Page 1

Festool GmbH

Wertstraße 20

73240 Wendlingen

Germany

www.festoolusa.com

Instruction manual

Page 6

IMPORTANT: Read all instructions before using.

Guide d’utilisation

Page 19

IMPORTANT: Lire toutes les instructions avant de démarrer les travaux.

Manual de instrucciones

Página 34

IMPORTANTE: Lea todas las instrucciones antes de usar.

-

Drywall Sander

-

Ponceuses autoportées à rallonges

-

Lijadora de pared

708919_002

Instruction manual

Guide d’utilisation

Manual de instrucciones

P L A N E X easy

LHS-E 225 EQ

Page 2

Page 3

Page 4

1

1-1

1-3

1-4

1-5

1-6

1-9

1-2

1-7

1-8

1

1-1

1-2

1-8

1-9

Page 5

1

1-1

1-3

1-4

1-5

1-6

1-9

1-2

1-7

1-8

1-10

1-3

1-4

1-5

1-6

1-7

Page 6

Original operating manual

Settings ................................................ 12

About this manual ................................ 6

Symbols................................................ 6

Safety instructions ............................... 7

General safety instructions ................. 7

Machine-related safety instructions ... 8

Health hazard by dust.......................... 10

Intended use......................................... 10

Technical data ...................................... 10

Functional description ......................... 11

Commissioning..................................... 11

Extension Cord..................................... 12

About this manual

Save these instructions

Electronics............................................ 12

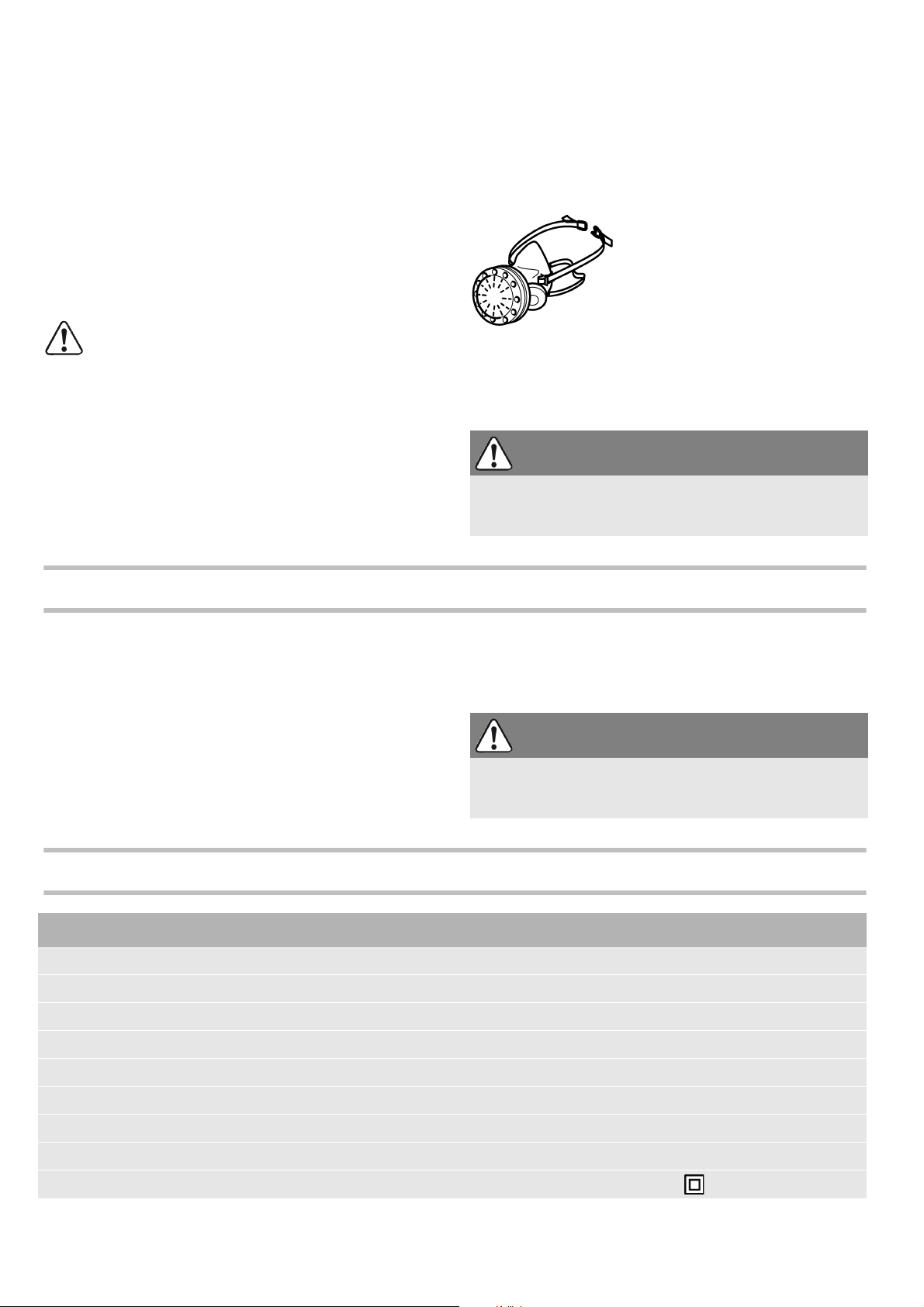

Replacing the sanding pad [5].............. 13

Changing the sanding discs [6]............ 13

Sanding close to edges [7] ................... 13

Dust extraction..................................... 14

Working with the power tool................ 14

Service and maintenance .................... 15

Cleaning the cool air filter [8] .............. 15

Accessories.......................................... 16

Environment......................................... 16

Troubleshooting................................... 17

It is important for you to read and understand this manual. The information it contains relates to protecting

your safety

and

preventing problems

DANGER Description of imminent haz-

ard and failure to avoid hazard

will result in death.

WARNING Description of hazard and

possible resulting injures or

death.

CAUTION Description of hazard and

possible resulting injuries.

. The symbols below are used to help you recognize this information.

NOTICE Statement including nature of

hazard and possible result.

HINT Indicates information, notes,

or tips for improving your success using the tool.

Symbols

Symbol Significance

Warning of general danger

Symbol Significance

Disconnect from the power supply!

Risk of electric shock

Read operating instructions and safety

notices!

Wear ear protection.

Wear a dust mask.

Wear protective goggles.

6

Vvolts

A amperes

Hz hertz

Do not dispose of as domestic waste.

Tip or advice

Handling instruction

Safety class II

Page 7

Symbol Significance

~ a.c. alternating current

lb. pound

ft foot

diameter

rpm

min

n

0

revolutions per minute

-1

no load speed

Safety instructions

General safety instructions

WARNING

structions, illustrations and specifications

provided with this power tool.

instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1 WORK AREA SAFETY

a.

Keep work area clean and well lit.

dark areas invite accidents.

b.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust.

which may ignite the dust or fumes.

c.

Keep children and bystanders away while operating a power tool.

lose control.

d.

Never leave the power tool unattended.

leave the power tool when the tool in use has

come to a complete standstill.

2 ELECTRICAL SAFETY

a.

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

will reduce risk of electric shock.

b.

Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

Unmodified plugs and matching outlets

Read all safety warnings, in-

Failure to follow all

Cluttered or

Power tools create sparks

Distractions can cause you to

Only

refrigerators.

tric shock if your body is earthed or grounded.

c.

Do not expose power tools to rain or wet conditions.

the risk of electric shock.

d.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

crease the risk of electric shock.

e.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

a cord suitable for outdoor use reduces the risk of

electric shock.

f.

If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply.

the risk of electric shock.

3 PERSONAL SAFETY

a.

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

moment of inattention while operating power

tools may result in serious personal injury.

b.

Use personal protective equipment. Always

wear eye protection.

as a dust mask, non-skid safety shoes, hard hat

or hearing protection used for appropriate conditions will reduce personal injuries.

c.

Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

Water entering a power tool will increase

There is an increased risk of elec-

Damaged or entangled cords in-

Use of

Use of an RCD reduces

Protective equipment such

Carrying power tools with your

A

7

Page 8

finger on the switch or energising power tools

that have the switch on invites accidents.

d.

Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e.

Do not overreach. Keep proper footing and balance at all times.

This enables better control of

the power tool in unexpected situations.

f.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away

from moving parts.

Loose clothes, jewellery or

long hair can be caught in moving parts.

g.

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of

dust collection can reduce dust-related hazards.

h.

Do not let familiarity gained from frequent use

of tools allow you to become complacent and ignore tool safety principles.

A careless action can

cause severe injury within a fraction of a second.

4 POWER TOOL USE AND CARE

a.

Do not force the power tool. Use the correct

power tool for your application.

The correct

power tool will do the job better and safer at the

rate for which it was designed.

b.

Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c.

Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool.

Power tools are dangerous in the

hands of untrained users.

e.

Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

f.

Keep cutting tools sharp and clean.

Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g.

Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and the

work to be performed.

Use of the power tool for

operations different from those intended could

result in a hazardous situation.

h.

Keep handles and grasping surfaces dry, clean

and free from oil and grease.

Slippery handles

and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5 SERVICE

a.

Have your power tool serviced by a qualified repair person using only identical replacement

parts.

This will ensure that the safety of the pow-

er tool is maintained.

b.

Only use original Festool parts for repair and

maintenance.

The use of incompatible accessories or spare parts can result in electric shocks or

other injuries.

Machine-related safety instructions

General safety instructions for sanding:

a.

This power tool is designed to be used as a

sander with sandpaper. Read all safety instructions, information, illustrations and technical

data enclosed with the machine.

instructions are not observed, this may lead to

electrical shock, fire and/or serious injuries.

b.

This power tool is not suitable for coarse sanding, sanding with a wire brush, abrasive cutting

or polishing.

Applications for which the power

tool is not intended can pose a serious risk and

cause injuries.

c.

Do not use any accessories that the manufacturer has not specially designed or recommended

for this power tool.

Just because you can attach

accessories to your power tool does not guarantee that they can be used safely.

d.

The permissible speed of the insertion tool

must be at least the maximum speed specified

on the tool itself.

Accessories that rotate faster

than the permitted speed can break and fly off.

e.

The outer diameter and thickness of the insertion tool must correspond to the dimensions of

your power tool.

Insertion tools which are mea-

If the following

8

Page 9

sured incorrectly cannot be sufficiently shielded

or controlled.

f.

Sanding discs, flanges, sanding pads and other

accessories must be fully compatible with the

rotary spindle on your power tool.

Insertion

tools which are not fully compatible with the rotary spindle on the power tool will rotate unevenly, vibrate strongly and may lead to a loss of

control.

g.

Do not use insertion tools that are damaged.

Before each use, check insertion tools such as

sanding discs for chipping and cracks and sanding pads for cracks, wear or heavy abrasive

wear. If the power tool or insertion tool is

dropped, check whether it is damaged.

Damaged insertion tools will generally break after a

short time.

h.

Make sure that any other persons in the vicinity

are at a safe distance from your work area. Anyone entering the work area must wear personal

protective equipment.

Fragments of the workpiece may fly off and even cause injuries outside

the immediate work area.

i.

Keep the mains cable away from rotating insertion tools.

If you lose control of the machine, the

mains cable may be severed or caught and your

hand or arm could get caught in the rotating insertion tool.

j.

Never place the power tool down before the insertion tool has come to a complete halt.

The rotating insertion tool may make contact with the

storage area, which could cause you to lose control of the power tool.

k.

Do not leave the power tool running when you

are carrying it.

Your clothing may accidentally

come into contact with and get caught in the rotating insertion tool.

l.

Clean the vents in your power tool on a regular

basis.

The fan draws dust into the housing and a

large accumulation of metal dust may create

electrical hazards.

Kickbacks and corresponding safety instructions:

A kickback occurs as a result of using the power

tool incorrectly or misguidedly. It can be prevented

by taking appropriate precautions, as described below.

a.

Hold the power tool firmly with both hands and

move your body and arms into a position that allows you to intercept the kickback forces. Always use the additional handle, if there is one,

so that you have the best possible control over

the kickback forces or torque reactions during

start-up.

The operator can control the kickback

and reaction forces by taking suitable precautionary measures.

b.

Never place your hands near rotating tools.

The

power tool may move across your hand in the

event of a kickback.

c.

Take particular care when working on corners

and sharp edges, for example. Prevent the insertion tool from rebounding away from the

workpiece and jamming.

The rotating insertion

tool tends to get jammed when working on corners and sharp edges, or if it rebounds in the process. This results in loss of control or kickbacks.

Special safety instructions for sanding

a.

Do not use oversized sanding discs. Follow Festool's specifications when selecting sanding

discs.

A sanding disc that is too large and protrudes over the sanding pad represents a cutting

injury hazard and can cause catching, disc breakage or kickback.

Further safety instructions

–

Harmful/toxic dust can be produced during your

work (e.g. lead-containing paint, some types of

wood and metal).

Contact with this dust, especially inhaling it, can represent a hazard for operating personnel or persons in the vicinity. Comply

with the safety regulations that apply in your

country. Connect the electric power tool to a suitable extraction system.

To protect your health, wear a P2 protective

mask.

Always wear protective goggles to protect

against sanding hazards.

– If potentially explosive or self-igniting dust is

produced during sanding, the machining instructions issued by the material manufacturer must

always be followed.

–

Attention: Risk of fire! Avoid overheating the

grinding material and the sander. Always empty

the dust container before taking a break.

Swarf

in the filter bag or filter of the mobile dust extractor may self-ignite in unfavourable conditions such as flying sparks when grinding metals.

Particular danger exists if the swarf is mixed with

paint, polyurethane residue or other chemical

materials and the grinding material is hot after

long periods of work.

–

Hold the power tool firmly with both hands and

assume a stable stance when performing work.

Using both hands ensures that the power tool is

guided safely.

9

Page 10

–

Always use an antistatic suction hose with the

power tool.

to panic briefly and become distracted, which

may result in an accident.

–

Always use original Festool sanding pads.

eign pads are not suitable for the speed of the

sander and may break.

–

Keep the carry bag out of reach of children.

Children may suffocate or be strangled when

playing with the carry bag.

A slight electric shock may cause you

For-

Health hazard by dust

WARNING!

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause cancer,

Various dust created by power

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemically treated

lumber.

The risk from these exposures

varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ven-

tilated area, and work with approved safety equipment, such as dust masks that

are specially designed to filter out microscopic particles. Wash hands after handling.

WARNING

TO REDUCE THE RISK OF INJURY, USER MUST

READ INSTRUCTION MANUAL.

Intended use

The drywall sander is designed for sanding primed

drywall constructions, ceilings and walls indoors

and also for removing carpet residue, coats of

paint, coverings, adhesives and loose plaster. When

sanding outside or in damp rooms, an isolating

transformer must be used.

Always use an appropriate mobile dust extractor.

The Festool CTL/M 36 E AC

PLANEX

mobile dust

extractor is optimally designed for large quantities

of dust.

The drywall sander is

not

suitable for wet sanding.

WARNING

The user will be liable for damage due to improper use.

Technical data

Drywall Sander LHS-E 225 EQ

Power 400 W

No-load speed 400 - 920 min

Sanding pad diameter 8-15/32’’ (215 mm)

-1

Abrasive diameter 8-27/32’’ (225 mm)

Tool holder Dia. 13/10

Dust extractor connection 36 mm (27 mm)

Length 5.2 ft (1.59 m)

Weight (without mains cable, with sanding pad) 8.8 lbs (4 kg)

Safety class /II

10

Page 11

Functional description

1

1

2

2

2

3

2

2

1

1

The pictures for the functional description are on a

fold-out page at the beginning of the instruction

manual. While reading the manual you can fold out

the page for comparison and quick reference.

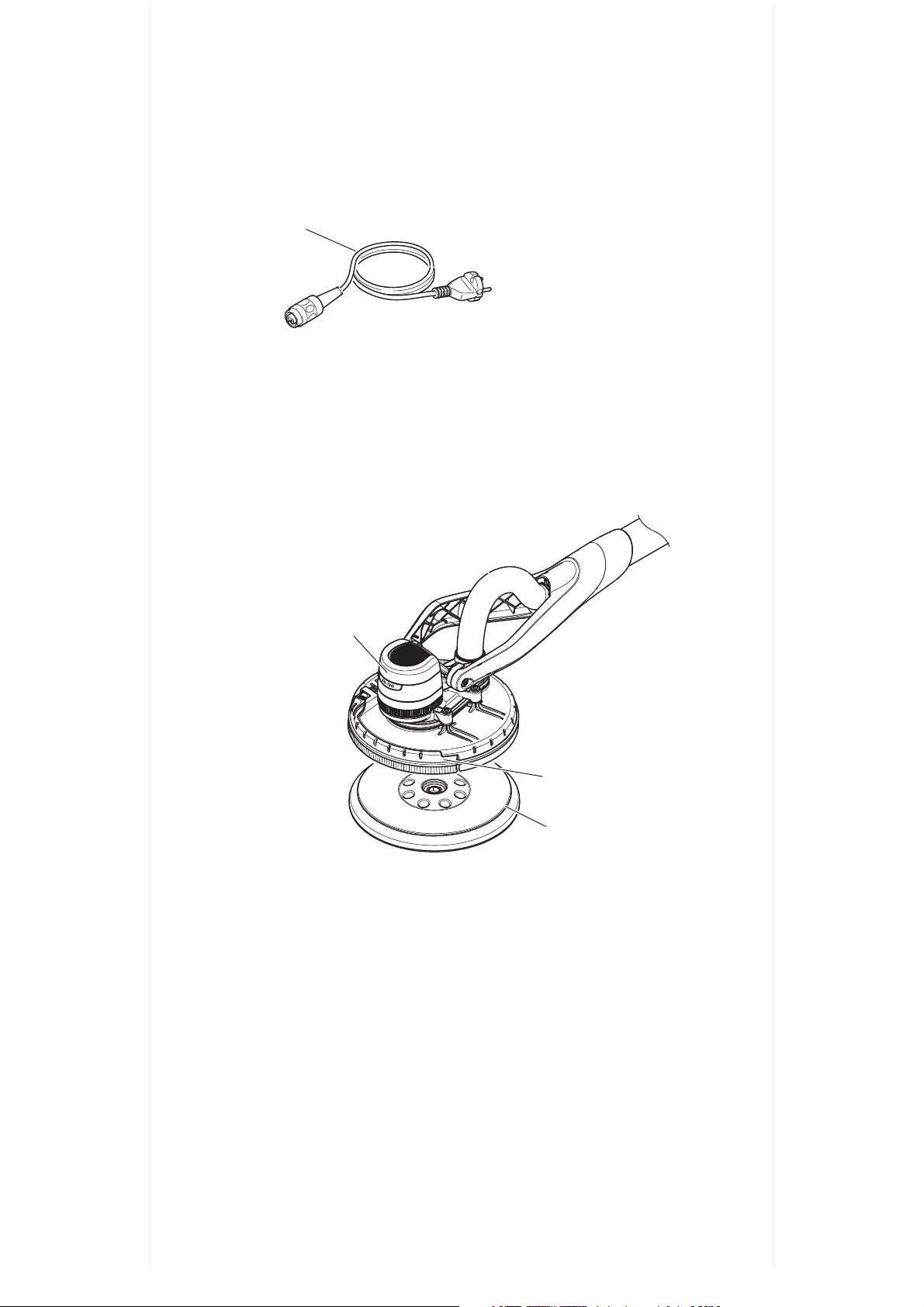

[1-1]

[1-2]

[1-3]

[1-4]

Sanding head

plug it mains cable

On/Off switch

Extractor connector

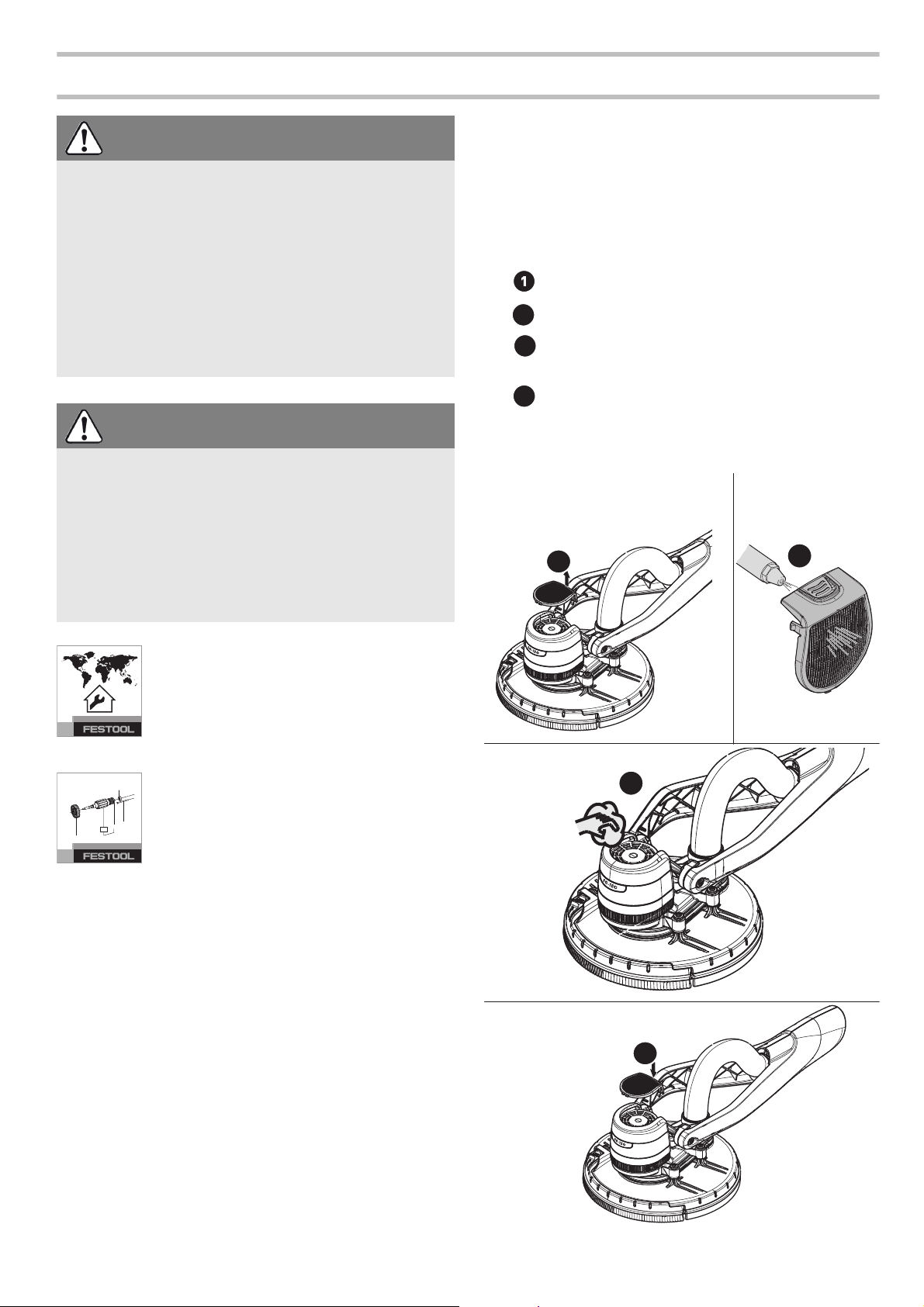

Commissioning

WARNING

Unauthorised voltage or frequency!

Risk of accident

The mains voltage and the frequency of the power source must correspond with the specifications on the machine's name plate.

In North America, only Festool machines with

the voltage specifications 120 V/60 Hz may be

used.

[1-5]

[1-6]

[1-7]

[1-8]

[1-9]

[1-10]

Plug it-connection

Suction sleeve stop

Speed control

Detachable brush segment

Insertion tool/sanding pad

Gripping surfaces

Before switching on the power tool, make

sure that the bayonet fitting at the mains cable is closed fully and locked.

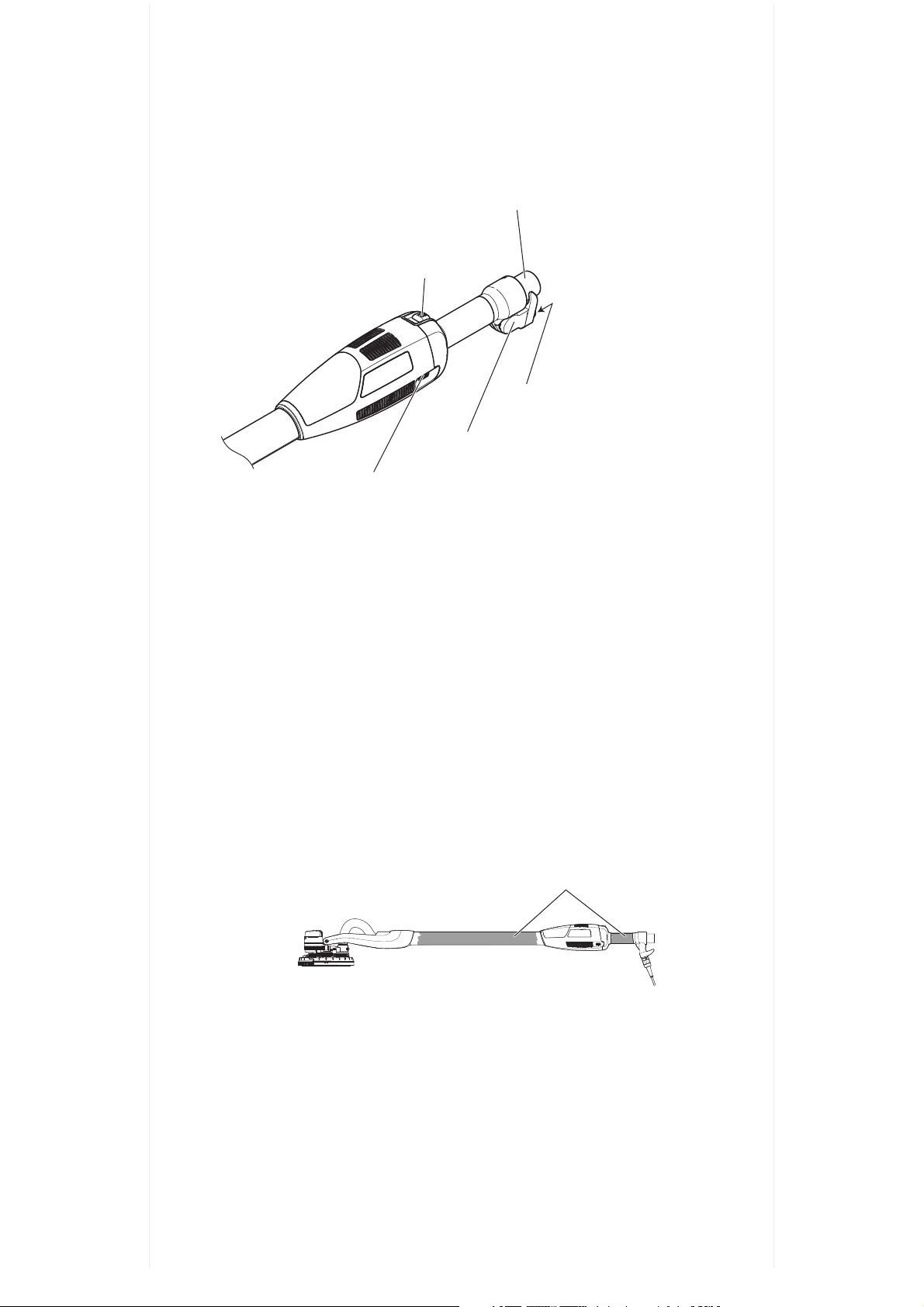

To connect the suction hose

tion Dust extraction.

Using a special vacuum sleeve, the

[3]

, see also Sec-

PLANEX

suction hose guarantees a permanent fixing

and better protection against kinking.

Connecting and disconnecting the mains cable -

[2]

ON/OFF button [4]

ON (I)

Push the on/off switch

forward.

[4-1]

down and

On/off switch is locked.

11

Page 12

OFF (0)

4

4-1

1

2

1

I

O

Push the on/off switch

unlock it.

On/off switch moves back to the 0 position.

[4-1]

down and

Extension Cord

Use only a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot receptacle that accepts the plug on the product. Make sure you extension cord is not damaged.

If an extension cord is required, it must have sufficient cross-section to prevent an excessive drop in

voltage or overheating. An excessive drop in voltage

reduces the output and can lead to failure of the

motor. The table below shows you the correct cord

diameter as a function of the cord length for this

tool.

WARNING

Risk of injury, electric shock

Always pull the mains plug out of the socket before performing any type of work on the machine!

Electronics

The power tool is equipped with a brushless ECTEC motor for a long service life and power electronics with the following properties:

Smooth start-up

The electronically controlled smooth start-up ensures that the machine starts up jolt-free.

Total Extension Cord

Lenght (feet)

Cable size (AWG) 18161614

Use only U.L. and CSA listed extension cords.

Never use two extension cords together. Instead,

use one long one.

Settings

to prevent overheating.

Speed control

You can regulate the speed steplessly within the

speed range using the adjusting wheel

Technical data).

This enables you to optimise the sanding speed to

suit the material you are working on.

Overheating protection

Overheating protection is triggered when the pressure is too high or the cool air openings are dirty.

The power tool beeps three times and switches off.

Let the power tool cool down for approx. 15 minutes

before using it again.

25 50 100 150

The lower the AWG number, the stronger the

cord.

[1-7]

(see

Constant speed

The preselected motor speed is kept constant

through electronic control to ensure a uniform

sanding speed up to a certain load.

Overload protection

If the pressure becomes too high while working, the

power of the machine will be automatically reduced

12

Page 13

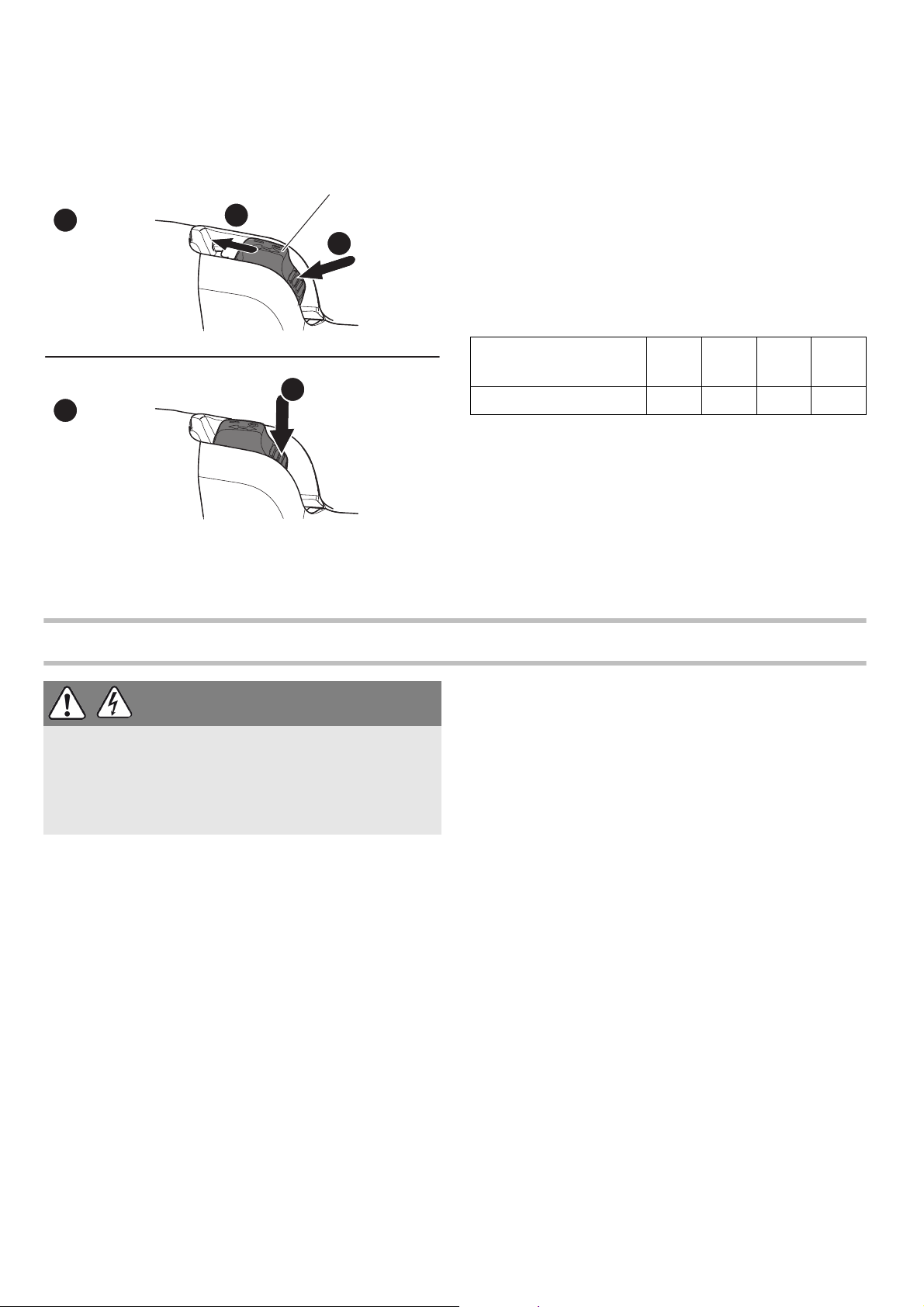

Replacing the sanding pad [5]

Changing the sanding discs

[6]

5

Compatible StickFix sanding discs are quick and

easy to attach to the StickFix sanding pad.

CAUTION! The holes in the sanding disc

must be aligned with the holes in the sanding pad.

paired and there is more exposure to dust.

Do not use interface pads.

Otherwise, the suction power is im-

6

Observe the following instructions:

– An optimal work result can only be achieved us-

ing original accessories and consumables. The

use of non-original accessories or consumables

invalidates the right to claim under warranty.

– Only fit and remove the sanding pads using the

tool supplied.

– Make sure that both flat edges engage in the

opening on the sanding pad.

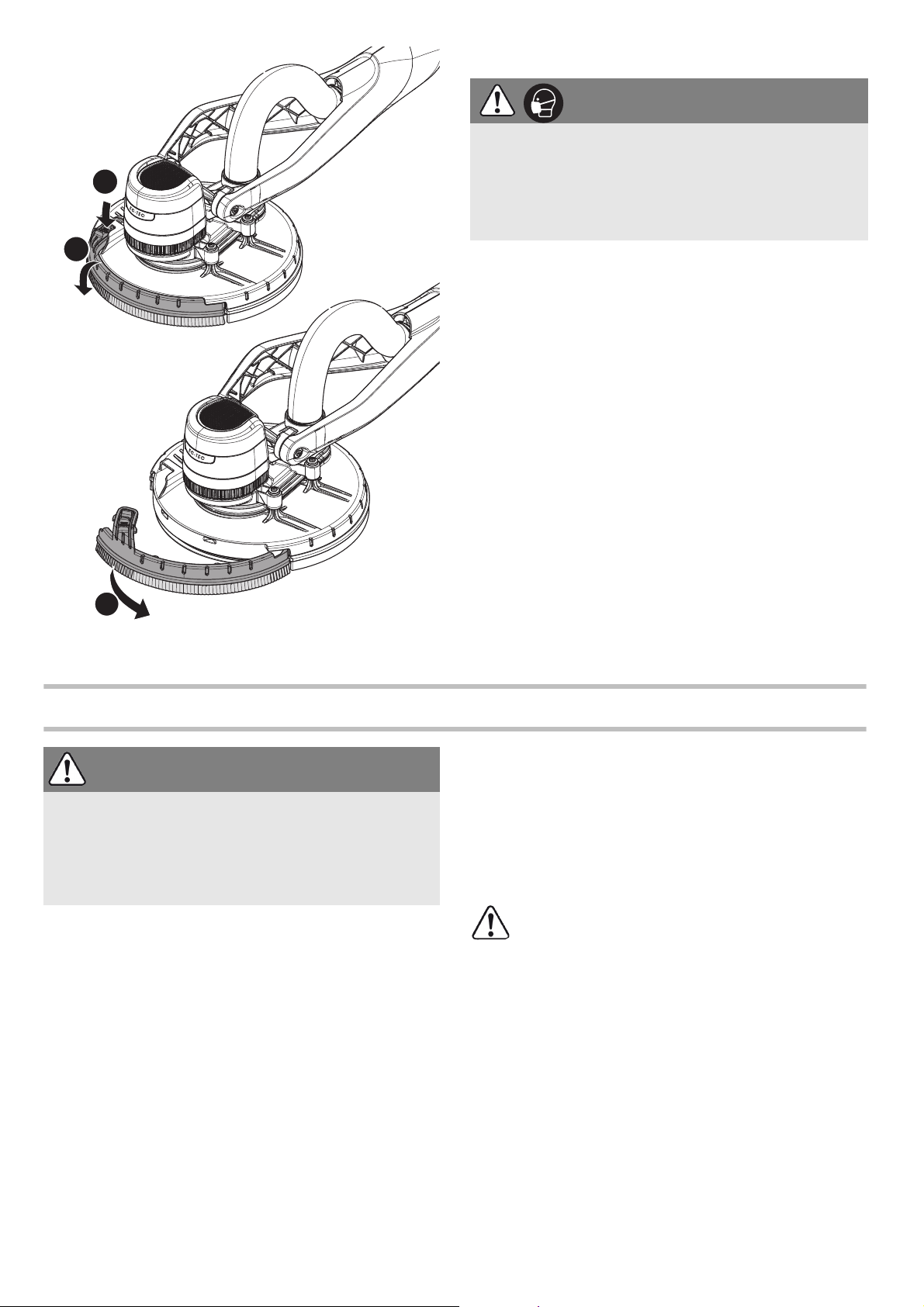

Sanding close to edges

The removable brush segment means that the distance at the side between the wall/ceiling and the

sanding pad is reduced.

CAUTION! Without a brush segment, there

is more exposure to dust:

specific applications.

The brush segment is fitted in reverse order to the

process for removing it.

[7]

Only remove it for

13

Page 14

Dust extraction

7

2

1

3

WARNING

Heath hazard posed by dust

Always work with an extractor.

Comply with national regulations.

Wear a dust mask.

A Festool mobile dust extractor with an extractor

hose diameter of 27 mm or 36 mm (36 mm recommended due to the reduced risk of clogging) can be

connected to the extractor connector

Festool CTL/M 36 E AC

PLANEX

extractors are adapted to the quantity of dust

generated and permanently ensure the necessary suction power.

[1-4]

.

mobile dust

Risk of injury

Do not hold the power tool by the sanding head.

Hold the power tool with both hands using the

gripping surfaces

To switch on the power tool, see Section Commissioning.

Carefully place the sanding head onto the sanding surface.

Perform the sanding work.

Do not apply too much pressure on the power

tool as this will cause overloading. The best

sanding results are achieved with moderate ap-

WARNING

[1-10]

.

Recommendation:

This helps reduce the electric charge.

Working with the power tool

plication pressure. The sanding performance

and quality depend mainly on selecting the correct abrasive.

After finishing work

Once you have finished the sanding work, set

the power tool down.

CAUTION! Do not set the power tool down

with the sanding head facing downwards –

always lay it on the floor so that it is on its

side with the brush ring facing down.

wise the sanding pad could be deformed.

To protect the sanding pad and the sanding

head, always transport and store the power tool

in the accompanying carry bag without the

sanding discs.

Use anti-static extractor hose!

Other-

14

Page 15

Service and maintenance

8

1

2

4

3

WARNING

Any maintenance or repair work that requires

opening of the motor or gear housing should only

be carried out by an authorised Customer Service

Centre (name supplied by your dealer)!

Maintenance or repair work carried out by an

unauthorised person can lead to the wrong connection of the power cord or other components,

which in turn can lead to accidents with serious

consequences.

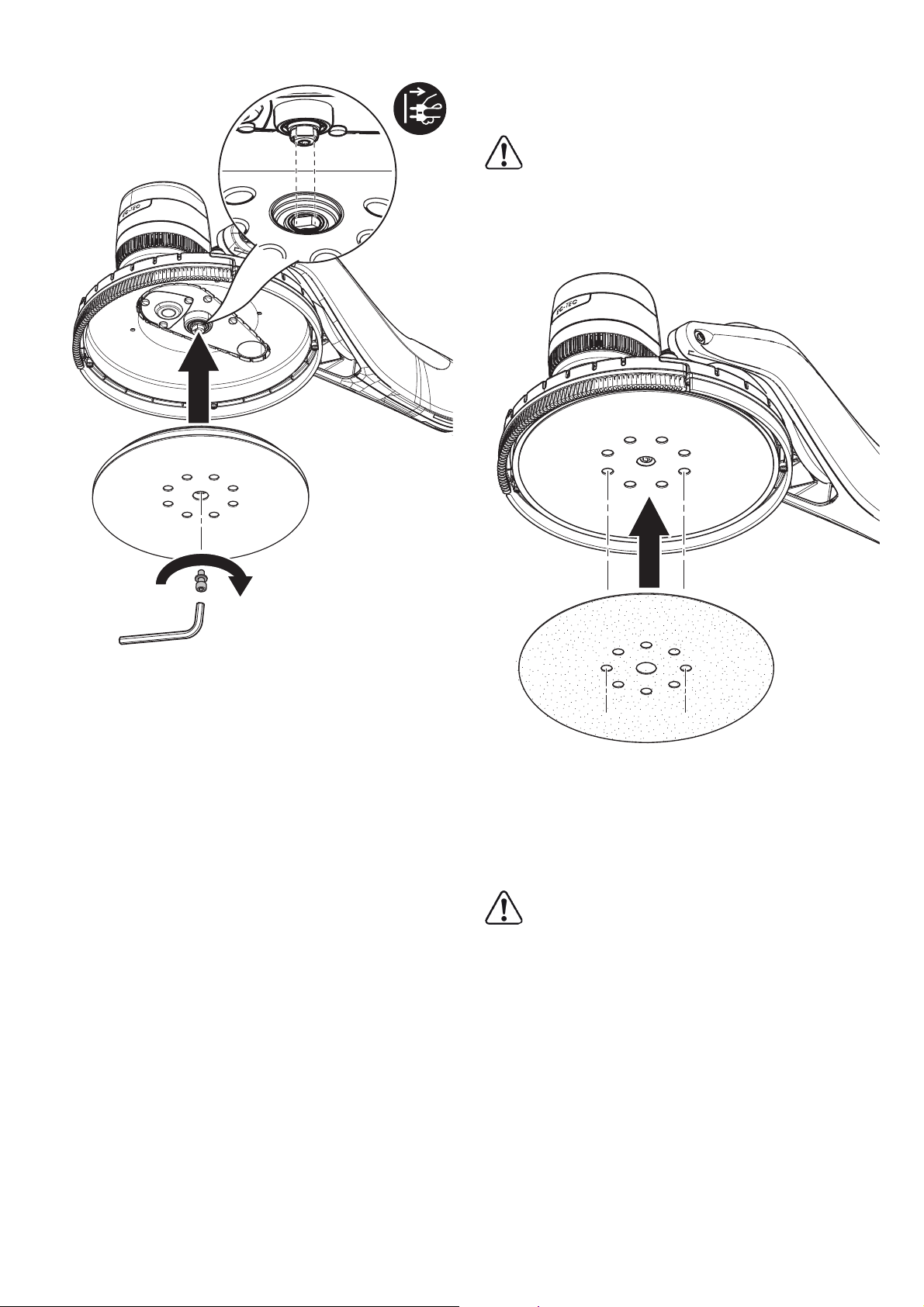

Cleaning the cool air filter [8]

If the cool air filter is blocked, the motor may not be

sufficiently cooled and the power tool may switch

off after three beeps because the temperature is

too high.

Clean all cool air openings on a regular basis.

Remove the filter sieve on the sanding head.

2

Remove any deposits in the sieve.

3

Remove any deposits in the openings in the

housing.

4

Insert the filter sieve until it engages.

WARNING

To prevent accidents, always remove the plug

from the power supply socket before carrying out

any changes or maintenance work on the tool!

Do not use compressed air to clean the electrical

tool! Do not try to clean parts inside the tool in

this way, as you could let foreign objects in

through the openings of the tool housing.

EKAT

1

Customer service and repair

through manufacturer or service

workshops: Please find the nearest

address at:

www.festoolusa.com/service

4

Use only original Festool spare parts!

Order No. at:

5

3

2

www.festoolusa.com/service

only

Let the power tool cool down for approx. 15 minutes

before using it again.

– Check the plug and the cable regularly and

should either become damaged, in order to avoid

a hazard, have them replaced by an authorised

after-sales service workshop.

To ensure constant air circulation, always keep the

cooling air openings in the motor housing clean and

free of any obstruction.

In the event of a slowdown in performance or increased vibrations, blow and clean cooling air openings.

15

Page 16

Accessories

open

lock

connect

connect

T-loc

9-1

A

9

B

Use only original Festool sanding pads. Low-quality

sanding and polishing pads may cause serious machine imbalances that decrease the quality of the

work results and increase wear on the power tool.

Festool provides comprehensive accessories which

allow you to use your power tool effectively and for

diverse applications, e.g.

• Additional hand grip ZG-LHS 225

• Harness TG-LHS 225

• Mobile dust extractor CTL/M 36 E AC

PLANEX

The order numbers of the accessories and tools can

be found in the Festool catalogue or on the Internet

under "www.festoolusa.com".

Systainer

Many Festool products are shipped in a unique system container, called "Systainer". This provides

protection and storage for the tool and accessories.

The Systainers are stackable and can be interlocked together. They also can be interlocked atop

Festool CT dust extractors.

The Systainers are connected and locked.

A new generation Systainer is connectable on

top of a previous generation Systainer by the

four latches of the previous Systainer.

To open the Systainer

Turn the T-loc

[9-1]

to this position.

To lock the Systainer

Turn the T-loc

[9-1]

to this position.

To connect two Systainers

Place one Systainer on the top of the other (Fig.

A]

).

[9-1]

Turn the T-loc

tions (Fig.

[9 B]

to one of this posi-

).

Do not throw the power tool in your household

waste!

Dispose of machines, accessories and

[9

Environment

packaging at an environmentally responsible recycling centre. Observe the valid national regulations.

16

Page 17

Troubleshooting

Problem Possible causes Remedy

LHS-E 225 does not run

smoothly over the surface.

Extraction power is insufficient.

Hard spackling paste or hard

Reduce speed.

sub-layers

Deformed sanding pad Use a new sanding pad.

Filter element on the CTL/M 36 E

AC

PLANEX

is blocked/

clogged.

Clean the filter element regularly:

Option 1:

Set the suction power adjustment to maximum. Using the surface of

your hand, keep the nozzle, suction hose

or suction opening on the mobile dust

extractor covered for 10 seconds until

automatic cleaning begins.

Option 2:

Manually clean the filter element (dust extraction).

Option 3:

Check the filter element for

damage and clogging. Use a new filter

element regularly.

Disposal bag inserted incorrectly. The holes punched in the disposal bag

must be inside the container.

Filter bag inserted instead of disposal bag.

Always work with the disposal bag when

operating the PLANEX (grey bag).

Excessive material

removed from workpiece

Surface quality not perfect

The suction power on the CTL/M

36 E AC

PLANEX

is set too

Adjust the suction power to a higher setting.

low.

LHS-E 225 speed too high Reduce speed.

Suction hose blocked or kinked. Remove blockage and straighten hose.

Disposal bag full Dispose of the bag.

Brush segment open/not fitted. Only remove the brush segment when

sanding close to edges, refit it, see Section Sanding close to edges [7].

The holes in the sanding discs are

not aligned with the holes in the

Fit the sanding discs correctly, see Section Changing the sanding discs [6].

sanding pads.

LHS -E 225 speed too high Reduce the speed, see Section Electron-

ics

Grit on abrasive too coarse Select a finer grit.

Incorrect abrasive grit Select a finer grit.

Drying times of the spackling

paste not observed.

Read the technical data sheets and manufacturer's recommendations.

Spackling paste with a high percentage of filler/soft filler

Power tool running when set

down on the surface (groove formation).

Select a finer grit, e.g. P180.

Place the power tool in position and then

switch it on.

Always use a detachable brush segment

when working on the surface.

17

Page 18

Problem Possible causes Remedy

Sanding marks on the

surface

LHS-E 225 switches off

while working and after

three beeps

Sanding pad is placed down on

the surface at an angle

The abrasive grit is too coarse for

very soft spackling paste.

Cool air filter on the LHS-E 225 is

blocked.

Excessive pressure -> power tool

activates overheating protection.

Place the sanding pad down so that it is

level.

Choose a finer abrasive grit (abrasive

Brilliant 2 available up to grit P 320).

Clean the cool air filter on the LHS-E 225,

see Section. Cleaning the cool air filter [8]

.

Let the power tool cool down for approx.

15 minutes and then apply less pressure.

LHS-E 225 not working plug it is not connected correctly. Check that the plug it is securely con-

nected.

Interruption to power supply Switch the power tool off and on again.

LHS-E 225 not working

and beeps three times

when an attempt is made

Overheating protection active Let the power tool cool down for approx.

15 minutes before switching it back on

again.

to switch it on

If problems other than those listed occur, please contact your Festool service workshop or your local specialist dealer.

Information on data protection

The power tool contains a chip which automatically

stores machine and operating data (RFID). This

data saved cannot be traced back directly to an individual.

The data can be read using special (contactless) devices and shall only be used by Festool for fault di-

agnosis, repair and warranty processing and for

quality improvement or enhancement of the power

tool. The data shall not be used in any other way

without the express consent of the customer.

18

Page 19

Notice d'utilisation d'origine

Réglages............................................... 26

À propos de ce manuel ........................ 19

Symboles.............................................. 19

Consignes de sécurité ......................... 20

Consignes générales de sécurité pour

outils électroportatifs........................... 20

Consignes de sécurité spécifiques à la

machine................................................ 22

La poussière, un risque pour la santé. 23

Utilisation en conformité avec les instructions 24

Caractéristiques techniques................ 24

Description fonctionnelle..................... 24

Mise en service .................................... 25

Cordon d'extension .............................. 26

À propos de ce manuel

Électronique......................................... 26

Remplacement du plateau de ponçage

[5] ......................................................... 27

Changer les disques de ponçage [6] ... 27

Poncer près des bords [7] ................... 28

Aspiration............................................. 28

Travail avec l'outil électroportatif ........ 28

Entretien et maintenance..................... 29

Nettoyer le filtre de ventilation [8] ...... 29

Accessoires........................................... 30

Environnement ..................................... 31

Elimination des défauts........................ 31

Conservez ces instructions

Il est important pour vous de lire et de comprendre ce manuel. Les informations qu'il contient, se rapporte

à la protection

vous aider à reconnaître cette information.

DANGER Description du risque immi-

AVERTISSEMENT

ATTENTION

de votre sécurité

nent et l'incapacité à éviter

tout risque qui peut entraîner

la mort.

Description des dangers possibles et des blessures qui en

résultent ou la mort.

Description des dangers et

des éventuelles blessures qui

en résultent.

et

de prévention des problèmes

. Les symboles suivants sont utilisés pour

AVIS Déclaration incluant le type de

danger et conséquences possibles.

CONSEIL Indique des informations, des

notes ou des conseils pour

améliorer votre succès en utilisant l'outil.

Symbole Signification

Avertissement de danger

Avertissement contre le risque d'électrocution

Notice d'utilisation, lire les consignes de

sécurité !

Symboles

Symbole Signification

Porter une protection auditive !

Porter une protection respiratoire !

Porter des lunettes de protection !

19

Page 20

Symbole Signification

Débrancher la fiche secteur !

Ne pas jeter l'appareil avec les ordures

ménagères.

Astuce, information

Consignes opératoires

Classe de protection II

VVolt

AAmpère

Hz Hertz

~ a.c. Tension alternative

lb. livre

ft pied

Diamètre

rpm

-1

min

tours ou course par minute

tr/mn

n

0

Vitesse de rotation à vide

Consignes de sécurité

Consignes générales de sécurité pour ou-

tils électroportatifs

AVERTISSEMENT !

les consignes de sécurité, instructions,

images et caractéristiques techniques avec lesquels cet outil électrique est fourni. Des négligences relatives aux instructions ci-dessous

peuvent occasionner un choc électrique, un incendie et/ou des blessures graves.

Conserver toutes les consignes de sécurité et instructions pour une référence future.

Le terme "outil électrique" utilisé dans les

consignes de sécurité se rapporte aux outils électroportatifs fonctionnant sur secteur (avec câble) et

aux outils électroportatifs fonctionnant sur accumulateurs (sans câble).

1 SÉCURITÉ DU POSTE DE TRAVAIL

a.

Veillez à ce que la zone de travail soit propre et

bien éclairée.

mal éclairé peut entraîner des accidents.

b.

Ne vous servez pas de l'outil électroportatif

dans un environnement où il y a un risque d'ex-

Un poste de travail en désordre et

Veuillez lire toutes

plosion dû à la présence de liquides inflammables, de gaz ou de poussières.

électroportatifs peuvent générer des étincelles

susceptibles d'enflammer la poussière ou les vapeurs.

c.

Éloignez les enfants et d'autres personnes pendant l'utilisation de l'outil électroportatif.

vous êtes distrait, vous pouvez perdre le contrôle

de l'outil.

d.

Ne laissez pas l'outil électroportatif fonctionner

sans surveillance.

électroportatif que lorsque l'accessoire est complètement immobilisé.

2 SÉCURITÉ ÉLECTRIQUE

a.

Le connecteur de l'outil électroportatif doit correspondre à la prise électrique. Le connecteur

ne doit être modifié d'aucune façon. N'utilisez

pas d'adaptateur avec des outils électroportatifs mis à la terre.

prises correspondantes diminuent le risque d'un

choc électrique.

b.

Évitez tout contact avec des surfaces mises à la

terre telles que des tuyaux, chauffages, cuisi-

Ne vous éloignez de l'outil

Des connecteurs intacts et des

Les outils

Si

20

Page 21

nières et réfrigérateurs.

Un risque élevé de choc

électrique existe si votre corps est relié à la terre.

c.

Protégez les outils électroportatifs de la pluie

et de l'humidité.

L'infiltration d'eau dans un outil

électroportatif augmente le risque de choc électrique.

d.

Ne détournez pas l'utilisation du câble de raccordement pour porter l'outil électroportatif,

l'accrocher ou pour tirer le connecteur de la

prise. Éloignez le câble de la chaleur, de l'huile,

de bords tranchants ou de pièces de l'appareil

en mouvement.

Un câble endommagé ou enche-

vêtré augmente le risque de choc électrique.

e.

Si vous travaillez avec un outil électroportatif à

l'extérieur, utilisez uniquement des rallonges

prévues pour l'extérieur.

L'utilisation d'un câble

prévu pour l'extérieur diminue le risque d'un choc

électrique.

f.

Utilisez un disjoncteur à courant de défaut

quand le fonctionnement de l'outil électroportatif en environnement humide ne peut pas être

évité.

L'utilisation d'un disjoncteur à courant de

défaut diminue le risque d'un choc électrique.

3 SÉCURITÉ DES PERSONNES

a.

Soyez attentif à ce que vous faites, faites preuve

de bon sens lorsque vous travaillez avec l'outil

électroportatif. N'utilisez pas l'outil électroportatif si vous êtes fatigué ou si vous êtes sous

l'influence de drogues, de l'alcool ou de médicaments.

Un moment d'inattention lors de l'utilisation de l'outil électroportatif peut entraîner des

blessures graves.

b.

Portez un équipement de protection individuelle et des lunettes de protection en permanence.

Le port d'un équipement de protection

individuelle tel que masque contre la poussière,

chaussures de sécurité antidérapantes, casque

ou protection auditive, en fonction du type et de

l'utilisation de l'outil électroportatif, diminue le

risque de blessures.

c.

Évitez toute mise en service involontaire. Assurez-vous que l'outil électroportatif est déconnecté avant de le raccorder à l'alimentation

électrique et/ou à la batterie, avant de le soulever ou de le porter.

Si, en portant l'outil électroportatif, vous avez le doigt sur l'interrupteur ou si

vous raccordez l'appareil connecté à l'alimentation électrique, cela peut entraîner des accidents.

d.

Retirez les outils de réglage ou les clés anglaises avant de connecter l'outil électroportatif.

Un outil ou une clé qui se trouve dans une

partie de l'outil en rotation peut entraîner des

blessures.

e.

Évitez toute position de travail anormale. Veillez à maintenir une position stable et un bon

équilibre à tout moment.

Vous pourrez ainsi à

tout moment contrôler l'outil électroportatif dans

des situations inattendues.

f.

Portez des vêtements adaptés. Ne portez pas de

vêtements amples ou de bijoux. Éloignez vos

cheveux et vos vêtements des pièces en mouvement.

Des vêtements amples, des bijoux ou des

cheveux longs pourraient se prendre dans les

pièces en mouvement.

g.

Si des dispositifs d'aspiration et de récupération des poussières peuvent être montés, raccordez-les et utilisez-les correctement.

L'utilisation d'une aspiration des poussières peut

diminuer les dangers dus aux poussières.

h.

Ne vous croyez pas faussement en sécurité et

n'enfreignez pas les règles de sécurité destinées aux outils électroportatifs, même si vous

maîtrisez l'outil électroportatif après de multiples utilisations.

Un manque d'attention peut en

un quart de seconde entraîner de graves blessures.

4 UTILISATION ET TRAITEMENT DE L'OUTIL ÉLECTROPORTATIF

a.

Ne surchargez pas l'appareil. Utilisez l'outil

électroportatif destiné à votre travail.

L'outil

électroportatif adapté vous permet de travailler

mieux et avec plus de sécurité dans la plage de

puissance indiquée.

b.

N'utilisez aucun outil électroportatif dont l'interrupteur serait défectueux.

Un outil électroportatif qui ne peut plus être mis en marche ou

arrêté est dangereux et doit être réparé.

c.

Débranchez le connecteur de la prise de courant et/ou retirez une batterie amovible avant

d'effectuer des réglages sur l'appareil, de remplacer des accessoires ou de déposer l'outil.

Cette mesure de précaution empêche un démarrage involontaire de l'outil électroportatif.

d.

Rangez toujours les outils électroportatifs inutilisés hors de portée des enfants. Ne laissez

pas les personnes auxquelles vous ne faites pas

confiance ou qui n'ont pas lu ces consignes se

servir de l'appareil.

Les outils électroportatifs

sont dangereux lorsqu'ils sont utilisés par des

personnes inexpérimentées.

e.

Prenez soin de vos outils électroportatifs et accessoires. Vérifiez que les parties mobiles fonctionnent sans problème, qu'elles ne coincent

pas et qu'il n'y a pas de parties cassées ou en-

21

Page 22

dommagées qui pourraient entraver le bon

fonctionnement de l'outil électroportatif. Faites

réparer les parties endommagées avant d'utiliser l'appareil.

un mauvais entretien des outils électroportatifs.

f.

Maintenez les outils de coupe affûtés et

propres.

soin dotés de bords de coupe affûtés se coincent

moins et sont plus faciles à utiliser.

g.

Utilisez l'outil électroportatif, les accessoires,

outils, etc. en respectant ces instructions. Tenez compte des conditions de travail et de la

tâche à effectuer.

portatifs pour d'autres applications que celles

prévues peut entraîner des situations dangereuses.

h.

Veillez à ce que les poignées et surfaces des

poignées soient sèches, propres et exemptes

d'huile ou de graisse.

de poignées glissantes ne permettent pas une

utilisation en toute sécurité ni un contrôle de l'outil électroportatif dans des situations imprévues.

5 SERVICE

a.

Faites réparer votre outil électroportatif uniquement par un personnel qualifié ; les réparations doivent être effectuées avec des pièces

d'origine uniquement,

de l'outil électroportatif.

De nombreux accidents sont dus à

Des outils de coupe entretenus avec

L'utilisation des outils électro-

Des poignées et surfaces

afin de garantir la fiabilité

Consignes de sécurité spécifiques à la ma-

chine

Consignes de sécurité générales pour le

ponçage :

a.

Le présent outil électroportatif doit être utilisé

comme une ponceuse avec du papier abrasif.

Respectez toutes les consignes de sécurité, instructions, représentations et données que vous

recevez avec la machine.

instructions suivantes peut aboutir à un choc

électrique, à un incendie et/ou à des blessures

graves.

b.

Le présent outil électroportatif ne convient pas

pour le dégrossissage, le ponçage avec une

brosse métallique, le tronçonnage et le polissage.

Des utilisations non prévues de l'outil électroportatif peuvent être à l'origine de situations

dangereuses et de blessures.

c.

Utilisez uniquement les accessoires spécialement prévus pour cet outil électroportatif et recommandés par le fabricant.

Le non-respect des

Le simple fait de

pouvoir fixer l'accessoire sur votre outil électroportatif ne garantit pas une utilisation sûre.

d.

La vitesse admissible de l'accessoire doit au

moins être égale à la vitesse supérieure indiquée sur l'outil électroportatif.

dont la vitesse de rotation est supérieure à celle

admissible risquent de se briser ou de voltiger.

e.

Le diamètre extérieur et l'épaisseur de l'accessoire doivent correspondre aux cotes de votre

outil électroportatif.

mensionnés peuvent ne pas être suffisamment

protégés ou contrôlés.

f.

Les disques de ponçage, la bride, les plateaux

de ponçage ou autres accessoires doivent correspondre exactement à la broche porte-meule

de votre outil électroportatif.

qui ne correspondent pas exactement à la broche

porte-meule de l'outil électroportatif ont une vitesse de rotation irrégulière, génèrent des vibrations importantes et peuvent entraîner une perte

de contrôle.

g.

N'utilisez pas d'accessoires endommagés.

Avant chaque utilisation, vérifiez que les accessoires tels que les disques de ponçage ne sont

ni écaillés ni fendus, que les plateaux ne ponçage ne sont pas fendus, usés ou fortement détériorés. En cas de chute de l'outil

électroportatif ou de l'accessoire, contrôlez s'il

est endommagé.

se cassent généralement rapidement.

h.

Veillez à ce que les autres personnes se

tiennent à une distance de sécurité par rapport

à votre zone de travail. Toute personne qui pénètre dans la zone de travail doit porter un équipement de protection individuelle.

la pièce peuvent être projetés en l'air et provoquer des blessures, même à l'extérieur de la

zone de travail directe.

i.

Maintenez le câble secteur à l'écart des accessoires en rotation.

l'outil, le câble secteur peut être sectionné ou

happé et votre main ou votre bras risque de toucher l'accessoire en rotation.

j.

Ne posez jamais l'outil électroportatif avant que

l'accessoire ne soit complètement arrêté.

cessoire en rotation peut entrer en contact avec

la surface de dépose, si bien que vous pouvez

perdre le contrôle de l'outil électroportatif.

k.

Ne faites pas fonctionner l'outil électroportatif

pendant que vous le transportez.

risquent d'être happés par un contact accidentel

avec l'accessoire en rotation.

l.

Nettoyez régulièrement les fentes d'aération de

votre outil électroportatif.

Des accessoires mal di-

Les accessoires endommagés

Si vous perdez le contrôle de

Les accessoires

Les accessoires

Des éclats de

L'ac-

Vos vêtements

Le ventilateur attire

22

Page 23

la poussière dans le carter, et une forte accumulation de poussière métallique peut engendrer

des risques électriques.

Recul et consignes de sécurité correspondantes :

Un recul est la conséquence d'un mauvais usage ou

d'une utilisation incorrecte de l'outil électroportatif. Il peut être évité en suivant les mesures de précaution appropriées décrites ci-après.

a.

Tenez fermement l'outil électroportatif à deux

mains et placez votre corps et vos bras dans une

position dans laquelle vous serez en mesure de

résister à la force du recul. Utilisez toujours la

poignée supplémentaire, si elle existe, pour

avoir le plus grand contrôle possible sur la force

du recul ou sur les couples de réaction au moment de l'accélération.

tion adéquates permettent à l'utilisateur de

maîtriser la force de recul et les couples de réaction.

b.

Ne placez jamais votre main à proximité d'outils

en rotation.

déplacer sur votre main.

c.

Travaillez avec beaucoup de précaution dans les

coins, au niveau des arêtes vives etc. Évitez que

les accessoires rebondissent à partir de la pièce

et se coincent.

dance à se coincer dans les coins, les arêtes vives

ou quand il rebondit, ce qui provoque une perte

du contrôle ou un recul.

Consignes de sécurité particulières pour le ponçage

a.

N'utilisez pas de disques de ponçage surdimensionnés. Suivez les indications de Festool lors

du choix des disques de ponçage.

ponçage trop grand dépassant largement du plateau de ponçage constitue un risque de coupure

et peut entraîner un coincement, une rupture du

disque ou un recul.

Consignes de sécurité additionnelles

–

Au cours du travail, des poussières nocives/

toxiques peuvent être générées (comme les

poussières de peintures au plomb ou certaines

poussières de bois ou de métal).

l'inhalation de ces poussières peut présenter un

danger pour l'utilisateur ou les personnes se

trouvant à proximité. Veuillez respecter les prescriptions de sécurité en vigueur dans votre pays.

Raccordez l'outil électrique à un dispositif d'aspiration adapté.

Au moment du recul, l'outil peut se

L'accessoire en rotation a ten-

Des mesures de précau-

Un disque de

Le contact ou

Pour votre santé, portez un masque de protection respiratoire de classe P2.

Portez systématiquement des lunettes de

protection pour vous protéger des risques

inhérents au ponçage.

– Si le ponçage génère des poussières explosives

ou inflammables, il convient impérativement

d'observer les consignes d'usinage du fabricant

du matériau.

–

Attention au risque d'incendie ! Évitez la surchauffe des matériaux travaillés et de la ponceuse. Videz systématiquement le bac de

récupération des poussières avant de faire une

pause dans votre travail.

sières se trouvant dans le sac filtre ou le filtre de

l'aspirateur peuvent s'enflammer d'ellesmêmes dans des conditions défavorables,

comme par ex. la projection d'étincelles lors du

ponçage de pièces en métal. Le risque est particulièrement important lorsque les particules de

poussières sont mélangées à des résidus de vernis, de polyuréthane ou d'autres substances

chimiques et que les matériaux travaillés sont

très chauds après avoir été longtemps travaillés.

–

Tenez fermement l'outil électroportatif avec les

deux mains lors des travaux, et veillez à une

bonne position stable des pieds.

portatif est guidé de manière sûre avec deux

mains.

–

Utilisez toujours un tuyau d’aspiration antistatique (AS) avec l'outil électroportatif.

choc électrique peut faire brièvement peur et

perturber l'attention, risquant ainsi de provoquer

un accident.

–

N'utilisez que des plateaux de ponçage d'origine Festool.

sont pas adaptés au régime de la ponceuse et

peuvent se casser.

–

Conserver la housse de transport hors de portée des enfants.

fants risquent de s'étouffer ou de s'étrangler.

Les plateaux d'autres marques ne

En jouant avec la housse, les en-

Les particules de pous-

L'outil électro-

Un simple

La poussière, un risque

pour la santé

AVERTISSEMENT!

créées par le ponçage mécanique, le sciage,

le meulage, le perçage et autres activités reliées à la construction contiennent des substances

chimiques connues (dans l’État de la Californie)

comme pouvant causer le cancer, des anomalies

congénitales ou représenter d’autres dangers pour

la reproduction. Voici quelques exemples de telles

substances:

Certaines poussières

23

Page 24

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’oeuvre traité avec un

produit chimique.

ces substances chimiques : travaillez dans un endroit adéquatement ventilé et utilisez un équipement de sécurité approuvé, tel que masques antipoussières spécialement conçus pour filtrer les

particules microscopiques.

Le risque d’exposition à de tels

produits varie selon la fréquence à laquelle vous faites

ce genre de travail. Pour réduire les risques d’exposition à

Utilisation en conformité avec les instructions

La ponceuse autoportée à rallonges est conçue de

façon conforme aux prescriptions pour le ponçage

de murs de construction sèche spatulés, de plafonds et de murs à l'intérieur, ainsi que pour l'élimination de restes de papiers peints, de couches de

peinture, d'enrobements, de résidus de colle et de

crépi. Un transformateur de séparation doit être

utilisé pour le ponçage à l'extérieur ou dans des

pièces humides.

Utilisez toujours un aspirateur approprié. L'aspirateur Festool CTL/M 36 E AC

PLANEX

est conçu

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE DE DOMMAGES,

L'UTILISATEUR DOIT LIRE LE MANUEL D'INSTRUCTION.

de façon optimale pour les conditions de fort empoussièrement.

La ponceuse autoportée à rallonges

pas

pour le ponçage humide.

ne convient

AVERTISSEMENT

Seul l’utilisateur est tenu responsable des dommages qui résulteraient d’une utilisation non

conforme aux prescriptions.

Caractéristiques techniques

Ponceuses autoportées à rallonges LHS-E 225EQ

Puissance 400 W

Vitesse de rotation à vide 400 - 920 tr/mn

Ø du plateau de ponçage 8-15/32’’ (215 mm)

Diamètre d'abrasif 8-27/32’’ (225 mm)

Porte-outils Dia. 13/10

Raccord d’aspiration 36 mm (27 mm)

Longueur 5.2 ft (1.59 m)

Poids (sans câble secteur, avec plateau de ponçage) 8.8 lbs (4 kg)

Classe de protection /II

Description fonctionnelle

Des eléments fournis sont disponibles sur le volet

qui se trouve au début de cette notice d'utilisation.

Vous pouvez ainsi déplier cette page et visualiser

en permanence les différentes parties de l'outil

lorsque vous lisez la notice.

[1-2]

[1-3]

[1-4]

[1-5]

Câble de raccordement secteur plug-it

Interrupteur de marche/arrêt

Raccord d'aspiration

Raccordement plug-it

[1-1]

24

Tête de ponçage

Page 25

[1-6]

1

1

2

2

2

3

2

2

1

1

Système de verrouillage de manchon

d'aspiration

[1-7]

[1-8]

[1-9]

[1-10]

Régulation de la vitesse

Segment de brosse amovible

Accessoire/plateau de ponçage

Surfaces de préhension

Mise en service

AVERTISSEMENT

Tension ou fréquence non admissible !

Risque d'accident

La tension et la fréquence d'alimentation électrique doivent être conformes aux indications de

la plaque signalétique.

En Amérique du nord, utilisez uniquement les

outils Festool fonctionnant sous une tension de

120 V/60 Hz.

baïonnette est complètement fermé et verrouillé

sur le câble de raccordement secteur.

Brancher le tuyau d’aspiration

ment le chapitre Aspiration.

[3]

, voir égale-

Avec le manchon d'aspiration spécial, le tuyau

d’aspiration

PLANEX

garantit une fixation

durable et une meilleure protection anti-pli.

Brancher et débrancher le câble de raccordement secteur -

Avant de mettre en marche l'outil électroportatif, assurez-vous que le raccord à

[2]

Marche/arrêt [4]

MARCH

E (I)

ARRÊT

(0)

Pousser vers le bas et avancer l'interrupteur MARCHE/ARRÊT

L'interrupteur MARCHE/ARRÊT est bloqué.

Pousser vers le bas et déverrouiller

l'interrupteur MARCHE/ARRÊT

L'interrupteur MARCHE/ARRÊT revient en

position 0.

[4-1]

.

[4-1]

.

25

Page 26

fentes acceptant la fiche du produit. Assurez-vous

4

4-1

1

2

1

I

O

que votre cordon d'extension ne soit pas endommagé.

Si un cordon d'extension est nécessaire, celui-ci

doit présenter une section suffisante afin d'éviter

une chute de tension excessive ou une surchauffe.

Une chute de tension excessive réduit la puissance

et peut entraîner la destruction du moteur. Le tableau ci-dessous vous présente la section correcte

du câble en fonction de sa longueur pour cet outil.

Cordon d'extension

Utiliser uniquement un cordon d'extension à 3 fils

avec une fiche de terre à 3 lames et une prise à 3

Réglages

AVERTISSEMENT

Risques de blessures, choc électrique

Débranchez prise de courant avant toute intervention sur la machine !

Longueur totale du

cordon d'extension

(pieds)

Taille de câble (AWG)18181614

Utiliser exclusivement des cordons recommandés

par U.L. et CSA.

Ne jamais utiliser deux cordons reliés l'un à l'autre.

Les remplacer par une rallonge plus longue.

Plus le numéro AWG est petit, plus la section du

cordon est grande.

Protection contre les surcharges

Si la pression est trop élevée pendant le travail, la

puissance de la machine est automatiquement réduite pour éviter toute surchauffe.

Régulation de la vitesse

25 50 100 150

Électronique

L'outil électroportatif équipé d'un moteur EC-TEC

sans charbons pour une longévité accrue dispose

d'un système électronique puissant et des caractéristiques suivantes :

Démarrage progressif

Le démarrage progressif assure un fonctionnement sans à-coups de la machine.

Vitesse de rotation constante

La vitesse sélectionnée est maintenue constante de

manière électronique. La vitesse de ponçage reste donc

homogène jusqu'à une certaine charge de travail.

La molette

tesse de rotation dans la plage de régimes (voir Caractéristiques techniques).

Vous pouvez ainsi adapter de façon optimale la vitesse de ponçage à chaque matériau.

Contrôle de la température

En cas de pression trop forte ou d'ouïes de ventilation encrassées, le contrôle de la température se

déclenche. L'outil électroportatif émet trois bips et

s'éteint. Après une période de refroidissement

d'env. 15 minutes, l'outil électroportatif est à nouveau prêt à l'emploi.

[1-7]

permet de régler en continu la vi-

26

Page 27

Remplacement du plateau de ponçage [5]

Changer les disques de ponçage [6]

5

Les disques de ponçage StickFix peuvent être fixés

rapidement et simplement sur le plateau de ponçage StickFix.

ATTENTION ! La perforation des disques de

ponçage doit coïncider avec la perforation

des plateaux de ponçage.

conduit à une dégradation de la puissance

d’aspiration et à un empoussièrement accru.

Ne pas utiliser de pads d’interface !

Sinon, cela

6

Observez les consignes suivantes :

– Pour obtenir un résultat exceptionnel, utiliser

uniquement les accessoires et consommables

d'origine. En cas de non-utilisation des accessoires et consommables d'origine, les dommages qui pourraient s'ensuivre ne sont pas

couverts par la garantie.

– Montage et démontage du plateau de ponçage

uniquement avec l'outil fourni.

– Veiller à ce que le deux pans s'enclenche dans

l'orifice au niveau du plateau de ponçage !

27

Page 28

Poncer près des bords [7]

7

2

1

3

Grâce au segment de brosse amovible, la distance

latérale entre le mur/plafond et le plateau de ponçage peut être réduite.

ATTENTION ! L'absence de segment de

brosse entraîne un empoussièrement accru,

ne l'enlever qu'en cas d'application spé-

ciale.

Aspiration

AVERTISSEMENT

Risques pour la santé dus aux poussières

Ne jamais travailler sans aspiration.

Respecter les prescriptions nationales.

Portez une protection respiratoire !

Le montage du segment de brosse s'effectue dans

l'ordre inverse du démontage.

Le manchon d'aspiration

[1-4]

permet de raccorder un aspirateur Festool doté d'un flexible de 27 ou

36 mm (conseil : un flexible de 36 mm réduit le

risque de colmatage).

Les aspirateurs Festool CTL/M 36 E AC

PLANEX

sont adaptés pour la quantité de

poussière produite et garantissent durablement

la puissance d’aspiration nécessaire.

Notre recommandation :

utilisez un tuyau d'aspiration antistatique ! La fonction antistatique empêche la charge d'électricité statique.

Risque de blessures

Ne pas tenir l'outil électroportatif au niveau de

la tête de ponçage.

Tenir l'outil électroportatif avec les deux mains

au niveau des surfaces de préhension

Travail avec l'outil électroportatif

AVERTISSEMENT

[1-10]

Mettre en marche l'outil électroportatif, voir le

chapitre Mise en service.

Poser avec précaution la tête de ponçage sur la

surface de ponçage.

Réaliser les travaux de ponçage.

Ne pas appuyer trop fort sur l'outil électropor-

.

tatif pour ne pas le solliciter de manière

excessive ! Pour obtenir des résultats optimaux,

il convient d'exercer une pression modérée. Les

performances de ponçage et la qualité du pon-

28

Page 29

çage dépendent essentiellement du choix de

l'abrasif.

Après le travail

A la fin des travaux de ponçage, déposer l'outil

électroportatif.

ATTENTION ! Ne pas poser l'outil électroportatif sur le sol avec la tête de ponçage

vers le bas, mais toujours latéralement sur

Entretien et maintenance

la couronne de brossage !

Sinon, cela peut

conduire à une déformation du plateau de ponçage.

Pour protéger le plateau de ponçage et la tête

de ponçage, toujours transporter et stocker

l'outil électroportatif sans disques de ponçage

dans la housse de transport fournie.

AVERTISSEMENT

Tout travail de maintenance ou de réparation, qui

nécessite l'ouverture du moteur ou du carter

d'engrenages doit uniquement être effectué par

un centre service-client autorisé (nom fourni par

votre revendeur) !

Les travaux de maintenance ou de réparation effectués par un personnel non autorisé peuvent

conduire à la mauvaise connexion de câbles

d'alimentation ou d'autres composants, ce qui

peut entraîner à son tour des accidents avec des

conséquences graves.

AVERTISSEMENT

Pour éviter les accidents, retirez toujours la fiche

mâle de la prise d'alimentation électrique avant

d'effectuer tout travail de maintenance ou de réparation sur la machine !

N'utilisez pas d'air comprimé pour nettoyer l'outil électrique ! N'essayez pas de nettoyer des

parties à l'intérieur de la machine de cette façon,

étant donné que des corps étrangers pourraient

pénétrer dans les ouvertures du carter de la machine.

EKAT

4

Utilisez uniquement des pièces de rechange Festool d‘origine. Référence

5

3

2

1

sur: www.festoolusa.com/service

– Contrôlez régulièrement le connecteur et le

câble pour éviter tout danger ; en cas d'endommagement, les faire remplacer par un des ateliers de service après-vente agréés.

Pour assurer la circulation de l'air, il est impératif

que les ouïes de ventilation du carter moteur soient

maintenues dégagées et propres.

En cas de pertes de puissance ou de vibrations accrues, purgez et nettoyez les ouvertures de circulation d'air de refroidissement.

Nettoyer le filtre de ventilation [8]

Un filtre de ventilation bouché ne permet pas de refroidir suffisamment le moteur et, en fonction de la

température, l'outil électroportatif s'éteint après

avoir émis trois bips.

Nettoyer régulièrement toutes les ouïes de ventilation.

Enlever le tamis filtrant au niveau de la tête

de ponçage.

2

Enlever les dépôts dans le tamis.

Seuls le fabricant et un atelier homologué sont habilités à effectuer

réparation ou service

. Les adresses à

toute

proximité sont disponibles sur:

www.festoolusa.com/service

3

Enlever les dépôts au niveau des ouvertures

dans le carter.

4

Insérer le tamis filtrant jusqu'à ce qu'il

s'enclenche.

Après une période de refroidissement d'env. 15 minutes, l'outil électroportatif est à nouveau prêt à

l'emploi.

29

Page 30

8

2

3

1

4

Utilisez uniquement des plateaux de ponçage d'origine (de marque Festool). L'utilisation de plateaux

de ponçage et de polissage de moindre qualité peut

provoquer un balourd considérable, entraînant une

dégradation de la qualité du résultat et une usure

prématurée de l'outil électroportatif.

Festool propose des accessoires complets, vous

permettant une utilisation polyvalente et efficace

de votre outil électroportatif, p. ex. :

• Poignée supplémentaire ZG-LHS 225

• Harnais TG-LHS 225

• Aspirateur CTL/M 36 E AC

Accessoires

PLANEX

Les références des accessoires et des outils figurent dans le catalogue Festool ou sur Internet

"www.festoolusa.com".

Systainer

De nombreux produits Festool sont fournis dans

une caisse exclusive, appelée "Systainer". Celle-ci

permet de protéger et de ranger des outils et des

appareils complémentaires. Les Systainer sont

empilables et peuvent être solidarisés. En outre, il

se fixent sur les aspirateurs CT Festool.

Pour ouvrir le Systainer

Tournez le T-loc

[9-1]

à cette position.

30

Page 31

Pour fermer le Systainer

open

lock

connect

connect

T-loc

9-1

A

9

B

Tournez le T-loc

[9-1]

à cette position.

Pour connecter deux Systainers

Placez un Systainer au dessus de l'autre (Fig.

A]

).

Tournez le T-loc

tions (Fig.

[9 B]

[9-1]

).

à une de cette posi-

Les Systainers sont combinés.

Un Systainer de la nouvelle génération peux

être attaché au dessus d' un Systainer de l'ancienne génération par les quatre loquets de

l'ancien Systainer.

[9

Environnement

Ne jetez pas les outils électriques avec les ordures ménagères !

Eliminez les appareils, les ac-

cessoires et les emballages de façon compatible

Problème Causes possibles Remèdes

Le fonctionnement de la

LHS-E 225 n'est pas

Matériau d'enduit dur ou supports durs

Elimination des défauts

régulier sur la surface.

avec l'environnement. Respectez en cela les dispositions nationales en vigueur.

Réduire la vitesse de rotation.

Plateau de ponçage déformé Utiliser un nouveau plateau de ponçage.

31

Page 32

Problème Causes possibles Remèdes

La puissance d'aspiration

est insuffisante.

L'élément filtrant sur le CTL/M 36

E AC

PLANEX

est bouché, col-

maté.

Nettoyage régulier de l'élément filtrant :

Possibilité 1 :

régler le dispositif de régulation de la puissance d’aspiration sur la

valeur maximale. Avec la paume de la

main, boucher pendant 10 sec. l'ouverture de la buse, l'ouverture du tuyau

d’aspiration ou l'orifice d'aspiration sur

l'aspirateur jusqu'à l'activation du nettoyage automatique.

Possibilité 2 :

nettoyer (aspirer) mécaniquement l'élément filtrant.

Possibilité 3 :

contrôler l'état d'endommagement et de colmatage de l'élément

filtrant. Utiliser régulièrement un nouvel

élément filtrant.

Sac jetable mal inséré. Les trous perforés du sac jetable doivent

se trouver à l'intérieur du bac.

Sac filtre au lieu de sac d'élimination des déchets.

Puissance d’aspiration trop faible

réglée au niveau du CTL/M 36 E

AC

PLANEX

.

Travailler en mode Planex uniquement

avec un sac jetable (sac gris).

Régler le dispositif de régulation de la

puissance d'aspiration sur une valeur

plus élevée.

Enlèvement trop important du matériau à usiner

Qualité de surface pas

optimale

Vitesse de rotation de la LHS -E

Réduire la vitesse de rotation.

225 trop élevée

Tuyau d’aspiration bouché ou

Éliminer le colmatage ou le pli.

plié.

Sac jetable plein Jeter le sac jetable.

Segment de brosse ouvert, pas

monté.

Enlever le segment de brosse uniquement

en cas de ponçage près des bords, puis le

remonter, voir le chapitre Poncer près des

bords [7].

La perforation du disque de ponçage ne coïncide pas avec la perforation du plateau de ponçage.

Vitesse de rotation de la LHS -E

225 trop élevée

Appliquer correctement les disques de

ponçage, voir le chapitre Changer les

disques de ponçage [6].

Réduire la vitesse de rotation, voir le chapitre Électronique

Grain de l'abrasif trop grossier Choisir un grain plus fin.

Grain d'abrasif incorrect Choisir un grain plus fin.

Temps de séchage du matériau

d'enduit pas respecté correcte-

Tenir compte des fiches techniques et des

recommandations du fabricant.

ment.

32

Matériau d'enduit avec teneur en

agent diluant trop élevée, enduit

doux

Choisir un grain plus fin, p. ex. P180.

Page 33

Problème Causes possibles Remèdes

Application sur la surface de la

pièce avec l'outil électroportatif

en marche (formation de

rayures).

Rayures de ponçage sur

la surface

Application inclinée du plateau de

ponçage sur la surface

En cas de matériau d'enduit très

tendre, le grain d'abrasif est trop

grossier.

Arrêt de la LHS -E 225

pendant le travail et trois

Filtre de ventilation bouché au

niveau de la LHS -E 225.

bips émis

Pression trop forte -> l'outil électroportatif déclenche le contrôle

de la température.

LHS -E 225 sans fonction Le plug-it n'est pas branché cor-

rectement.

Appliquer l'outil électroportatif sur la surface et le mettre en marche seulement

après.

Lors du travail sur la surface, travailler

toujours avec le segment de brosse amovible.

Appliquer le plateau de ponçage à plat.

Choisir un grain plus fin (abrasif Brilliant

2 jusqu'à grain P 320).

Nettoyer le filtre de ventilation sur la LHS

-E 225, voir le chapitre Nettoyer le filtre

de ventilation [8].

Laisser refroidir l'outil électroportatif env.

15 min. et exercer ensuite une pression

moins importante.

Vérifier le branchement correct du plugit.

Coupure de tension Éteindre et rallumer l'outil électroportatif.

LHS-E 225 sans fonction

et trois bips émis en cas

Contrôle de la température actif Laisser refroidir l'outil électroportatif env.

15 min., puis le rallumer.

de tentative d'allumage

Si d'autres problèmes que ceux mentionnés apparaissent, veuillez contacter votre atelier de service aprèsvente Festool ou votre revendeur spécialisé.

Informations relatives à la protection des données

L'outil électroportatif contient une puce permettant

l'enregistrement automatique des données de machine et de fonctionnement (RFID). Les données

enregistrées ne permettent pas d'effectuer un lien

direct avec les personnes.

tool uniquement pour le diagnostic d'erreurs, la

gestion des réparations et de la garantie, ainsi que

pour l'amélioration de la qualité et/ou le perfectionnement de l'outil électroportatif. Toute utilisation des données dépassant ce cadre – sans l'accord exprès du client – est exclue.

Les données peuvent être lues sans contact à l'aide

d'appareils spéciaux. Elles sont utilisées par Fes-

33

Page 34

Manual de instrucciones original

Ajustes.................................................. 41

Sobre este manual............................... 34

Símbolos .............................................. 34

Indicaciones de seguridad................... 35

Indicaciones de seguridad generales

para herramientas eléctricas.............. 35

Indicaciones de seguridad específicas 37

Riesgos para la salud producidos por

el polvo................................................. 38

Uso conforme a lo previsto.................. 39

Datos técnicos...................................... 39

Descripción de las funciónes .............. 39

Puesta en servicio................................ 40

Cable alargador ................................... 41

Sobre este manual

Sistema electrónico.............................. 41

Cambiar el plato lijador [5] .................. 42

Cambio de los discos de lijar [6] .......... 42

Lijado cerca de los bordes [7] .............. 43

Aspiración............................................. 43

Trabajo con la herramienta eléctrica... 43

Mantenimiento y cuidado..................... 44

Limpieza del filtro del aire de refrige-

ración [8]............................................... 45

Accesorios............................................ 45

Medio ambiente.................................... 46

Reparación de averías.......................... 46

Guarde estas instrucciones

Es importante que usted lea y entienda este manual. La información que contiene se relaciona con la protección de

a reconocer esta información.

su seguridad

PELIGRO Descripción de peligro inmi-

ADVERTENCIA

PRECAUCIÓN

y

la prevención de problemas

nente y fracaso para evitar