Page 1

Sanding with built-in dust conveying system.

NEW!

MULTI JETSTREAM Sanding System

Tools for the toughest demands

Page 2

Let's not talk about holes. But about

performance. The MULTI JETSTREAM

principle with built-in dust

conveying.

High material removal capacity with maximum dust extraction.

Thanks to its unique functional principle, the patented

MULTI JETSTREAM pad guarantees significantly improved sanding

results combined with time and cost benefits. The MULTI JETSTREAM

is not defined by the number of extraction holes but rather by the

perfect interaction of intake and exhaust air. An air flow is thus

created that actively conveys the sanding dust to nearest extraction

channel. The result: Virtually 100% dust extraction to ensure a

constantly high material removal rate and top surface quality.

A suction performance up to 6 times faster ensures cleaner fastener

and abrasives, thus resulting in longer service lives. The additional

cooling of the work surface reduces clogging of the abrasive and,

once again, improves the quality of the work results.

Unique worldwide – the

MULTI JETSTREAM principle:

2 2

Better suction performance: only pad with built-in dust conveying X

system based on cleverly distributed intake and exhaust air channels

Longer service life of abrasives, sanding pads and tools X

Perfection in the system: Ideal interplay of tool, pad and abrasive X

for healthier, ergonomic work

Page 3

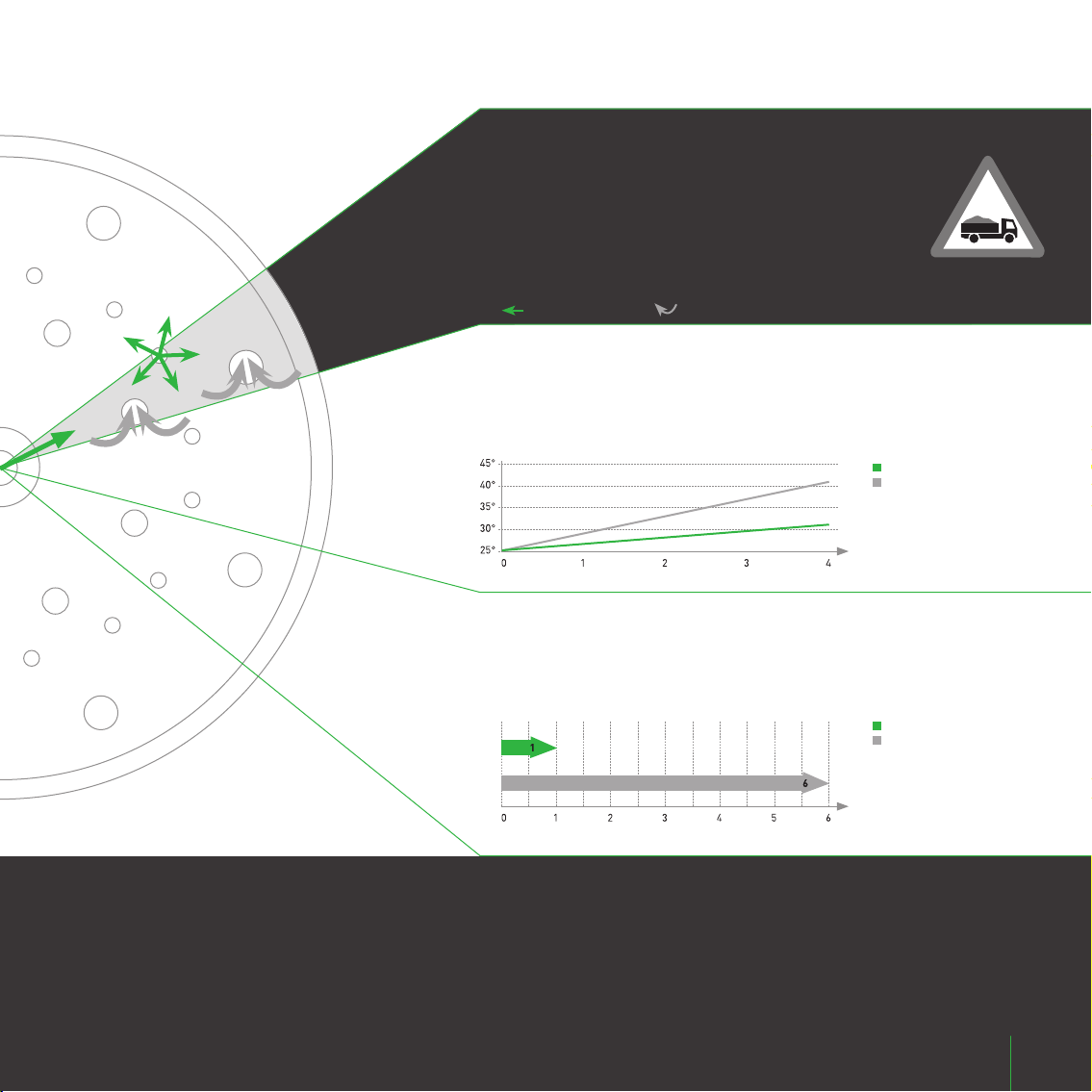

Built-in dust conveying system

A flow is created between the intake and ex haust air

channels similar to ventilation of a room. It collects the dust

and acti vely conveys it to the ex traction channels. Thank s to

the ingenious arr angement of the channels, the dust is

extrac ted ever ywhere on the pad. In only one second at a

rate of 97.2%.*

Intake air channels Exhaust air channels

25% cooler fastener

The MULTI JETSTREAM principle supplies cool intake air for the fastener,

abrasive and work surface. Clogging and obstructions are effectively

prevented.

Festool MULTI JETSTREAM

Competitor product

Temperature on the fastener

after 4 min. sanding:

MULTI JETSTREAM 31°,

Minutes

Competitor 41°

Dust-free, 6 x faster

Thank s to the fast dust extr action, the fastener and abrasi ve remain free of

dust for longer periods. The sanding effect remains high, the service life

increases.

Festool MULTI JETSTREAM

Competitor product

Sanding pad free of dust:

MULTI JETSTREAM after 1 s,

Competitor after 6 s

Seconds

* Festool testing laboratory,

Top extraction effect with maximum sanding capacity X

June 2009

Fast abrasive change thanks to symmetrical hole pattern X

9-hole-compatible: existing pads and abrasives can still be used X

Outstanding surface results X

ww w.festool.co.uk

33www.festool.com

Page 4

Makes the MULTI JETSTREAM principle even

more valuable: the MULTI JETSTREAM

sanding system.

Unbeatable combination – the

MULTI JETSTREAM sanding

system:

X

Health protection through

minimal vibrations

X

Increased surface quality

thanks to perfect smooth

running

X

Sustained, ergonomic

work

X

99.9% of the dust is

extracted*

The perceptible differences include the smooth running, guide

behaviour and hardly noticeable vibrations. A minimal 0.3 mm

axial runout was measured compared to up to 1 mm with other

systems. The optical difference is the dust-free sanding surface. All of this proves that the MULTI JETSTREAM principle in

the system with Festool abrasives, sanders and mobile dust

extractors is superior to any other combination. Perceptible,

measurable and visible. Reflected in improved health and work

results.

Film for the system now available under ww w.festool.co.uk* Festool mobile dust extractor, dust class M

4 4

Page 5

Sanding pad | Ranges of application

Sanding pad Order no.

FastFix

ST-STF D150/17MJ-FX-SW Extra soft, for high arches and curves, elastic

construction

ST-STF D150/17MJ-FX-W-HT Soft, for heavy-duty and universal use, new

HT fastener

ST-STF D150/17MJ-FX-H Hard, for flat surfaces and nar row edges, high

edge strength, new HT fastener

PT-STF D150 MJ-FX Polishing pad 4961 51

M8

ST-STF D150/17MJ-M8-SW Extra soft, high arches and curves, elastic

construction, connecting thread M8

ST-STF D150/17MJ-M8-W-HT Soft, new HT fastener for univers al use of flat and

arche d surfaces, for heavy-duty use with gr its up

to P220, connecting thread M8

ST-STF D150/17MJ-M8-W Soft, for univer sal us e on flat and cur ved

surfaces, connection thread M8

ST-STF D150/17MJ-M8-H Hard, for flat surfaces and nar row edges, high

edge strength, connecting M8, new HT fastener

PT-STF D150 MJ-M8 Polishing pad, connec ting thread M8 4961 52

5/16"

ST-STF D150/17 MJ 5/16" 496210

Inter face pad

IP-STF D 150/17 MJ Damping element bet ween sanding disc and pad,

for sanding curved par ts and eccentric sanding

4961 44

4961 47

496149

4961 45

4961 48

4961 60

4961 50

496647

FESTOOL RO 150 FEQ

FESTOOL ETS | WTS | LEX 150

HAMACH RUPES | ORK A | DESOUT TER

55www.festool.co.uk

Page 6

Abrasives | Ranges of application

Abrasives Application

For painting applications such as:

Acr ylic enamels, nitro lacquer, undercoat •

lacquer

Repair compound, fine and polyester filler•

Ther mopl astic and fibre-reinforced •

plastics

Undercoat, filler, protective paint, primer•

Filler (polyester filler, 2-component •

materials)

Repair compound•

Old paint layers•

P40-400

P4 0-12 0

Paint and lacquer

Preliminary, intermediate

and final sanding

Paints, la cquers and

fillers

Coar se, rapid preliminary

sanding

Grit

Package contents

Order no.

P40 10 496579 P100 100 49658 8

P60 10 496580 P120 100 4965 89

P80 10 4965 81 P150 100 49659 0

P120 10 496582 P180 100 496591

P180 10 49658 3 P220 100 496592

P320 10 4965 84 P240 100 496593

P40 50 496585 P320 100 496594

P60 50 496586 P4 00 10 0 496595

P80 50 496587

P40 10 496596 P40 50 496601

P60 10 496 597 P60 50 496 602

P80 10 496598 P80 50 496603

P100 10 49659 9 P10 0 100 496 604

P120 10 496600 P120 100 496605

Grit

Package contents

Order no.

NEW

6

P2 4-18 0

P2 4-12 0

P500–P3000

Wood

Preliminary and

intermediate sanding

Hard un dercoats,

coatings, old paint

Extreme load in coarse

sanding

Hard surfaces

Finishing

Hard wood•

Soft wood•

Tropical wood•

Wood composites•

Primed wood•

Coatings and old paints•

Coar se preliminary s anding with high •

temperature development

Fibre-reinforced plastic s•

Sanding extremely hardened fillers•

Sanding heavily worn stairs•

Sanding of uncoated, roughened metal •

surfaces

Debur ring, rust removal, de-sc aling•

Scratch-resistant clear coats (ceramic •

clear v arnishes)

UV paints•

Conventional paint systems•

Light s anding of hard cataphoretic coatings•

Hard mineral mater ials•

GRP composites•

Stainless steel and non-ferrous metals•

P50 10 496606 P36 50 49 6613

P80 10 496607 P50 50 49 6614

P100 10 49660 8 P80 50 496 615

P120 10 496609 P100 50 49 6616

P150 10 496 610 P 120 50 4 96617

P180 10 49 6611 P 150 50 49 6618

P24 50 49 6612 P180 50 49 6619

P24 5 49662 0

P36 5 496621

P50 5 496622

P80 5 496623

P24 25 496624

P36 25 496625

P50 25 496626

P80 25 496 627

P100 25 496 628

P500 2 49 6512

P1000 2 496513

P2000 2 496 514

P3000 2 496 515

Page 7

Abrasives Application

Repair compound, filler

P40-500, P80 0-F 3000

S400 - S4 000

and lacquer s

Preliminary, intermediate

and final sanding

Miner al materials,

high- gloss pain ts and

plastics

Finishing

Filling material s, sy nthetic resin, •

nitro -cellulose, thick-layer and

combination filler s, priming filler

Primers, reaction pr imers•

2-component mater ials•

Water-dilutable paints•

Light s anding / matt sanding of varnish •

prior to repainting

Finishing work on:

Filler products•

Finish sanding for polishing preparation, •

from grit 60 0, for mineral materials such

®

as Cor ian

Acrylglas, Plexiglas

PUR high-gloss paint•

Water-dilutable paints•

, Varicor®, Cristalan®,

®

Grit

Package contents

Order no.

P40 50 496629 P280 10 0 496638

P60 50 496630 P320 100 496639

P80 50 4966 31 P360 10 0 496 640

P100 100 49663 2 P400 100 49 66 41

P120 100 496633 P500 100 49664 2

P150 100 496634 P800 100 496643

P180 100 496635 P1200 10 0 49236 3

P220 100 49663 6 P150 0 100 49 2364

P240 100 496637 P3000 100 492365

Grit

Package contents

Order no.

S400 15 4923 68

S500 15 492 369

S1000 15 492370

S2000 15 492371

S4000 15 492372

Wood, paints, lacquers

A100, A2 80, S 800

P40-5 00

NEW

High material

remov al capacit y,

long service life

Order from a re tail ou tlet or on the Inter net under w ww.festool.co.uk

and metals

Light s anding, cleaning,

degreasing and matting

Repair compound, fillers ,

clear coats (especially

VOC clear coats)

Preliminary, intermediate

and final sanding

Remov ing oxidation (efflorescence) from •

light metals

Polishing of ferrous and non-ferrous •

metal s, solders and welds

Pore deep cleaning of natural woods, •

veneered and glaze d surfaces

Light s anding old coats of paint before •

repainting

Oiling and waxing of natural wood•

The most modern paint systems•

VOC clear coats•

Toughest undercoats•

Plastics, mineral materials, acrylic•

A100 5 482778

A280 5 482779

S800 5 482780

Green 10 4965 08

White 10 496509

P40 10 497151 P120 10 0 496979

P60 10 497152 P150 100 496980

P80 10 497153 P180 100 496981

P120 10 49 7154 P220 100 496982

P180 10 497155 P240 100 496983

P320 10 49 7156 P280 10 0 496984

P40 50 496975 P320 100 496985

P60 50 496976 P360 100 49698 6

P80 50 4969 77 P400 100 496987

P100 100 49697 8 P500 100 496988

7www.festool.co.uk

Page 8

Tools for the toughest demands

TTS Tooltechnic Systems AG & Co. KG

Wertstraße 20

D-73240 Wendlingen

represented by:

TTS Tooltechnic Systems GB Ltd

Saxham Business Park

Saxham

Bury St Edmunds

Suffolk

IP28 6RX

GREAT BRITAIN

Phone: +44 (0) 1284 760791

Fax: +44 (0) 1284 702156

E-mail: info@festool.co.uk

Deal er

Errors and omissions excepted. Products may differ from those pictured.

Created for TTS Tooltechnic Systems AG & Co. KG, 73240 Wendlingen, 07/09

Festool

MULTI JET STREAM

Valid a s of Septemb er 2009

Order No. 60660

www.festool.co.uk

Loading...

Loading...