Page 1

Instruction manual

Page 3 - 11

IMPORTANT: Read and understand all instructions before

using.

Guide d’utilisation

Page 13 - 21

IMPORTANT: Lire et comprendre toutes les instructions

avant de démarrer les travaux.

Manual de instrucciones

Pagina 22 - 31

IMPORTANTE: Lea y comprende todas las instrucciones

antes de usar.

475235_003

Instruction manual

Guide d’utilisation

Manual de instrucciones

MFT/3 MFT/KAPEX

Page 2

2

Page 3

Table of Contents

Technical data 3

Symbols 4

Design 4

Intended use 4

MFT/3: Setting up and assembly 5

Step 1: Setting up 5

Step 2: Trim splinter guard 5

Step 3: Setting up the guide rail support 6

Step 4: Attaching the guide rail 7

Step 5:

Step 6: Calibrating angle 8

Step 7: Adjusting the pre-set profi le set-

Step 8: Adjusting the guide rail in rela-

Step 9: Adjusting the cutting depth for

MFT/KAPEX: Mounting the KAPEX 10

Attaching the pre-set profi le setting

rail 7

ting rail 8

tion to the workpiece 9

sawing [Fig. 11] 9

Health hazard by dust

Various dust created by

power sanding, sawing, grinding, drilling

and other construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products,

• Arsenic and chromium from chemically-

treated lumber.

The risk from these exposures varies, depending on how often you do this type of

work.

To reduce your exposure to these

chemicals work in a well ventilated area and use approved

safety equipment, such as dust

masks that are specially designed to fi lter out

microscopic particles.

Maintenance 10

Turning the perforated top 10

Accessories, tools 10

Warranty 11

The multifunction table offers a wide range of application options! To fi nd out more L

about possible machine applications, order the MFT application manual on the internet.

INJURY, USER MUST READ AND UNDERSTAND INSTRUCTION MANUAL.

TO REDUCE THE RISK OF

Technical data

MFT/3

Bench dimensions

(width x length)

Bench height

1157 x 773 mm

MFT/KAPEX

Bench dimensions

(width x length)

Bench height

869 x 581 mm

- with foldaway legs 900 mm

- without foldaway legs

max. working width 700 mm

max. workpiece thickness

Weight 28 kg

180 mm

78 mm

- with foldaway legs 790 mm

- without foldaway legs 180 mm

Weight 18 kg

3

Page 4

Symbols

Intended use

Warning of general danger

Read the Operating Instructions/

Notes!

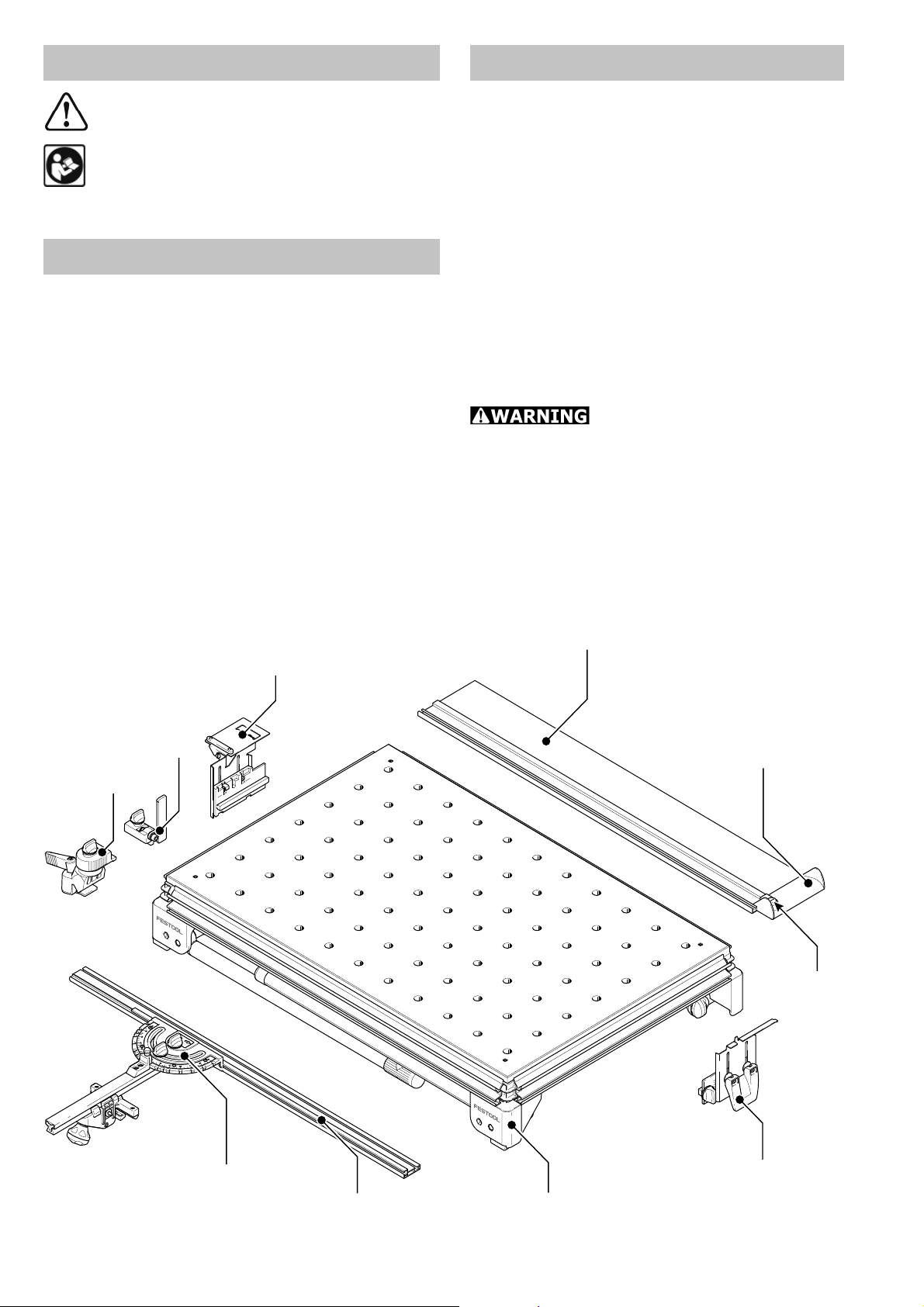

Design

MFT/3 and MFT/KAPEX

[1-1] Bench consisting of: profi le frame,

corner feet, perforated top, foldaway legs

MFT/3 only

[1-2] Support unit

[1-3] Guide rail FS 1080

[1-4] Swivel unit

[1-5] Pre-set profi le setting rail and

[1-6] Stop ruler

The multifunction table MFT/3 is designed for safe, accurate sawing and

routing in combination with Festool electric power tools.

The clamping systems included in the accessories programme enable the user to

attach workpieces securely to the worktop. The base becomes a work bench for

various tasks such as planing, sanding,

carving, etc.

The multifunction table MFT/KAPEX was

specially designed for attaching the

KAPEX KS 120.

The user bears the responsibility for damage and accidents caused

by improper use.

[1-7] Additional clamp for stop ruler

[1-8] Stop fl ag MFT/3-AR

[1-9] Defl ector

1-4

1-4

1-8

1-8

1-7

1-7

1-3

1-3

1-9

1-9

1

1-10

1-10

1-5

1-5

1-6

1-6

4

1-1

1-2

Page 5

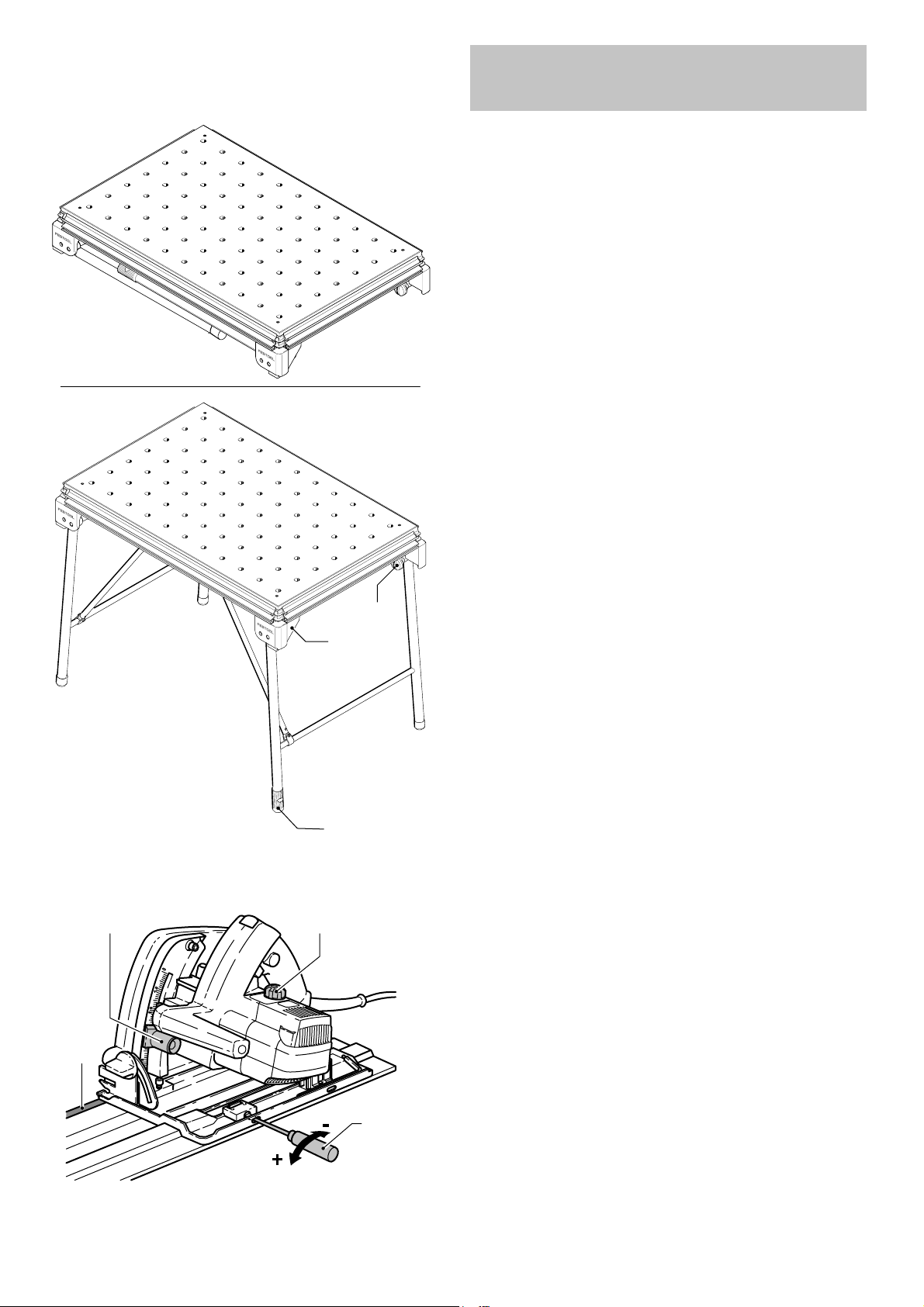

MFT/3:

Setting up and assembly

Accessory attachments can be secured at

different points on the multifunction table

to enable different working positions.

In the standard working position, the user

stands along one side of the bench [Fig. 2].

In these operating instructions, this side of

the bench is referred to as the "front".

Step 1: Setting up

Take the table out of the box. Screw on

the knobs [2-3] until the stop is reached.

Unfold the foldaway legs and tighten the

knobs on the joints to secure. Turn the end

cap [2-1] on the right to adjust the length

of the leg and compensate for an uneven

fl oor surface.

2

3-1

3-2

2-2

2-1

2-3

NOTE: The corner feet [2-2] are fi tted

with rubber caps so that the bench stands

securely when the legs are folded away.

Step 2: Trim splinter guard

Now you are ready to set up the guide rail

system. The fi rst thing to do is to trim the

splinter guard [3-4] of the guide rail using

your Festool plunge-cut saw.

3-4

3-3

3

Place your saw on top of the guide rail

and tune it to the track on the rail using a

screwdriver [3-3] to loosen or tighten the

front and back set screws so that there

is no play between the sole plate of the

saw and he raised portion of the guide

rail. However, make sure that the saw still

glides smoothly on top of the guide rail.

5

Page 6

REAR

REAR

FRONT ( Working side)

4-4

Adjust the speed of the saw [3-2] to a

setting of „6“ (maximum speed). Set the

depth of cut, using the depth stop adjustment [3-1], to 8 mm (5 mm for the thickness of the guide rail plus 3 mm cutting

depth) and cut the splinter guard along

the full length without interruption.

For trimming the splinter guard it is best

to use some sort of backing piece, such as

plywood or fi berboard.

The edge of the splinter guard now corresponds exactly to the cutting edge.

Step 3: Setting up the

guide rail support

The table comes from the factory with two

stops [4-2, 4-4] pre-set on the long sides

of the profi le frame, opposite each other.

These are recommended working positions

for the support unit [4-2] and swivel unit

[4-4].

4-5

4-1

4-2

4-3

FRONT ( Working side)

4

NOTE: During transport it is possible that

the set screws holding the stops may have

loosened. If this is the case, you will have

to position and retighten the registering

stops. Facing the front of the table, the

measurement is 8 3/4’’ from the side face

of the profi le frame at the right side of the

table. Facing the rear, the stop is approximately 7 2/3’’ from the side face at the left

side of the table.

The swivel unit [4-4] is mounted on the

rear long side, the support unit [4-2] on

the front side.

Both units are inserted into the profi le

groove from the left up to the stops with

the height adjustment [4-2] and the rotary knob [4-1] released, and then clamped

with the rotary knob [4-1].

6

Page 7

5

6-1 6-2

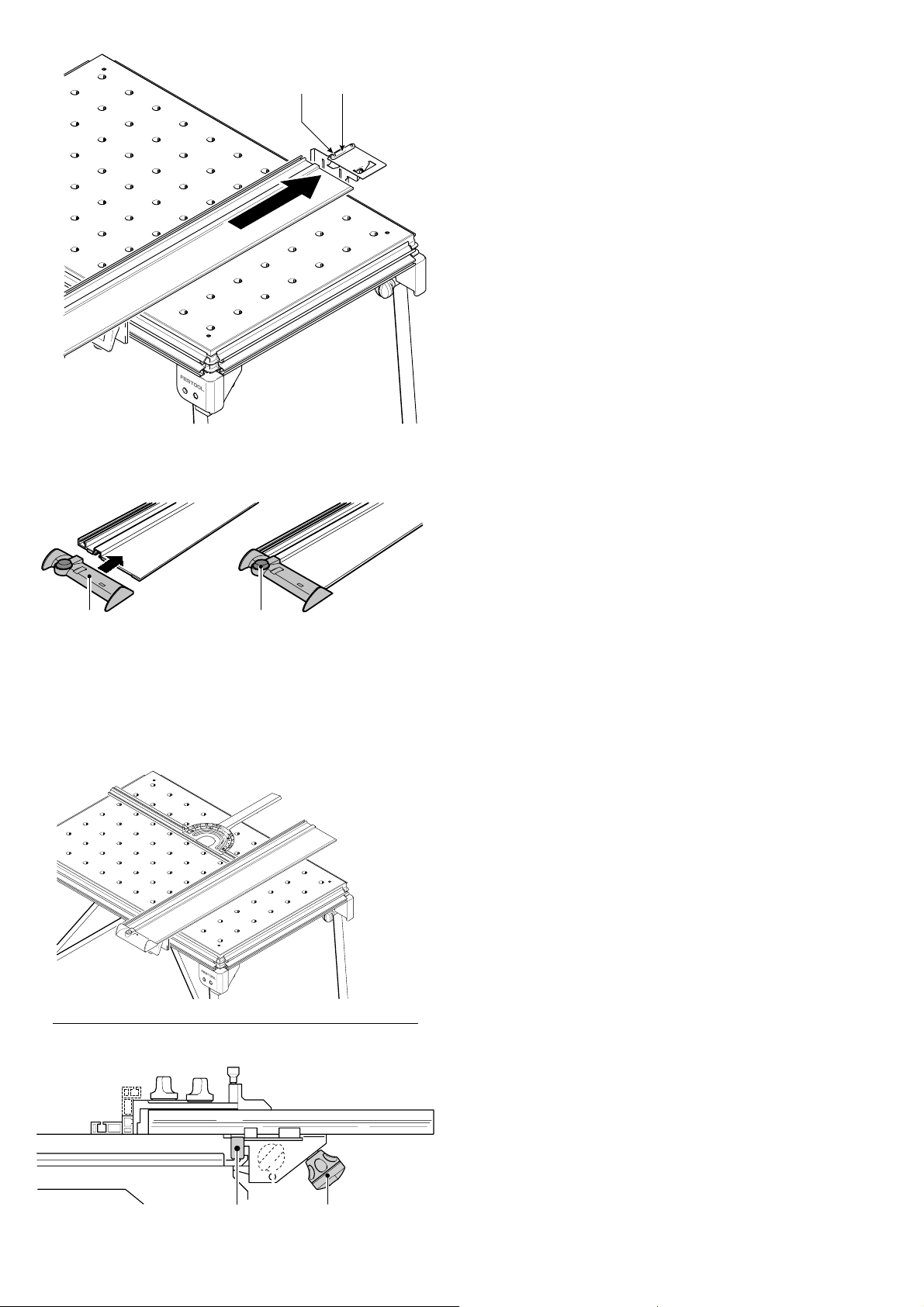

Step 4: Attaching the guide rail

5-25-1

To attach the guide rail, place on the key

[5-2] and make sure that the end of the

rail is resting on the support plate and the

key is located correctly in the groove.

Secure the guide rail in this position with

the two screws [5-1] and tighten using the

hexagon wrench.

Lower the guide rail onto the support unit

so that the groove in the underside of the

guide rail fi ts on to the pin [4-5] of the

support unit. The guide rail is properly attached when only a very slight lateral pressure is necessary for the pin to engage into

the guide rail.

The defl ector [6-1] is pushed onto the end

of the guide rail. Close the rotary knob

[6-2]. The defl ector prevents the extrac-

tion hose and the power cable from catching on the guide rail.

6

7

Step 5:

Attaching the pre-set

profi le setting rail

The rail can be attached at any point along

the clamping edge of the bench and is so

versatile, it can be used as a cross stop or

a longitudinal stop.

NOTE: Before attaching, make sure that

the V groove on the fence is not dirty.

Open the clamping jaws using the knob

[7-2]. Place the fence with guide rail [7-1]

onto the clamp rail from above. Secure the

clamp segment using the knob [7-2].

7-1

7-2

7

Page 8

8

9-1

90°

9-2

9-3

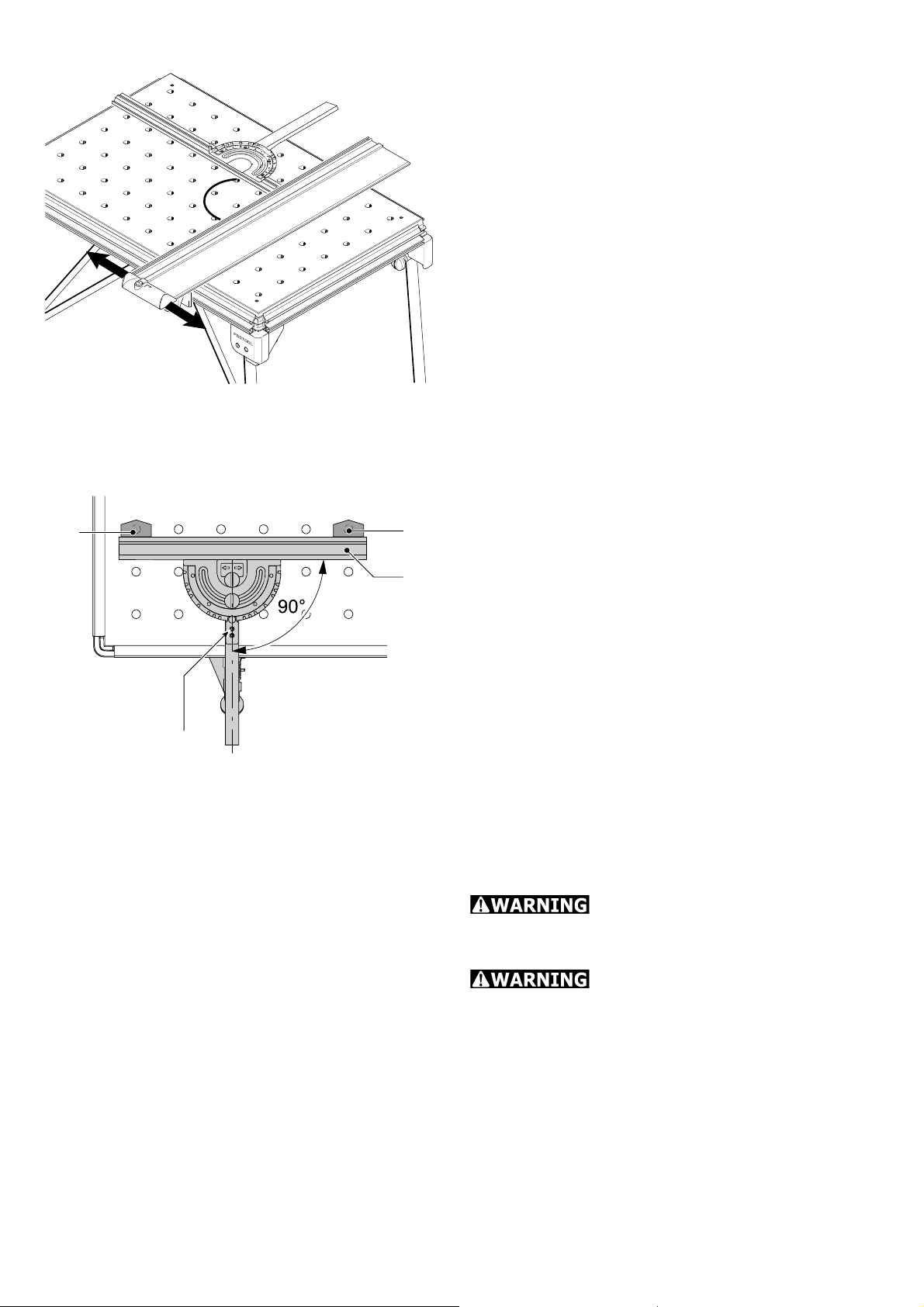

Step 6: Calibrating angle

Check the angle setting of the pre-set profi le setting rail before starting work. Align

the guide rail fi rst of all [Fig. 8].

Align the guide rail at right angles to the

pre-set profi le setting rail. If an angle of

90° is not possible, slide a support unit on

the guide rail until the angle is correct. Secure the guide rail.

NOTE: Slide the relevant stop [4-3] along

the table profi le to retain the setting per-

manently.

If required, the pre-set profi le setting rail

can also be aligned in relation to the perforated top provided the necessary clamps

(accessories) are available.

Insert the clamps [9-1] and [9-2] as shown

in Fig. [9] and move the stop ruler [9-3] to

a 90° position.

If the stop ruler does not rest evenly

against the clamps:

9

9-4

Loosen the screws [9-4] and the rotary

knob [7-2]. The retaining pin must be engaged in the 90° notch.

Set the angle at 90° in relation to the

clamps and tighten the screws.

Step 7: Adjusting the pre-set

profi le setting rail

Risk of injury! Always use

the fence in a fi xed position and do not use

to slide the workpiece along!

Risk of injury! Make sure

that all rotary knobs on the fence are tightened before starting work.

The fence can be adjusted in the following

ways:

8

Page 9

10-1

10-2 10-3

Adjustment parallel to the bench edge:

Loosen the rotary knob [10-4].

10-6

10

10-5

10-4

Adjustment at right angles to the

bench edge:

Loosen the rotary knob [10-4].

Adjusting the stop ruler [10-5]

lengthways

Loosen the rotary knob [10-1]. The stop

ruler can be moved to a lower position for

thin workpieces or a higher position for

thicker workpieces.

Angle adjustment using the scale

Loosen the rotary knob [10-2] and lift the

retaining pin [10-3]. The rotary retaining

pin engages in the most common angle

positions.

Step 8: Adjusting the guide rail

in relation to the workpiece

max. 5 mm

For sawing and routing applications, the

guide rail can be lowered via [1-2] and

[1-4] so that the rail rests evenly on the

workpiece. The workpiece and the rail are

retained securely.

A support piece of suitable thickness is

placed centrally under the guide rail between

the workpiece and the support unit [1-2] so

that the guide rail does not tilt when narrow

workpieces are machined.

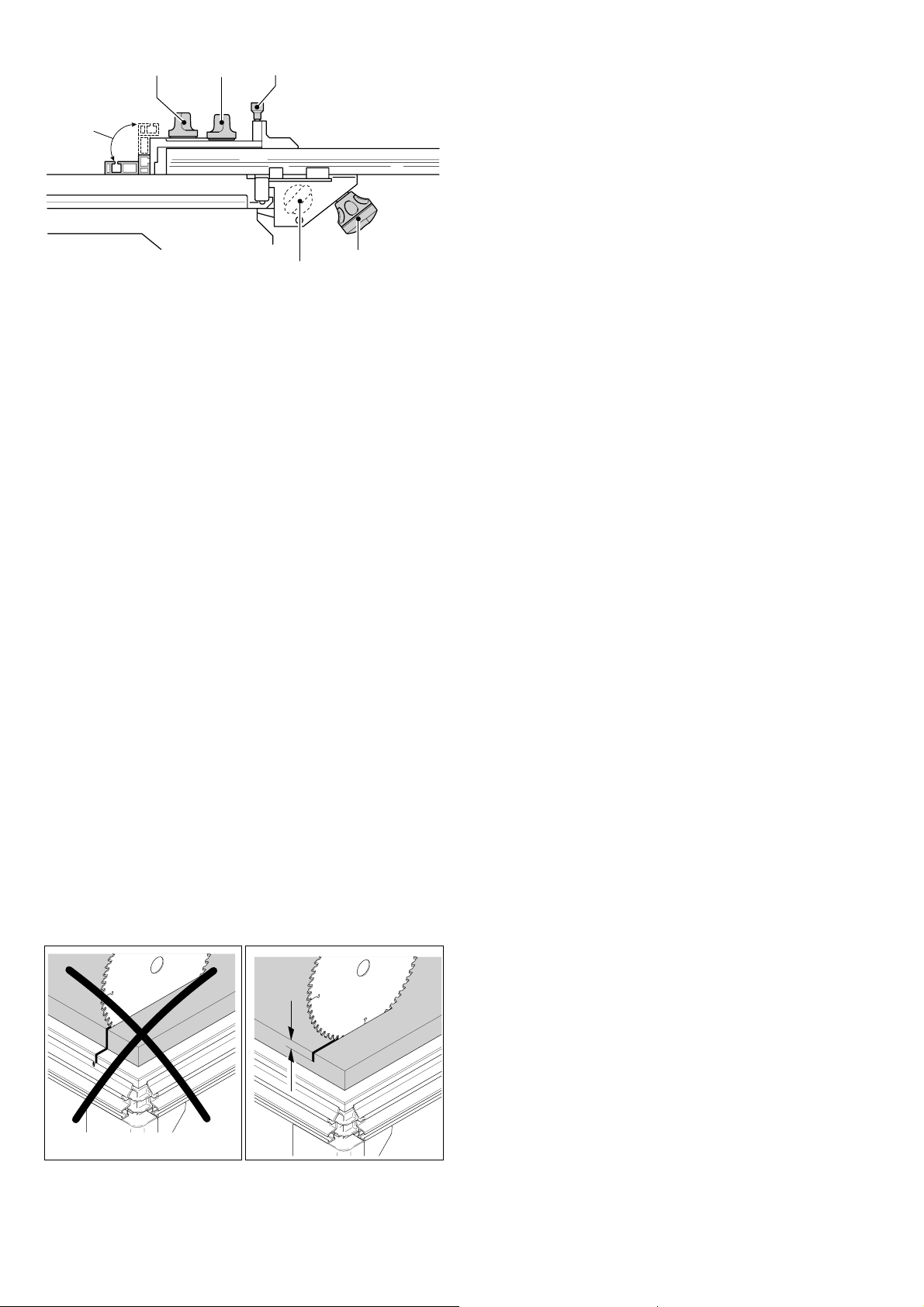

Step 9: Adjusting the cutting

depth for sawing [Fig. 11]

Always make sure that the cutting depth

setting is correct in relation to the workpiece

thickness. We recommend setting a cutting

depth to a maximum of 5 mm more than

the workpiece thickness to protect the profi le frame from damage.

11

9

Page 10

12

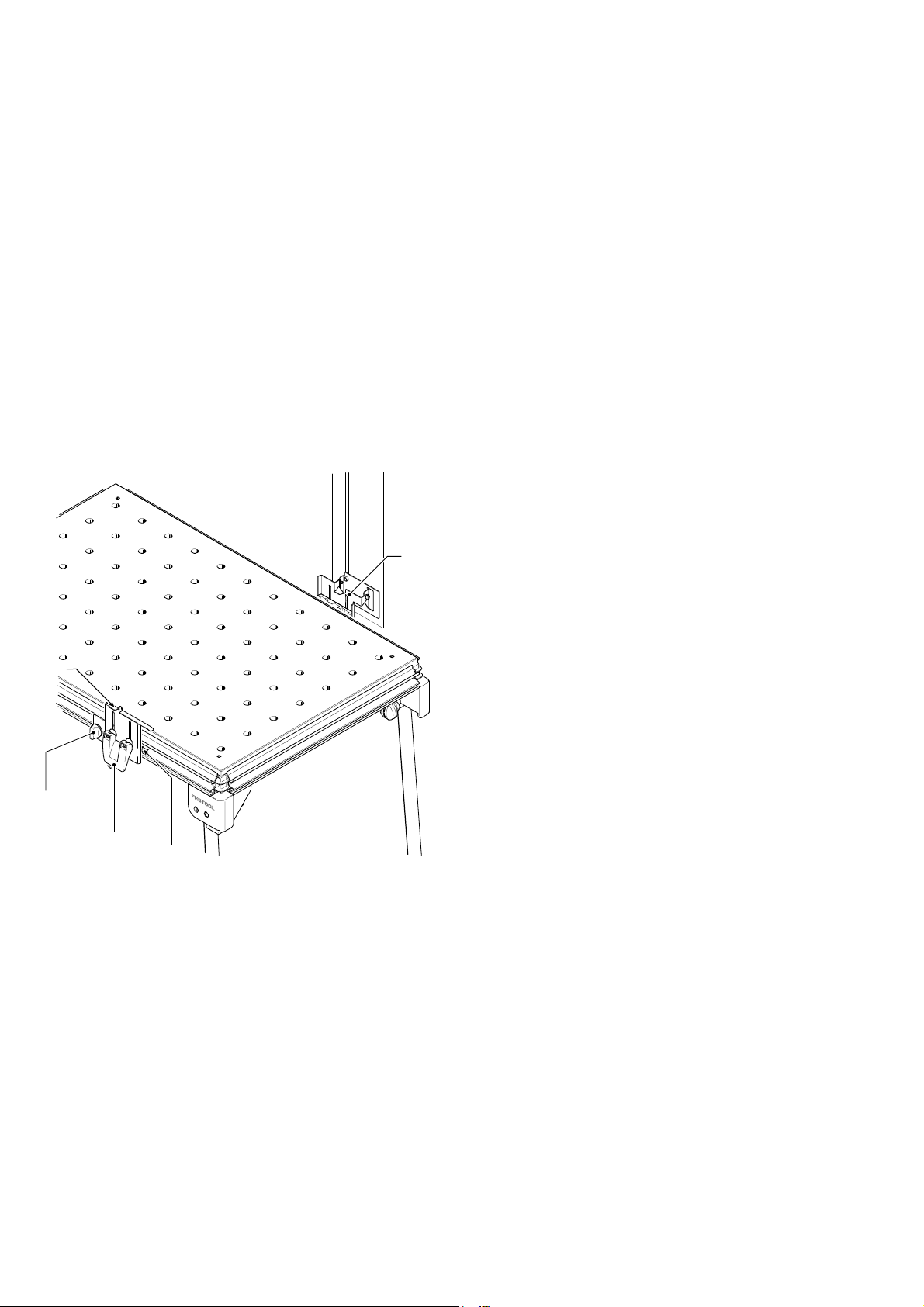

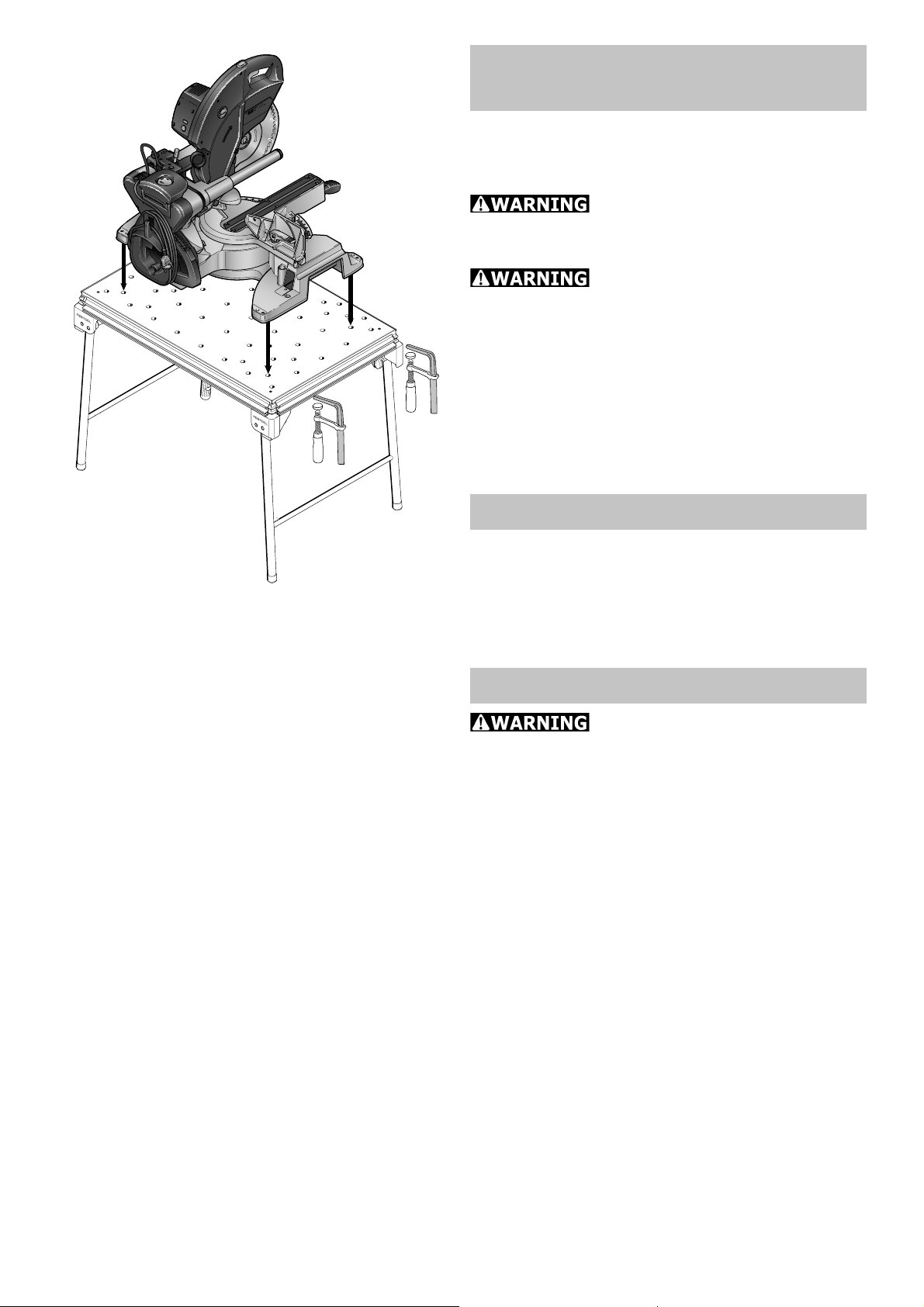

MFT/KAPEX:

Mounting the KAPEX

The perforated top on the MFT/KAPEX was

specially designed for mounting the KAPEX

KS 120.

Risk of injury! Before start-

ing work, make sure that the machine is

secured properly

Risk of injury! Respect the

maximum workpiece dimensions.

Mount the machine on the MFT/KAPEX as

shown in Fig.[12].

Secure the machine to the MFT using

clamps.

Maintenance

Turning the perforated top

When worn on one side, the perforated top

can be turned over. Loosen the four screws

in the corners underneath the bench.

Accessories, tools

For safety reasons, only

use original Festool accessories and

tools!

The accessory and tool order number can

be found in the Festool catalogue or on the

Internet under www.festool-usa.com.

10

Page 11

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1 year + 2 years = 3 years) for

your Festool power tool. Festool shall be

responsible for all shipping costs during

the fi rst year of the warranty. During the

second and third year of the warranty the

customer is responsible for shipping the

tool to Festool. Festool will pay for return shipping to the customer using UPS

Ground Service. All warranty service is

valid 3 years from the date of purchase on

your receipt or invoice.

Festool Limited Warranty

This warranty is valid on the pre-condition

that the tool is used and operated in compliance with the Festool operating instructions. Festool warrants, only to the original consumer purchaser, that the specifi ed

tool will be free from defects in materials

and workmanship for a term of one year

from the date of procurement. Festool

makes no other warranty, express or implied, for Festool portable power tools. No

agent, representative, distributor, dealer

or employee of Festool has the authority

to increase or otherwise change the obligations or limitations of this warranty. The

obligations of Festool in its sole discretion

under this warranty shall be limited to the

repair or replacement of any Festool portable power tool that is found to be defective as packaged with the User Manual.

Excluded from coverage under this warranty are: normal wear and tear; damages

caused by misuse, abuse or neglect; dam-

age caused by anything other than defects

in material and workmanship. This warranty does not apply to accessory items

such as circular saw blades, drill bits, router bits, jigsaw blades, sanding belts, and

grinding wheels. Also excluded are “wearing parts”, such as carbon brushes, lamellas of air tools, rubber collars and seals,

sanding discs and pads, and batteries.

Festool portable power tools requiring replacement or repair are to be returned

with the receipt of purchase to Festool (call

800-554-8741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF

THIS OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED WHATSOEVER.

ALL WARRANTIES IMPLIED BY STATE

LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY LIMITED TO THE

DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian provinces do not allow the limitations

on how long an implied warranty lasts, so

the above limitation may not apply to you.

With the exception of any warranties implied by state or province law as hereby

limited, the foregoing express limited warranty is exclusive and in lieu of all other

warranties, guarantees, agreements and

similar obligations of Festool.

This warranty gives you specifi c legal rights

and you may also have other rights which

vary from state to state in the U.S. and

province to province in Canada.

11

Page 12

12

Page 13

Table des matières

Caractéristiques techniques 13

Symboles 14

Eléments fournis 14

Utilisation conforme aux

prescriptions 14

MFT/3:Installation et montage 15

Etape 1: Installation 15

Etape 2: Sciage du pare-éclats 15

Etape 3: Mis en place des fi xations

du rail de guidage 16

Etape 4: Fixation de la réglette

de butée 16

Etape 5: Montage de la guide-butée

angulaire 17

Etape 6: Réglage de la butée angulaire 17

Etape 7: Réglage de la guide-butée

angulaire 18

Etape 8: Réglage du rail de guidage par

rapport à la pièce 19

Etape 9: Réglage de la profondeur de

coupe pour le sciage [fi gure 11]

19

MFT/KAPEX: Installation de l'outil

KAPEX 20

Maintenance 20

Retournement de la plaque trouée 20

Accessoires, outils 20

Garantie 21

La poussière, un ris-

que pour la santé

Certaines poussières

créées par le ponçage mécanique, le sciage,

le meulage, le perçage et autres activités

reliées à la construction contiennent des

substances chimiques connues (dans l’État

de la Californie) comme pouvant causer

le cancer, des anomalies congénitales ou

représenter d’autres dangers pour la reproduction. Voici quelques exemples de telles

substances:

plomb provenant de peintures à base de •

plomb,

silice cristallisée utilisée dans les briques, •

le ciment et autres matériaux de maçonnerie, et

arsenic et chrome du bois d’œuvre traité •

avec un produit chimique.

Le risque d’exposition à de tels produits

varie selon la fréquence à laquelle vous

faites ce genre de travail.

Pour réduire les risques d’expo-

sition à ces substances chimi-

ques : travaillez dans un endroit

adéquatement ventilé et utilisez un

équipement de sécurité approuvé, tel

que masques antipoussières spécialement conçus pour fi ltrer les particu-

les microscopiques.

POUR RÉDUIRE LE

RISQUE DE DOMMAGES, L'UTILISATEUR DOIT LIRE ET COMPRENDRE LE

MANUEL D'INSTRUCTION.

La table multifonctions offre des possibilités d’utilisation multiples ! Si vous souhaitez L

en savoir davantage sur les champs d’application de l’appareil, veuillez commander

le manuel d’utilisation MFT sur le site Internet.

Caractéristiques techniques

MFT/3

Dimensions de la table

(largeur x longueur)

Hauteur de la table

- avec pieds rabattables

- sans pieds rabattables

largeur de travail max.

Epaisseur de pièce max.

Poids

1157 x 773

mm

900 mm

180 mm

700 mm

78 mm

28 kg

MFT/KAPEX

Dimensions de la table

(largeur x longueur)

Hauteur de la table

- avec pieds rabattables 790 mm

- sans pieds rabattables 180 mm

Poids 18 kg

869 x 581

mm

13

Page 14

Symboles

prescriptions

Avertissement de danger

Lire les instructions / les remarques !

Eléments fournis

MFT/3 et MFT/KAPEX

[1-1] Table, composée de : cadre profi lé,

pieds angulaires, plaque trouée,

pieds rabattables

uniquement MFT/3

[1-2] Unité d'appui

[1-3] Rail de guidage FS 1080

[1-4] Unité orientable

[1-5] Guide-butée angulaire et

[1-6] Règle de butée

[1-7] Blocage additionnel pour règle de

butée

La table multifonctions MFT/3 est prévue

pour le sciage et le fraisage sûrs et précis

avec des outils électriques Festool.

Les systèmes de serrage proposés dans

la gamme des accessoires permet de serrer de façon sûre les pièces sur le plan de

travail. La table devient ainsi une table de

travail pour de nombreux travaux artisanaux tels que le rabotage, le ponçage, le

taillage, etc.

La table multifonctions MFT/KAPEX est

spécialement conçue pour le montage de

l'outil KAPEX KS 120.

L'utilisateur est responsable des dommages et accidents provoqués par une utilisation non conforme.

MFT/3:

[1-8] Curseur de butée MFT/3-AR

[1-9] Défl ecteur

Utilisation conforme aux

1-8

1-8

1-7

1-7

1-4

1-4

1-3

1-3

1

1-9

1-9

1-10

1-10

14

1-5

1-5

1-6

1-6

1-2

1-1

Page 15

Installation et montage

Les éléments rapportés de la table multifonctions peuvent être montés en divers

endroits, ce qui permet différentes positions de travail.

En position de travail standard, l'opérateur

se trouve du côté de la longueur de la table [fi g. 2]. Dans cette notice, ce côté de

la table est désigné par le terme "avant".

Etape 1: Installation

Déballez la table. Dévisser les poignées

[2-3] jusqu'en butée. Déplier les pieds rabattables et les visser à nouveau au niveau

des articulations au moyen des poignées.

Les irrégularités de niveau peuvent être

compensées derrière à droite en tournant

le capuchon d'extrémité [2-1].

2

3-1

3-2

2-2

2-1

2-3

Remarque: Les pieds angulaires [2-2]

sont pourvus sur la partie inférieure de capuchons en caoutchouc, afi n que la table

repose également de façon stable lorsque

les pieds rabattables sont repliés.

Etape 2: Sciage du pare-éclats

Vous êtes maintenant en mesure de monter le système de guidage. D‘abord, il vous

faut scier le pare-éclats [3-4] du rail de

guidage avec votre scie circulaire plongeante Festool.

Positionnez votre scie sur le rail de guidage et adaptez-la au rail en desserrant

ou en serrant les vis avant et arrière avec

un tournevis [3-3]. Il ne doit y avoir aucun

jeu entre la semelle de la scie et le profi lé du rail de guidage. Assurez-vous que

la scie coulisse bien sur le rail de guidage

même sans serrer.

3-4

3-3

3

Positionnez le variateur [3-2] de la scie

sur ‘‘6“(vitesse maximum). Réglez la profondeur de coupe avec le réglage de profondeur de coupe [3-1] sur 8 millimètres

(5 millimètres pour l‘épaisseur du rail de

guidage + 3 millimètres de profondeur de

coupe) et sciez le pare-éclats sans interruption sur l‘intégralité de la longueur.

15

Page 16

4-5

ARRIÈRE

AVANT

4-1

ARRIÈRE

4-4

Pour le sciage du pare-éclats, il est recommandé de s‘aider de contre-plaqué ou de

panneaux de particules.

L‘arête du pare-éclats correspond exactement à l‘arête de coupe.

Etape 3: Mis en place des

fi xations du rail de guidage

A la livraison, les longueurs du châssis en

profi lés sont munies de deux butées se

fraisant face [4-2, 4-4]. Ce sont les positions de travail recommandées pour l’unité

d‘appui [4-2] et la unité orientable [4-4]

du rail de guidage.

Remarque: Lors du transport, les vis de

serrage des butées peuvent se desserrer.

Dans ce cas, il vous faut repositionner et

bloquer les butées. Sur l‘avant de la table,

l‘écart de la butée avec le bord droit du

châssis en profi lés est de 8 3/4’’. Sur l‘ar-

rière de la table, l‘écart de la butée avec

le bord gauche du châssis en profi lés es

d‘environ 7 2/3’’.

4-2

AVANT

4-3

4

5-25-1

La unité orientable [4-4] se fi xe sur la lon-

gueur arrière, tandis que la unit d‘appui

[4-2] du rail de guidage sur fi xe sur la lon-

gueur avant.

Unie fois le réglage en hauteur [4-2] et la

molette [4-1] desserrés, insérez les deux

entités par la gauche dans la gorge du profi lé jusqu‘aux butées et serrez-les avec la

molette [4-1].

Etape 4: Fixation de

la réglette de butée

Pour monter le rail de guidage, celui-ci est

engagé sur les clavettes [5-2] de manière

à ce que le rail repose sur la tôle d'appui et

que les clavettes se trouvent entièrement

dans la rainure.

16

5

Le rail de guidage est vissé dans cette

position par le biais des deux vis [5-1], à

l'aide de la clé hexagonale fournie.

Abaissez le rail de guidage sur son sup-

Page 17

6-1 6-2

6

7

port, de sorte que les tenons [4-5] du support s’enclenchent dans la gorge située au

dos du rail de guidage. Le rail de guidage

est correctement positionné lorsque, sous

l’effet d’une légère pression latérale, les

tenons s’enclenchent dans la gorge du rail

de guidage.

Poussez le défl ecteur [6-1] en bout de rail.

Fermez le sélecteur de fonction [6-2]. Le

défl ecteur empêche un éventuel accrocha-

du tuyau d'aspiration et du câble électri-

ge

que au niveau du rail de guidage.

8

7-1

7-2

Etape 5: Montage de la guide-

butée angulaire

La butée peut être fi xée dans une position

quelconque sur la table. Du fait de sa possibilité de réglage multiple, elle peut être

utilisée en tant que butée transversale ou

en tant que butée longitudinale.

Remarque: Assurez-vous avant le montage de la butée que la rainure en V ne soit

pas encrassée (position à angle droit).

Ouvrez les mâchoires de serrage par le

biais de la poignée [7-2]. Posez la butée

avec la barre de guidage [7-1] sur la barre

de blocage, par le haut. Serrez le segment

de blocage à l'aide de la poignée [7-2]

.

90°

Etape 6: Réglage de la

butée angulaire

Avant le début des travaux, contrôlez la

position angulaire de la guide-butée angulaire. A cet égard, le rail de guidage doit

être aligné au cours de l'étape 1 [Fig. 8].

Alignez le rail de guidage à angle droit

par rapport à la guide-butée angulaire. SI

17

Page 18

9-1

9-2

9-3

l'angle n'est pas correct, décalez l'une des

unités d'appui du rail de guidage, jusqu'à

ce que l'angle soit de 90°. Fixez le rail de

guidage.

Remarque: Pour fi xer le réglage durable-

ment, décalez la butée [4-3] dans le profi lé de la table en conséquence.

Si nécessaire et en cas de présence d'éléments de serrage (accessoires), le guidebutée angulaire peut être aligné additionnellement au niveau de la plaque trouée.

Insérez les éléments de serrage [9-1] et

[9-2] comme illustré sur la fi gure [9] et

appliquez la règle de butée [9-3] contre,

en position 90°.

Si la règle de butée ne repose pas uniformément contre les éléments de serrage :

9

10-1

9-4

10-2 10-3

Ouvrez les vis [9-4] et le bouton de réglage [7-2]. La broche de fi xation doit être

engagée dans l'entaille à 90°.

Aljustez l'angle de 90° d'après les éléments de serrage et fermez les vis.

Etape 7: Réglage de la

guide-butée angulaire

Risques de blessures! Utilisez la butée uniquement en

position fi xe, et non pas pour pousser la

pièce!

Risques de blessu-

res! Assurez-vous avant le début des travaux que tous les boutons de réglage de la

butée sont serrés.

La butée permet les possibilités de réglage

suivantes :

10-6

10

18

10-5

10-4

Décalage parallèlement par rapport

au bord de la table :

Ouvrir le bouton de réglage [10-4].

Décalage perpendiculairement par

rapport au bord de la table :

Ouvrir le bouton de réglage [10-4].

Page 19

Décalage de la règle de butée [10-5]

dans le sens longitudinal

Ouvrir le bouton de réglage [10-1]. La règle de butée peut être fi xée sur le support

dans une position basse pour les pièces

minces ou dans une position haute pour

les pièces épaisses.

Décalage angulaire à l'aide de

l'échelle graduée

Ouvrir le bouton de réglage [10-2] et soulever la broche de fi xation [10-3]. La bro-

che de fi xation orientable s'engage aux

positions angulaires usuelles.

Etape 8: Réglage du rail de gui-

dage par rapport à la pièce

Pour le sciage et le fraisage, le rail de guidage est abaissé au moyen de [1-2] et

[1-4] jusqu'à ce que le rail repose à plat

sur la pièce à travailler. Ainsi, la pièce est

retenue de façon sûre avec le rail.

max. 5 mm

Afi n que le rail de guidage ne coince pas

lors de l'usinage de pièces minces, une

cale de même épaisseur est positionnée

au centre entre la pièce et l'unité d'appui

[1-2].

Etape 9: Réglage de la profon-

deur de coupe pour le sciage

[fi gure 11]

Assurez-vous que la profondeur de coupe soit toujours réglée correctement par

rapport à l'épaisseur de la pièce. Nous recommandons de régler une profondeur de

coupe au maximum 5 mm plus grande que

l'épaisseur de la pièce. De ce fait, vous éviterez d'endommager le cadre profi lé.

11

19

Page 20

MFT/KAPEX:

Installation de l'outil KAPEX

La plaque trouée de la table MFT/KAPEX

est spécialement conçue pour le montage

de l'outil KAPEX KS 120.

Risques de blessu-

res! Assurez-vous de la bonne fi xation de

l'outil avant de commencer les travaux!

Risques de blessu-

res! Observez les dimensions de pièces

maximales.

Montez l'outil sur la table MFT/KAPEX,

comme illustré sur la fi gure [12].

Fixez l'outil sur la table MFT à l'aide de serre-joints.

12

Maintenance

Retournement de la plaque

trouée

Après usure, vous pouvez retourner la plaque trouée. Pour ce faire, ouvrez les quatre vis dans les coins, sur le côté inférieur

de la table.

Accessoires, outils

20

Pour des raisons de

sécurité, il faut utiliser exclusivement

des accessoires et outils d’origine

Festool!

Les références des accessoires et outils

fi gurent dans le catalogue Festool ou sur

Internet sous www.festool-usa.com.

Page 21

Garantie

Conditions de la ga-

rantie (1+2 ans)

Vous avez droit à une prolongation de garantie gratuite (1 an + 2 ans = 3 ans) sur

votre outil électrique Festool. Festool assumera tous les coûts d’expédition pendant

la première année de la garantie alors que

les deuxième et troisième années, les coûts

devront être assumés par le client. Festool

paiera les frais de retour de l’outil au client

par service de livraison terrestre UPS. La

garantie est valable pour une période de 3

ans à compter de la date d’achat indiquée

sur votre reçu ou votre facture.

Garantie limitée de Festool

Cette garantie est valable à condition

que l’outil soit utilisé conformément aux

instructions de Festool. Festool garantit,

à l’acheteur initial seulement, que l’outil

indiqué sera exempt de tout défaut de

matériau et de fabrication pendant un an

à compter de la date d’achat. Festool ne

donne aucune garantie supplémentaire,

implicite ou explicite, sur les instruments

portables électriques Festool. Aucun agent,

représentant commercial, distributeur, vendeur ou employé de Festool n’est autorisé

à prolonger ou à modifi er les obligations

ou restrictions de la présente garantie. Les

obligations de Festool sont, à son entière

discrétion, limitées à la réparation ou à

l’échange des outils portables électriques

Festool trouvés défectueux dans le présent

emballage, tels que fournis avec le présent

Guide d’utilisation.

Cette garantie exclut l’usure normale, les

dommages causés par un usage impropre,

les abus ou la négligence, ou tout dommage

autre que ceux attribuables à des défauts

de matériau et de fabrication. Cette garantie ne s’applique pas aux accessoires

tels que lames de scie circulaire, mèches

de perceuse et vilebrequin, lames de scie

sauteuse, bandes abrasives et meules.

Sont également exclues les pièces d’usure,

telles que balais de charbon, lamelles pour

outils à air comprimé, joints et manchons

de caoutchouc, disques et patins ponceurs,

ainsi que les piles.

Les outils électriques portables Festool à

remplacer ou à réparer doivent être retournés avec le reçu d’achat à Festool (appelez

au 800-554-8741 pour connaître l’adresse

d’expédition).

FESTOOL N’EST EN AUCUN CAS RESPONSABLE DES DOMMAGES DIRECTS

OU INDIRECTS, IMPLICITES OU EXPLICITES, DÉCOULANT DE LA RUPTURE

DE CETTE GARANTIE OU DE TOUTE

AUTRE GARANTIE. TOUTES LES GARANTIES IMPLICITES, Y COMPRIS LES

GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET D’ADÉQUATION À UN

USAGE PARTICULIER, SONT LIMITÉES

À UNE PÉRIODE DE TROIS ANS.

Certains états américains et certaines

provinces canadiennes ne permettent pas

la limitation des garanties implicites; il se

pourrait donc que les limites indiquées cidessus ne s’appliquent pas dans votre cas.

À l’exception de certaines garanties implicites des provinces ou des états indiquées

ici, la présente garantie est exclusive et

remplace toute autre garantie, convention

et obligation similaire de Festool.

Cette garantie vous confère des droits

légaux spécifi ques, et vous pouvez aussi

avoir d’autres droits pouvant varier d’un

état à l’autre, ou d’une province à l’autre

au Canada.

21

Page 22

22

Page 23

Contenido

Datos técnicos 23

Símbolos 24

Dotación de suministro 24

Uso conforme a lo previsto 24

MFT/3: Instalación y montaje 25

Paso 1: Instalación 25

Paso 2: Serrar la protección anti-astillas

25

Paso 3: Fijar los soportes para el

riel de guía 26

Paso 4: Fijar el riel de guía 27

Paso 5: Montaje del tope angular

escalonado 27

Paso 6: Ajustar el tope angular 28

Paso 7: Ajuste del tope angular

escalonado 29

Paso 8: Ajuste del riel de guía a la pieza

de trabajo 29

Paso 9: Ajuste de la profundidad de corte

al serrar

MFT/KAPEX: Instalación

de la KAPEX 30

Mantenimiento 30

[Fig. 11] 30

Riesgos para la salud pro-

ducidos por el polvo

Algunos polvos creados

por lijadoras motorizadas, aserraderos, trituradores, perforadoras y otras actividades

de construcción contienen sustancias químicas que se sabe (en el Estado de California)

causan cáncer, defectos de nacimiento u

otros daños al sistema reproductivo. Algunos ejemplos de estas sustancias químicas

son:

Plomo de las pinturas con base de plo-•

mo

Sílice cristalino de los ladrillos y cemento •

y otros productos de mampostería, y

Arsénico y cromo de madera tratada con •

sustancias químicas

El riesgo de exposición a estas sustancias

varía, dependiendo de cuantas veces se

hace este tipo de trabajo.

Para reducir el contacto con estas sustancias químicas: trabaje

en un área con buena ventilación

y trabaje con equipo de seguridad aprobado, como mascarillas para

el polvo diseñadas específi camente

para fi ltrar partículas microscópicas.

Accesorios, herramientas 31

Garantía 31

La mesa multifuncional ofrece una gran variedad de posibilidades de uso. Si desea L

más información acerca de los campos de aplicación de la mesa, solicite el manual

del usuario de la MFT a través de Internet.

RIESGO DE LESIÓN, EL USUARIO DEBE

LEER Y ENTENDER EL MANUAL DE INSTRUCCIÓN.

PARA REDUCIR EL

Datos técnicos

MFT/3

Dimensiones de la mesa

(anchura x longitud)

Altura de la mesa

- con patas plegables 900 mm

- sin patas plegables 180 mm

Anchura máxima de

trabajo

1157 x 773

mm

700 mm

MFT/KAPEX

Dimensiones de la mesa

(anchura x longitud)

Altura de la mesa

- con patas plegables 790 mm

- sin patas plegables 180 mm

Peso 18 kg

869 x 581 mm

Espesor máximo de la

pieza de trabajo

Peso 28 kg

78 mm

23

Page 24

Símbolos

Uso conforme a lo previsto

Aviso ante un peligro general

¡Leer las instrucciones e indicaciones!

Dotación de suministro

MFT/3 y MFT/KAPEX

[1-1] Mesa compuesta por: bastidor de

perfi les, escuadras de apoyo, placa

perforada, patas plegables

sólo MFT/3

[1-2] Tope de apoyo

[1-3] Riel de guía FS 1080

[1-4] Tope giratorio

[1-5] Tope angular escalonado y

[1-6] Guía de tope

La mesa multifuncional MFT/3 es apropiada para serrar y fresar con seguridad y

precisión utilizando herramientas eléctricas Festool.

Los sistemas de fi jación ofertados en el

programa de accesorios permiten sujetar

de forma segura las piezas de trabajo sobre la base. La mesa se convierte así en

una base de trabajo ideal para muchas

aplicaciones, tales como cepillar, lijar, tallar, etc.

La mesa multifuncional MFT/KAPEX está

especialmente concebida para el montaje

de la KAPEX KS 120.

El usuario es responsable de los daños y accidentes producidos

por un uso indebido.

[1-7] Sujeción adicional para la guía de

tope

[1-8] Tope desplazable MFT/3-AR

[1-9] Derivador

1-4

1-4

1-8

1-8

1-7

1-7

1-3

1-3

1-9

1-9

1

1-10

1-10

24

1-5

1-5

1-6

1-6

1-2

1-1

Page 25

MFT/3:

Instalación y montaje

En la mesa multifuncional se pueden colocar los elementos adicionales en diferentes posiciones, dando como resultado distintas posiciones de trabajo.

En la posición de trabajo estándar el usuario se coloca en el lateral largo de la mesa

[Fig. 2]. En el presente manual de instrucciones, este lado de la mesa se denominará "frontal".

Paso 1: Instalación

Saque la mesa del embalaje. Atornillar los

ajustadores [2-3] hasta el tope. Desplegar

las patas y apretarlas con los ajustadores

de las articulaciones. Los posibles desniveles en la superfi cie de apoyo pueden elimi-

narse girando la caperuza de tope [2-1],

situada en la pata trasera derecha.

2

3-4

3-1

3-2

2-2

2-1

3-3

2-3

Atención: Las escuadras de apoyo [2-2]

están provistas de piezas de goma en su

parte inferior, gracias a las cuales la mesa

descansa con seguridad incluso con las

patas en posición plegada.

Paso 2: Serrar la protección an-

ti-astillas

Ahora está preparado para montar el sistema de guía. Primero debe serrar la protección anti-astillas [3-4] del riel de guía

con su sierra circular de incisión Festool.

Coloque su sierra sobre el riel de guía y

ajústela a éste afl ojando o apretando con

un destornillador [3-3] los tornillos de sujeción delanteros y traseros. No debe haber juego entre la placa base de la sierra

y el perfi l del riel guía. Asegúrese de que

la sierra aún sin fi jar se desliza por el riel

guía.

3

Sitúe el regulador de velocidad [3-2] de la

sierra en la posición ‘‘6’’ (velocidad máxi-

25

Page 26

ma). Ajuste la profundidad de corte con

parte posterior

delante

el regulador de profundidad de corte [3-1]

a 8 milímetros (5 milímetros para el grosor de riel de guía más 3 milímetros de

profundidad de corte), y sierre la protección anti-astillas sin apoyarse sobre toda

la longitud.

Para serrar la protección anti-astillas utilice preferentemente un apoyo como madera contrachapada o una placa de aglomerado.

El canto de la protección contra anti-astillas se corresponde exactamente con el

canto de corte.

Paso 3: Fijar los soportes para

el riel de guía

4-5

4-1

delante

4-2

4-3

parte posterior

4

4-4

En el suministro hay fi jados en los latera-

les de bastidor de perfi les dos topes en-

frentados. Estas son las posiciones de trabajo recomendadas para el tope de apoyo

[4-2] y para el tope giratorio [4-4] del riel

de guía.

Atención: es posible que durante el transporte se afl ojen los tornillos de fi jación de

los topes. En ese caso, debe colocar de

nuevo los topes y fi jarlos. En la parte de-

lantera de la mesa, la distancia del tope

con respecto al borde derecho del bastidor

de perfi les asciende a 8 3/4’’. En la parte

trasera de la mesa, la distancia del tope

con respecto al borde izquierdo del bastidor de perfi les asciende aproximadamente

a 7 2/3’’. En el lateral trasero se fi ja el tope

giratorio [4-4], en el lateral delantero se

fi ja el tope de apoyo [4-2] para el riel de

guía.

26

Con la tensión del ajuste en altura [4-2]

afl ojada y el botón giratorio afl ojado [4-1]

se introducen ambas unidades desde la izquierda hasta los topes en la ranura del

perfi l, y después se fi jan con el botón gi-

ratorio [4-1].

Page 27

5

Paso 4: Fijar el riel de guía

Para realizar el montaje del riel de guía,

5-25-1

se introducirá este en el resorte de ajuste [5-2] de tal forma que el riel descanse

sobre la chapa de apoyo y el resorte de

ajuste quede insertado por completo en la

ranura.

En esta posición se fi ja el riel de guía con

los dos tornillos [5-1] usando la llave de

espiga hexagonal suministrada.

Descienda el riel de guía sobre el tope de

apoyo de forma que el taco [4-5] del tope

de apoyo encaje en la ranura de la parte

inferior del riel de guía. El riel de guía está

correctamente fi jado si es sufi ciente con

una ligera presión lateral para que el taco

encaje en la ranura del riel de guía.

6-1 6-2

6

7

El derivador [6-1] se desplaza al fi nal del

riel de guía. Cerrar el botón giratorio. El

derivador evita que

piración y el cable de la corriente se puedan

enganchar en el riel de guí

el tubo fl exible de as-

a.

Paso 5: Montaje del tope angu-

lar escalonado

El tope puede colocarse en cualquier punto del borde de sujeción de la mesa. Su

versátil ajuste permite usarlo como tope

transversal o como tope longitudinal.

Atención: Antes de montar el tope, compruebe que la ranura en V no presente suciedad (debido a su angulosidad).

7-1

7-2

Afl oje las mordazas de sujeción del ajusta-

dor [7-2]. Coloque por arriba el tope junto

con el listón guía [7-1] sobre el listón de

apriete.

ajustador [7-2].

Fije el segmento de apriete con el

27

Page 28

8

Paso 6: Ajustar el tope angular

Antes de empezar el trabajo, compruebe

el correcto ajuste del tope angular escalonado. Para ello debe alinearse en primer

lugar el riel de guía [8].

90°

Alinee el riel de guía con el tope angular

escalonado mediante una escuadra rectangular. Si la escuadra no cabe, desplace

uno de los topes de apoyo del riel de guía

hasta que el ángulo formado sea recto.

Fije ahora el riel de guía.

Atención: Para fi jar este ajuste de for-

ma permanente, desplace correspondientemente el tope [4-3] en el perfi l de la

mesa.

Si fuera necesario y en caso de disponer

de elementos de sujeción (accesorios), el

tope angular escalonado puede alinearse

adicionalmente con la placa perforada.

9-1

9

9-4

9-2

9-3

Monte los elementos de sujeción [9-1] y

[9-2] como se muestra en la fi gura [9] y

desplace la guía de tope [9-3] hasta formar con ellos un ángulo de 90°.

Si la guía de tope no queda uniformemente nivelada en contacto con los elementos

de sujeción:

Afl oje los tornillos [9-4] y el botón gira-

torio [7-2]. La clavija posicionadora debe

estar enclavada en la muesca de 90°.

Alinee el angulo de 90° con los elementos

de sujeción y apriete los tornillos.

28

Page 29

Paso 7: Ajuste del tope angular

escalonado

Peligro de lesiones!

Utilice el tope sólo en posición fi ja y no para

desplazar la pieza de trabajo.

Peligro de lesiones!

Antes de empezar a trabajar, cerciórese de

que todos los botones giratorios del tope y

de la máquina están apretados.

El tope ofrece las siguientes posibilidades

de ajuste:

10-6

10

10-1

10-2 10-3

10-5

10-4

Posición paralela al borde de mesa:

Afl ojar el botón giratorio [10-4].

Posición perpendicular

al borde de mesa:

Afl ojar el botón giratorio [10-4].

Posición de la guía de tope [10-5]

en dirección longitudinal

Afl ojar el botón giratorio [10-1]. La guía

de tope puede fi jarse al soporte en una

posición más baja en caso de piezas de

trabajo fi nas, o bien subirse para piezas de

trabajo gruesas.

Ajuste del ángulo por

medio de la escala

Afl ojar el botón giratorio [10-2] y levantar

la clavija posicionadora [10-3]. La clavija

posicionadora giratoria encaja en los ángulos de uso más frecuente.

Paso 8: Ajuste del riel de guía a

la pieza de trabajo

A la hora de serrar y fresar, el riel de guía

debe desplazarse hacia abajo mediante [1-2] y [1-4] hasta que el riel quede

uniformemente apoyado sobre la pieza de

trabajo. La pieza de trabajo quedará así

inmovilizada de forma segura.

Para que el riel de guía no se ladee al trabajar con piezas de trabajo estrechas, se

coloca una pieza de apoyo de igual espesor debajo del riel de guía, de modo que

quede en una posición intermedia entre la

pieza de trabajo y el tope de apoyo [1-2].

29

Page 30

11

max. 5 mm

Paso 9: Ajuste de la profundi-

dad de corte al serrar [Fig. 11]

Asegúrese de que la profundidad de corte siempre esté ajustada correctamente

atendiendo al espesor de la pieza de trabajo. Recomendamos ajustar la profundidad

de corte con un margen máximo de 5 mm

sobre el espesor de la pieza de trabajo.

De esta manera evitará que el bastidor de

perfi les se dañe.

MFT/KAPEX:

Instalación de la KAPEX

12

La placa perforada MFT/KAPEX está especialmente concebida para el montaje de la

KAPEX KS 120.

Peligro de lesiones!

Antes de empezar los trabajos asegúrese

de que la máquina está sujeta de forma

segura.

Peligro de lesiones!

Tenga en cuenta las dimensiones máximas

de la pieza de trabajo.

Coloque la máquina sobre la MFT/KAPEX

tal como se describe en la fi gura [12].

Fije la máquina a la MFT sirviéndose para

ello de sargentos.

Mantenimiento

Reverso de la placa perforada

30

Cuando se haya desgastado, puede volver

la placa perforada. Afl oje para ello los cua-

tro tornillos de las esquinas situados en la

parte inferior de la mesa.

Page 31

Accesorios, herramientas

¡Por razones de seguridad, solamente deben emplearse

accesorios y herramientas originales

de Festool!

Los números de pedido para los respectivos

accesorios y herramientas se encuentran

en su catálogo Festool o en la dirección de

Internet www.festool-usa.com.

Garantía

Condiciones de la Ga-

rantía 1 + 2

Usted tiene derecho a una garantía extendida gratuita (1 año + 2 años = 3 años) para

su herramienta mecánica Festool. Festool

se hará responsable por los gastos de envío

durante el primer año de garantía. Durante

el segundo y tercer año de garantía el cliente es responsable por el costo del envío de

la herramienta a Festool. Festool pagará el

embarque de regreso al cliente usando UPS

Ground Service. Todo el servicio de garantía

es válido por 3 años desde la fecha de la

compra de acuerdo a la fecha de su recibo

o factura de compra.

Garantía limitada de Festool

Esta garantía es válida con la condición

previa de que la herra mienta se usa y opera

de conformidad con las instrucciones de

operación de Festool. Festool garantiza, sólo

al comprador original, que la herramienta

especifi cada estará libre de defectos de fa-

bricación y materiales durante un periodo

de un año a partir de la fecha de compra.

Festool no otorga otras garantías, ni explícitas ni implícitas para ninguna de las

herramientas mecánicas portátiles Festool.

Ningún agente, representante, distribuidor,

comerciante o empleado de Festool está

autorizado para extender o modifi car de

cualquier manera las obligaciones o limitaciones de esta garantía. Las obligaciones

de Festool, a su propia entera discreción,

están limitadas a la reparación o sustitución

de cualquier herramienta portátil Festool

que se encuentre estar defectuosa en el

momento de ser embalada junto con el

manual de usuario.

Quedan excluidos de la cobertura en esta

garantía: el desgaste normal; los daños

causados por uso indebido, el abuso o negligencia; los daños causados por cualquier

otra causa que no sean defectos del material o de la fabricación. Esta garantía no

aplica a accesorios como cuchillas de sierras

circulares, brocas de taladro, barrenas de

buriladora, cuchillas de sierra, cuchillas para

sierras de calado, correas de lijadoras y

ruedas de esmeril. También se excluyen las

“partes que se desgastan” como cepillos de

carbón, laminillas de herramientas de aire,

collarines de hule y sellos, discos y cojines

de lijado, y baterías.

Las herramientas mecánicas portátiles

Festool que requieran de reemplazo o reparación deben devolverse con el recibo de

compra a Festool (llame al 800-554-8741

para los detalles de la dirección).

EN NINGÚN CASO FESTOOL SE HARÁ

RESPONSABLE POR LOS DAÑOS SECUNDARIOS O CONSECUENTES OCASIONADOS POR LA VIOLACIÓN DE ESTA

O CUALUQUIER OTRA GARANTÍA, SEA

EXPLÍCITA O IMPLÍCITA. TODAS LAS

GARANTÍAS IMPLICADAS POR LEYES

ESTATALES, INCLUYENDO LAS GARANTÍAS IMPLICADAS DE COMERCIALIZACIÓN Y ADECUACIÓN A UN PROPÓSITO

PARTICULAR, QUEDAN LIMITADAS A

TRES AÑOS DE DURACIÓN.

Algunos estados de EE.UU. y algunas provincias de Canadá no permiten las limitaciones en cuanto a la duración de las garantías

implícitas, de modo que la limitación arriba

indicada puede que no le afecte. A excepción de algunas garantías implicadas por

leyes estatales o provinciales, limitadas por

la presente, la anteriormente citada garantía, expresamente limitada, es exclusiva y

sustituye a cualquier otra garantía, acuerdo

u obligación similar de Festool.

Esta garantía le concede derechos legales

específi cos y usted podría tener otros de-

rechos legales que varían de estado a estado en EE.UU. y de provincia a provincia

en Canadá.

31

Page 32

NOTES/ NOTACIONS/ NOTAS

32

Loading...

Loading...