Page 1

No. 530

Routing circles using the MFS

routing template

A

Description

By using the MFS 400 or the MFS 700 templates, radii (1), round cutouts (2)

and circles (3) can be made easily and quickly.

1

3

Applications: loudspeaker enclosures, transparent cutouts, counters,

wash basins, ...

The largest radius that can be routed, depending upon the particular MFS,

can be found from the table. However, the cutter dia. and the type of radius

that is to be produced must be taken into consideration!

MFS 400

Reference dimension (mm) Calculation

Max. outer radius 306 306 + cutter diameter / 2

Max. inner radius 306 306 – cutter diameter / 2

Max. outer radius 37 37 + cutter diameter / 2

Min. inner radius 37 37 – cutter diameter / 2

MFS 700

Reference dimension (mm) Calculation

Max. outer radius 606 606 + cutter diameter / 2

Max. inner radius 606 606 – cutter diameter / 2

Max. outer radius 37 37 + cutter diameter / 2

Min. inner radius 37 37 – cutter diameter / 2

2

530/01

Example: For a 12 mm dia. router

bit, the following radius values are

produced:

MFS 400 MFS 700

Max. radius (mm)

Outer 312 612

Inner 300 600

Min. radius (mm)

Outer 43 43

Inner 31 41

1/3

Page 2

530/02

B

Required equipment

Equipment Order No.

Routing template MFS 400

or routing template MFS 700

Router OF 1010 or

router OF 1400 or

router OF 2200

Copying ring holder (included with MFS)

Copying ring dia. 30 mm

(included with OF 1400 and OF 2200)

Groove cutter *

CT series mobile dust extractor *

• 8 mm drill bit with centring point 492517

* Please obtain the Order No. from the Festool main catalogue or from its website.

C

Preparation/Set-up

492610

492611

*

*

*

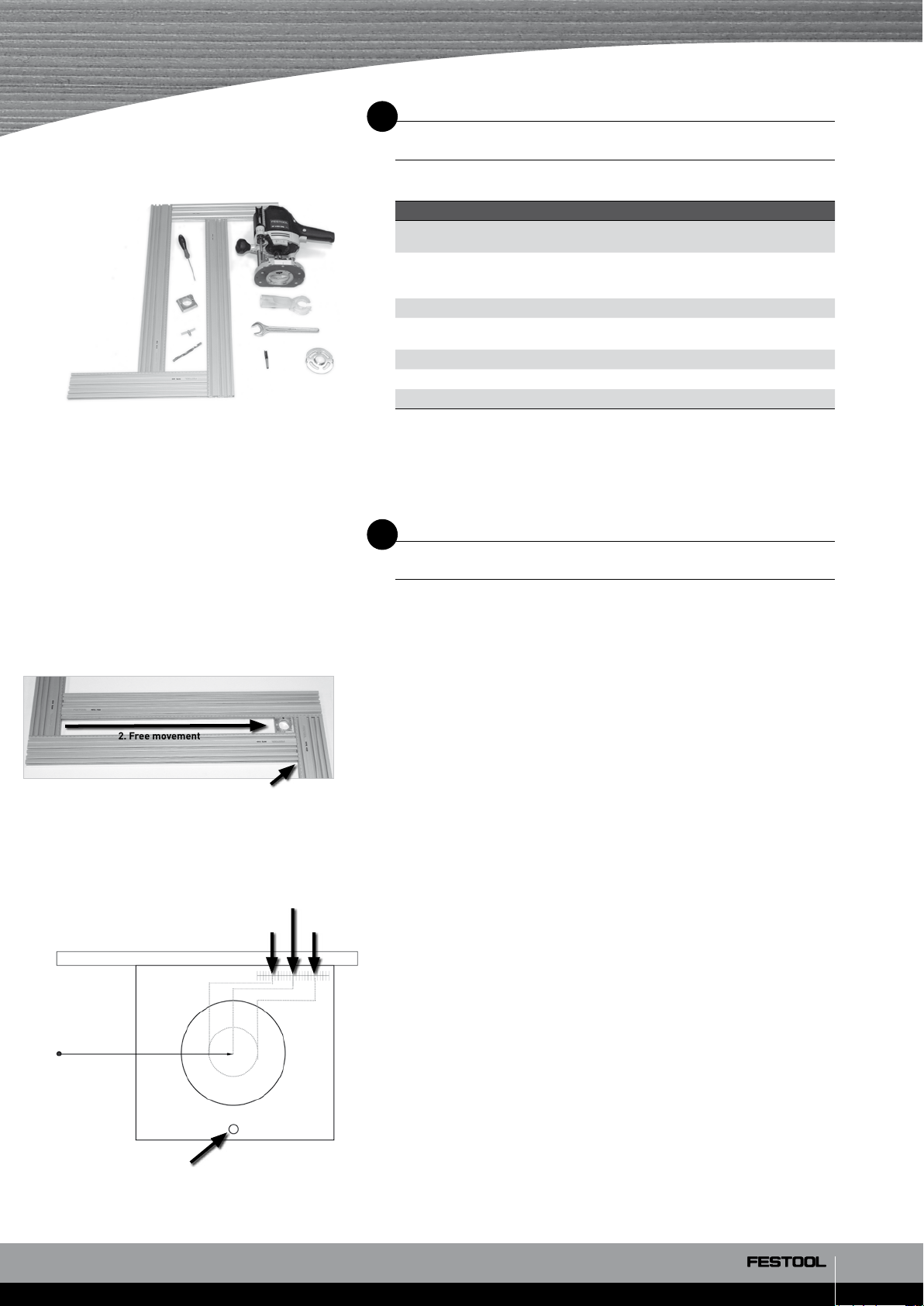

Centre of

rotation

2. Free movement

MFS profile

1. Screw

Cutter

inner dimension

530/03

Cutter

centre

Cutter

outer dimension

Mount the routing template according to the directions, and install the copying ring holder and centring mandrel (see Section 5.4 in the instructions).

Adjust the copying ring holder so that it can move freely along the entire

length of the MFS groove. To do this, slide the copying ring holder in a

corner and fasten securely with the fixing screw (Fig. 530/03). Finally, move

the copying ring holder into the other corner, tighten the fixing screw on the

MFS and the check the free movement of the copying ring holder over the

entire length.

Setting the routing template

1. For an outer radius:

Set the radius minus ½ cutter dia. using the scale on the MFS,

e. g., radius 200 mm – (cutter dia. 14 mm / 2) = 193 Move the "0" on the

copying ring holder vernier scale so that it coincides with the number

193 on the MFS scale.

2. For an inner radius:

Set the radius minus ½ cutter dia. using the scale on the MFS,

e. g., radius 200 mm + (cutter dia. 14 mm / 2) = 207 Move the "0" on the

copying ring holder vernier scale so that it coincides with the number

207 on the MFS scale.

Set screw

Clamp the copying ring holder to the lower part of the MFS. •

530/04

2/3

Page 3

Preparing the router

Mount copying ring dia. 30 mm on the router and centre it by using •

the centring mandrel (not applicable for the OF 1400 and the OF 2200).

Attach extractor hood and extractor hose. •

Insert the groove cutter in the router and tighten. •

Set the speed to 6. •

Drill 8 mm in the centre of the radius in the workpiece. •

D

Procedure

Insert the routing template with circle routing insert in the hole in the •

workpiece (Fig. 530/05).

Insert router in the copying ring holder. •

530/05

530/06

530/07

Set the routing depth and plunge cut. •

Guide the routing template together with the router in the opposite direc- •

tion (clockwise) up to the scribe mark or the start of the routing (circle)

(Fig. 530/06).

Tip: For complete circle cutouts, care must be taken to cut through

since the centre is no longer securely fixed around which the MFS

is rotated.

To ensure a secure centre position, three or four pieces of wood

can be used for connecting on the back side of the workpiece

(Fig. 530/07). When routing through, these wood pieces will only

be slightly cut but they will nevertheless provide a material interconnection.

Our example for use is a recommendation tried and tested in practice. However the

different conditions are completely outside of our control. We therefore do not provide

any form of guarantee. Any legal claims arising out of this are not to be made against

Festool. Make sure you follow the safety directions and product instructions provided

with the product.

www.festool.com

3/3

Loading...

Loading...