Terminal CPX

Bus node CPX-FB39

Electronics

description

Network protocol

Sercos III

8028633

1504NH

[8028639]

Bus node CPX-FB39

Translation of the original instructions

P.BE-CPX-FB39-EN

CODESYS®, SERCOS®, SPEEDCON® are registered trademarks of the respective trademark owners in

certain countries.

Identification of hazards and instructions on how to prevent them:

Warning

Hazards that can cause death or serious injuries.

Caution

Hazards that can cause minor injuries or serious material damage.

Other symbols:

Note

Material damage or loss of function.

Recommendations, tips, references to other documentation.

Essential or useful accessories.

Information on environmentally sound usage.

Text designations:

Activities that may be carried out in any order.

1. Activities that should be carried out in the order stated.

– General lists.

2 Festo – P.BE-CPX-FB39-EN – 1504NH – English

Bus node CPX-FB39

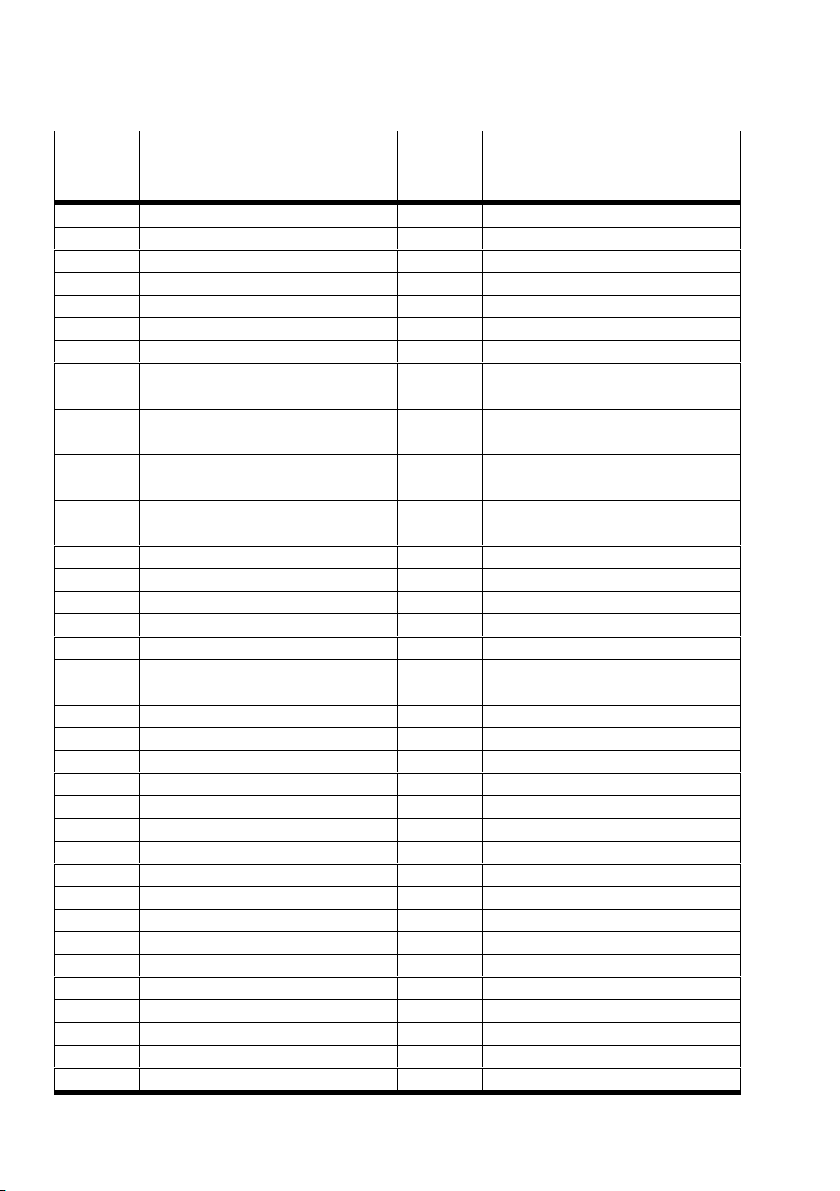

Table of Contents – Bus node CPX-FB39

1 Safety and requirements for product use 7......................................

1.1 Safety 7..................................................................

1.1.1 General safety instructions 7.........................................

1.1.2 Use for intended purpose 7...........................................

1.2 Requirements for product use 8...............................................

1.2.1 Technical requirements 9............................................

1.2.2 Qualification of the specialized personnel (requirements for the personnel) 9...

1.2.3 Range of application and certifications 9................................

1.2.4 Quoted guidelines and standards 9....................................

2 Installation 10..............................................................

2.1 General instructions on installation 10...........................................

2.2 Electrical connections and indicators 11..........................................

2.3 Mounting and dismantling 12..................................................

2.3.1 Mounting 12.......................................................

2.3.2 Dismantling 12.....................................................

2.3.3 Complying with degree of protection IP65/IP67 13.........................

2.4 Settings of the DIL switches on the bus node 14...................................

2.4.1 Removing and attaching the DIL switch cover 14...........................

2.4.2 Arrangement of the DIL switches 14.....................................

2.4.3 Setting the DIL switches 15...........................................

2.4.4 Setting the operating mode 15.........................................

2.4.5 Setting of the diagnostic mode (remote I/O) 16...........................

2.4.6 Setting of the I/O mode (remote controller) 17............................

2.4.7 Set the Sercos address 18............................................

2.5 Connecting to the network 19..................................................

2.5.1 General notes about Sercos networks 19.................................

2.5.2 Overview of connection technology and network plugs 19...................

2.5.3 Cable specification 20................................................

2.5.4 Network connections 20..............................................

2.5.5 Setting the IP address 21.............................................

2.5.6 Webserver function 22...............................................

2.6 Power supply 23.............................................................

3 Commissioning 24...........................................................

3.1 General points about Sercos III 24..............................................

3.2 Depiction of the CPX system on the Sercos-device model 25..........................

3.3 Device description 25........................................................

Festo – P.BE-CPX-FB39-EN – 1504NH – English 3

Bus node CPX-FB39

3.4 Address assignment 26.......................................................

3.4.1 Bus node 27........................................................

3.4.2 Digital modules 28..................................................

3.4.3 Analogue modules 31................................................

3.4.4 Technology modules 32...............................................

3.4.5 Determination of the address assignment 34..............................

3.5 Addressing 35..............................................................

3.5.1 Basic rules for addressing 35..........................................

3.5.2 Example 1: CPX terminal with electronic modules VMPA1 and VMPA2 36........

3.5.3 Example 2: CPX terminal with electrical interface (CP interface) 37............

3.5.4 Example 3: CPX terminal with analogue module and pneumatic interface 38.....

3.5.5 Address assignment after extension/conversion 39........................

3.6 Incorporation in the host system 40.............................................

3.6.1 Codesys control software 40...........................................

3.6.2 Installing device description files (SDDML files) 40.........................

3.6.3 Inserting field bus 42.................................................

3.6.4 Insert bus node 44..................................................

3.6.5 Inserting other modules 47............................................

3.6.6 I/O assignment 48...................................................

3.6.7 Changing parameters in Codesys 49.....................................

3.7 Parameterisation 50.........................................................

3.7.1 Introduction to parameterisation 50.....................................

3.7.2 Prerequisite for parameterization 51....................................

3.7.3 Methods of parameterisation 51.......................................

3.7.4 Parameterisation via the Festo Maintenance Tool (CPX-FMT) software 52.......

3.7.5 Parameterization with the control device (CPX-MMI) 52.....................

3.7.6 Parameterization via Sercos III 52......................................

4 Diagnostics and error handling 53..............................................

4.1 Summary of diagnostics options 53.............................................

4.2 Diagnostics via LED displays 54.................................................

4.2.1 Standard operating status 55..........................................

4.2.2 CPX-specific LEDs 55.................................................

4.2.3 Network-specific LEDs 57.............................................

4.3 Diagnostics via status bits 59..................................................

4.4 Diagnostics via the I/O diagnostics interface 60....................................

4.5 Diagnostics via Sercos III 61...................................................

4.5.1 Basic diagnostic functions 61..........................................

4.5.2 I/O diagnostics 61...................................................

4.5.3 I/O diagnostics with Festo-specific extensions 62..........................

4.6 Error handling 63............................................................

4 Festo – P.BE-CPX-FB39-EN – 1504NH – English

Bus node CPX-FB39

A Technical appendix 64........................................................

A.1 Technical data 64............................................................

A.2 List of abbreviations 65.......................................................

B Identification Numbers (IDNs) 67...............................................

B.1 Sercos Communication Profile (SCP) 67..........................................

B.1.1 Function Group - SCP Identification 67...................................

B.1.2 Function Group - Timing 67............................................

B.1.3 Function Group - Telegram Setup 67.....................................

B.1.4 Function Group - Control 68...........................................

B.1.5 Function Group - Bus Diagnosis 68......................................

B.1.6 Function Group - Connection 69........................................

B.1.7 Function Group - NRT 69..............................................

B.2 Generic Device Profile (GDP) 70................................................

B.2.1 Function Group - Diagnosis 70.........................................

B.2.2 Function Group - Administration 70.....................................

B.2.3 Function Group - Identification 71......................................

B.2.4 Function Group - Time 71.............................................

B.3 Function Specific Profile IO (FSP IO) 72...........................................

B.3.1 Function Group - Generic I/O 72........................................

B.3.2 Function Group - Bus Coupler 72.......................................

B.3.3 Manufacturer-specific extensions to the Function Specific Profile IO (FSP IO) 73..

B.4 Overview of the supported classes 74...........................................

B.4.1 Supported classes of the Sercos Communication Profile (SCP) 74.............

B.4.2 Supported classes of the Generic Device Profile (GDP) 74...................

C Diagnostic messages 75......................................................

C.1 Depiction of CPX diagnostic classes on Sercos diagnostic classes 75...................

C.2 Depiction of CPX diagnostic messages on Sercos status codes 75.....................

Index 79........................................................................

Festo – P.BE-CPX-FB39-EN – 1504NH – English 5

Bus node CPX-FB39

Instructions on this documentation

This description contains specific information about the installation, commissioning and diagnostics of

the CPX bus node for Sercos III as well as specific information about Sercos III relating to the paramet

erization, commissioning, programming and diagnostics of a CPX terminal in a Sercos III network.

You will find further information about Sercos III on the Internet:

è www.sercos.org

General basic information about the mode of operation, mounting, installation and commissioning of

CPX terminals can be found in the CPX system description (è P.BE-CPX-SYS-…).

Information about additional CPX modules can be found in the description for the respective module.

An overview of the structure of user documentation for the CPX terminal can be found in

the CPX system description (è P.BE-CPX-SYS-…).

Service

Please consult your regional Festo contact if you have any technical problems.

6 Festo – P.BE-CPX-FB39-EN – 1504NH – English

1 Safety and requirements for product use

1 Safety and requirements for product use

1.1 Safety

1.1.1 General safety instructions

The general safety information in the corresponding chapters must be observed.

Special safety and danger warnings are written directly before the action instruction.

Please Note

Damage to the product from incorrect handling.

Switch off the supply voltage before mounting and installation work. Switch on sup

ply voltage only when mounting and installation work are completely finished.

Never unplug or plug in a product when powered!

Observe the handling specifications for electrostatically sensitive devices.

1.1.2 Use for intended purpose

The module described in this document, used in conjunction with a CPX terminal, makes it possible to

connect up as a participant on a Sercos III network.

The module is intended for use in an industrial environment. Outside of industrial environments, e.g. in

commercial and mixed-residential areas, actions to suppress interference may have to be taken.

The module is intended exclusively for use in CPX terminals from Festo for installation in machines or

automated systems and may be used only in the following ways:

– In perfect technical condition

– in original status without unauthorised modifications, except for the adaptations described in this

documentation

– within the limits of the product defined through the technical data (è A.1 Technical data).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 7

1 Safety and requirements for product use

Warning

Electrical voltage

Injury caused by electric shock, damage to machine and to system

For the electrical power supply, use only PELV circuits in accordance with

IEC 60204-1 (Protective Extra-Low Voltage, PELV).

Observe the general requirements of IEC 60204-1 for PELV circuits.

Use only voltage sources which guarantee reliable electrical isolation of the operat

ing and load voltage in accordance with IEC 60204-1.

, U

Always connect all circuits for operating and load voltage supply U

U

.

OUT

EL/SEN

VAL

and

Through the use of PELV circuits, protection against electric shock (protection against direct and indir

ect contact) is ensured in accordance with IEC 60204-1.

Note the information about the power supply and about the applicable grounding

measures provided in the CPX system description (è P.BE-CPX-SYS-…).

Please Note

In the event of damage caused by unauthorised manipulation or other than intended

use, the guarantee is invalidated and the manufacturer is not liable for damages.

1.2 Requirements for product use

Make this documentation available to the design engineer, installer and personnel responsible for

commissioning the machine or system in which this product is used.

Make sure that the specifications of the documentation are always complied with. Consider also the

documentation for other components and modules (e.g. CPX system description, P.BE-CPX-SYS-…).

Take into consideration the legal regulations applicable for the location as well as:

– Regulations and standards

– Regulations of the testing organisations and insurers

– national specifications.

8 Festo – P.BE-CPX-FB39-EN – 1504NH – English

1 Safety and requirements for product use

1.2.1 Technical requirements

General conditions for the correct and safe use of the product, which must be observed at all times:

Comply with the connection and ambient conditions specified in the technical data of the product

(è Appendix A.1) and for all connected components.

Only compliance with the limit values or load limits permits operation of the product in accordance

with the relevant safety regulations.

Observe the notes and warnings in this documentation.

1.2.2 Qualification of the specialized personnel (requirements for the personnel)

This description is directed exclusively to technicians trained in control and automation technology,

who are experienced in:

– the installation, commissioning, programming and diagnosis of programmable controllers (PLCs)

and field bus systems

– the applicable regulations for operating safety-engineered systems

– the applicable regulations for accident prevention and industrial safety

– the documentation for the product.

1.2.3 Range of application and certifications

Standards and test values, which the product complies with and fulfils, can be found in the “Technical

data” section (è Appendix A.1). The product-relevant EU directives can be found in the declaration of

conformity.

Certificates and declaration of conformity on this product can be found at www.festo.com.

1.2.4 Quoted guidelines and standards

Issue status

ANSI/TIA-568-B.1-3:2003-02 IEC 61076-2:2011-06

IEC 60204-SER:2013-04 IEEE 802.3:2012

IEC 60204-1:2009-02 ISO/IEC 11801:2008-09

IEC 60529:2001-02

Tab. 1.1

Festo – P.BE-CPX-FB39-EN – 1504NH – English 9

2 Installation

2 Installation

2.1 General instructions on installation

Warning

Uncontrolled movement of the actuators, loose tubing, undefined switching states of

the electronics

Injury caused by moving parts, damage to machine and to system

Before mounting and installation work:

Switch off the power supply

Switch off the compressed air supply

Vent the pneumatics.

Caution

The CPX bus node contains electrostatically sensitive devices.

Therefore, do not touch any components.

Observe the handling specifications for electrostatically sensitive devices.

They will help you avoid damage to the electronics.

Please Note

Ensuring degree of protection IP65/IP67

Use cover caps or dummy plugs to seal unused connections

(è 2.3.3 Complying with degree of protection IP65/IP67).

10 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.2 Electrical connections and indicators

The following connections and displays are located on the bus node:

1 Network status and CPX-specific LEDs

2 Network connection X1

3 Network connection X2

1)

1)

4 DIL switch cover

5 Service interface2) for the control device

(CPX-MMI) or the Festo Maintenance Tool

software (CPX-FMT)

1) Connection bush M12, D-coded, 4-pin

2) Connection bush M12, A-coded, 5-pin

Fig. 2.1

5

4

1

2

3

Festo – P.BE-CPX-FB39-EN – 1504NH – English 11

2 Installation

2.3 Mounting and dismantling

Warning

Electrical voltage

Injury caused by electric shock, damage to machine and to system

Switch supply power off before assembly work.

2.3.1 Mounting

Please Note

Material damage due to incorrect mounting

Select screws that are suitable for the material of the interlinking block:

– plastic: thread-cutting tapping screws

– metal: screws with metric thread.

When ordering an individual module, all the screws required are enclosed.

1. Check seal and sealing surface. Replace

damaged parts.

2. Push the module carefully and without tilting

into the interlinking block up to the stop.

3. Turn the screws into the existing thread.

4. Tighten the screws in diagonally opposite

sequence. Tightening torque: 0.9 … 1.1 Nm.

1 Screws

2 Module

3 Interlinking block

Fig. 2.2

Please Note

In the Remote I/O operating mode, the bus node must be placed as the first module

(slot 0) to the far left of the CPX terminal.

2.3.2 Dismantling

1. Unscrew screws.

2. Pull the module without tilting out of the interlinking block.

1

2

3

12 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.3.3 Complying with degree of protection IP65/IP67

Use connection technology with type of protection IP65/IP67 (è www.festo.com/catalogue,

examples in Tab. 2.1).

Use cover caps to seal unused connections.

connection

Network connection Plug connector NECU-M-S-D12G4-C2-ET ISK-M12

Service interface Connecting cable KV-M12-M12-…

1) Connecting cable for operator unit (CPX-MMI)

2) Included in the scope of delivery

Connection technology Cover cap

2)

1)

Tab. 2.1

Festo – P.BE-CPX-FB39-EN – 1504NH – English 13

2 Installation

2.4 Settings of the DIL switches on the bus node

In order to set the bus node, you must first remove the cover for the DIL switches.

Caution

The CPX bus node contains electrostatically sensitive devices.

Therefore, do not touch any components.

Observe the handling specifications for electrostatically sensitive devices.

They will help you avoid damage to the electronics.

2.4.1 Removing and attaching the DIL switch cover

Use an appropriate tool to remove or attach the DIL switch cover.

Please Note

Observe the following notes when removing or attaching the DIL switch cover:

Disconnect the power supply before removing the cover.

Make sure that the seal is seated correctly when attaching the cover!

Tighten the two mounting screws with a max. torque of 0.4 Nm.

2.4.2 Arrangement of the DIL switches

There are 3 DIL switches available for configuring the bus node. These are located under the DIL switch

cover (è 2.4.1 Removing and attaching the DIL switch cover).

12

3

1 DIL switch 1:

– operating mode “remote I/O”

– operating mode “remote controller”

2 DIL switch 2:

1)

– diagnostics mode (remote I/O)

– I/O mode (remote controller)

3 DIL switch 3:

– Sercos address (1 … 255)

1) The function is dependent on the set operating mode (è DIL switch 1)

Fig. 2.3

14 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.4.3 Setting the DIL switches

1. Switch supply power off.

2. Remove DIL switch cover (è 2.4.1).

3. Perform required settings (è 2.4.4 … 2.4.7).

4. Reinstall DIL switch cover (è 2.4.1).

Please Note

Parameterisation via DIL switch settings is taken over only when the power supply is

switched on.

2.4.4 Setting the operating mode

With the DIL switch element 1.1 on DIL switch 1 the operating mode of the bus node is set.

Operating mode Setting DIL switch 1

Remote I/O operating mode

All functions of the CPX terminal are controlled directly by the

1.1: OFF

(factory setting)

Sercos controller or by a superordinate PLC/IPC. The bus node

takes charge of connection to the Sercos III network.

Remote Controller operating mode

1.1: ON

An FEC or CEC integrated into the CPX terminal controls all

functions of the CPX terminal, i.e. the FEC or CEC undertakes the

I/O control. The bus node takes charge of connection to the

Sercos III network.

Tab. 2.2

Please Note

Setting of the operating mode via DIL switch 1 has priority over all other settings.

The switch element 1.2 of DIL switch 1 is reserved and without function.

Festo – P.BE-CPX-FB39-EN – 1504NH – English 15

2 Installation

2.4.5 Setting of the diagnostic mode (remote I/O)

The diagnostic mode is available only in the remote I/O operating mode.

Diagnostic mode (remote I/O operating mode) Setting DIL switch 2

I/O diagnostics interface and status bits are switched off 2.1 OFF

2.2 OFF

(factory setting)

I/O diagnostics interface is switched on

1)

2.1 ON

2.2 OFF

Status bits are switched on

2)

2.1 OFF

2.2 ON

Reserved 2.1 ON

2.2 ON

1) The I/O diagnostic interface occupies an additional 16 input and 16 output bits

2) The status bits occupy an additional 16 input bits

Tab. 2.3

Please Note

The diagnostics mode reduces the available address space.

When planning your CPX terminal, consider that the number of input and output bits

available for communication is reduced with usage of the diagnostic mode.

Subsequent activation of the diagnostics mode requires a reconfiguration.

Observe that the CPX-internal I/O image can be displaced during subsequent activa

tion of the diagnostics mode.

In this case, repeat the network configuration.

16 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.4.6 Setting of the I/O mode (remote controller)

The I/O mode is available only in the remote controller operating mode.

Number of I/O bytes (Remote Controller operating mode) Setting DIL switch 2

8 byte I/8 byte O for communication of the bus node with the

CPX-FEC or CPX-CEC.

2.1 OFF

2.2 OFF

(factory setting)

Reserved 2.1 ON

2.2 OFF

16 byte I/16 byte O for communication of the bus node with the

CPX-FEC or CPX-CEC.

2.1 OFF

2.2 ON

Reserved 2.1 ON

2.2 ON

Tab. 2.4

Festo – P.BE-CPX-FB39-EN – 1504NH – English 17

2 Installation

2.4.7 Set the Sercos address

DIL switch elements 3.1 to 3.8 are used for setting the binary coding of the Sercos address.

If all switch elements of DIL switch 3 are in the OFF setting, the Sercos address can

altered dynamically by write accesses to parameter S-0-1040.

Sercos address

Permitted addresses:

– 1 … 255 (via DIL switches)

– 0 … 511 (dynamically via S-0-1040)

1)

Factory reset:

– 0 (DIL switch)

– 254 (dynamic)

1) Only with dynamic address issue (all switch elements in the OFF setting)

Setting DIL switch 3

3.8: 2

3.7: 2

3.6: 2

3.5: 2

3.4: 2

3.3: 2

3.2: 2

12 34 56 78

3.1: 2

7

128

6

64

5

32

4

16

3

8

2

4

1

2

0

1

Tab. 2.5

Address 05 Address 38 Address 55 Address 106 Address 239

–

–

–

–

+

–

1234 5678

+

Address:–5

4

1

Address:+38

1234 5678

–

–

32

–

–

+

4

+

2

–

Address:+55

1234 5678

–

–

32

+

16

–

+

4

+

2

+

1

Address:+106

1234 5678

–

+

64

32

–

+

8

–

+

2

–

1234 5678

Address:

Tab. 2.6

+

128

+

64

+

32

–

+

8

+

4

+

2

+

1

239

18 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.5 Connecting to the network

2.5.1 General notes about Sercos networks

Please Note

A Sercos network must always be structured as as ring or line topology.

For this reason, the use of hubs or switches is not permitted.

Please Note

Connecting a PC to the Sercos network (e.g. to use the bus node with the CPX-FMT soft

ware).

– With line topology:

Connect the PC to the free port of the Sercos slave.

– With ring topology:

Use a network tap suitable for Sercos.

Please Note

Sub-assemblies with Ethernet interfaces should only be operated in networks if all con

nected network components are supplied by PELV circuits or integrated power circuits

with equivalent protection.

Installation guidelines

Installation guidelines can be sourced from the Sercos user organization

(è http://www.sercos.org).

2.5.2 Overview of connection technology and network plugs

Note

Faulty installation and high transmission rates may cause data transmission errors as a

result of signal reflections and attenuations.

Note wiring specification (è Tab. 2.8).

Transmission errors can be caused by:

– faulty screened connection

– branches

– transmission over distances which are too long

– unsuitable cables.

Connection technology Network connectors

2 x M12 bush, D-coded, 4-pin, in accordance with

IEC 61076-2, SPEEDCON compatible

Tab. 2.7

Festo – P.BE-CPX-FB39-EN – 1504NH – English 19

Plug connector NECU-M-S-D12G4-C2-ET

2 Installation

2.5.3 Cable specification

Use sheathed Industrial Ethernet wiring of category Cat 5 or higher.

The bus node supports the “crossover detection” function (Auto-MDI/MDI-X).

To connect the bus node to the network or to a PC, this means you can choose between

patch cables or crossover cables.

The circuitry for network connections X1 and X2 is adapted automatically.

CPX-FB39

Cable specification

Cable type Industrial Ethernet cable, screened

Transmission class Category Cat 5

Cable diameter 6 … 8 mm

Wire cross section 0.14 … 0.75 mm², AWG 22

Connection length Maximum 100 m

1) Required for maximum connection length between the network participants

2) corresponding to specification for Ethernet networks, based on ISO/IEC 11801, ANSI/TIA/EIA-568

2)

1)

Tab. 2.8

Please Note

When mounting the CPX terminal on a moving part of a machine.

Use network wiring with tension relief.

Note corresponding stipulations of IEC 60204.

2.5.4 Network connections

There are two 4-pin, D-coded M12 sockets on the bus node for the network connection. The sockets are

compatible with SPEEDCON plugs.

1)

Socket

M12, 4-pin Pin

1

2

3

4

1) Functional earth is accomplished via the housing.

Connection [X1] Connection [X2]

Signal Explanation Signal Explanation

TX+

RX+

TX–

RX–

Transmitted data +

Received data +

Transmitted data –

Received data –

RX+

TX+

RX–

TX–

Received data +

Transmitted data +

Received data –

Transmitted data –

Tab. 2.9

Functional earth

Please Note

The shielded connection for both network connections is linked by RC element to the

ground potential of the CPX terminal.

Connect the ground connection of left-hand terminal plate in a low-current and

low-impedance manner to the ground potential (è CPX system description

P.BE-CPX-SYS-…).

20 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.5.5 Setting the IP address

Alternatively the IP address for the bus node can be set via:

– Dynamic addressing via DHCP/BOOTP

– Stored network setting.

The IP address is factory-set to 192.168.1.20.

Dynamic addressing via DHCP/BOOTP

Make sure that a DHCP/BOOTP server is located in the network.

Alternatively activate dynamic addressing by DHCP/BOOTP via:

– Operator unit (CPX-MMI)

– Festo Maintenance Tool (CPX-FMT) software

– Sercos IDNs.

Saved network settings

The bus node CPX-FB39 offers the option of saving network settings in a non-volatile memory unit.

DHCP/BOOTP is thereby deactivated.

Alternatively change the network settings via:

– Operator unit (CPX-MMI)

– Festo Maintenance Tool (CPX-FMT) software

– Higher-order system

– Sercos IDNs.

This activates saving of the network settings.

Festo – P.BE-CPX-FB39-EN – 1504NH – English 21

2 Installation

2.5.6 Webserver function

A web server is integrated in the bus node CPX-FB39. It makes available read access to the most im

portant parameters and diagnostic functions of the CPX terminal.

Procedure

1. Open an Internet browser on a PC with a connection to the network.

2. Enter the set/identified IP address of the bus node in the address line of the Internet browser

(è 2.5.5 Setting the IP address).

Fig. 2.4

22 Festo – P.BE-CPX-FB39-EN – 1504NH – English

2 Installation

2.6 Power supply

The operating and load voltage supply is directed via the interlinking blocks (è CPX system descrip

tion P.BE-CPX-SYS-…).

Warning

Electrical voltage

Injury caused by electric shock, damage to machine and to system

For the electrical power supply, use only PELV circuits in accordance with

IEC 60204-1 (Protective Extra-Low Voltage, PELV).

Observe the general requirements of IEC 60204-1 for PELV circuits.

Use only voltage sources which guarantee reliable electrical isolation of the operat

ing and load voltage in accordance with IEC 60204-1.

Always connect all circuits for operating and load voltage supply U

U

.

OUT

/SEN, U

EL

Through the use of PELV circuits, protection against electric shock (protection against direct and indir

ect contact) is ensured in accordance with IEC 60204-1.

Note the information about the power supply and about the applicable grounding meas

ures (è CPX system description P.BE-CPX-SYS-…).

VAL

and

Festo – P.BE-CPX-FB39-EN – 1504NH – English 23

3 Commissioning

3 Commissioning

Please Note

Only commission a correctly installed CPX terminal (è 2 Installation).

Please Note

A firmware update can be performed by the Festo Field Device Tool (FFT).

The current version is available on the Festo Support Portal on the Internet

(è www.festo.com/sp).

– General information on commissioning the CPX terminal as well as a detailed

description of individual parameters is found in the CPX system description

(è P.BE-CPX-SYS-…).

– Information on commissioning the analogue pneumatic interfaces and I/O modules

can be found in the description (è P.BE-CPX-EA-…).

– Instructions on commissioning the pneumatic components can be found in the corres

ponding description of pneumatics.

3.1 General points about Sercos III

Please Note

The bus node CPX-FB39 is a remote I/O system that communicates with the Sercos

controller via the Sercos IO profile (Function Specific Profile IO).

Sercos III is an Ethernet-based communication protocol for automation applications.

Communication on a Sercos III network is based on the time-stop process with cyclical data transmis

sion in the form of telegrams based on the master-slave principle. This combines real-time and nonreal-time communication channels in a communication system.

Real Time Channel (RTC)

During transmission in real-time, a distinction is made between two types of telegram.

– Master data telegram (MDT): For communication of nominal/setpoint data from master to slaves.

– Acknowledge telegram (AT): For communication of status data from slaves to master and for trans

verse communication between the individual controllers or slaves.

Non-real-time channel (Universal Communication Channel - UCC)

For the exchange of standard Ethernet telegrams between any participants on the network.

You will find further information about Sercos III on the Internet:

è www.sercos.org

24 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.2 Depiction of the CPX system on the Sercos-device model

The underlying depiction of the CPX system on Sercos is illustrated by the next graphic (è Fig. 3.1).

The CPX system is illustrated here as a Sercos device with a Sercos interface, a Sercos slave and the

associated sub device. Communication is performed by the Sercos interface and the Sercos slave. Gen

eric parts of the device application are implemented as part of the sub device. The resource IO is as

signed to the sub device: It depicts the Sercos function profile (Function Specific Profile IO) and in

cludes a depiction of the individual CPX modules on Sercos.

CPX system CPX modules

1

corresponds

Device

(logical)

owns owns

11

Sercos

interface

consists uses

1

Generic Device Profile Function Specific Profile IO

11

1

Sub Device Resource IO

includes

Sercos

slave

Sercos Communication Profile

0…n1 1…n

includesincludes

11

11

0…n1

Physical structure

Application

communication

Sercos-III network

Fig. 3.1

3.3 Device description

During initial commissioning of a Sercos participant, the controller software is notified of certain prop

erties of the participant. These properties are administered in what are known as device description

files in standardized XML format.

The device description of Sercos-III devices is in the form of SDDML files (Sercos Device Description

Markup Language) and is based on the Sercos-III device model. This provides a separate device de

scription file for each device.

The device description files (SDDML files) are available on the Festo support portal on the

Internet (è www.festo.com/sp).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 25

3 Commissioning

3.4 Address assignment

A CPX terminal consists of a different number of inputs and outputs, depending on your order and the

configuration of the bus node.

The inputs and outputs are assigned automatically within the CPX terminal.

When using device description files (SDDML files) the controller software can extrapolate

the complete address assignment automatically.

Warning

Uncontrolled movement of the actuators, undefined switching statuses.

Injury to people, damage to the machine and system.

The byte sequence of the process data is Little Endian.

Ensure that the process data is interpreted correctly.

Please Note

– Including bus nodes, a maximum of 10 electrical modules plus a pneumatic interface

and/or MPA pneumatic module is permitted in a CPX terminal.

– The address space of a CPX terminal is limited. The bus node provides the CPX ter

minal a maximum address space of 64 bytes for inputs and 64 bytes for outputs.

– An activated diagnostic mode reduces the number of available I/O bytes.

– Each module of the CPX terminal occupies a specific number of bits, bytes or words

for module communication.

Establish the address assignment (number of allocated inputs/outputs) on the CPX terminal prior to

commissioning.

Tab. 3.8 serves to determine the address assignment and/or the number of assigned

inputs and outputs on the CPX terminals.

The number of assigned inputs and outputs for modules can be found in the following

tables:

– Bus node CPX-FB39:

– FG S-0-1500.SI.0 – Bus Coupler (è Tab. 3.1)

– Digital modules:

– FG S-0-1502.SI.0 – Digital Output (è Tab. 3.2)

– FG S-0-1503.SI.0 – Digital Input (è Tab. 3.3).

– Analog modules:

– FG S-0-1504.SI.0 – Analog Output (è Tab. 3.4)

– FG S-0-1505.SI.0 – Analog Input (è Tab. 3.5).

– Technology modules:

– FG S-0-1507.SI.0 – Complex Protocol (è Tab. 3.6)

– FG S-0-1508.SI.0 – Sub Bus Master(è Tab. 3.7).

26 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.4.1 Bus node

FG S-0-1500.SI.0 (Bus Coupler)

Bus node CPX-FB39 Module type Module

identifiers

Allocated address space

1)

Inputs Outputs

Remote I/O operating mode

without diagnostics mode CPX-FB39 FB39-RIO – –

Status bits

I/O diagnostics interface

Remote Controller operating

mode

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) The additional input data are set up as FG S-0-1503.SI.0 (Digital Inputs).

3) Diagnostic mode status bits assigns 2 byte address space (8 inputs and/or 8 bits remain unused).

4) The additional input and output data are set up as FG S-0-1507.SI.0 (Complex Protocol).

5) Assigned address space depends upon the setting of DIL switch 2.2.

2)

4)

1x 16 bit3)–

1x 16 bit 1x 16 bit

CPX-FB39 FB39-RC 8x 8bit

4)

8x 16 bit

Tab. 3.1

If the bus node is operated in Remote Controller operating mode, then only the FG Bus

Coupler with additional FG Complex Protocol is depicted on structural entity 0. No depic

tion of I/O modules takes place on Sercos objects.

5)

8x 8 bit

8x 16 bit

5)

Festo – P.BE-CPX-FB39-EN – 1504NH – English 27

3 Commissioning

3.4.2 Digital modules

FG S-0-1502.SI.0 (Digital Output)

Module designation Module type Module

identifiers

Allocated address space

1)

Inputs Outputs

Output module

4-fold CPX-4DA 4DO – 4x 1 bit

8-fold CPX-8DA 8DO – 8x 1 bit

8-fold (high current) CPX-8DA-H 8DO-H – 8x 1 bit

Input/output module

each 8x CPX-8DE-8DA 8DI/8DO 8x 1 bit

each 8-fold (with terminal

strip)

CPX-L-8DE-8DA-16-KL3POL

L-8DI8DO-PI 8x 1 bit

3)

3)

Electronics module

for MPA1 pneumatics module

VMPA1-FB-EMS-8 MPA1S – 8x 1 bit

(1 … 8 valves)

for MPA2 pneumatic module

VMPA2-FB-EMS-4 MPA2S – 8x 1 bit

(1 … 4 valves)

Electronics module (electrically isolated)

for MPA1 pneumatics module

VMPA1-FB-EMG-8 MPA1G – 8x 1 bit

(1 … 8 valves)

for MPA2 pneumatic module

VMPA2-FB-EMG-4 MPA2G – 8x 1 bit

(1 … 4 valves)

Electrical module with diagnostic function

for MPA1 pneumatics module

VMPA1-FB-EMS-D2-8 MPA1S-D – 8x 1 bit

(1 … 8 valves)

for MPA2 pneumatic module

VMPA2-FB-EMS-D2-4 MPA2S-D – 8x 1 bit

(1 … 4 valves)

Electrical module with diagnostic function (electrically isolated)

for MPA1 pneumatics module

VMPA1-FB-EMG-D2-8 MPA1G-D – 8x 1 bit

(1 … 8 valves)

for MPA2 pneumatic module

VMPA2-FB-EMG-D2-4 MPA2G-D – 8x 1 bit

(1 … 4 valves)

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Digital 4x output modules (CPX-4DA) always occupy 8 outputs or 1 byte of address space.

3) Input data è FG S-0-1503.SI.0 (Digital Input)

4) VMPA1 modules always occupy 8 outputs regardless of the number of valves fitted.

5) VMPA2 modules always occupy 8 outputs, although only 4 bits are used.

6) Setting via DIL switches of the pneumatic interface.

2)

8x 1 bit

8x 1 bit

4)

5)

4)

5)

4)

5)

4)

5)

28 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

Module designation Allocated address spaceModule

Module typeModule designation

Module type

Module

identifiers

identifiers

1)

1)

End plate (pneumatic interface

for valve terminal MPA-S VMPA-FB-EPL-… – – –

for valve terminal MPA-F VMPAF-FB-EPL-… – – –

for valve terminal MPA-L VMPAL-FB-EPL-…

1 ... 4 solenoid coils – – 8x 1 bit

1 ... 8 solenoid coils – – 8x 1 bit

1 ... 16 solenoid coils – – 16x 1 bit

1 ... 24 solenoid coils – – 24x 1 bit

1 ... 32 solenoid coils – – 32x 1 bit

Pneumatic interface

for valve terminal

VTSA-/VTSA-F

with setting:

6)

VABA-… VTSA -

type 44/45

1 ... 8 solenoid coils – 8x 1 bit

1 ... 16 solenoid coils – 16x 1 bit

1 ... 24 solenoid coils – 24x 1 bit

1 ... 32 solenoid coils – 32x 1 bit

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Digital 4x output modules (CPX-4DA) always occupy 8 outputs or 1 byte of address space.

3) Input data è FG S-0-1503.SI.0 (Digital Input)

4) VMPA1 modules always occupy 8 outputs regardless of the number of valves fitted.

5) VMPA2 modules always occupy 8 outputs, although only 4 bits are used.

6) Setting via DIL switches of the pneumatic interface.

Tab. 3.2

OutputsInputs

Festo – P.BE-CPX-FB39-EN – 1504NH – English 29

3 Commissioning

FG S-0-1503.SI.0 (Digital Input)

Module designation Module type Module

identifiers

Allocated address space

1)

Inputs Outputs

input module

4-fold CPX-4DE 4DI 4x 1 bit

2)

8 valves CPX-8DE 8DI 8x 1 bit –

8-fold (n-switching) CPX-8NDE 8NDI 8x 1 bit –

8-fold (with channel

CPX-8DE-D 8DI-D 8x 1 bit –

diagnostics)

16 valves CPX-16DE 16DI 16x 1 bit –

16-fold (with channel

CPX-M-16DE-D 16DI-D 16x 1 bit –

diagnostics)

16-fold (with terminal strip) CPX-L-16DE-16-KL-3POL L-16DI-PI 16x 1 bit –

INPUT/OUTPUT MODULE

each 8x CPX-8DE-8DA 8DI/8DO 8x 1 bit 8x 1 bit

each 8-fold (with terminal

strip)

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Digital quadruple input modules (CPX-4DE ) always occupy 8 inputs.

3) Output data è FG S-0-1502.SI.0 (Digital Output)

CPX-L-8DE-8DA-16-KL-

3POL

L-8DI8DO-PI 8x 1 bit 8x 1 bit

Tab. 3.3

– The address assignment within the individual CPX I/O modules can be found in the

description for the I/O modules (è P.BE-CPX-EA-…).

– Information about pneumatic interfaces and pneumatic modules can be found in the

corresponding pneumatics descriptions.

– An overview of the “Descriptions of the CPX terminal” documentation can be found in

the CPX system description (è P.BE-CPX-SYS-…).

– From the technical point of view, the individual pneumatic modules each represent an

electric module for controlling the attached valves.

–

3)

3)

30 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.4.3 Analogue modules

FG S-0-1504.SI.0 (Analog Output)

Module designation Module type Module

identifiers

Allocated address space

1)

Inputs Outputs

Analog module (2 outputs) CPX-2AA-U-I 2AO – 2x 16 Bit

Proportional pressure regulator VPPM-…TA-L-1-F… VPPM 1x 16 bit2)1x 16 bit

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Input data è FG S-0-1505.SI.0 (analog input)

Tab. 3.4

FG S-0-1505.SI.0 (Analog Input)

Module designation Module type Module

identifiers

Allocated address space

1)

Inputs Outputs

Pressure sensors VMPA-FB-PS-… MPA-P 1x 16 bit –

Proportional pressure regulator VPPM-…TA-L-1-F… VPPM 1x 16 bit 1x 16 bit

Analogue module

2 inputs CPX-2AE-U-I 2AI 2x 16 Bit –

4 inputs CPX-4AE-U-I 4AI 4x 16 bit –

4 inputs CPX-4AE-I 4AI-I 4x 16 bit –

4 inputs (temperature module

for RTD sensors)

4 inputs (temperature module

CPX-4AE-T 4AI-T 2x 16 Bit

3)

4x 16 bit

CPX-4AE-TC 4AI-TC 4x 16 bit –

–

for TC sensors)

4 inputs (pressure sensor

CPX-4AE-P-D10 4AI-P-D10 4x 16 bit –

module 0 … 10 bar)

4 inputs (pressure sensor

CPX-4AE-P-B2 4AI-P-B2 4x 16 bit –

module –1 … 1 bar)

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Output data è FG S-0-1504.SI.0 (analog output)

3) Depending on the configuration.

Tab. 3.5

2)

The address assignment within the individual CPX analogue I/O modules can be found in

the description for the analogue I/O modules (è P.BE-CPX-AX-…).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 31

3 Commissioning

3.4.4 Technology modules

FG S-0-1507.SI.0 (Complex Protocol)

Module designation Module type Module

identifiers

Allocated address space

1)

Inputs Outputs

INPUT/OUTPUT MODULE CPX-2ZE2DA 2CI2DO 3x 32 bit 3x 32 bit

Axis controller CPX-CMAX-C1-1 CMAX-C1-C 8x 8bit 8x 8 bit

Control block

CPX-CMXX CMXX 8x 16 bit 8x 16 bit

(multi-axis interface)

End-position controller CPX-CMPX-C-1-H1 CMPX-C-1 6x 8 bit 6x 8 bit

Control block

CPX-CM-HPP CM-HPP 32x 8 bit 32x 8 bit

(FHPP interface)

Measuring module CPX-CMIX-CM-M1-1 CMIX 3x 16 bit 3x 16 bit

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

Tab. 3.6

FG S-0-1508.SI.0 (Sub bus Master)

Module designation Module type Module

identifiers

Electrical interface

CPX-CP-4-FB CPI maximum

(CP interface)

Electrical interface

CPX-CTEL-4-M12-5POL CTEL

Allocated address space

1)

Inputs Outputs

maximum

2)

16x 8 bit

16x 8 bit

with setting:

0E/0A byte – –

0E/8A byte – 8x 8bit

0E/16A byte – 16x 8 bit

0E/24A byte – 24x 8 bit

0E/32A byte – 32x 8 bit

8E/0A byte 8x 8bit –

16E/0A byte 16x 8 bit –

24E/0A byte 24x 8 bit –

32E/0A byte 32x 8 bit –

8E/8A byte 8x 8bit 8x 8bit

16E/16A byte 16x 8 bit 16x 8 bit

24E/24A byte 24x 8 bit 24x 8 bit

32E/32A byte 32x 8 bit 32x 8 bit

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Maximum assigned address space is dependent on the string allocation

2)

32 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

Module designation Allocated address spaceModule

Electrical interface

with setting:

Module typeModule designation

Module type

Module

identifiers

identifiers

CPX-CTEL-2-M12-5POL-LK CTEL-2-LK

I-port LK

1)

1)

master

8E/8A byte 8x 8bit 8x 8bit

16E/16A byte 16x 8 bit 16x 8 bit

24E/24A byte 24x 8 bit 24x 8 bit

1) Module identifier in the operator unit or in the hardware configuration of the programming software.

2) Maximum assigned address space is dependent on the string allocation

Tab. 3.7

Details on the technology modules can be found in the corresponding descriptions

(è P.BE-CPX-…).

OutputsInputs

Festo – P.BE-CPX-FB39-EN – 1504NH – English 33

3 Commissioning

3.4.5 Determination of the address assignment

Tab. 3.8 serves to determine the address assignment and/or the number of assigned

inputs and outputs on the CPX terminals.

Modules (analogue/digital) and diagnostics mode Inputs Outputs

bus node

With status bits + 16 I + _____ I

with I/O diagnostics interface + 16 I/O + _____ I + _____ O

Analogue modules

CPX-2AE-U-I + ___ x 32 I + _____ I

CPX-4AE-I, CPX-4AE-U-I, CPX-4AE-P-…, CPX-4AE-TC + ___ x 64 I + _____ I

CPX-4AE-T + ___ x 32/64 I1)+ _____ I

CPX-2AA-U-I + ___ x 32 O + _____ O

VMPA-FB-PS-… (pressure sensors) + ___ x 16 I + _____ I

VPPM-…TA-L-1-F… (Proportional pressure regulators) + __ x 16 I/O + _____ I + _____ O

Technology modules

e.g. CPX-CMAX-C1-1, CPX-2ZE2DA, CPX-CP-4-FB + ___ I/O + _____ I + _____ O

Digital modules

CPX-4DE, CPX-8DE, CPX-8NDE, CPX-8DE-D + ___ x 8 I

2)

+ _____ I

CPX-16DE, CPX-M-16DE-D, CPX-L-16DE-16-KL-3POL + ___ x 16 I + _____ I

CPX-4DA, CPX-8DA, CPX-8DA-H + ___ x 8 O

2)

+ _____ O

CPX-8DE-8DA, CPX-L-8DE-8DA-16-KL-3POL + __ x 8 I/O + _____ I + _____ O

VMPA1-…, VMPA2-… (Pneumatic modules) + ___ x 8 O

2)

+ _____ O

VMPAL-…, VABA-… (pneumatic interfaces)

Number of configured valve solenoid coils (+8 O … 32 O)

3)

+ _____ O

Sum total of the assigned inputs and outputs of your CPX terminal

(maximum 512 I and 512 O): = _____ I = _____ O

1) The number of inputs is dependent on the setting.

2) Digital modules with 4 inputs or outputs (CPX-4DE, CPX-4DA ) as well as electric modules and electronic modules VMPA2 always

occupy 8 inputs or 8 outputs.

3) At the factory, 32 O (VABA, VMPAL) are configured.

Tab. 3.8

34 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.5 Addressing

3.5.1 Basic rules for addressing

– The address assignment of the inputs does not depend on the address assignment of the outputs.

– Counting is byte-wise from left to right, in ascending order without gaps.

Even modules with less than 8 bits occupy 8 bits of address space, but do not use all this space.

– The bus node counts as a module with 0 inputs and 0 outputs when the status bits and the I/O dia

gnostic interface are deactivated.

Please Note

Address assignment with activated status bits or activated I/O diagnostics interface.

– If the 8 status bits are activated, these occupy the first 16 inputs in the address

range, although only 8 inputs are used.

– If the I/O diagnostics interface is activated, it will occupy the first 16 inputs and

outputs in the address range.

– The inputs and outputs of various different types of module are assigned separately from one an

other, and the sequence depends on the arrangement of modules in the CPX terminal.

– Input data: S-0-1500.SI.9 (Container Input Data)

– Output data: S-0-1500.SI.5 (Container Output Data).

Please Note

In the Remote I/O operating mode, the bus node must be placed as the first module

(slot 0) to the far left of the CPX terminal.

Festo – P.BE-CPX-FB39-EN – 1504NH – English 35

3 Commissioning

3.5.2 Example 1: CPX terminal with electronic modules VMPA1 and VMPA2

The following graphic shows a CPX terminal with electronic modules VMPA1 and VMPA2 and the follow

ing setting:

– status bits and I/O diagnostics interface deactivated.

Module no.: 0

1

8DI 4DO

23456

12

1 Bus node CPX-FB39

2 End plate VMPAL (pneumatic interface)

3

4

3 Electronic module VMPA1 (8DA)

4 Electronic module VMPA2 (4DA)

Fig. 3.2

The following diagram shows an example of the address assignment for the CPX terminal depicted:

No. Module Function group

0 CPX-FB39

1 CPX-8DE S-0-1503.1.9

2 CPX-4DA S-0-1502.2.5

3 VMPA-1 (8DA) S-0-1502.3.5

4 VMPA-1 (8DA) S-0-1502.4.5

5 VMPA-2 (4DA) S-0-1502.5.5

6 VMPA-2 (4DA) S-0-1502.6.5

1) 8 bit assigned, 4 bit used

S-0-1500.0.9 (input data 1 byte)

S-0-1503.1.9 (module 1) 8 bit

S-0-1500.0.5 (output data 5 byte)

S-0-1502.2.5 (module 2) 8 bit

1)

S-0-1502.3.5 (module 3) 8 bit

S-0-1502.4.5 (module 4) 8 bit

S-0-1502.5.5 (module 5) 8 bit

S-0-1502.6.5 (module 6) 8 bit

1)

1)

Fig. 3.3

36 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

)

3.5.3 Example 2: CPX terminal with electrical interface (CP interface)

The following graphic shows a CPX terminal with electrical interface and the following setting:

– status bits and I/O diagnostics interface deactivated.

123 4 5

8DI 4DO 8DI 8DO

1

2

3

6Module no.: 0

4

5

6

1 Bus node CPX-FB39

2 CPV valve terminal (16DO) on string 1 of the

electrical interface

3 cylinders

4 CP input module (16DI)

5 Sensor

6 CP output module (16DO) on string 4 of the

electrical interface

Fig. 3.4

The following diagram shows an example of the address assignment for the CPX terminal depicted:

No. Module Function group

0 CPX-FB39

1 CPX-8DE S-0-1503.1.9

2 CPX-4DA S-0-1502.2.5

3 CPX-CP-4-FBI

1)

S-0-1508.3.9

S-0-1508.3.5

4 CPX-8DE-8DA S-0-1503.4.9

S-0-1502.4.5

5 VMPA-1 (8DA) S-0-1502.5.5

6 VMPA-1 (8DA) S-0-1502.6.5

1) Here 4 byte inputs and 16 byte outputs 2) 8 bit assigned, 4 bits used

S-0-1500.0.9 (input data 6 byte

S-0-1503.1.9 (module 1) 8 bit

S-0-1508.3.9 (module 3) 4x 8 bit

S-0-1503.4.9 (module 4) 8 bit

S-0-1500.0.5 (output data 20 byte)

S-0-1502.2.5 (module 2) 8 bit

S-0-1508.3.5 (module 3) 16x 8 bit

2)

S-0-1502.4.5 (module 4) 8 bit

S-0-1502.5.5 (module 5) 8 bit

S-0-1502.6.5 (module 6) 8 bit

Fig. 3.5

Festo – P.BE-CPX-FB39-EN – 1504NH – English 37

3 Commissioning

3.5.4 Example 3: CPX terminal with analogue module and pneumatic interface

The following graphic shows a CPX terminal with pneumatic interface and the following setting:

– status bits activated and I/O diagnostic interface deactivated

– pneumatic interface set with DIL switch to 1 ... 8 solenoid coils (8 DO).

Module no.: 0 1 2 3 4 5 6

8DI 8DI 4DO 8DI 2AO

12

1 Bus node CPX-FB39 (status bits activated)

8DO

3

3 VTSA pneumatics

2 Pneumatic interface (set with DIL switch to

1 ... 8 solenoid coils)

Fig. 3.6

The following diagram shows an example of the address assignment for the CPX terminal depicted:

No. Module Function group

0 CPX-FB39 S-0-1503.0.9

1 CPX-8DE S-0-1503.1.9

2 CPX-8DE S-0-1503.2.9

3 CPX-4DA S-0-1502.3.5

4 CPX-8DE-8DA S-0-1503.4.9

S-0-1502.4.5

5 CPX-2AA-U-I S-0-1504.5.5

6 VABA (8DA)

1) 16 bit assigned, 8 bit used

2) 8 bit assigned, 4 bits used

3)

S-0-1502.6.5

S-0-1500.0.9 (input data 5 byte)

S-0-1503.0.9 (module 0) 16 bit

S-0-1503.1.9 (module 1) 8 bit

S-0-1503.2.9 (module 2) 8 bit

S-0-1503.4.9 (module 4) 8 bit

S-0-1500.0.5 (output data 7 byte)

S-0-1502.3.5 (module 3) 8 bit

S-0-1502.4.5 (module 4) 8 bit

S-0-1504.5.5 (module 5) 2x 16 bit

S-0-1502.6.5 (module 6) 8x 1 bit

3) Set via DI L switches to 1 … 8 valve coils

1)

2)

Fig. 3.7

38 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.5.5 Address assignment after extension/conversion

If the requirements for the machine or system change, the CPX terminal can be adapted as required due

to its modular design.

Caution

If the CPX terminal is extended or converted at a later stage, input/output addresses

may be shifted. This applies in the following cases:

– Additional modules are inserted between existing modules.

– Existing modules are removed or replaced by other modules which have fewer or

more input/output addresses.

– Interlinking blocks or pneumatic connection blocks for monostable valves are re

placed by interlinking blocks/connection blocks for bistable valves or vice versa

(è Pneumatics description).

– Additional interlinking blocks or connection blocks are inserted between existing ones.

– Status bits or the I/O diagnostic interface are activated/deactivated.

– The configured addresses of the pneumatic interface are modified.

Please Note

If the configuration of a CPX terminal was changed, new requirements for the CPX ter

minal that may be necessary must be checked and adjusted, if necessary.

Moreover, it should be noted that the needed address space may increase due to modific

ation of the CPX terminal and thus the slave addresses of the following slaves in the net

work must be checked and adjusted if necessary.

Festo – P.BE-CPX-FB39-EN – 1504NH – English 39

3 Commissioning

3.6 Incorporation in the host system

3.6.1 Codesys control software

To incorporate a CPX terminal in a Sercos-III network you can for example use Codesys control software

from 3S (Smart Software Solution) (è www.codesys.com).

The contents of this documentation serve as an example of the use of Codesys software

and relate to version 3.5 SP4 in the Professional presentation format and an English

language setting.

The user interface for this software can be adapted individually and the window arrangement can be

changed. The following illustration shows a possible layout for the user interface.

4

1

2

3

1 Parameter register (“Parameter tab”)

2 Editor window (“Editor window”)

Fig. 3.8

3.6.2 Installing device description files (SDDML files)

To insert the module extension of your CPX terminal in the control software and to be able to configure

it, the device description files (SDDML files) of all modules used in the CPX terminal need to be installed

once.

The device description files (SDDML files) are available on the Festo support portal on the

Internet (è www.festo.com/sp).

Please Note

Requirements for execution of the subsequent steps:

– Device description files (SDDML files) downloaded from the Festo Support Portal

and unpacked.

40 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Device window (“Device window”)

4 Device tab (“Device tab”)

3 Commissioning

Approach:

1. Start Codesys software.

2. Menu Tools (“Tools”) > Device Repository… (“Device Repository…”).

The device repository dialog (“Device Repository”) opens up.

Fig. 3.9

3. Press the Install button … (“Install…”).

The “Install Device Description”dialog opens up.

Fig. 3.10

4. Mark the required XML files and press the “Open”button.

The selected device description files (SDDML files) are then installed.

The device description files (SDDML files) are then available in the Codesys control

software.

Festo – P.BE-CPX-FB39-EN – 1504NH – English 41

3 Commissioning

3.6.3 Inserting field bus

Please Note

Requirements for execution of the subsequent steps:

– Codesys project set up with programmable controller (PLC)

– Device description files (SDDML files) available in Codesys

(è 3.6.2 Installing device description files (SDDML files)).

Procedure

1. Highlight entry of device in device window (“Device window”).

2. Project menu (“Project”) > Add device… (“Add Device…”).

The “Add Device”dialog opens up.

Fig. 3.11

3. Extend the “sercos”entry and highlight the “sercos Master”entry.

4. Press the “Add Device”button.

The “sercos Master”entry appears in the device window (“Device window”).

The Sercos master is now available as field bus in the Codesys project and the bus node

can be added to the device tree (è 3.6.4 Insert bus node).

42 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

Setting the cycle time

1. Highlight “sercos_Master (sercos Master)”entry in the device window (“Device window”).

2. Project menu (“Project”) > Edit object (“Edit Object”).

The device tab (“Device tab”) “sercos_Master”appears in the Editor window (“Editor window”).

Fig. 3.12

3. In the parameter tab (“Parameter tab”) “sercos Master”, set the Sercos cycle time (“sercos Cycle

time”).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 43

3 Commissioning

3.6.4 Insert bus node

Please Note

Requirements for execution of the subsequent steps:

– Codesys project set up with programmable controller (PLC)

– Device description files (SDDML files) available in Codesys

(è 3.6.2 Installing device description files (SDDML files))

– Field bus inserted in project (è 3.6.3 Inserting field bus).

Procedure

1. Highlight “sercos_Master (sercos Master)”entry in the device window (“Device window”).

2. Project menu (“Project”) > Add device… (“Add Device…”).

The “Add Device”dialog opens up.

Fig. 3.13

Please Note

Depending on the diagnostics mode, there is a choice of 3 entries:

– CPX-FB39-RIO (without diagnostic mode)

– CPX-FB39-RIO-ST (with status bits)

– CPX-FB39-RIO-STI (with diagnostic interface).

3. Highlight corresponding bus node entry.

4. Press the “Add Device”button.

44 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

In the device window (“Device window”), 2 entries appear for the bus node (è Fig. 3.14).

– First entry: Bus node gateway

– Second entry: Bus node module.

1

2

1 Bus node gateway 2 Bus node module

Fig. 3.14

The CPX-FB39 module is now available as a bus node in the Codesys project and other

modules of the CPX terminal can be added to the device tree

(è 3.6.5 Inserting other modules).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 45

3 Commissioning

Setting the Sercos address

1. Highlight bus node gateway entry in the device window (“Device window”).

2. Project menu (“Project”) > Edit object (“Edit Object”).

The corresponding device tab (“Device tab”) appears in the editor window (“Editor window”).

Fig. 3.15

3. Enter the correct Sercos address in the “sercos Slave”parameter tab (“Parameter tab”).

Please Note

The entry for the Sercos address must match the setting of DIL switch 3 on the bus node

(è 2.4.7 Set the Sercos address).

46 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.6.5 Inserting other modules

Please Note

Requirements for execution of the subsequent steps:

– Codesys project set up with programmable controller (PLC)

– Device description files (SDDML files) available in Codesys

(è 3.6.2 Installing device description files (SDDML files))

– Field bus inserted in project (è 3.6.3 Inserting field bus)

– Bus node inserted in project (è 3.6.4 Insert bus node).

Procedure

1. Highlight bus node gateway entry (upper entry) in the device window (“Device window”).

2. Project menu (“Project”) > Add device… (“Add Device…”).

The “Add Device”dialog opens up.

Fig. 3.16

3. Highlight the module.

4. Press the “Add Device”button.

5. Insert other modules in accordance with steps 3. and 4.

Expansion of the CPX terminal is now available in the Codesys project and assignment of

the inputs and outputs to variables in the higher-level controller (I/O mapping) is now

possible (è 3.6.6 I/O assignment).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 47

3 Commissioning

3.6.6 I/O assignment

Once all devices on the CPX terminal have been inserted in the Codesys controller software project, the

inputs and outputs on the individual modules can be depicted on a higher-level control unit.

Procedure

1. Click entry of device in the device window (“Device window”) with the right-hand mouse button.

A context menu appears on screen.

2. In the context menu, select “Edit IO mapping”.

The device tab (“Device tab”) “Edit IO mapping”appears in the editor window (“Editor window”).

Fig. 3.17

All inputs and outputs on the individual modules are displayed in the Editor window

(“Editor window”) and can be assigned to the variables in the higher-level controller.

48 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.6.7 Changing parameters in Codesys

With the help of Codesys software, the user-defined parameters (“User Parameters”) of the modules

inserted in a project can be displayed and changed.

Procedure

1. Highlight the entry of a module in the device window (“Device window”).

2. Project menu (“Project”) > Edit object (“Edit Object”).

The corresponding device tab (“Device tab”) appears in the editor window (“Editor window”).

3. Select parameter tab (“Parameter tab”) for user-defined parameters (“User Parameters”).

The parameter appear in the editor window (“Editor window”).

Fig. 3.18

4. Select the parameter settings by double-clicking “Value”in the (“Value”) column and edit the value

using the pulldown menu.

The parameter settings can be displayed as a symbolic value (standard) or as a numerical

value. Refer to the corresponding CPX modules to find the meaning of the applicable

numerical values.

The changeover of display involves setting or not setting the tick on Symbolic Values

(“Symbolic values”).

Festo – P.BE-CPX-FB39-EN – 1504NH – English 49

3 Commissioning

3.7 Parameterisation

3.7.1 Introduction to parameterisation

The CPX terminal is supplied with factory-preset parameters (default parameterisation).

The system characteristics of a CPX terminal and of individual modules and channels can be parameter

ized individually. A distinction is made here between the following parameters:

Parameter Description Examples

System parameters Global system functions for the

complete CPX terminal

Module parameters Module and channel-specific functions

of the respective module

Diagnostic memory

parameters

Tab. 3.9

Operating method of the diagnostic

memory

A detailed description of the individual parameters as well as basic principles of applica

tion can be found in the CPX system description (è P.BE-CPX-SYS-...).

Which parameters stand for the modules used are found in the description for the re

spective module.

Caution

If the Modify-LED (M) lights up permanently, the parameterisation is not stored locally in

the bus node and is not restored automatically by the higher-order system upon re

placement.

In these cases, check before replacement to see which settings are required and

carry out these settings.

Changes in parameterisation or application-specific parameter settings result in

changes to the module or system behaviour.

Check especially when replacing CPX terminals to see which settings are necessary

and make sure that these are restored, if necessary (e.g. by appropriate system-

start parameterisation).

– Short-circuit monitoring

– System start

– Input debounce time

– Signal extension time

– Remaining entries with Power ON

– Error number filter

Warning

The connected actuators can move unexpectedly!

Modification of the signal statuses and parameters can trigger dangerous movements of

the connected actuator technology.

Make sure that nobody is in the positioning range of connected actuators, and be

very careful with the parameterisation or manipulation of signal statuses.

Always note the instructions relating to “Force”, “Idle Mode”and “Fail Safe”in the

CPX system description (è P.BE-CPX-SYS-…), in the description for the CPX-MMI

(è P.BE-CPX-MMI-1-…) and in the online help for the CPX-FMT.

50 Festo – P.BE-CPX-FB39-EN – 1504NH – English

3 Commissioning

3.7.2 Prerequisite for parameterization

Please Note

A CPX terminal can be parameterised only if the function “System start with default

parameterisation and current CPX expansion” is activated.

Set the system parameter “System start”accordingly.

With the system parameter “System start”, you can define the starting characteristics of the CPX ter

minal.

Factory settings are used unless parameterization is altered.

Select the setting “System start with default parameterization and current CPX expansion”to permit

the required parameterization.

To conduct the parameterization, use the Festo Maintenance Tool (CPX-FMT) software or the control

device (CPX-MMI).

After parameterization, change the setting of the system parameter “System start”to “System start

with stored parameterization and stored CPX expansion”to define the settings and to save them in

the module.

After a reboot of the CPX terminal, the Modify-LED (M) lights up continuously on the bus node. The

terminal uses the saved parameter settings.

Caution

If the Modify-LED (M) is lit continuously, the parameterization during replacement is not

set up automatically by the higher-level controller.

In such cases, examine before replacement which settings are required and imple

ment them.

3.7.3 Methods of parameterisation

A CPX terminal with the bus node CPX-FB39 can be parameterised with various methods.

Method Benefits Disadvantages

Festo Maintenance Tool

(CPX-FMT)

Menu-guided parameter

entries via PC software

Operator unit (CPX-MMI)

Menu-guided parameter

entry

Easy parameter entry guided by

menu in plain text.

Easy parameter entry guided by

menu in plain text.

Parameterisation is saved locally

in the CPX terminal and is lost if

the CPX terminal or bus node is

replaced.

Parameterisation is saved locally

in the CPX terminal and is lost if

the CPX terminal or bus node is

replaced.

Sercos III Parameterisation can be carried

out via the control system.

The controller must support the

configuration via SDDML files.

Tab. 3.10

Festo – P.BE-CPX-FB39-EN – 1504NH – English 51

3 Commissioning

3.7.4 Parameterisation via the Festo Maintenance Tool (CPX-FMT) software

With the Festo Maintenance Tool (CPX-FMT) software, a CPX terminal can be parameterized via a USB or

Ethernet connection.

Please Note

To run the software on the bus node via a USB connection, you need a USB connector

cable and the USB adapter NEFC-M12G5-0.3-U1G5.

The current version of the Festo Maintenance Tool (CPX-FMT) software is available for

download in the Festo Support Portal (è www.festo.com/sp).

3.7.5 Parameterization with the control device (CPX-MMI)

With the operator unit (CPX-MMI), a CPX terminal can be parameterised through a menu even without

controller software.

Information on general operation of the operator unit can be found in the corresponding

description (è P.BE-CPX-MMI-1-…).

Please Note

The last parameterisation set or received in the CPX terminal is always valid.

3.7.6 Parameterization via Sercos III

The bus node can be parameterized directly by the controller via Sercos III.

This has the advantage that all parameters are saved in the controller software and auto

matically transferred to the bus node at run-up of the controller.

As a result, parameterisation remains intact if the bus node is replaced.

52 Festo – P.BE-CPX-FB39-EN – 1504NH – English

4 Diagnostics and error handling

4 Diagnostics and error handling

4.1 Summary of diagnostics options

The CPX terminal provides comprehensive and user-friendly options for diagnostics and error handling.

The following options are available, depending on the configuration:

Diagnostic

possibility

LED display The LEDs show directly

Status bits Internal inputs that supply

I/O

diagnostics

interface

Diagnostics via

the operator

unit (CPX-MMI)

Diagnostics

via Sercos III

Tab. 4.1

Brief description Benefits Detailed

Description

configuration errors, hardware

errors, bus errors, etc.

coded common diagnostic

messages.

Bus-independent diagnostic

interface at I/O level, which

enables access to the internal

data of the CPX terminal

(16 inputs and 16 outputs).

Diagnostic information can be

displayed on the operator unit

in a convenient and

menu-driven manner.

Access to all system data of

the CPX terminal over the

network.

Fast “on-the-spot” error

detection

Fast access to error

messages, irrespective of

the module and master.

Detailed error recognition:

the diagnostic data can be

processed further, e.g.

with a PLC user program.

Fast “on-the-spot”

recognition of errors

Detailed error detection Section 4.5

Section 4.2

Section 4.3 and CPX

system description

(è P.BE-CPX-SYS-…)

Section 4.4 and CPX

system description

(è P.BE-CPX-SYS-…)

Operator unit

description

(è P.BE-CPX-MMI-1-…)

Please Note

Note that the available diagnostic information is dependent on the DIL switch settings

on the bus node, (è 2.4.5 Setting of the diagnostic mode (remote I/O)) as well as on

the parameterisation of the CPX terminal.

You can find additional information on general diagnostics of the CPX terminal in the CPX

system description (è P.BE-CPX-SYS-…).

Information on diagnostics of the pneumatics, of the pneumatic interface and of the I/O

module are found in the corresponding descriptions.

Festo – P.BE-CPX-FB39-EN – 1504NH – English 53

4 Diagnostics and error handling

4.2 Diagnostics via LED displays

LED displays for the diagnostics of the CPX terminal are available on the bus node as well as on the

individual modules.

The significance of the LED displays on the electric modules can be found in the descrip

tion for the relevant module.

LED displays on the bus node CPX-FB39

PS

S

PL

SD

TP1

TP2

S

SD

TP1

TP2 M

SF

M

PS

PL

SF

1

2

1 Network-specific LEDs:

– S (green, orange, red)

– SD (green, orange, red)

1)

1)

– TP1 (green)

– TP2 (green)

1) This figure depicts a green LED as an example.

2 CPX-specific LEDs:

– PS (green)

– PL (green)

– SF (red)

– M (yellow)

Fig. 4.1

In the following sections, the different statuses of the LED displays are represented as follows:

LED lights up; LED flashes; LED is out

54 Festo – P.BE-CPX-FB39-EN – 1504NH – English

4 Diagnostics and error handling

4.2.1 Standard operating status

LED display

These LEDs light up green:

operating status

Standard

–S

PS

S

SD

TP1

PL

SF

TP2 M

1) Depending on the data communication or configuration.

–SD

–PS

–PL

These LEDs flash green:

– TP1 and TP2

The yellow LED (M) lights up, flashes or is dark.

The red LED (SF) is dark.

1)

4.2.2 CPX-specific LEDs

PS (power system) – power sensor/logic supply

LED (green) Process Status Significance / error handling

LED

ON

OFF

No error. Operating voltage/

sensor supply applied.

–

illuminated

ON

OFF

LED flashes

ON

OFF

Operating voltage/sensor

supply outside the toler

ance range.

Internal fuse for the operat

ing voltage/sensor supply

has responded.

Eliminate undervoltage.

1. Eliminate short circuit/overload.