Page 1

The Festool MFS Multi-Routing

Template System

A User's Guide by Brice Burrell

Contents

Introduction .................................................................................................................................................. 2

Connecting the MFS profiles. ................................................................................................................... 10

Template Routing with the MFS System .................................................................................................. 17

Inlays .......................................................................................................................................................... 27

Jack Miters, Stair Stringers, and Circle Cutting ....................................................................................... 41

Cutting Applications .................................................................................................................................. 58

Using the MFS As A Clamping Aid ............................................................................................................ 71

Miscellaneous Uses For the MFS ............................................................................................................. 74

Closing Thoughts ....................................................................................................................................... 78

© 2008-2009, Brice Burrell Page 1

Page 2

Introduction

Here is a look at the Festool MFS 400 and MFS 700, multi-routing template system.

While these tools excel as routing templates they are capable of far more. Routing operations like

open-field inlays, borders, cutouts, mortises, routing circles, curves and arcs are just part of what the

MFS system can do. Use the MFS with your Multi Function Table to help square the guide rail with

the table, or as a cutting fence. I've even used the profiles as a temple to make cuts with my jigsaw!

To understand the full value of this accessory, don't think of it as a "Routing Template". Envision

profiles that form templates, squares, fences, stops, story sticks and jigs of every kind, a "MultiFunction Profile" system.

The first thing I'd like to do is credit Jerry Work, Ned Young and John Lucas for the work that they

have already done to help us get the most out of the MFS and the Festool system. Some of the

methods, techniques and ideas you will see here have come from their writings. So, thank you

gentlemen.

Here is a link to Jerry Work's MFS manual. Jerry Work designs and hand crafts fine furniture in Kerby,

OR. Check out his site, The Dovetail Joint.

Ned Young started a thread on the Festool Owners Group forum, Notes on the MFS.

John Lucas has shared a lot of great ideas on his site, WoodShopDemos.

© 2008-2009, Brice Burrell Page 2

Page 3

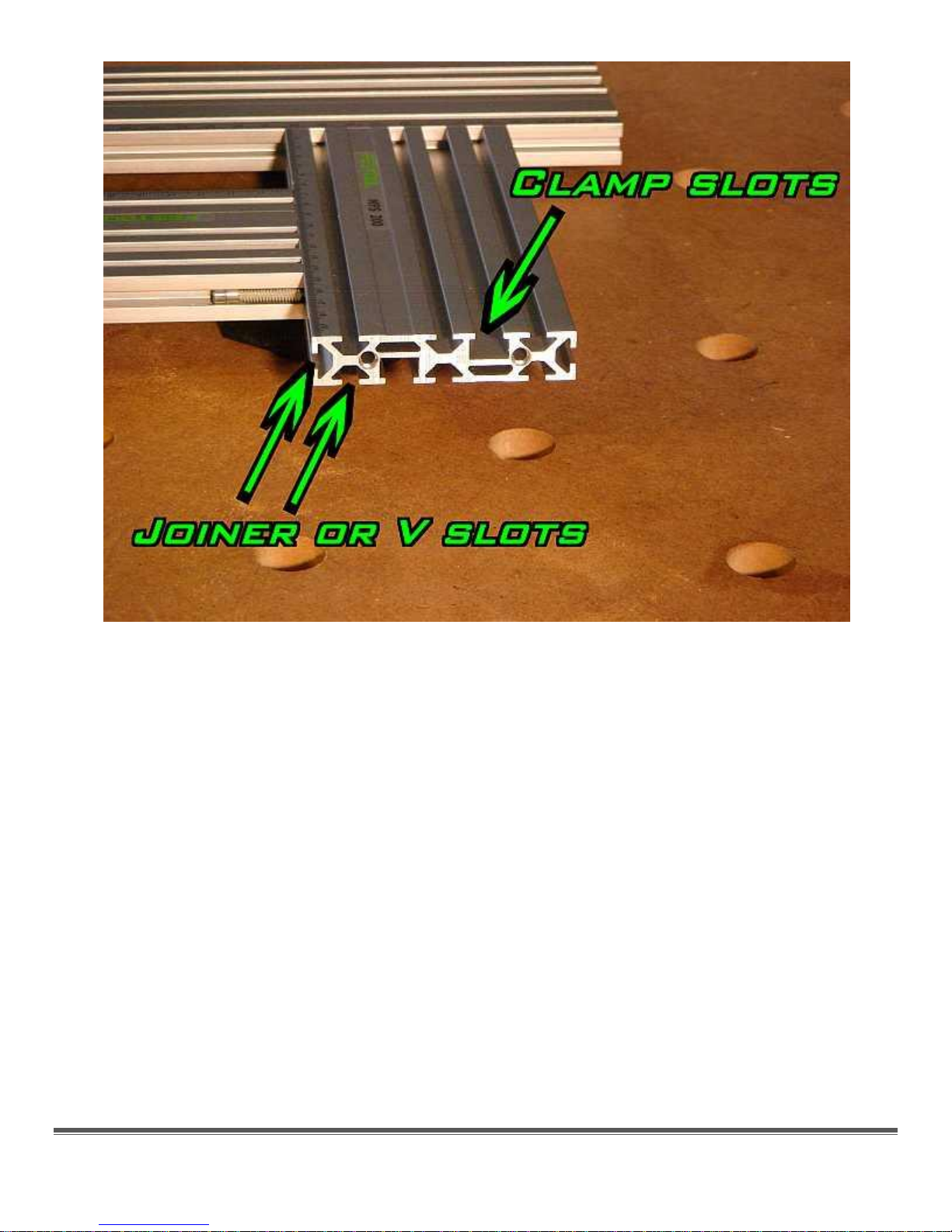

The components of the MFS 400 and MFS 700.

To get started let’s take a look at the components that make up the MFS template system.

Knowing what the parts are and what they do from the beginning will help you understand the

functions and methods later on in this review.

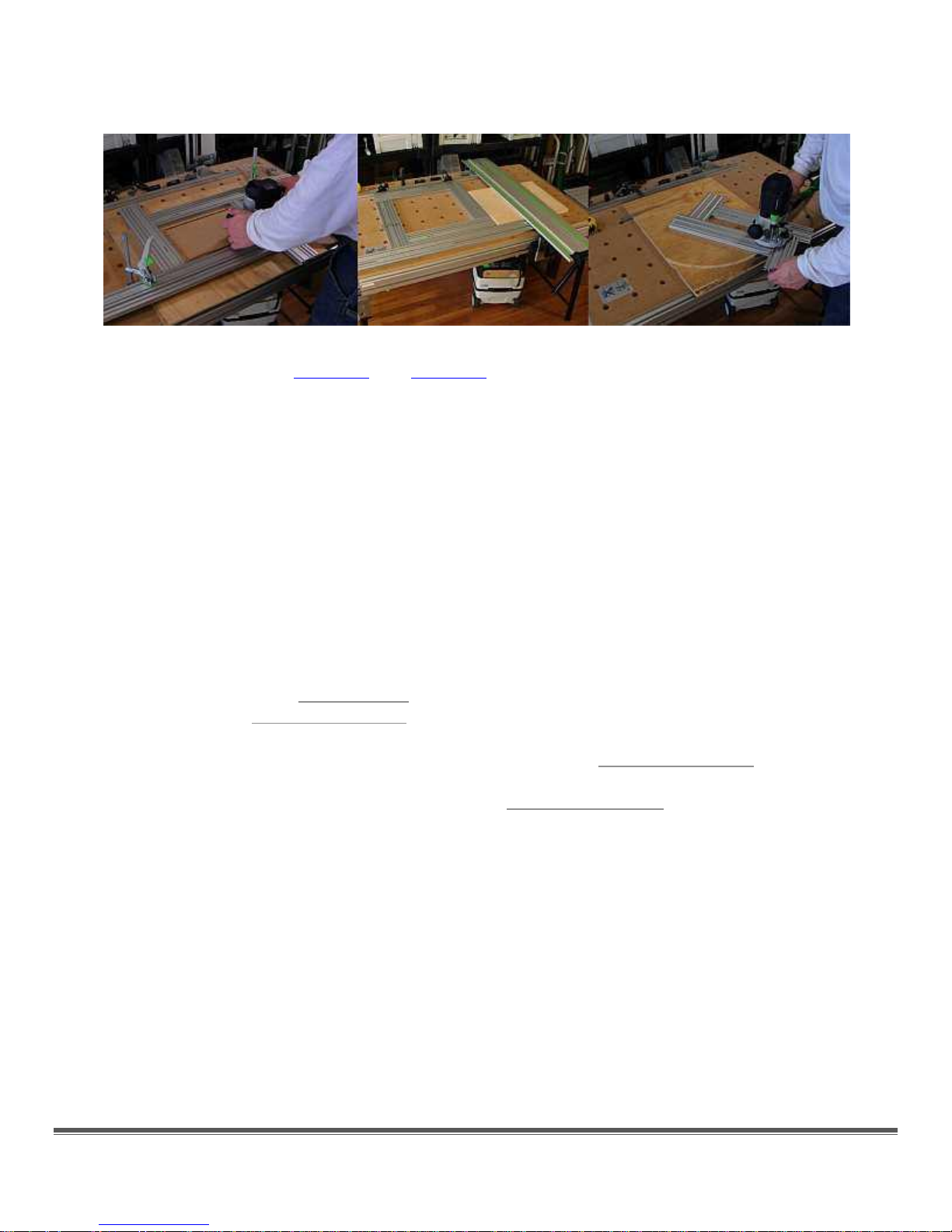

In this photo you see what is included with the MFS 400 set: two 400 mm and two

200 mm profiles, two angle stops, anti-tilting insert, circle-cutting insert and pivot, 3 mm ball head

Allen driver, connecting hardware and an instruction manual.

The MFS 700 set (not pictured above) includes all of the same components, except its profiles are

400 mm and 700 mm.

© 2008-2009, Brice Burrell Page 3

Page 4

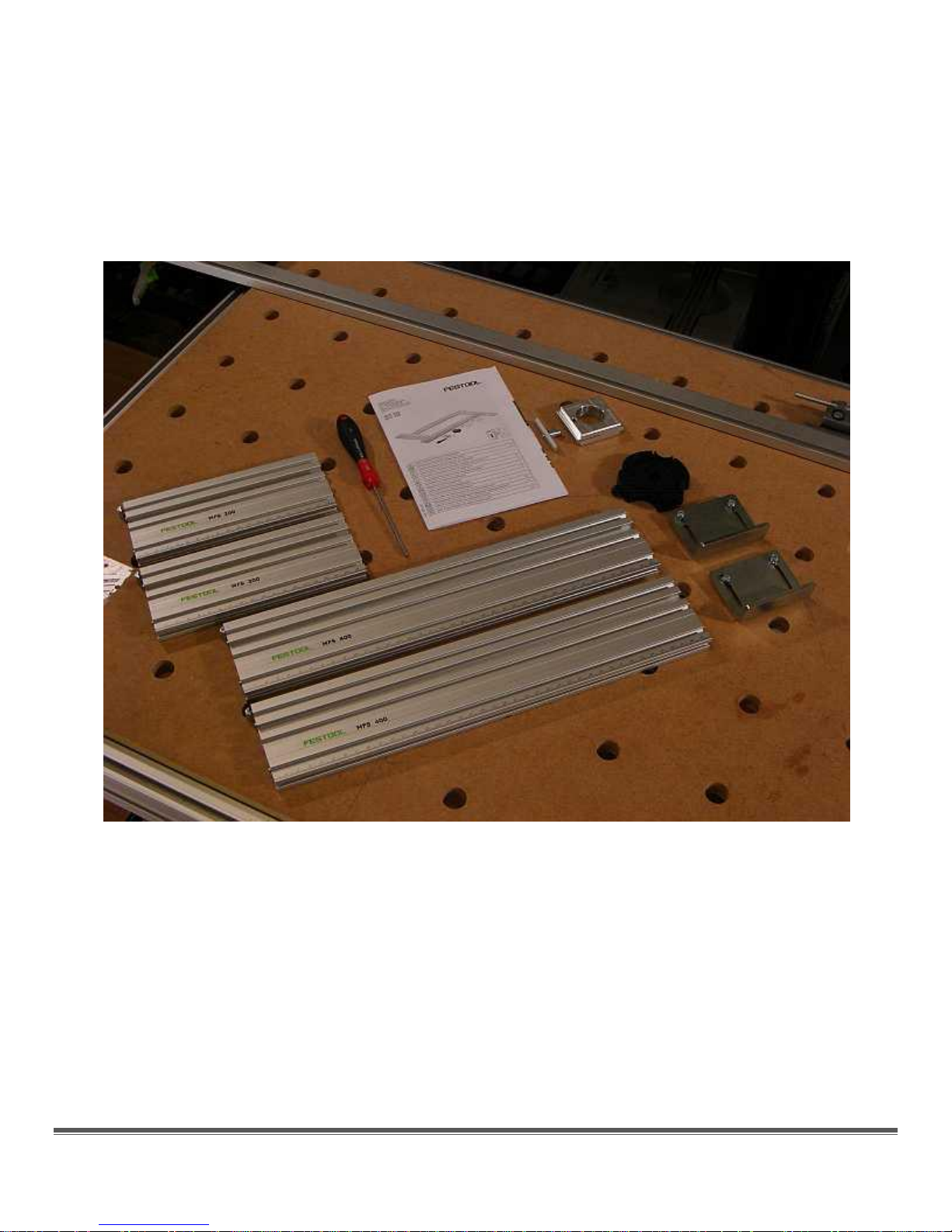

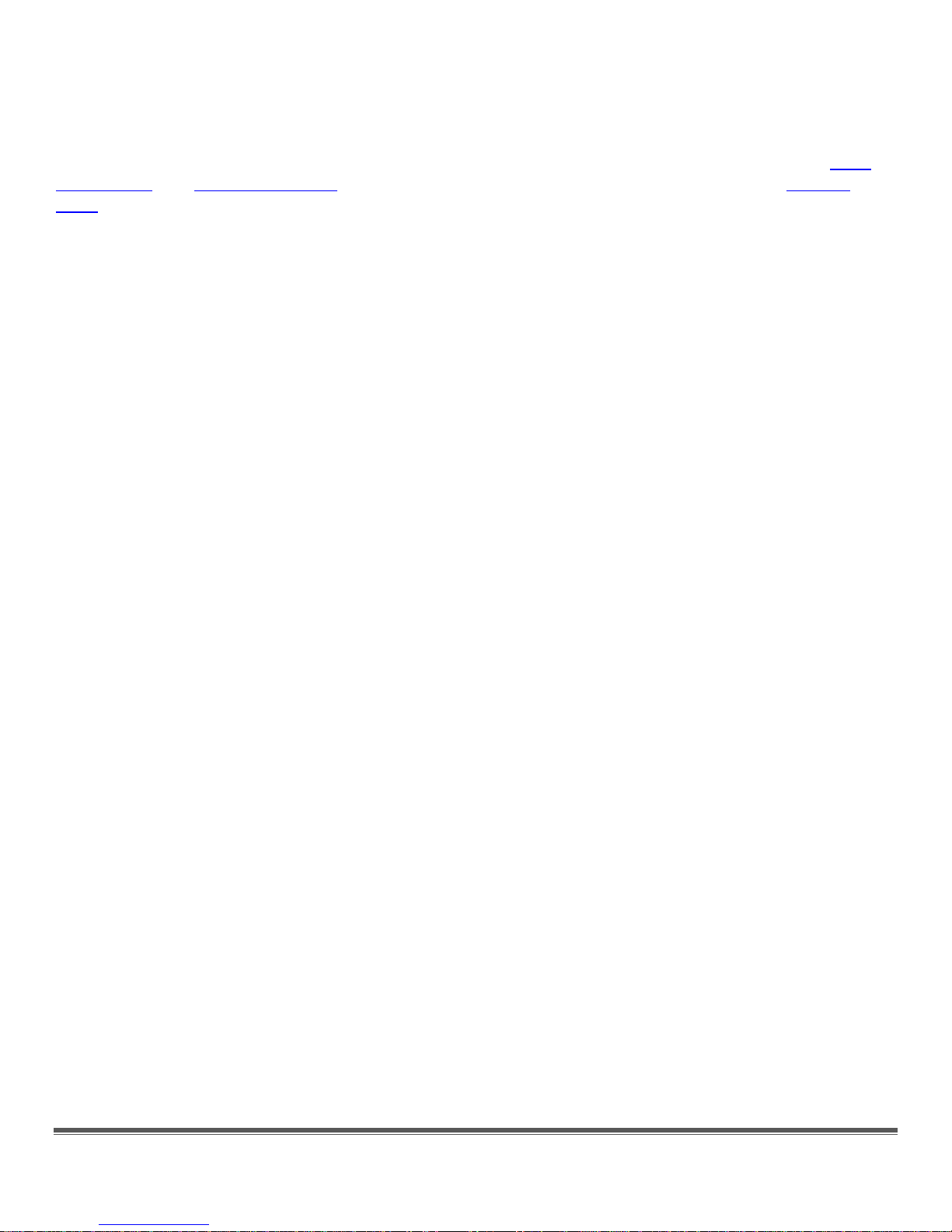

The MFS profiles are aluminum extrusions with graduated metric scales printed on them. Profiles are

80 mm wide and 16 mm thick with a series of "Joiner" or "V" slots and "Clamp" slots. The Joiner or V

slots are for the connecting hardware, circle-cutting insert and pivot and the coupling hardware (not

included with the sets) for joining profiles length-wise. I'll go into detail on how to join the profiles in its

own section in this review.

© 2008-2009, Brice Burrell Page 4

Page 5

The Festool FSZ 120, FSZ 300 and FS-HZ clamps fit in the clamp slots, as do the guide rail

connectors. The guide connectors can also be used to join the profiles in length. Also, 1/4" square

and hex nuts fit the slots if you want to add a fixture to the profiles or mount them to jig or table with

your own (imperial or “inch” style) hardware.

© 2008-2009, Brice Burrell Page 5

Page 6

© 2008-2009, Brice Burrell Page 6

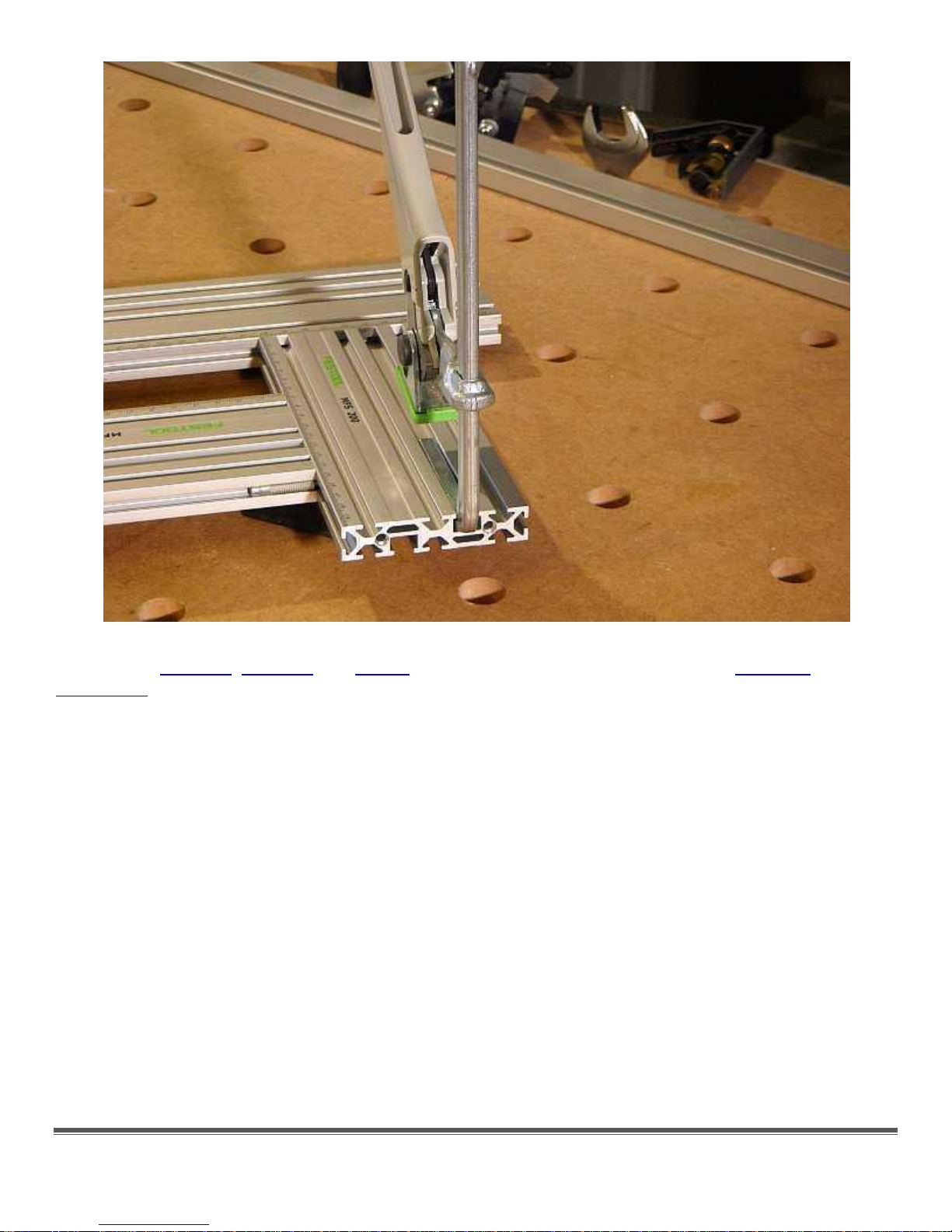

The 3 mm ball head driver is used on almost all of the MFS hardware. The ball head allows the driver

to be used on an angle as shown in this photo.

The angle stops mount into the V slots and are used to help position the MFS.

Page 7

© 2008-2009, Brice Burrell Page 7

Here the angle stops are mounted on the bottom of the MFS to precisely locate the MFS for an inlay.

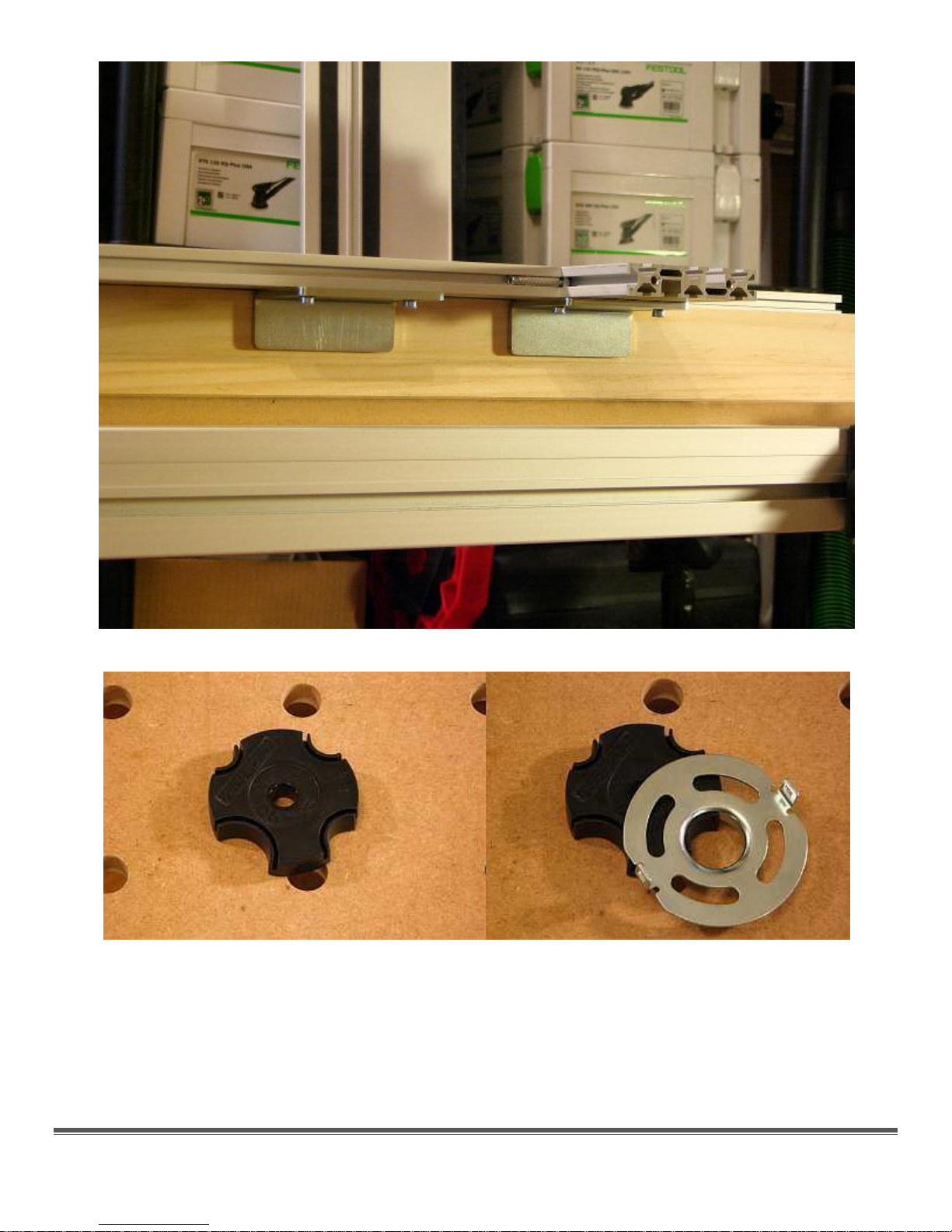

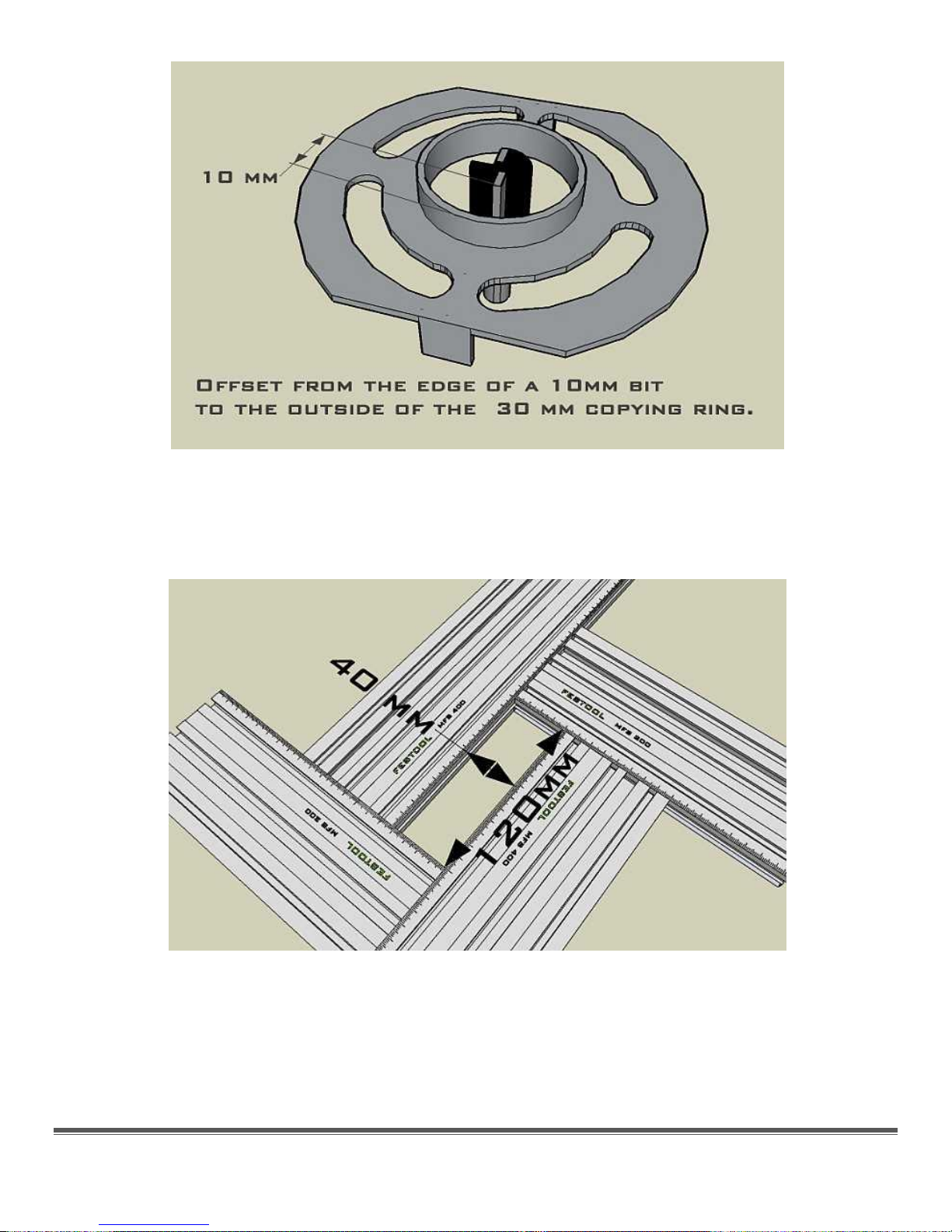

This is the anti-tilting insert. It is used to prevent the router from tipping or tilting during routing operations. If the

router is tilted the work piece can be ruined. Copying rings fit into the anti-tilting insert, this allows it to travel

with the router. The insert can fit 24, 27, 30 and 40 mm copying rings.

Page 8

© 2008-2009, Brice Burrell Page 8

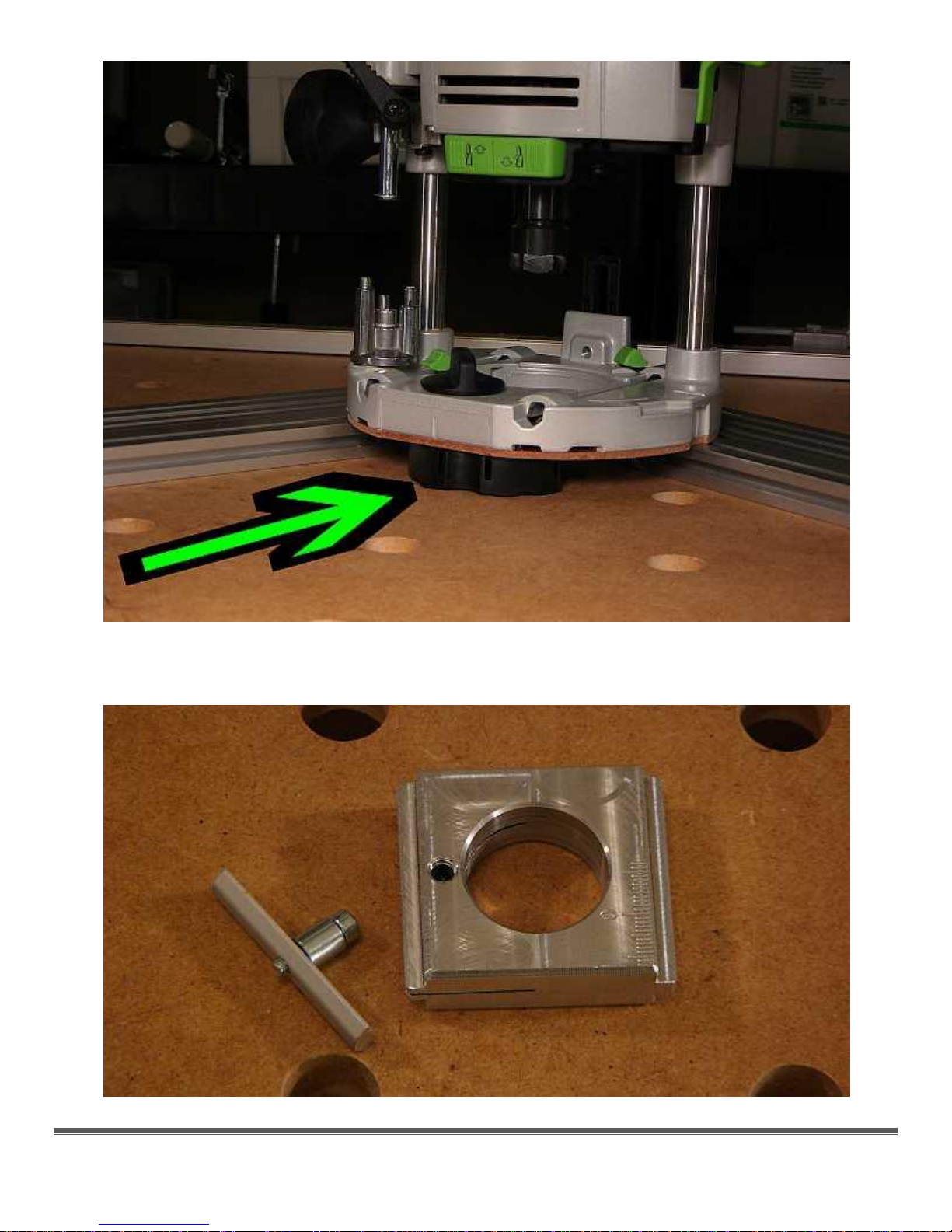

Here you can see the insert in place under the router. The insert is only needed when the profiles are

spread too far apart for the router's base to be fully supported by the profiles themselves.

Page 9

This is the circle-cutting insert and pivot. I'll go into more detail about how to use the MFS to rout

circles, curves and arcs later in this review.

Festool offers some other accessories not shown in this review. Longer profiles are available, 1000

mm profiles and 2000 mm profiles to extend the MFS template system. You can use the Routing

Slide with the MFS to support the router when routing out large areas, for example open field inlays.

Also offered, as spare parts, are a set of 4 MFS "Joiners" (part # 493235) that fit into the V slots to

connect profiles length-wise. You'll need to call Festool's service department to order the joiners.

© 2008-2009, Brice Burrell Page 9

Page 10

Connecting the MFS profiles.

In this section I'm going to you show how to connect the profiles into rectangles and end-to-end.

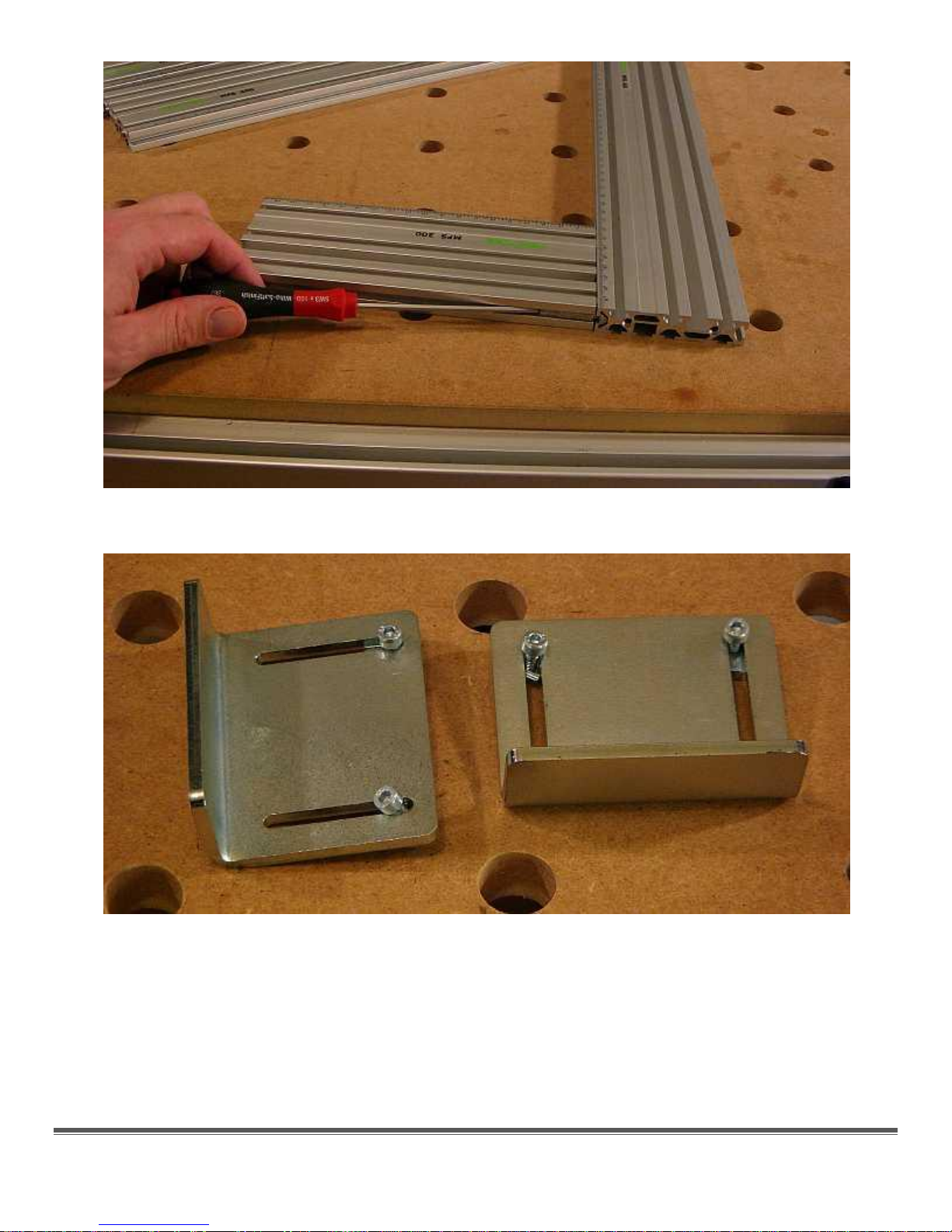

The MFS profiles have male and female ends, as shown here. The male ends have two small studs

or indexing pins to align the profiles. Also the male ends have the connecting hardware, notice the "V"

nut with a ball detent.

© 2008-2009, Brice Burrell Page 10

Page 11

The male end fits into the female end to align the profiles end-to-end. A guide rail connector or the

MFS joiner can be used to secure the connection. Guide rail connectors (fitted into the clamp slot) are

used in the photo above.

The V nut on the male end of the profile fits into the V slot in the edge of another profile. The male's

indexing pins also fit into the edge V slots to ensure perfect alignment.

© 2008-2009, Brice Burrell Page 11

Page 12

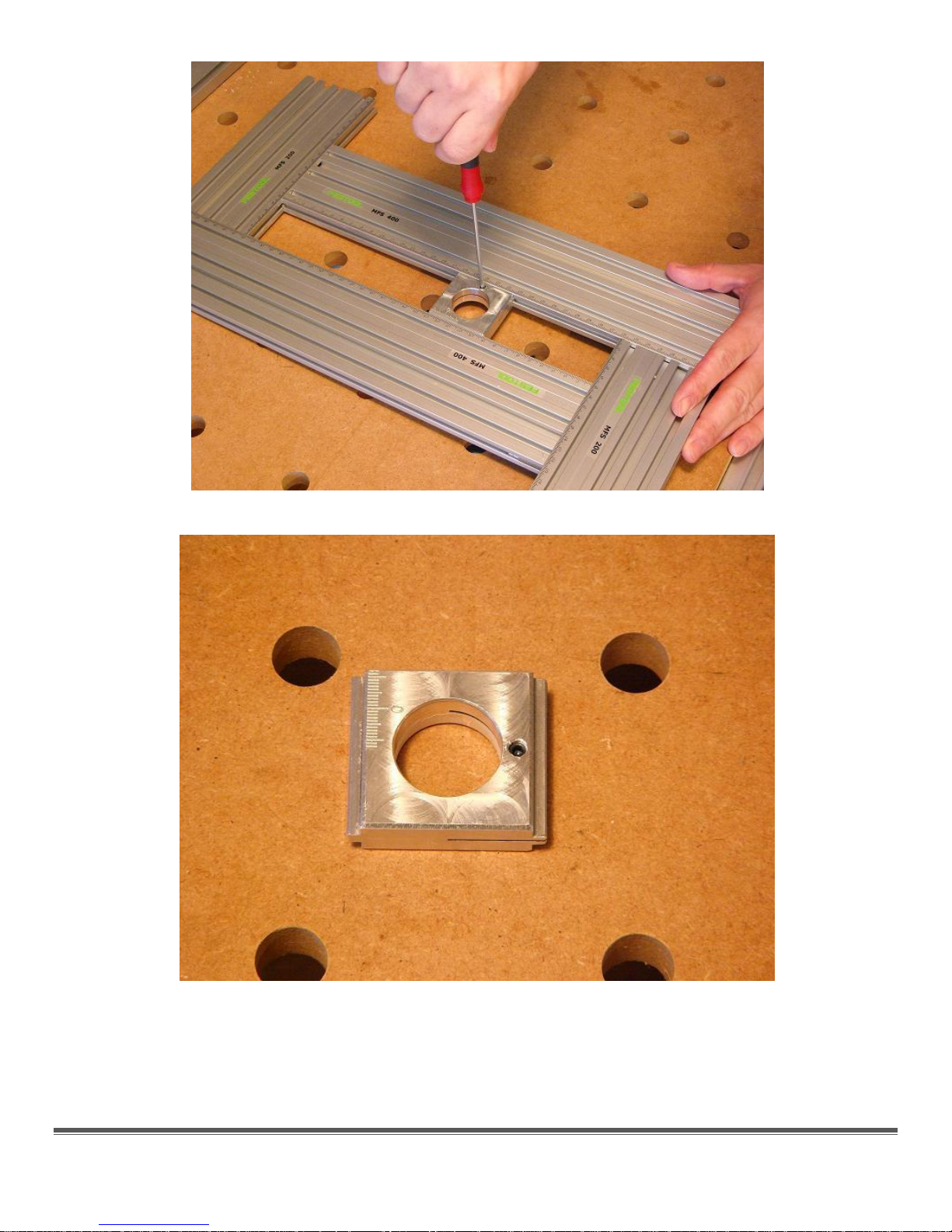

This shot is a close-up of two profiles connected.

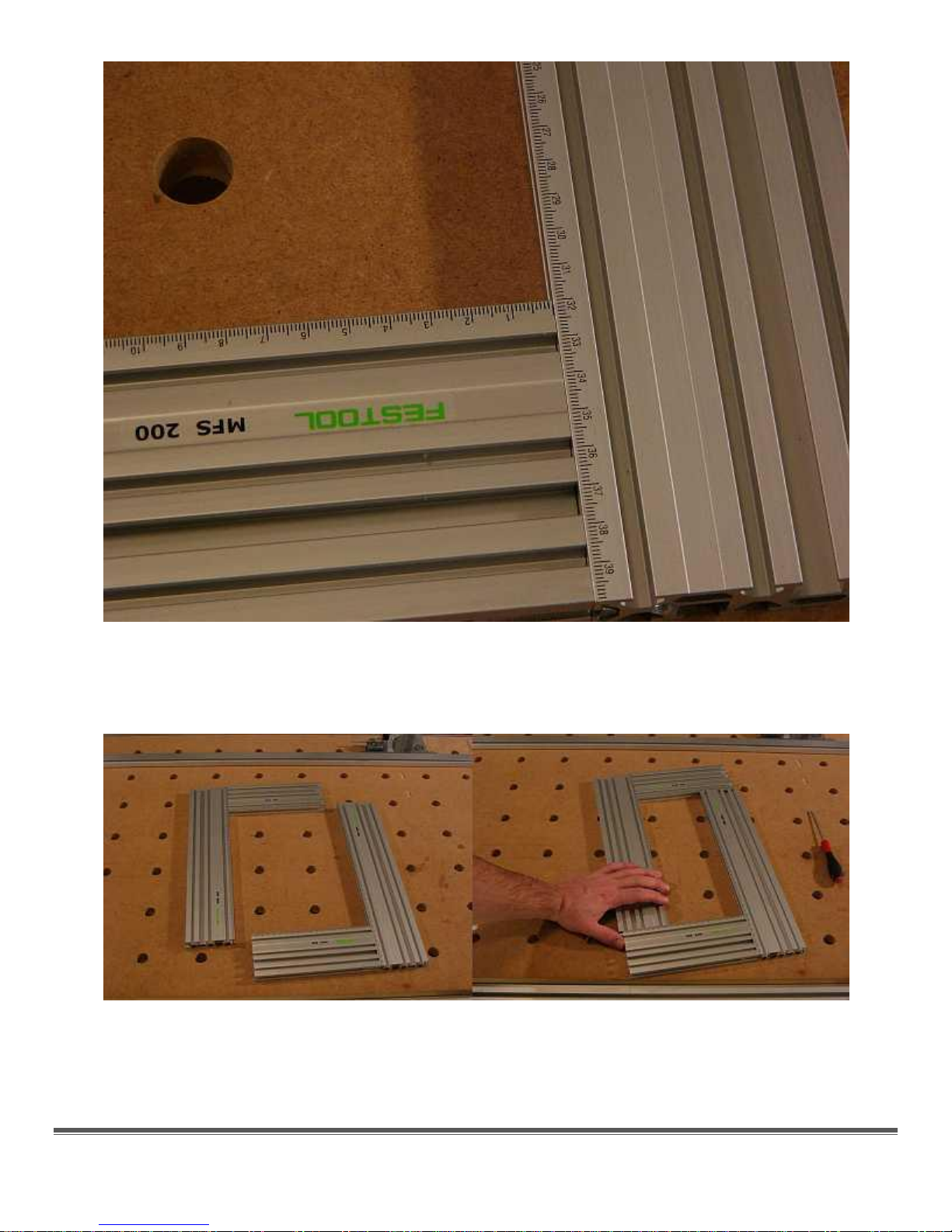

To make a rectangle, connect two profiles, a short and long one, to form a "L"

with the scales on the inside. Use the Allen driver to secure the joint.

© 2008-2009, Brice Burrell Page 12

Page 13

You can see from this picture that the scales are on the inside of the "L". The scales are an important

feature of the MFS. They allow the template to be quickly set to size.

Once you have two "L" shapes formed, connect the two to make a rectangle.

© 2008-2009, Brice Burrell Page 13

Page 14

You can adjust the sizes of the MFS rectangles by moving the sort of

"L" shaped pairs to set the width and length. At first, assembling the

profiles can be kind of tough, but after doing it a few times you get the

feel for it. I've sprayed my profiles, including the hardware, with a dry

lubricant. This helps reduce some of the friction while adjusting them.

As another added benefit, it lets tools slide on them easily.

By combining sets and/or the longer profiles, different shapes can be made. This will greatly increase

the usefulness of the system.

© 2008-2009, Brice Burrell Page 14

Page 15

It may be necessary to add the connecting hardware to both ends of some of the profiles to join

different shapes. The hardware can be removed from one profile and added to another. The bolt and

V nut have to be removed and the threaded insert can be taken out. The insert has an Allen recess,

the insert is reverse threaded, turn clockwise to remove, use a 4 mm Allen key. The insert can

then be screwed into another profile, turning counter-clockwise (anti-clockwise), and it will self tap

into the aluminum.

I recommend exercising great care removing and installing the connecting hardware, it would

not be hard to strip the aluminum, especially if you forget about the reverse threading.

© 2008-2009, Brice Burrell Page 15

Page 16

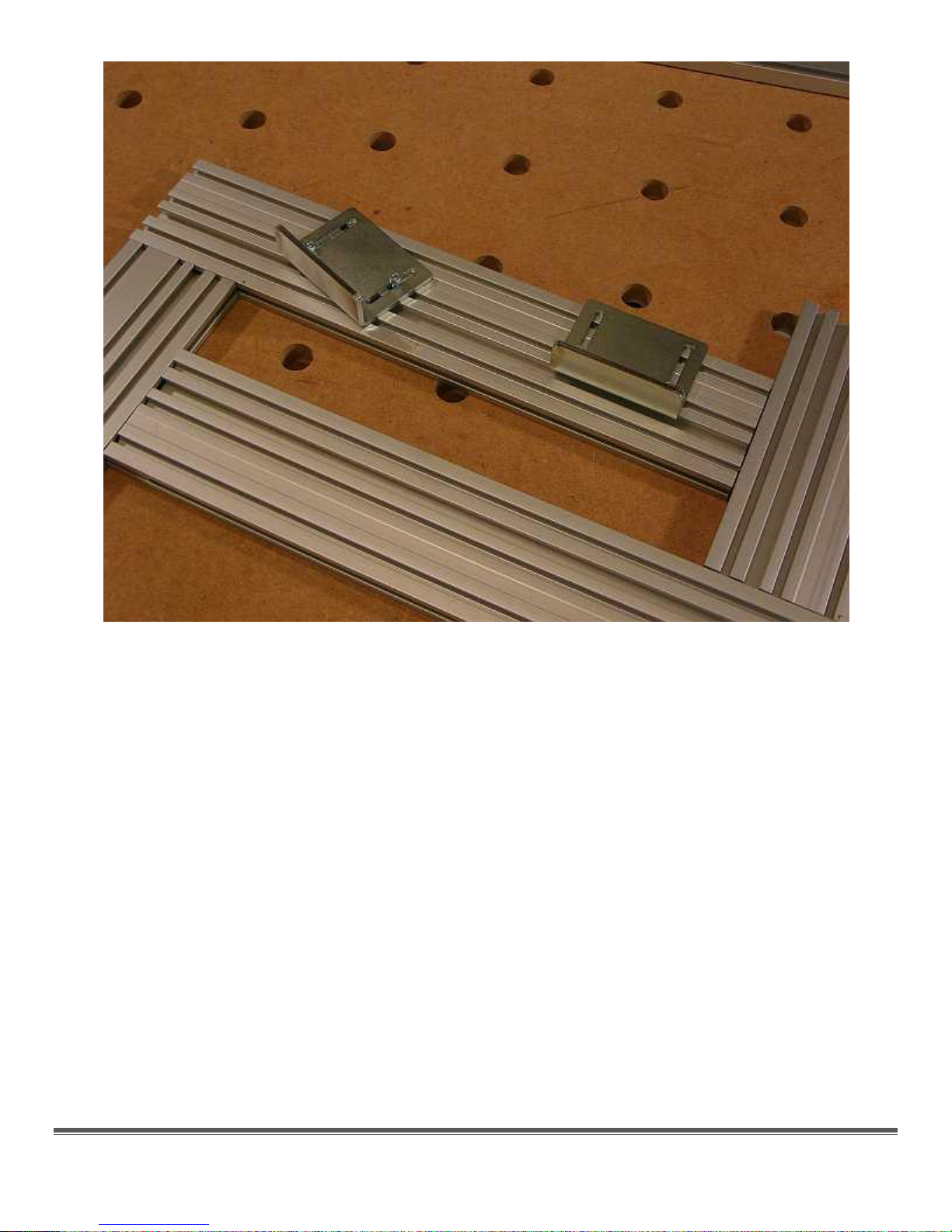

The angle stops have V nuts that slide into the V slots to mount the stops to the profiles. The stops

can be mounted square or on an angle.

Connecting the profiles can be tricky in the beginning as I've already mentioned, sometimes you wish

you had another set of hands to line up all of the hardware. The key is to be patient when connecting

and adjusting the MFS profiles. Taking the time to perfectly set the template will show in the end

results you achieve with this system.

Moving on to using the MFS system, it's hard to know what to cover first. I think most people imagine

the MFS being used as a routing template, so why not start there.

© 2008-2009, Brice Burrell Page 16

Page 17

Template Routing with the MFS System

Routing inlays, borders, cutouts, mortises, circles, curves and arcs can be very accurately done

with the MFS. I know my results are much better now that I'm using the MFS instead of the

wooden jigs and fixtures I've used in the past. Template routing with the MFS is a fairly

straightforward concept. However, there are a few things to keep in mind when deciding how to

use and set up this system as a routing template, I'll go over some of them in this section, as well

as show you how I use the MFS for my routing projects.

If you happen to be unfamiliar with what template routing is, I'll explain. It is using a jig, fixture or in

this case, the MFS profiles to guide a router's travel. The router must have a copying ring (guide

bushing) or a bit with a bearing to prevent the bit from cutting into the template as it travels. When

using a bit with a bearing, like a flush cut or pattern bit, the profiles can be set to the exact size

needed, whether it is a cutout or mortise. This really simplifies the setup.

However, using a pattern bit is not without its risks. The issue is with the bit accidentally cutting into

the template/profile. This can happen one of two ways.

First, while plunging the bit into the work piece, before the bearing can engage the template

(with the bearing still above the profile) it can't stop the bit from going astray and doing bad

things to your profile.

The second issue occurs if the bearing happens to land in the V slot in the edge of the profile.

You can run into this with smaller bits as they usually have small bearings that can fall into the

slot.

© 2008-2009, Brice Burrell Page 17

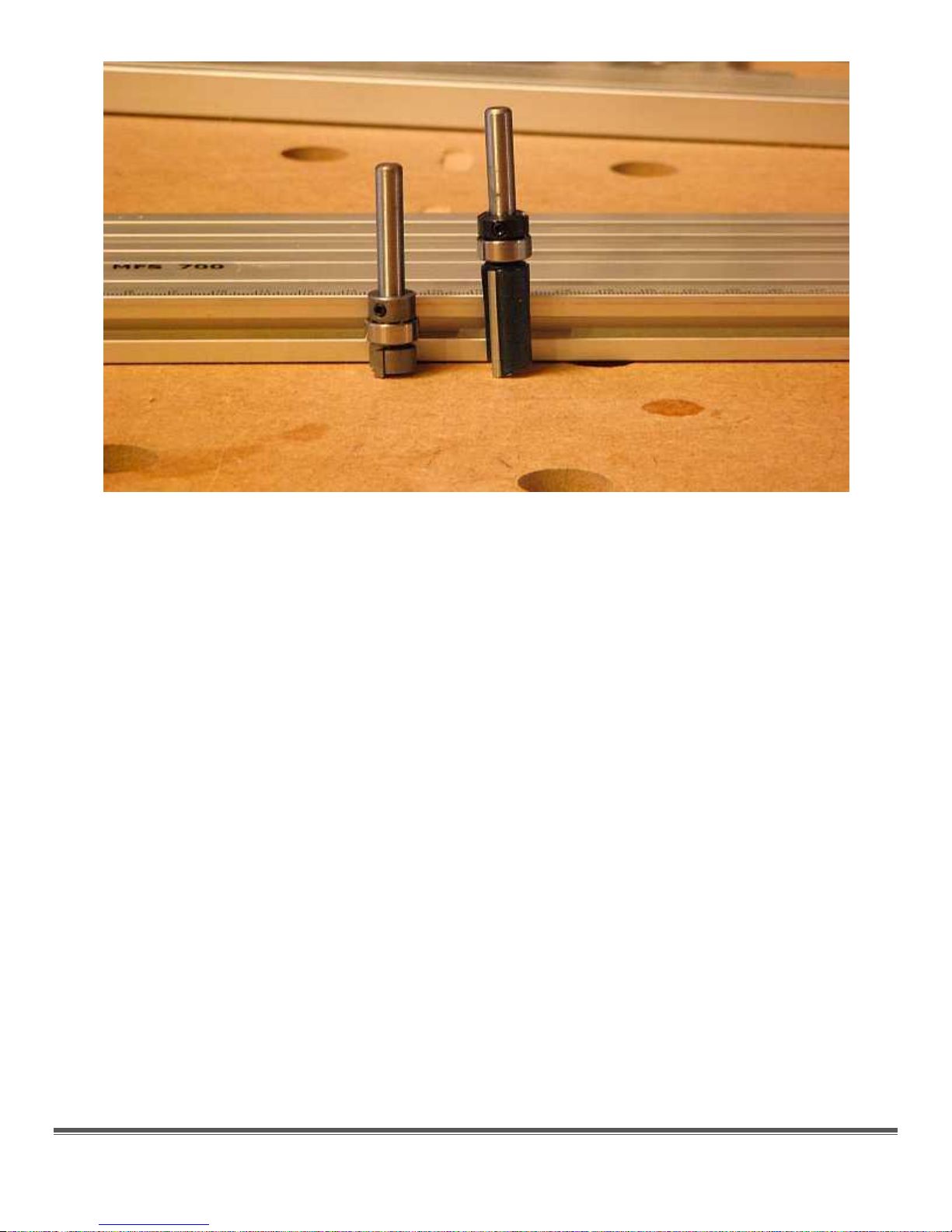

Page 18

The picture above shows the potential dangers of using a pattern bit with the MFS. I'm not suggesting

pattern bits can't be used, but, care must be taken when selecting the right bit. Bearing size, cutting

length and diameter should all factor into the decision. When used in the right circumstances they can

be a real asset.

I use the MFS most often to rout for hardware like lock sets, strikes, latches and catches, but, most of

all hinges. I've made all kinds of jigs to rout hinges, all of them out of wood or MDF. While they do

work, it is usually only a short time before they become inaccurate from relatively light use. If you

have ever used a wooden jig you know what I mean. I've had to add very thin shims to my hinge

templates to finish jobs, not wanting to make a new jig to rout one or two more hinges.

That drove me nuts! Now, I use the MFS, it is so much faster, easier and far more accurate than the

wooden jigs ever were. I can set up the MFS and make a test cut in about five minutes or less. If it

needs to be adjusted, that can usually be done in less than one minute. If a wooden jig is off, you're

stuck shimming or remaking the entire jig. So let me show you how I use the MFS with a small pattern

bit to rout hinges.

© 2008-2009, Brice Burrell Page 18

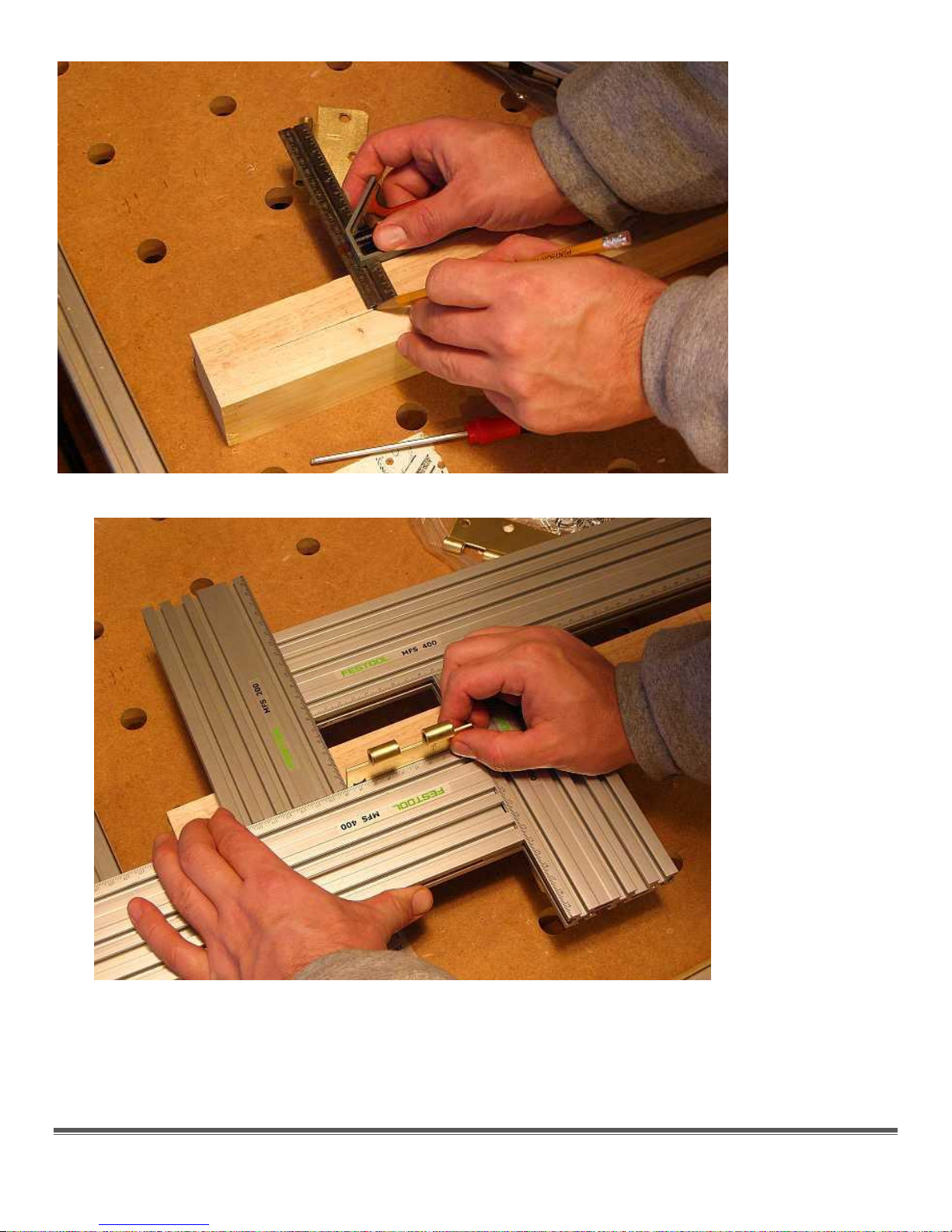

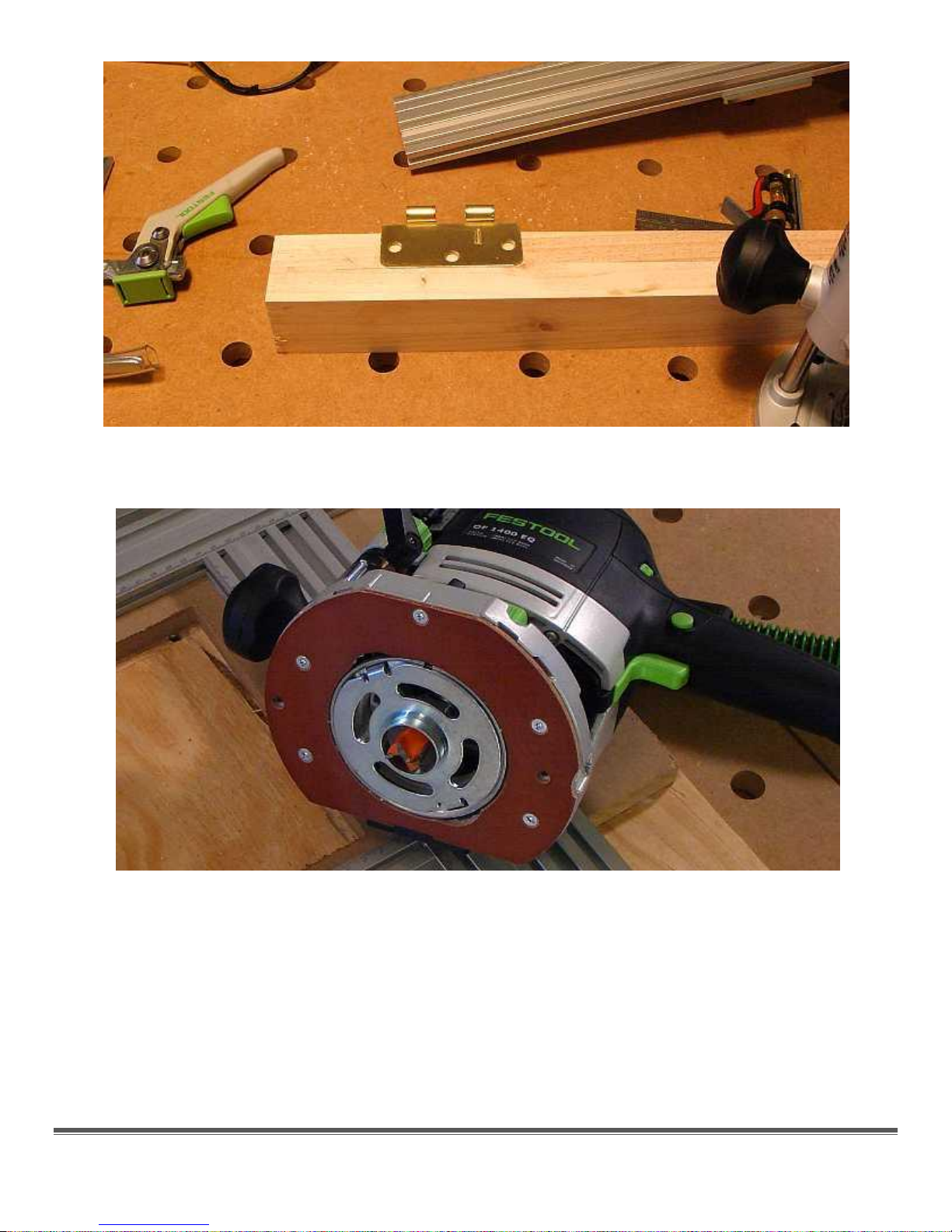

Page 19

The first step is to mark the setback for the hinge. I'll use this line to index the MFS.

With the small pattern bit I use to rout my hinges I can set the MFS to the exact length of the hinge.

The width is set wide enough so I can test fit the hinge without removing the MFS.

© 2008-2009, Brice Burrell Page 19

Page 20

© 2008-2009, Brice Burrell Page 20

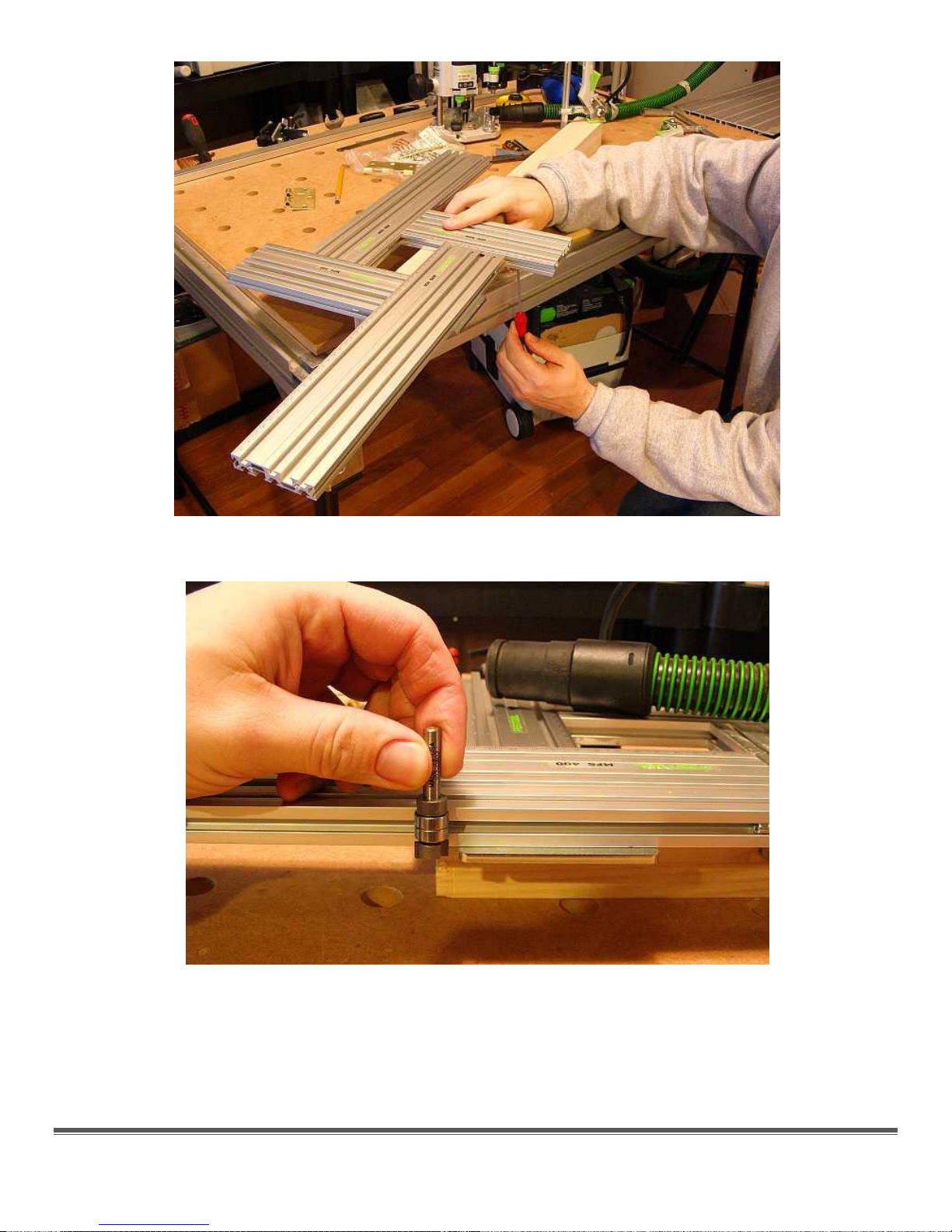

Once the MFS is set to size, I place it on the pencil line then set the angle stops and clamp the work

piece/MFS down.

Here is a close look at the bit I'll be using. It is the same type that I showed earlier, you can see I've

add a second bearing to solve the problem of the bearing falling into the

V slot. It is a 1/2" diameter; this will match the 1/4" radius on the hinges.

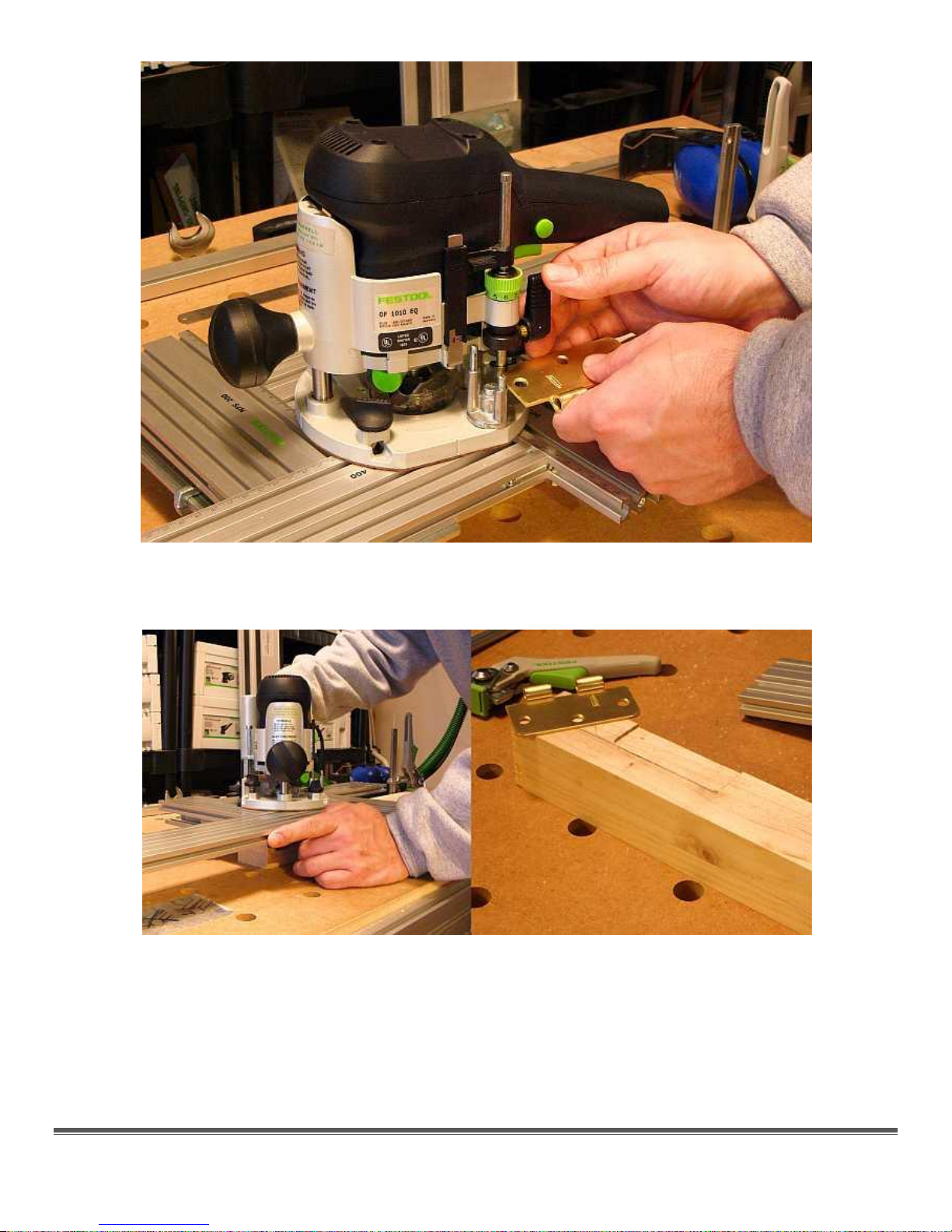

Page 21

After installing the bit, the next step is to set the router's depth, plunge the router until it comes into

contact with the work piece. This is called zeroing the bit. Now, I use the hinge itself between one of

the turret stops and the depth rod to set the exact depth.

It's time to rout, with the profiles set to be wider than the hinge, this leaves an open space for me to

fully plunge the bit before contacting the work piece. I make systematic passes removing small

amounts per pass. Again with the MFS wider than the hinge, I can test fit the hinge without removing

the template. When I'm happy with the fit, I remove the MFS, test the fit once more, and make

adjustments as needed.

© 2008-2009, Brice Burrell Page 21

Page 22

I got a perfect fit on the first try, but remember to always make test cuts on scrap first.

Let's now look at using copying rings or guide bushings with the MFS. The advantage of using

copying rings is twofold: they are always in place while routing, greatly reducing the chance of cutting

into the profile; and they work with most bits used for template routing, regardless of the bit's cutting

length. Unlike bearing-guided bits where the cutter's length is so important. Of course you do have to

account for the offset between the bit and the copying ring when setting the MFS to size.

© 2008-2009, Brice Burrell Page 22

Page 23

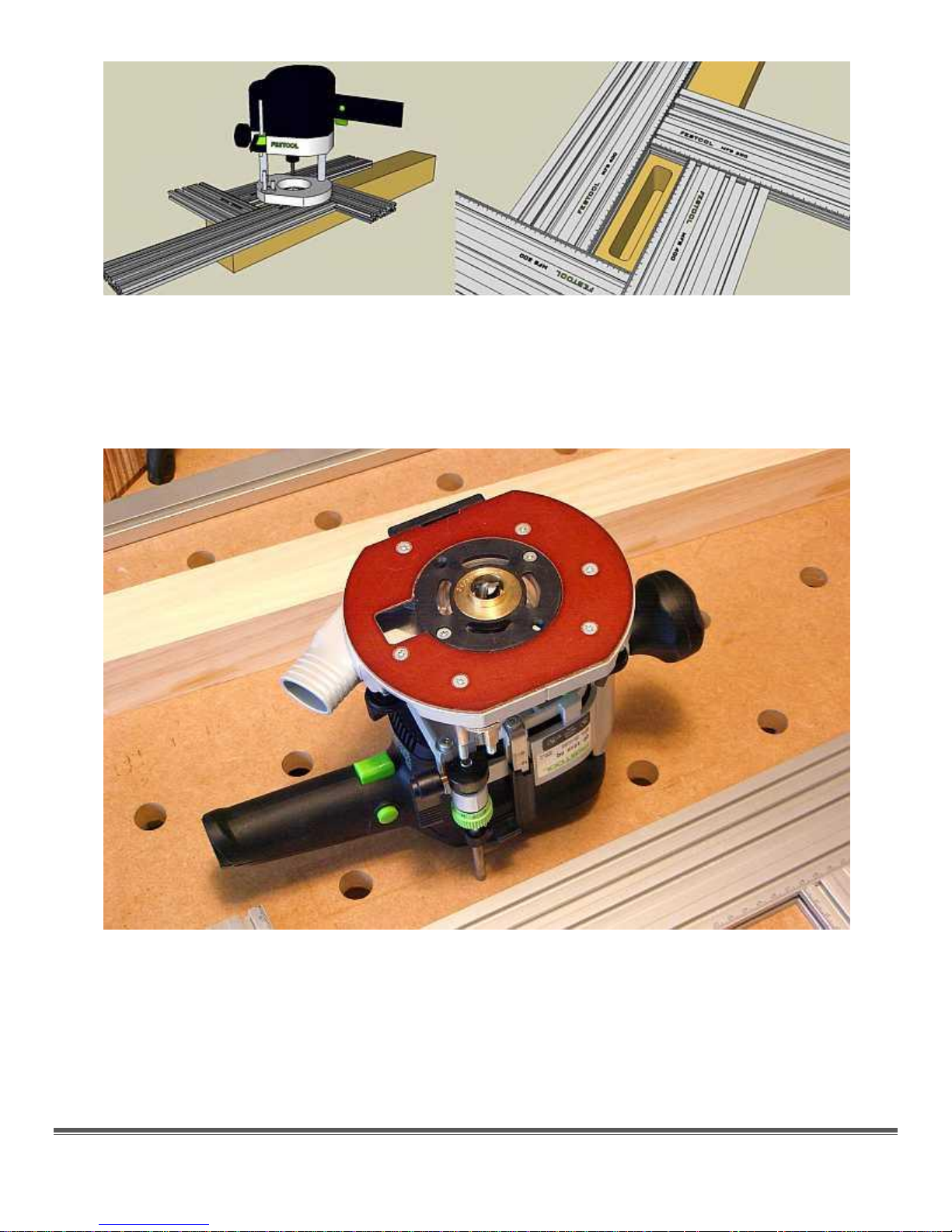

The following is a series of drawings showing the setup of the MFS for a mortise (imagine a mortise

for a table or chair leg). Our mortise will be 20 mm wide by 100 mm long and 50 mm deep. A 10 mm

bit will be used with a 30 mm copying ring in the router. We need to account for the space between

the bit and to the outside edge of the copying ring, called offset, when we set the MFS profiles to size.

The offset for this bit/copying ring combination is 10 mm.

Knowing the offset is 10 mm, we add that number twice (20 mm) to the width and length of the

mortise. 40 mm x 120 mm is what the MFS should be set at to produce our

20 mm X 100 mm mortise.

© 2008-2009, Brice Burrell Page 23

Page 24

© 2008-2009, Brice Burrell Page 24

Clamp the MFS down where you want it, set the depth of the bit, and rout...... The result should be

this, a mortise 20 mm X 100 mm X 50 mm.

Working in metric makes setting the MFS to size pretty easy. However, I understand that most of you

are much more comfortable working in imperial (inches). So let's do another mortise with imperial

measurements, but this time I'll be cutting real wood.

How about a mortise 3/4" wide, 3" long and 1/2" deep? In the router is a 1/2" straight bit with a 3/4"

bushing. So the total offset I need to account for is 1/4".

Page 25

© 2008-2009, Brice Burrell Page 25

Setting the MFS to size in Imperial measurements I use a steel rule. With the offset added the

dimensions are 1" X 3 1/4".

With the MFS set to size, I place the template on the work piece, I've drawn lines to indicate were the

MFS will be set and the mortise will be cut. Once everything has been set (MFS and the bit depth)

and then clamped, I start the routing.

Page 26

A shallow mortise like this one only takes a few passes.

The finished mortise. The angle stops make it a breeze to set the MFS up quickly when you need to

rout the same location/size mortises on multiple work pieces. Just imagine the ease of routing

traditional M&T joints for table and chair legs or mission style furniture.

© 2008-2009, Brice Burrell Page 26

Page 27

Inlays

Inlays are a great way to add some interesting detail to your projects. The inlay I am going to do now

is simple and small but it is going to have a huge impact on the piece.

We start the same way as the rest of the examples, by selecting the bit/copying ring combo and

setting the MFS to size. In the picture here I'm adding some scrap stock to act as shims to help

support the MFS.

© 2008-2009, Brice Burrell Page 27

Page 28

More of the same; set the depth of the bit and rout. I need to be a little careful because I'm routing off

each edge, and tear out can happen here. Removing small amounts near the edges will greatly

reduce the chance of tear out.

Here are the pieces I’ll be using for the inlay, zebra wood.

© 2008-2009, Brice Burrell Page 28

Page 29

© 2008-2009, Brice Burrell Page 29

With the pieces fitting perfectly, some blue tape will help hold the pieces in alignment until I can glue

and clamp them.

In the photo above the excess zebra wood has been cut off and the piece sanded. Using the MFS to

rout this inlay was not much effort, but, added a lot of visual appeal to this piece.

Page 30

Taking offset routing one step farther, we'll take a look at making the male portion and female recess

for inlays with the MFS. Keeping the MFS the same size and changing the copying rings/bits allows

inlays to be cut quickly and accurately.

You may be familiar with inlay sets available today. The sets have a bit and a guide bushing with a

second bushing (with a larger diameter) that slips onto the first. With this type you follow the template

to rout the female recess with both the guide bushing and second bushing installed on the router.

Then, rout out the male insert with the larger second bushing removed, using the same template. I'll

illustrate this principle with the MFS using different size bits and copying rings/guide bushings.

© 2008-2009, Brice Burrell Page 30

Page 31

This drawing shows how to use the same bit to rout the male and female potions of an inlay by

changing the copying rings. In the drawing the 10 mm bit/20 mm copying ring combo cuts out the

male inlay and the 10 mm bit/40 mm copying ring the female recess. The 40 mm copying ring with the

10 mm bit produces a 15 mm offset from the outside edge of the copying ring to the edge of the bit.

With the 20 mm ring and 10 mm bit combo used for the male portion, the offset between the edge of

the bit and the copying ring is 5 mm. When we add the 5mm offset and the 10 mm bit diameter we

get 15 mm, equal to the offset of the female bit/ring combo. The goal is to have the offset of the

female's combination of bit/ring be equal to the offset, plus the diameter of the bit used for the male

portion. (Offset of Female bit/ring = Offset of Male bit/ring + bit diameter)

Let me show the whole process with a few drawings using these same bit/ring combinations. This

example will be an open field inlay 200 mm X 50 mm.

© 2008-2009, Brice Burrell Page 31

Page 32

© 2008-2009, Brice Burrell Page 32

The MFS is set to 230 mm X 80 mm. The rectangle inside the MFS represents the where the inlay will

be.

With the 40 mm copying ring and the 10 mm bit in the router, we can rout out the female recess 5 mm

deep. The red arrow shows the path of the router making systematic passes to remove all of the

material to form the recess.

Page 33

The recess should look like this. Note the corners have a radius; a chisel will square them up.

With the female recess finished, let’s turn our attention to the male cut out. The male inlay stock is 5

mm thick to match the female's recess. It is a good idea to place the stock on top of a sacrificial piece

of scrap to prevent cutting into the work table. Also the area that will be the cut out is adhered to the

scrap with double-sided tape to keep it from being damaged by the bit when it is cut free.

© 2008-2009, Brice Burrell Page 33

Page 34

© 2008-2009, Brice Burrell Page 34

To make the male inlay piece I've installed the 20 mm ring, leaving the 10 mm bit in. To cut out the

inlay, the router's depth is set to cut all the way through the 5 mm stock. In this picture, the red arrow

indicates the router's path, only traveling around the template's perimeter.

Here is the piece cut free. Unlike the female piece the male has square corners.

Page 35

Now, with the male inlay cut free, carefully

remove it from the two sided tape and try the

fit. If all goes according to plan you should

have a perfect fit, or, one that will require

very little trimming to make fit correctly. If the

male piece is too small, trash it, adjust the

MFS and make another one, if you have

enough stock. It will only take a few minutes,

remember, a prefect inlay adds to the value

of your project and a sloppy fit takes away

from it.

I should mention in my example of the ring/bit combinations shown earlier that Festool doesn't offer a

20 mm copying ring. I used that ring/bit combo hypothetical example because it is easy to understand

the relationships between the offsets. How about if I show you examples with rings and bits Festool

does offer, as well as some imperial combos.

The first bit/ring combination, on the left in the drawing, is the 10 mm bit and 40 mm ring used to rout

the female recess, then the 6 mm bit and 24 mm ring to cut the male piece. The second set on the

right, to rout the female portion, the 10 mm bit with the 40 mm ring then, the 3 mm bit and 27 mm ring

for the male cut out.

For a couple of imperial (inch) combos, set one: 1/2" bit / 1" bushing (female) and 1/8" bit / 3/8"

© 2008-2009, Brice Burrell Page 35

Page 36

bushing (male). Second set: 1/2" bit / 1 1/4" bushing (female) and 1/4" bit / 1/2" bushing (male). The

examples given are only a few of the possible bit/ring combinations commonly available.

I want to fit a router into this piece of MDF to act as a makeshift router table I can set between two

saw horses on the job site. This is the plate I'll be recessing into the MDF. Fitting the plate is a twostep process, making a cutout for the router to pass through and a recessed lip or rebate for the plate

to sit on. First thing is to measure the plate and the radius of its corners to set the MFS on, and to

choose the right diameter bit to match the corners.

© 2008-2009, Brice Burrell Page 36

Page 37

© 2008-2009, Brice Burrell Page 37

I decided to make the cutout first; the router has a 1/4" spiral bit with a 1 1/2" bushing.

The bit is set to cut all of the way through the MDF, so I placed a scrap under the work piece to

protect my MFT's top. I'll guide the router slowly around the template.

Page 38

I've switched to my OF1400 router to make the lip for the plate. I've already put an

18 mm bit and a 30 mm copying ring in the router, I set the MFS for the 7 mm offset. The 18 mm bit

should fit the radius on the corners of the plate perfectly.

© 2008-2009, Brice Burrell Page 38

Page 39

© 2008-2009, Brice Burrell Page 39

This picture shows the lip routed in, now, I'll test fit the plate.

It looks like I've got the fit right on the first try. There isn't much of a learning curve to setting up the

MFS. It didn't take me long before I got perfect results, the first time every time.

Page 40

The process, from start to finish, was only about 15 minutes, and that was while shooting the pictures

too.

© 2008-2009, Brice Burrell Page 40

Page 41

Jack Miters, Stair Stringers, and Circle Cutting

Mortises and inlays are the types of routing that came immediately to mind when I first thought about

how to use the MFS. When I received the MFS I wasn't sure how I was going to adapt it for carpentry

use. I was pretty sure I was going to use it to rout hinges, but what else?

The first carpentry job for the MFS to tackle was the jack miter, a joint used when trim or molding

needs to butt together and still have part or all of the profiles continue around. This joint requires

careful and precise setup, a job perfect for the MFS. The pictures here show the process: measure

the offset, set up, rout, test fit…does this sound familiar by now?

© 2008-2009, Brice Burrell Page 41

Page 42

© 2008-2009, Brice Burrell Page 42

The finished joint. With some creative thinking, the MFS made this tough routing job easy! Check out

the story over at my "How To" page Jack miter page.

Page 43

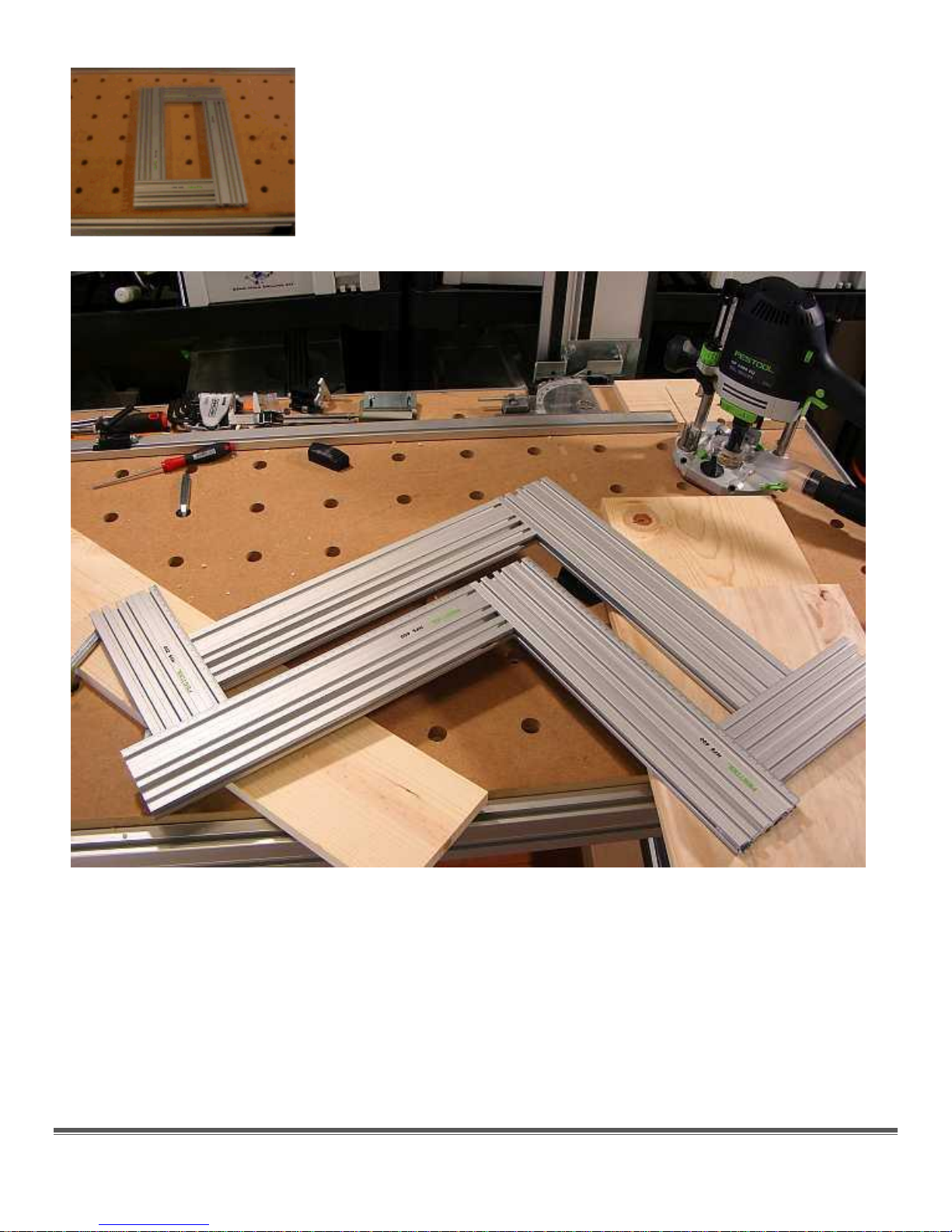

I also routed stringers for a small staircase. This is where having both the MFS 400 and 700 sets

really paid off. Two sets allowed me to make the L-shaped template I needed to rout in the treads and

risers for this job. You may never need to rout stringers, but it is nice to know you can. More details

can be found in my "Projects" page, Small Staircase.

© 2008-2009, Brice Burrell Page 43

Page 44

Now we’ll move from using the router to travel around the MFS as a template, to moving the router

and template on a pivot to create circles, curves and arcs.

I'll start with a quick overview of the process for circle cutting before I go into detail. The circle-cutting

insert fits into the interior V grooves of the profiles, the template is closed on and capturing the insert

(see photo above). A 30 mm copying ring fits into the insert, so the next thing to do is install the ring

in the router.

© 2008-2009, Brice Burrell Page 44

Page 45

© 2008-2009, Brice Burrell Page 45

The pivot goes in the underside of the profiles, in the V groove closest to the inside of the template.

Slide the pivot in as far as it will go, then tighten it with the Allen driver.

We need a hole for the pivot to go into. An 8 mm or 5/16" drill bit will do the job.

Page 46

Slip the pivot in the pilot hole, set the insert to the desired radius and tighten it in place, then set the

copying ring/router in the insert. The template and router pivot around the stock to cut the circle. You

can see from the picture that I'm working out the process on scrap first before committing to the real

work piece.

I initially thought using the MFS to cut circles would be a little awkward; turns out I was wrong.

However, setting the size of the MFS to cut circles for the first time was a bit of a challenge for me.

Well, until I realized the instructions show the insert installed incorrectly. I have some drawings to

help illustrate the setup.

© 2008-2009, Brice Burrell Page 46

Page 47

© 2008-2009, Brice Burrell Page 47

I'm going to start by showing the finished piece for this example so you can see what I am setting up

to rout, a cutout with a lip or rebate.

Step one is to lay out for the pivot point, then drill the pilot hole.

Page 48

The next step is to set the insert to rout the proper size circle, the pivot is already installed.

Before we move to the next step, let me explain the set up process in detail. The insert is set using

the scale on the MFS profile and the insert's own scale. The insert's scale is not centered on the hole

for the copying ring (see picture above), at first that doesn't seem make much sense. But remember

the pivot is offset from the profile's scale, this accounts for the insert's offset scale (say that three

times fast). Now, take into account the bit, its cutting edges are offset from the zero point on the

insert. I know, a lot of offsets here, so let me show you a couple of drawings to help clarify things.

© 2008-2009, Brice Burrell Page 48

Page 49

This drawing shows the insert. The scale is larger in this picture than the real one, to make it a little

easier to see. The first thing to notice, the scale has graduations on both sides of zero. Zero is the

centerline of the cut. The graduations above zero (towards the top of this drawing) represent the

outside of the cutting radius, also referred to as R2 in this drawing. And the gradations below zero are

the inside radius or R1. In this example a 10 mm bit is used, the outside radius is plus 5 mm from

zero and the inside radius is minus 5 mm.

This drawing shows how to set the insert with the MFS scale. With the 10 mm bit, the insert is set to

cut a 310 mm outside radius and 300 mm inside radius.

© 2008-2009, Brice Burrell Page 49

Page 50

All right, back to the example. I have a 10 mm bit in the router and the insert set to cut a 100 mm

outside radius (90 mm inside). My MFT has a piece of scrap on it to protect the top, and the work

piece has double-sided tape to hold it down to the scrap. I've dropped the pivot in the pilot hole, set

the depth of the bit to 8 mm. Plunge the router and start turning the template on the pivot to rout the

circle.

© 2008-2009, Brice Burrell Page 50

Page 51

© 2008-2009, Brice Burrell Page 51

Here is the result.

Now I want the center cut out, leaving the lip. I've changed bits, a 6 mm spiral bit now in the router. I'll

move the insert to cut a 90 mm outside radius for the 6 mm bit. The depth is set to cut all the way

through the stock.

Page 52

Remove the center cutout from the double-sided tape and that takes us back to the finished piece,

the first picture at the top of page 47.

© 2008-2009, Brice Burrell Page 52

Page 53

For circle cutting the MFS 400 has a maximum diameter of around 32" and the MFS 700 around 55".

For template routing the 400 set's maximum size is about 4 11/16" x 12 9/16", the 700 set 12 9/16" x

24 7/16". Combining sets and/or the longer profiles greatly increases these sizes (and the usefulness

of the MFS system as a whole).

© 2008-2009, Brice Burrell Page 53

Page 54

I've found making overlapping, systematic passes while template routing offers the best results. I

always check to make sure I haven't missed any spots and the bottom of the routed area is perfectly

flat. Be sure to test fit your work before removing the template anytime you can. It is difficult is get the

template back exactly where it was to rout a missed spot.

Another tip, test your bit and copying ring combinations on scrap stock first to ensure the results are

what you expect. Remember the MFS is as accurate as you set it up to be, so give it the time it

requires. Calipers help me set the MFS for smaller work where the routing being off the tiniest amount

is not acceptable.

© 2008-2009, Brice Burrell Page 54

Page 55

Adding profiles with the angle stops to the outside of the template helps to place and clamp the MFS.

The anti-tilt insert is made to fit 24, 27, 30 and 40 mm copying rings. But, what if you want to use

imperial sized guide bushings? No problem, just use the router's support foot (outrigger) to do the job.

Holding the router flat on the template is the key. If the router tilts it can ruin your work piece, so

exercise care. One more very important thing to mention: let the router bit come to a stop or release

the plunge mechanism before lifting the router out of the template! If the bit contacts the template, you

could damage the bit and most certainly cut into the profile. If the profile is cut where the bushing

rides that edge of the profile, it will no longer produce true cuts. The profile is not ruined; it can be

© 2008-2009, Brice Burrell Page 55

Page 56

turned to have the blemish facing out or turned upside down. However, since you can’t use the scale,

it can greatly affecting ease of set up.

You'll notice the router's dust collection is not as good while routing with the MFS. The open space

the template creates lets chips escape. The chips find their way into the profiles. If you let the chips

build up in or around the profiles they can affect the template accuracy by getting between the

copying ring and the template. I take time to vacuum off the template as needed. Placing the template

on the work-piece perfectly flat is a must. Check to make sure it is still flat after you have clamped

everything down. Again, make sure no chips are under the template.

What I've shown in this section are just some of the routing jobs that can done with the MFS template.

With a little practice (and imagination) you'll be able to do projects that you thought were beyond your

skill level. If you are a novice woodworker, the MFS can have you creating more complicated projects

in no time. Once you have a grasp of the basics, it's pretty easy to build on those skills. Because the

concepts are the same from the simple mortise, to the more complicated routing tasks like intricate

inlay work, your skills will build quickly.

For the more experienced or the professional woodworker, the MFS simplifies some of the routing

jobs we used to do with custom wooden or single purpose built jigs. If you happen to have accurate,

well-made custom jigs, by all means use them. Building custom jigs can be time consuming, sort of a

trial and error process. That's time I'd rather be spending in some other, more productive way. Plus,

© 2008-2009, Brice Burrell Page 56

Page 57

I'm glad not to store custom jigs anymore. I have a notebook, with what Ned Young calls "recipes," of

the MFS settings used on past jobs. Sure you have to spend time assembling the template each time

you want to use it. I happen to feel the flexibility the MFS offers outweighs the small amount of time

spent on set up. Accuracy of the MFS is far better than almost any wooden jig I've ever made.

My final comments on the MFS as a routing template, no matter if you are a beginner or a pro: the

MFS is fast and easy to set up, the routing is accurate and the results are great.

© 2008-2009, Brice Burrell Page 57

Page 58

Cutting Applications

Jerry Work in his manual shows how he uses the MFS as a fence for the MFT and as story sticks to

place guide rails for cutting or routing. In this section I'll show how I have taken Jerry's techniques and

adapted them to my own work.

Using an MFS profile as a story stick is an easy way to accurately place Festool's guide rails. I use

one of the angle stops with a profile to set razor blades to act as stops for the rail, John Lucas' idea.

Install the angle stop in the profile, with the scale up. Using the scale I set the square on the

measurement I want. Then butt the stop up to the square and tighten the bolts.

© 2008-2009, Brice Burrell Page 58

Page 59

© 2008-2009, Brice Burrell Page 59

With the profile lined up with the edge of the work piece and the stop butted to the end, I have a

perfect story stick to help place the rail.

Now it's as simple as sticking a razor blade in the work piece at the end of the profile.

Page 60

© 2008-2009, Brice Burrell Page 60

Registering the rubber edge of the guide rail off the blades will give me the exact location I want to cut

this piece to.

Be sure to remove the razor blades before you make the cut. Use this technique any time you

need to make multiple cuts the same size. It works just as well with short or long rails.

Page 61

An often asked question on Internet forums is "How do I make narrow rips with the Festool plunge cut

saw and guide rail?"

Using the MFS 400 with my MFT is what I've found to be the easiest, fastest, safest and most

accurate. In this picture you see the setup I use. Note the wooden fence extension (green arrow).

This prevents the rip from being thrown forward if it gets caught in the blade. For the rest of the setup,

the MFS is butted up to the MFT's fence, acting as stop to set the width of the rip. The stock is then

placed against the fence and the MFS, clamped and ripped.

© 2008-2009, Brice Burrell Page 61

Page 62

Step one in the setup is to assemble the profiles with the scales on the outside and checking to make

sure the setup is square. Now, I slide it under the guide rail and set the edge to be even with the

rubber splinter guard on the rail.

© 2008-2009, Brice Burrell Page 62

Page 63

© 2008-2009, Brice Burrell Page 63

One of the things that makes this technique so fast and easy is using the scale on the MFS to set the

width of the rip. With the MFS lined up with the rail make a pencil mark at the profile's zero point (end

of the profile). With this mark I'll be able to use the scale, in reverse, to set the width of the rip.

In this picture you see the MFS set to make a 10 mm rip.

Page 64

© 2008-2009, Brice Burrell Page 64

The MFS has to be clamped in place to prevent it from moving during the cut, I also clamp the stock

to be extra safe.

Then it's like any other cut, drop the rail, plunge the saw and cut.

Page 65

Here are a few 10 mm rips. When I want to make imperial (inch) widths I use a small combination

square. I set it to the size I need, and then place it against the rubber edge with the blade of the

square under the rail. Butt the MFS to the square's blade and clamp the MFS.

© 2008-2009, Brice Burrell Page 65

Page 66

Here is a look at Jerry Work's idea of how to use the MFS as a fence for cutting and routing with the

MFT. It consists of profiles to form a square or rectangle and a single long profile as a fence. The

scales on the profiles are used to set the distance from the square/rectangle to the guide rail's rubber

splinter guard.

I am intrigued by this setup, although I have yet to fully incorporate it into my work so far. I find myself

using the profiles for other jobs and unable to dedicate them to the MFT. I think the addition of the

longer 1000 mm profiles would allow me to take full advantage of this ingenious idea.

© 2008-2009, Brice Burrell Page 66

Page 67

© 2008-2009, Brice Burrell Page 67

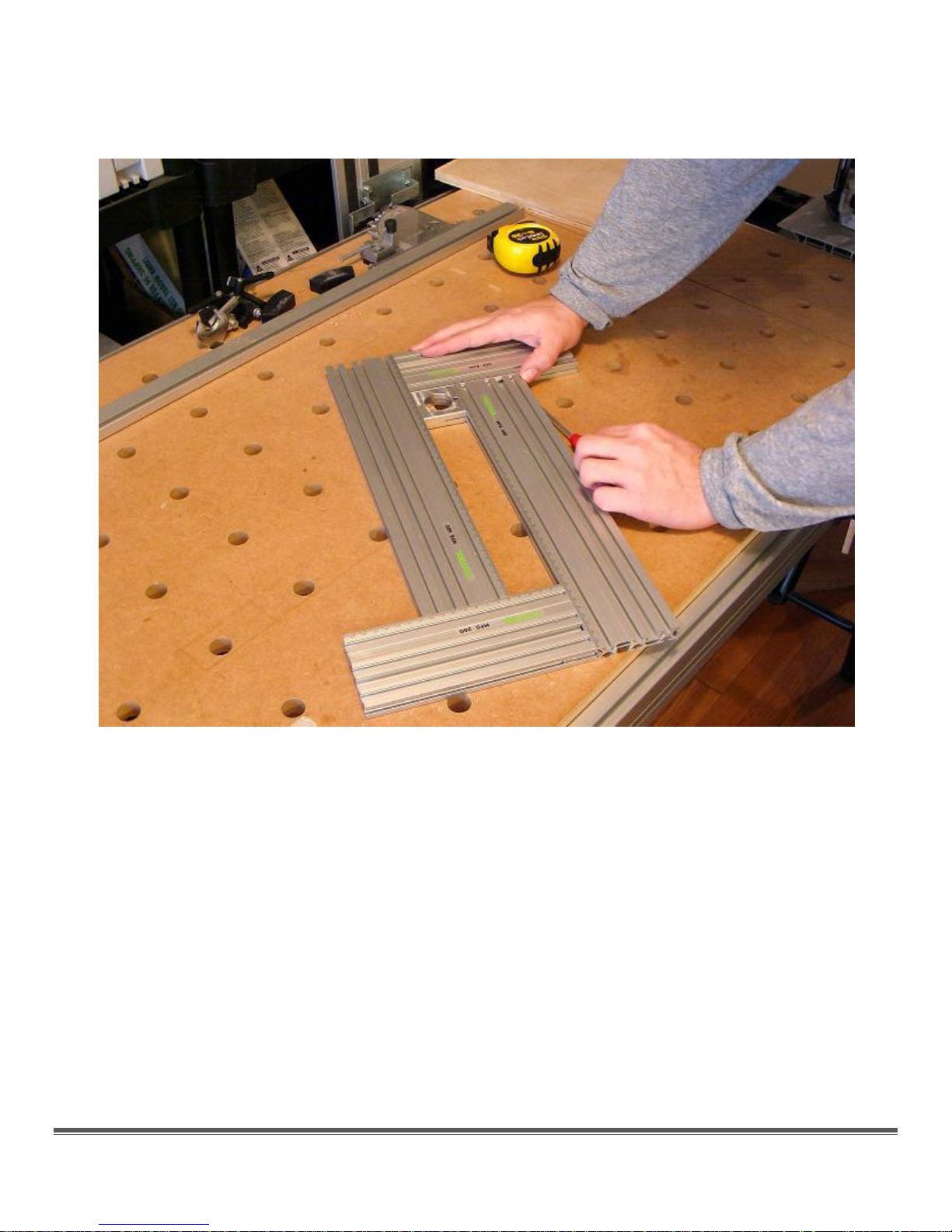

The following is the process I used for the setup. I've used 400 mm profiles to make a square (scales

facing out) and two profiles joined lengthwise to act as the fence.

To hold the two profiles that will be the fence, two clamps are placed in from the bottom the MFT.

Then the profiles slide onto the clamps. The clamps are not tightened yet. That gives me what you

see in the first picture on this page.

Page 68

The next step in the process is to set the square to the guide rail's edge, like I did with the setup for

narrow rips.

Now the square is indexed perfectly with the guide rail, then the square gets clamped down. I want to

calibrate the scale on the fence profiles with the square's scale. However, I'm going to offset them by

10 mm. Holding the fence profiles tight to the square I want to line up the 39 cm mark with the fence's

zero mark at the end of the profile. With everything lined up I'll tighten the clamps for the fence

profiles (under the MFT).

© 2008-2009, Brice Burrell Page 68

Page 69

© 2008-2009, Brice Burrell Page 69

This is a close up of the offset of the scales. The 39 cm mark on the zero point of the fence's scale.

Now to set the distance of the square from the guide rail I use the scale on the fence profile.

Slide the square to the distance needed and clamp it. Now you can cut or rout the work piece. The

insert in the picture shows the square is set to 290 mm.

Page 70

This setup shows great promise. It's fast, easy and accurate (there are those same three words

again).

I've not fully explored cutting applications for the MFS. Most of my time with this system has focused

on routing. I'm sure to find more uses for MFS to cut and rout as time goes by. As it stands now, I'm

fairly happy using the techniques shown here.

© 2008-2009, Brice Burrell Page 70

Page 71

Using the MFS As A Clamping Aid

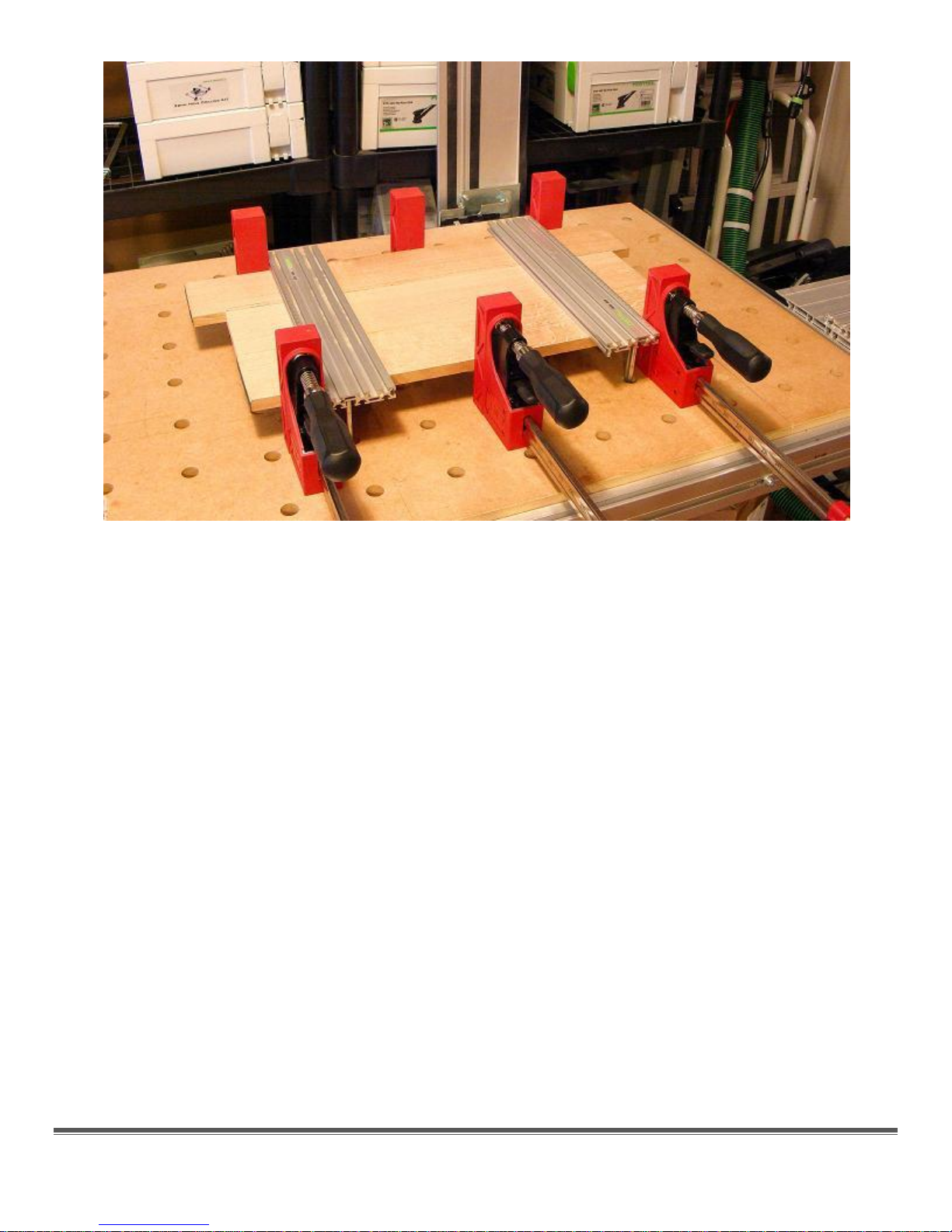

The MFS profiles offer a lot of options for different configurations. I use one shown here most often

for clamping face frames. Once the profiles are clamped to the MFT they provide a sturdy squaring

fixture.

Clamps can be added almost any place needed to square the frame.

© 2008-2009, Brice Burrell Page 71

Page 72

Both the MFS 400 and 700 sets were used in the configuration shown above. A much simpler version

for smaller projects can be made from the MFS 400 set. The profiles are clamped against the MFT

fence, making a perfect right angle clamping jig, as seen in this picture.

© 2008-2009, Brice Burrell Page 72

Page 73

Squaring is not the only way to use the MFS to aid in clamping. I've used my profiles as cauls. With

clamps from below the MFT the profiles can be clamped, pressing the stock down onto the bars of

the parallel clamps, giving me flat glue ups.

The profiles can be quickly put together to make a custom clamping jig and when the glue dries, take

them apart for the next project.

© 2008-2009, Brice Burrell Page 73

Page 74

Miscellaneous Uses For the MFS

Finding creative solutions to the everyday problems that affect productivity or enjoyment of our work

is the key to successful projects. I use the MFS, not just as a routing template or as cutting and

clamping aids, but to make any task easier, faster. It’s a problem solver.

I've used the MFS to index my Domino to cut mortises in the middle of panels. I set the angle stops to

square the profiles to the edge of the work piece so the zero point is right on the edge. This will let me

use the scale on the profiles to index the Domino.

© 2008-2009, Brice Burrell Page 74

Page 75

I set the MFS to the location on the panel where the mortises will be cut and clamp in down.

With the base of the Domino against the MFS profile, I can cut all of the mortises in a perfectly

straight line, at a right angle to edge of the work piece. Using the center line on the Domino's base

and the scale on the MFS, the mortises can be cut quickly and accurately. I would normally use the

backside of the guide rail on the MFT for this, but when I'm on a jobsite without my MFT this really

comes in handy.

© 2008-2009, Brice Burrell Page 75

Page 76

© 2008-2009, Brice Burrell Page 76

I've struggled to find a good way to use the 42" LR32 rail on stock longer than the rail itself. No

problem; install a guide rail connector to join an MFS profile to the rail and clamp the profile to the

edge of the stock. Now drill your holes.

Stock eight feet long posed an even bigger challenge. Using the same technique and the circlecutting pivots to re-index the rail, you can drill holes in a full sheet of plywood.

Page 77

How about a jig to cut toe kicks for cabinets? One edge of the saw's base rides against the profile and

the second profile acts as a stop for the cut. The first picture shows the setup, the angles stops are on

both the top and bottom of the profiles to index the jig.

Second photo, I'm holding the jig and making the first cut. Third, I've flipped over and turned the jig 90

degrees to make the second cut. Fourth, the finished toe kick. I can make the cuts in less time it

would have taken to do the layout. It’s easy, fast and, you guessed it, accurate.

Again, the MFS flexibility is shown here. Finding different uses, both within the Festool system and

out, for the MFS is only as far away as your imagination.

© 2008-2009, Brice Burrell Page 77

Page 78

Closing Thoughts

As I've touched on already, this review of the MFS system has a recurring theme: Easy, Fast and

Accurate. Add to those attributes a great deal of flexibility of the system and the value of the MFS

becomes very apparent.

Let me give you one example of why the MFS is so valuable to my work. I get jobs a few times a year

where homeowners want to upgrade their old, hollow core doors to a much nicer, solid core doors.

This means routing for hinges and other hardware in the new door. Blanks, jigs or templates are

needed to quickly and accurately do the job. In the past I would have to spend time making all of the

different jigs. I could need the table saw, chop saw, jig saw, compressor/brad nailer and the stock to

build the jigs.

With the MFS I only spend a few minutes setting up the template to rout the hinges. When finished

with all of the hinges, I readjust it for the next piece of hardware. I've tried other adjustable routing

jigs; some I've liked and some I wouldn't even use again to scrape chewing gum off the sidewalk. But

for the most part, they were not the right tool for the job. Now, I only keep the MFS on the truck. It's so

easy to use I can hand the job off to one of my guys so I can turn my attention elsewhere. Being able

to get in and out of a job quickly and not having to come back because of poor quality work is how I

make my work profitable. The MFS is a real help in this regard. You don't need to be a finish

carpenter to realize the same time savings and ease of use that I've found with the MFS.

To take full advantage of the flexibility of the MFS system I'd recommend both the MFS 400 and 700

sets. I found I tend to use the smaller 400 set for most of my template routing, but the larger 700 set

for cutting and clamping applications. If your budget doesn't allow for both, take a close look at your

particular needs and decide which set best suits them. You can always add another set and/or the

longer 1000 or 2000 mm profiles later as your needs grow.

© 2008-2009, Brice Burrell Page 78

Page 79

The flexibility the MFS is its single greatest attribute. Routing template, cutting, routing and clamping

aid all in one. Normally I don't buy into a tool that claims to do it all. You know the saying, "jack of all

trades, master of none.” However, that is not the case with the MFS. It does all of these things equally

well and all of them very well. In true Festool fashion, the MFS meshes perfectly with the entire

"Festool System".

I've not yet reached the limits of what the MFS has to offer, that's part of what I like so much about

Festool products. It's what I call "built in value". It may be unseen at first, but the solution to a problem

or a new easier, faster and more accurate way to do the everyday jobs we do for a living or for pure

enjoyment. Good luck and I hope you enjoy using the MFS system as much as I do. -Brice Burrell

Visit my website for more Festool tips and reviews, Burrell Custom Carpentry.

I'd like to thank a few people, first, goes to Mr. Jerry Work, his manuals are the foundation that we all

built our Festool knowledge on. I had the luxury of his MFS manual as a starting point, also, John

Lucas for all he's done to help users better understand the Festool system, thank you. Also thanks to

Ned Young for his editing work and Noel Nyman for helping with this PDF file.

In the interests of full disclosure, this tool was provided by Festool for review purposes.

© 2008-2009, Brice Burrell Page 79

Loading...

Loading...