Page 1

Advanced Cutting and Routing Techniques

Using the Festool MFS Fence System

Text and Photos by Jerry Work

Isn’t it interesting how every so often a simple appearing new tool or technique comes

along that offers us the opportunity to make a quantum leap in our productivity? Once

put to use, we can’t believe we ever got along without it. Yet, when we first look at it we

have trouble comprehending just how it can make such an impact. I want to share with

you one such simple appearing new tool that can radically improve the accuracy and

flexibility of Festool guided rail cutting and routing - the Festool MFS fence system.

While it is described in the Festool literature as a “multi-routing template,” and it is very

good at that function, we will discover here just how much more than that it becomes

when used in conjunction with Festool guide rails as a universal squaring, aligning,

cutting and routing guide. We will learn how greatly it increases the versatility and

accuracy of setting guide rails for precise and repeatable cutting and routing operations.

We will learn how it facilitates cutting of everything from multiple, identical narrow strips

to adding sliding table-saw-like accuracy to breaking down large panels. We will also

see how using it we can prep solid wood stock to be perfectly square and precisely dimensioned just as one would normally do on large industrial machinery as well as how

we can cut complex joints like haunched tenons and interlocking sliding dovetails using

just Festool hand power tools, the Festool Multi Function Table, Festool guide rails and

the Festool MFS fence system.

Most readers of this piece already have

some experience with or

at least an

understanding of Festool guided

rail cutting.

Since the introduction of

hand power

tools, users

have created

a whole variety of jigs

and fixtures

to help guide

a saw or

1

router in a straight line.

Unfortunately, most

of those efforts depend

on the user

being able to

keep the

base of the

saw or router

firmly against

the edge of

some sort of

fence. Many

find it hard to

do that with

accuracy and

repeatability

Page 2

since saws and routers are subjected

both to in-thrust forces which tend to

push the saw or router against the fence

as well as out-thrust forces which tend to

push the saw or router away from the

fence. Far too often the result is a less

than perfect straight cut.

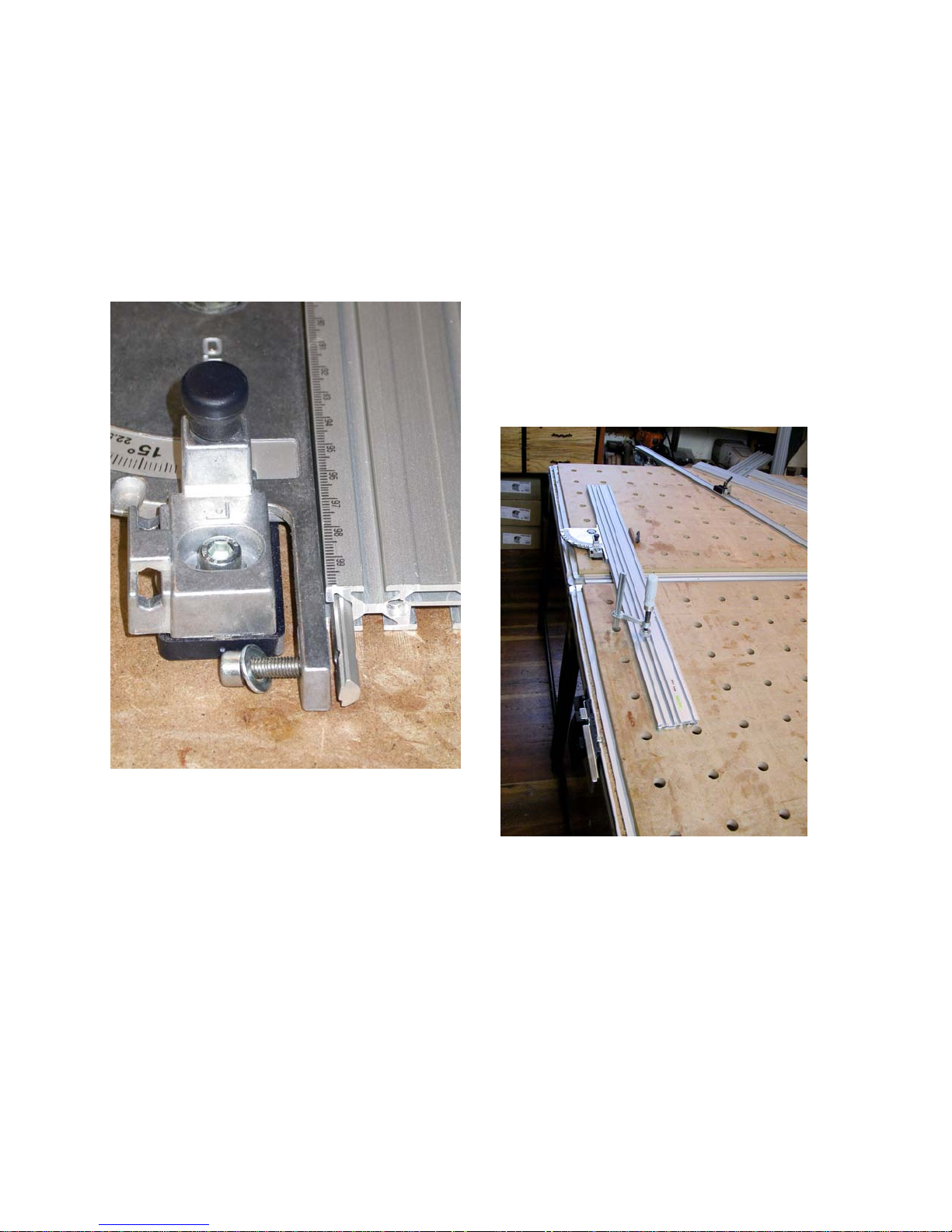

The innovative engineers at Festool developed a unique guide rail (the horizontal piece in this photo) which features a

hat shaped track onto which each of its

cutting tools rides. A “U” shaped channel

is cast or cut

into the base

of each cutting tool or

into a guide

made just for

that cutting

tool. That

channel has

gibbs which

can be adjusted so the

channel fits

firmly on the

hat shaped

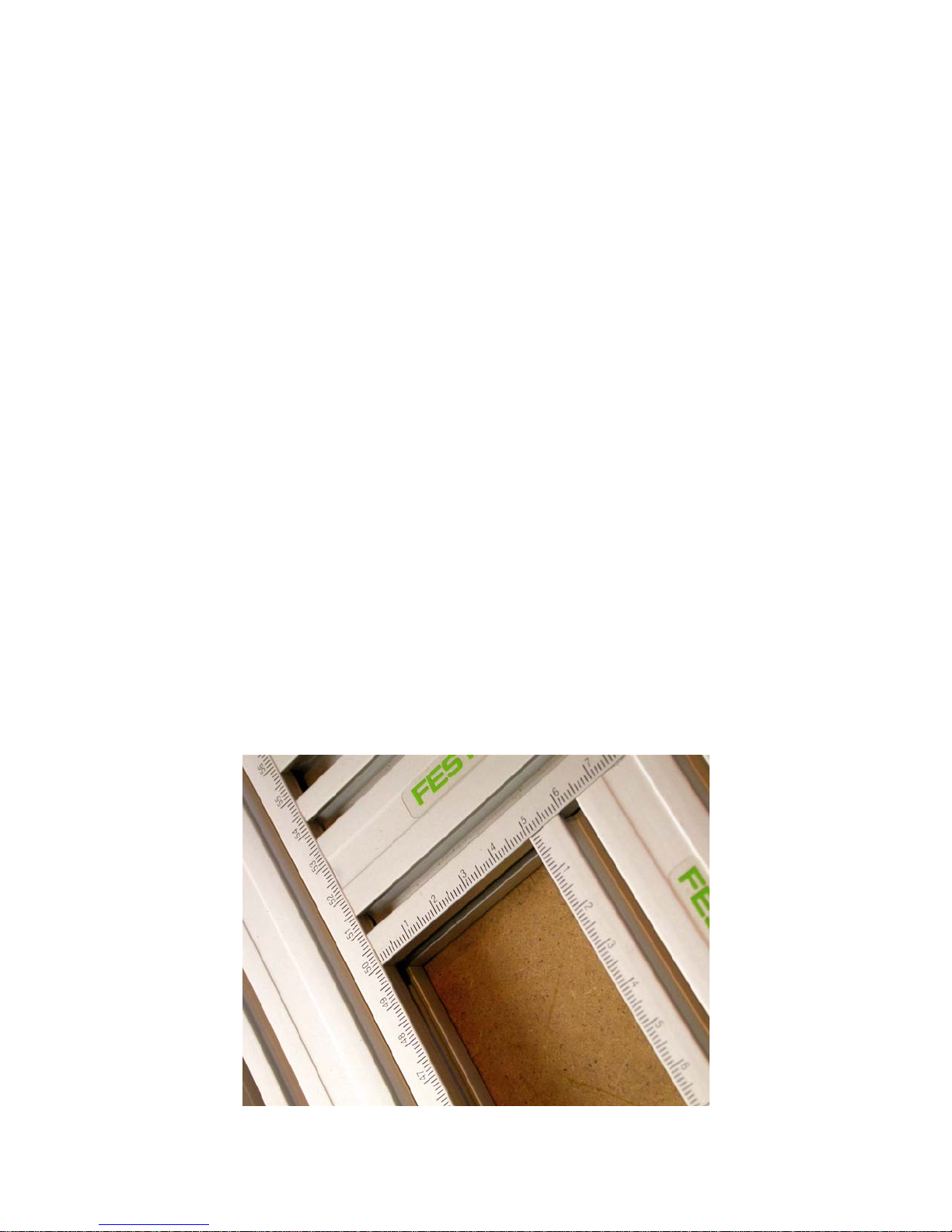

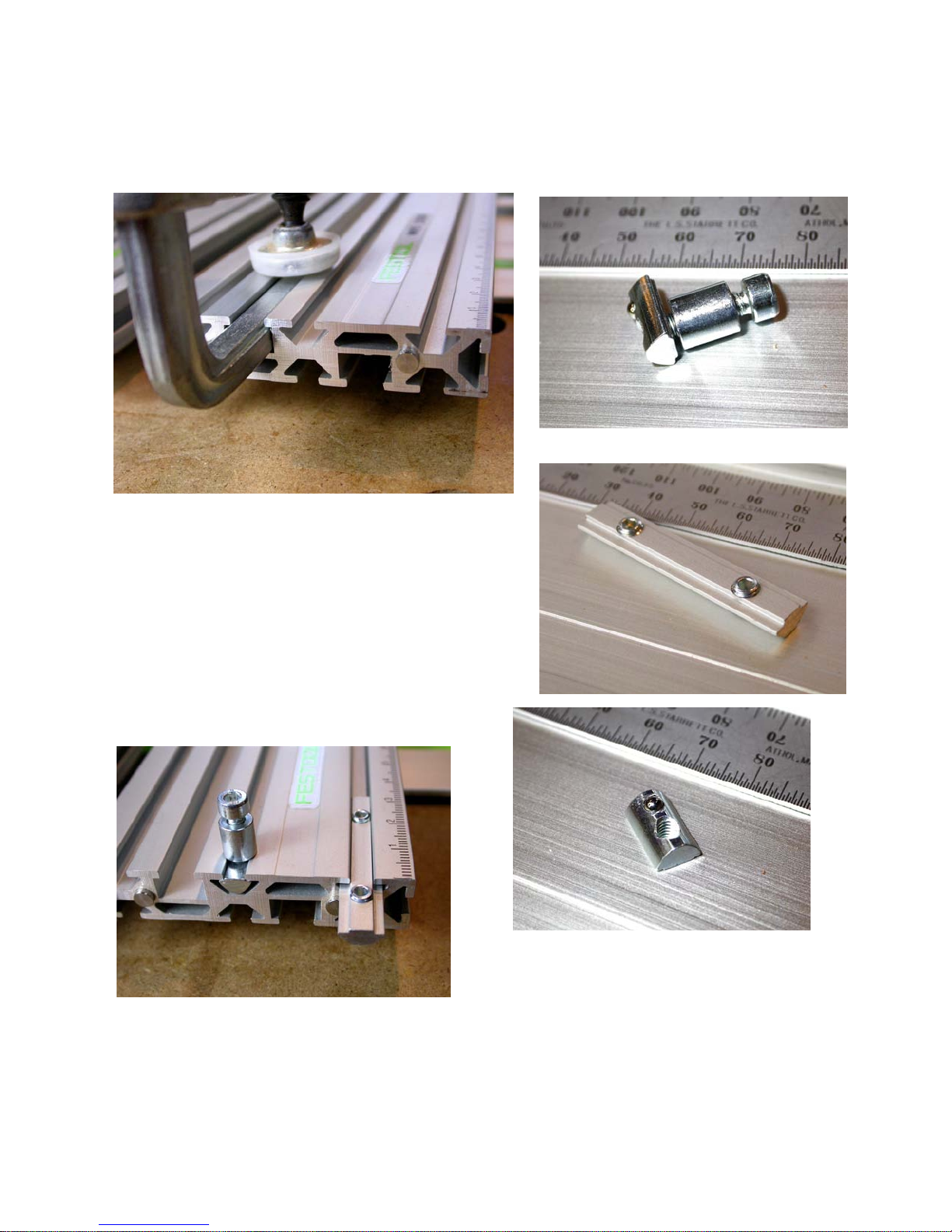

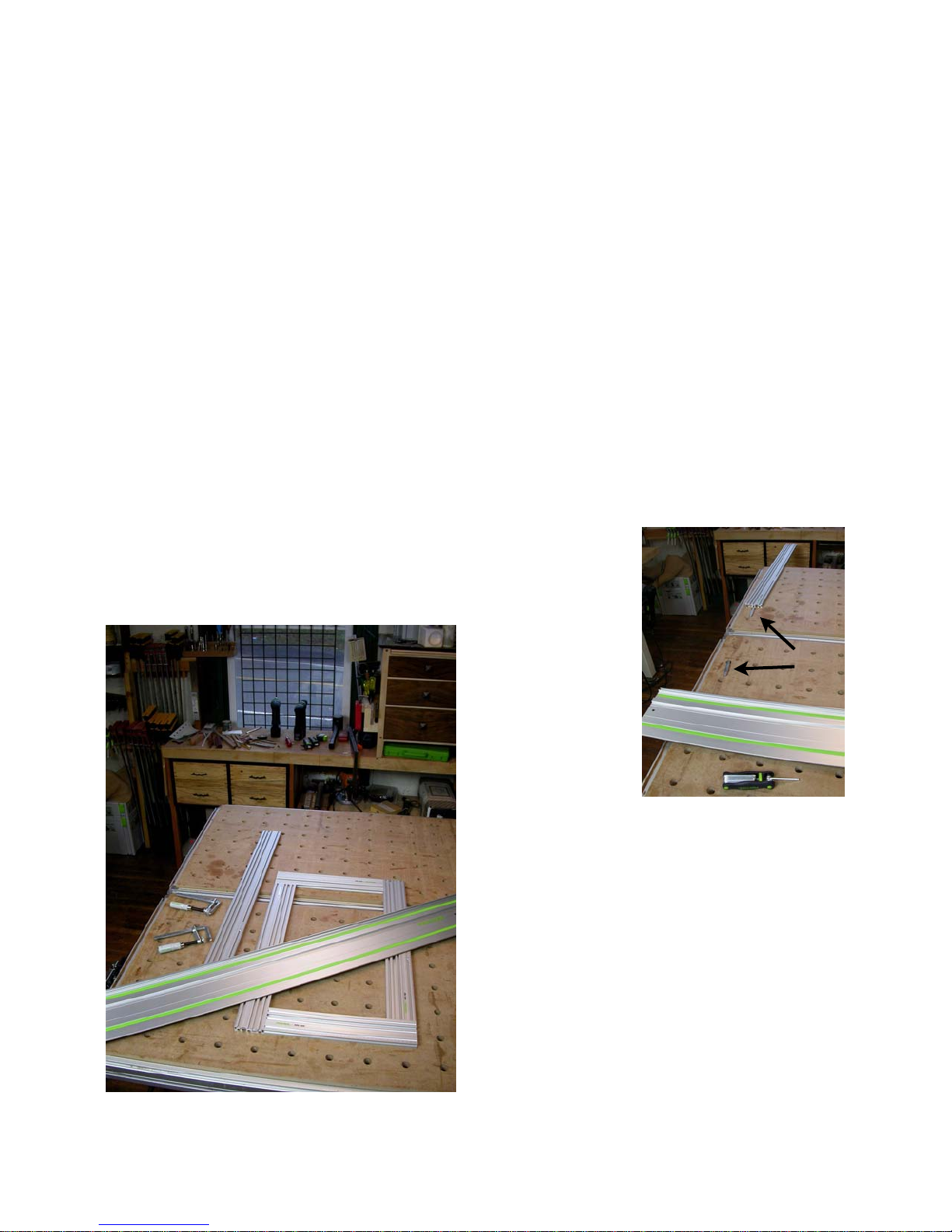

Festool MFS system components

section on

the guide

rail. Since

the base of

the cutting tool is held firmly on both

sides as the two sides of the “U” engage

the two sides of the hat, the tool is guided

in a perfectly straight line whether subjected to in-thrust or out-thrust forces.

This is the heart of Festool guided rail

cutting and routing.

What this allows is a whole new way of

machining wood. Instead of passing the

work piece by a stationary cutter, guided

rail machining allows the cutter to be

moved past the stationary work piece in a

highly controlled manner. This opens up

all sorts of things that become easy to do

which previously, using the old techniques, were hard to do.

One example is the ability to easily cut

multiple mirrored stopped dados or sliding dovetail slots on either side of a cabinet carcass. When you try to do this with

conventional stationary cutting tools you

wind up referencing some of the cuts off

of the top of one piece and their mates off

of the bottom of the other piece. You

might get lucky and have two such

stopped mir-

rored slots

line up that

way, but it is

a rare craftsperson who

can make

four, five, six

or more such

slots line up.

Using Festool guided

rail routing it

is easy to do

as many

such stopped

mirrored

slots as you

wish and

have them all align perfectly.

Since the Festool offerings are all considered parts of one system, there are

many components from which to choose.

Many people start with a Festool circular

saw, a guide rail, some clamps to hold

the guide rail firmly to the work piece and

one of the excellent Festool dust collectors so that the cutting operation makes

far less mess of saw dust all over the

place.

2

Page 3

The first few cuts using this set up are

often a revelation for the user. Suddenly

it is easy to break down that large sheet

of plywood or MDF that is so awkward

and potentially dangerous to cut on a

conventional table saw. The user is

blown away by the fact that the first cut

with the circular saw cuts a rubber edge

on the guide rail to be zero clearance to

the saw blade from that point forward.

That zero clearance edge on the guide

rail makes setting the guide rail to measured marks a cinch, and it

also provides for a splinter

free cut along the inside of

the cut line. On the TS series circular saws there is

also a sacrificial plastic part

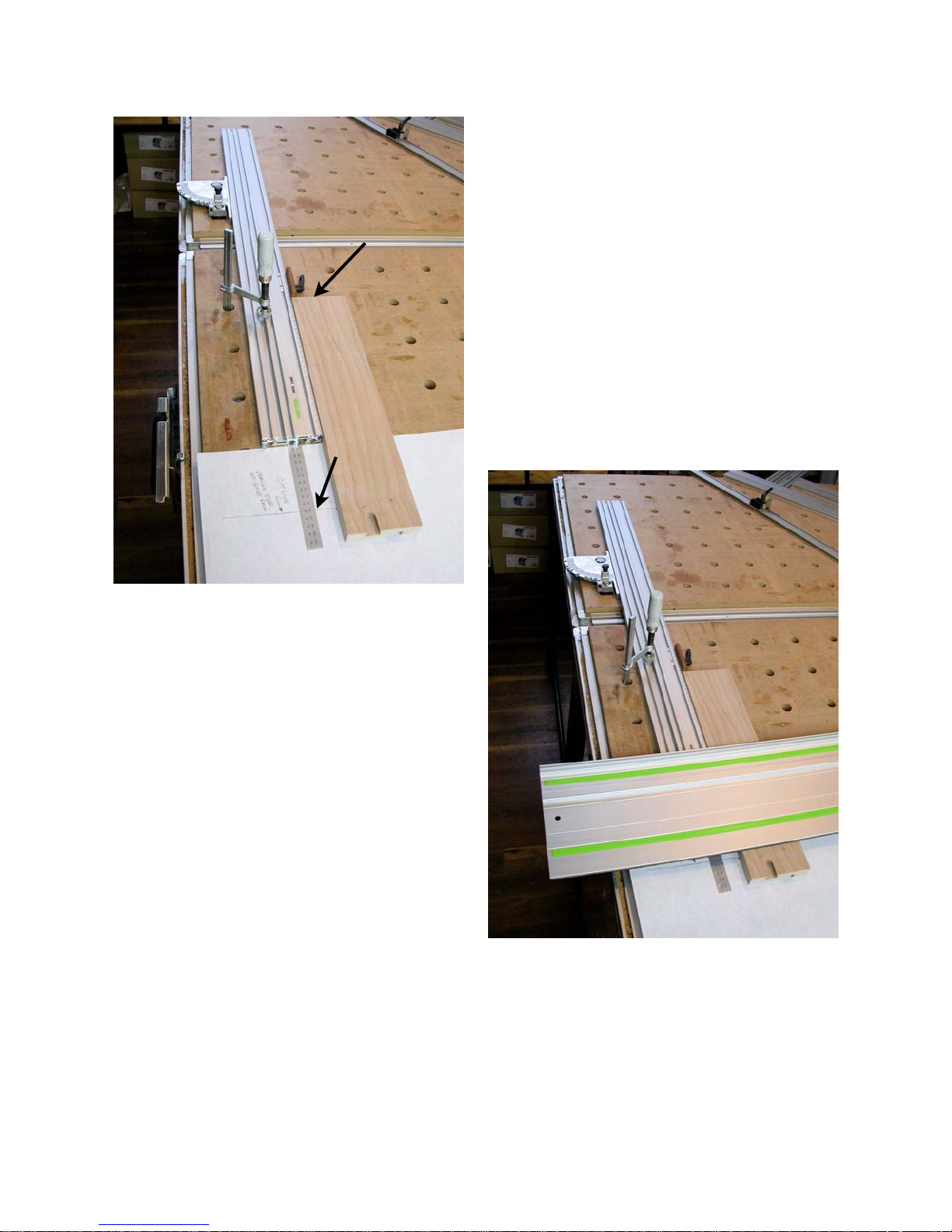

The MFS system used as a very

precise vernier fence for positioning the work piece relative to

Festool guide rails

that provides a zero clearance, chip free cut on the

outside of the cut line as well.

work pieces at a more comfortable working height.

When they first look at the MFT, they see

a nicely constructed portable table with a

bunch of holes in the top. A bit closer inspection reveals that the table also

comes with supports to hold the guide rail

in exactly the same place every time it is

mounted to the table and with a miter

fence so the work piece can be held at a

precise angle relative to the guide rail.

While it is easy to set the

guide rail accurately to marks

measured out on both edges

of a work piece, measurement errors can creep in if

you want to cut multiple

pieces of exactly the same

size. We will show in a moment how to use the MFS

universal squaring, aligning, cutting and

routing guide to make multiple perfectly

sized pieces with one simple set up.

Since we will be referring to the MFS

guide frequently in this manual I will leave

off the “universal squaring, aligning, cutting and routing” part of its name and

simply refer to it as the “MFS guide” or

“fence” from here on.

Once new users get used to guided rail

cutting, they often will add next a Festool

Multi-function Table (MFT) to support the

The miter fence has a “T” slot which accepts stops so that once a measured distance back from the front edge of the

guide rail is established, work pieces can

be positioned for repeat cross cuts of the

same length with very good results.

Again, however, the precision of the

length dimension is a function of how well

users read the tape measure, how accurately they make their mark at the intended length of cut, and how accurately

they set the stop to the mark. The process works very well for most cross cuts

3

Page 4

but measurement errors can again creep

in.

Rips, especially thin rip cuts, are another

matter all together. Most users find it difficult to accurately set up the guide rail for

rip cuts as they again must rely on measured marks on two edges of the work

piece. Then they must align the front

edge of the guide rail to those marks.

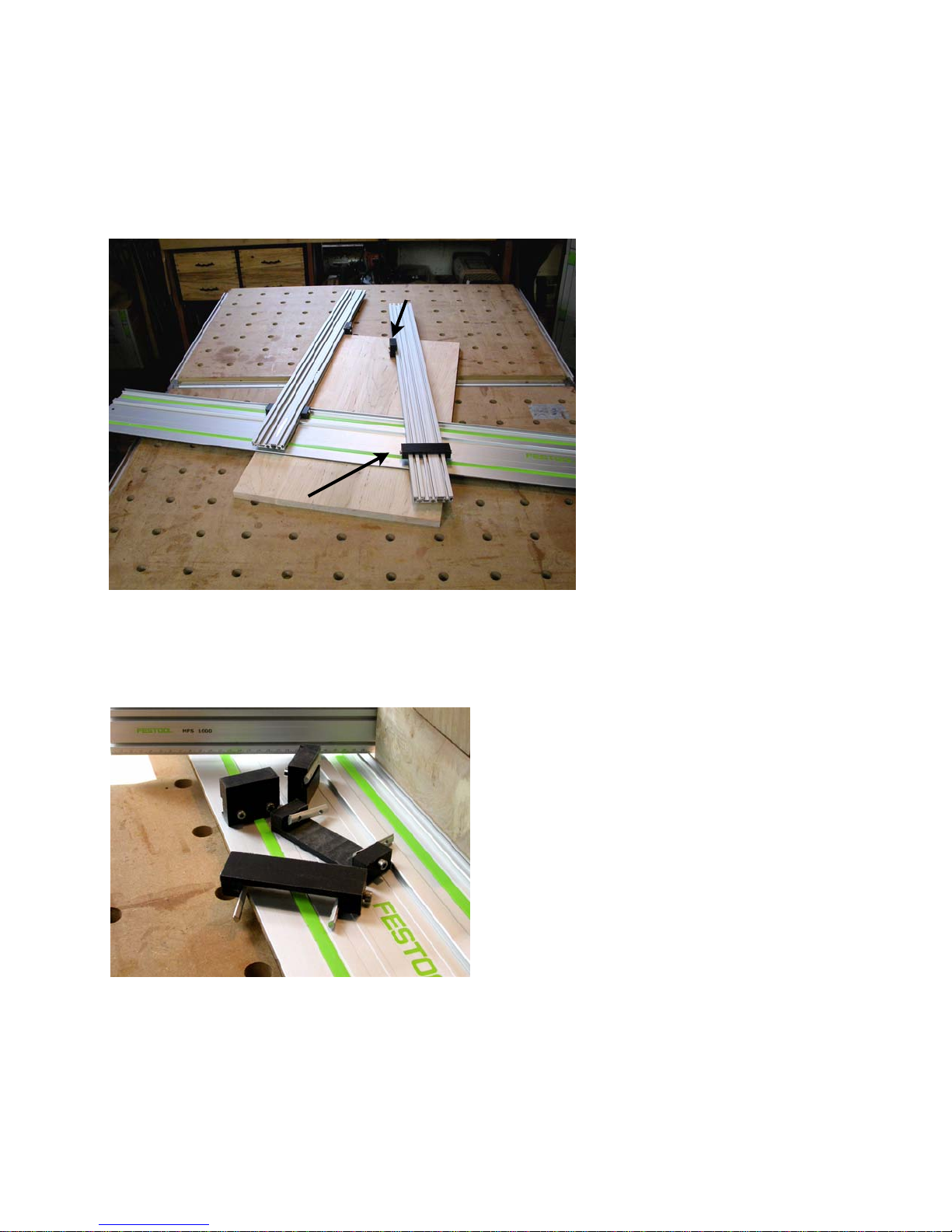

MFS profiles used as “story

sticks” to accurately position

Festool guide rails

Doing so for one rip cut usually works

okay so long as the work piece is wide

enough to provide good purchase for the

guide rail. If the intent is to produce multiple rip cuts of exactly the same width, as

in making rail and stile components,

things get a bit more difficult, especially

for first time users.

Also, if the intent is to produce multiple

thin strips, say 10mm (3/8”) or less in

width, that is also difficult for most to do

accurately. If the work piece is set under

the guide rail for good purchase then the

work piece has to be moved out each

time by the sum of the intended work

piece width plus the actual saw kerf

width. It is certainly possible to set up

stops or fences to do that, but the process is not very fast and can be frustrating

for some.

We will see shortly how we can use the

Festool MFS fence components to make

very precisely dimensioned thin or wide

rip cuts limited only by the length of the

guide rail in use and the ability to support

the work piece across its length. One

example we will use will be making rail

and stile components to a very close tolerance and cutting haunched tenons on

the ends of the rails all using just the Fes-

tool guide rails and MFS fence components. In another example we will rip

multiple 5mm wide strips to use as inlay

material, again just using Festool guide

rails and MFS guides.

We will also show how to use the components of the MFS fence system as

measured “story sticks” to aid setting

guide rails on large sheet goods very

precisely as is shown in this photo.

Then we will turn our attention to the

use of the MFS fence system for guiding

a Festool router for doing everything

from open field inlay work to delicate

string inlays, to complex pattern and template routing to produce multiple complexly shaped parts quickly and easily.

Once we tackle all of these uses for the

MFS fence system, I think you will reach

the same conclusion I did that the Festool

MFS is a simple looking tool which can

radically improve the accuracy of all your

guided rail cutting and routing operations

thereby helping you make a quantum

leap in your productivity.

So, grab a beverage, sit back and let’s

take this journey together.

4

Page 5

What is the Festool

MFS fence or guide

system?

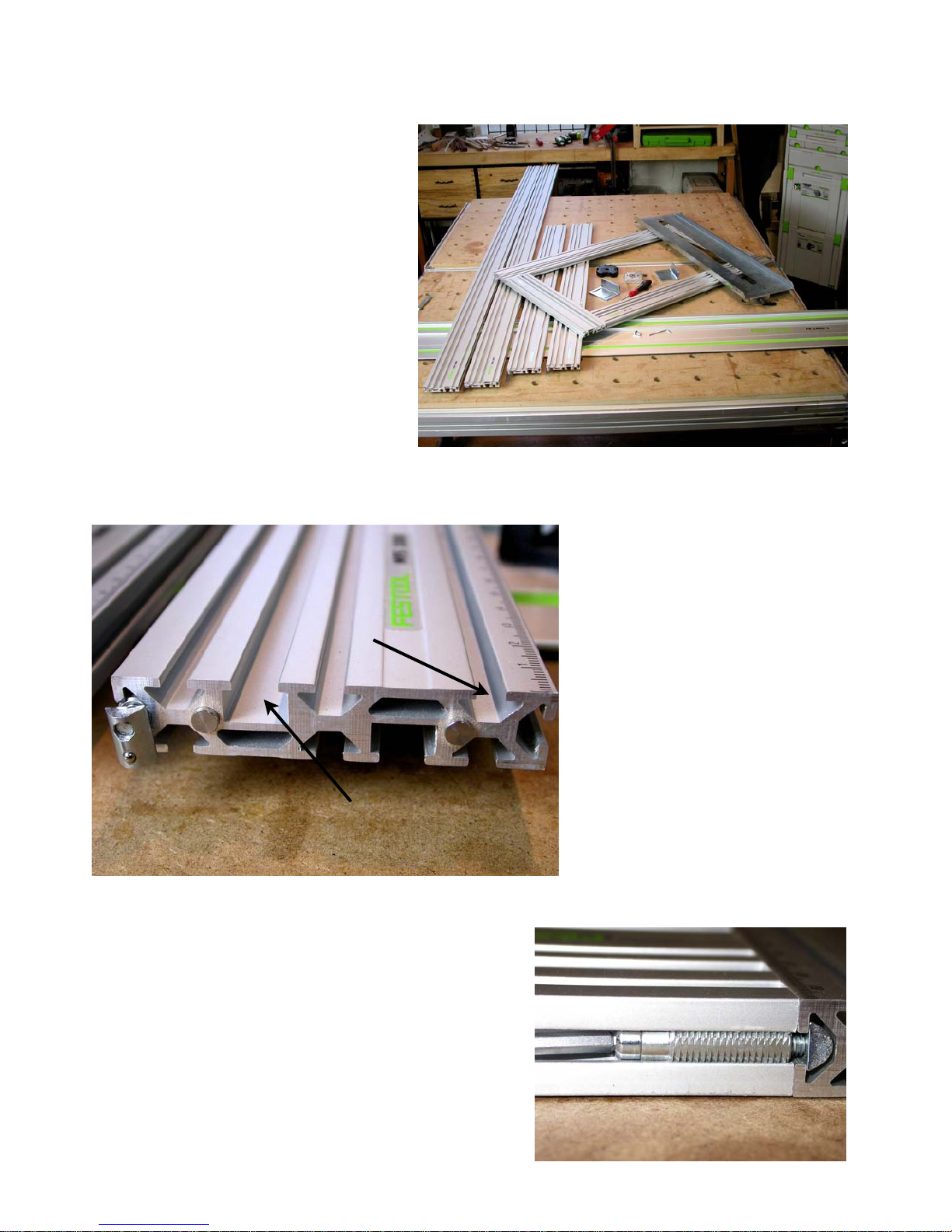

At it’s heart, the MFS is a very

precise, complex aluminum extrusion 80mm wide and 16mm thick.

It comes in 200mm, 400mm,

700mm, 1000mm and 2000mm

lengths shown in this photo sitting

on top of a Festool guide rail.

That is roughly 3 1/8” wide, 5/8”

thick with standard lengths of a bit

over 8”, a bit over 16”, 27 1/2”, 39

3/8” and 78 3/4”. From here on I

will only refer to the metric sizes as that is

Special MFS “V” track, one

on each side and three on

each face

the Festool guide rail “T” tracks so the

same Festool clamps and other

accessories will fit.

On both sides of the 80mm

widths and along each 16mm

side are “V” shaped tracks

unique to the MFS. Festool

supplies a variety of different

nuts that slide into these “V”

tracks to allow the attachment

of different supplied and shop

built components.

how each of these extrusions is identified

and marked.

Along one edge are ruled marks in millimeters starting at zero and going to the

length of the extrusion. The ends are cut

very accurately at 90 degrees.

On the top and bottom 80mm widths are

“T” tracks the same size and shape as

5

Standard Festool “T”

track on each face

One of the nuts that fits into the

track on one or both 16mm

sides is a threaded insert

(shown below) which is held

firmly in place. A hole through

that insert allows a 4mm cap

Page 6

head machine screw to pass through to

thread into a short “V” nut. By sliding that

short “V” nut into the side “V” track in another unit, two extruded pieces can be

assembled at right angles to one another.

circle and arc routing which is easily done

using the MFS profiles. Here are detailed

shots of that standard piece and the

The picture above shows how a standard

Festool “F” style clamp (48957 and

489571) fits into the “T” slot on either face

so you have lots of options as to how to

clamp these profiles to your work piece or

to a Festool Multi-function table.

This picture shows how the special MFS

“V” nuts fit into the “V” track to hold all

kinds of jigs and fixtures. The round

piece in the center is a pivot point for the

two standard “V” nuts. The one with two

holes is threaded for 5mm, the smaller

one with the detent ball for 4mm.

6

Page 7

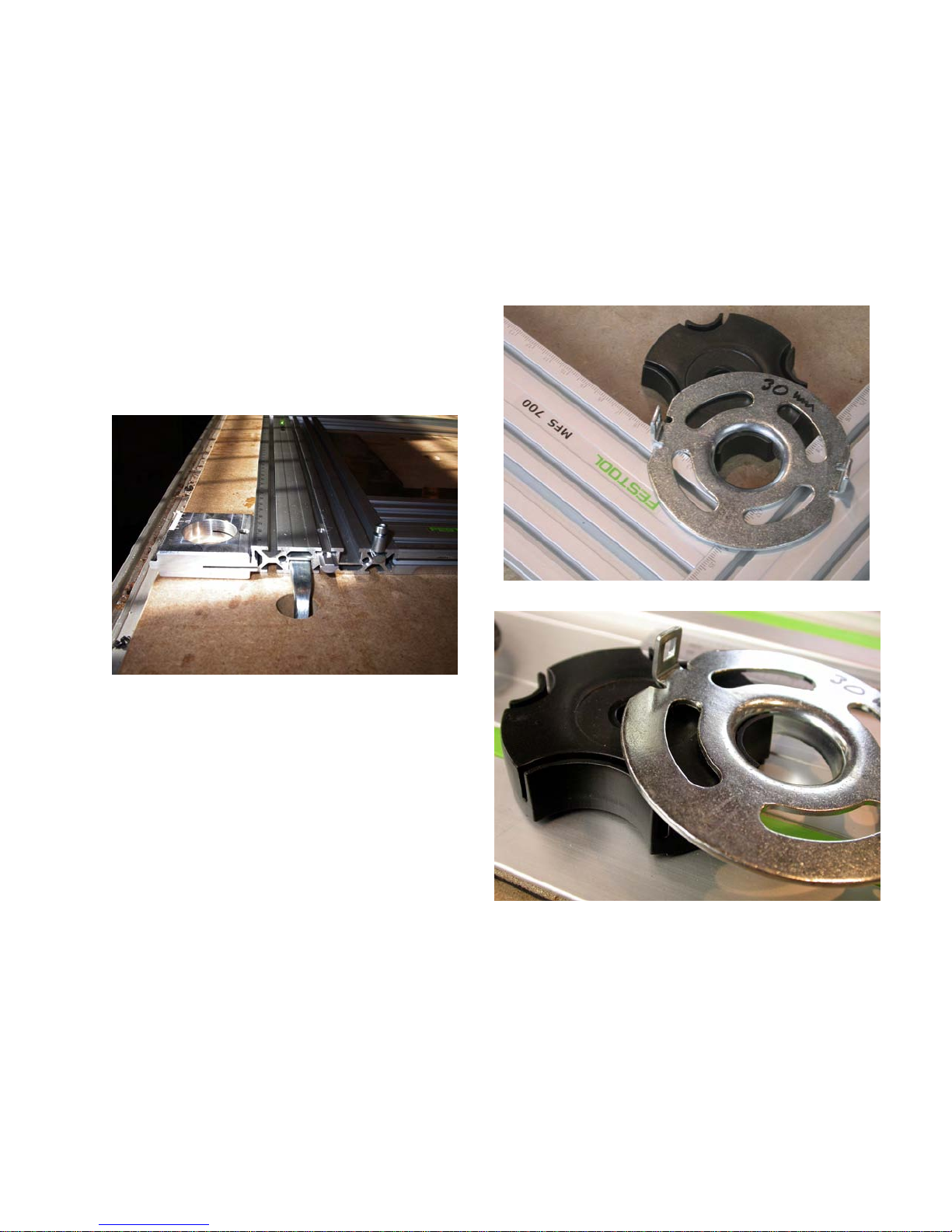

Four such extruded pieces assembled at

right angles to one another form a very

square and adjustable rectangle.

Standard components shipped

with the MFS 700 starter kit

A ball headed

3mm Allen key

is supplied to

allow you to

easily tighten or

loosen these

connecting

points so you

can slide the

extruded pieces

to form rectangles of any size

up to the length

of the extrusion

plus the 80mm

width of the adjoining extruded

piece. The inside rectangle

formed is the

length of the extruded piece less

the 80mm width of the adjoining

extruded piece.

as 780mm by 480mm outside and

320mm by 620mm inside.

You can also purchase

additional longer extrusions in either 1000mm

or 2000mm lengths.

Two or more extrusions

can be joined end to

end with MFS joining

units (the two hole “V”

nuts and 5mm set

screws shown on the

previous page) so there

is really no limit to how

large a rectangle you

can form for special applications.

The starter kits also include two heavy metal

angles (shown in the

photo left) roughly

80mm wide with one

30mm and one 60mm

side. These have two

For example, the starter set

492610 which is listed in the Festool catalog as 15.7” by 7.8” and

called MFS 400 has two 200mm

extruded pieces and two 400mm

extruded pieces. They will make

a rectangle up to 280mm by

480mm outside and 120mm by

320mm inside.

Starter set MFS 700 shown

above with the Festool catalog

open for size comparison has two

400mm and two 700mm extrusions so it will make a rectangle as large

7

4.5mm slots cut into them through which

4mm bolts can pass to thread into one of

Page 8

the special nuts that fit into the “V” slots.

This allows the heavy metal angle pieces

to be used to locate the extrusions relative to the sides or edges of a work piece

and/or to fasten the extrusions to the

work piece.

Festool also supplies a machined aluminum piece shown below that is 50mm by

50mm and 16mm thick with a 30.25mm

hole in the center and a tongue on two of

its sides that fits into the “V” slots. One of

the tongues is split with a set screw that

will widen the split to fasten the aluminum

For example, an elegant head board can

be made with a sophisticated long radius

arc across the top that would be very

hard to duplicate any other way.

The final component supplied with either

the MFS 400 or MFS 700 starter kits is

the clever molded plastic anti-tip ring

piece in place anywhere along the edge

of any of the extruded pieces.

This piece has a number of uses, the

most common of which is to receive a

30mm guide bushing on a router. A 5mm

pivot point (shown before) is also supplied which will fasten to one of the special nuts that slide in the “V” slots. With a

pivot point at one end and a guide bushing holder at the other, you can quickly

establish a circle or arc routing jig limited

only by the combined lengths of all of the

MFS extrusions you own. With the wide

variety of router bits available you can

use this set up to cut and/or edge route a

bewildering array of arced or circular

shaped work pieces.

shown in the two photos above which will

support the router base while you are

edge routing around either the inside or

the outside of the formed rectangle. This

black molded piece accommodates

24mm, 27mm, 30mm or 40mm diameter

router guide bushings. The design of this

piece allows the guide bushing to rotate

while you move along the edge keeping

8

Page 9

this anti-tip piece always with maximum

support for the overhanging base of the

router. Note how the lip on the guide

bushing sits in a recess in the anti-tip

piece so, no matter where you go with the

router, this anti-tip piece stays in place

doing its job of stabilizing the router so it

stays flat and level with the top of the

MFS profiles. Very slick and very useful.

Stamped tongues

keep the routing

slide square

into one of the special “V” nuts. This is

shown at the front of the slide in the picture below left.

When you insert the “V” nut into one of

the “V” grooves on the 16mm edges of

the extruded piece, two stamped tongues

also engage in one of the top “V” grooves

on that same extruded piece which will

allow the bridge to move easily

side to side at 90 degrees to

the MFS profile or be locked

into place by the lever bolt

shown.

A pointer indicating the center

line of the slot, and hence the

router bit, makes setting the

desired center line measurement a breeze. In the photo

below it is set to exactly

120mm from the right inner

edge of the MFS rectangle.

Lever bolt locks

position

Also available is what Festool calls a

“routing slide” shown in the picture above.

This is a heavy stamped metal bridge

750mm long and 180mm wide with a slot

cut down the center sized to receive a

30mm guide bushing and a bent up lip on

each long side for rigidity. The Festool

router bases fit comfortably inside the two

bent lips so you can attach a 30mm guide

bushing and pass a router bit across the

full inside width of any rectangle up to the

size of the MFS 700. The guide bushing

keeps the router and the bit centered on

the slot.

Along one short edge the bridge features

a lip bent down with holes in it positioned

for a 4mm threaded lock lever screwed

With the router slide you have

two dimensional control over

the movement of the router

suspended over the top face of the work

piece. Since the router can plunge up or

down, you wind up with three dimensional

control of the router cutter.

9

Page 10

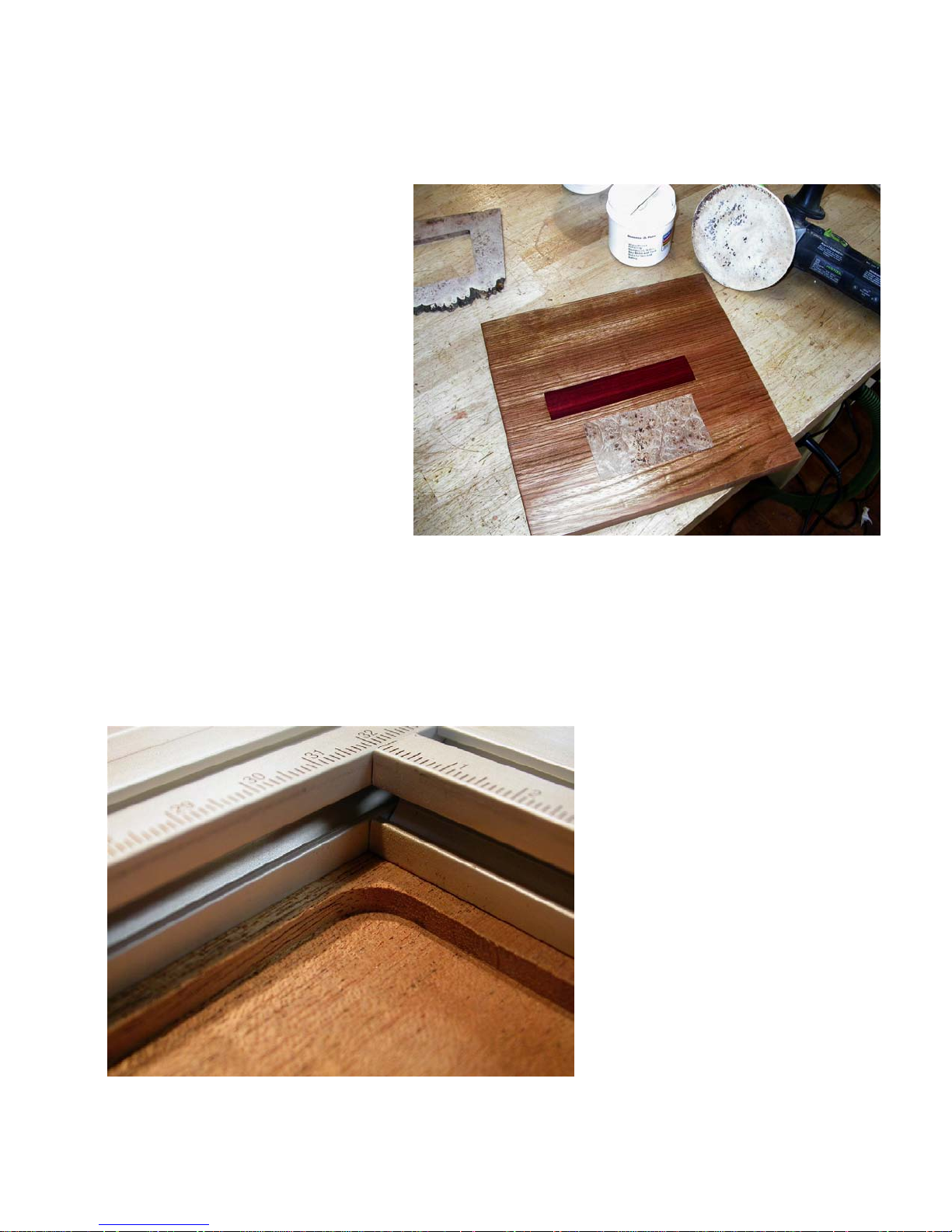

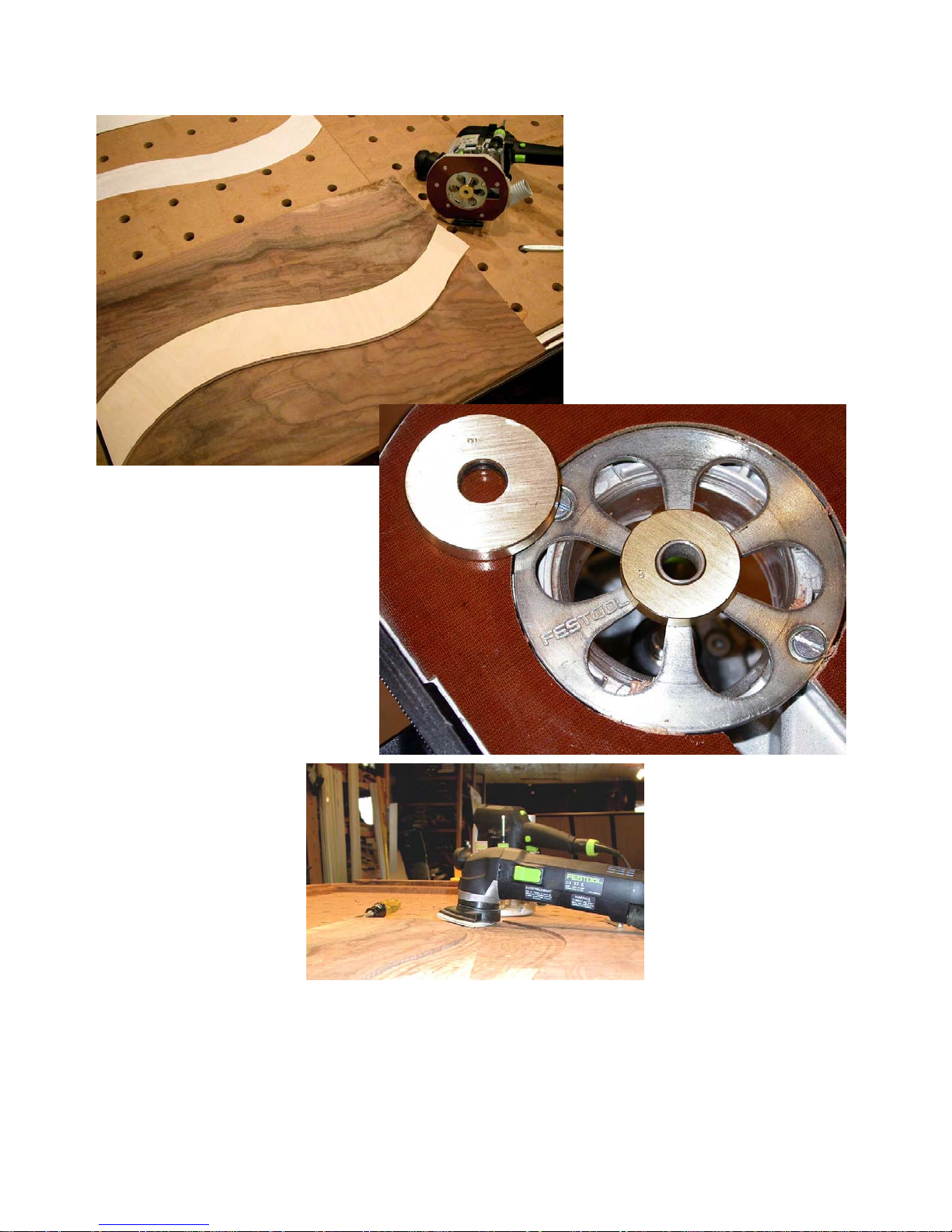

While there are many uses for this arrangement, the most common is to route

a recess into the face of a work

piece to receive what is called

“open field” inlays like the sample

shown here.

Adding inlays such as these to a

top, front or sides of a chest or

shelf unit is a fast way to really

increase the perceived value of

your work with little additional effort on your part. This is just one

of the ways the MFS helps you

make a quantum leap in your

productivity. We will cover this

feature in more detail when we

get to the chapter on inlays.

Open field inlay in sample piece after

being polished with the Festool

RO150. The field is Brazilian cherry.

The dark red inlay is South African

blood wood. The lighter colored inlay

is Oregon Big Leaf maple burl that

was cut from the piece above.

Notice how clean the corners, floor and

edges of an open field female recess

are when your router is guided by the

MFS profiles and the router slide. This

piece is African Mahogany, a wood notorious for its tendency to splinter along

edges like this.

10

Page 11

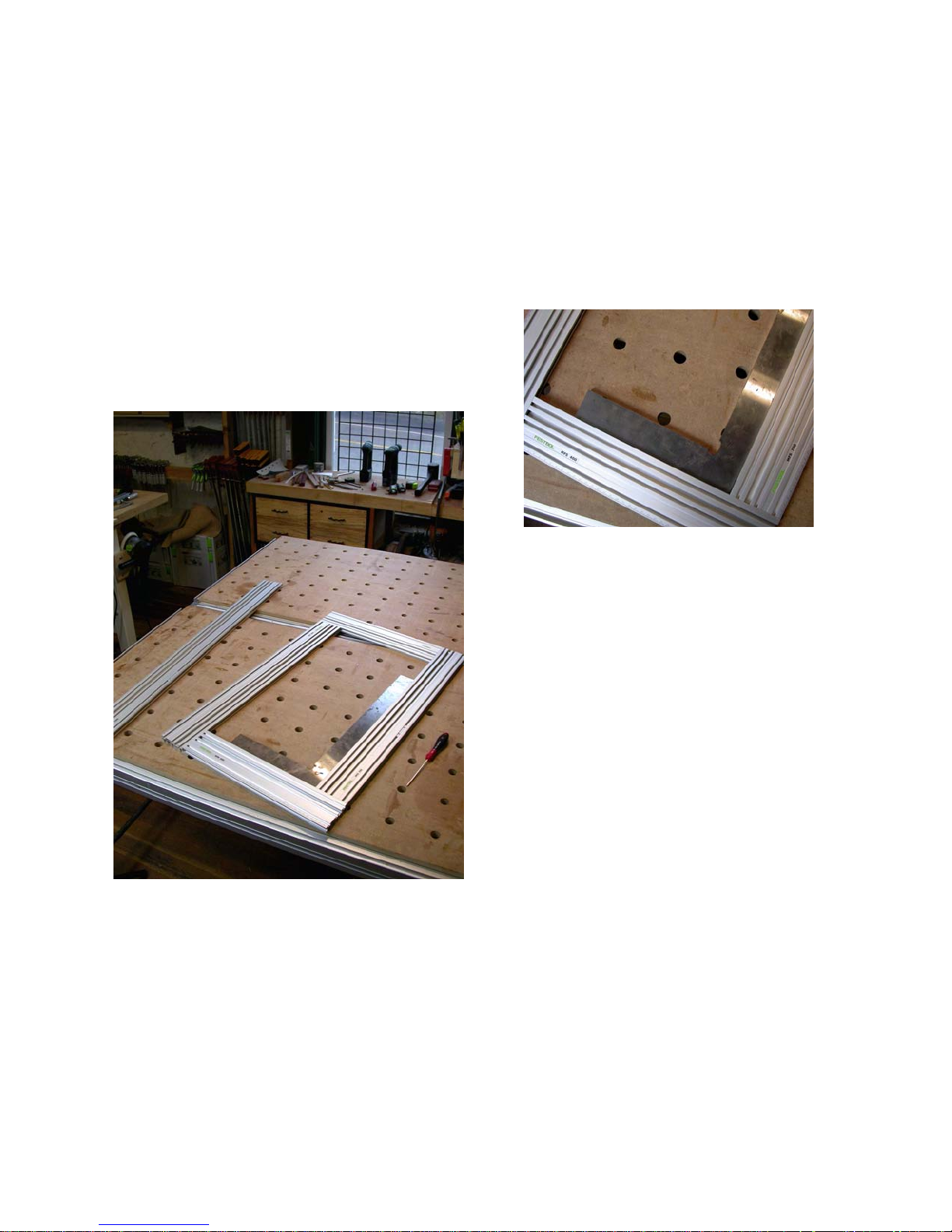

Using the MFS as a large

and very accurate square.

Now matter what kind of furniture you

build, it is critical to be able to create very

accurate square components that are exactly the size you want them to be. By

aligning all of the outer edges and ends

of the MFS extrusions, you form a very

accurate rectangle with close to perfect

90 degree corners.

square you are likely to encounter. For

visual reference that is a one meter (39”

long) MFS extrusion in the photo to the

left.

To use the MFS extrusions as a large

square, assemble the MFS into a rectangle of maximum proportions and with the

ruler marked edges facing out. This is

easily done by using a block of wood to

make sure that each end and each edge

are carefully aligned at all four corners.

Tighten down the attachment screws and

recheck to make sure you really have a

rectangle. Measure the diagonals to

make sure.

In this photo you can see a large class 2

steel reference square placed inside the

MFS rectangle. To the right is a closer

view showing just how very square the

MFS rectangle really is.

The one shown is formed from the MFS

700 starter kit so it is 780mm by 480mm

outside. That is a square that is over 30”

by nearly 19”, larger than any accurate

11

With the MFS700 shown here the diagonal measurement will be 915.8mm. From

high school geometry you will remember

that any right triangle has a diagonal that

is the square root of the sum of the two

sides squared. In the case of the

MFS700 the two sides are 780mm (the

700mm profile length and the 80mm adjoining profile width) and 480mm long.

Square those numbers, add them together and take the square root of the

sum and you should get 915.86025mm.

Before you get carried away trying to

measure the diagonals with such precision, keep in mind that one millimeter is

about .040” (forty thousands of an inch)

Page 12

so one tenth of a millimeter is just .004”

(four thousands of an inch) which most of

us would have a hard time seeing even

with the most accurate measuring stick.

sides of one extrusion so you draw it very

tightly up against the edge of another to

form a large “L” or “T” with very close to a

perfect 90 degree corner.

If the cut lengths of your extruded pieces

are off by just one tenth of a millimeter,

the resulting diagonal measurement will

change by more than one tenth of a millimeter. So, don’t get hung up on what

your measured diagonal is, only that the

two are the same so you know you have

as close to a perfect square as you can

measure.

Or, as I do, if you have a good reference

square that you trust, use it to confirm

that your MFS rectangle

is really square. If you

measure any difference

at all across the diagonals, loosen the

screws, make sure your

ends and edges are

carefully aligned and

tighten them again.

The resulting rectangle

is very rigid and populated with all those nice

“T” and “V” grooves so

there is no limit to how

you can use it to square

up just about anything

you make. The ruler

Two MFS profiles can be joined

anywhere along the edges to

form a “T” or “L” square

markings along all four

edges make for good

reference settings.

If you need an even bigger square, simply use longer extrusions or put two or

more extrusions end to end to form

longer ones.

If you need an open “L” or “T” shaped

square rather than a rectangle, you can

place the end connector inserts on both

I can’t measure any out of square on my

extrusions joined this way when measured with the class 2 steel reference

square shown which has 500mm by

250mm arms. Since the degree of

square with just two pieces joined together is dependent on just how square

the ends of the extrusions were cut, I

would hesitate to call it “perfect”, but it is

very close.

When you put all four sides together, any

error in how square the

ends were cut will tend

to be cancelled out resulting in a rectangle of

quite significant accuracy, certainly more accurate than that

stamped framing

square you might have

been using up to this

point and, as we will

see in the next section,

far more useful than a

similar sized reference

square.

Now that you have a

really good large

square, start by laying

out a known square

corner into which you

can clamp all your square and rectangular components like rail and stile doors,

panels and the like. If you own a Festool

Multi-function Table you can quickly make

squaring arms as shown in the manual

“Getting the Most from the Festool Multifunction Table” available for free download from the Festool USA web site.

12

Page 13

Using the Festool MFS

fence system to accurately position your guide

rails

This is one of the most basic things you

will do every day whether for cutting stock

to size or for routing grooves or for machining joints. There are several variations, but one of my favorites is using the

metric markings along the edges of two

extruded MFS profiles as a long and very

accurate vernier attached to a moveable

fence.

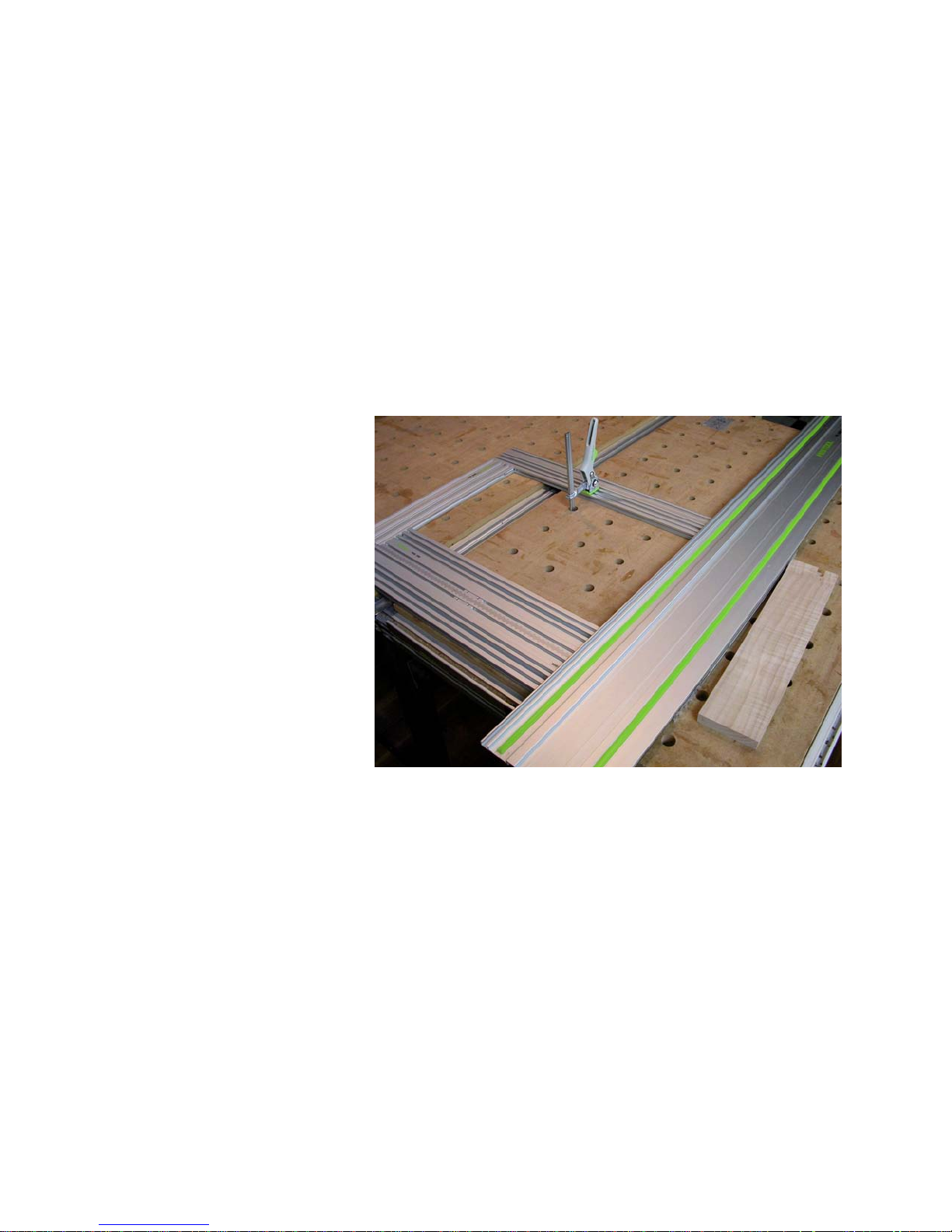

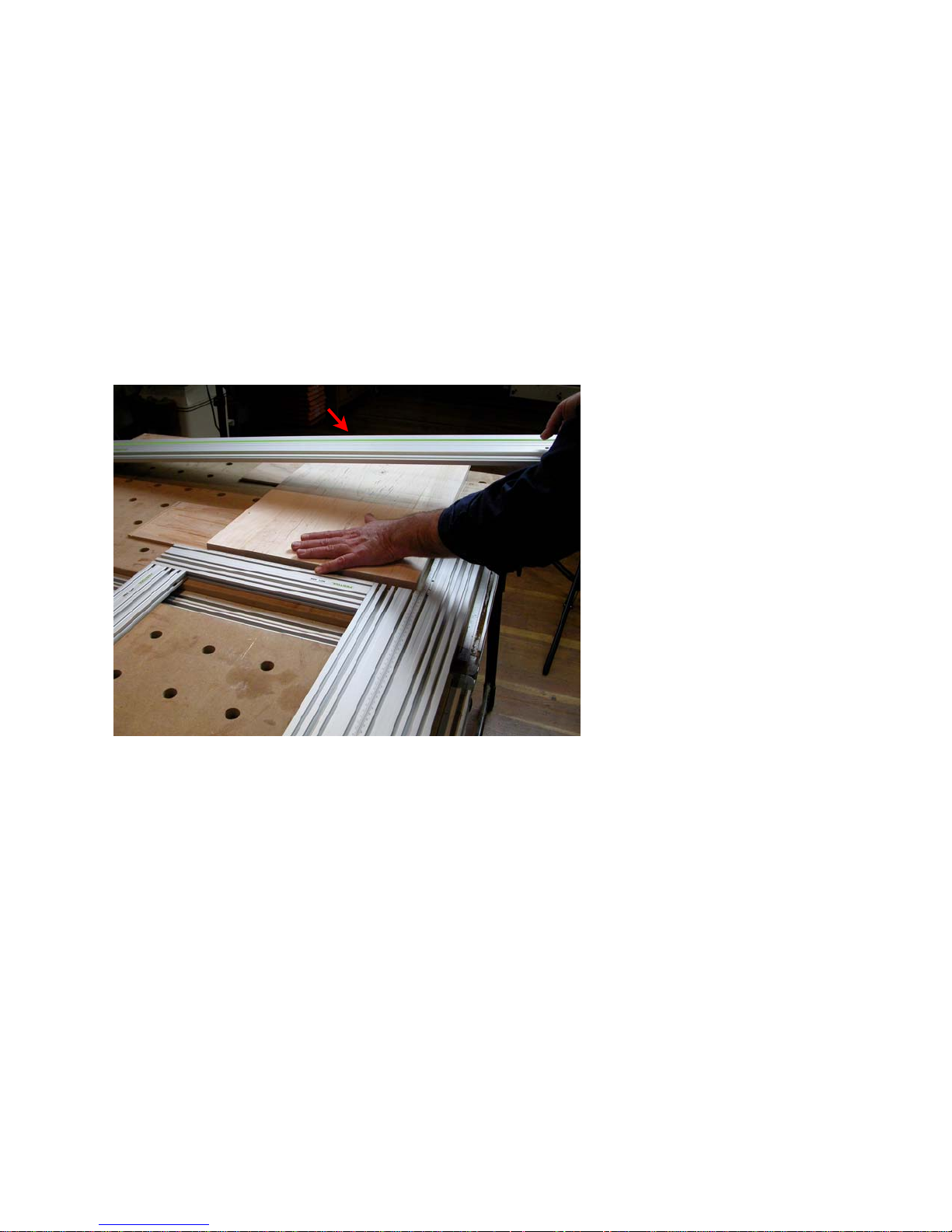

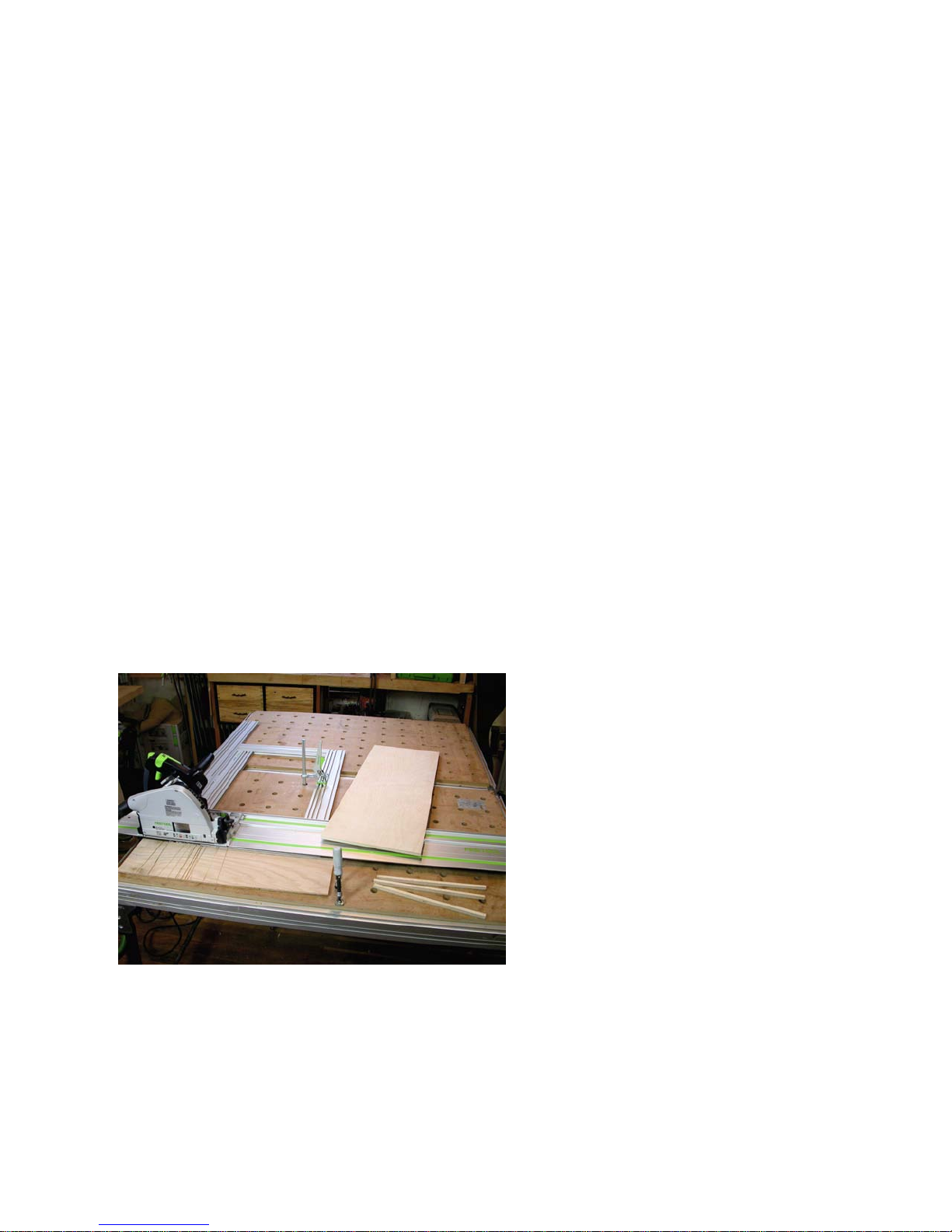

This photo shows the components you

will use sitting on top of a Festool MultiFunction table. (Actually, in use here are

two Festool tables hooked together side

by side with table joining units.)

These tables are in daily use in my studio

and have been for a couple of years so

they show the spots and wear of heavy

industrially use. Even so they remain

dead on flat and, along with another table

made from three Festool table tops (they

call them “plates”), serve as my primary

assembly work stations.

The components you will use include a

MFS rectangle (in this case a 400mm by

700mm rectangle), one additional MFS

profile (in this case a 1000mm one), two

standard Festool “F” clamps which will

come up from under the table to secure

the individual profile against which the

rectangle will slide, a standard Festool

guide rail, and the side table mounts.

The first thing

is to mount the

single profile

into the “F”

clamps from

below the table

so the clamps

are not in the

way. In the

photo to the

right you can

see how the

“T” track on the

bottom of the

MFS profile receives the standard Festool

“F” clamp arm. I slide the arm over two

clamps (arrows) inserted from below the

table in the side most row of 20mm table

holes. Do not tighten the clamps yet.

13

Now mount the guide rail in the table side

mounts, set it on top of the individual

MFS profile and the MFS rectangle and

lock the height cams to hold the guide rail

properly in place. Make sure the underside of the hat groove on the guide rail

sits in the lip on the table side mount op-

Page 14

posite the

pivot so it

is rigidly

controlled.

Use a

block of

wood to

register the

MFS rectangle with the front edge of the guide rail

and bring the individual profile up against

the side of the rectangle so it is exactly

90 degrees to the leading edge of the

guide rail.

When you put two rulers side by side you

form a vernier that is very easy to read.

Actually in a true vernier you would have

nine marks on one side and ten in the

same space on the other so you can easily dial in .1 increments. With the MSF

profiles they are all marked the same so

we will just use the marks as a visual ref-

The shot above shows a closer look at

how simple it is to align the

individual profile to be at 90

degrees to the guide rail.

Now tighten the clamps from

below so the individual profile cannot move.

At this point you could use

the rectangle to set all your

cutting lengths for both rip

and cross cuts, but let’s do

one more thing to take advantage of those nice ruler

markings along the edges of

the MFS profiles.

erence. It is easy to estimate down to

.2mm or lower with a bit of practice.

To quickly do the calibration, set a clamp

to lock down the rectangle as shown

above as we now want to slide the indi-

vidual profile

without altering square so

the marks

line up conveniently for

us.

I like to slide

the individual

profile until

an even unit

mark on it

lines up with

an even unit

mark on the rectangle. Where I have

14

Page 15

them set for this photo the two 30 marks

conveniently align as is shown below.

“V” nuts make an easy-to-see

reminder of which two marks (30

in this case) represent zero

length of cut relative to the front

edge of the guide rail

Tighten the clamps again on the individual profile and release the clamp on the

rectangle as you now have calibrated the

scales so zero length of cut is when the

two 30 marks line up. To help me remember where zero is, I slide a couple of

the two hole “V” nuts into the “V” tracks,

align one end of each with the zero point

(the 30 marks in this case) and lock them

down with set screws.

move the rectangle 50mm as shown

here.

Note that the 50mm (or whatever

length of cut you set) will also show

when you lift the guide rail and see

how the leading edge of both the

fixed individual profile and the rectangle line up as pictured below.

50 millimeters

Now we can slide the rectangle down to

whatever length of cut we want. As long

as you keep the edge of the rectangle

tightly against the edge of the individual

MFS profile, the leading

edge of the rectangle will

always be parallel with the

guide rail and a known

distance away from it’s

front edge.

So, if you want to rip a series of 5mm strips, just

move the rectangle 5mm

and clamp it down as

shown to the right. If you

want a 50mm wide cut,

15

Page 16

Now that we know we can set any length

of cut easily and with great precision we

are ready to do some cutting.

Set the rectangle for the desired length of

cut. Let’s say we want to cut this glued

up maple board to 350mm long. Once

the rectangle is clamped down at 350mm

back from the front edge of the guide rail,

check to make sure it is snug against the

fixed individual profile and slide the work

Cut line

Good practice is to first make a squaring

cut on this end before you set the rectangle for the desired length of cut. Just

move the rectangle a bit further away and

put the edge of the work piece snugly

against the edge fence (the fixed individual MFS profile that is clamped to your

table top). Make a cut taking off just a bit

so you now know you have a really

square corner. Flip the board end for end

so the same edge is against the edge

fence, set your rectangle to

the desired length of cut and

slide the work piece into

place as shown in the photo

to the left. When you make

this cut you know you will

have two 90 degree angles

with the length exactly what

you want it to be.

piece into place.

One edge will be against the fixed individual profile acting as a side fence and

the end will be against the leading edge

of the rectangle acting as a length stop.

A couple of things to note at this point.

Look at the photo above. Notice how,

just by positioning the work piece, your

eye can quickly confirm whether the corner closest to my hand is really square or

not. If it is not square, then your work

piece will not come out square since the

cut you are about to make will be 90 degrees to the side against the side fence.

This is the same principle as

using a sliding table industrial table saw. Since you

calibrated your guide rail to

the fixed edge fence and are

sliding a known square rectangle to act as the length

stop, you know your cuts will

be bang on straight (thanks

to the Festool guide rail and saw), with

perfect 90 degree corners (thanks to the

individual profile that you calibrated to be

at 90 degrees to the guide rail) and exactly to the length you need (thanks to

the ruler marks on the MFS profiles).

Note one other thing in this photo. I have

my work piece set on top of a couple of

sacrificial scraps of thin plywood. That is

where the saw kerf is going to go, not into

my table top. Using this practice I never

need to be concerned about where I happen to set the guide rail table side supports. I just put them wherever it is most

convenient for the cuts I need to make.

16

Page 17

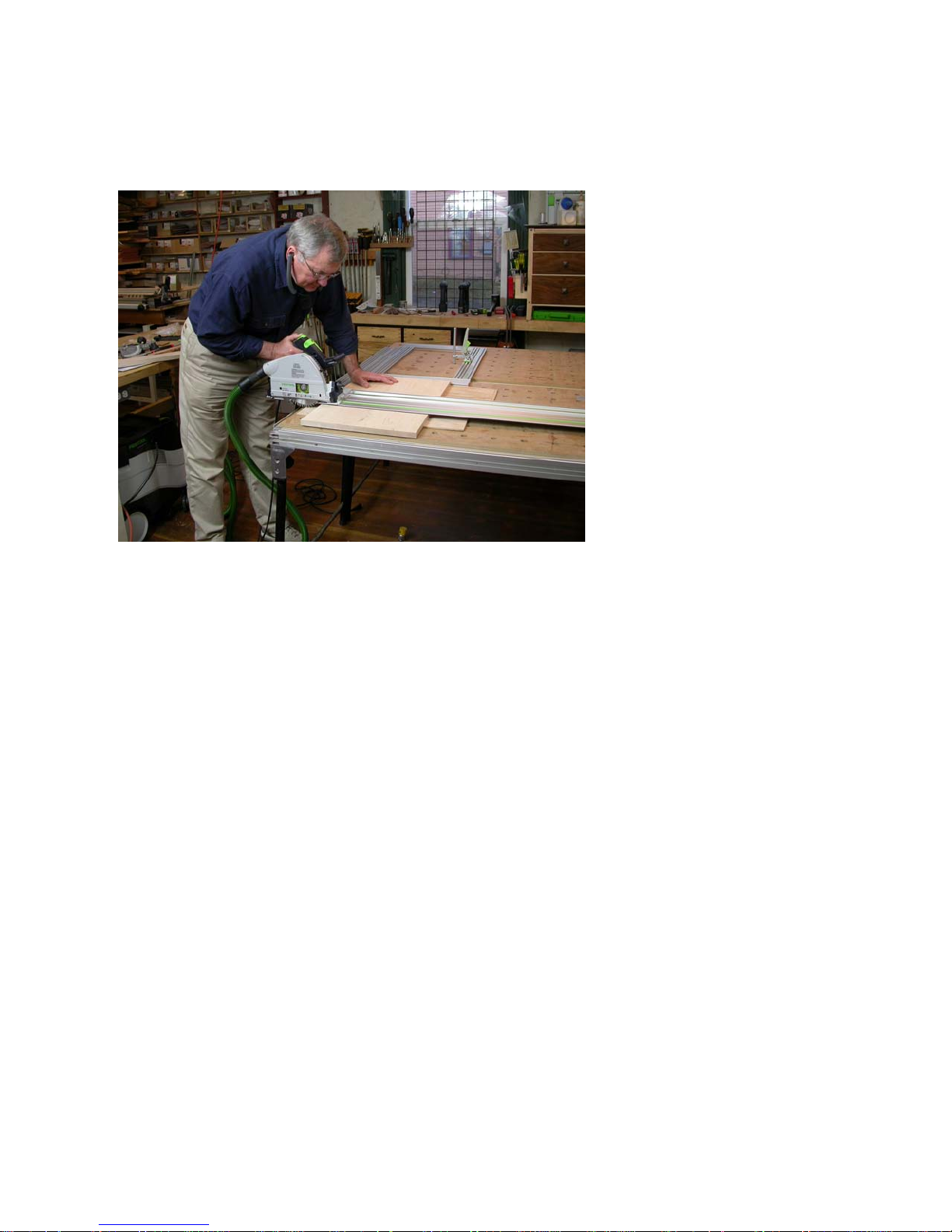

Now we can make the cut as shown below. Wear ear protection, use the Festool

dust collector (the CT33 shown below the

table behind me) and make sure you

have the right blade mounted for the cut

you are about to make.

With the TS line of circular saws it is so

fast and easy to change blades that there

never is a reason to force a cross cut

blade to make a rip or to use a rip blade

to try to do a clean cross cut.

A couple of other things to note. In this

sequence of photos the cut I am about to

make is on stock that is thicker than the

16mm thickness of the MFS profiles. As

a result the stock itself supports the guide

rail and keeps it from flexing down. If you

need to cut stock that is thinner than

16mm add sacrificial spacer stock like the

plywood I use either below (much preferred) or above the work piece so the

guide rail is supported across the full

width of the cut.

If you plan to work on relatively smaller

work pieces, say up to around 700mm

long (27 1/2”), having the fixed side extruded piece back 60mm from the cut

edge of the guide rail will re-

sult in the 30 marks lining

up as shown before and will

provide good support for the

rectangle to move over this

range. For longer work

pieces it works best to move

the fixed side extrusion back

further away from the leading edge of the guide rail so

the MFS rectangle will be

well supported when pulled

back more than 700mm or

so.

With this set up it doesn’t

matter whether you use one

Multi-Function Table or two

or more joined together.

You don’t need to worry about the factory

guide rail support stops. They have to be

removed to attach two or more MFTs together side to side anyway. No matter

where you set the guide rail, since you

are calibrating everything to it, you can

get perfectly square cuts from any position on any number of tables.

For all of your normal cross cuts this set

up is fast, reliable and repeatable. It

doesn’t matter whether you need a dozen

pieces all the same size or a dozen

pieces all different sizes. You have the

work piece referenced at 90 degrees to

the cut line by the fixed MFS side extrusion and the length determined by the

moveable MFS rectangle acting as your

length depth stop.

Cutting very narrow strips that are all exactly the same width is also easy so long

as the length of the strips is shorter than

the length of the guide rail. The MFS rec-

tangle under the guide rail is now going

17

Page 18

to act as your rip fence. For longer rips

turn the rectangle so the long edge is

parallel with the guide rail to properly

support the work piece if you need to.

If you need narrow strips that are longer

than the length of the table, you can join

the two tables end to end instead of side to side. That

way you can use a longer

guide rail, or join two or more

to make up a longer guide

rail. You may also want to

make a larger rectangle from

the available longer MFS extrusions so your work piece

is well supported along the

length of the cut.

As the length of cut increases, the requirement

for care and precision in

your set up increases

dramatically. Once the cut

length exceeds the length

of a 1080 MFT I suggest instead that you use the “story stick”

method outlined in an upcoming section.

Before starting to cut these narrow strips,

first move the MFS rectangle back out of

the way and make a rip to straighten one

edge of the work piece. Once you know

you have a perfectly straight edge you

can place that edge against the fence

(the leading edge of the MFS rectangle

that is under the guide rail) and know

that your first and all subsequent rip cuts

will be exactly parallel with that edge.

size. I always clamp the work piece to

the table so it can’t move which would

spoil this accuracy. When the work piece

becomes too narrow to safely clamp

down it is also too narrow to safely cut

into more strips.

In this photo you can see the set up (the

DC hose, saw power cord and the outside splinter guard have been removed

for clarity). The rectangle was moved

back 5mm from the edge of the guide rail.

The work piece is cut straight and then

butted against the leading edge of the

rectangle and clamped down. Notice that

I have the work piece on top of a sacrificial hunk of thin plywood to bring it up to

a bit beyond the 16mm thickness of the

MFS profiles so the guide rail will sit flat

on the work piece without deflecting

downward. In this photo the first thin strip

is about half way cut off.

I find it easy with this set up to rapidly

make repeat rips to get a bunch of narrow

strips and can’t measure any difference in

width from one end to the other or from

one strip to another. All are the same

18

Since the cut off piece is under the guide

rail and the remainder of the work piece

is in front of the guide rail clamped to the

table, cutting these narrow strips is inherently safe. With guided rail sawing the

Page 19

saw blade is turning away from you and

is held by the uncut portion of the work

piece until after the leading edge of the

blade passes the far end of the work

piece. With the blade set to cut just a

couple of millimeters deeper than the

thickness of the work piece, the cut off

piece is only exposed to that small

amount of blade travel and the cut off

piece is trapped from above so it cannot

be lifted off of the table. If the cut off

piece does get trapped between the

fence and the blade, it will be thrown

away from you but usually is secured by

the rubber on the bottom of the guide rail.

On a traditional table saw it is just the reverse. The blade is rotating towards you

so the trapped portion of the cut off is free

to be thrown up and back at you, a situation called “kickback” that nearly everyone who has used a conventional table

saw to cut narrow strips against a fence

has experienced. This is a far more dangerous situation than using the Festool

behind them, this done with no kick back

and no fingers in harm’s way.

One of the nicest things about this MFS

rectangle sliding against a stationary

MFS profile set up is that you can reconfigure it on a moment’s notice and reestablish the right angle relationship between the leading edge of the guide rail

and the MFS rectangle acting as a rip

fence or as a length stop in less than a

minute, no matter where you set the

guide rail. For example, the whole set up

could have been moved further down on

the table to more fully support the work

piece, but I find clamping the work piece

usually does the job even with the set up

this far towards one edge of the table(s).

You can take down and transport the

MFS extrusions as a stack of 80mm by

16mm by whatever length components

and do the whole set up in an off site

work place or can leave the set up just

like it is for repeated in work shop or stu-

dio use. The “V” track nuts, fasteners

and other MFS system components

are very small and easily stored or

transported in a Festool Systainer or

Sortainer.

MFS fence and Festool guide rail to make

these thin strip rip cuts.

Here you can see three thin strips all

5mm wide, safely and quickly cut from

the work piece on top of the guide rail

19

The MFS is certainly one way to unlock the full potential of Festool

guided rail cutting.

Use this set-up for routing as

well

Just cutting pieces to exact size is not

where the usefulness of this set up

stops. You can also rout joints such as

square shouldered tenons to quickly

make rail and stile components, or you

can rout precisely established sliding

dovetails or dados. You also can quickly

rout matching dovetail or dado slots ex-

Page 20

actly the same distance from two ends of

a work piece by simply moving the rectangle to establish the desired cut line on

one end, make the cut, reverse the work

piece and make the other cut.

Remember, with Festool guided rail routing it doesn’t matter which way you move

the router since the guide rail will hold

against in-thrust or out-thrust forces.

Machining clean tenons

Just take all the pieces that are to have

the tenons and stack them together

aligned with the fixed MFS side extrusion.

I still like to add a side clamp such as the

Festool clamping element 488030 to

make sure nothing moves.

Move the the MFS rectangle towards the

guide rail to establish the exact length

you want the tenons to be. Set the saw

blade to cut down into the work piece the

depth you want the shoulder to be. Make

one pass cutting the shoulder in all of the

pieces at one time. Rotate them

and make a second pass to cut

the other side of the shoulder. If

you want the tenon to be

haunched, rotate the pieces up

on edge, place the guide rail on

top and make the third pass. Rotate and make the fourth pass to

establish haunches on both

edges.

rail so as not to tear up the zero clearance rubber edge.

I like to set the router so the center of the

cut is 20mm in front of the guide rail.

There is a convenient center mark on the

base of Festool routers so it is easy and

fast to make that alignment. If you use a

20mm diameter router bit, the edge of the

cut will be 10mm in front of and parallel

with the guide rail. That makes it easy to

set the fence to remove the rest of the

tenon with the router.

You can skip the part about making a saw

blade cut to establish the shoulders of the

tenons, but usually cutting them just with

the router will leave a bit of fuzz, and on

some woods may result in a bit of tear out

on the shoulders.

A quick additional routing example

The next few photos show the MFS components utilized to quickly make a small

stand with a shelf, half back and drawer.

To remove the remainder of the

tenon you will use your Festool

router with a flat bottom bit. Unlike the saw blade which cuts

zero clearance to the front edge

of the guide rail, you need to adjust the router and slide to establish the

desired cut line to be in front of the guide

20

To make it easier to see, I have prefinished all the components, shown here

and in the next several photos.

Page 21

I took the time to first band the maple

top with bloodwood all the way around

as well as on the front of the shelf. You

can see (photo previous page) the underside of the top with its two sliding

dovetails to receive the two sides (to

the left of the top in photo). The sides

have two horizontal sliding dovetails,

one which holds the shelf (to the rear in

the photo) and one which holds the

drawer slide (the bloodwood pieces to

the back right). There is a third, vertical, sliding dovetail that receives the

of the sides at each corner to

act as leveling feet and to

pull the unit visually off of the

surface upon which it stands.

It is easy to see how you can

scale up this small stand and

add a bottom and toe kick to

make a multi-drawer chest or

add doors for a cabinet, and

so on.

half back (just to the rear of the top) that

seals the drawer area and adds lateral

stiffness to the piece.

Above it is partially assembled so you

can see what it will look like. The sides

slide into the dovetail groves on the under

side of the top, the shelf slides into the

two sides, the drawer guides slide into

the two sides below the shelf and the half

back (shown here in front of the partial

assembly) will slide up from the bottom

as the locking part of the assembly. The

white things on the top are four plastic

bolts that will be threaded into the bottom

To build it, first use the set

up we have been discussing

to cut all the components to

size. Do the edge banding if

you wish. Now cut the fe-

male dovetail grooves into the

underside of the top as shown in the pho-

21

Page 22

tos on the right side of the previous

page. I removed the dust collector

hose and cord from the router to make

it easier to see. The router is set to a

centerline 20mm forward of the front

edge of the guide rail just as we talked

about earlier.

Note that this cut is stopped at the

front so you need to set a stop on the

guide rail as shown (previous page).

Since the Festool guide rail holds the

router against both in-thrust and outthrust loads, you can cut in either direction as is required for these two

cuts. Also, note the clamping element

which holds the work piece to the

edge or side fence for stability.

Make the first cut, reverse the top piece

end for end without altering the MFS set

up, and rout the second cut. You are

done with the top.

In making a piece like this, after you cut

the two grooves in the top, lay the shelf

piece down with an edge on each groove

to make sure your shelf is exactly the

same length as the centerline to center-

with the centerline of the the two sides

which is the centerlines of the two

grooves you just cut into the underside of

the top.

Now it is time to cut the three dovetail

grooves in each side. The photo left

shows cutting the vertical groove which

will receive the half back. Notice the stop

so that groove only goes as far as the

shelf groove. The already cut other side

is shown so it is a bit easier to

tell what is going on. The

photo above shows cutting the

two horizontal DT grooves.

Since the shelf DT passes all

the way across the sides, no

guide rail stop is needed to limit

the travel of the router. The DT

for the drawer slides is stopped

at the groove for the back.

line distance between the two grooves

you just cut in the top. If using a standard

such as the one I use where the work

pieces are 20mm thick and the DT

grooves are 10mm deep, the shelf with its

male DT on each end will need to line up

22

All of the male DT’s I cut on either a router table or on a horizontal

router jig I made that fits onto the side of

a Festool Multi-Function Table. That jig is

shown in the appendix to this manual.

Page 23

Earlier I said one of my favorite set ups

was this use of the MFS rectangle and

fixed side extrusion as a very accurate rip

fence or depth stop to cut work pieces as

large as the guide rail you are using. But,

it is not the only such set up.

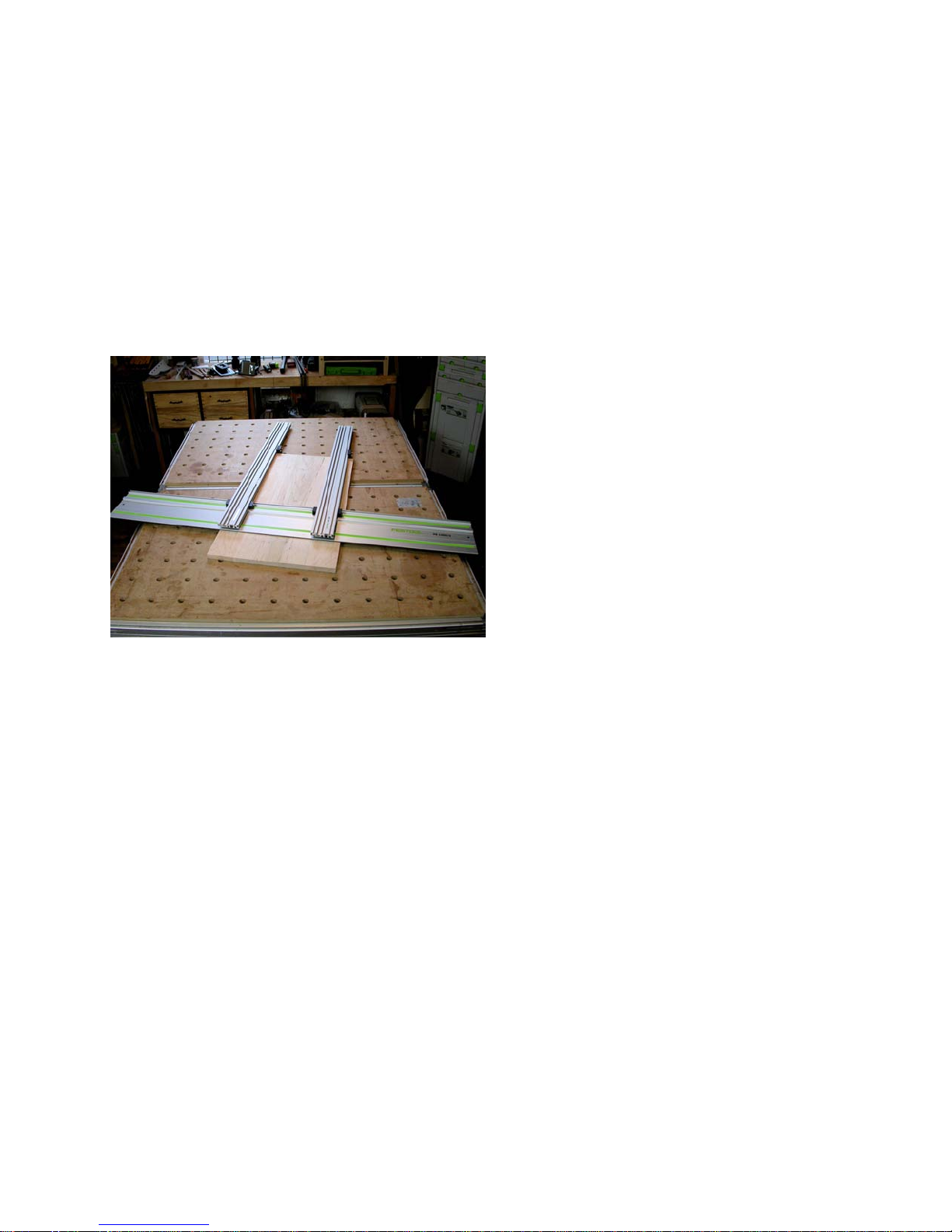

Let’s next move to using the MFS components as “story sticks” to accurately locate a guide rail whether the guide rail is

placed freely on a work piece or held by

the table side brackets.

23

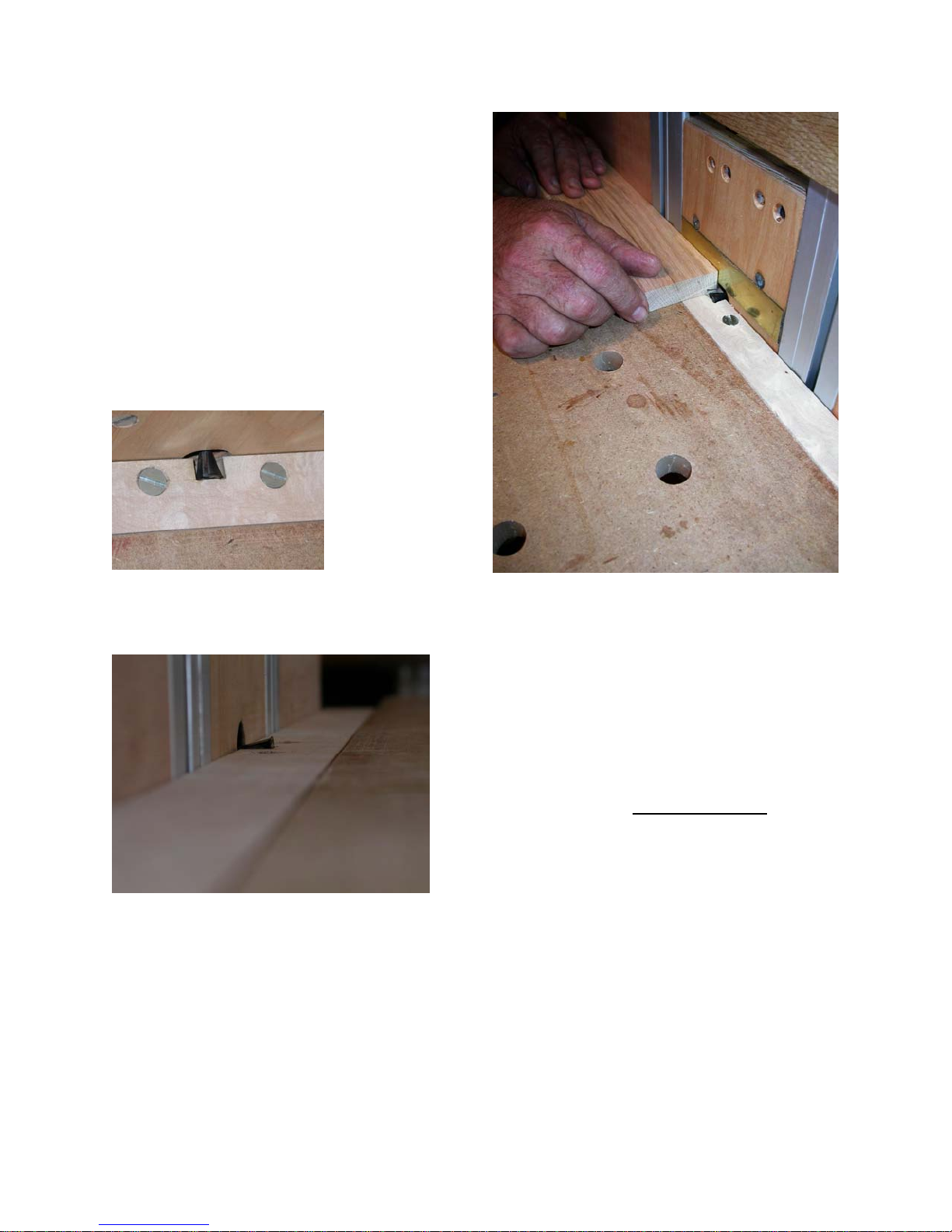

Page 24

Using the MFS components to accurately locate

the guide rail to be parallel with and the desired

This is where the next use of the MFS

extrusions can be of invaluable service.

Since the 200mm, 400mm, 700mm and

1000mm extrusions all have metric ruler

marks along one edge, you can quickly

use them as a very accurate “story stick”.

distance away from the

edge of a work piece

Another common set up where the MFS

earns it stripes as a valuable addition to

Festool guided rail cutting and routing is

where you want to establish a cut line

that is a precise

distance away

from the existing

back edge of a

work piece.

Normally you

would simply

measure out the

desired distance

on both ends of

the work piece

and then manually set the leading edge of the

guide rail to your

marks by eye.

This can be very

accurate for one piece, but

accuracy is dependent on a

clean narrow mark, good

light so you can see those

marks, and an eye held

perpendicular above to the guide rail so

you can accurately place the guide rail on

those marks. If you are only going to cut

one piece to that dimension, usually you

can get close enough this way, but, if you

want multiple pieces that are all exactly

the same size, there is too much room for

error relying on the measure, mark and

align visually approach.

630mm mark on MFS extrusions produces 630 line of cut for guide rail

MFS extrusions with shop made

saddles and stops set to position

the guide rail for a 630mm cut

For hundreds of years craftspersons have

used marks on a piece of wood (called a

“story stick”) to do repetitive layout work.

In more recent times sliding stops and

ruler marked edges were added to make

these story sticks faster to set up and

use.

If you

calibrate

the zero

marked

end of

one of

the MFS

extrusions to

the zero

clearance

rubber

lip on the

guide rail

you can

then use

a simple

stop to set the desired length of cut

and the story stick

becomes the way

to set the guide rail a precise distance

away from one edge of the work piece.

This is the same principle Festool uses

with their shelf hole drilling fixture. In that

case two short story sticks are provided

along with a lock to fit over the hat section on the guide rail on one end and an

24

Page 25

adjustable spring loaded pin to use as an

edge reference at the other end.

For our purpose I suggest a couple of

simple shop made guide rail registration

Shop made stop

Shop made saddle

Place the guide rail down on the work

piece, place the guide rail registration

saddles on the guide rail and move the

guide rail until the back edge stops come

firmly up against the back edge of the

work piece as is shown in the

photo on the previous page.

That will position your guide

rail a very precise distance

away from that edge on both

ends of the work piece so

you can cut a clean line that

is about as close to parallel

with the other edge of the

work piece as you can get.

And, you can do it on work

piece after work piece to

come out with multiple parts

that are as close to exactly

the same size as you are

likely to be able to measure.

saddles and a couple of shop made sliding stops to hook over the back edge of

the work piece. Both are shown below.

By calibrating to the front edge of the

guide rail you can then use the ruler

markings to set the back edge stops to

exactly the same measurement time after

time.

The guide rail saddles and

back edge stops shown I made from

scrap UHMW plastic sheet that I buy in

bulk from a wonderful old fashioned

hardware store in Bellingham, WA, a favorite stop whenever we are visiting our

son and his family, but you can make

them just as easily from wood or whatever you have lying around your shop.

The guide rail registration saddles shown

fit snugly into the space between the rear

“T” track and the hat shaped ridge that

the Festool cutting and routing tools slide

along. That space is 32mm wide. I suggest you cut your stock a bit wider than

that and then use a router to shave off

about an 8mm high rebate recess on

each side until it fits quite snugly in that

space. That hat shaped slide is about

6.5mm high so 8mm will give good clearance. My material happened to be 19mm

thick and that works well with the 16mm

thickness of the MFS profiles.

25

Page 26

I plowed a 13mm deep groove

80mm wide so the saddle fits

snugly over the MFS profile

and snugly into the space on

the guide rail. That way the

profiles will project out behind

the guide rail at very close to

a 90 degree angle which will

add to your accuracy.

I then drilled a couple of

5.5mm holes in the sides of

the saddle aligned with the

center of the side “V” tracks

on the MFS extrusions. Slide

in a two hole “V” nut and fasten the saddle with a 5mm

machine screw.

If you use the normally available hardware store metric cap head screws, then

you can use a 4mm Allen key to tighten

and loosen all of the 5mm fasteners and

the 3mm Allen key supplied as part of the

MFS system for all the 4mm fasteners.

You could also get a bit fancy and use

some form of purchased or shop made

quick set 5mm thread handles.

Once the saddles are in place with the

screws still loose, put the saddle onto the

guide rail and use

a block of wood

to bring the end

of the MFS extrusion marked zero

up to be exactly

even with the

rubber edge on

your guide rail as

shown in this

photo. Since you

cut that rubber

edge with your saw and blade the first

time you used it this procedure will cali-

brate your “story stick” to your saw, blade,

and guide rail.

With the edges aligned tighten the side

screws on the saddle so you can remove

the MFS profile and saddle from the

guide rail and replace it, always keeping

the front edge of the guide rail aligned

with the zero mark on the profile. If you

want to be able to remove and replace

the saddles without reregistering them to

your guide rail, just slide another “V” nut

in place and lock it down against the “V”

nut you use to secure the saddle.

Festool offers a small bag of “V”

nuts and set screws as part

number 493235.

You can use just one profile if

you wish, but two will be faster

and far more accurate. If you do

plan to use two, then calibrate

the other one to your saw, blade,

and guide rail the same way.

You can use any of the MFS profile lengths you wish. I find the one meter

(1000mm) length the handiest. If I want

26

Page 27

to cut off a longer piece than that will allow, I attach another MFS profile to the

end of this one using two of the profile

joining “V” nuts. The second profile zero

mark will set against the 1000mm mark

so it is easy to set precise measurements

beyond one meter.

To make the back edge stops I used the

same 19mm scrap UHMW and plowed a

shallow dado in the side a fraction over

16mm wide. This will allow the back

chine screws threaded into the two hole

“V” nuts.

As we discussed above, in use, set both

stops to the desired length of cut, place

the saddles on the guide rail, and move

the guide rail and story sticks until the

stops fall over the back edge of the work

piece -- slick, fast, highly accurate and

very repeatable.

You will find that in use both of these

methods of positioning the

guide rail relative to the

work piece (the MFS rectangle and these story

sticks) will allow you to

reach a level of accuracy

and repeatability that is

most likely far beyond

what you have been able

to achieve using the

measure, mark, and align

technique.

Back edge of work piece

edge stop to register cleanly along the

edge of the MFS profile with a clearly

readable shoulder to align with the desired measurement mark.

I find 40mm high about right with the

16mm dado set down about 4mm from

the top edge. That allows the lower edge

of the stop to fall below the top edge of

the work piece so I can get a nice clean

hook action to catch the back edge of the

work piece as shown above.

Those back edge stops are secured to

the MFS side “V” track with 5mm ma-

While the MFS rectangle as

a vernier scale does require

the guide rail to be mounted

on a Multi-Function Table,

the story sticks do not. Ei-

ther way both of these techniques employing the accuracy of the

Festool MFS extruded profiles offer a fast

way to make one cut or dozens that are

all the same.

It also doesn’t matter whether you are

making rip cuts or cross cuts or whether

the cut off pieces are narrow or wide,

both techniques work equally as well.

Best of all, since you always calibrate off

of your saw, your blade, and your guide

rail, you don’t have to worry about how

straight or square your table is or whether

things “change” on you from one work

session to the next.

27

Page 28

Now let’s turn our attention to using the MFS

system in advanced routing applications

Everything we have talked about in terms

of aligning the Festool guide rails for cutting work pieces applies equally to routing

operations as well.

Since most of you have experience with

free hand routing using bearing guided

bits riding against the edge of the work

piece (such as when putting a rounded

edge on a shelf or table top,) I won’t

spend any time here on how to do that.

Instead we are going to concentrate on

advanced guided rail routing, pattern

routing, and template routing operations,

especially those for which the Festool

MFS is ideally suited.

Most all routing operations require some

means of positioning the work piece and

router bit in a desired alignment while either the work piece is moved past the

router (as in a router table application) or

while the router is moved past the work

piece.

The former is accomplished either by the

work piece being held against the router

table fence or by a bearing on the bit

which rides on the work piece, a template

or a pattern. The latter is accomplished

either by a fence that is attached to the

router base, or by the router being guided

by a Festool guide rail, or by a bearing on

the bit which rides against the work piece,

a template or a pattern.

Since this manual is all about techniques

using Festool products, we will skip the

discussion on router tables and cover

only guided rail routing here. I will assume you know how to set up and handle

your Festool router safely so those basics

will not covered here.

If you have any question about your

ability to set up or handle your router

safely, please do not proceed with this

manual. Move instead to literature,

videos, or training programs designed

for that purpose.

First, let’s clarify some definitions. People often use the terms “template” and

“pattern” interchangeably. I don’t. I use

the term “template” to mean a way of

guiding a router bit to cut a female recess

in the face of a work piece. It can also be

used to cut a (nearly) matching male

shape in inlay material to be inserted into

that recess if you wish. By “pattern” I

mean a way of guiding a router bit to produce an area that mimics the area under

or beside the pattern while other areas of

the work piece are routed away.

By my definitions one would use a “pattern” to establish and duplicate curves on

table legs, for example. In that same table we might want to inlay a different material as a decorative accent. That would

be done using a “template.”

Offset Routing

To fully appreciate all that can be done

using templates and patterns, we need to

explore the notion of offsets, guide bushings, and bearings as they relate to guiding the router bit.

Guide bushings fit onto the router base

concentrically located around the router

bit. On routers such as the Festool 1010,

concentricity is established via a cone

shaped mandrel which is placed in the

28

Page 29

collet. The guide bushing is placed over

the cone shape which holds it concentric

to the collet as the guide bushing is tightened down. On the Festool 1400 the

guide bushings snap into place, automatically being held concentric to the

collet by the tangs and receivers machined into the guide ring and router base

as pictured below.

The outer edge of the guide bushing follows the pattern or template to produce

the desired cut. If the guide bushing is,

say, 20mm in diameter and the router bit

is 10mm in diameter, then one edge of

the cut will be 5mm away from the edge

of the pattern or template and the other

edge of the cut will be 15mm away.

Removing the 1010 baseplate.

Guide bushing and centering

mandrel in foreground

Guide bushings simply snap in

place properly centered on 1400

Guide bushing centered over

mandrel and tightened down on

1010

This relationship is always such that one

cut edge is away from the edge of the

pattern or template by half of the difference in diameter between the (outside

diameter of the) guide bushing and the

diameter of the router bit. The other cut

edge is that plus the diameter of the

router bit since the router bit will plow a

groove in the work piece its own diameter

wide.

Knowing this, one can use the same

router bit and template and, by changing

guide bushings, can cut both a female

recess and a matching male insert which

will exactly fit the recess everywhere ex-

29

Page 30

cept in corners where the

guide bushing used to cut

the female recess will produce radiused corners

while the male piece cut will

have sharp corners. One or

the other must be hand

trimmed for the male to fit

perfectly into the female recess. This is usually not an

issue and can be done easily.

In our example, if we used

the 20mm diameter guide

bushing to cut the male and

a 40mm guide bushing to

Sample of 1400 guide bushings in different sizes

cut the female, they would

fit together perfectly. The 40mm guide

bushing with a 10mm bit will plow a

groove that is 15mm away from the edge

of the template and 10mm wide. We

would route out all the interior leaving the

profile of the female recess that is 15mm

time the groove will be

5mm away from the edge of the template

on the side nearest the template and

15mm away on the side furthest away

from the template, exactly the size and

shape of our female recess.

smaller than our template.

When we cut the matching male we just

put on the 20mm guide bushing. This

Using bearings on the router

bit instead of guide bushings

on the router base will produce a similarly predictable

result. The photo to the left

shows (left to right) a top

bearing bit the same size as

the cutter (called a flush trim

bit), a top bearing bit smaller

than the cutter (called a rebate cutter), and a bottom

bearing bit the same size as

the cutter.

If the template will be held

between the router base and

the work piece (as in most

plunge cut applications and

many router table applications), the bearing needs to be mounted on the shank

end of the bit like the one on the right. If

the work piece is held between the router

30

Page 31

base and the template (as in most

through cut applications), then the

bearing needs to be mounted on the

cutter end of the router bit (the left most

bit in the photo on the previous page).

In either case, if the bearing is larger

than the router bit, it will act like the

guide bushing in our examples above,

and the same relationships will exist.

The work piece will be machined to be

smaller than the inside of the template

by one half of the difference in diameter

between the router bit and the bearing.

If, on the other hand, the bearing is

smaller than the router bit, as is the bit

pictured in the center of the photo on

the previous page, then the work piece

will be machined to be larger than the inside of the template, again by one half of

1400 guide bushings and rings in inch sizes mounted

on a 1400 “universal” guide bushing adapter

There is still a third way of establishing

the offset between the inside of the template and the line of cut and that is

through the use of what are

called “snap on guide

rings.” This is a two piece

guide bushing set. The

guide bushing itself is one

diameter and a machined

ring is fashioned which has

a hole in it the same diameter as the guide bushing but with a larger outside

diameter.

1010 guide bushing and ring set in metric

sizes designed around 4mm, 6mm and

8mm bits. 8mm carbide insert bit shown

the difference in diameter between the bit

and the bearing. Doing this will be undercutting the template so use a thin

scrap between the template and work

piece to avoid scarring the template.

31

For any given router bit,

the difference in the diameter of the guide bushing and guide ring required to make a male

and female cut from the

same template fit to-

gether is twice the diame-

ter of the router bit.

So, whether working in inch size bits,

bushings, and rings, or with metric

size bits, bushings, and rings, you

Page 32

want to find pairs where the difference

in diameter between the bushing and

the ring is twice the diameter of the

router bit itself.

These pairs will cut female recesses of

any shape with matching males that fit

into those recesses which will be

smaller than the template by a known

amount, which I refer to as the “offset.”

The offset from the side of the template to the edge of the inlay is half the

diameter of the largest bushing or ring

plus half the diameter of the bit.

If you are starting with a male shape

that you want to fit into a female recess, the template needs to be larger

than the male by this offset amount. If

you are starting with a female shape

that you want to cut a male to fit you

will wind up with a female recess and

matching male that fits that is smaller

than the original female by the offset

amount.

The guide bushing on the Festool set

shown has a diameter of 10.6mm. There

are five rings marked, in increasing diameter 4, 6-4, 8s, 6 and 8l. You can use

a 4, 6 or 8mm bit. With a 4mm bit you

can get male/female matching pairs with

various offsets by using the bushing

alone with ring 4, ring 4 with ring 8s and

ring 8s with ring 8l. Likewise you can use

a 6mm bit and get matching pairs with the

guide bushing and ring 6-4 or with ring 64 and ring 8l. With an 8mm bit the combinations are guide bushing and ring 8s

or ring 4 and ring 8l. Each produces a

different offset so you can select which

best fits your situation. See the table in

Appendix B for details.

I like the metric set for use with the MFS

profiles since they are both denominated

in metric sizes so the math is easy.

The inch denominated set shown in combination with the 1400 universal guide

bushing adapter is designed to work with

1/8”, 1/4”, 3/8”, 1/2” and 3/4” bits. You

can probably find others as well.

As you begin to explore the fascinating

world of template and pattern routing it is

very important to understand these relationships. I know it seems a bit confusing

at first, but hang in there and it will slowly

begin to sink in.

Let’s take a look at the very capable metric set from Festool. It is not a regular

catalog item but was developed for the

flooring installers who needed to do various kinds of fancy inlays in their floors.

This is the metric set shown at the bottom

of the previous page. It only fits the 1000

and 1010 routers, not the 1400. There

are lots of inch sets available that fit the

universal guide bushing adapter for the

1400 from a variety of manufacturers.

32

If using the 3/4” bit, bushing and ring set

the bushing diameter is 7/8” and the ring

diameter is 2 3/8” so the offset is going to

be 3/8” plus 1 3/16” or 1 9/16”. You cut

the female recess with the 2 3/8” diameter ring installed and the male with just

the 7/8” diameter of the guide bushing so

the male will just fit into the female recess.

These snap on guide bushing sets produce the same outcome as using two different guide bushings but are a bit faster

to use with the 1010 and most other routers since you don’t need to change guide

bushings. With the 1400, changing guide

bushings is so fast that it is a toss up, but

the range of available sizes is limited.

Page 33

Using the Festool MFS

profiles as an adjustable

rectangular router template

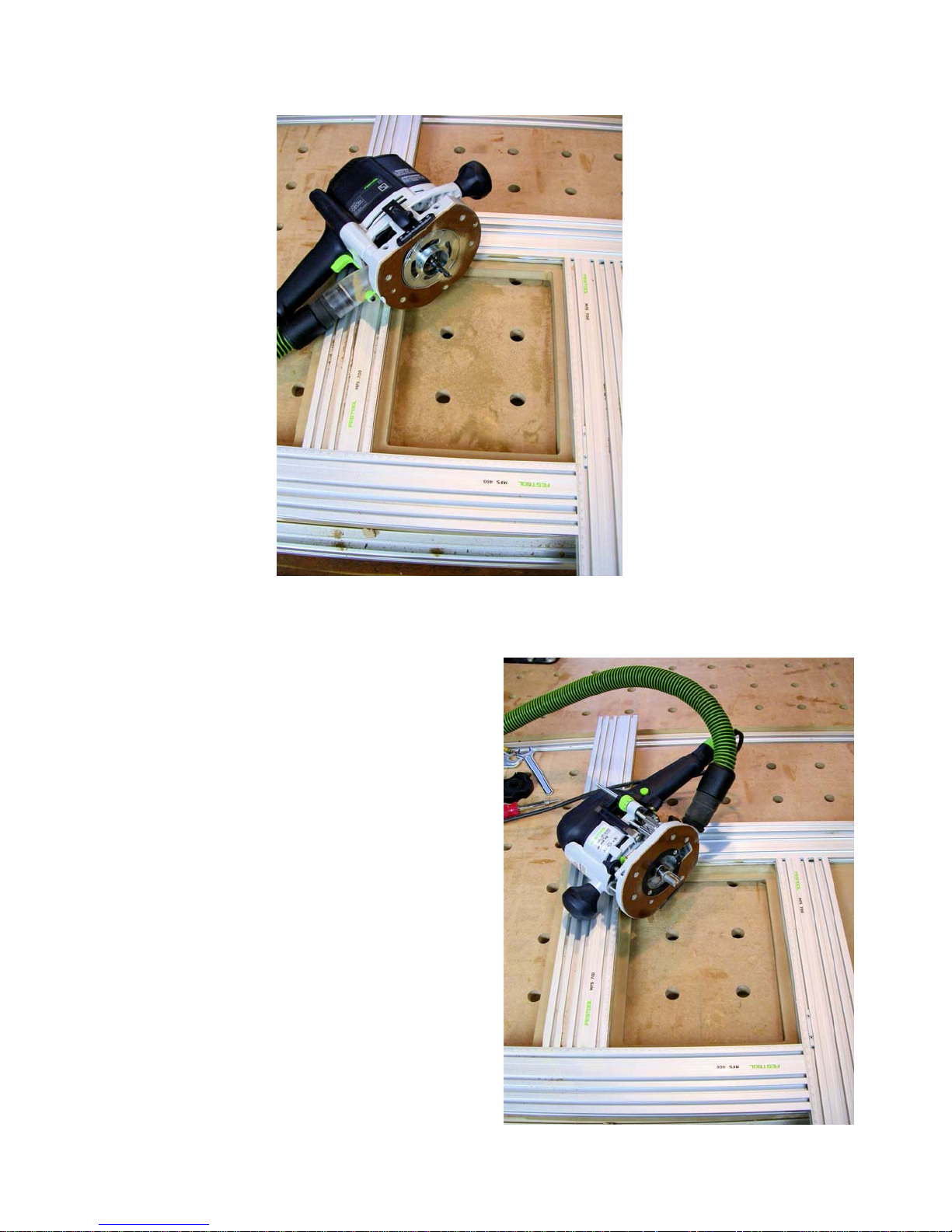

So far we have only looked at the MFS in

terms of using its various components as

fences or guide rail positioning aids. If

you assemble four of the MFS extrusions

as a rectangle with the ruler markings on

the inside it now be-

comes an adjustable

rectangular router

template. It is easy to

adjust to whatever

size rectangle you

want.

As we will see in a

moment it is just as

easy to change the

size of the template to

do offset routing as it

is to leave the template the same size

and change bearings

or guide bushings or

guide bushing and

ring sets. Either works

well for most applications.

Let’s start with a

commonly requested

example. Let’s recess

a router plate into the top of a Festool

Multi-Function Table. I’m not going to actually cut into my tables because I already have large industrial router tables.

Instead I will cut into a piece of 3/4” mdf

which we will pretend is a Festool MFT

top plate.

To set a router plate into a table surface,

the male already exists (the plate itself)

so we just need to fit it into a proper female recess. We need to rout a groove

the thickness of the router plate and exactly the same size as the router plate.

Then we need to cut clear through the

table top surface leaving about a 10mm

to 15mm lip all around to support the

router plate. The router plate pictured

below with the router still attached is designed for a lip that is 11mm deep.

Begin by

setting the

selected

router plate

flat on the

table top.

Assemble

four MFS

extrusions

into a rectangle with

the ruler

markings

on the inside.

Place this

rectangle

over the

router plate

and adjust

the rectangle to just

fit the

router plate

as is shown in this photo.

That is all it takes to make a template that

is exactly the same size as the router

plate.

Now, place the rectangular template you

just made on top of the intended work

piece positioned just where you want it.

33

Page 34

Draw a line around the inside so you can put it back

in that same spot. Also

draw a line a to form a lip a

bit wider than you want.

This is to allow you to cut

out the majority of the center with a jig saw or “recip”

saw before you do any of

the routing. As you can see

from the photo below, it

doesn’t need to be a careful

or even straight cut. All you

are doing is removing the

bulk of the material to reduce the amount of work

the router bit has to do

when you next rout the

actual inside edges of the

work piece.

Put the template back

aligned with the pencil line

you drew a moment ago.

Mount a guide bushing

and straight cut bit sized

to produce the width of lip

you want. Remember

how the guide bushing will

ride on the inside edge of

the template and hold the

Draw lines to mark the inset location and a rough line a bit wider

than the lip you want

Cut out the center with a jig

saw or “recip” saw

inside edge of the bit away

from the template by half

the diameter of the guide

bushing less half the diameter of the bit.

For this router plate, a

really beat up unit that has

been in use daily for several years, the lip needs to

be about 1/2”. A 40mm

guide ring snapped into

the Festool 1400 router

shown in the lower picture

and 10mm router bit will

produce a 15mm lip, a bit

wider than 1/2” but certainly close enough to 1/2”

to work well.

Use a guide bushing and

straight bit to cleanly trim the

rough inside edges of the cut

34

I placed scrap pieces of

plywood under the work

piece to hold it off of the

surface of the multifunction table so as not to

scar it up. Set the depth

of cut to just clear the bottom of the work piece.

Follow the template with

Page 35

the guide bushing moving in a

counter clockwise direction.

Go slowly as you

are removing a

lot of nasty mdf

material, and

carefully guard

against tipping

the router. Be

sure to use dust

collection with

your router and

wear ear protection.

The result will be

a very clean,

Inside cut with 1400 router,

straight bit and guide bushing

smooth cut-out,

in this case

30mm smaller

than the router

plate all around, so as to form the 15mm

lip we were after.

ing the base flat on the

MFS profiles. At 80mm

wide it is easy to perch