Page 1

1 table.

1000 possibilities.

The multifunction table

MFT 3: arguably the most

versatile worktop in the world.

Tools for the

toughest demands

Page 2

Ready for use everywhere: the new MFT 3

For some people,

simply a table.

Practical for laying down tools and papers. Or for

making quick notes. Just like all tables. But you expect

something different from Festool: Tools and accessories

that facilitate your everyday work, developed by experts

for practical applications, and which t into the Festool

system perfectly. And all of this in the highest quality.

This is why a table from Festool is not simply a table.

2

Page 3

3

Page 4

4

For others it is arguably the

most versatile worktop in the world.

Modular work with the new MFT 3.

MFT 3 extension

Guide rail with

defl ector

CMS module

The new MFT 3 is a lot more than just a table. It is a work surface that

makes absolutely precise work possible. For example, with its guide rail

and angle stop. Screw clamps and clamping elements also have a secure

hold on your workpiece and the MFT 3 extension can be used to connect all

modules from the Compact Module System CMS and many CMS accessory

parts. And because Festool has a system concept, it is also compatible with

the new vacuum clamping system VAC SYS. In short: a table with 1000

possibilities.

Page 5

5

Screw clamps and

clamping elements

Vacuum clamping

system VAC SYS*

Adapter VAC SYS

Angle stop with sliding

fence, additional

clamping device and

stop slide

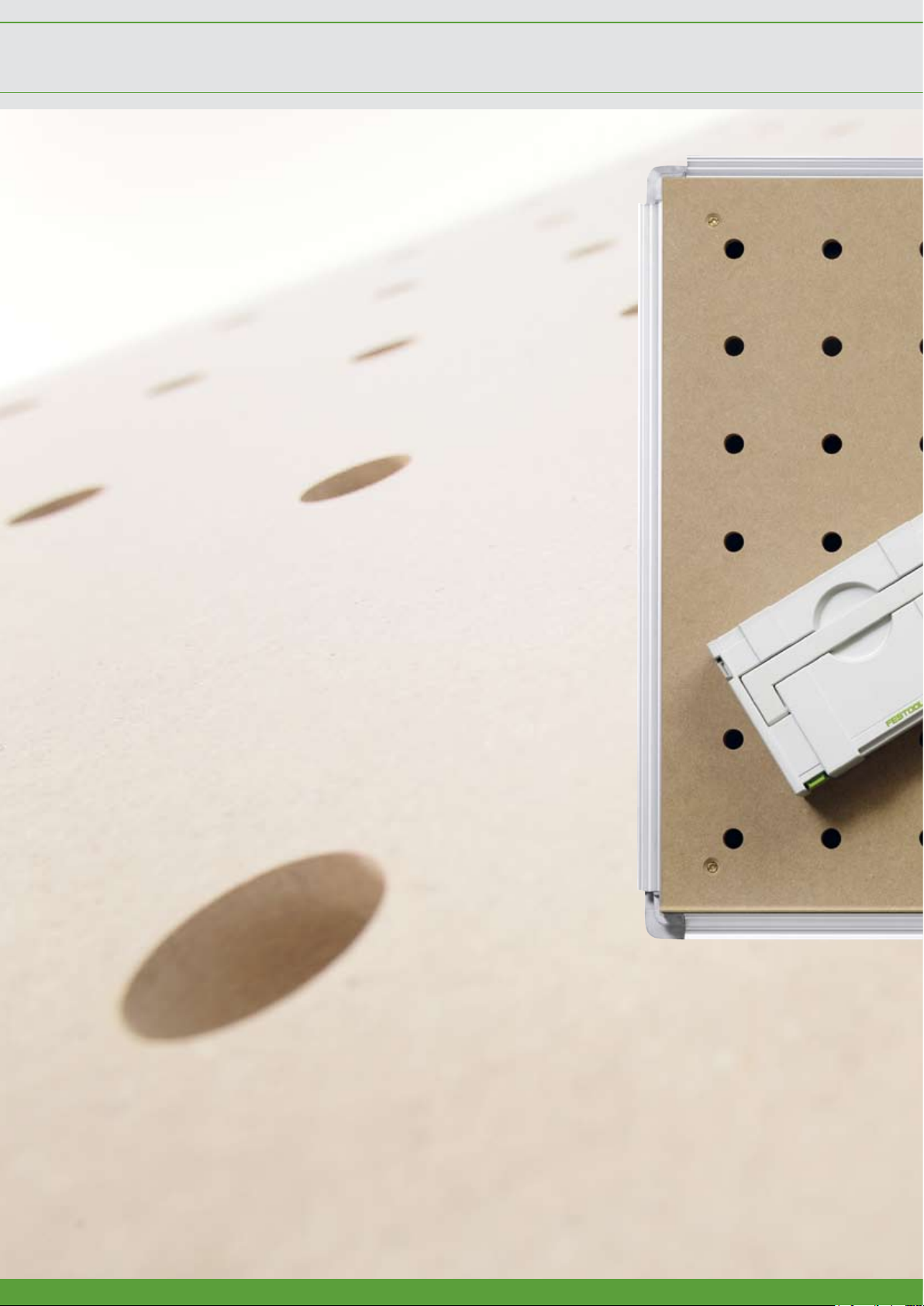

Perforated plate

Festool V-groove

* Available from autumn 2008

Page 6

The new MFT 3: versatile, precise and mobile.

Flexible work on a

secure base.

Precise results.

The guide rail can be set to different material thicknesses and

guarantees precise guidance of the Festool jig saw and handheld circular saw or router – for exact results. You can also

safely position and align your workpieces at the angle stop for

processing at the correct angle. Repeat cuts and even duplicate production are also possible with the help of the stop

slide.

Ergonomic and cost-efcient work.

The work height of 90 cm makes ergonomic work possible,

which is also easy on the back, even for taller users. Furthermore, the multifunction table MFT 3 can be folded away very

easily and is thus ideal for use in the workshop and mobile

on-site use.

Maximum support.

When sanding, planing, bonding or routing with templates, it is

important that the workpiece is held rmly on the table – irrespective of whether it is large, small, angular or round, the

MFT 3 offers you precisely this exibility. The perforated plate

allows you to clamp the objects to be processed simply and

quickly on the table top with the clamping elements optional.

Screw clamps are additionally provided for vertical and horizontal clamping.

6

Page 7

Extendable work surface

Connecting pieces allow several multifunction tables to be

joined laterally with one another. The larger work space thus

created permits you to easily clamp and process larger workpieces, or several workpieces at the same time.

Flexible and reliable with the new VAC SYS.

The clamping solution of the future: VAC SYS. This new product gives you the option for the rst time of turning your workpieces up to 360° and swivelling them by up to 90° – with a

single hand movement. You can now process workpieces from

all sides without having to secure the workpiece in a different

position. The new vacuum clamping system is connected to the

MFT 3 by an adapter plate. If the VAC SYS is not required for a

while, it can simply be swivelled

away.

Optimised connection to the CMS modular system.

You can use the Festool V-groove to connect the CMS modular

system and accessories to the MFT 3. This means that you

have circular saws, jig saws, routers and a belt sander available for your work. This increases the versatility of your workplace and you also have the option of executing several steps

in sequence without having to reclamp. In short: the MFT 3

becomes a mobile and efcient work station.

7

Page 8

The new MFT 3 with system accessories at a glance.

Whether as a table or work bench,

the MFT 3 has a lot to offer you.

Clamping difcult shapes.

Clamping elements provide smaller

workpieces with the support

required for safe and precise

processing.

Use of the guide rail.

The guide rail support can be

used to fold up the guide rail or

set the guide rail to different

material thicknesses.

Ideal work height.

With a work height of 90 cm, the

MFT 3 also permits taller users to

work ergonomically in a manner

that prevents back pain.

Optimised system connection.

The MFT 3 extension allows you to

use all CMS modules for sawing,

routing and sanding.

Ready for use everywhere.

The foldaway legs of the

MFT 3 allow it to be folded

away to save space and for

transportation.

8

Page 9

Horizontal and vertical clamping.

Using clamp clips and perforated plate and/

or prole section, the workpieces can be

secured at any point, simply and rmly.

Extended clamping options.

Through the connection of the new

vacuum clamping system VAC SYS.

Compatible with CMS thanks

to V-groove.

The new V-groove also permits the

use of many accessories of the

Compact Module System CMS at

the MFT 3.

Impressive stability.

The additional cross braces make

the MFT 3 even more stable and

can be folded in easily for

transportation.

System accessories (see page 11) not included in the scope of supply.

Precise results.

Workpieces can be positioned

exactly at the angle stop. The stop

slide makes exact repeat cuts and

even duplicate production possible.

Absolute precision is also guaranteed by the additional clamping

device, with which the sliding fence

is secured to the V-groove.

9

Page 10

All things considered: variable work with a system.

Multifunction table MFT 3

Applications

Safe clamping and securing of different workpieces

•

Precise processing of workpieces, also with connection to the

•

Compact Module System CMS

Extended clamping and securing options through the vacuum clamping

•

system VAC SYS, which can be connected to the MFT with adapters

Technical data

900 mm (180 mm)

Work height (folded in)

Overall dimensions

Work surface

Max. workpiece height

(when using the guide rail)

Max. workpiece width

Drill hole diameter

Drill hole pattern

Load capacity

Weight

900 mm (180 mm)

1157 x 773 mm

1157 x 773 mm

1102 x 718 mm

1102 x 718 mm

78 mm

78 mm

700 mm

700 mm

20 mm

20 mm

96 mm

96 mm

120 kg

120 kg

28 kg

28 kg

Version

Multifunction table MFT 3

Scope of delivery

Table with perforated plate and foldaway legs, angle stop, stop slide, additional clamping

device, guide rail FS 1080/2 with swivel unit, support unit and deector, contained in a box

Strengths and benets

Safe sawing and precise routing thanks to the guide rail

•

Angle stop, stop slide and additional clamping device ensure exact

•

results

Ergonomic work positioning thanks to the new table height of 90 cm

•

Mobile use of the MFT 3 through space-saving foldaway legs

•

Compatibility with Compact Module System CMS

•

Festool V-groove permits the use of many accessory parts of the

•

CMS modular system

Optional connection of the vacuum clamping system VAC SYS

•

Ideal connection to the Festool system

•

Order no.

495315

Further information on the products of the Festool system is available in the main catalogue, or under www.festool.co.uk

10

Page 11

System overview and accessories

1

4

2 3

5

System accessories

1

Additional clamping device

MFT/ 3-ZK

Stop slide MFT/3-AR

2

3

Cross brace MFT/3-QT

4

Extension MFT/ 3-VL

5

Connector VS

6

Perforated plate MFT 3-LP

Clamps MFT-SP

7

Clamps FSZ 120

8

9

Clamps FSZ 300

7

Lever clamp FS-HZ 160

10

Adapter VAC SYS AD-MFT/ 3

11

6 7 8 109

+

Explanations/Dimensions

For securing the stop rail to the V-groove

For stopping workpieces at the angle stop, can be folded away

For additional stabilisation of the table, qty. in pack: 2

Permits the use of the CMS modules

For joining several MFT 3s

Dimensions: length x width 1102 x 718 mm

For attaching workpieces safely and precisely for sawing, sanding, routing, drilling etc., qty. in pack: 2

Polished steel version, clamping range: 120 mm, qty. in pack: 2

Polished steel version, clamping range: 300 mm, qty. in pack: 2

Polished steel version, clamping range: 160 mm, qty. in pack: 1

Adapter plate for connecting the VAC SYS to the MFT/3

11

Order no.

495541

495542

495502

495510

484455

495543

488030

489570

489571

491594

494977

1111

Page 12

Your link to more information...

www.festool.co.uk

Home

About Festool

Products

Woodworking

Automotive

Customer Service

Press Area

Downloads

TTS Tooltechnic Systems GB Ltd

Saxham Business Park

Saxham

Bury St Edmunds

Suffolk, IP28 6RX

GREAT BRITAIN

Phone: +44 (0) 1284 760791

Fax: +44 (0) 1284 702156

E-mail: info@festool.co.uk

www.festool.co.uk

On our Festool website you can nd information about

the complete product range,

•

detailed introductions of our new products,

•

Dates of Exhibitions and Open Days with Festool,

•

the registration for our Festool Facts online

•

Newsletter,

Brochures, price lists, the catalogue and

•

user manuals for you to download,

countless product animations,

•

our comprehensive service offer,

•

interesting reports about Festool products from

•

the press,

exciting quiz and competitions - always with

•

the chance to win something great,

and all of this at your leisure.

Three Years warranty –

that means three years security

Festool grants a 2 year warranty from the

date of purchase, as long as the tool has

been used correctly. This warranty is automatically extended by a further year, provided that the warranty form with every

new tool is completed correctly and returned within 30 days of the date of

purchase.

Make a contribution yourself – support the

WWF together with Festool!

Dealer

Our most important contribution to preserving our environment is the quality of

our products, which are characterised by

their durability and positive eco-features

such as recyclability and environmental

compatibility.

By purchasing one of the promotional

products, you are supporting our collaboration with the WWF and will receive a

WWF panda keyring pendant as a thank

you gift.

© 1986 Panda symbol WWF – World Wide Fund For Nature

(Formerly World Wildlife Fund)

® „WWF“ and „living planet“ are WWF Registered Trademarks

www.festool.com/wwf

Type no. 59429

Subject to alterations and errors. All illustrations are non-binding. Created for TTS Tooltechnic Systems AG & Co. KG, DE - 73240 Wendlingen, 03/2008

Loading...

Loading...