Page 1

Festool GmbH

Wertstrasse 20

73240 Wendlingen

Germany

Te.:+49(0)7024/804-0

Telefax: +49(0)7024/804-20608

E-Mail: info@tts-festool.com

Instruction manual

Page 6

IMPORTANT: Read and understand all instructions before using.

Guide d’utilisation

Page 19

IMPORTANT: Lire et comprendre toutes les instructions avant de

démarrer les travaux.

Manual de instrucciones

Pagina 33

IMPORTANTE: Lea y comprende todas las instrucciones antes de

usar.

Instruction manual

Guide d’utilisation

Manual de instrucciones

PLANEX

473967_002

LHS 225 EQ

Page 2

Page 3

Page 4

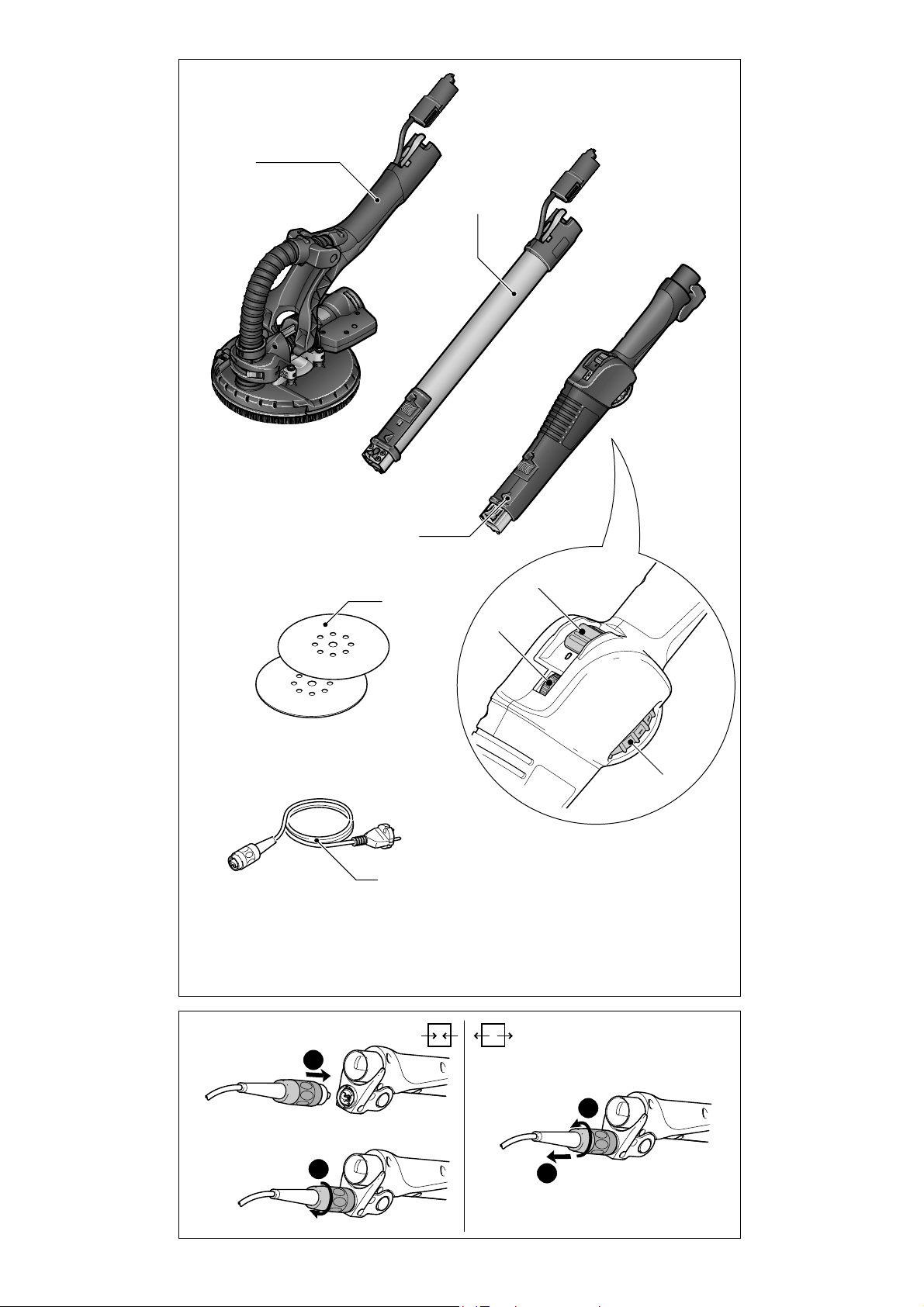

1

1-1

1-2

1-6

1-7

1-8

1-4

1-3

1-5

2

1

1

2

2

Page 5

Page 6

Content

Symbols .............................................................6

Safety instructions ............................................6

Technical data ................................................... 9

Functional description ......................................9

Intended use .................................................... 10

Commissioning ................................................10

Extension cord ................................................ 10

Machine settings .............................................10

Fitting the

Electronics ....................................................... 11

Changing sanding pads ................................... 11

Affi xing abrasives ............................................ 12

Adjusting the internal/external extraction ..... 12

Adjusting the suction power ............................ 12

Sanding close to edges .................................... 13

Dust extraction ................................................ 13

Operation .........................................................13

Service and maintenance ................................ 15

Accessories, tools ...........................................15

Disposal ...........................................................16

Warranty .........................................................16

Troubleshooting ..............................................16

PLANEX ........................................... 10

Symbols

min-1 Revolutions per minute

Ø Diameter

Tip, advice L

Safety instructions

General safety instructions

Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fi re and/

or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1 WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered

and dark areas invite accidents.

b) Do not operate power tools in explosive atmo-

spheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while op-

erating a power tool. Distractions can cause you

to lose control.

Warning of general danger

Risk of electric shock

Wear a dust mask!

Wear ear protection.

Clean the air vent slits and dust fi lter

Read the Operating Instructions/Notes!

V Volts

A Amperes

Hz Hertz

W Watt

~ Alternating current

No load speed

n

0

Class II Construction

rpm

2 ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets

will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase

the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords in-

crease the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

6

Page 7

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3 PERSONAL SAFETY

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the infl uence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your fi nger on the switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4 POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source

and/or battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in

the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool‘s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions taking into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

h) Keep handles dry, clean and free of oil and

grease. Slippery handles do not allow for safe

handling and control of the tool in unexpected

situations.

5 SERVICE

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

Machine-related safety instructions

This machine is designed for sanding. – Please

read all of the safety information, instructions,

illustrations and descriptions delivered with the

machine. If the following instructions are not

observed, this can result in an electric shock,

fi re and/or serious injury.

Do not use this machine to perform work –

such as roughing, brushing, polishing or

disc sanding. Performing tasks for which the

machine is not designed can create hazards

and lead to injury.

Never use accessories that were not specially –

developed and intended for this machine. Just

because an accessory part can be fitted on

your machine does not guarantee danger-free

operation.

The permissible rotational speed of the –

accessory must be at least as high as the

maximum speed specifi ed on the machine.

Accessories that rotate faster than the

permissible level can rupture.

7

Page 8

The outside diameter and the thickness of –

accessories must be within the specified

size range of the machine. Accessories with

incorrect dimensions cannot be sufficiently

protected or controlled.

The bore diameter of discs, fl anges, support –

plates and all other accessories must fi t the

machine spindle exactly. Accessories with an

unsuitable diameter are out of round, vibrate

excessively and lead to loss of control.

Do not use damaged accessories. Before use, –

always check accessories such as sanding pads

for nicks or cracks and check support plates

for cracks and excessive wear. Every time the

machine is dropped, check the machine and

accessories for damage, or install undamaged

accessories. Following the check and assembly

of accessories, ensure that all persons are

beyond the rotating range of the tool and run

the machine for one minute at maximum speed.

Damage accessories usually break completely

during this test time.

Wear personal protective equipment. –

Depending on the application, use a shield

or protective goggles. If practical, wear a

breathing mask, ear protectors, safety gloves

and a work apron suitable to protect against

impact or small sanding or workpiece parts.

The protective goggles must be capable of

blocking fl ying debris caused by the various

work operations. The breathing mask or device

must be capable of fi ltering particles generated

during work. Continuous exposure to loud noise

can cause loss of hearing.

Ensure that persons standing near the machine –

are at a safe distance from the work area. All

persons in the work area must wear personal

protective equipment. Parts of the workpiece or

broken accessories can fl y off and cause injury

outside the immediate work area.

Always hold the machine by the insulated –

handles if you intend to perform work that

may pose a risk of cutting into hidden power

cables or your own machine cable. Contact

with live cables transfers an electric current

to metallic machine components and causes

electric shocks.

Keep the power cable away from rotating parts. –

If you lose control, the power cable could be cut

or become stuck and your hand or arm could be

drawn into the rotating parts.

Never set the machine down until the tool has –

stopped completely. Turning tools can catch on

the storage surface, causing you to lose control

of the machine.

Never allow the machine to operate while –

carrying it at your side. The rotating tool can

catch on your clothing by accident and cause

serious cutting injuries.

Clean the air vent slits on your machine on a –

regular basis. The cooling air fan sucks the dust

into the machine and excessive deposits of metal

dust can result in electrical hazards.

Never operate the machine near combustible –

materials. Sparks can ignite these materials.

Never use tools that have to be liquid-cooled. –

Water and other liquid coolants can cause

potentially fatal electric shocks.

Cause and prevention of kickbacks

A kickback is a sudden reaction to jamming or

catching of a rotating disc, a support plate, a

brush or other accessory. Jamming or catching results in a rapid standstill of the rotating

accessory, whereby, as a counter-reaction, an

out-of-control machine is accelerated around the

jamming point in a direction of rotation opposed

to the accessory.

If, for example, a sanding disc is jammed or

caught by the workpiece, the disc circumference

can dig into the workpiece surface at the jamming point, causing the disc to be expelled. The

disc can either fl y towards or away from the user,

depending on the direction of rotation of the disc

at the jamming point. This can also cause sanding

discs to break. A kickback is the result of misuse

of the machine and/or incorrect method of work

or operation and can be avoided by closely observing the following precautionary measures.

Always hold the machine fi rmly and position –

your body and arms such that you can control

any kickback force. Always use the auxiliary

handle, if included in the delivery, to ensure

optimum control over kickbacks or reaction

torques during start-up. The user can control

reaction torques or kickbacks if suitable

precautionary measures are taken.

Never place your hands near rotating tools. –

Tools can kick back over your hand.

Never position your body in the area in which –

the machine moves in the event of a kickback.

A kickback accelerates the machine in the

direction of rotation opposed to the disc at the

jamming point.

Take extra care when working in corners, on –

sharp edges, etc. Avoid kickbacks and prevent

8

Page 9

the tool from seizing. Corners, sharp edges

or a jump back tend to cause the rotating tool

to catch, thus leading to a loss of control or a

kickback.

Special safety instructions for fi ne sanding

Do not use excessively large sanding discs –

when fi ne sanding. Observe the specifi cations

of the manufacturer when selecting abrasive

discs. A sanding disc that is too large and

protrudes over the sanding pad represents a

cutting injury hazard and can cause catching,

disc tears or kickbacks.

Additional warning notes

Hold the machine fi rmly with both hands and –

assume a stable stance when performing work.

Hold the machine with both hands to guide more

securely.

If potentially explosive or self-igniting dust –

is produced during sanding, the processing

instructions of the material manufacturer must

be observed under all circumstances.

Harmful/toxic dusts can be produced during –

your work (e.g. lead-containing paint, some

types of wood and metal). Contact with these

dusts, especially inhaling them, can represent a

hazard for operating personnel or persons in the

vicinity. Comply with the safety regulations that

apply in your country. Connect the electric power

tool to a suitable extraction system. To protect

your health, wear a P2 protective mask.

Never use machines with a damaged cable. –

Do not touch damaged cables and pull the

plug from the mains power supply if the cable

becomes damaged during work. Damaged

cables increase the risk of electric shock.

Use a maximum of two extension pipes on the –

machine.

Health hazard by dust

Various dust created by power

sanding, sawing, grinding, drilling and other construction activities contains chemicals known (to

the State of California) to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

Lead from lead-based paints, –

Crystalline silica from bricks and cement and –

other masonry products,

Arsenic and chromium from chemically-treated –

lumber.

The risk from these exposures varies, depending

on how often you do this type of work.

To reduce your exposure to these

chemicals work in a well ventilated

area and use approved safety equipment, such as dust masks that are

specially designed to fi lter out microscopic particles. Wash hands after

handling.

TO REDUCE THE RISK OF INJURY,

USER MUST READ INSTRUCTION MANUAL.

Technical data

Power 550 W

Rotational speed 340 – 910 rpm

Sanding pad dia. 215 mm (8.5’’)

Abrasive dia. 225 mm (8.9’’)

Tool holder D 13/10

Dust extractor connection dia. 36 mm (1.4’’)

(27 mm (1.06’’))

Length of short version (without extension pipe)

1.10 m (43.3’’)

Length of long version (with extension pipe)

1.60 m ( 63.0’’)

Weight without cable

Short version 3.80 kg (8.4 lbs)

Long version 4.60 kg (10.1 lbs)

Protection class II/

Functional description

The pictures for the functional description are on

a fold-out page at the beginning of the instruction

manual. When reading of the manual you can fold

out this page for having always an overview of the

machine.

[1-1] Sanding head

[1-2] Extension pipe

[1-3] Speed control adjusting wheel

[1-4] On/off switch

[1-5] Suction power adjusting wheel

[1-6] Handle section

[1-7] Abrasive

[1-8] Mains power cable

9

Page 10

Intended use

The PLANEX is designed for sanding primed drywall constructions, ceilings and walls in internal

and external applications as well as removing

carpet residue, coats of paint, coverings, adhesives and loose plaster.

We recommend using the Festool dust extrac- L

tor CT 36 E AC-LHS when sanding large fi lled

surfaces, which generates large quantities of

dust.

The user bears the responsibility

for damage and accidents caused by improper

use.

Total Extension Cord

Lenght (feet)

Cord size (AWG) 18 16 16 14

25 50 100 150

Commissioning

Risk of accident if the machine is operated using

unauthorised voltages or frequencies.

The mains voltage and the frequency of the f

power source must correspond with the specifi cations on the machine’s name plate.

In North America, only Festool machines with f

voltage specifi cations of 120 V may be used.

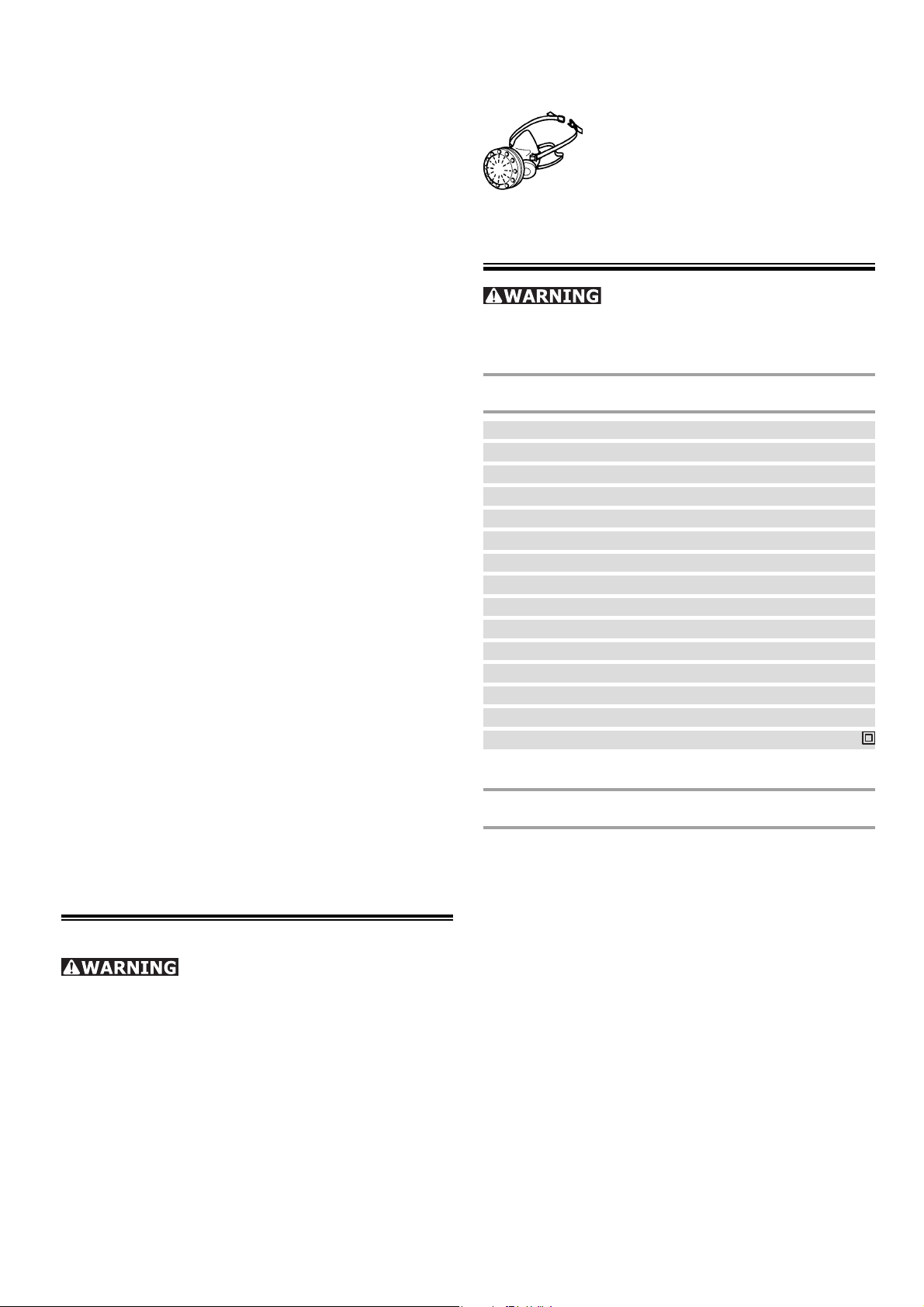

The switch [1-4] is an on/off switch (I = ON, 0 =

OFF). Connecting and detaching the mains power

cable [1-8], see Fig. [2].

WARNING

Extension cord

If an extension cord is required, it must have suffi cient cross-section to prevent an excessive drop

in voltage or overheating. An excessive drop in

voltage reduces the output and can lead to failure

of the motor. The table adjacent shows you the

correct cord diameter as a function of the cord

length for the LHS 225.

3

4

Use only U.L. and CSA listed extension cords.

3-1

2

1

2

Never use two extension cords together. Instead,

use one long one.

Note: The lower the AWG number, the stronger

the cord.

Machine settings

3-2

3

3

4-1

4-2

Risk of accident, electric shock

Always pull the plug out of the socket before f

performing any type of work on the machine.

Hold the sanding head [1-1] with the sanding f

pad facing downwards.

If closed, release the clamping levers f [3-1]

and [3-2].

Slide the extension pipe [1-2] into the opening f

up to the stop as illustrated in [3].

Close the clamping levers [3-1] and [3-2]. f

Slide the contact slide f [4-2] into the retainer

as illustrated in [4].

WARNING

Fitting the

PLANEX

10

Page 11

Press the contact slide down until it latches f

into position.

Insert the handle section [1-6] at the same f

way.

If you wish to use the L

walls in cramped spaces, for example, reduce

the length of the machine by fi tting the sanding

head [1-1] directly to the handle section [1-6].

When disassembling the machine, do not forget f

to press the button [4-1] to release the contact

slide before opening clamping levers [3-1] and

[3-2].

PLANEX

for sanding

Electronics

The machine features full-wave electronics with

the following properties:

Smooth start-up

The electronically controlled smooth start-up

function ensures that the machine starts up

smoothly.

5

5-1 5-2

Speed control

You can regulate the rotational speed steplessly

between 310 and 920 rpm using the adjusting

wheel [1-3]. This enables you to optimise the cutting speed to suit the respective material.

Constant speed

The preselected motor speed remains constant

through electronic control. This ensures a uniform

cutting speed even when under strain.

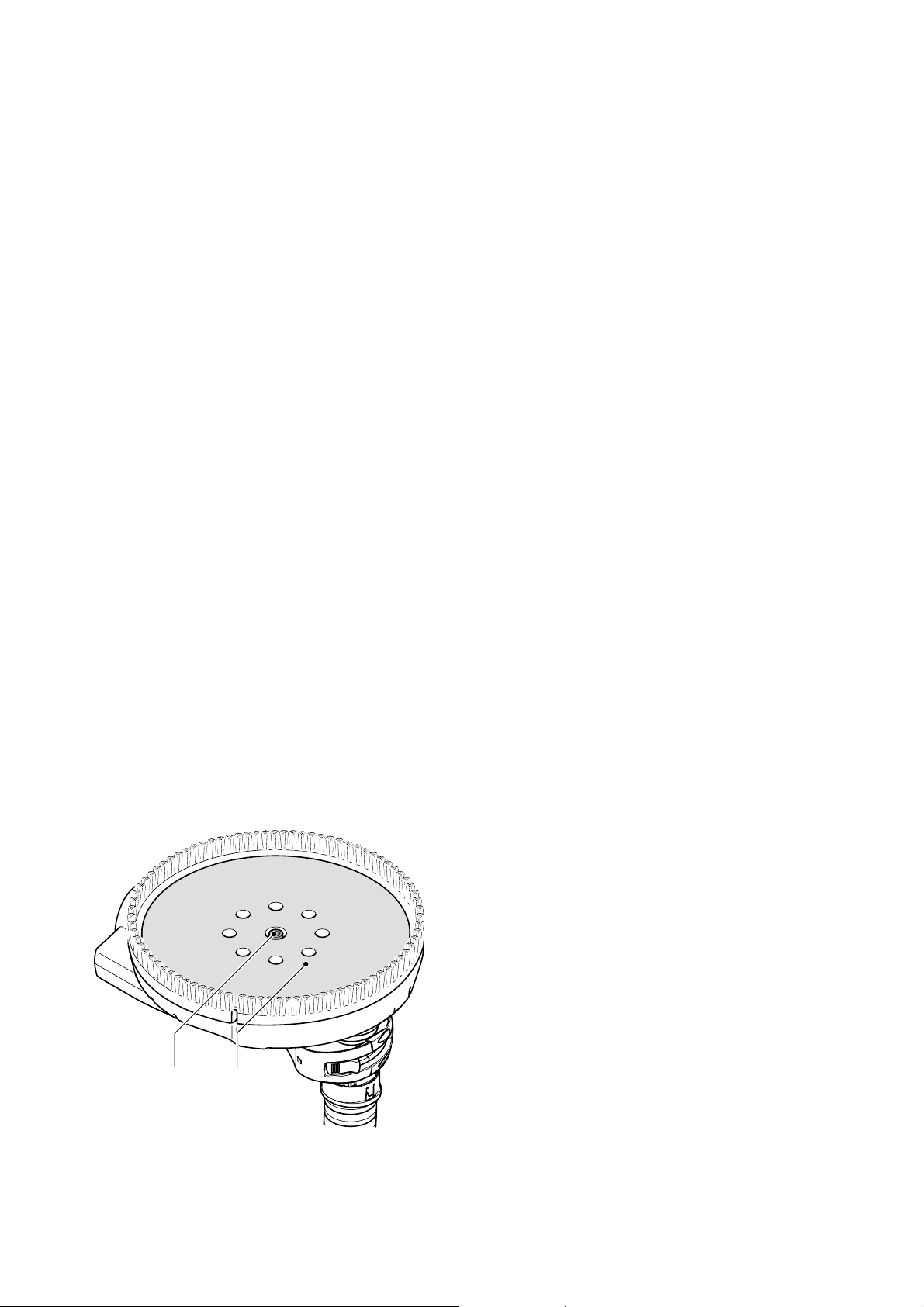

Changing sanding pads

Insert an Allen key (size 5) into the Allen screw f

[5-1] on the sanding pad.

Hold the sanding pad securely and turn the f

Allen key to release.

In order to further ensure optimum axial run- L

out, you must fi rst clean the bearing surface

for the grinding disk on the driveshaft.

Attach the new sanding pad. f

Tighten the screw f [5-1].

Only attach specifi ed sanding pads to the ma- L

chine.

In order to guarantee optimum suction output, L

the sealing face between the machine and

the grinding disk is ground in during the fi rst

few minutes after the disk has been changed.

During this time, the r.p.m. of the machine is

slightly lower and white foam particles form

during the grinding process. However, they do

not damage the machine.

11

Page 12

6

6-1

Affi xing abrasives

Compatible StickFix sanding discs are quick and

easy to attach to the StickFix sanding pad. Simply

press the self-adhesive sanding discs [1-7] onto

the sanding pad [5-2]. The adhesive coating holds

the StickFix sanding pad securely in position. Make

sure that the sanding disc holes line up with the

suction holes [6-3]. Tear off the sanding disc when

worn.

6-26-3

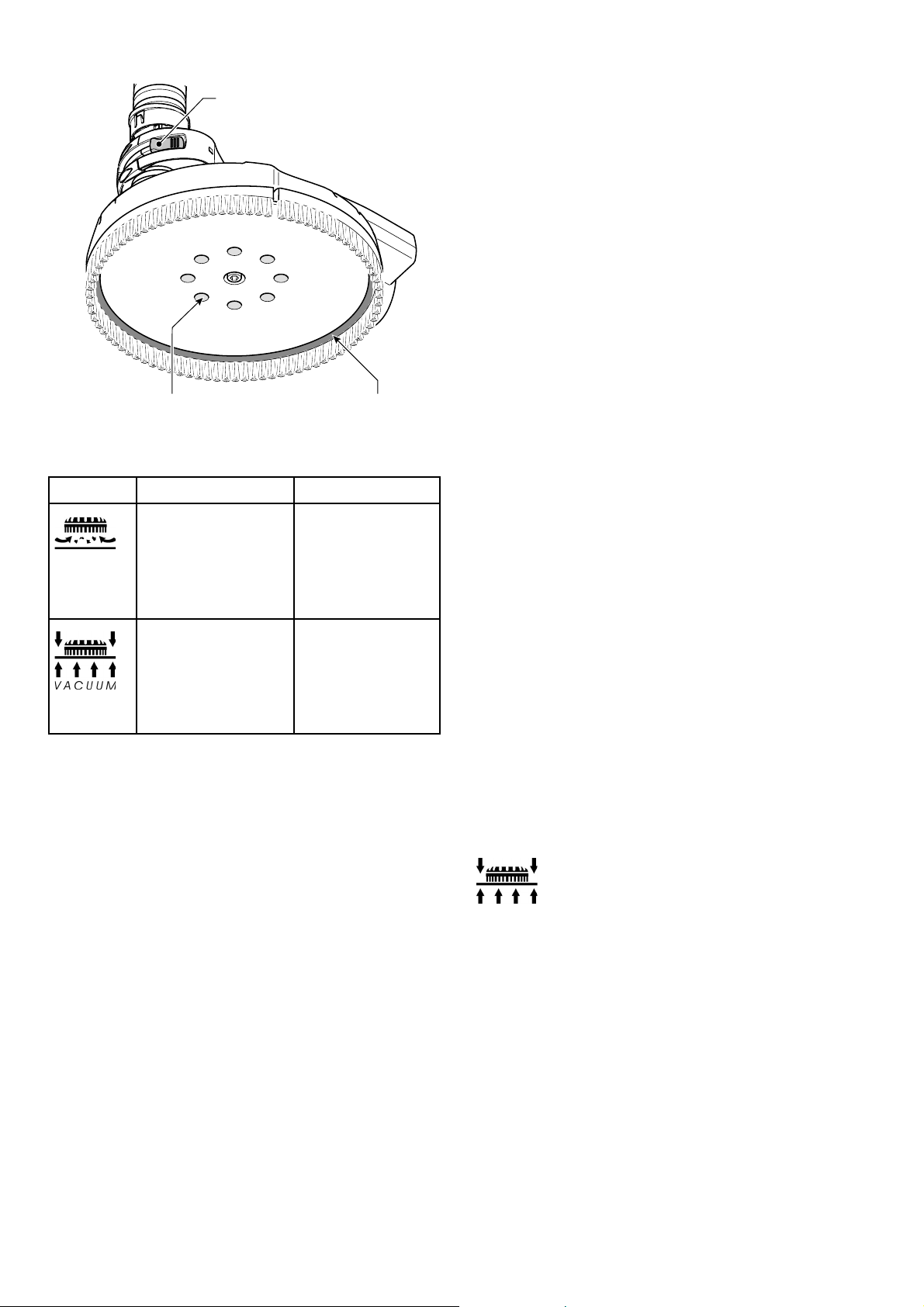

Symbol

Dust extraction

External extraction [6-2]

(between sanding

disc and brush

ring)

Internal extraction

[6-3]

(suction hole)

Use

Extracting

larger particles

such as carpet

residue

Extracting small

particles such as

fi ller with maximum suction effect

Adjusting the internal/ex-

ternal extraction

You can switch between internal and external

extraction depending on the size of the particles

produced by the sanding process.

Push the switch [6-1] to change between the f

two dust extraction modes.

Adjusting the suction power

You can adjust the suction power to match the

surface type, but only when internal extraction

is active (see chapter “Adjusting the internal/

external extraction).

Use the adjusting wheel [1-5] to adjust the f

suction power.

1: Low suction power

6: High suction power

Start with a low suction power (position 1) and f

slowly increase until you can feel that the application pressure has noticeably changed.

A high suction power makes sanding work on L

ceilings and walls less tiring.

Excessive suction power can cause the ma- L

chine to vibrate and become more diffi cult to

guide. The machine may also be overloaded.

This activates the protective circuit. The red

diode flashes slowly. The electronic circuit

switches to recovery speed. If this happens,

you must stop working immediately until the

machine has cooled down again.

12

Page 13

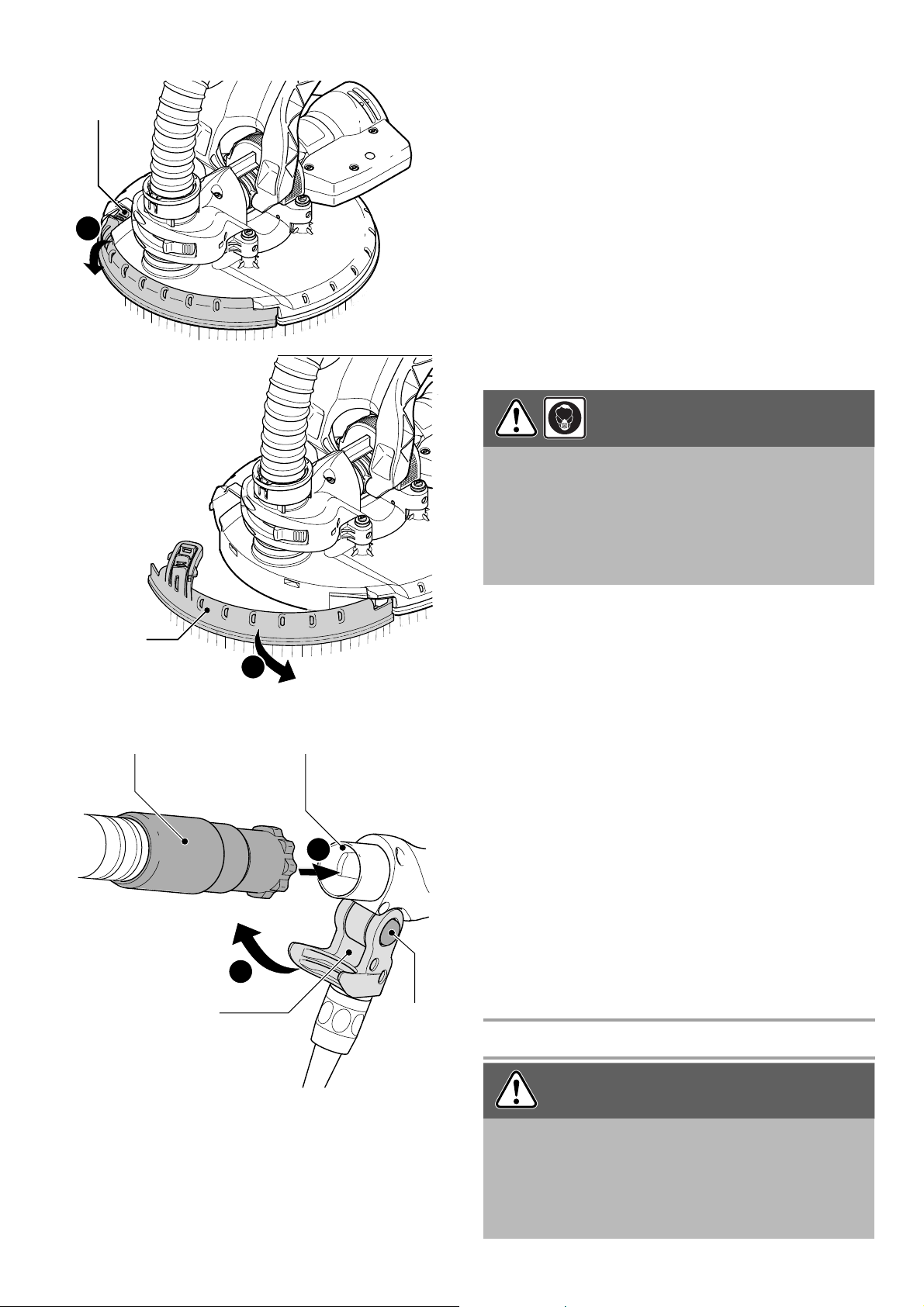

Sanding close to edges

7-1

1

The detachable brush segment allows you to reduce the distance between the wall/ceiling and

the side of the sanding pad.

Press and hold the knob [7-1]. f

Remove the brush segment [7-2]. f

There is a retainer in the lid of the SYSTAINER L

for storing the brush segment.

Hook in the brush segment at the opposite end f

to the knob [7-1], swivel towards the sanding

head and engage into position.

Dust extraction

Breathing in dust can damage the respiratory

passage!

Always connect the machine to a dust extrac- f

tor.

When performing work that generates dust, f

always wear a dust mask.

CAUTION

7

8

7-2

8-1

8-4

A Festool dust extractor with an extractor hose

diameter of 27 mm or 36 mm (recommended due

to the improved suction power) can be connected

2

8-2

1

2

8-3

to the extractor connector [8-2].

The special extraction hose and special suction L

sleeve [8-1] (available as an accessory) ensure

permanent attachment and protect against

kinking.

Use the dust extractor CT 36 E AC-LHS on large L

surfaces because this extractor guarantees the

permanent suction power required.

Press the green button [8-4] to open the me- f

chanical lock [8-3].

Attach the extraction hose on the dust extractor f

to the outlet spigot [8-2].

Swivel the mechanical lock [8-3] upwards until f

it engages.

Operation

Risk of injury

Do not hold the machine by the head. f

Hold the machine with both hands. f

Make sure that all clamping levers are closed f

before operating the machine.

WARNING

13

Page 14

Connect the machine to the mains power sup- f

ply.

Before switching on, hold the sanding head L

a slight distance away from the working surface.

Switch on the machine. f

The on/off switch has a zero voltage actuator, L

which prevents the machine from starting automatically after the power supply is interrupted

(e.g. after a power failure). After an interruption in voltage, press the on/off switch [1-4] to

switch the machine on again.

Perform the necessary sanding work. f

Do not overload the machine by pressing with L

excessive force! The best sanding results are

achieved with moderate press-on pressure.

The sanding performance and quality are

mainly dependent on the selection of the correct abrasive.

Switch the machine off once the sanding task f

is complete.

9

9-1

9-2

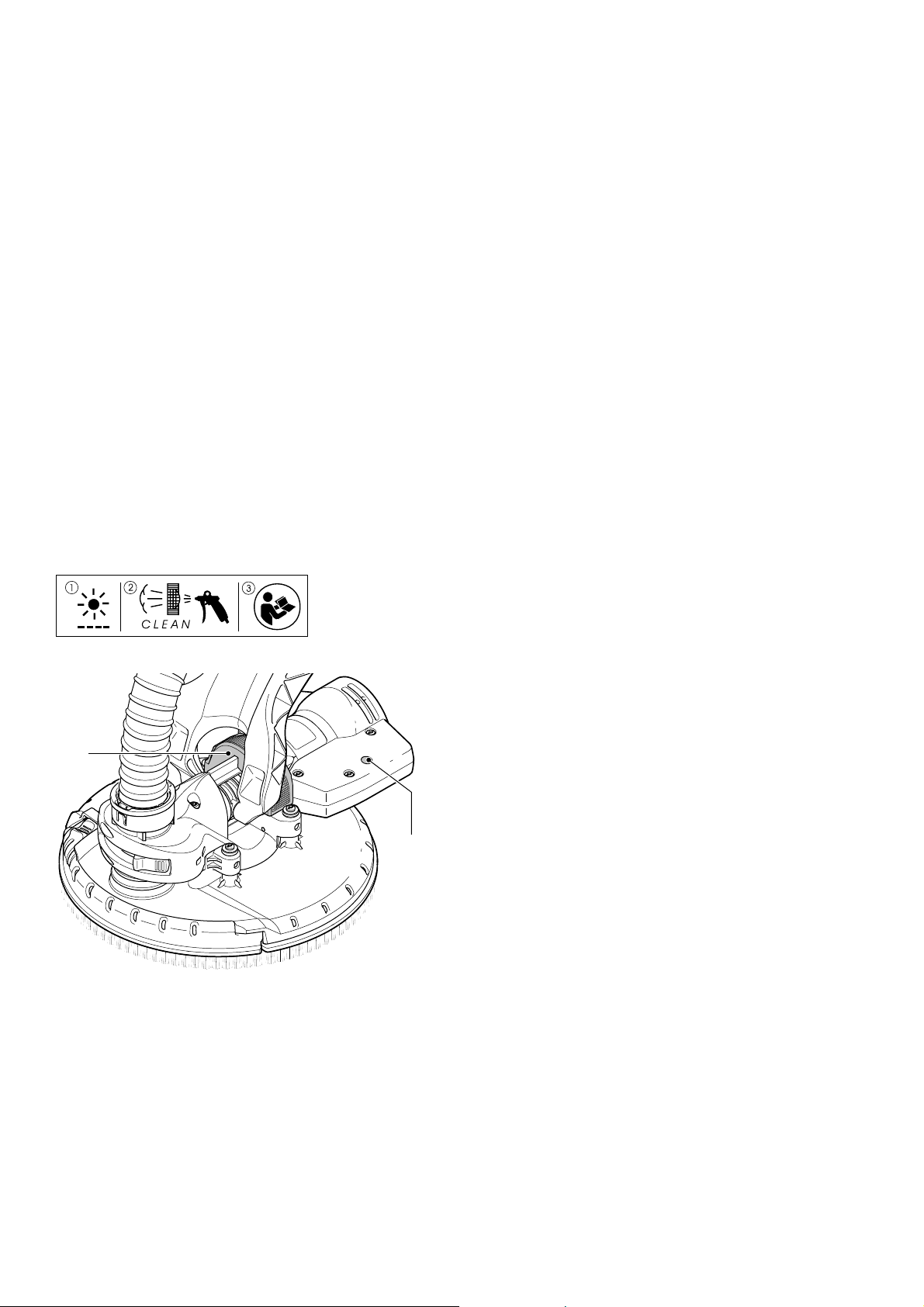

Visual warning signals on the sanding head

The following visual signals appear on the LED

[9-2] on the motor housing and the machine decreases in speed if necessary.

LED fl ashing slowly

The machine is overheating due to heavy dirt

deposits around the air vent slits and the dust

fi lter [9-1].

Clean the air vent slits. f

Remove the dust fi lter [9-1]. f

Remove the dirt deposits. f

Insert the dust fi lter [9-1] until it audibly en- f

gages.

The LED stops fl ashing once the machine is L

cleaned and cools down. You can then continue

with your work.

If the LED is still fl ashing after the fi lter sieve and

air vent slits have been cleaned:

Apply less pressure on the surface. f

Reduce the suction output with the handwheel f

[1-5].

14

LED fl ashing quickly

If a malfunction occurs and the speed signal is

transferred incorrectly from the handle to the motor, the motor increases to maximum speed when

switched on and the LED [9-2] fl ashes quickly until

the machine is switched off.

Page 15

The machine has an internal malfunction. Have L

the machine inspected by an authorised service

workshop.

Service and maintenance

Risk of accident, electric shock

Always pull the plug out of the socket before f

performing any type of work on the machine.

All maintenance or repair work requiring the f

motor housing to be opened must be carried

out only by an authorized service workshop.

Maintenance or repair work carried out by an

unauthorized person can lead to the incorrect

connection of the wiring or other components,

which in turn can lead to accidents with serious consequences.

Check the plug and the cable regularly and should f

either become damaged, have them replaced

by an authorised after-sales service workshop.

WARNING

To ensure constant air circulation, always keep f

the air vent slits in the motor housing clean and

free of blockages. Read the instructions on visual warning signals in chapter “Operation".

Clean the contact slide regularly. Do not use f

hard objects.

The machine is equipped with self-disconnecting

special carbon brushes. If they are worn, power is

interrupted automatically and the machine comes

to a standstill.

Tighten the clamping levers if they no longer L

capable of retaining the extension pipe properly:

Turn the screws on the clamping levers [3-1] f

and [3-2] approx. 1/8 of a turn.

Accessories, tools

For safety reasons, only use origi-

nal Festool accessories and tools!

The accessory and tool order number can be found

in the Festool catalog or on the Internet under

www.festoolusa.com.

connect

open

T-loc

lock

connect

Systainer

Many Festool products are shipped in a unique

system container, called “Systainer”.

This provides protection and storage for the tool

and accessories. The Systainers are stackable

and can be connected together. They also can be

conntected atop Festool CT dust extractors.

To open the Systainer:

Turn the T-loc [1 – 0-1] to the position

To lock the Systainer:

Turn the T-loc [10-1] to the position –

To connect two Systainers:

Place one Systainer on the top of the other –

(Fig. 10A).

Turn the T-loc [10-1] to the position –

(Fig. 10B).

.

.

or

The Systainers are connected and locked.

A new generation Systainer is connectable on L

top of a previous generation Systainer by the

four latches of the previous Systainer.

15

Page 16

Disposal

Do not throw the power tool in your household

waste! Dispose of machines, accessories and

packaging at an environmentally-responsible

recycling centre. Observe the valid national regulations.

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1

year + 2 years = 3 years) for your Festool power

tool. Festool shall be responsible for all shipping

costs during the fi rst year of the warranty. During the second and third year of the warranty the

customer is responsible for shipping the tool to

Festool. Festool will pay for return shipping to the

customer using UPS Ground Service. All warranty

service is valid 3 years from the date of purchase

on your receipt or invoice.

Festool Limited Warranty

This warranty is valid only on condition that the

tool is used and operated in compliance with the

Festool operating instructions. Festool warrants,

only to the original consumer purchaser, that the

specifi ed tool will be free from defects in materials and workmanship for a term of one year from

the date of procurement. Festool makes no other

warranty, express or implied, for Festool portable

power tools. No agent, representative, distributor,

dealer or employee of Festool has the authority

to increase or otherwise change the obligations

or limitations of this warranty. The obligations of

Festool in its sole discretion under this warranty

shall be limited to the repair or replacement of

any Festool portable power tool that is found to be

defective as packaged with the User Manual.

Excluded from coverage under this warranty are:

normal wear and tear; damages caused by misuse, abuse or neglect; damage caused by anything

other than defects in material and workmanship.

This warranty does not apply to accessory items

such as circular saw blades, drill bits, router bits,

jigsaw blades, sanding belts, and grinding wheels.

Also excluded are “wearing parts”, such as carbon

brushes, vanes of air tools, rubber collars and

seals, sanding discs and pads, and batteries.

If your Festool power tools require repair, please

go to www.festoolusa.com and download the Repair Order Form. Enclosing the completed form

with your tool will expedite the repair. You can fi nd

address details at the bottom of the form. Please

call our Service Department at 888-337-8600 to

arrange a shipping label if the tool is eligible for

free shipping to our repair facility (see Conditions

of 1+2 Warranty section for eligibility). No collect

shipments will be accepted.

IN NO EVENT SHALL FESTOOL BE LIABLE FOR

ANY CONSEQUENTIAL OR INCIDENTAL DAM

AGES FOR BREACH OF THIS OR ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED WHAT

SOEVER. ALL WARRANTIES IMPLIED BY STATE

LAW, INCLUDING THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE HEREBY LIMITED

TO THE DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian provinces do not allow the limitations on how long an

implied warranty lasts, so the above limitation

may not apply to you. With the exception of any

warranties implied by state or province law as

hereby limited, the foregoing express limited

warranty is exclusive and in lieu of all other warranties, guarantees, agreements and similar

obligations of Festool.

This warranty gives you specifi c legal rights and

you may also have other rights which vary from

state to state in the U.S. and province to province

in Canada.

16

Page 17

Troubleshooting

Problem Possible causes Remedy

PLANEX bumps over

the surface.

Extraction power is

insuffi cient.

Excessive material

removed from workpiece

Suction power too strong Reduce suction power or switch to external

extraction if necessary.

Hard repair compound or hard sublayers Reduce suction power or switch to external

extraction if necessary.

Reduce speed.

Main fi lter on CT 36 E AC-LHS blocked /

clogged.

Disposal bag inserted incorrectly. The holes punched in the disposal bag must

Filter bag inserted instead of disposal

bag.

Suction power setting on CT 36 E ACLHS too low.

Speed of PLANEX too fast Reduce speed.

Internal extraction on PLANEX with ex-

traction control on setting 1

Repair compound with a high percent-

age of fi ller, soft fi ller

Suction hose blocked or kinked. Remove blockage and straighten hose.

Disposal bag full Dispose of the bag.

Speed of PLANEX too fast Reduce speed.

Suction power of the PLANEX too strong Reduce suction power or switch to external

Repair compound with a high percentage of fi ller, soft fi ller

Grit on abrasive too coarse Select a fi ner grit.

Clean the main fi lter regularly:

Option 1: Clean the main fi lter with AutoClean, set the suction power control to the

maximum setting. Cover the nozzle, suction

hose or intake opening on the extractor with

the surface of your hand for 10 seconds until the automatic cleaning cycle starts.

Option 2: Clean the main fi lter mechanically

(extracting).

Option 3: Check the main fi lter for damage

and clogging. Insert a new fi lter element

regularly.

be inside the container.

Always work with the disposal bag when

operating the PLANEX (grey bag).

Adjust the suction power to a higher set-

ting.

Increase suction power or switch to external extraction.

Switch on the external extractor connected

to the PLANEX, set the extraction control to

setting 6, in extreme cases, turn down the

speed.

extraction.

Switch on the external extractor connected

to the PLANEX, set the extraction control to

setting 6, in extreme cases, turn down the

speed.

17

Page 18

Problem Possible causes Remedy

Surface quality not

perfect

Sanding grooves on

the surface

PLANEX switches

off during work – red

LED on the head of

the machine fl ashes

PLANEX does not

function

Incorrect abrasive grit Select a fi ner grit.

Drying times of the repair compound not

observed.

Suction power of PLANEX too strong Reduce the suction power of the PLANEX

Repair compound with a high percent-

age of fi ller, soft fi ller

Machine set down on the surface while

running (groove formation)

Hard sanding pad set down on the surface at an angle.

Sanding pad is too hard or abrasive grit

too coarse for very soft repair compound.

Dust fi lter on PLANEX clogged Clean the dust fi lter on the PLANEX.

Excessive pressure -> machine activates

overheating protection

Electrical plug is not connected correctly.

Read the technical data sheets and manufacturer recommendations.

Select a fi ner grit, e.g. P180.

Place the machine in position and then

switch on.

Always use detachable brush segments

when working on surfaces.

Use sanding pad IP with interface pad.

Use sanding pad IP with interface pad.

Select a fi ner abrasive grit (Brilliant 2 abra-

sive with grit up to P 320).

Allow the machine to cool and apply less

pressure; in extreme cases, switch on the

external extraction system and set the extraction control to setting 6.

Check that the electrical plug is inserted

properly.

If other problems other than those listed occur, please contact your Festool service workshop or your

local specialist dealer.

18

Page 19

Sommaire

Symboles ......................................................... 19

Consignes de sécurité ..................................... 19

Caractéristiques techniques ..........................23

Composants de l'outil ......................................23

Utilisation conforme aux prescriptions ...........23

Mise en service ...............................................24

Câble de rallonge ............................................ 24

Réglages de la machine ..................................24

Montage de la ponceuse PLANEX .................. 24

Système électronique ...................................... 25

Remplacement du plateau de ponçage .......... 25

Fixation de l'abrasif ......................................... 26

Réglage de l'aspiration intérieure /

extérieure ......................................................... 26

Réglage de la puissance d'aspiration ............. 26

Ponçage près des bords .................................. 27

Aspiration ......................................................... 27

Fonctionnement ..............................................28

Entretien .........................................................29

Accessoires et outils .......................................29

Elimination ...................................................... 30

Garantie ..........................................................30

Dépannage ......................................................31

Symboles

Avertissement de danger

Avertissement contre le risque d'électro-

cution

Portez un masque antipoussières !

Portez une protection acoustique !

Construction de classe II

tr/min

-1

min

Tours par minute

Ø Diamètre

tuyau, renseignement L

Consignes de sécurité

Consignes de sécurité générales

Lire toutes les consignes

de sécurité et indications. Le non-respect des

avertissements et instructions indiqués ci-après

peut entraîner un choc électrique, un incendie et/

ou de graves blessures.

Conserver tous les avertissements et toutes les

instructions pour pouvoir s’y reporter ultérieurement.

Le terme «outil» dans les avertissements fait

reference à votre outil électrique alimenté par

le secteur (avec cordon d’alimentation) ou votre

outil fonctionnant sur batterie (sans cordon d’alimentation).

1 PLACE DE TRAVAIL

a) Maintenez l’endroit de travail propre et bien

éclairé. Un lieu de travail en désordre ou mal

éclairé augmente le risque d’accidents.

b) N’utilisez pas l’appareil dans un environne-

ment présentant des risques d’explosion et où

se trouvent des liquides, des gaz ou poussières

infl ammables. Les outils électroportatifs gé-

nèrent des étincelles risquant d’enfl ammer les

poussières ou les vapeurs.

c) Tenez les enfants et autres personnes éloignés

durant l’utilisation de l’outil électroportatif.

En cas d’inattention vous risquez de perdre le

contrôle sur l’appareil.

Nettoyer les fentes d'aération et le fi ltre

antipoussières

Lire la notice / les instructions !

V Volt

A Ampère

Hz Hertz

W Watt

~ Tension alternative

n

Vitesse de rotation à vide

0

2 SECURITE RELATIVE AU SYSTEME ELECTRIQUE

a) La fi che de secteur de l’outil électroportatif

doit être appropriée à la prise de courant. Ne

modifi ez en aucun cas la fi che. N’utilisez pas

de fi ches d’adaptateur avec des appareils avec

mise à la terre. Les fi ches non modifi ées et les

prises de courant appropriées réduisent le risque de choc électrique.

b) Evitez le contact physique avec des surfaces

mises à la terre tels que tuyaux, radiateurs,

fours et réfrigérateurs. Il y a un risque élevé de

choc électrique au cas où votre corps serait relié

à la terre.

19

Page 20

c) N’exposez pas l’outil électroportatif à la pluie

ou à l’humidité. La pénétration d’eau dans un

outil électroportatif augmente le risque d’un

choc électrique.

d) N’utilisez pas le câble à d’autres fi ns que cel-

les prévues, n’utilisez pas le câble pour porter

l’appareil ou pour l’accrocher ou encore pour le

débrancher de la prise de courant. Maintenez

le câble éloigné des sources de chaleur, des

parties grasses, des bords tranchants ou des

parties de l’appareil en rotation. Un câble en-

dommagé ou torsadé augmente le risque d’un

choc électrique.

e) Au cas où vous utiliseriez l’outil électroportatif

à l’extérieur, utilisez une rallonge autorisée

homologuée pour les applications extérieures.

L’utilisation d’une rallonge électrique homologuée pour les applications extérieures réduit le

risque d’un choc électrique.

f) Si l’usage d’un outil dans un emplacement hu-

mide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel résiduel (RCD). L’usage d’un RCD réduit le

risque de choc électrique.

3 SECURITE DES PERSONNES

a) Restez vigilant, surveillez ce que vous faites.

Faites preuve de bon en utilisant l’outil électroportatif. N’utilisez pas l’appareil lorsque

vous êtes fatigué ou après avoir consommé de

l’alcool, des drogues ou avoir pris des médicaments. Un moment d’inattention lors de l’uti-

lisation de l’appareil peut entraîner de graves

blessures sur les personnes.

b) Portez des équipements de protection. Por-

tez toujours des lunettes de protection. Le

fait de porter des équipements de protection

personnels tels que masque anti-poussières,

chaussures de sécurité antidérapantes, casque

de protection ou protection acoustique suivant le

travail à effectuer, réduit le risque de blessures.

c) Evitez une mise en service par mégarde. Assu-

rez-vous que l’interrupteur est effectivement

en position d’arrêt avant de retirer la fi che de

la prise de courant. Le fait de porter l’appareil

avec le doigt sur l’interrupteur ou de brancher

l’appareil sur la source de courant lorsque l’interrupteur est en position de fonctionnement,

peut entraîner des accidents.

d) Enlevez tout outil de réglage ou toute clé avant

de mettre l’appareil en fonctionnement. Une

clé ou un outil se trouvant sur une partie en rotation peut causer des blessures.

e) Ne surestimez pas vos capacités. Veillez à gar-

der toujours une position stable et équilibrée.

Ceci vous permet de mieux contrôler l’appareil

dans des situations inattendues.

f) Portez des vêtements appropriés. Ne portez

pas de vêtements amples, ni de bijoux. Gardez

les cheveux et les vêtements à distance des

pièces mobiles. Des vêtements amples, des bi-

joux ou des cheveux longs peuvent être happés

par les pièces en mouvement.

g) Si des dispositifs servant à aspirer ou à re-

cueillir les poussières doivent être utilisés,

vérifi ez que ceux-ci soient effectivement raccordés et qu’ils sont correctement utilisés.

L’utilisation de tels dispositifs réduit les dangers

dus aux poussières.

4 UTILISATION ET EMPLOI SOIGNEUX DE

L’OUTIL ELECTROPORTATIF

a) Ne surchargez pas l’appareil. Utilisez l’outil

électroportatif approprié au travail à effectuer. Avec l’outil électroportatif approprié, vous

travaillerez mieux et avec plus de sécurité à la

vitesse pour laquelle il est prévu.

b) N’utilisez pas un outil électroportatif dont l’in-

terrupteur est défectueux. Un outil électroportatif qui ne peut plus être mis en ou hors fonctionnement est dangereux et doit être réparé.

c) Retirer la fi che de la prise de courant avant

d’effectuer des réglages sur l’appareil, de

changer les accessoires, ou de ranger l’appareil. Cette mesure de précaution empêche une

mise en fonctionnement par mégarde.

d) Gardez les outils électroportatifs non utilisés

hors de portée des enfants. Ne permettez pas

l’utilisation de l’appareil à des personnes qui

ne se sont pas familiarisées avec celui-ci ou

qui n’ont pas lu ces instructions. Les outils

électroportatifs sont dangereux lorsqu’ils sont

utilisés par des personnes non initiées.

e) Prenez soin des outils électroportatifs. Vérifi ez

que les parties en mouvement fonctionnent

correctement et qu’elles ne soient pas coincées, et contrôlez si des parties sont cassées

ou endommagées de telle sorte que le bon

fonctionnement de l’appareil s’en trouve entravé. Faites réparer les parties endommagées avant d’utiliser l’appareil. De nombreux

accidents sont dus à des outils électroportatifs

mal entretenus.

f) Maintenez les outils de coupe aiguisés et pro-

pres. Des outils soigneusement entretenus avec

des bords tranchants bien aiguisés se coincent

20

Page 21

moins souvent et peuvent être guidés plus facilement.

g) Utilisez les outils électroportatifs, les acces-

soires, les outils à monter etc. conformément

à ces instructions et aux prescriptions en vigueur pour ce type d’appareil. Tenez compte

également des conditions de travail et du travail à effectuer. L’utilisation des outils électro-

portatifs à d’autres fi ns que celles prévues peut

entraîner des situations dangereuses.

h) Gardez les poignées dans un état sec, propre

et exempt d’huile et de graisse. Des poignées

glissantes ne permettent pas une prise en main

sûre et le contrôle de l’outil électrique dans des

situations inattendues.

6 SERVICE

a) Ne faites réparer votre outil électroportatif

que par un personnel qualifi é et seulement

avec des pièces de rechange d’origine. Ceci

permet d’assurer la sécurité de l’appareil.

Consignes de sécurité spé-

cifi ques à la machine

Cette machine est conçue de façon conforme –

aux prescriptions pour le ponçage. Lisez tou-

tes les consignes de sécurité, modes d'emploi,

fi gures et descriptions livrées avec la machine.

En cas de non-respect des consignes de sécurité, vous risquez une décharge électrique, une

incendie ou de graves blessures.

Les travaux tels que le dégrossissage, le –

brossage, le polissage et le tronçonnage ne

doivent pas être exécutés à l'aide de cette machine. Les travaux pour lesquels la machine n'a

pas été conçue peuvent faire courir des risques

aux personnes et entraîner des lésions.

N'utilisez pour cet outil aucun accessoire qui –

n'a pas été spécialement conçu et développé

par Festool. Ce n'est pas parce qu'un acces-

soire peut être monté sur un outil qu'un fonctionnement sans danger peut être garanti.

La vitesse admissible de l'accessoire doit être –

au moins aussi élevée que la vitesse maximale

indiquée sur la machine. Les accessoires dé-

passant la vitesse admise peuvent se briser.

Le diamètre extérieur et l'épaisseur de l'ac- –

cessoire doivent se trouver dans la plage de

grandeur indiquée de la machine. Un accessoi-

re de dimensions inadaptées ne peut être ni suffi samment protégé, ni suffi samment maîtrisé.

L'alésage des disques, des brides, des pla- –

teaux de support et des autres accessoires

doit s'adapter avec précision à la broche de la

machine. Un accessoire dont le diamètre est

inadapté ne tourne pas rond, vibre excessivement et peut entraîner une perte de contrôle.

N'utilisez pas d'accessoires défectueux. Avant –

chaque utilisation, contrôlez si le plateau de

ponçage ne présente pas de ruptures ou de

fi ssures et si le plateau de support ne présente pas de fi ssures et d'usure excessive. Si

les accessoires ont subi des détériorations,

montez des accessoires non endommagés.

Après vérifi cation et montage des accessoires, éloignez-vous, ainsi que les personnes

qui vous entourent, du plan de rotation de

l'outil, puis laissez tourner la machine pendant une minute à vitesse maximale. Habituel-

lement, un accessoire endommagé se brise au

cours de ce test.

Portez un équipement de protection indi- –

viduelle. Selon l'utilisation, employez un

bouclier de protection ou des lunettes de

protection. Si nécessaire, portez un masque

respiratoire, une protection auditive, des

gants de sécurité et un tablier de travail, permettant de se protéger des projections provoquées par le polissage de petites pièces. Les

lunettes de protection permettent d'intercepter

les débris volants dus à différents travaux. Le

masque respiratoire ou l'appareil respiratoire

doivent être en mesure de fi ltrer les particules

générées par vos travaux. Une pollution sonore

durable peut entraîner la surdité.

Maintenez les personnes environnantes à dis- –

tance de sécurité de la zone de travail. Toute

personne présente dans la zone de travail doit

porter une protection personnelle. Des par-

ties de la pièce à travailler ou de l'accessoire

brisé peuvent être éjectées et provoquer des

blessures en dehors de l'entourage immédiat

du lieu de travail.

Tenez uniquement l'appareil par le biais des –

poignées isolées lorsque vous réalisez des

travaux au cours desquels l'outil de coupe

pourrait entrer en contact avec des conduites

électriques cachées ou toucher son propre

câble de raccordement. Le contact avec un

câble sous tension met également les pièces

métalliques de l'appareil sous tension et peut

provoquer un choc électrique.

Maintenez le câble électrique à l'écart des –

éléments en rotation. Si vous perdez le contrô-

le, le câble électrique pourrait être sectionné

ou rester accroché ; votre main ou votre bras

pourrait également être happé par les parties

en rotation.

21

Page 22

Ne posez jamais la machine tant que l'outil –

n'est pas complètement à l'arrêt. Les outils

en rotation peuvent s'enfoncer dans la surface

sur laquelle vous les avez déposés et échapper

ainsi à votre contrôle.

Ne laissez pas la machine tourner pendant –

que vous la portez sur le côté. En cas de

contact fortuit, l'outil en rotation pourrait

agripper votre vêtement et occasionner des

blessures graves (coupures...).

Nettoyez régulièrement les fentes d'aération –

de votre machine. Le ventilateur aspire la

poussière dans le carter de l'outil, et des dépôts excessifs de poussière métallique peuvent

être source de risques électriques.

N'utilisez pas l'outil à proximité de matières –

infl ammables. Des étincelles pourraient en-

fl ammer ces matières.

N'utilisez aucun outil à refroidissement li- –

quide. L'eau ou d'autres réfrigérants liquides

peuvent provoquer des décharges électriques

(mortelles).

Origine et prévention des retours

Le retour est une réaction soudaine due au blocage d'un disque en rotation, d'un plateau de

support, d'une brosse ou d'autres accessoires. Le

blocage ou l'accrochage provoque un arrêt très

rapide de l'accessoire en rotation, ce qui entraîne

par contre-réaction l'accélération incontrôlée de

la machine au niveau du point de blocage dans

le sens inverse de la rotation de l'accessoire. Si

par exemple le disque de ponçage est bloqué ou

coincé par la pièce, le bord du disque peut s'enfoncer au niveau du point de blocage dans la surface

de la pièce et ainsi éjecter le disque. Le disque

peut être éjecté soit en direction de l'utilisateur

soit en sens opposé, selon le sens de rotation

au niveau du point de blocage. Les plateaux de

ponçage peuvent se briser à cette occasion.

choc en retour résulte d'une mauvaise utilisation

de l'outil et/ou d'une manière de travailler incorrecte, et peut être évité en respectant les mesures

de précaution suivantes.

Tenez toujours fermement la machine et pla- –

cez votre corps et vos bras de façon à pouvoir

contrôler un éventuel choc en retour. Pour

un contrôle optimal des retours ou des temps

de réaction au démarrage ; utilisez la poignée

supplémentaire si elle faisait partie de la livraison. L'utilisateur peut contrôler des temps

de réaction ou des forces engendrées par le

retour; si les mesures de sécurité adéquates

sont prises.

Un

Ne placez jamais votre main à proximité –

d'outils en rotation. Les outils peuvent reculer

sur votre main.

Ne placez jamais votre corps dans la zone –

dans laquelle la machine peut effectuer un

mouvement de retour. Un retour accélérera

l'outil dans le sens opposé à la rotation au

niveau du point de blocage.

Soyez particulièrement prudent lors des tra- –

vaux dans les coins, au niveau de bords à arête

vive, etc. Evitez un recul et un coincement de

l'outil. Les coins, les arêtes vives ou un recul

ont tendance à bloquer l'outil en rotation et à

provoquer une perte de contrôle ou un choc

en retour.

Consignes de sécurité particuliè-

res pour le ponçage de précision

N'utilisez pas de disques de ponçage surdi- –

mensionnés pour le ponçage de fi nition. Suivez les indications du fabricant lors du choix

des disques de ponçage. Un disque de ponçage

trop grand dépassant largement du plateau

de ponçage constitue un risque de coupure et

peut entraîner un coincement, une rupture du

disque ou un choc en retour.

Indications d'avertisse-

ment supplémentaires

Tenez fermement la machine avec les deux –

mains lors des travaux, et veillez à une bonne

position stable des pieds. La machine est gui-

dée de façon sûre avec deux mains.

Si le ponçage génère des poussières explosives –

ou infl ammables, il convient impérativement

d'observer les consignes d'usinage du fabricant

du matériau.

Au cours du travail, des poussières nocives –

/ toxiques peuvent être générées (p. ex. enduit au plomb, certaines essences de bois et

certains métaux). Le contact ou l'inhalation

de ces poussières peut présenter un danger

pour l'utilisateur ou les personnes se trouvant

à proximité. Veuillez respecter les prescriptions

de sécurité en vigueur dans votre pays. Raccordez l'outil électrique à un dispositif d'aspiration

adapté. Pour votre santé, portez un masque de

protection respiratoire de classe P2.

N'utilisez pas la machine avec un câble en- –

dommagé. Ne touchez pas le câble endommagé et débranchez la fiche secteur si le

câble est endommagé pendant le travail. Un

22

Page 23

câble endommagé augmente le risque de choc

électrique.

Utilisez au maximum deux tubes de rallonge –

sur la machine.

La poussière, un risquepour la san-

té

Certaines poussières

créées par le ponçage mécanique, le sciage, le

meulage, le perçage et autres activités reliées

à la construction contiennent des substances

chimiques connues (dans l’État de la Californie)

comme pouvant causer le cancer, des anomalies

congénitales ou représenter d’autres dangers pour

la reproduction. Voici quelques exemples de telles

substances:

plomb provenant de peintures à base de f

plomb,

silice cristallisée utilisée dans les briques, le f

ciment et autres matériaux de maçonnerie, et

arsenic et chrome du bois d’œuvre traité avec f

un produit chimique.

Le risque d’exposition à de tels produits varie

selon la fréquence à laquelle vous faites ce genre

de travail.

Pour réduire les risques d’exposition à

ces substances chimiques : travaillez

dans un endroit adéquatement ventilé

et utilisez un équipement de sécurité

approuvé, tel que masques antipoussières spécialement conçus pour

fi ltrer les particules microscopiques.

Caractéristiques techniques

Puissance 550 W

Régime 340 - 910 min

Ø plateau de ponçage 215 mm (8.5’’)

Ø abrasif 225 mm (8.9’’)

Porte-outil D 13/10

Raccord aspiration de poussières 36 mm (1.4’’)

(27 mm (1.06’’))

Longueur version courte

(sans tube de rallonge) 1,10 m (43.3’’)

Longueur version longue

(avec tube de rallonge) 1,60 m (63.0’’)

Poids sans câble

Version courte 3,80 kg (8.4 lbs)

Version longue 4,60 kg (10.1 lbs)

Degré de protection II/

-1

Composants de l'outil

Des schémas de l‘outil sont disponibles sur le

volet qui se trouve au début de cette notice d‘utilisation. Vous pouvez ainsi déplier cette page et

visualiser en permanence les différentes parties

de l‘outil lorsque vous lisez la notice.

[1-1] Tête de ponçage

[1-2] Tube de rallonge

[1-3] Régulation de la vitesse

[1-4] Interrupteur de marche / arrêt

[1-5] Réglage de la puissance d’aspiration

[1-6] Poignée

[1-7] Abrasif

[1-8] Câble d’alimentation électrique

POUR RÉDUIRE LE RISQUE

DE DOMMAGES, L’UTILISATEUR DOIT LIRE LE

MANUEL D’INSTRUCTION

Utilisation conforme

aux prescriptions

La ponceuse PLANEX est conçue de façon conforme aux prescriptions pour le ponçage de murs de

construction sèche spatulés, de plafonds et de

murs à l’intérieur comme à l’extérieur, ainsi que

pour l’élimination de restes de papiers peints, de

couches de peinture, d’enrobements, de résidus

de colle et de crépi.

Lors du ponçage de grandes surfaces spatu- L

lées générant beaucoup de poussières, nous

recommandons l’utilisation de l’aspirateur

mobile CT 36 E AC-LHS.

L’utilisateur est respon-

sable des dommages et accidents provoqués par

une utilisation non conforme.

23

Page 24

Mise en service

AVERTISSEMENT

Le commutateur [1-4] sert d'interrupteur de marche / arrêt (I = "ON", 0 = "OFF"). Branchement et

débranchement du câble d'alimentation électrique [1-8], voir fi gure [2].

Risque d'accident si la machine est utilisée

sur une tension ou fréquence d'alimentation

inadaptée.

La tension et la fréquence d'alimentation élec- f

trique doivent être conformes aux indications

de la plaque signalétique de la machine.

En Amérique du nord, utilisez uniquement les f

outils Festool fonctionnant avec une tension

de 120 V.

Longueur totale

rallonge (pieds)

Section du câble (AWG) 18 16 16 14

3

25 50 100 150

3-1

Câble de rallonge

Si une rallonge électrique est nécessaire, elle doit

présenter une section suffi sante pour éviter une

chute de tension excessive ou une surchauffe. Une

chute de tension excessive réduit la puissance

et peut entraîner une défaillance du moteur. Le

tableau ci-contre vous présente la section correcte du câble en fonction de sa longueur pour la

norme LHS 225.

Utilisez exclusivement des rallonges recommandées par les organismes U.L. et CSA. N’utilisez

jamais deux rallonges branchées l’une après

l’autre, mais remplacez-les par une rallonge plus

longue.

Remarque : plus le numéro AWG est petit, plus

la section du câble est grande.

Réglages de la machine

4

2

1

2

3-2

3

3

4-1

4-2

Risque d'accident, risque d'électrocution

• f Avant toute intervention sur la machine,

débranchez toujours la fi che secteur de la

prise de courant.

Montage de la ponceuse PLANEX

Maintenez la tête de ponçage [1-1] avec le f

plateau de ponçage vers le bas.

Si fermés, ouvrez les leviers de serrage f [3-1]

et [3-2].

Insérez le tube de rallonge [1-2] jusqu'en butée f

dans l'ouverture, comme indiqué sur la fi gure [3].

Fermez les leviers de serrage [3-1] et [3-2]. f

Poussez le curseur de contact [4 f -2] dans la pri-

se de contact, comme indiqué sur la fi gure [4].

Pressez le curseur de contact vers le bas, f

jusqu'à ce qu'il s'engage.

Montez la poignée [1-6]. f

Si vous souhaitez utiliser la ponceuse PLANEX L

en version courte, p. ex. pour le ponçage de

murs dans des locaux étroits, montez directement la tête de ponçage [1-1] sur la poignée

[1-6].

AVERTISSEMENT

24

Page 25

Lors du démontage, n'oubliez pas de dégager L

le curseur de contact en pressant le bouton

[4-1] avant d'ouvrir les leviers de serrage [3-1]

et [3-2].

Système électronique

Cette machine dispose d'une électronique complète qui présente les caractéristiques suivantes :

Démarrage progressif

Le démarrage progressif à régulation électronique assure un démarrage sans à-coups de la

machine.

Régulation de la vitesse

La vitesse de rotation peut être réglée en continu au

moyen de la molette [1-3], entre 310 et 920 min

Vous pouvez ainsi adapter de façon optimale la

vitesse de coupe à chaque matériau.

Vitesse de rotation constante

La vitesse sélectionnée est maintenue constante

de manière électronique. Elle reste donc homogène, même lorsque l'outil est fortement sollicité.

-1

.

5

5-1 5-2

Remplacement du pla-

teau de ponçage

Insérez une clé hexagonale (taille 5) dans la f

vis à six pans creux [5-1] sur le plateau de

ponçage.

Bloquez le plateau et desserrez le plateau de f

ponçage en tournant la clé hexagonale.

Afi n de garantir une planéité optimale, nettoyez L

tout d'abord la surface d'appui du plateau de

ponçage sur l'arbre de sortie.

Montez le nouveau plateau de ponçage. f

Serrez la vis [5-1]. f

Utilisez uniquement des plateaux de ponçage L

spécifi és pour la machine.

Afi n de pouvoir garantir une puissance d'aspi- L

ration optimale, la surface d'étanchéité entre

la machine et le plateau de ponçage est rodée

pendant les premières minutes après le changement de plateau. Pendant ce temps, la vitesse de rotation de la machine est légèrement

plus basse et lors du processus de ponçage il

en résulte des particules de mousse blanches

qui sont inoffensives pour la machine.

25

Page 26

6

6-1

Fixation de l'abrasif

Les disques de ponçage StickFix peuvent être

fi xés rapidement et simplement sur le plateau de

ponçage StickFix. Les disques de ponçage[1-7]

auto-agrippants sont simplement pressés sur le

plateau de ponçage [5-2] et maintenus de façon

sûre par le revêtement auto-agrippant du plateau de ponçage StickFix. Assurez-vous à cette

occasion que les trous du disque de ponçage

coïncident avec les trous d'aspiration [6-3]. Après

utilisation, le disque de ponçage est simplement

retiré.

Réglage de l'aspiration in-

6-26-3

térieure / extérieure

Symbole Aspiration Utilisation

Aspiration extérieure [6-2]

(entre le disque

de ponçage et

la couronne de

brossage)

Aspiration intérieure [6-3]

(trous d'aspiration)

Aspiration de

particules de

grande taille,

p. ex. restes de

papiers peints

Aspiration de

petites particules, p. ex. enduit ou en cas

d'effet d'aspiration élevé

En fonction de la taille des particules de ponçage,

vous pouvez commuter entre aspiration intérieure

et aspiration extérieure.

Utilisez le commutateur [6-1] pour commuter f

l'aspiration.

Réglage de la puis-

sance d'aspiration

Vous pouvez adapter la puissance d'aspiration en

fonction du support.

La régulation peut uniquement avoir lieu si l'aspiration intérieure est activée (voir chap. «Réglage de

l’aspiration intérieure / extérieure»).

Utilisez la molette [1-5] pour régler la puis- f

sance d'aspiration.

1 : puissance d'aspiration faible

6 : puissance d'aspiration élevée

Commencez avec une faible puissance d'aspi- f

ration (position 1) et augmentez-la lentement

jusqu'à ce qu'une pression soit perceptible.

Une puissance d'aspiration élevée permet un L

ponçage sans fatigue aux plafonds et sur les

murs.

Une puissance d'aspiration trop forte peut L

conduire à une vibration de la machine et détériorer le comportement de guidage. En outre,

la machine peut être surchargée et le circuit de

protection déclenche. La diode rouge clignote

lentement. Le système électronique commute

en vitesse de rotation de régénération. En pareil cas, vous ne devez en aucun cas continuer

de travailler jusqu'à ce que la machine soit à

nouveau refroidie.

26

Page 27

7-1

1

Ponçage près des bords

Du fait du segment à brosse démontable, vous

pouvez réduire la distance latérale entre le mur /

plafond et le plateau de ponçage.

Maintenez le bouton [7 f -1] pressé.

Retirez le segment à brosse [7-2]. f

Le couvercle du SYSTAINER est pourvu d'un L

compartiment de rangement pour le segment

à brosse.

Pour le montage, engagez le segment à brosse f

du côté opposé au bouton [7-1], puis pivotez-le

vers la tête de ponçage jusqu'à ce qu'il s'emboîte.

Aspiration

8

7

7-2

8-1

8-4

L'inhalation de poussières peut être nocive pour

les voies respiratoires !

Raccordez toujours la machine à un dispositif f

d'aspiration.

Portez une protection des voies respiratoires si f

les travaux génèrent des poussières.

2

8-2

1

2

8-3

Les raccords d'aspiration [8-2] permettent de

brancher un aspirateur Festool avec un tuyau

d'aspiration de diamètre 27 mm ou 36 mm (recommandé en raison d'une plus grande puissance

d'aspiration).

Le tuyau d'aspiration spécial avec le manchon L

spécial [8-1] (disponible en tant qu'accessoire)

garantit une fi xation durable et une protection

anti-brisure améliorée.

Dans le cas de grandes surfaces, utilisez l'as- L

pirateur mobile CT 36 E AC-LHS, étant donné

qu'il garantit en permanence la puissance

d'aspiration nécessaire à cet égard.

Ouvrez le dispositif de blocage mécanique [8-3] f

en pressant le bouton vert [8-4].

Branchez le tuyau d'aspiration de l'aspirateur f

sur la tubulure d'aspiration [8-2].

Pivotez le dispositif de blocage mécanique [8-3] f

vers le haut, jusqu'à ce qu'il s'engage.

ATTENTION

27

Page 28

Fonctionnement

Risques de blessures

Ne tenez pas la machine au niveau de la tête f

de ponçage.

Maintenez fermement la machine avec les f

deux mains.

Assurez-vous que tous les leviers de serrage f

sont fermés, avant de mettre la machine en

service.

Raccordez la machine au réseau électrique. f

Avant de mettre la machine en marche, gardez L

une petite distance entre la tête de ponçage et

la surface de ponçage.

Mettez la machine en marche. f

L'interrupteur marche / arrêt est équipé d'un L

déclencheur à minimum de tension. Ce dispositif empêche une remise en marche automatique après une coupure d'alimentation (p. ex.

panne de courant). Pour remettre la machine

en marche après une coupure d'alimentation,

pressez à nouveau l'interrupteur marche /

arrêt [1-4].

Exécutez les travaux de ponçage. f

Ne surchargez pas la machine en exerçant L

une pression trop importante ! Pour obtenir

des résultats optimaux, il convient d'exercer

une pression modérée. Les performances de

ponçage et la qualité du ponçage dépendent

essentiellement du choix de l'abrasif.

Arrêtez la machine après la fi n des travaux de f

ponçage.

AVERTISSEMENT

9-1

28

9

9-2

Signaux d'avertissement visuels sur la tête de

ponçage

Les signaux visuels suivants apparaissent au

niveau de la LED [9-2] sur le carter moteur, et

la machine régule le cas échéant une vitesse de

rotation plus basse.

Clignotement lent de la LED

La machine est surchauffée du fait d'un fort

encrassement des fentes d'aération et du fi ltre

antipoussières [9-1].

Nettoyez les fentes d'aération. f

Retirez le fi ltre antipoussières [9-1]. f

Eliminez les dépôts. f

Insérez le fi ltre antipoussières [9-1], jusqu'à ce f

qu'il s'engage de façon audible.

Page 29

Le clignotement s'éteint après le nettoyage et L

le refroidissement de la machine. Vous pouvez

poursuivre votre travail.

Si la LED clignote toujours, malgré le nettoyage

du tamis fi ltrant et des fentes d'aération:

Réduisez la force d'appui. f

Réduisez la puissance d'aspiration au moyen f

de la molette [1-5].

Clignotement rapide de la LED

En cas de dysfonctionnement de la transmission

de la vitesse de rotation entre la poignée et le

moteur, le moteur augmente la vitesse de rotation jusqu'à la vitesse maximale après la mise en

marche et la LED [9-2] clignote simultanément

à fréquence rapide tant que la machine est en

marche.

Il y a présence d'un dysfonctionnement interne. L

La machine doit être contrôlée par un atelier

de service après-vente agréé.

Pour assurer la circulation de l'air, il est im- f

pératif que les fentes d'aération du boîtier

moteur soient systématiquement maintenues

dégagées et propres. Tenez compte des indications concernant les signaux d'avertissement

visuels, voir chapitre »Fonctionnement».

Gardez le curseur de contact dans un état pro- f

pre. Nettoyez-le régulièrement. N'utilisez pas

d'objets durs à cet égard.

L'appareil est équipé de charbons spéciaux à

coupure automatique. Lorsque ceux-ci sont usés,

l'alimentation est coupée et l'appareil s'arrête.

Si les leviers de serrage ne présentent pas la L

force de blocage nécessaire, il convient de les

resserrer :

Vissez les vis sur les leviers de serrage [3-1] f

et [3-2] d'env. 1/8 de tour.

Accessoires et outils

Entretien

Risque d'accident, risque d'électrocution

Avant toute intervention sur la machine, dé- f

branchez toujours la fi che secteur de la prise

de courant.

Les travaux d’entretien et de réparation né- f

cessitant une ouverture du carter moteur ne

doivent être effectués que par le personnel

d’un atelier autorisé du service après-vente.

La maintenance ou la réparation de l’outil par

des personnes non autorisées peut entraîner

un branchement incorrect de câbles électriques ou d’autres composants, ce qui peut provoquer des accidents avec blessures graves.

Contrôlez régulièrement le connecteur et le f

câble, et, en cas d'endommagement, faites

les remplacer par un atelier de service aprèsvente agréé.

AVERTISSEMENT

Pour des raisons de sécurité, il faut utiliser exclusivement des accessoires

et outils d’origine Festool!

Les références des accessoires et outils fi gurent

dans le catalogue Festool ou sur Internet sous

www.festoolusa.com.

Systainer

De nombreux produits Festool sont fournis dans

une caisse exclusive, appelée «Systainer». Celleci permet de protéger et de ranger des outils et

des appareils complémentaires. Les Systainer

sont empilables et peuvent être solidarisés. En

outre, il se fi xent sur les aspirateurs CT Festool.

29

Page 30

Pour ouvrir le Systainer:

Tournez le T-loc [10- – 1] à la position

Pour fermer le Systainer:

Tournez le T-loc [10-1] à la position –

Pour connecter deux Systainers:

Placez un Systainer au dessus de l’autre –

(Fig. 10A).

Tournez le T-loc [10-1] à la position –

(Fig. 10B).

Les Systainers sont combinés.

Un Systainer de la nouvelle génération peux L

être attaché au dessus d’ un Systainer de l’ancienne génération par les quatre loquets de

l’ancien Systainer.

ou

Elimination

.

.

Ne jetez pas les outils électriques avec les ordures

ménagères ! Eliminez les appareils, les accessoires et les emballages de façon compatible avec

l’environnement. Respectez en cela les dispositions nationales en vigueur.

Garantie

Conditions de la garantie (1+2 ans)

Vous avez droit à une prolongation de garantie

gratuite (1 an + 2 ans = 3 ans) sur votre outil

électrique Festool. Festool assumera tous les

coûts d’expédition pendant la première année de

la garantie alors que les deuxième et troisième

années, les coûts devront être assumés par le

client. Festool paiera les frais de retour de l’outil

au client par service de livraison terrestre UPS.

La garantie est valable pour une période de 3 ans

à compter de la date d’achat indiquée sur votre

reçu ou votre facture.

30

Garantie limitée de Festool

Cette garantie est valable à condition que l’outil

soit utilisé conformément aux instructions de

Festool. Festool garantit, à l’acheteur initial seulement, que l’outil indiqué sera exempt de tout

défaut de matériau et de fabrication pendant un

an à compter de la date d’achat. Festool ne donne

aucune garantie supplémentaire, implicite ou explicite, sur les instruments portables électriques

Page 31

Festool. Aucun agent, représentant commercial,

distributeur, vendeur ou employé de Festool n’est

autorisé à prolonger ou à modifi er les obligations

ou restrictions de la présente garantie. Les obligations de Festool sont, à son entière discrétion,

limitées à la réparation ou à l’échange des outils

portables électriques Festool trouvés défectueux

dans le présent emballage, tels que fournis avec

le présent Guide d’utilisation.