Page 1

Instruction manual

Page 6 - 13

IMPORTANT: Read and understand all instructions before

using.

Guide d’utilisation

Page 14 - 23

IMPORTANT: Lire et comprendre toutes les instructions

avant de démarrer les travaux.

Manual de instrucciones

Pagina 24 - 33

IMPORTANTE: Lea y comprende todas las instrucciones

antes de usar.

474129_004

Instruction manual

Guide d’utilisation

Manual de instrucciones

MFK 700

Page 2

Page 3

Page 4

1.1

Page 5

1-2

1-4

1-3

Page 6

6

Table of contents

Safety rules 6

Technical data 8

Symbols 8

Scope of delivery 8

Intended use 8

Electrical connection 8

Switching the machine on and off 9

Tool settings 9

Electronic control 9

Changing the router table 9

Changing the routing tool 10

Changing the clamping collet 10

Adjusting the routing depth 11

Dust extraction 11

Working with the machine 11

Machine guidance methods 11

Aluminium processing 12

Service and maintenance 12

Accessories, tools 12

Warranty 13

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodifi ed plugs

and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

Safety rules

General safety rules

Read and understand all instructions. Failure to follow all instructions listed below may result in electric

shock, fi re and/or serious personal in-

jury.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit. Clut-

tered and dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable liquids, gases or dust.

Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distractions

can cause you to lose control.

3) Personal safety

a) Stay alert, watch what you are doing

and use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the infl uence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use safety equipment. Always wear

eye protection. Safety equipment such as

dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the

switch is in the off position before plugging in. Carrying power tools with your fi nger

on the switch or plugging in power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected

situations.

Page 7

7

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of these devices

can reduce dust related hazards.

4) Tool use and care

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing power

tools. Such preventive safety measures re-

duce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions and in the manner intended

for the particular type of power tool, taking into account the working conditions

and the work to be performed. Use of

the power tool for operations different from

those intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a

qualifi ed repair person using only identi-

cal replacement parts. This will ensure that

the safety of the power tool is maintained.

Specifi c Safety Rules

a) Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact with a

”live” wire will make exposed metal parts of

the tool ”live” and shock the operator.

b) Use clamps or another suitable means

to support and secure the workpiece to

a stable platform. Holding the workpiece

by hand or against your body is unstable and

may lead to loss of control.

Health hazard by dust

Various dust created by power

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals

are:

lead from lead-based paints,•

crystalline silica from bricks and cement •

and other masonry products, and

arsenic and chromium from chemically-•

treated lumber.

The risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chem-

icals: work in a well ventilated area, and

work with approved safety equipment,

such as dust masks that are specially

designed to fi lter out microscopic par-

ticles. Wash hands after handling.

TO REDUCE THE RISK OF

INJURY, USER MUST READ AND UNDERSTAND INSTRUCTION MANUAL.

Page 8

8

Technical data

Power consumption 720 W

Rotational speed (no load)

10000 - 26000 rpm

Tool holder 8 mm (0.31")

optional: 6 mm (0.24")

1/4"(6.35 mm)

Max. routing tool diameter 26 mm (1")

Weight 1.9 kg (4.2 lbs)

Safety

/II

Symbols

V Volts

A Amperes

Hz Hertz

~ Alternating current

n

No load speed

0

Class II Construction

Intended use

The MFK 700 EQ is designed for routing wood,

plastic and similar materials.

The user shall be responsible

and liable for damages and accidents

resulting from misuse or abuse of this

tool.

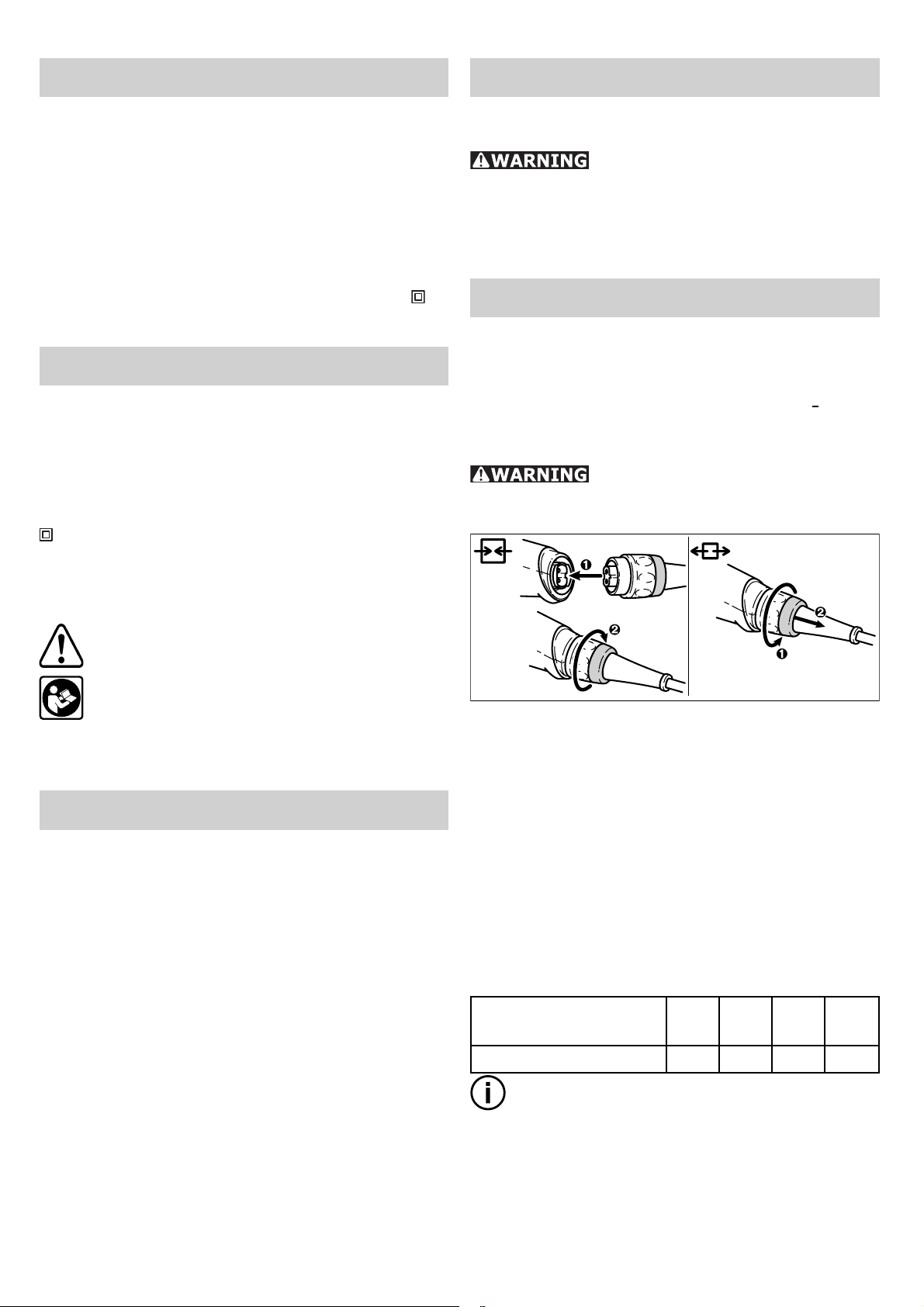

Electrical connection

The network voltage must conform to the

voltage indicated on the rating plate. A 16

A safety fuse (for 120 V) or a corresponding

protective circuit-breaker is required.

See the following fi gure [2] for connection and

disconnection of the power cable.

Always switch the machine

off before connecting or disconnecting

the power cable!

rpm Revolutions or reciprocation per

minute

Ø Diameter

Warning of general danger

Read the Operating Instructions/

Notes!

f Advice or tip

Scope of delivery

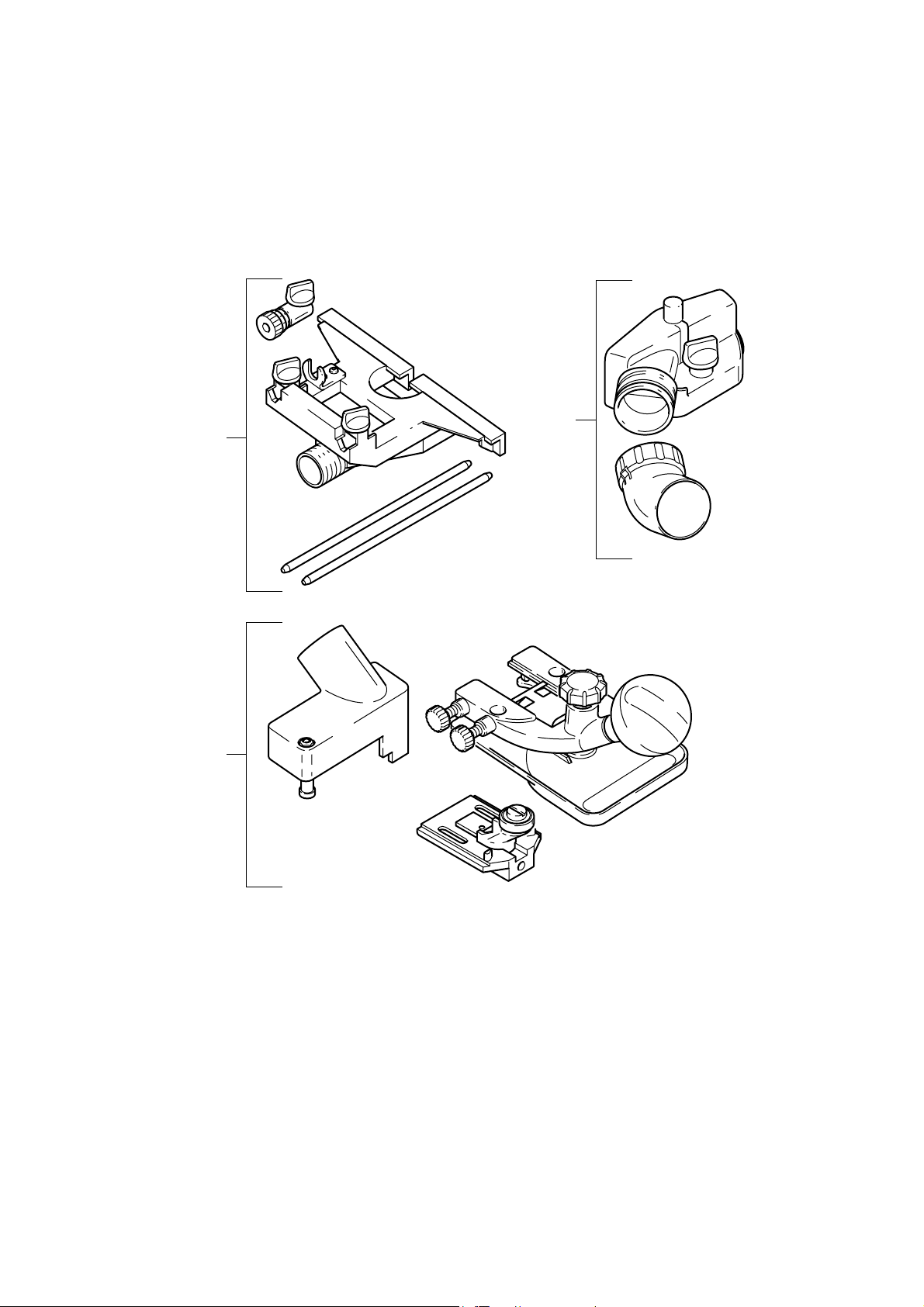

The pictures for the scope of delivery are on a

fold-out page at the beginning of the instruction manual. When reading of the manual you

can fold out this page for having always an

overview of the machine.

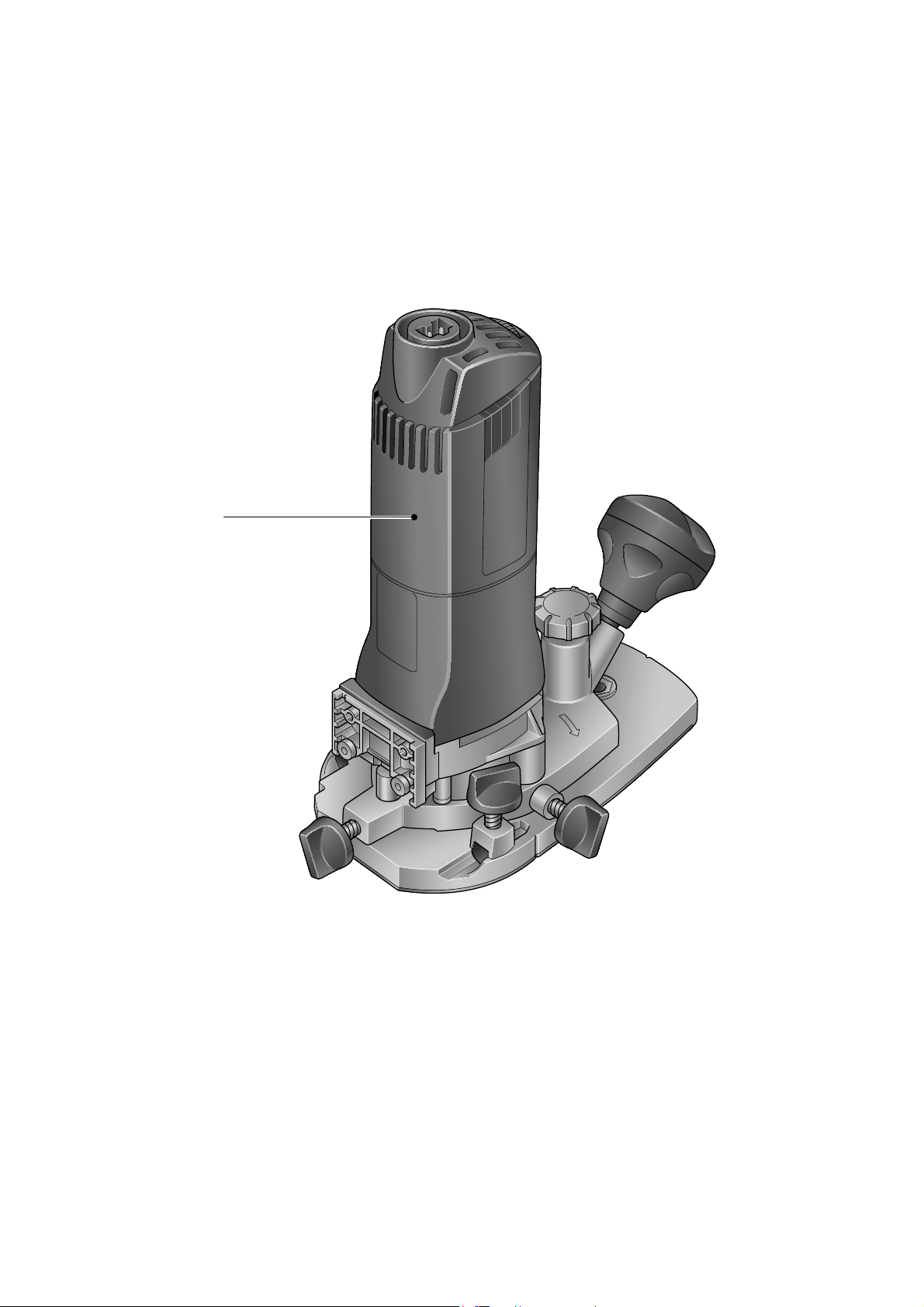

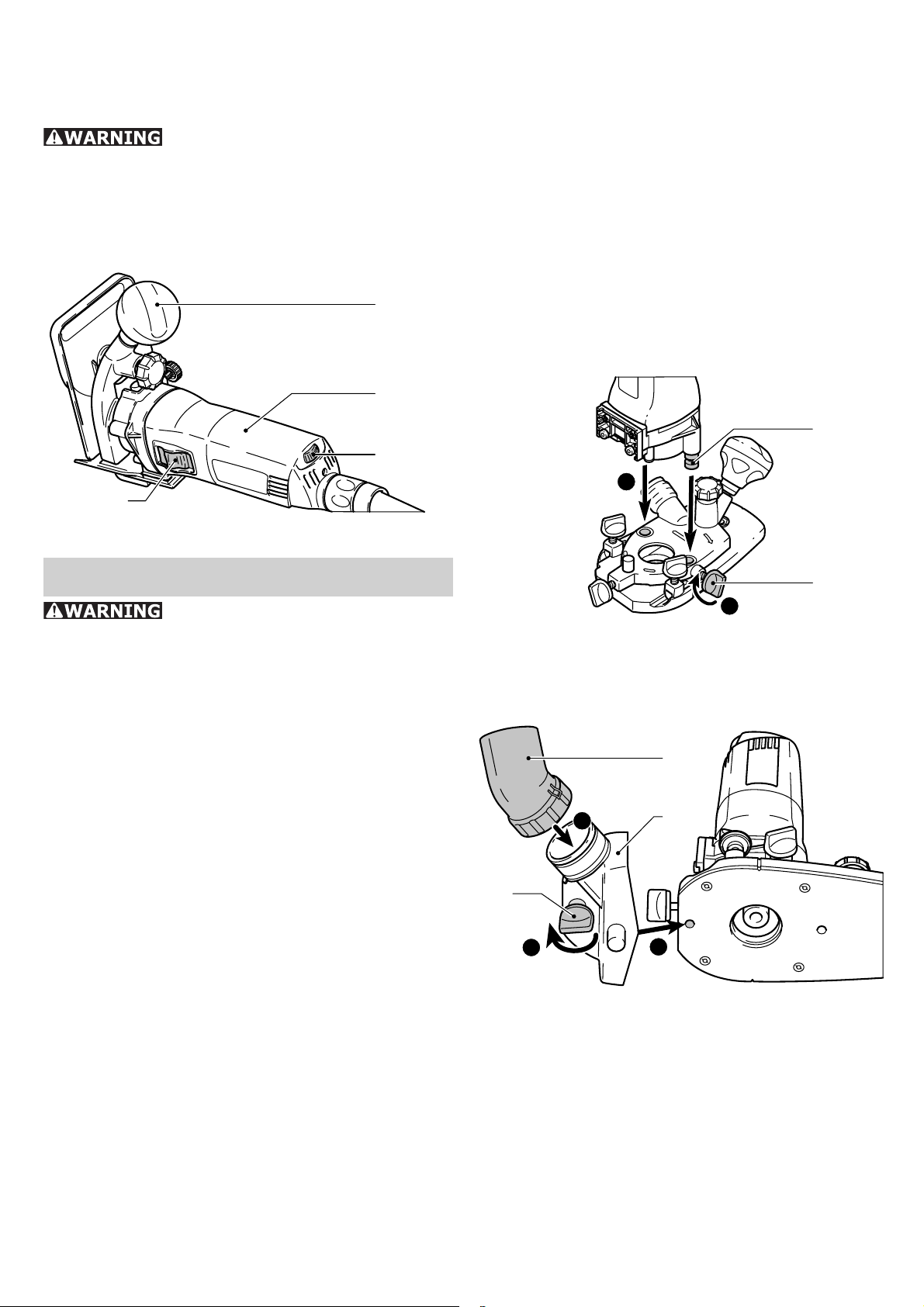

[1-1] MFK 700 with large surface router ta-

ble

[1-2] Side stop with guide rods and fi ne ad-

juster

[1-3] Extraction hood for large surface router

table with extractor connector

[1-4] Router table for edge veneer with feeler

roller and extraction hood (only in SET

scope of delivery)

2

Extension cable

If an extension cable is required, it must have

a suffi cient cross-section so as to prevent an

excessive drop in voltage or overheating. An

excessive drop in voltage reduces the output

and can lead to failure of the motor. The table

below shows you the correct cable diameter as

a function of the cable length for the MFK 700.

Use only U.L. and CSA listed extension cables.

Never use two extension cables together. Instead, use one long one.

Total Extension Cord

Lenght (feed)

Cord size (AWG) 18 16 16 14

Note:

The lower the AWG number, the stronger f

the cable.

25 50 100 150

Page 9

9

Switching the ma-

chine on and off

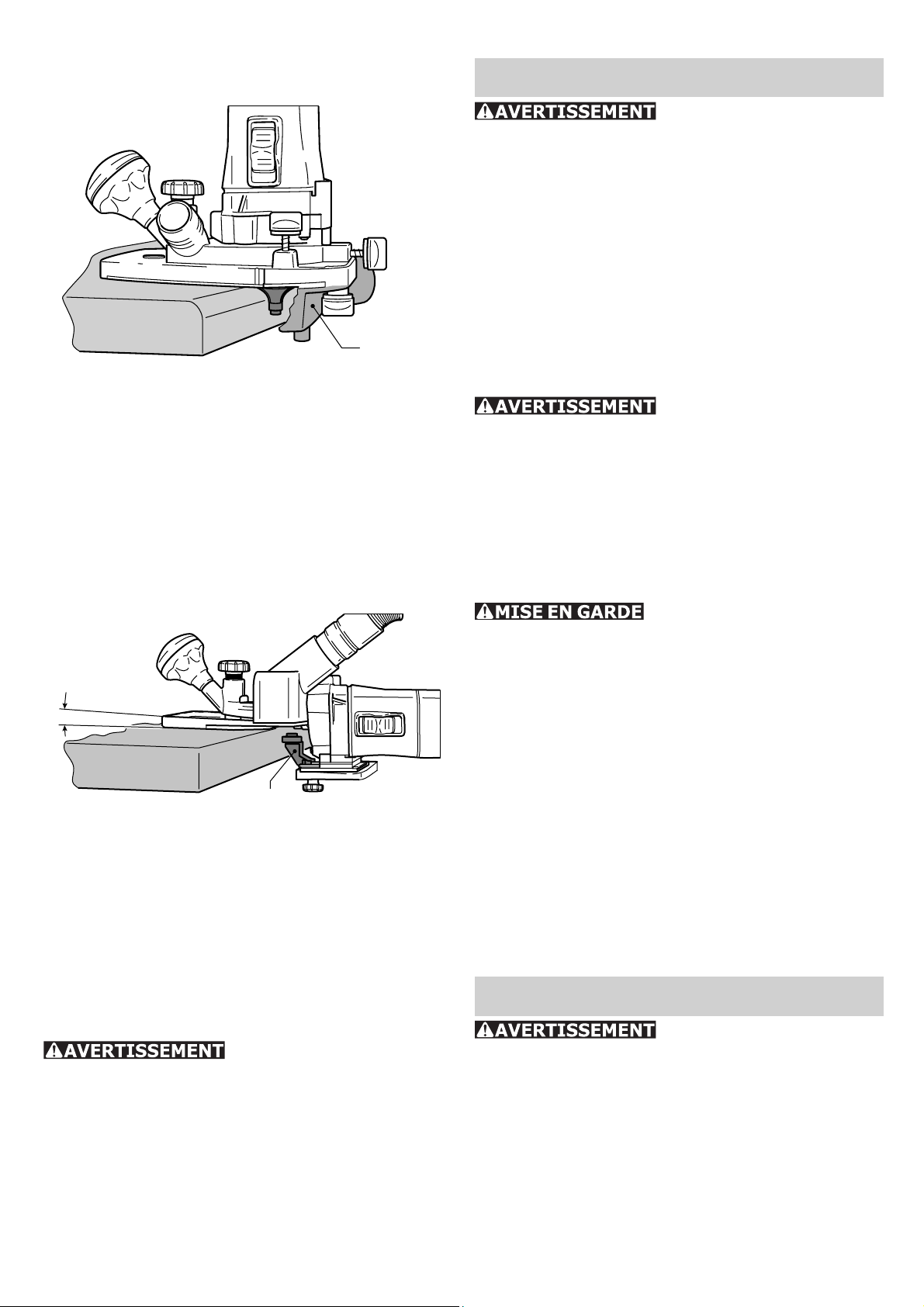

Keep the machine steady

during switching and during use by holding the handles [3-1] [3-2] with both

hands.

The switch [3-4] is an on/off switch (I = ON,

0 = OFF).

3-1

3-2

3-3

3-4

cool down for approx. 3-5 minutes before using it again. The machine requires less time

to cool down if it is running, i.e. in neutral

position.

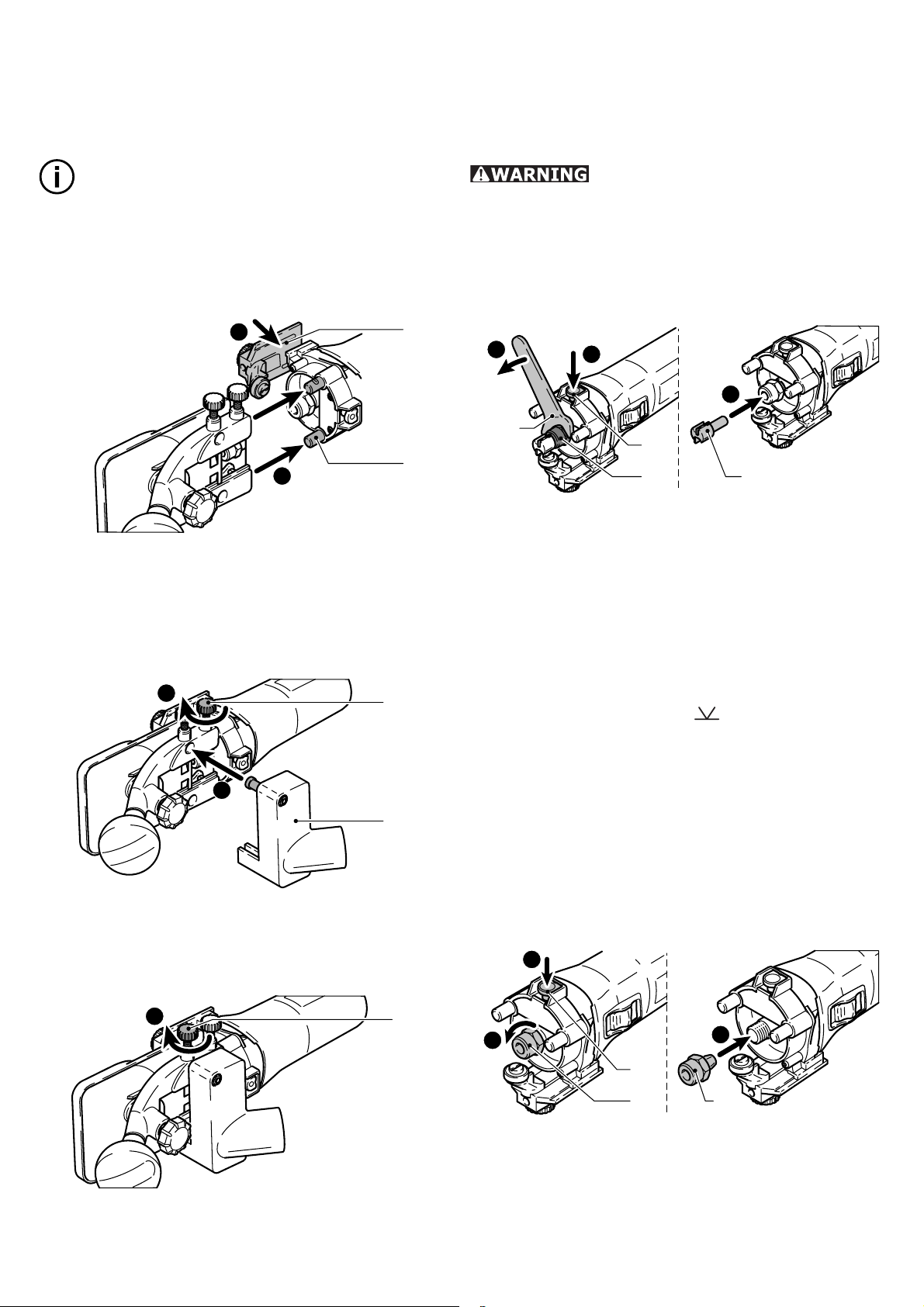

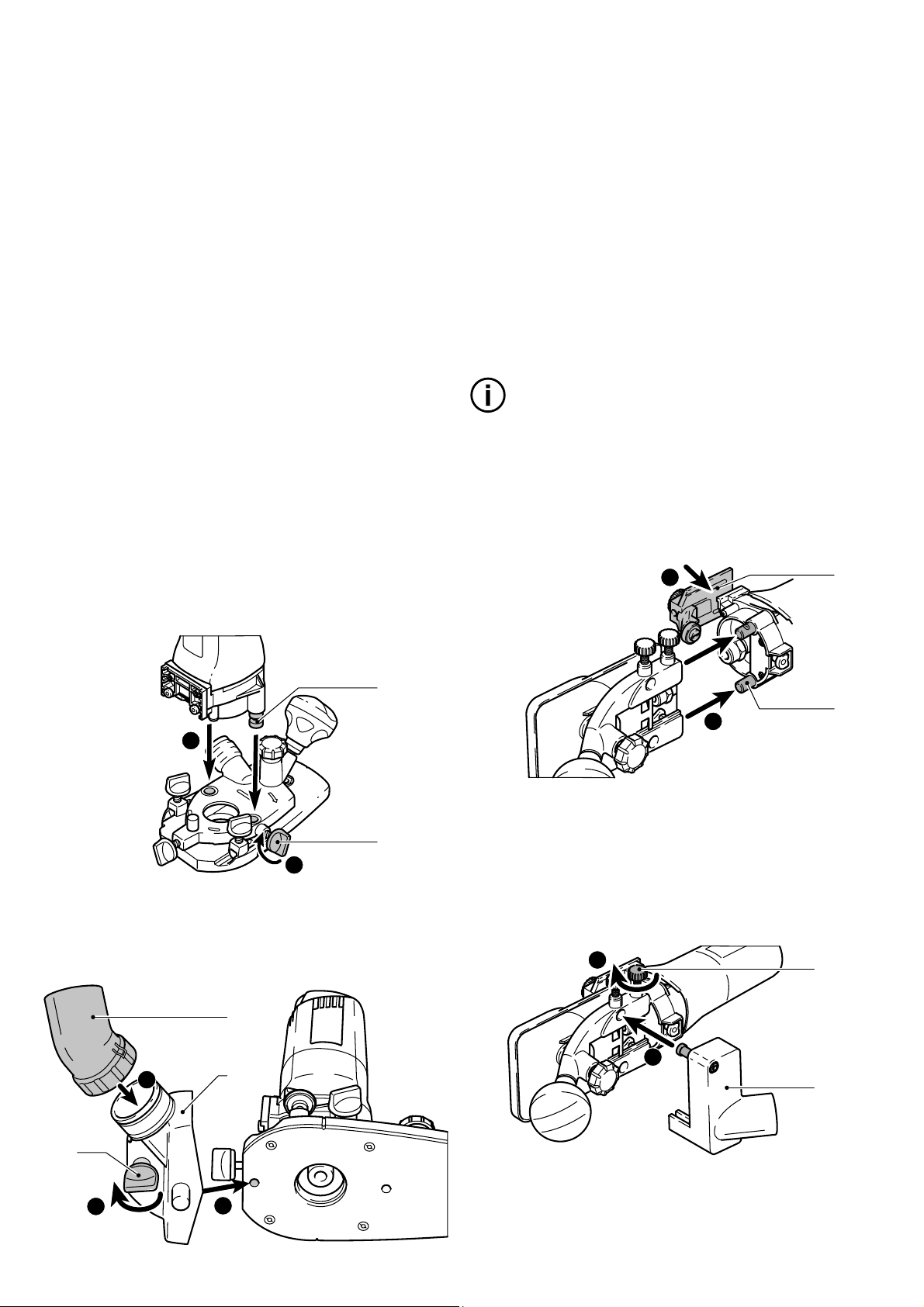

Changing the router table

The “large surface router table” is already fi t-

ted as standard. The large contact surface and

precision adjustment features of this router

table enable a high degree of accuracy. Other

router tables are included in the accessories

programme.

a) Large surface router table

4-1

1

Tool settings

Disconnect the plug from the

power source before making any adjustments, changing accessories, or storing

power tools.

Electronic control

The machine features full-wave electronics

with the following properties:

Smooth start-up

The electronically controlled smooth start-up

function ensures that the machine starts up

smoothly.

Speed control

You can regulate the rotational speed

steplessly between 10000 and 26000 rpm

using the adjusting wheel [3-3]. This enables

you to optimise the cutting speed to suit the

respective material.

Constant speed

The preselected motor speed remains constant through electronic control. This ensures

a uniform cutting speed even when under

strain.

Temperature control

4-2

2

Slide the router table onto the retaining pin –

[4-1] on the machine.

Tighten the screw [4-2] to clamp the router –

table in position.

4-5

5

4-3

4

4-4

3

Place the extraction hood [4-4] in posi- –

tion.

Tighten the screw [4-3] to clamp the ex- –

traction hood in position.

Place the extractor connector [4-5] on the –

extraction hood.

Removal is performed in reverse sequence to

installation.

To prevent overheating, the safety electronics

switches the machine off when it reaches a

critical motor temperature. Let the machine

Page 10

10

b) Router table for edge veneer

The "router table for edge veneer" (only in SET

scope of delivery) is designed for fl ush trim-

ming veneer overhang and profi le routing.

Notes:

The router table is tilted 1.5° so that the f

surface coating is not damaged during edge

routing. A router table with 0° inclination

angle for precise cuts is available as an

accessory.

1

2

5-1

5-2

Secure the sensor [5-1] to the machine –

using the preassembled screws. Slide the

sensor in the long holes to adjust the routing tool to the perfect position.

Slide the router table onto the retaining pin –

[5-2] on the machine.

3

4

5-3

Removal is performed in reverse sequence to

installation.

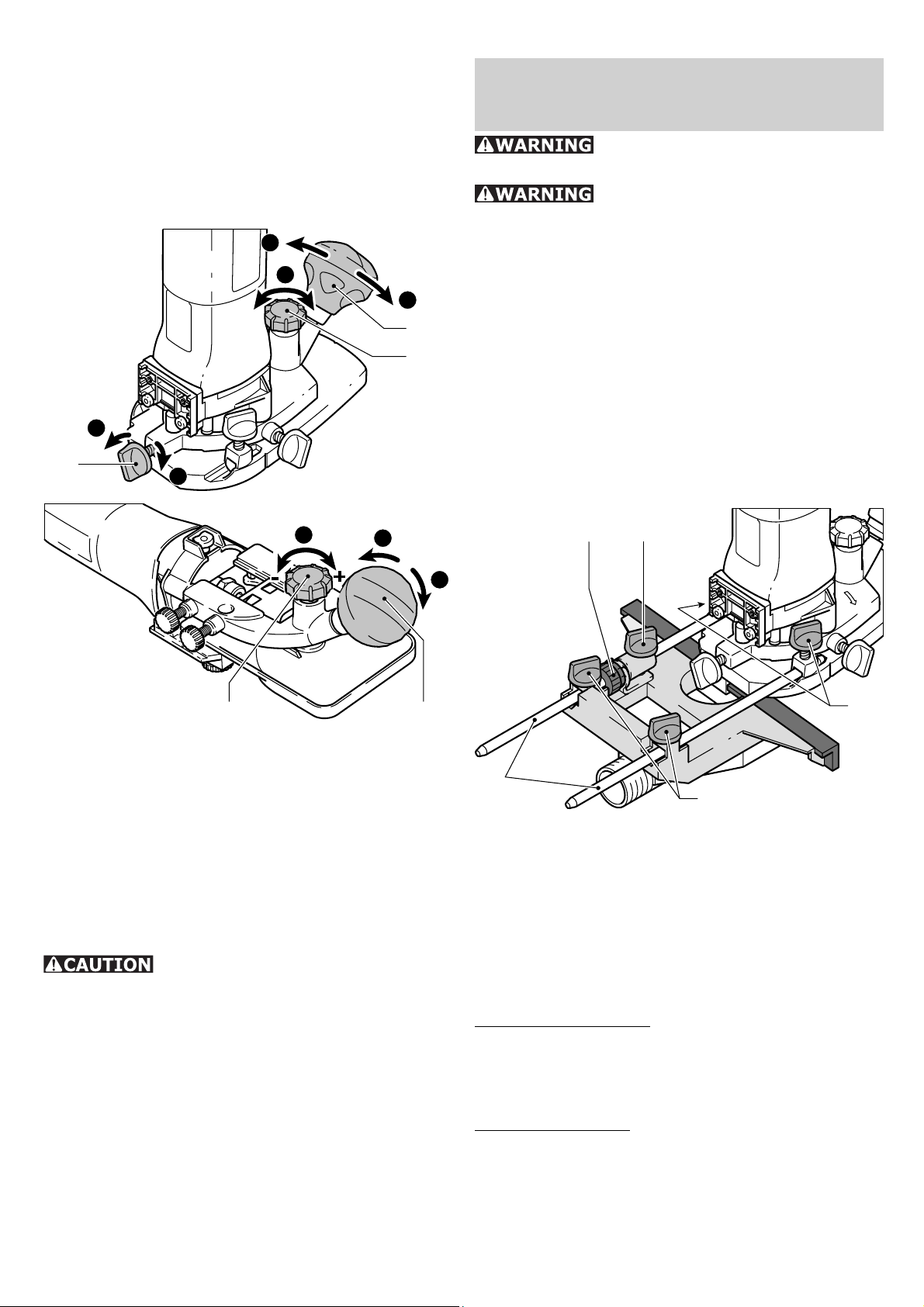

Changing the routing tool

Risk of accident - the routing

tool may be hot after use and has sharp

edges. Allow the tool to cool before chang-

ing. Wear protective gloves when changing

tools.

Remove the router table before changing –

the routing tool.

2

SW 19

a) Removing the tool

Press the spindle lock [6-1]. –

Unscrew the locking nut [6-2] using the –

open-end wrench (size 19) until you are

able to remove the tool.

b) Inserting the tool

Insert the routing tool [6-3] into the open –

clamping collet as far as possible, but at

least up to the mark (

Press the spindle lock [6-1]. –

Tighten the locking nut [6-2] using the –

open-end wrench (size 19).

1

3

6-1

6-2 6-3

) on the shank.

Tighten the screw [5-3] to clamp the router –

table in position.

Place the extraction hood [5-4] in posi- –

tion.

5

Tighten the screw [5-5] to clamp the ex- –

traction hood in position.

5-4

5-5

Changing the clamping collet

Only compatible tools can be used in combination with the clamping collets supplied.

8 mm, 6 mm and 1/4" (6.35 mm) clamping

collets can be used.

1

2

7-1

7-2 7-3

Press the spindle lock [7-1]. –

Unscrew the locking nut [7-2] completely. –

Remove the locking nut from the spindle –

together with the clamping collet [7-3]. Do

not separate the locking nut and clamping

collet as these form a single component.

3

Page 11

11

Attach a different clamping collet with lock- –

ing nut to the spindle.

Screw on the locking nut loosely. Do not –

tighten the locking nut until a router bit is

inserted.

Adjusting the routing depth

3

2

1

8-3

8-2

1

8-1

3

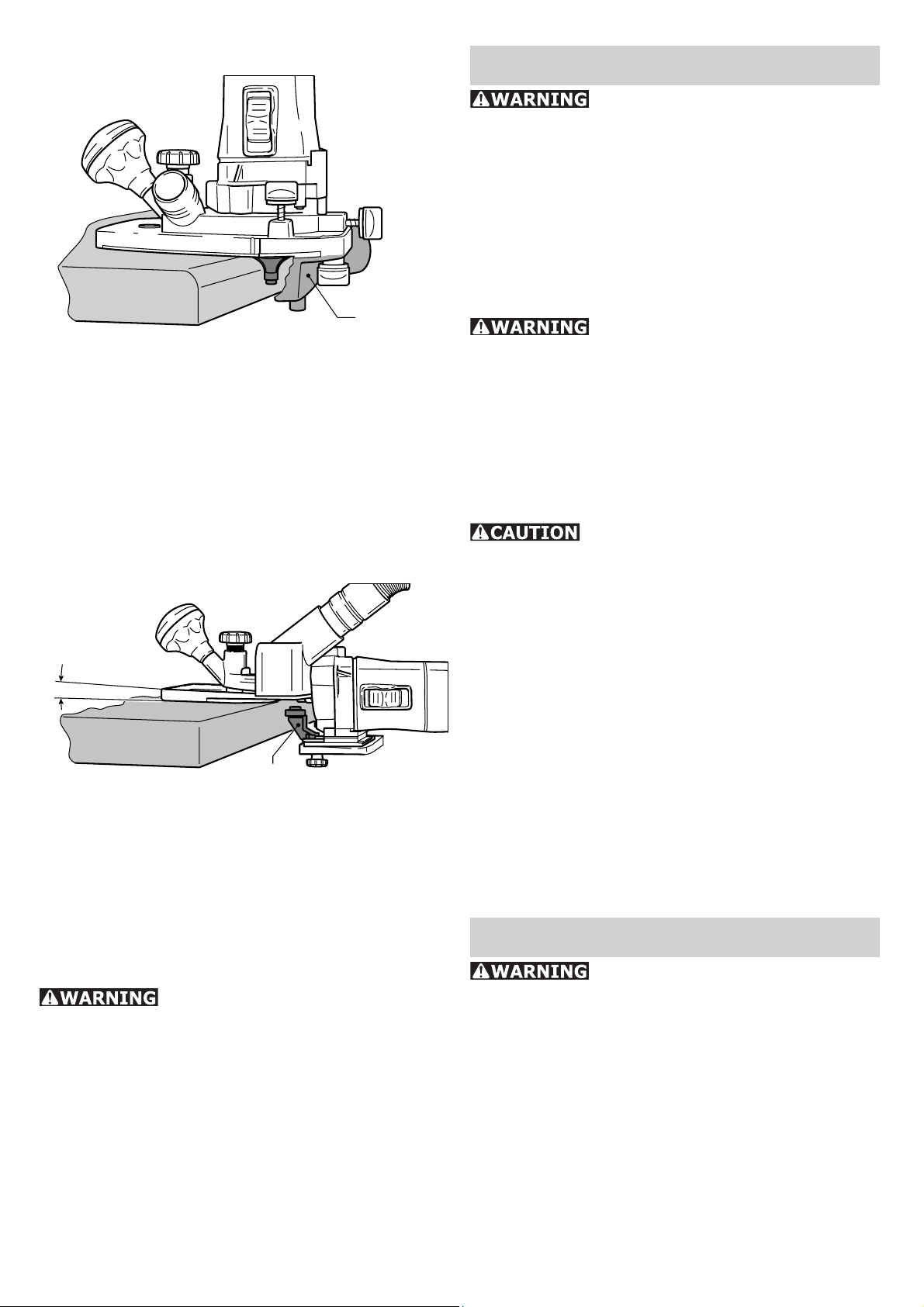

Working with

the machine

Always hold the machine

with both hands during working.

Always secure the workpiece

in such a manner that it cannot move

while being routed.

Guide the machine along the workpiece at f

a steady rate of advance.

Machine guidance methods

a) Routing with side stop

The side stop is positioned parallel to the

workpiece edge.

The side stop can only be fi tted to the “large

surface router table” without a fi tted extrac-

tion hood.

2

1

3

8-38-2

Unscrew the rotary knob [8-3] and the –

clamp [8-1] (“large surface router table”

only).

Turn the rotary wheel [8-2] to set the router –

table to the required routing depth.

Tighten the rotary knob [8-3] and the clamp –

[8-1] (“large surface router table” only).

Dust extraction

Breathing in dust can dam-

age the respiratory passage! Always con-

nect the machine to a dust extractor. When

performing work that generates dust, always

wear a dust mask.

Extraction hoods are supplied for both router

tables; a Festool extractor (extractor hose

with a diameter of 27 mm) can be connected

to these extraction hoods.

The dust extractor (extractor hose with dia.

27 mm) can also be attached to the “large

surface router table” or the side stop depending on the application.

9-49-3

9-5

9-2

Insert the fi ne adjuster [9-3] into the side –

stop.

Secure both guide rods [9-5] with the two –

rotary knobs [9-2] on the side stop.

Insert the side stop into the grooves on the –

router table to the required distance and

secure the guide rods by turning the rotary

knob [9-1].

Rough adjustment

Loosen the screws [9-2] and [9-4] and slide –

the side stop.

Tighten the screws. –

Fine adjustment

Loosen the screws [9-2] and turn the green –

wheel on the fi ne adjuster [9-3].

The distance between each line on the ro- f

tary wheel is 0.1 mm - one full turn of the

ring represents 1 mm.

Tighten the screws [9-2]. –

9-1

Page 12

12

b) Edge trimming with bearing guide

10-1

Use routing tools with a bearing guide in the

machine when edge trimming with the large

surface router table. The machine is then

guided in such a way that the bearing guide

rolls off the workpiece.

When trimming edges, always use the undertable extractor adapter [10-1] for improved

dust extraction.

c) Edge trimming with sensor and router

table for edge veneer

1,5°

11-1

When edge trimming with the router table for

edge veneer (only in SET scope of delivery), fi t

the sensor [11-1] to the machine (see “Router

table for edge veneer “). The machine is then

guided in such a way that the sensor rests

against the workpiece.

Service and maintenance

Any maintenance or repair

work that requires opening of the motor

or gear housing should only be carried

out by an authorised Customer Service

Centre (name supplied by your dealer)!

Maintenance or repair work carried out by an

unauthorised person can lead to the wrong

connection of the power leads or other components, which in turn can lead to accidents

with serious consequences.

To prevent accidents, always

remove the plug from the power supply

socket before carrying out any maintenance or repair work on the machine! Do

not use compressed air to clean the electrical tool! Do not try to clean parts inside the

machine in this way, as you could let foreign

objects in through the openings of the machine housing.

Certain cleaning agents and

solvents are harmful to plastic parts.

Some of these are: gasoline, carbonyl chloride, cleaning solutions containing chlorine,

ammonia and household cleaners containing

ammonia.

To assure the circulation of air, the cool air f

vents in the motor housing must always be

kept clear and clean.

This unit is fi tted with special, automati- f

cally disconnecting carbon brushes. If these

become worn, the current is automatically

switched off and the unit shuts down. In

this case, take the unit to an authorised

Customer Service Centre and have the

carbon brushes changed.

Accessories, tools

Aluminium processing

Risk of accident - always

perform the following safety measures

when routing aluminium:

Add a residual-current circuit-breaker f

(FI, PRCD).

Connect the machine to a suitable dust f

extractor.

Remove dust deposits from the motor hous- f

ing on a regular basis.

Wear protective goggles. f

For safety reasons, only use

original Festool accessories and tools!

The accessory and tool order number can be

found in the Festool catalogue or on the Internet under www.festool-usa.com.

Systainer

Many Festool products are shipped in a unique

system container, called "Systainer". This provides protection and storage for the tool and

accessories. The Systainers are stackable and

can be interlocked together. They also can be

interlocked atop Festool CT dust extractors.

Page 13

12.3

12.2

12.1

Place one systainer on top of the other. –

Release all four latches on the lower sys- –

tainer by pulling back at their top edges

(12.1).

Slide all four latches upward (12.2). –

Snap all four latches back to their fl at po- –

sition (12.3) so they engage the stacking

tabs of the upper systainer.

13

tools. No agent, representative, distributor,

dealer or employee of Festool has the authority to increase or otherwise change the

obligations or limitations of this warranty. The

obligations of Festool in its sole discretion under this warranty shall be limited to the repair

or replacement of any Festool portable power

tool that is found to be defective as packaged

with the User Manual.

Excluded from coverage under this warranty

are: normal wear and tear; damages caused

by misuse, abuse or neglect; damage caused

by anything other than defects in material and

workmanship. This warranty does not apply to

accessory items such as circular saw blades,

drill bits, router bits, jigsaw blades, sanding

belts, and grinding wheels. Also excluded

are “wearing parts”, such as carbon brushes,

lamellas of air tools, rubber collars and seals,

sanding discs and pads, and batteries.

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty

(1 year + 2 years = 3 years) for your Festool

power tool. Festool shall be responsible for

all shipping costs during the fi rst year of the

warranty. During the second and third year of

the warranty the customer is responsible for

shipping the tool to Festool. Festool will pay

for return shipping to the customer using UPS

Ground Service. All warranty service is valid

3 years from the date of purchase on your

receipt or invoice.

Festool Limited Warranty

This warranty is valid on the pre-condition that

the tool is used and operated in compliance

with the Festool operating instructions. Festool warrants, only to the original consumer

purchaser, that the specifi ed tool will be free

from defects in materials and workmanship

for a term of one year from the date of procurement. Festool makes no other warranty,

express or implied, for Festool portable power

Festool portable power tools requiring replacement or repair are to be returned with the

receipt of purchase to Festool (call 800-5548741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE

FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF THIS OR

ANY OTHER WARRANTY, EXPRESSED OR

IMPLIED WHATSOEVER. ALL WARRANTIES IMPLIED BY STATE LAW, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ARE HEREBY

LIMITED TO THE DURATION OF THREE

YEARS.

Some states in the U.S. and some Canadian

provinces do not allow the limitations on how

long an implied warranty lasts, so the above

limitation may not apply to you. With the exception of any warranties implied by state or

province law as hereby limited, the foregoing

express limited warranty is exclusive and in

lieu of all other warranties, guarantees, agreements and similar obligations of Festool.

This warranty gives you specifi c legal rights

and you may also have other rights which vary

from state to state in the U.S. and province

to province in Canada.

Page 14

14

Table des matières

Régles de sécurité 14

Caractéristiques techniques 16

Symboles 16

Eléments fournis 17

Utilisation conforme aux

prescriptions 17

Raccordement électrique 17

Mise en marche et arrêt de la machine 17

Réglages de la machine 18

Système électronique 18

Remplacement de la table de fraisage 18

Changement de fraise 19

Changement de pince de serrage 19

Réglage de la profondeur de fraisage 20

Aspiration 20

Travail avec la machine 20

Types de guidage de la machine 20

Usinage de l'aluminium 21

Maintenance et entretien 21

Accessoires, outils 21

Garantie 22

Régles de sécurité

Assurez-vous de lire

et de bien com prendre toutes les instructions. Le non-respect, même partiel,

des instructions ci-dessous peut entraîner un

risque de choc électrique, d’incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS

Régles de sécu-

rité générales

1) Sécurité de aire de travail

a) Maintenez l’endroit de travail propre et bien éclairé. Un lieu de travail en

désordre ou mal éclairé augmente le risque

d’accidents.

b) N’utilisez pas l’appareil dans un environnement présentant des risques d’explosion et où se trouvent des liquides,

des gaz ou poussières infl ammables. Les

outils électroportatifs génèrent des étincelles

risquant d’enfl ammer les poussières ou les

vapeurs.

c) Tenez les enfants et autres personnes

éloignés durant l’utilisation de l’outil

électroportatif. En cas d’inattention vous

risquez de perdre le contrôle sur l’appareil.

2) Sécurité électrique

a) La fi che de secteur de l’outil électro-

portatif doit être appropriée à la prise

de courant. Ne modifi ez en aucun cas la

fi che. N’utilisez pas de fi ches d’adapta-

teur avec des appareils avec mise à la

terre. Les fi ches non modifi ées et les prises

de courant appropriées réduisent le risque de

choc électrique.

b) Evitez le contact physique avec des

surfaces mises à la terre tels que tuyaux,

radiateurs, fours et réfrigérateurs. Il y a

un risque élevé de choc électrique au cas où

votre corps serait relié à la terre.

c) N’exposez pas l’outil électroportatif

à la pluie ou à l’humidité. La pénétration

d’eau dans un outil électroportatif augmente

le risque d’un choc électrique.

d) N’utilisez pas le câble à d’autres fi ns

que celles prévues, n’utilisez pas le câble

pour porter l’appareil ou pour l’accrocher ou encore pour le débrancher de

la prise de courant. Maintenez le câble

éloigné des sources de chaleur, des parties grasses, des bords tranchants ou des

parties de l’appareil en rotation. Un câble

endommagé ou torsadé augmente le risque

d’un choc électrique.

e) Au cas où vous utiliseriez l’outil électroportatif à l’extérieur, utilisez une

rallonge autorisée homologuée pour les

applications extérieures. L’utilisation d’une

rallonge électrique homologuée pour les applications extérieures réduit le risque d’un

choc électrique.

f) Ne tenez l‘outil qu‘à l‘aide des poignées

isolées, lorsque vous êtes susceptibles de

toucher des lignes électriques cachées

ou votre propre câble électrique, lorsque

vous travaillez avec des outils de tronçonnage. Si des outils de tronçonnage touchent

des lignes électriques, des pièces métalliques

de l‘outil peuvent être mises sous tension et asséner une décharge électrique à l‘utilisateur.

Page 15

15

3) Sécurité des personnes

a) Restez vigilant, surveillez ce que vous

faites. Faites preuve de bon en utilisant

l’outil électroportatif. N’utilisez pas l’appareil lorsque vous êtes fatigué ou après

avoir consommé de l’alcool, des drogues ou avoir pris des médicaments. Un

moment d’inattention lors de l’utilisation de

l’appareil peut entraîner de graves blessures

sur les personnes.

b) Portez des équipements de protection.

Portez toujours des lunettes de protection. Le fait de porter des équipements de

protection personnels tels que masque antipoussières, chaussures de sécurité antidérapantes, casque de protection ou protection

acoustique suivant le travail à effectuer, réduit

le risque de blessures.

c) Evitez une mise en service par mégarde. Assurez-vous que l’interrupteur est

effectivement en position d’arrêt avant

de retirer la fi che de la prise de courant.

Le fait de porter l’appareil avec le doigt sur

l’interrupteur ou de brancher l’appareil sur la

source de courant lorsque l’interrupteur est

en position de fonctionnement, peut entraîner

des accidents.

d) Enlevez tout outil de réglage ou toute

clé avant de mettre l’appareil en fonctionnement. Une clé ou un outil se trouvant

sur une partie en rotation peut causer des

blessures.

e) Ne surestimez pas vos capacités.

Veillez à garder toujours une position

stable et équilibrée. Ceci vous permet de

mieux contrôler l’appareil dans des situations

inattendues.

f) Portez des vêtements appropriés. Ne

portez pas de vêtements amples ni de

bijoux. Maintenez cheveux, vêtements et

gants éloignés des parties de l’appareil

en rotation. Des vêtements amples, des

bijoux ou des cheveux longs peuvent être

happés par des pièces en mouvement.

g) Si des dispositifs servant à aspirer

ou à recueillir les poussières doivent

être utilisés, vérifi ez que ceux-ci soient

effectivement raccordés et qu’ils sont

correctement utilisés. L’utilisation de tels

dispositifs réduit les dangers dus aux poussières.

4) Utilisation et entretien des outils

a) Ne surchargez pas l’appareil. Utilisez

l’outil électroportatif approprié au travail à effectuer. Avec l’outil électroportatif

approprié, vous travaillerez mieux et avec

plus de sécurité à la vitesse pour laquelle il

est prévu.

b) N’utilisez pas un outil électroportatif

dont l’interrupteur est défectueux. Un

outil électroportatif qui ne peut plus être mis

en ou hors fonctionnement est dangereux et

doit être réparé.

c) Retirer la fi che de la prise de courant

avant d’effectuer des réglages sur l’appareil, de changer les accessoires, ou de

ranger l’appareil. Cette mesure de précau-

tion empêche une mise en fonctionnement

par mégarde.

d) Gardez les outils électroportatifs non

utilisés hors de portée des enfants. Ne

permettez pas l’utilisation de l’appareil

à des personnes qui ne se sont pas familiarisées avec celui-ci ou qui n’ont pas lu

ces instructions. Les outils électroportatifs

sont dangereux lorsqu’ils sont utilisés par des

personnes non initiées.

e) Prenez soin des outils électroportatifs.

Vérifi ez que les parties en mouvement

fonctionnent correctement et qu’elles ne

soient pas coincées, et contrôlez si des

parties sont cassées ou endommagées

de telle sorte que le bon fonctionnement

de l’appareil s’en trouve entravé. Faites

réparer les parties endommagées avant

d’utiliser l’appareil. De nombreux accidents

sont dus à des outils électroportatifs mal entretenus.

f) Maintenez les outils de coupe aiguisés

et propres. Des outils soigneusement entre-

tenus avec des bords tranchants bien aiguisés

se coincent moins souvent et peuvent être

guidés plus facilement.

g) Utilisez les outils électroportatifs,

les accessoires, les outils à monter etc.

conformément à ces instructions et aux

prescriptions en vigueur pour ce type

d’appareil. Tenez compte également des

conditions de travail et du travail à effectuer. L’utilisation des outils électroportatifs à

d’autres fi ns que celles prévues peut entraîner

des situations dangereuses.

Page 16

16

5) Entretien et réparation

a) Ne faites réparer votre outil électroportatif que par un personnel qualifi é et

seulement avec des pièces de rechange

d’origine. Ceci permet d’assurer la sécurité

de l’appareil.

Règle de sécurité parti-

culière supplémentaire

a) Tenez l’outil par ses surfaces de prise

isolées pendant toute opération où l’outil

de coupe pourrait venir en contact avec

un câblage dissimulé ou avec son propre

cordon. En cas de contact avec un conduc-

teur sous tension, les pièces métalliques à

découvert de l’outil transmettraient un choc

électrique à l’utilisateur.

b) Immobilisez l’outil sur une surface

stable au moyen de brides ou de toute

autre façon adéquate. Le fait de tenir la

pièce avec la main ou contre votre corps offre

une stabilité insuffi sante et peut amener un

dérapage de l’outil.

Pour réduire les risques d’exposition à

ces substances chimiques : travaillez

dans un endroit adéquatement ventilé

et utilisez un équipement de sécurité

approuvé, tel que masques antipoussières spécialement conçus pour fi ltrer les

particules microscopiques.

POUR RÉDUIRE LE

RISQUE DE DOMMAGES, L'UTILISATEUR

DOIT LIRE ET COMPRENDRE LE MANUEL

D'INSTRUCTION.

Caractéristiques

techniques

Puissance absorbée 720 W

Vitesse de rotation (à vide)

10000 - 26000 min

Porte-outil 8 mm (0.31”)

option : 6 mm, (0.24”)

1/4”(6.35 mm))

Diamètre de fraise, max. 26 mm (1”)

Poids 1,9 kg (4.2 lbs)

Sécurité

-1

/II

La poussière, un ris-

que pour la santé

Certaines poussières

créées par le ponçage mécanique, le sciage,

le meulage, le perçage et autres activités reliées à la construction contiennent des substances chimiques connues (dans l’État de la

Californie) comme pouvant causer le cancer,

des anomalies congénitales ou représenter

d’autres dangers pour la reproduction. Voici

quelques exemples de telles substances:

plomb provenant de peintures à base de •

plomb,

silice cristallisée utilisée dans les briques, •

le ciment et autres matériaux de maçonnerie, et

arsenic et chrome du bois d’œuvre traité •

avec un produit chimique.

Le risque d’exposition à de tels produits varie

selon la fréquence à laquelle vous faites ce

genre de travail.

Symboles

V Volts

A Ampères

Hz Hertz

~ Courant alternatif

Vitesse à vide

n

0

Construction de classe II

tr/mn Nombre de tours par minute

Ø diamètre

Avertissement de danger général

Lire les instructions / les remarques !

f Information, astuce

Page 17

Eléments fournis

Des eléments fournis sont disponibles sur le

volet qui se trouve au début de cette notice

d'utilisation. Vous pouvez ainsi déplier cette

page et visualiser en permanence les différentes parties de l'outil lorsque vous lisez la

notice.

[1-1] Fraise MFK 700 avec table de fraisage

grande surface

[1-2] Butée latérale avec tiges de guidage et

réglage fi n

[1-3] Capot d'aspiration pour table de fraisage

grande surface avec tubulure d'aspiration

[1-4] Table de fraisage pour couvre-chants

avec galet palpeur et capot d'aspiration

(uniquement dans volume de livraison

SET)

Utilisation conforme

aux prescriptions

17

2

Câble de rallonge

Si une rallonge électrique est nécessaire, elle

doit présenter une section suffi sante afi n d’évi-

ter une chute de tension excessive ou une surchauffe. Une chute de tension excessive réduit

la puissance et peut entraîner la destruction

du moteur. Le tableau suivant vous présente

la section correcte du câble en fonction de sa

longueur pour la MFK 700. Utilisez exclusivement des rallonges recommandées par U.L.

et CSA. N’utilisez jamais deux rallonges branchées l’une après l’autre, mais remplacez-les

par une rallonge plus longue.

Longueur totale

rallonge (pieds)

25 50 100 150

La fraise MFK 700 EQ est prévue de façon

conforme aux prescriptions pour le fraisage de

bois, de matières plastiques et de matériaux

similaires.

L'utilisateur est le

seul responsable des dommages et accidents provoqués par une utilisation non

conforme de l'outil.

Raccordement électrique

La tension du secteur doit correspondre à

l’indication de la tension sur la plaquette signalétique. Un fusible de 16 A (à 120 V) ou

un disjoncteur de puissance approprié est

nécessaire.

Voir en fi gure [2] la connexion et la décon-

nexion du câble de raccordement au secteur.

Mettez la machine

hors marche, avant de connexion ou de

déconnexion le câble de raccordement

secteur.

Section du câble

(AWG)

Remarque:

Plus le numéro AWG est petit, plus la sec- f

tion du câble est grande.

18 16 16 14

Mise en marche et ar-

rêt de la machine

3-1

3-2

3-3

3-4

Lors de la mise en

marche et en cours d’utilisation, tenez

toujours la scie à deux mains à les poignées [3-1] [3-2].

Le commutateur [3-4] sert d'interrupteur de

marche / arrêt (I = "ON", 0 = "OFF").

Page 18

18

Réglages de la machine

Retirer la fi che de la

prise de courant avant d‘effectuer des

réglages sur l‘appareil, de changer les

accessoires, ou de ranger l‘appareil.

Système électronique

Cette machine dispose d'une électronique

complète qui présente les caractéristiques

suivantes :

Démarrage progressif

Le démarrage progressif à régulation électronique assure un démarrage sans à-coups de

la machine.

Régulation de la vitesse

La vitesse de rotation peut être réglée en

continu au moyen de la molette [3-3], entre

10000 et 26000 min

adapter de façon optimale la vitesse de coupe

à chaque matériau.

-1

. Vous pouvez ainsi

a) Table de fraisage grande surface

4-1

1

4-2

2

Montez la table de fraisage sur les axes de –

réception [4-1] de la machine.

Bloquez la table de fraisage en serrant la –

vis [4-2].

4-5

5

4-4

Vitesse de rotation constante

La vitesse sélectionnée est maintenue

constante de manière électronique. Elle reste

donc homogène, même lorsque l'outil est

fortement sollicité.

Protection thermique

Pour assurer une protection contre la surchauffe, le système électronique de sécurité

arrête la machine dès qu’une température

critique du moteur est atteinte. Après une période de refroidissement d’env. 3 à 5 minutes,

la machine est à nouveau prête à l’emploi. Le

temps de refroidissement diminue quand la

machine fonctionne (marche à vide).

Remplacement de la ta-

ble de fraisage

La "table de fraisage grande surface" est

prémontée et comprise dans le volume de

livraison de série. Cette table de fraisage garantit une grande précision de fraisage grâce

à sa grande surface d'appui et à ses possibilités de réglage précises. D'autres tables

de fraisage sont disponibles dans la gamme

d'accessoires.

4-3

4

3

Montez le capot d'aspiration [4-4]. –

Bloquez le capot d'aspiration en vissant la –

vis [4-3].

Montez la tubulure d'aspiration [4-5] sur le –

capot d'aspiration.

Le démontage s'effectue dans l'ordre inverse.

b) Table de fraisage pour couvrechants

La "table de fraisage pour couvre-chants"

(uniquement dans le volume de livraison SET)

est prévue pour le fraisage d'affl eurement de

dépassements de couvre-chants ainsi que

pour le profi lage.

Remarque:

Afi n de ne pas endommager le revêtement f

de la table lors de l'affl eurage, la table

de fraisage est inclinée de 1,5°. Pour des

fraisages à angle droit précis, une table de

fraisage non inclinée (0°) est disponible en

tant qu'accessoire.

Page 19

19

1

2

5-1

5-2

Fixez le galet palpeur [5-1] sur la machine –

à l'aide des vis prémontées. Le galet palpeur peut être réglé de façon optimale par

rapport à la fraise en le décalant dans les

trous oblongs.

Montez la table de fraisage sur les axes de –

réception [5-2] de la machine.

3

4

5-3

5-4

2

SW 19

1

3

6-1

6-2 6-3

a) Retrait de l'outil

Pressez le dispositif de blocage de la broche –

[6-1].

A l'aide d'une clé à fourche de 19 mm, –

desserrez l'écrou-raccord [6-2] jusqu'à ce

qu'il soit possible de retirer l'outil.

b) Insertion de l'outil

Introduisez la fraise [6-3] aussi loin que –

possible dans la pince de serrage ouverte,

au moins jusqu'au repère (

) sur la tige

de la fraise.

Pressez le dispositif de blocage de la broche –

[6-1].

Serrez l'écrou-raccord [6-2] à l'aide de la –

clé à fourche de 19.

Bloquez la table de fraisage en serrant la –

vis [5-3].

Montez le capot d'aspiration [5-4]. –

5

5-5

Bloquez le capot d'aspiration en vissant la –

vis [5-5].

Le démontage s'effectue dans l'ordre inverse.

Changement de fraise

Risque d'accident - la

fraise peut être chaude après le travail

et possède des tranchants très coupants.

Laissez refroidir l'outil avant le changement

d'outil. Portez des gants de protection pour

changer l'outil.

Retirez la table de fraisage avant le chan- –

gement de la fraise.

Changement de pin-

ce de serrage

Seuls des outils adaptés doivent être insérés

dans les pinces de serrage fournies. Il est

possible d'utiliser des pinces de serrage de

8 mm, 6 mm et 1/4” (6,35 mm).

1

2

7-1

7-2 7-3

Pressez le dispositif de blocage de la broche –

[7-1].

Dévissez entièrement l'écrou-raccord –

[7-2].

Retirez l'écrou-raccord de la broche, –

conjointement avec la pince de serrage [73]. Ne séparez jamais l'écrou-raccord de sa

pince, étant donné que les deux forment

un ensemble inséparable.

Insérez une autre pince de serrage avec –

écrou-raccord dans la broche.

Vissez légèrement l'écrou-raccord. Ne –

serrez pas l'écrou-raccord en l'absence de

fraise.

3

Page 20

20

8-1

Réglage de la profon-

deur de fraisage

3

2

1

3

2

Travail avec la machine

Maintenez fermement

la machine avec les deux mains.

Fixez toujours la pièce

1

8-3

8-2

1

à fraiser de manière à ce qu'elle ne puisse

pas bouger pendant le travail.

Guidez la machine le long de la pièce avec f

une avance régulière.

Types de guida-

ge de la machine

a) Fraisage avec butée latérale

9-49-3

3

8-38-2

Desserrez le bouton tournant [8-3] et le –

dispositif de blocage [8-1] (uniquement

"table de fraisage grande surface").

Réglez la table de fraisage sur la profon- –

deur de réglage souhaitée par le biais de

la molette [8-2].

Serrez le bouton tournant [8-3] et le dis- –

positif de blocage [8-1] (uniquement "table

de fraisage grande surface").

Aspiration

L'inhalation de poussières peut être nocive pour les voies

respiratoires ! Raccordez toujours la ma-

chine à un dispositif d'aspiration. Portez une

protection des voies respiratoires si les travaux génèrent des poussières.

Des capots d'aspiration permettant le raccordement d'un aspirateur Festool (tuyau

d'aspiration Ø 27 mm) sont fournis pour les

deux tables de fraisage.

En fonction de l'application, le dispositif d'aspiration (tuyau d'aspiration Ø

également être fi xé sur la "table de fraisage

grande surface" ou sur la butée latérale.

27 mm) peut

9-1

9-5

9-2

La butée latérale est utilisée pour des travaux

de fraisage parallèlement au bord de la pièce.

La butée latérale peut uniquement être montée sur la "table de fraisage grande surface"

et sans capot d'aspiration monté.

Montez le dispositif de réglage fi n [9-3] sur –

la butée latérale.

Serrez les deux tiges de guidage [9-5] sur –

la butée latérale [9-2] par le biais des boutons tournants.

Insérez la butée latérale dans les rainures –

de la table de fraisage jusqu'à la cote souhaitée et bloquez les tiges de guidage à

l'aide du bouton tournant [9-1].

Réglage approximatif

Desserrez les vis [9-2] et [9-4] et déplacez –

la butée latérale.

Serrez les vis. –

Réglage fi n

Desserrez les vis [9-2] et tournez la molette –

verte du dispositif de réglage fi n [9-3].

Un trait de graduation sur la molette est de f

0,1 mm - un tour correspond à 1 mm.

Serrez les vis [9-2]. –

Page 21

21

b) Fraisage de chants avec roulement de

guidage

10-1

Des fraises avec roulement de guidage sont

montées sur la machine pour le fraisage de

chants. Dans ce cas, la machine est guidée

de sorte à faire rouler le roulement à billes

sur la pièce.

Lors du fraisage de chants, utilisez toujours

le dispositif d'aspiration sous la table [10-1]

pour améliorer l'aspiration.

c) Fraisage de chants avec galet palpeur

et table de fraisage pour couvre-chants

1,5°

11-1

Le galet palpeur [11-1] est monté sur la machine pour le fraisage de chants avec la table

de fraisage pour couvre-chants (uniquement

dans le volume de livraison SET) (voir “Table

de fraisage pour couvre-chants“). A cette occasion, la machine est guidée de façon à ce

que le galet palpeur repose contre la pièce.

Maintenance et entretien

Toutes les interventions de maintenance et de réparation

qui exigent l’ouverture du carter du

moteur ou de l’engrenage doivent uniquement être réalisées par un atelier de

service après-vente agréé (demandez

ses coordonnées à votre revendeur)! La

maintenance ou la réparation de la machine

par des personnes non autorisées peut entraîner un branchement incorrect de câbles

électriques ou d’autres composants, ce qui

peut provoquer des accidents avec de graves

blessures.

Afi n d’empêcher les

accidents, il faut toujours débrancher la

fi che de la source de courant avant toute

intervention de maintenance ou de réparation! N’utilisez pas d’air comprimé pour

nettoyer l’outil électrique ! N’essayez pas de

nettoyer des pièces à l’intérieur de la machine

en introduisant des objets par les ouvertures

de l’appareil.

Certains détergents et

solvants détériorent les pièces en matière plastique. Citons notamment l’essence,

le chlorure de carbonyle, les solutions de

détergents contenant du chlore, l’ammoniac

et les détergents ménagers contenant de

l’ammoniac.

Pour assurer la circulation de l'air, il est im- f

pératif que les fentes d'aération du boîtier

moteur soient systématiquement maintenues dégagées et propres.

L'appareil est équipé de charbons spéciaux f

à coupure automatique. Lorsque ceux-ci

sont usés, l'alimentation est coupée et

l'appareil s'arrête.

Usinage de l'aluminium

Risque d'accident respectez les consignes de sécurité suivantes lorsque vous usinez l'aluminium :

Installez en amont de l'appareil un disjonc- f

teur à courant de défaut (FI, PRCD).

Raccordez la machine à un dispositif d'as- f

piration approprié.

Nettoyez régulièrement les dépôts de pous- f

sières dans le corps du moteur.

Portez des lunettes de protection. f

Accessoires, outils

Pour des raisons de sécurité, il faut utiliser exclusivement des

accessoires et outils d’origine Festool!

Les références des accessoires et outils fi gu-

rent dans le catalogue Festool ou sur Internet

sous www.festool-usa.com.

Page 22

22

Systainer

De nombreux produits Festool sont fournis

dans une caisse exclusive, appelée "Systainer". Celle-ci permet de protéger et de ranger

des outils et des appareils complémentaires.

Les Systainer sont empilables et peuvent

être solidarisés. En outre, il se fi xent sur les

aspirateurs CT Festool.

12.3

12.2

12.1

Poser deux Systainer l'un sur l'autre, –

défaire les quatre éléments de verrouillage –

du Systainer inférieur en les tirant en arrière par leur bord supérieur (14.1).

pousser les quatre éléments de verrouillage –

vers le haut (14.2)

manoeuvrer les quatre éléments de ver- –

rouillage (14.3) de sorte qu'ils s'enclenchent au niveau des éléments récepteurs

du Systainer supérieur.

Garantie

Conditions de la ga-

rantie (1+2 ans)

Vous avez droit à une prolongation de garantie

gratuite (1 an + 2 ans = 3 ans) sur votre outil

électrique Festool. Festool assumera tous les

coûts d’expédition pendant la première année

de la garantie alors que les deuxième et troisième années, les coûts devront être assumés

par le client. Festool paiera les frais de retour

de l’outil au client par service de livraison terrestre UPS. La garantie est valable pour une

période de 3 ans à compter de la date d’achat

indiquée sur votre reçu ou votre facture.

Garantie limitée de Festool

Cette garantie est valable à condition que

l’outil soit utilisé conformément aux instruc-

tions de Festool. Festool garantit, à l’acheteur

initial seulement, que l’outil indiqué sera

exempt de tout défaut de matériau et de fabrication pendant un an à compter de la date

d’achat. Festool ne donne aucune garantie

supplémentaire, implicite ou explicite, sur

les instruments portables électriques Festool. Aucun agent, représentant commercial,

distributeur, vendeur ou employé de Festool

n’est autorisé à prolonger ou à modifi er les

obligations ou restrictions de la présente garantie. Les obligations de Festool sont, à son

entière discrétion, limitées à la réparation ou

à l’échange des outils portables électriques

Festool trouvés défectueux dans le présent

emballage, tels que fournis avec le présent

Guide d’utilisation.

Cette garantie exclut l’usure normale, les

dommages causés par un usage impropre,

les abus ou la négligence, ou tout dommage

autre que ceux attribuables à des défauts de

matériau et de fabrication. Cette garantie ne

s’applique pas aux accessoires tels que lames

de scie circulaire, mèches de perceuse et vilebrequin, lames de scie sauteuse, bandes abrasives et meules. Sont également exclues les

pièces d’usure, telles que balais de charbon,

lamelles pour outils à air comprimé, joints et

manchons de caoutchouc, disques et patins

ponceurs, ainsi que les piles.

Les outils électriques portables Festool à

remplacer ou à réparer doivent être retournés avec le reçu d’achat à Festool (appelez

au 800-554-8741 pour connaître l’adresse

d’expédition).

FESTOOL N’EST EN AUCUN CAS RESPONSABLE DES DOMMAGES DIRECTS

OU INDIRECTS, IMPLICITES OU EXPLICITES, DÉCOULANT DE LA RUPTURE DE

CETTE GARANTIE OU DE TOUTE AUTRE

GARANTIE. TOUTES LES GARANTIES IMPLICITES, Y COMPRIS LES GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE

ET D’ADÉQUATION À UN USAGE PARTICULIER, SONT LIMITÉES À UNE PÉRIODE

DE TROIS ANS.

Certains états américains et certaines provinces canadiennes ne permettent pas la limitation des garanties implicites; il se pourrait

donc que les limites indiquées ci-dessus ne

s’appliquent pas dans votre cas. À l’exception

de certaines garanties implicites des provinces ou des états indiquées ici, la présente

Page 23

garantie est exclusive et remplace toute autre

garantie, convention et obligation similaire de

Festool.

Cette garantie vous confère des droits légaux

spécifi ques, et vous pouvez aussi avoir d’autres

droits pouvant varier d’un état à l’autre, ou

d’une province à l’autre au Canada.

23

Page 24

24

Contenido

Normas de seguridad 24

Datos téchnicos 26

Símbolos 26

Dotación de suministro 26

Uso conforme a lo previsto 27

Conexión eléctrica 27

Conexión y desconexión de la máquina 27

Ajustes de la máquina 27

Sistema electrónico 27

Cambio de la mesa de fresar 28

Cambiar la fresadora 29

Cambio de la pinza de sujeción 29

Ajuste de la profundidad de fresado 29

Aspiración 30

Trabajo con la máquina 30

Tipos de guiado de la máquina 30

Trabajar con aluminio 31

Mantenimiento y limpieza 31

Accesorios, herramientas 31

Garantía 32

Normas de seguridad

pueden llegar a infl amar los materiales en

polvo o vapores.

c) Mantenga alejados a los niños y otras

personas de su puesto de trabajo al

emplear la herramienta eléctrica. Una

distracción le puede hacer perder el control

sobre el aparato.

2) Seguridad eléctrica

a) El enchufe del aparato debe corresponder a la toma de corriente utilizada.

No es admisible modifi car el enchufe en

forma alguna. No emplear adaptadores

en aparatos dotados con una toma de

tierra. Los enchufes sin modifi car adecuados

a las respectivas tomas de corriente reducen

el riesgo de una descarga eléctrica.

b) Evite que su cuerpo toque partes conectadas a tierra como tuberías, radiadores, cocinas y refrigeradores. El riesgo

a quedar expuesto a una sacudida eléctrica

es mayor si su cuerpo tiene contacto con

tierra.

c) No exponga las herramientas eléctricas a la lluvia y evite que penetren

líquidos en su interior. Existe el peligro

de recibir una descarga eléctrica si penetran

ciertos líquidos en la herramienta eléctrica.

Lea y entienda todas las

instrucciones. El incumplimiento con las

instrucciones aquí referidas puede resultar

en una descarga eléctrica, fuego y/o lesiones

personales serias.

CONSERVE ESTAS INSTRUCCIONES

Normas generales de seguridad

1) Seguridad del espacio de trabajo

a) Mantenga limpio y bien iluminado su

puesto de trabajo. El desorden y una ilu-

minación defi ciente en las áreas de trabajo

pueden provocar accidentes.

b) No utilice la herramienta eléctrica

en un entorno con peligro de explosión,

en el que se encuentren combustibles

líquidos, gases o material en polvo. Las

herramientas eléctricas producen chispas que

d) No utilice el cable de red para transportar o colgar el aparato, ni tire de él

para sacar el enchufe de la toma de corriente. Mantenga el cable de red alejado

del calor, aceite, esquinas cortantes o

piezas móviles. Los cables de red dañados

o enredados pueden provocar una descarga

eléctrica.

e) Al trabajar con la herramienta eléctrica en la intemperie utilice solamente

cables de prolongación homologados

para su uso en exteriores. La utilización

de un cable de prolongación adecuado para

su uso en exteriores reduce el riesgo de una

descarga eléctrica.

f) Sujete la máquina únicamente por

las empuñaduras aisladas si durante los

trabajos las herramientas para separar

pueden entrar en contacto con conducciones eléctricas ocultas o incluso con

el cable de la corriente. Cuando las herra-

mientas para separar entran en contacto con

conducciones eléctricas bajo tensión, las partes metálicas de la máquina pueden adquirir

Page 25

25

esta tensión y transmitir, de ese modo, una

descarga eléctrica al usuario.

3) Seguridad personal

a) Esté atento a lo que hace y emplee

la herramienta eléctrica con prudencia.

No utilice la herramienta eléctrica si

estuviese cansado, ni tampoco después

de haber consumido alcohol, drogas o

medicamentos. El no estar atento durante

el uso de una herramienta eléctrica puede

provocarle serias lesiones.

b) Utilice un equipo de protección y en

todo caso unas gafas de protección. El

riesgo a lesionarse se reduce considerablemente si, dependiendo del tipo y la aplicación de la herramienta eléctrica empleada,

se utiliza un equipo de protección adecuado

como una mascarilla antipolvo, zapatos de

seguridad con suela antideslizante, casco, o

protectores auditivos.

c) Evite una puesta en marcha fortuita

del aparato. Cerciorarse de que el aparato esté desconectado antes conectarlo a

la toma de corriente. Si transporta el apara-

to sujetándolo por el interruptor de conexión/

desconexión, o si introduce el enchufe en la

toma de corriente con el aparato conectado,

ello puede dar lugar a un accidente.

d) Retire las herramientas de ajuste o

llaves fi jas antes de conectar la herra-

mienta eléctrica. Una herramienta o llave

colocada en una pieza rotante puede producir

lesiones al ponerse a funcionar.

e) Sea precavido. Trabaje sobre una base

fi rme y mantenga el equilibrio en todo

momento. Ello le permitirá controlar mejor la

herramienta eléctrica en caso de presentarse

una situación inesperada.

f) Lleve puesta una vestimenta de trabajo

adecuada. No utilice vestimenta amplia

ni joyas. Mantenga su pelo, vestimenta

y guantes alejados de las piezas móviles. La vestimenta suelta, las joyas y el pelo

largo se pueden enganchar con las piezas en

movimiento.

4) Uso y cuidado de

la herramienta

a) No sobrecargue el aparato. Use la

herramienta prevista para el trabajo a

realizar. Con la herramienta adecuada po-

drá trabajar mejor y más seguro dentro del

margen de potencia indicado.

b) No utilice herramientas con un interruptor defectuoso. Las herramientas que

no se puedan conectar o desconectar son

peligrosas y deben hacerse reparar.

c) Saque el enchufe de la red antes de

realizar un ajuste en el aparato, cambiar

de accesorio o al guardar el aparato. Esta

medida preventiva reduce el riesgo a conectar

accidentalmente el aparato.

d) Guarde las herramientas fuera del

alcance de los niños y de las personas

que no estén familiarizadas con su uso.

Las herramientas utilizadas por personas

inexpertas son peligrosas.

e) Cuide sus aparatos con esmero. Controle si funcionan correctamente, sin

atascarse, las partes móviles del aparato,

y si existen partes rotas o deterioradas

que pudieran afectar al funcionamiento

de la herramienta. Si la herramienta eléctrica estuviese defectuosa haga repararla

antes de volver a utilizarla. Muchos de los

accidentes se deben a aparatos con un mantenimiento defi ciente.

f) Mantenga los útiles limpios y afi lados.

Los útiles mantenidos correctamente se dejan

guiar y controlar mejor.

g) Utilice herramientas eléctricas, accesorios, útiles, etc. de acuerdo a estas

instrucciones y en la manera indicada

específi camente para este aparato. Con-

sidere en ello las condiciones de trabajo

y la tarea a realizar. El uso de herramientas

eléctricas para trabajos diferentes de aquellos para los que han sido concebidas puede

resultar peligroso.

5) Mantenimiento

g) Siempre que sea posible utilizar unos

equipos de aspiración o captación de polvo, asegúrese que éstos estén montados

y que sean utilizados correctamente. El

empleo de estos equipos reduce los riesgos

derivados del polvo.

a) Únicamente haga reparar su herramienta eléctrica por un profesional,

empleando exclusivamente piezas de repuesto originales. Solamente así se mantie-

ne la seguridad de la herramienta eléctrica.

Page 26

26

Normas de seguri-

dad específi cas

a) Sujete la herramienta por la superfi -

cie de agarre aislada cuando realice una

operación donde la herramienta de corte

pueda contactar alambres ocultos o su

propio cable. El contacto con un alambre

con corriente hará traspasar la corriente a las

partes de metal de la herramienta resultando

en una descarga eléctrica al usuario.

b) Use abrazaderas u otras formas prácticas de sujetar y asegurar la pieza de

trabajo en una plataforma estable. El

sujetar la pieza de trabajo con la mano o

contra el cuerpo es inestable y puede causar

la pérdida de control.

Riesgos para la salud pro-

ducidos por el polvo

Algunos polvos creados por

lijadoras motorizadas, aserraderos, trituradores, perforadoras y otras actividades de construcción contienen sustancias químicas que

se sabe (en el Estado de California) causan

cáncer, defectos de nacimiento u otros daños

al sistema reproductivo. Algunos ejemplos de

estas sustancias químicas son:

Plomo de las pinturas con base de plomo•

Sílice cristalino de los ladrillos y cemento y •

otros productos de mampostería, y

Arsénico y cromo de madera tratada con •

sustancias químicas

Datos téchnicos

Consumo de potencia 720 W

Número de revoluciones (marcha

en vacío) 10000 - 26000 rpm

Alojamiento de la herramienta 8 mm (0.31”)

opcional: 6 mm (0.24”)

1/4" (6,35 mm))

Diámetro de fresa, máx. 26 mm (1")

Peso 1,9 kg

Seguridad

/II

Símbolos

V Voltios

A Amperios

Hz Hercios

~ Corriente alterna

n

Sin velocidad de carga

0

Construcción Clase II

rpm Revoluciones o reciprocidad por minu-

to

Ø Diámetro

Aviso ante un peligro general

¡Leer las instrucciones e indicaciones!

f Indicación, consejo

Dotación de suministro

El riesgo de exposición a estas sustancias

varía, dependiendo de cuantas veces se hace

este tipo de trabajo.

Para reducir el contacto con estas sus-

tancias químicas: trabaje en un área

con buena ventilación y trabaje con

equipo de seguridad aprobado, como

mascarillas para el polvo diseñadas

específi camente para fi ltrar partículas

microscópicas.

PARA REDUCIR EL RIES-

GO DE LESIÓN, EL USUARIO DEBE LEER

Y ENTENDER EL MANUAL DE INSTRUCCIÓN.

Las imágenes con la dotación de suministro

se encuentran en una hoja desplegable al

comienzo de este manual de instrucciones.

Cuando lea este manual, le recomendamos

que despliegue esta página para disponer

fácilmente de una vista general de la máquina.

[1-1] MFK 700 con mesa de fresar con gran

superfi cie de apoyo

[1-2] Tope lateral con barras de guía y ajuste

fi no

[1-3] Caperuza de aspiración para la mesa de

fresar con gran superfi cie de apoyo con

racor de aspiración

[1-4] Mesa de fresar para cantos preencolados

con rodillo tensor y caperuza de aspiración (sólo en la dotación de suministro

SET)

Page 27

27

Uso conforme a

lo previsto

La MFK 700 EQ está prevista para el fresado

de madera, plástico y materiales similares.

El usuario será respon-

sable de los posibles daños y accidentes

ocasionados por el mal uso o el abuso de

la herramienta.

Conexión eléctrica

La tensión de la red tiene que coincidir con

lo indicado en la placa de características. Se

requiere un fusible de 16 A (con 120 V), o un

correspondiente disyuntor de protección.

Vea la fi gura [2] para enchufar y desenchufar

el cable de conexión.

Apague siempre la má-

quina antes de conectar o sacar el cable

de conexión a la red.

Observación:

Cuanto más bajo es el número AWG, tanto f

mayor es el diámetro del cable.

Conexión y desco-

nexión de la máquina

3-1

3-2

3-3

3-4

La máquina tiene que ser

sujetada siempre con ambas manos por

las empuñaduras [3-1] [3-2] durante la

conexión y el uso.

2

Cable de prolongación

Cuando se necesite un cable de prolongación,

éste tiene que disponer de una sección sufi -

ciente a fi n de evitar una excesiva caída de

tensión o un sobrecalentamiento. Una excesiva caída de la tensión reduce la potencia y

puede conducir a una destrucción del motor.

En la tabla de abajo indica el diámetro de

cable correcto para la MFK 700, a saber, en

función de la longitud de cable. Emplear únicamente los cables de prolongación listados

por U.L. y CSA. No emplear nunca dos cables

de prolongación conectados el uno con el otro.

En lugar de ello, emplear uno correspondientemente largo.

Longitud total del

cable (pies)

Diámetro de cable

(AWG)

25 50 100 150

18 16 16 14

El interruptor [3-4] sirve de interruptor de

conexión y desconexión (I = CONECTADO, 0

= DESCONECTADO).

Ajustes de la máquina

Saque el enchufe de la

red antes de realizar un ajuste en el aparato, cambiar de accesorio o al guardar

el aparato.

Sistema electrónico

La máquina dispone de un sistema electrónico

de onda completa con las siguientes propiedades:

Arranque suave

El arranque suave mediante control electrónico garantiza una puesta en marcha de la

máquina sin sacudidas.

Regulación del número de revoluciones

El número de revoluciones puede regularse de

modo continuo con la rueda de ajuste [3-3]

entre 10000 y 26000 rpm. De este modo,

la velocidad de corte puede adaptarse de

manera óptima a cada material.

Número constante de revoluciones

El número preseleccionado de revoluciones

del motor se mantiene constante gracias

Page 28

28

a un sistema electrónico. De este modo se

consigue también bajo carga una velocidad

de corte estable.

Dispositivo protector contra sobre-temperaturas

Cuando el motor alcanza una temperatura

crítica, el sistema electrónico de seguridad

desconecta la máquina para prevenir un sobrecalentamiento. Después de un tiempo de

enfriamiento de aprox. 3-5 minutos, la máquina está preparada para volver a funcionar. Si

la máquina está en marcha (marcha en vacío)

el tiempo de enfriamiento se reduce.

Cambio de la mesa de fresar

La dotación de suministro de serie incluye la

"mesa de fresar con gran superfi cie de apoyo"

premontada. Esta mesa de fresar asegura una

elevada exactitud de fresado gracias a la gran

superfi cie de apoyo y a sus posibilidades de

ajuste de precisión. En el programa de accesorios encontrará más mesas de fresar.

a) Mesa de fresar con gran superfi cie de

apoyo

Coloque la caperuza de aspiración [4-4]. –

Bloquee la caperuza de aspiración apretan- –

do los tornillos [4-3].

Coloque el racor de aspiración [4-5] sobre –

la caperuza de aspiración.

El desmontaje se realiza en el orden inverso.

b) Mesa de fresar para cantos preencolados

La "mesa de fresar para cantos preencolados"

(sólo en la dotación de suministro SET) está

prevista para el fresado enrasado de restos de

colas, así como para el fresado de perfi les.

Observación:

La mesa de fresar está inclinada unos 1,5°

para que no se deteriore el recubrimiento de la

plancha al utilizar la fresadora de cantos. Para

realizar fresados con un ángulo recto exacto,

también está disponible una mesa de fresar

con una inclinación de 0° como accesorio.

1

5-1

4-1

1

4-2

2

Desplace la mesa de fresar sobre los pernos –

de alojamiento [4-1] de la máquina.

Bloquee la mesa de fresar apretando los –

tornillos [4-2].

4-5

5

4-4

2

5-2

Fije el dispositivo palpador [5-1] a la –

máquina con los tornillos premontados.

Desplazando el dispositivo palpador en los

agujeros alargados, éste puede ajustarse

de forma óptima en la fresadora.

Desplace la mesa de fresar sobre los pernos –

de alojamiento [5-2] en la máquina.

3

4

5-3

5-4

4-3

Bloquee la mesa de fresar apretando los –

4

3

tornillos [5-3].

Coloque la caperuza de aspiración [5-4]. –

Page 29

29

5

5-5

Bloquee la caperuza de aspiración apretan- –

do los tornillos [5-5].

El desmontaje se realiza en el orden inverso.

Cambiar la fresadora

Peligro de accidente: la

fresadora puede estar muy caliente después de su uso y cuenta con aristas de

corte muy afi ladas. Deje que la herramienta

se enfríe antes de proceder al cambio. Lleve

puestos guantes de protección para el cambio

de herramienta.

Retire la mesa de fresar antes de cambiar –

la fresadora.

1

2

7-1

7-2 7-3

3

Presione el bloqueo del husillo [7-1]. –

Cierre completamente la tuerca de racor –

[7-2].

Extraiga la tuerca de racor junto con la pin- –

za de sujeción [7-3] del husillo. No separe

la tuerca de racor y la pinza de sujeción,

ya que forman una unidad.

Coloque otra pinza de sujeción con tuerca –

de racor en el husillo.

Abra ligeramente la tuerca de racor. No –

apriete la tuerca de racor hasta que no haya

una fresa insertada.

Ajuste de la profun-

didad de fresado

3

2

SW 19

1

3

6-1

6-2 6-3

a) Extracción de la herramienta

Presione el bloqueo del husillo [6-1]. –

Afl oje con la llave bifurcada (SW 19) la –

tuerca de racor [6-2] hasta que pueda extraer la herramienta.

b) Inserción de la herramienta

Inserte la fresadora [6-3] hasta el tope, al –

menos hasta la marca (

) en el vástago de

la fresa, en la pinza de sujeción abierta.

Presione el bloqueo del husillo [6-1]. –

Apriete la tuerca de racor [6-2] con la llave –

bifurcada (SW 19).

8-1

2

1

8-3

8-2

1

3

2

1

3

8-38-2

Cambio de la pin-

za de sujeción

Con las pinzas de sujeción suministradas sólo

deben emplearse las herramientas adecuadas. Pueden emplearse pinzas de sujeción con

8 mm, 6 mm y 1/4" (6,35 mm).

Afl oje el botón giratorio [8-3] y el pinza- –

miento [8-1](sólo "mesa de fresar con gran

superfi cie de apoyo").

Ajuste la mesa de fresar en la rueda gi- –

ratoria [8-2] a la profundidad de fresado

deseada.

Page 30

30

Apriete el botón giratorio [8-3] y el pinza- –

miento [8-1](sólo "mesa de fresar con gran

superfi cie de apoyo").

Aspiración

El polvo aspirado puede

dañar las vías respiratorias. Conecte siem-

pre la máquina a un dispositivo de aspiración.

Lleve puesta una protección respiratoria para

los trabajos que generen polvo.

Para ambas mesas de fresar se suministran

caperuzas de aspiración que pueden conectarse a un aspirador Festool (tubo fl exible de

aspiración de Ø 27 mm).

Según el tipo de aplicación puede también

colocarse el dispositivo de aspiración (tubo

fl exible de aspiración con Ø

"mesa de fresar con gran superfi cie de apoyo"

o bien en el tope lateral.

27 mm) en la

9-49-3

9-1

9-5

9-2

Coloque el ajuste fi no [9-3] en el tope la- –

teral.

Fije las dos barras guía [9-5] con los boto- –

nes giratorios [9-2] en el tope lateral.

Introduzca el tope lateral en las ranuras de –

la mesa de fresar hasta la medida deseada

y fi je las barras guía con el botón giratorio

[9-1].

Trabajo con la máquina

Sujete la herramienta

siempre con ambas manos.

Fije la pieza de trabajo

siempre de forma que no se pueda mover

cuando se trabaje con ella.

Haga avanzar la máquina a lo largo de la f

pieza de trabajo con un movimiento uniforme.

Tipos de guia-

do de la máquina

a) Fresado con el tope lateral

Para trabajos de fresado se emplea el tope

lateral en paralelo al canto de la pieza de

trabajo.

Sólo puede montarse el tope lateral en la

"mesa de fresar con gran superfi cie de apoyo"

y sin que haya una caperuza de aspiración

montada.

Ajuste basto

Afl oje los tornillos [9-2] y [9-4] y desplace –

el tope lateral.

Apriete los tornillos. –

Ajuste fi no

Afl oje los tornillos [9-2] y manipule la rueda –

giratoria del ajuste fi no [9-3].

Una marca de la rueda giratoria equivale f

a 0,1 mm, una vuelta completa equivale a

1 mm.

Apriete los tornillos [9-2]. –

b) Tratamiento de cantos con cojinete

de arrastre

10-1

Para el tratamiento de cantos con la "mesa

de fresar con gran superfi cie de apoyo" se

colocan fresadoras con cojinete de arrastre

en la máquina. De esta manera, la máquina

Page 31

31

se guiará de modo que el cojinete de arrastre

gire en la pieza de trabajo.

Durante el tratamiento de cantos utilice siempre la aspiración debajo de la mesa [10-1]

para mejorar la aspiración.

c) Tratamiento de cantos con dispositivo

palpador y mesa de fresar para cantos

preencolados

1,5°

11-1

Para el tratamiento de cantos con la mesa

de fresar para cantos preencolados (sólo en

la dotación de suministro SET) se monta el

dispositivo palpador [11-1] en la máquina

(véase “Mesa de fresar para cantos preencolados“). De esta manera, la máquina se guiará

de modo que el dispositivo palpador entre en

contacto con la pieza de trabajo.

Trabajar con aluminio

Peligro de accidente: adopte

las siguientes medidas de seguridad al trabajar con aluminio:

Agregar un interruptor de corriente por f

defecto- (FI-, PRCD-).

Conecte la máquina en una herramienta de f

aspiración apropiada.

Limpie regularmente las acumulaciones de f

polvo en la carcasa del motor.

Lleve puestas gafas de protección. f

Mantenimien-

to y limpieza

Todos los trabajos de

mantenimiento y de repara ción que requieran una abertura de la carcasa del

motor o del meca nismo de transmisión,

solamente deben ser llevados a cabo

por un taller de servicio de asistencia

técnica autorizado (su concesionario le

facilitará la información adecuada)! Un

man-tenimiento o reparación de la máquina

por personas no autori-zadas puede ser la

causa de una conexión errónea de los cables

conductores de corriente eléctrica o de otros

componentes, lo cual puede ser la causa de

accidentes con lesiones graves.

¡A fi n de evitar acciden-

tes, antes de proceder a todo tipo de trabajos de mantenimiento o de reparación

en la máquina se tiene que desenchufar

el enchufe de la fuente de alimentación

de corriente! ¡No emplear aire comprimi-

do para limpiar la herramienta eléctrica! No

intente nunca limpiar piezas en el interior

de la máquina introduciendo algún objeto a

través de las aberturas de la carcasa de la

máquina.

Algunos detergentes y

disolventes pueden dañar los componentes de material sintético. Entre éstos

se encuentran: Bencina, carbonilcloruro, soluciones detergentes de contenido de cloro,

amoniaco, así como detergentes de uso doméstico amónicos.

A fi n de garantizar la circulación del aire, las f

aberturas para el aire de refrigeración en la

carcasa del motor tienen que ser mantenidas continuamente libres y limpias.

El aparato está equipado con escobillas f

especiales de autodesconexión. Al desgastarse, se efectúa una interrupción automática de la corriente y la máquina se

para. En este caso, el aparato deberá ser

llevado a un taller de servicio de asistencia

técnica autorizado, donde se cambiaran las

escobillas.

Accesorios, herramientas

¡Por razones de seguridad, solamente deben emplearse accesorios y herramientas originales de

Festool!

Los números de pedido para los respectivos

accesorios y herramientas se encuentran en