make sure the wires passing

strap are not pinched

► place. If the

Do not force the electronics into

by the strap.

into the router.

module does not press in freely, something must

be in the way.

► e top of the

When fully inserted, the tab on th

mot h the top of the

or housing will be flush wit

cop

per strap.

6. Carefully examine the wires. Make sure they are

routed properly and will not be pinched when the

covers are instal

led.

7. Reinstall the covers on the router.

Note that during the break-in period while the

new brushes conform to the shape of the

armature contacts, the brushes may exhibit more

arching (sparking) than normal.

Instruction Manual 27

Loading...

Loading...