Terminal CPX

Bus node CP X-(M)-FB33/34/35

Description

Network protocol

PROFINET IO

548760

en 1407c

[8032733]

Contents and general safety instructions

Original de.......................................

Version en 1407c...................................

Designation P.BE-CPX-PNIO-EN.......................

Order no. 548760..................................

© (Festo AG & Co. KG, 73726 Esslingen, Germany , 2014)

Internet: www.festo.com

E-mail: service_international@festo.com

Reproduction, distribution and utilisation of this document,

as well as the communication of its contents to others

without explicit authorisation, is prohibited. Offenders will

be liable for damages. All rights are reserved, in particular

the right to file patent, utility model or registered design

applications.

Festo P.BE-CPX-PNIO-EN en 1407c English

I

Contents and general safety instructions

PROFIBUS®, PROFIenergy®,PROFINETIO®, PROFIsafe®,SIMATIC®,TORX®,TÜV®and

®

VDE

are registered trademarks of the respective trademark owners in certain countries.

II

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

Ta b le o f co n tents

Intended use VII..........................................................

Target group IX..........................................................

Service IX...............................................................

Notes regarding this description X..........................................

Important user instructions XII..............................................

1. Installation 1-1...................................................

1.1 General instructions on installation 1-3................................

1.2 Electrical connection and display components 1-4.......................

1.3 Mounting and dismounting of the bus node 1-5.........................

1.4 Setting the DIL switches, use of the memory card 1-7.....................

1.4.1 Removing and attaching the cover for DIL switches

and memory card 1-7.......................................

1.4.2 Settingthe DIL switches 1-8...................................

1.4.3 Using the memory card 1-14...................................

1.5 Replacement of the bus node 1-15.....................................

1.6 Connecting to the netwo rk 1-17........................................

1.6.1 General information about PROFINET networks 1-17...............

1.6.2 Overview of connections, network connectors and cables 1-20.......

1.6.3 Network interface of the CPX-FB33 1-24.........................

1.6.4 Network interface of the CPX-M-FB34 1-25.......................

1.6.5 Network interface of the CPX-M-FB35 1-26.......................

1.7 Ensuring the protection class 1-27.....................................

1.8 Power supply 1-28..................................................

2. Commissioning 2-1................................................

2.1 General instructions 2-3.............................................

2.2 Address assignment 2- 5.............................................

2.3 Addressing 2-16....................................................

2.3.1 Basic rules for addressing 2-16................................

2.3.2 Address assignment and addressing after expansion

or conversion 2-18...........................................

Festo P.BE-CPX-PNIO-EN en 1407c English

III

Contents and general safety instructions

2.4 Instructions for commissioning with Siemens SIMATIC STEP 7 2-19...........

2.5 Preparing for commissioning 2-21......................................

2.5.1 Import device master file (GSDML) and symbol files 2-21...........

2.5.2 Select GSDML file (compatibility table) 2-23......................

2.5.3 Setting up automation project 2-24.............................

2.5.4 Setting up the controller system (PLC/Master) 2-25................

2.5.5 Install GSDML file 2-27.......................................

2.6 Basic hardware configuration 2-28.....................................

2.6.1 Localise and identify CPX terminal in the network 2-28..............

2.6.2 Select CPX terminal (station selection) 2-30......................

2.6.3 Assign “Device Name” 2-33...................................

2.6.4 Set up Prioritized Start-up (“Fast Start-up”) 2-35..................

2.6.5 Assigning or changing IP address 2-39..........................

2.6.6 Use MAC addressing 2-42.....................................

2.6.7 Determine port addresses 2-42................................

2.7 CPX-terminal configuration 2-43.......................................

2.7.1 Allocate configuration table (insert bus nodes and modules) 2-43....

2.7.2 Modify I/O address 2-47......................................

2.7.3 Modify diagnostics address 2-47...............................

2.8 Parameterisation 2-49...............................................

2.8.1 Start parameterisation during switch-on (system start) 2-51.........

2.8.2 Parameterisation of the CPX terminal with Siemens STEP 7 2-52......

2.8.3 Parameterisation with the operator unit 2-56.....................

2.8.4 Parameterisation through the Festo Maintenance Tool 2-56..........

2.8.5 Bus node parameters 2-57....................................

2.8.6 Application example for the parameterisation 2-60................

2.9 Identification & Maintenance 2-61......................................

2.10 Configuration in the Remote Controller operating mode 2-64................

2.11 Checklist for commissioning the CPX terminal 2-66........................

IV

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

3. Diagnostics 3-1...................................................

3.1 Overview of Diagnostic Functions 3-3..................................

3.2 Diagnostics via LEDs 3-5............................................

3.2.1 Network status/network error – LED NF,

Maintenance/PROFIenergy – LED M/P,

connection status – LEDs TP1, TP2 3-7..........................

3.2.2 CPX terminal status – LEDs PS, PL, SF, M 3-9.....................

3.3 Diagnostics via status bits 3-12........................................

3.4 Diagnostics via the I/O diagnostic interface (STI) 3-13.....................

3.5 Diagnostics via PROFINET 3-14........................................

3.5.1 Basic information 3-14........................................

3.5.2 Online diagnostics with Siemens STEP 7 3-17.....................

3.5.3 User-specific diagnostics with Siemens STEP 7 3-19................

A. Technical appendix A-1.............................................

A.1 Technical data, bus node CPX-FB33 A-3................................

A.2 Technical data, bus node CPX-M-FB34 A-4..............................

A.3 Technical data, bus node CPX-M-FB35 A-5..............................

A.4 Network-specific technical data

bus node CPX-FB33, CPX-M-FB34 and CPX-M-FB35 A-6...................

B. Glossary B-1......................................................

B.1 Bus node operating modes B-3.......................................

B.1.1 Remote I/O operating mode B-3...............................

B.1.2 Remote Controller operating mode B-4.........................

B.1.3 Additional function “Prioritized Start-up” (“Fast Start-up”) B-5......

C. Index C-1.........................................................

Festo P.BE-CPX-PNIO-EN en 1407c English

V

Contents and general safety instructions

VI

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

Intended use

The bus nodes documented in this description, CPX-FB33,

CPX-M-FB34 and CPX-M-FB35, are intended only for use as

participants (I/O device) on the Industrial Ethernet system

PROFINET IO.

The bus nodes can be used in three different operating

modes:

–RemoteI/O

– Remote controller

– Remote I/O with additional function “Prioritized Start-

up”, also designated “Fast Start-up” (FSU) or “Fast restart”.

“Fast Start-up” ensures a faster running up of the CPX terminal.

But this additional function has restrictions regarding commissioning and parameterisation Section B.1.3.

The CPX terminal must only be used as follows:

– as intended in industrial environments;

outside of industrial environments, e.g. in commercial and

mixed-residential areas, actions to suppress interference

may have to be taken

– exclusively in combination with modules and components

that are permissible for the respective product variant of

the CPX terminals www.festo.com/catalogue

– in original status without unauthorised modifications;

only the conversions or modifications described in the

documentation supplied with the product are permitted

Festo P.BE-CPX-PNIO-EN en 1407c English

– in perfect technical condition.

VII

Contents and general safety instructions

The limit values specified for pressures, temperatures, electrical data, torques etc. must be observed.

When connected with commercially available components,

such as sensors and actuators, the specified limits for pressures, temperatures, electrical data, torques etc. must be

observed.

Comply with the legal rules and regulations and standards,

rules of the testing organisati o ns and insurance companies

and national specifications applicable for the location.

Warning

Electric shock.

Injury to people, damage to the machine and system.

•

Use for the electrical power supply only PE LV circuits in

accordance with IEC 60204-1 (Protective Extra-Low

Voltage, PELV).

•

Observe the general requirements in accordance with

IEC 60204-1 for PELV circuits.

•

Useonlyvoltagesourcesthatguaranteeareliableelectric disconnection of operating and load voltage in accordance with IEC 60204-1.

•

Always connect the circuits for operating and load

voltage supplies U

EL/SEN,UVAL

and U

OUT

.

Through the use of PELV circuits, protection against electric

shock (protection against direct and indirect contact) is ensured in accordance with IEC 60204-1.

Observe the measures in section 2.11 and section 3.1 whe n

implementing an emergency off or emergency stop function.

VIII

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

Target gro up

This description is intended exclusively for technicians

trained in control and automation technology, who have experience in installation, commissioning, programming and

diagnostics of programmable logic controllers (PLC) and fieldbus systems.

Service

Please consult your local Festo repair service if you have any

technical problems.

Festo P.BE-CPX-PNIO-EN en 1407c English

IX

Contents and general safety instructions

Notes regarding this description

This description contains information

about the following modules:

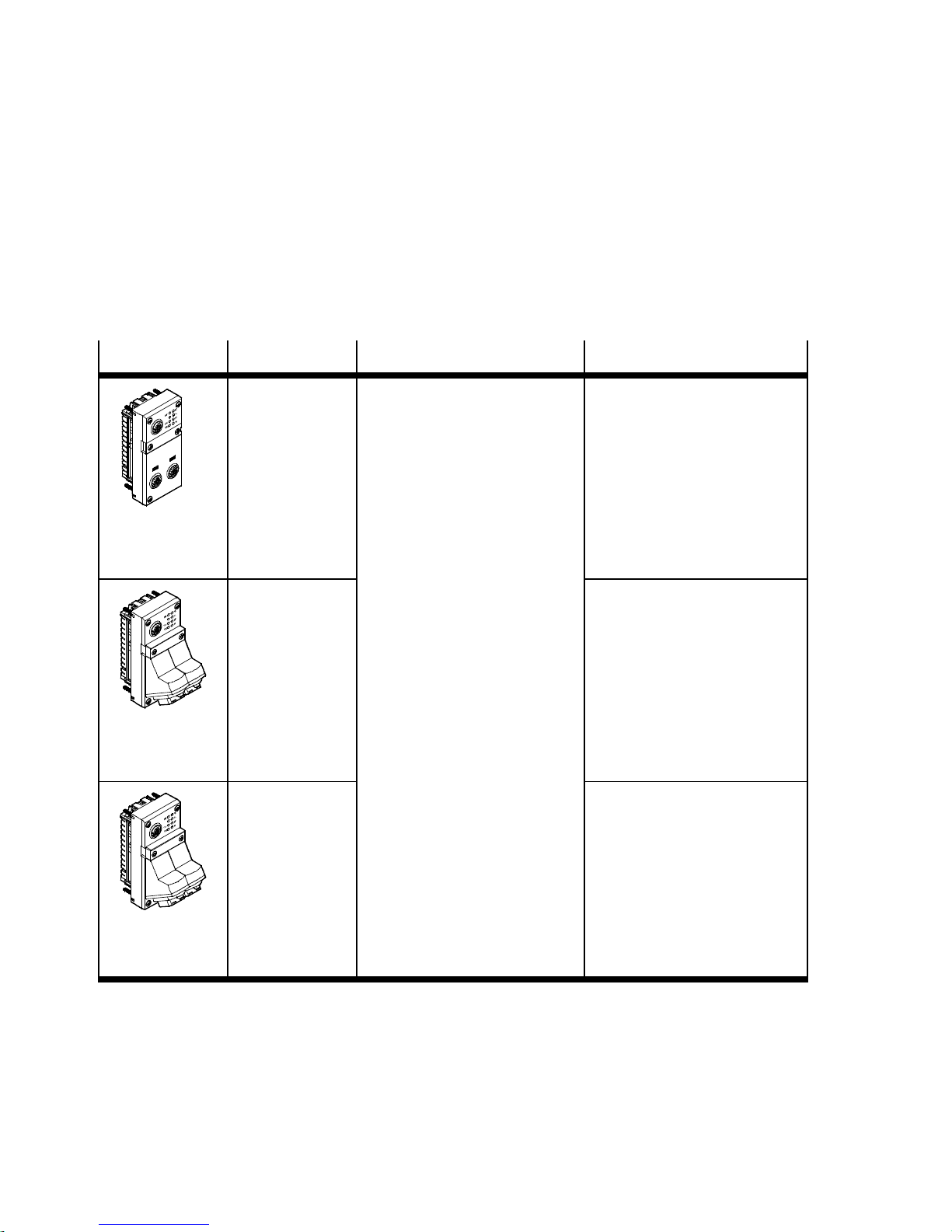

Bus node

Type code Brief description Connection technology

CPX-FB33 Bus node for PROFINET IO

The PROFINET fieldbus technology uses the Ethernet

standard and TCP/I P protocol

for real-time communication in

an industrial environment.

Data transmission:

CPX-M-FB34 2 x RJ45 socket, push-pull,

CPX-M-FB35 2 x SCRJ socket, push-pull,

–PROFINET,onthebasis

of Industrial Ethernet,

based on the Ethernet protocol (IEEE 802.3), realtime-capable

– Switched Fast Ethernet,

100 Mbit/s.

Selection of directives, standards and norms regarding

PROFINET:

– PROFINET installation

guidelines

– IEC 61158

– IEC 61784

– IEC 61918.

2xM12socket,

D-coded, 4-pin,

corresponding to IEC 61076-2

AIDA-compliant,

corresponding to IEC 60603,

IEC 61076-3

650 nm wavelength, suitable

for POF fibre-optic cable,

AIDA-compliant,

correspondi n g to IEC 61754-24

Tab. 0/1: Bus node for PROFINET – overview

X

Additional information:

www.profinet.com

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

This description includes information about installation and

configuration of the bus node for PROFINET as well as

PROFINET-specific information regarding parameterisation,

commissioning, programming and diagnostics of a CPX terminal in a PROFINET network.

Further information about PROFINET can be obtained in the

Internet:

www.profinet.com

Observe in particular the following data:

– PROFINET installation guidelines

(“PROFIN ET Installation Guide”,

“Installation Guideline PROFINET Part 2…”).

General, basic information on PROFINET can be found in the

following document:

– “PROFINET System Description

T echnology and Application”.

General basic information about the mode of operation, assembly, installation and commissioning of CPX terminals can

be found in the CPX system description (P.BE-CPX-SYS...).

Information about additional CPX modules can be found in

the description for the respective module.

An overview of the structure of the CPX terminal User Documentation can be found in the CPX system description

(P.BE-CPX-SYS...).

Festo P.BE-CPX-PNIO-EN en 1407c English

Product-specific information about the control system (IPC,

PLC or I/O controller) can be found in the manufacturer’s

product documentation accompanying the product.

XI

Contents and general safety instructions

Important user instructions

Danger categories

This description includes instructions on the possible dangers

which can occur if the product is used incorrectly. These instructions are marked with a signal word (Warning, Caution,

etc), printed on a shaded background and marked additionally with a pictogram.

A distinction is made between the foll owing danger warnings:

Warning

... means that failure to observe this instruction may result

in serious personal injury or material damage.

Caution

... means that failure to observe this instruction may result

in personal injury or material damage.

Note

... means that failure to observe this instruction may result

in material damage.

In addition, the following pictogram marks passages in the

text which describe activities with electrostatically sensitive

devices:

XII

Electrostatically sensitive devices: Incorrect handling may

cause damage to components.

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

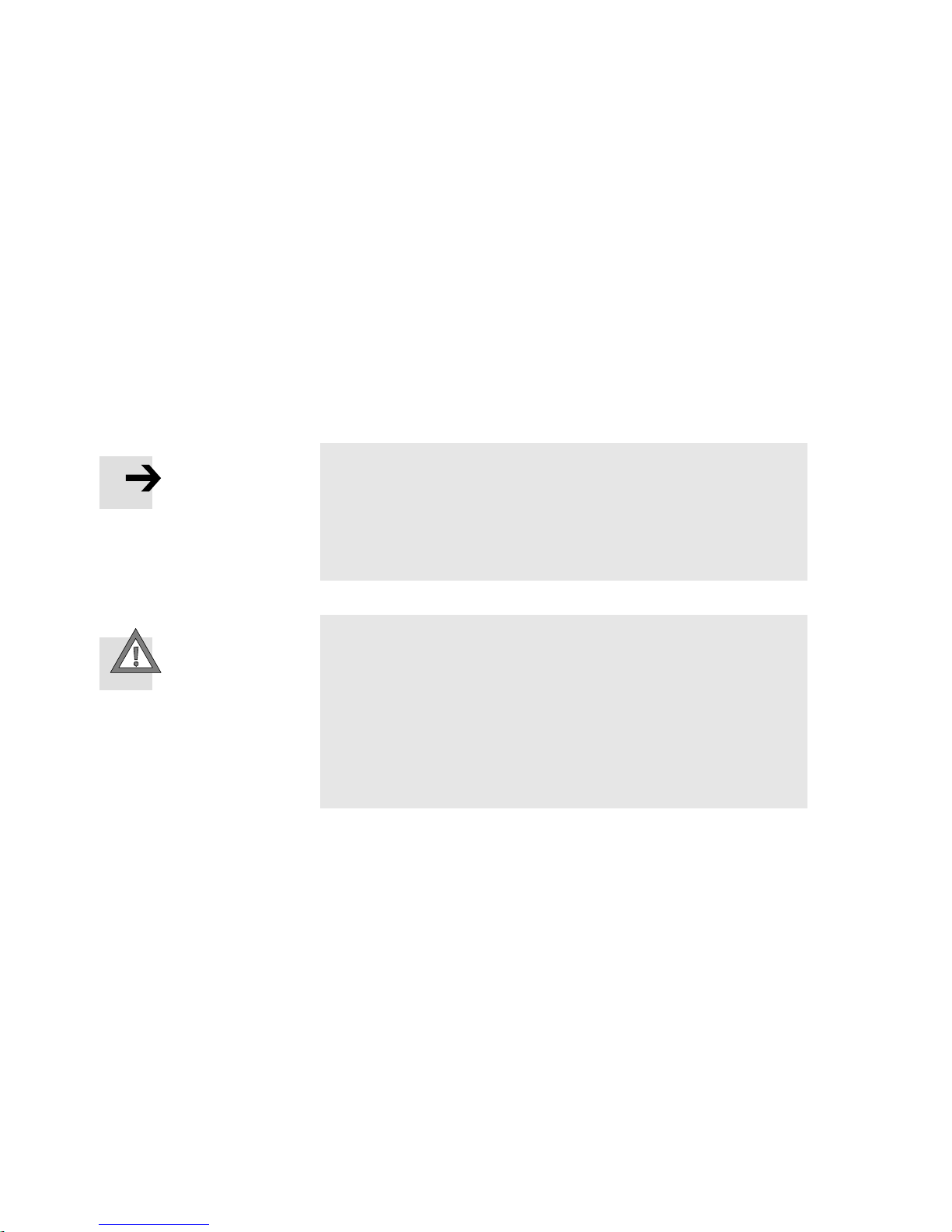

Identification of special information

The following pictograms mark passages in the text which

contain special information.

Pictograms

Information:

Recommendations, tips and references to other information

sources.

Accessories:

Information about necessary or useful accessories for the

product from Festo.

Environment:

Information on the environmentally friendly use of Festo

products.

Text designations

•

Bullet points denote activities that may be carried out in

any sequence.

1. Numerals label activities that must be carried out in the

sequence specified.

– Arrowheads indicate general lists.

Festo P.BE-CPX-PNIO-EN en 1407c English

XIII

Contents and general safety instructions

The following product-specific terms and abbreviations are

used in this manual:

T erm/abbreviation

A Digital output

A0

h

AB Output byte

AIDA Automation Initiative of German Domestic Automobile Manufacturers

Auto-MDI Auto-MDI designates the capability of automatically recognising the

Bus node Create the connection to certain networks or fieldbuses; pass on

CEC Control block, e.g. CPX-CEC/CPX-CEC..., usable for configuration,

CoDeSys Controller Development System

Significance

Hexadecimal numbers are identified by a subscript “h”

(Automatisierungsinitiative Deutscher Automobilhersteller)

circuitry of the transmitting and receiving lines or of the c onnected

device and to adjust to it (also designated “Crossover detection” or

“Auto-crossover”)

control signals to the connected modules and monitor their functioning

commissioning and programming of various components and

equipment from Festo

CP Compact Performance

CPX modules Collective term for the electrical modules which can be integrated into

a CPX terminal; CPX modules form the “electric” side of the CPX

terminal

CPX terminal Installation system comprising CPX modules with or without valve

terminal (pneumatics modules)

DIL dual in-line

DIL switches Miniature switch that consists of several switching elements, with

which, for example, basic settings can be made

Tab. 0/2: Specific terms and abbreviations – part 1

XIV

Festo P.BE-CPX-PNIO-EN en 1407c English

Contents and general safety instructions

T erm/abbreviation Significance

FEC Control block, e.g. CPX-FEC, usable as:

– stand-alone system controller (PLC, Stand Alone operating mode)

– system controller ( PLC, Remote Controller operating mode)

– fieldbus slave (Remote I/O operating mode)

FMT Festo Maintenance Tool (CPX-FMT); c onfiguration and programming

software for CPX modules for commissioning and service purposes

FO Fibre-optic cable (FOC, fibre optics)

FOC Fibre-optic cable

FSU “Fast Start-up”, also designated “Prioritized Start-up” or “Fast

Restart”; further information can be found in section B.1.3

I Digital input

IB Input byte

I/O modules Collective term fo r the CPX modules which provide digital inputs and

outputs

I/Os Digital inputs and outputs

IPC Industrial PC

MAC address Permanently assigned hardware address (“physical address”) for

Ethernet network devices or network adapters – for unique

identification in the worldwide computer network (Media Access

Control address)

MDI Medium Dependent Interface

MMI User interface (Man-Machine Interface)

Operator unit (CPX-MMI) Operator unit (CPX-MMI) for CPX modules for commissioning and

service purposes, also designated as “Handheld”

PLC Programmable logic controller, also designated system controller or

controller for short (see also SPS)

PLC Programmable Logic Controller (German: Speicherprogrammierbare

Tab. 0/3: Specific terms and abbreviations – part 2

Festo P.BE-CPX-PNIO-EN en 1407c English

Steuerung (SPS))

XV

Contents and general safety instructions

T erm/abbreviation Significance

Pneumatic interface The pneumatic interface (port pattern) is the interface between the CPX

modules and the pneumatics modules ( Valve terminal); the

pneumatic interface serves to connect the valve terminal pneumatics to

the CPX terminal; it creates the mechanical connection between the

electric and pneumatic side and ensures transmission of the electric

signals; the pneumatic interface counts functionally as on the “electric”

side of the CPX terminal

Pneumatic m odules Collective term for the pneumatic modules which can be integrated into

aCPXterminal( Valve terminal); pneumatic modules form the

“pneumatic” side of the CPX terminal

POF Polymeric Optical Fibre (also called Plastic Optical Fibre)

Prioritized Start-up “Prioritized Start-up”, also designated “Fast Start-up” (FSU) or “Fast

Restart”; further information can be found in section B.1.3

PROFIenergy PROFIenergy makes energy management settings possible;

for more extensive information www.profinet.com

PROFINET IO Fieldbus system based on Industrial Ethernet for data exchange

between system controller (PLC/IPC), system controller (e.g. CPX-FEC)

and field devices (I/O devices) or drives and valve terminals; for more

extensive information www.profinet.com

PROFINETIO IRT Profinet IO in the version with isochronous real-time protocol

(typ. cycle time: < 1 ms; typ. application: drive control)

PROFINET IO RT Profinet IO in the version with real-time protocol

(typ. cycle time: 10 ms; typ. application: production control)

PROFIsafe PROFIsafe makes possible shared transmission of operating

components of a reliable control and process control on the same

network; for more extensive information www.profinet.com

STI I/O diagnostic interface (System Table Interface)

Valve terminal Electromagnetic valves with shared power supply, air supply and

control; the valves and pneumatic components on the right side of the

pneumatic interface together form the valve terminal pneumatics

Tab. 0/4: Specific terms and abbreviations – par t 3

XVI

Festo P.BE-CPX-PNIO-EN en 1407c English

Installation

Chapter 1

Installation

Festo P.BE-CPX-PNIO-EN en 1407c English

1-1

1. Installation

Ta b le o f c o n tents

1. Installation 1-1...................................................

1.1 General instructions on installation 1-3................................

1.2 Electrical connection and display components 1-4.......................

1.3 Mounting and dismounting of the bus node 1-5.........................

1.4 Setting the DIL switches, use of the memory card 1-7.....................

1.4.1 Removing and attaching the cover for DIL switches

and memory card 1-7.......................................

1.4.2 Settingthe DIL switches 1-8...................................

1.4.3 Using the memory card 1-14...................................

1.5 Replacement of the bus node 1-15.....................................

1.6 Connecting to the network 1-17........................................

1.6.1 General information about PROFINET networks 1-17...............

1.6.2 Overview of connections, network connectors and cables 1-20.......

1.6.3 Network interface of the CPX-FB33 1-24.........................

1.6.4 Network interface of the CPX-M-FB34 1-25.......................

1.6.5 Network interface of the CPX-M-FB35 1-26.......................

1.7 Ensuring the protection class 1-27.....................................

1.8 Power supply 1-28..................................................

1-2

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.1 General instructions on installation

Warning

Before carrying out installation and maintenance work,

switch off the following:

– compressed air supply

– operating voltage supply for the electronics/sensors

– the load voltage supply for the outputs/valves.

In this way, you can avoid:

– uncontrolled movements of loose tubing

– accidental movements of the connected actuator techno-

logy

– undefined switching states of the electronics.

Caution

The bus node includes electrostatically sensitive devices.

•

Therefore, do not touch any components.

•

Observe the handling specifications for electrostatically

sensitive devices.

By doing so, you avoid malfunctions of and damage to the

electronics.

Information about mounting of the CPX terminal can be found

in the CPX system description (P.BE-CPX-SYS-..).

Festo P.BE-CPX-PNIO-EN en 1407c English

1-3

1. Installation

1.2 Electrical connection and display components

You wi l l find the following connection and display components on the bus node for PROFINET:

1

4

3

2

CPX-FB33 CPX-M-FB34

1

PROFINET-specific network/bus status

LEDs and CPX-specific LEDs

2

Mains connection

CPX-FB33: 2xM12socket,

D-coded, 4-pin

CPX-M-FB34: 2 x RJ45 socket,

Push-pull,

AIDA-conforming

CPX-M-FB35: 2 x SCRJ-Buchse,

Push-pull,

AIDA-conforming

2

55 1

4

3

2

CPX-M-FB35

3

Cover for DIL switch and memory card

4

Service interface

for operator unit (CPX-MMI; V24 interface) und USB adapter (for CPX-FMT)

5

Label with MAC-ID and CPX revision

code (“Rev ...”)

2

Fig. 1/1: Connection and display components on the bus node for PROFINET

1-4

Note

Use cover caps to seal unused connections ( Section 1.7).

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.3 Mounting and dismounting of the bus node

Warning

Electric shock

Injury to people, damage to the machine and system

– Switch supply power off before assembly work.

Note

Material damage due to incorrect mounting

•

Select screws that are suitable for the material of the

interlinking block:

– plastic: thread-cutting tapping screws

– metal: screws with metric thread.

When ordering a single bus node, all required screws are

supplied.

Mounting Mount the bus node as follows:

1. Check seal and seal surfaces. Replace damaged parts.

2. Push the bus node carefully and without tilting into the

interlinking block up to the stop ( Fig. 1/2).

3. Turn the screws into the existing thread.

4. Tighten the screws in diagonally opposite sequence.

Tightening torque: 0.9 ... 1.1 Nm.

Festo P.BE-CPX-PNIO-EN en 1407c English

1-5

1. Installation

1

Bus node

(example CPX-FB33)

2

Interlinking block

1

3

Screws

Fig. 1/2: Mounting/dismounting the bus node

Dismounting Dismount the bus node as follows:

1. Unscrew screws.

2. Pull the bus node without tilting out of the interlinking

block.

2

3

1-6

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.4 Setting the DIL switches, use of the m emory card

In order to make the settings for the bus node and to change

the memory card, you must first remove the cover for the DIL

switches.

Caution

The bus node includes electrostatically sensitive devices.

•

Therefore, do not touch any components.

•

Observe the handling specifications for electrostatically

sensitive devices.

By doing so, you avoid malfunctions of and damage to the

electronics.

1.4.1 Removing and attaching the cov er for DIL switches and memory card

You need a screwdriver in order to remove or attach the cover .

Note

Observe the following notes when removing or attaching

the cover:

•

Switch off the power supply before removing the cover.

•

Make sure that the seal is seated correctly when attaching the cover!

•

Tighten the two fastening screws at first by hand and

then with max. 0.4 Nm.

Festo P.BE-CPX-PNIO-EN en 1407c English

1-7

1. Installation

1.4.2 Settingthe DIL switches

You can set the following parameters with the DIL switches

under the cover (see Fig. 1/3):

– bus node operating mode

– diagnostics mode (remote I/O operating mode only)

– data field size (only in remote controller operating mode).

Approach:

1. Switch off the power supply.

2. Remove the co ver (see section 1.4.1).

3. Carry out the required settings

(see Tab. 1/1, Tab. 1/2 and Tab. 1/4).

4. Install the cover again

(see section 1.4.1).

Note

•

Make sure that the seal is seated correctly.

1

DILswitch1.1+1.2:

bus node operating mode

2

DIL switches 2.1 + 2.2:

diagnostics mode (only in remote I/O operating

mode);

data field size (only in remote controller

operating mode)

12

3

3

Memory card

(see section 1.4.3, 1.5 as well as 2.6.3 and 2.8.1)

Fig. 1/3: Settings of the DIL switches in the bus node

1-8

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

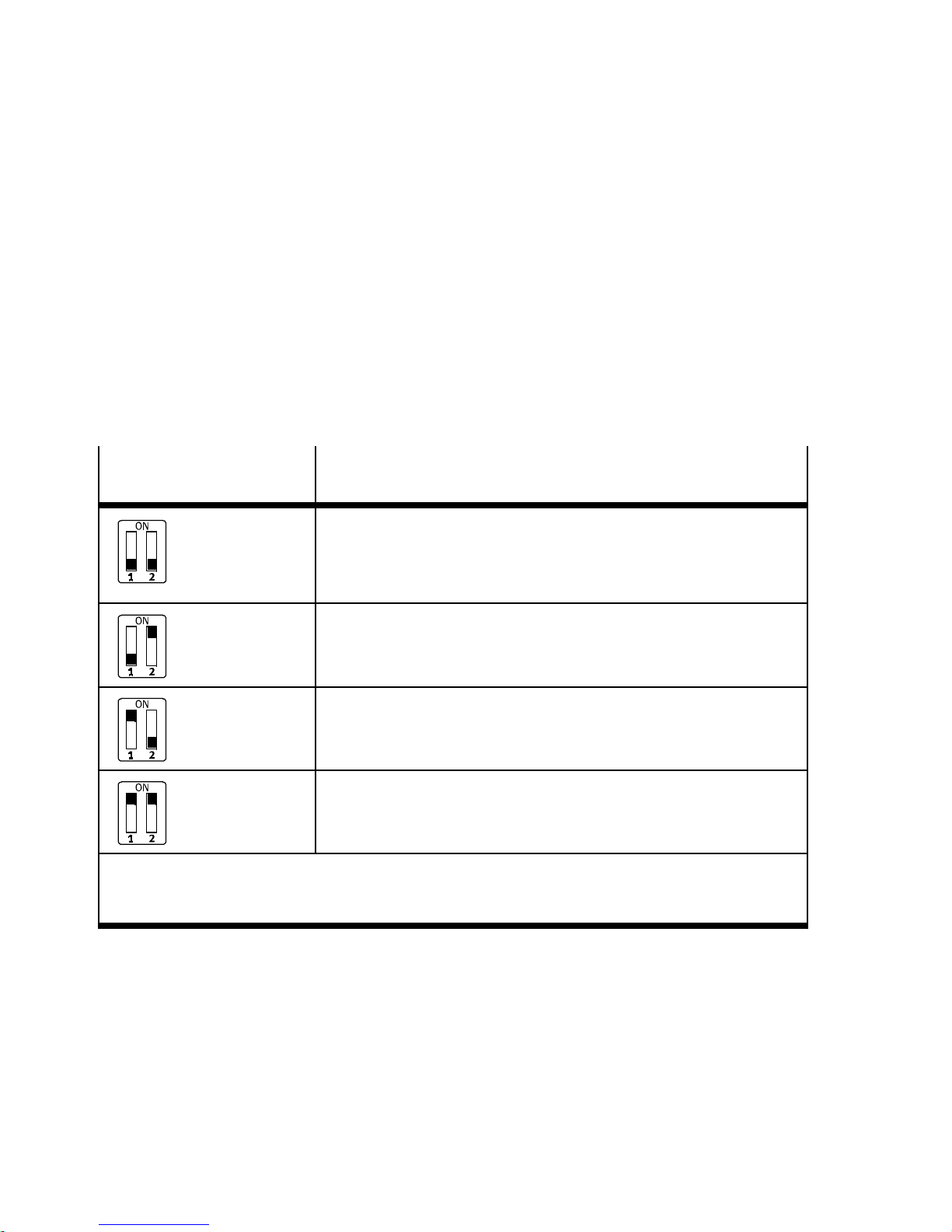

DIL switch

1

DIL 1.1: OFF

DIL 1.2: OFF

(Factory setting)

DIL 1.1: ON

DIL 1.2: OFF

Setting the operating mode with DIL switch

1

You can set the operating mode of the bus node with switch

1

element 1.1 of DIL switch

(see Tab. 1/1):

– remote I/O operating mode

– remote controller operating mode.

Set bus node operating mode

Remote I/O operating mode

All functions of the CPX terminal are controlled directly by the

PROFIN ET-I/O controller or a higher-level PLC.

The bus node undertakes the required connection to PROFINET.

Operating mode Remote Controller

Requirement:

A control block CPX-FEC or CPX-CEC is a component of the CPX

terminal.

The CPX-FEC or CPX-CEC control block integrated into the terminal

controls all functions of the CPX terminal, i.e. the control block takes

on the I/O control.

The bus node takes over the additional connection to PROFI N ET.

Tab. 1/1: Setting the bus node operating mode with DIL switch

Further explanations of the bus node operating mode can be

found in section B.1:

– remote I/O operating mode Section B.1.1

– remote controller operating mode Section B.1.2

– additional function “Fast Start-up” (FSU) Section B.1.3.

1

Festo P.BE-CPX-PNIO-EN en 1407c English

1-9

1. Installation

In the remote I/O operating mode:

setting the diagnostics mode with DIL switch

2

DIL switch

2

DIL 2.1: OFF

DIL 2.2: OFF

(factory setting)

DIL 2.1: OFF

DIL 2.2: ON

DIL 2.1: ON

DIL 2.2: OFF

The function of the DIL switch

the DIL switch

1

or the set operating mode of the CPX ter-

2

depends on the setting of

minal ( Tab. 1/1):

The diagnostics mode is set with DIL switch

2

in the remote

I/O operating mode ( Tab. 1/2).

Set diagnostics mode:

(in the remote I/O operating mode)

I/O diagnostics interface and status bits are switched off or

diagnostics mode is set via the hardware configuration of the

configuration software

(+ 0 byte I / 0 byte O)

Status bits are switched on

(+ 1 Byte E / 0 Byte A)

I/O diagnostics interface is switched on

(+2bytesI/2bytesO)

3)

1)

2)

DIL 2.1: ON

DIL 2.2: ON

1)

Diagnostics mode status bits occupy 1 byte of address spac e (8 I bits)

2)

Diagnostics mode I/O diagnostics interface occupies 4 bytes of address space (16 I and 16 O bits)

3)

From Revision 21

Tab. 1/2: Setting the diagnostics mode with DIL switch

1-10

Reserved for future extensions

2

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

Note

(1) Diagnostics mode reduces the available address space

Use of the diagnostics mode (status bits or I/O diagnostics

interface) occupies 8Ior 16 I/O bits and thus reduces the

number of I/O bits which are available for module communication. In this way, the number of addressable modules

is reduced in favour of additional status or diagnostic information.

T ake account of this fact for the planning of your CPX terminal.

(2) Subsequent activation changes configuration

During subsequent activation of the diagnostics mode

(status bits or I/O diagnostics interface), the CPX-internal

I/O illustration or address allocation can be shifted.

The system controller carries out this adjustment automat-

ically. Manual manipulation, e.g. a reconfiguration of the

CPX terminal or manual adaptation of the hardware and

network configuration, are not required.

Assignment of the I/O addresses and diagnostics addresses can be changed as needed.

T o do this, repeat the hardware and network configuration

in your configuration and programming software (e.g.

Siemens SIMATIC STEP 7), especially the assignment of the

inputs and outputs (see section 2.7.1 and section 2.7.2).

(3) Setting the diagnostics mode via the h ardware configuration

Starting with Revision 21, the diagnostics mode can be set

via the hardware configuration. The available address

space thereby remains intact: The number of I/O bits is not

reduced; the I/O bits are available for module communication without restriction.

Festo P.BE-CPX-PNIO-EN en 1407c English

Set the DIL switch

2

to the factory setting for this purpose (see Tab. 1/2). Parameterise the diagnostics mode

via the hardware configuration.

1-11

1. Installation

Note

The DIL switch settings for operating mode and diagnostics mode must match the bus node selection in the

context of a PLC hardware and network configuration (see

Tab. 1/3 and section 2.6.2).

1

2

3

Operating mode

of the bus node

Remote I/O Without

Remote controller – – CPX RC CPX-RC-FO

1) CPX Rev 18, CPX-FO Rev 18, CPX FSU Rev 18 or CPX-FO FSU Rev 18 for bus node with CPX revision

code Rev 12 … Rev 18

Diagnostics

mode

[Mode

identification]

diagnostics 1

Status bits

[Status] 2

I/O diagnostics

interface

[STI] 3

Additional

function

Fast start-up

(FSU)

No CPX

Yes, with FS U CPX FSU

No CPX

Yes, with FS U CPX FSU

No CPX

Yes, with FS U CPX FSU

Field device group

(station symbol)

FB33 (M12),

FB34 (RJ45)

1)

1)

1)

FB35 (SCRJ)

CPX-FO

1)

1)

1)

CPX-FO FSU

CPX-FO

CPX-FO FSU

CPX-FO

CPX-FO FSU

1)

1)

1)

1)

1)

1)

T ab. 1/3: Bus node selection (station symbol or field device group) dependent on

operating mode, diagnostics mode and additional function FSU

1-12

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

In the remote controller operating mode:

setting the data field size with DIL switch

2

DIL switch

2

The function of the DIL switch

the DIL switch

1

or the set operating mode of the CPX ter-

2

depends on the setting of

minal ( Tab. 1/1):

The required data field size is set with DIL switch

2

in the

remote controller operating mode ( Tab. 1/4).

Note

Observe that the data field size set with the DIL switch 2

( Tab.1/4)mustbethesamesizeorlargerthanthedata

field size, which you set in your control system.

Further explanations about the remote controller operating

modecanbefoundinsection2.10andB.1.2.

Set data field size

(in the remote controller operating mode)

DIL 2.1: OFF

DIL 2.2: OFF

(factory setting)

DIL 2.1: OFF

DIL 2.2: ON

DIL 2.1: ON

DIL 2.2: OFF

DIL 2.1: ON

DIL 2.2: ON

Tab. 1/4: Setting the data fiel d size with DIL switch

Festo P.BE-CPX-PNIO-EN en 1407c English

Maximum data field size:

8bytesI/8bytesO

Maximum data field size:

16 bytes I/16 bytes O

Reserved for future extensions

Reserved for future extensions

2

1-13

1. Installation

1.4.3 Using the memory card

The memory card is used as a carrier of configuration data for

PROFINET addressing and thus simplifies bus node replacement:

–PROFINETI/Odevicename

– IP address.

Note

Data stored on the card have priority over other configuration data which are stored, e.g. in the bus node memory or

in the controller system (see also section 2.8.1, sequence

of the start parameterisation with memory card).

Replacing

the memory card

Caution

Risk of malfunctions or damage.

Inserting or removing the memory card while the power

supply is switched on can result in malfunctions of or damage to the memory card.

•

Disconnect the power supply before you insert or

remove the memory card.

The memory card is under a cover (see Fig. 1/1). You need a

screwdriver in order to remove or attach this cover.

1-14

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.5 Replacement of the bus node

Easy replacement using memory card

The memory card is used as a carrier of configuration data,

e.g. of the fieldbus device name, i.e. of the PROFI N ET I/O

device name. Thus, a bus node can be conveniently replaced.

Note

Check the start behaviour of the CPX terminal

before replacing the bus node.

If the Modify LED (M) lights up or flashes permanently

after the system start, “System start with saved parameterisation and saved CPX expansion” is set or “Force” is

active.

For CPX terminals with a permanently lit or flashing M-LED,

the parameterisation at replacement of the bus node or

CPX terminal during servicing is not automatically created

by the higher-level system.

In this case, verify which settings are required before replacement and restore these settings after replacement.

Caution

Risk of malfunctions or damage.

Inserting or removing the memory card while the power

supply is switched on can result in malfunctions of or damage to the memory card.

•

Disconnect the power supply before you insert or remove the memory card.

Festo P.BE-CPX-PNIO-EN en 1407c English

1-15

1. Installation

Bus node replacement with memory card:

1. Switch off the power supply.

2. Remove the co ver

(see section 1.4.1).

3. Remove the memory card from the bus node.

4. Replace the bus node (mounting/dismounting: see section 1.1).

5. Insert the memory card in the new bus node.

6. Install the cover again

(see section 1.4.1).

7. Switch the power supply back on.

8. Start the automation program if necessary.

9. The controller recognises the bus node using the device

name on the memory card and loads all required data.

Bus node replacement without memory card:

1. Switch off the power supply.

2. Replace the bus node (mounting/dismounting: see section 1.1).

3. Switch the power supply back on.

4. S tart your configuration and programming software (e.g.

Siemens STEP 7).

5. Perform a new configuration (hardware configuration, in

STEP 7 using HW Config).

1-16

6. The controller loads all required data into the bus node.

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.6 Connecting to the network

1.6.1 General information about PROFINET networks

Note

Subassemblies with PROFINET interfaces may only be operated in networks where all connected network components are supplied with PELV power supplies or integrated

power supplies with similar protection.

Installation guidelines

Observe the installation guidelines of the PROFINET user organisation (PNO):

www.profibus.com/download/

Note

Unauthorised access to the device can cause damage or

malfunctions.

When connecting the device to a network:

•

Protect your network from unauthorised access.

Measures for protecting the network include:

– firewall

– Intrusion Prevention System (IPS)

– network segmentation

–virtualLAN(VLAN)

Festo P.BE-CPX-PNIO-EN en 1407c English

– virtual private network (VPN)

– security at physical access level (Port Security).

For further information, please refer to the guidelines and

standards for security in information technology, e.g.

IEC 62443, ISO/IEC 27001.

1-17

1. Installation

An access password protects only against accidental

changes.

1-18

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

Use of switches and routers

The switch integrated in the bus node permits division of the

network into several segments.

With use of additional switches and routers, the network can

be divided into additional segments. Thus, it is possible to

structure the PROFINET network and realize greater network

expansions.

Independent of the network structure, the expansion of a

PROFINET segment must not exceed certain connection

lengths:

– Copper connecting cable:

(Ethernet twisted pair cable, 22 AWG):

max. 100 m between network participants

(PROFINET-End-to-end-Link)

– Optical connecting cable

(POF fibre-optic cable, max. 12.5 dB signal attenuation

over the entire connection length):

max. 50 m PROFINET-End-to-end-Link.

Switches and routers for Industrial EtherCat are available on

the market from various companies. There are many IP20,

IP65 or IP67 components.

– Unmanaged Switches:

for small network solutions with a low network load or

minimal requirements for deterministics

– Managed switches:

for comprehensive network solutions, with diagnostics

and control functions.

Festo P.BE-CPX-PNIO-EN en 1407c English

Note

Make sure that any intermediate switches and routers support the PROFINET function “Fast Start-up” (FSU) when

you use this additional function. Further information on

FSU can be found in section B.1.3.

1-19

1. Installation

Note

PROFINET devices (I/O devices) that are connected over

Industrial Wireless LAN (IWLAN access points)donot support the FSU function.

1.6.2 Overview of connections, network connectors and cables

Note

Faulty installation and high transmission rates may cause

data transmission errors as a result of signal reflections

and attenuations.

Transmission errors can be caused by:

– faulty screened connection

–branches

– transmission over distances which are too long

– unsuitable cables.

Observethecablespecification.

Refer to the manual of your controller for information

about the required type of line or cable.

Bus node

CPX-FB33 2xM12socket,

CPX-M-FB34 2 x Push-pull RJ45 copper,

CPX-M-FB35 2 x SCRJ sockets, push-pull, AIDA-compli-

Connection technology Network connectors

D-coded, 4-pin,

corresponding to IEC 61076-2

AIDA-compliant, corresponding to

IEC 60603, IEC 61076-3

ant, corresponding to IEC 61754-24,

650 nm wavelength, suitable for POF

fibre-optic cable

Plug connector NECU-M-S-D12G4-C2-ET

Plug connector FBS-RJ45-PP-GS

Plug FBS-SCRJ-PP-GS

Tab. 1/5: Overview of connection technolo gy and network plugs

1-20

www.festo.com/catalogue/

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

RJ45 to M12 converter

For PROFINET installations, it may be necessary to change

between RJ45- and M12 connection technology.

Example for use: connections between devices in the switch

cabinet with RJ45 connection and IP65/IP67 devices with

M12 connection.

Cable specification

Use shielded Industrial Ethernet cables of category Cat 5 or

higher. Y ou can find details regarding cable specification in

Tab. 1/6.

Crossover detection The bus nodes for PROFINET support crossover detection

(“Auto-MDI”): Y ou can either use patch cables or crossover

cables for connecting your bus node to a network or PC.

Make sure that the function “Autonegotiation/Autocrossover”

is activated in your controller software if you use patch and

crossover cables in the same system. You will find additional

instructions on this function in section 2.6.4.

Crossover detection is not available in the remote I/O operating mode with additional function “Fast start-up” (FSU):

•

Use only suitable lines.

•

Observe the following note regarding pin allocation of

port TP2.

Festo P.BE-CPX-PNIO-EN en 1407c English

1-21

1. Installation

Note – pin allocation port TP2

Deactivation of the crossover detection changes the pin

allocation of the outgoing port TP2 to “crossover”.

Choose the network line (patch cable or crossover cable)

depending on the pin allocation of the devices connected

to TP2 (I/O devices) Fig. 1/4:

– crossover cables with the same allocation of the ports

– patch cable with different allocation of the ports.

•

Make sure that the function “Autonegotiation/Autocrossover” is deactivated in your control software before pla-

cing the system in operation (see section 2.6.4).

•

If necessary, the function “Autonegotiation/Autocrossover” must also be deactivated on the hardware-side, in the

basic setting of your controller (PLC) or switches or

routers in between: check the port settings for this purpose.

PLC or switch I/O device I/O device

TP1 TP2 TP1 TP2 TP1 TP2

123 3

1

Switch port, e.g. of the PLC

3

Patch cable

2

(“crossover” pin allocation)

2

Terminal port of an I/O device

Fig. 1/4: Wiring of the I/O devices for “Fast start-up” with deactivated “crossover” de-

tection or “autonegotiation” (configuration example)

1-22

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

Bus node +

network

plug

CPX-FB33

+ ...D12G4...

CPX-M-FB34

+ ...RJ45...

Cable specification

– Cable type: Ethernet twisted-pair cable, shielded

– Transmission class

(link class): category Cat 5

– Cable diameter: 6 ... 8 mm

– Wire c ross section: 0.14 ... 0.75 mm

– Connection length: max. 100 m PROFINET-End-to-end-Link

– Cable type: Ethernet twisted-pair cable, shielded

– Transmission class

(link class): category Cat 5

– Cable diameter: 5 ... 8 mm

– Wire c ross section: 0.13 ... 0.36 mm

– Wire/conductor

configuration: 1-wire or 7-wire

– Connection length: max. 100 m PROFINET-End-to-end-Link

1)

(Shielded Twisted Pair, STP)

2

;

22 AWG required for max. connection length

between net wor k participants (PROFINET-End-to-end-Link)

(Shielded Twisted Pair, STP)

2

(Z ca. 26 ... 22 AWG);

22 AWG required for max. connection length

between net wor k participants (PROFINET-End-to-end-Link)

CPX-M-FB35

+ ...SCRJ...

1) Length corresponding to specification for PROFINET networks (PROFINET Installation Guide)

based on ISO/IEC 11801, ANSI/TIA/EIA-568 (see also section 1.6.1)

www.profinet.com, www.profibus.com/download/

– Cable type: fibre-optic cable, polymer-optic fibre

(polymeric/plastic optical fibre, POF)

– cable composition

(core/sheath

diameter): 980/1000 ìm

– Cable diameter: 6.5 ... 9.5 mm

– Connection length: max. 50 m PROFINET-End-to-end-Link

– Signal attenuation: ≤ 12.5 dB

(over the entire connection length)

T ab. 1/6: Overview of line specification (in combination with Festo bus node and Festo

network plug)

Festo P.BE-CPX-PNIO-EN en 1407c English

1-23

1. Installation

Note – strain relief

If the CPX terminal is fitted onto the moving part of a machine, the network cable on the moving part must be

provided with strain relief. Also observe the corresponding

regulations in EN 60204 Part 1.

1.6.3 Network interface of the CPX-FB33

There are two 4-pin, D-coded M12 sockets on the CPX-FB33

for the network connection.

Socket

M12, D-coded

2

1

4

Pin Signal Explanation

3

1

2

3

4

Housing

TD+

RD+

TD–

RD–

Shield/FE

Transmission data (transmit data, TD) +

Receivedata(receivedata,RD)+

Transmitted data –

Received data –

Shield/functional earth (FE)

Tab. 1/7: Pin allocation of the network interfaces of the CPX-FB33 (M12)

Connection with plug from Festo

Connect the CPX terminal to the network with a Festo plug

NECU-M-S-D12G4-C2-ET. The plug is designed for Ethernet

cable with cable diameters of 6 ... ... 8 mm.

To achieve the required degree of protection, e.g. IP65/IP67:

1-24

– Use Festo plugs.

– Seal unused connections (see section 1.7).

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.6.4 Network interface of the CPX-M-FB34

There are two RJ45 push-pull sockets (AIDA-compliant) on the

CPX-M-FB34 for the network connection:

Socket

RJ45, push-pull

456

7

8

Pin Signal Explanation

1

2

3

123

4

5

6

7

8

Housing

TD+

TD–

RD+

n.c.

n.c.

RD–

n.c.

n.c.

Shield/FE

Transmission data (transmit data, TD) +

Transmitted data –

Receivedata(receivedata,RD)+

Not connected

Not connected

Received data –

Not connected

Not connected

Shield/functional earth (FE)

Tab. 1/8: Pin allocation of the network interfaces of the CPX-M-FB34 (RJ45)

Connection with plug from Festo

Connect the CPX terminal to the network with a Festo plug

FBS-RJ45-PP-GS. The plug is designed for Ethernet cable with

cable diameter of 5 ... ... 8 mm.

Festo P.BE-CPX-PNIO-EN en 1407c English

To achieve the required degree of protection, e.g. IP65/IP67:

– Use Festo plugs.

– Seal unused connections (see section 1.7).

1-25

1. Installation

1.6.5 Network interface of the CPX-M-FB35

There are two SCRJ push-pull sockets (AIDA-compliant) on the

CPX-M-FB35 for the network connection:

Socket

SCRJ, push-pull

21

Connection Signal Explanation

1

2

TX

RX

Transmitted data

Received data

Tab. 1/9: Pin allocation of the network interfaces of the CPX-M-FB35 (SCRJ)

Connection with plug from Festo

Connect the CPX terminal to the network with a Festo plug,

FBS-SCRJ-PP-GS. The plug is designed for POF fibre-optic

cable with cable diameter of 6.5 ... 9.5 mm.

To achieve the required degree of protection, e.g. IP65/IP67:

1-26

– Use Festo plugs.

– Seal unused connections (see section 1.7).

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

1.7 Ensuring the protection class

•

Use connection technology with the required degree of

protection ( www.festo.com/catalogue, examples

in Tab. 1/10).

•

Use cover caps to seal unused connections.

Connection

CPX-FB33:

Network connection (M12)

CPX-M-FB34:

Network connection (RJ45)

CPX-M-FB35:

Network connection (SCRJ)

Service interface Connecting cable KV-M12-M12-…

1) Connecting c able for the operator unit (CPX-MMI)

2) Included in scope of delivery

Connection technology Cover cap

Plug connector NECU-M-S-D12G4-C2-ET ISK-M12

Plug connector FBS-RJ45-PP-GS

Plug FBS-SCRJ-PP-GS

1)

CPX-M-AK-C

ISK-M12

2)

2)

Tab. 1/10: Connection technology and cover caps for degree of protection IP65/IP67

(examples)

Festo P.BE-CPX-PNIO-EN en 1407c English

1-27

1. Installation

1.8 Power supply

Warning

Electric shock.

Injury to people, damage to the machine and system.

•

Use for the electrical power supply only PE LV circuits in

accordance with IEC 60204-1 (Protective Extra-Low

Voltage, PELV).

•

Observe the general requirements in accordance with

IEC 60204-1 for PELV circuits.

•

Useonlyvoltagesourcesthatguaranteeareliableelectric disconnection of operating and load voltage in accordance with IEC 60204-1.

•

Always connect the circuits for operating and load

voltage supplies U

EL/SEN,UVAL

and U

OUT

.

Through the use of PELV circuits, protection against electric

shock (protection against direct and indirect contact) is ensured in accordance with IEC 60204-1.

CPX terminals are supplied with operating and load voltage

through interlinking blocks, end plates or bus nodes.

Note

Observe the notes on installation and power supply as well

as potential equalisation (earthing measures) in the CPX

system description (P.BE-CPX-SYS-... Electrical connection) and in the descriptions for the valve terminal used.

1-28

Festo P.BE-CPX-PNIO-EN en 1407c English

1. Installation

Note

The current consumption of a CPX terminal depends on the

number and type of modules and connected components.

Observe the instructions on the maximum permissible

current load in the CPX system description ( Calculation

of current consumption) and in the appendix for the

product “Pin allocation, power supply” (CPX-PIN-BEL- …

Load rating per pin).

Observe the measures in sections 2.11 and 3.1 when implementing an EMERGENCY-OFF function.

Festo P.BE-CPX-PNIO-EN en 1407c English

1-29

1. Installation

1-30

Festo P.BE-CPX-PNIO-EN en 1407c English

Commissioning

Chapter 2

Commissioning

Festo P.BE-CPX-PNIO-EN en 1407c English

2-1

2. Commissioning

Ta b le o f c o n tents

2. Commissioning 2-1................................................

2.1 General instructions 2-3.............................................

2.2 Address assignment 2-5.............................................

2.3 Addressing 2-16....................................................

2.3.1 Basic rules for addressing 2-16................................

2.3.2 Address assignment and addressing after expansion

or conversion 2-18...........................................

2.4 Instructions for commissioning with Siemens SIMATIC STEP 7 2-19...........

2.5 Preparing for commissioning 2-21......................................

2.5.1 Import device master file (GSDML) and symbol files 2-21...........

2.5.2 Select GSDML file (compatibility table) 2-23......................

2.5.3 Setting up automation project 2-24.............................

2.5.4 Setting up the controller system (PLC/Master) 2- 25................

2.5.5 Install GSDML file 2-27.......................................

2.6 Basic hardware configuration 2-28.....................................

2.6.1 Localise and identify CPX terminal in the network 2-28..............

2.6.2 Select CPX terminal (station selection) 2-30......................

2.6.3 Assign “Device Name” 2-33...................................

2.6.4 Set up Prioritized Start-up (“Fast Start-up”) 2-35..................

2.6.5 Assigning or changing IP address 2-39..........................

2.6.6 Use MAC addressing 2-42.....................................

2.6.7 Determine port addresses 2-42................................

2.7 CPX-terminal configuration 2-43.......................................

2.7.1 Allocate configuration table (insert bus nodes and modules) 2-43....

2.7.2 Modify I/O address 2-47......................................

2.7.3 Modify diagnostics address 2-47...............................

2.8 Parameterisation 2-49...............................................

2.8.1 Start parameterisation during switch-on (system start) 2-51.........

2.8.2 Parameterisation of the CPX terminal with Siemens STEP 7 2-52......

2.8.3 Parameterisation with the operator unit 2-56.....................

2.8.4 Parameterisation through the Festo Maintenance Tool 2-56..........

2.8.5 Bus node parameters 2-57....................................

2.8.6 Application example for the parameterisation 2-60................

2.9 Identification & Maintenance 2-61......................................

2.10 Configuration in the Remote Controller operating mode 2-64................

2.11 Checklist for commissioning the CPX terminal 2-66........................

2-2

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

2.1 General instructions

Configuration of the bus nodes for PROFINET depends on the

control system used.

The basic approach and required configuration data are

presented in the following pages.

Switching on the power supply

Caution

Danger of malfunctions, damage or injuries to people

Before commissioning, make sure that the connected com-

ponents (e.g. actuators) do not perform any unexpected or

uncontrollable movements.

Note

Please observe the switch-on instructions in the manual of

your control system (PLC/IPC).

Separate supply If the control system and fieldbus station have separate

voltage supplies, the devices must be switched on in the following sequence:

1. Switch on the operating voltage supply of all bus stations

(I/O devices).

2. Switch on the operating voltage supply for the controller.

Festo P.BE-CPX-PNIO-EN en 1407c English

2-3

2. Commissioning

Addressing, configuration and parameterisation

Addressing The address space of a CPX terminal in the PROFIN ET network

is limited. Determine the number of assigned inputs and outputs before commissioning or configuring the CPX terminal

(see section 2.2 regarding address assignment and section

2.3 regarding addressing).

Addressing of the individual modules is done by the higherorder controller: PROFINET uses module-oriented addressing,

i.e. each module is addressed separately (in contrast to

block-oriented addressing of other fieldbus systems).

The controller uses the follow ing for addressing:

– IP addresses and MAC-IDs

– fiel dbus devi ce names, in short Device Names .

Configuration Configuration of a CPX terminal and the related bus node

depends on the control system used. The fundamental procedure, PROFIN ET-specific preparations and the main configuration steps are depicted on the following pages (see section 2.6).

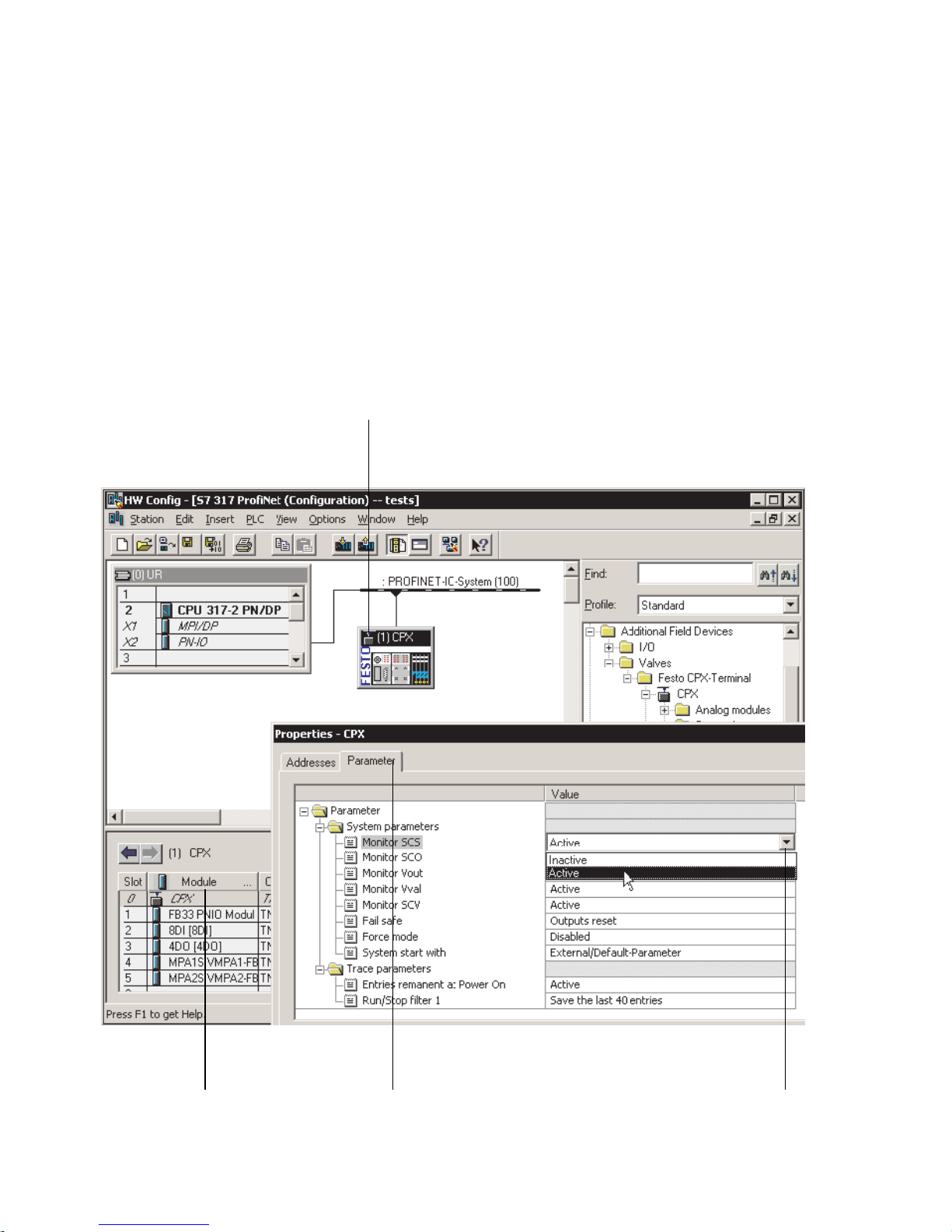

Parameterisation A CPX terminal in the PRO FINET network can be paramet-

erised through the control system (PLC/IPC), an operator unit

(CPX-MMI) or the Festo Maintenance Tool (CPX-FMT) (see section 2.8).

2-4

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

2.2 Address assignment

Note

The address space of a CPX terminal in the PROFINET network is limited.

The bus node for PROFINET provides the CPX terminal with

an address space of up to 64 bytes for inputs (I) and

64 bytes for outputs (O).

Each module of the CPX terminal occupies a cer tain number of I/O bits, I/O bytes or I/O words in the context of

module communication.

The number of occupied I/O bytes (of the respective module) can be found in the follo w ing tables (Tab. 2/2 to

Tab. 2/7).

T ake account of this fact for the planning of your CPX terminal.

Determine the number of assigned inputs and outputs prior

to commissioning or configuring the CPX terminal. Tab. 2/8

provides help with this.

Use the configuration documents, the operator unit (CPXMMI) or the Festo Maintenance Tool (CPX-FMT) to determine

address assignment or terminal configuration.

In the operator unit, the individual modules of the CPX terminal are displayed with the respective module identifiers.

Using the module identifier and the following tables, you can

determine the module type and, with it, the number of inputs

and outputs occupied by the module.

Festo P.BE-CPX-PNIO-EN en 1407c English

2-5

2. Commissioning

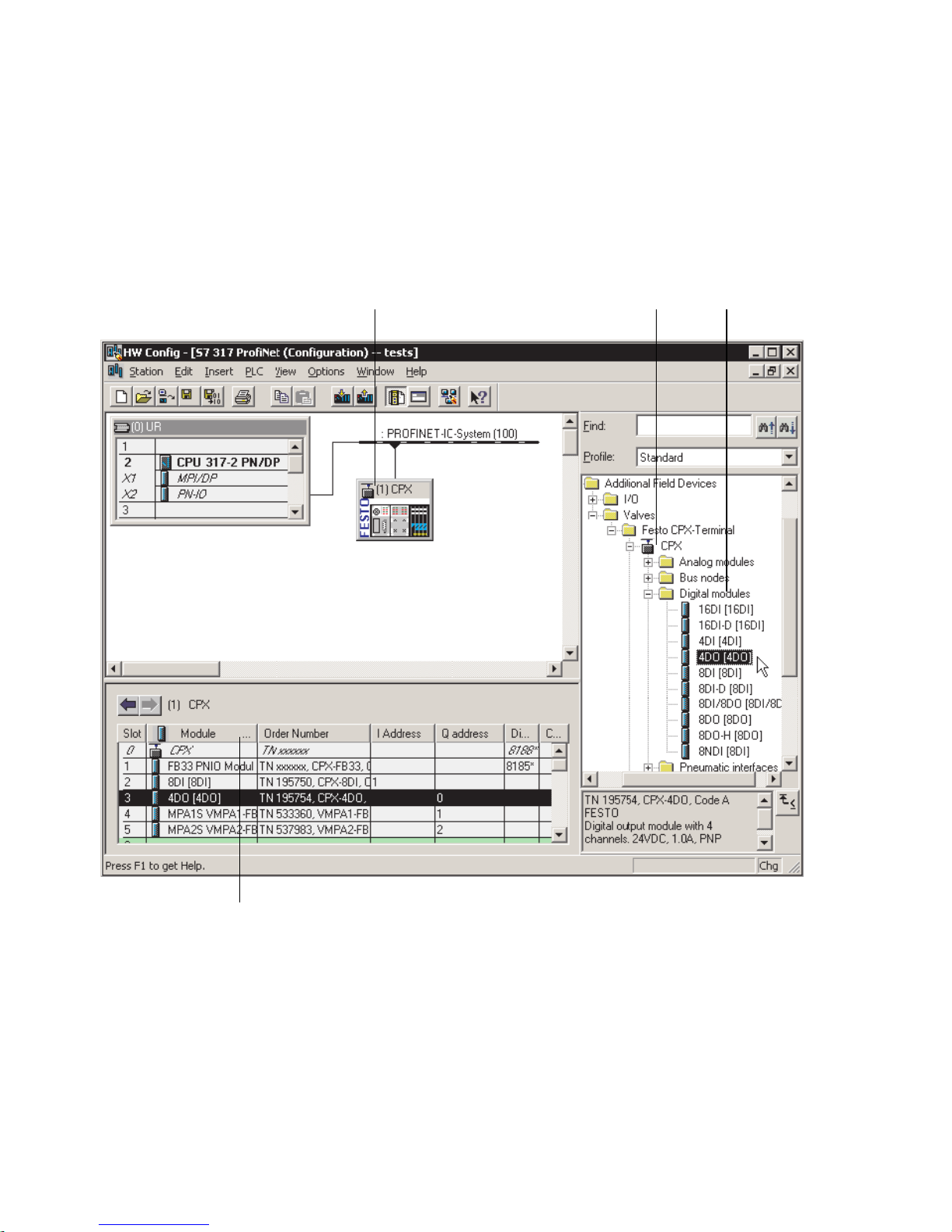

Module identifiers Each module, including the bus node, has its own identifier,

the so-called module identifier. It serves to determine and

localise the module type, for example as part of configuration. Apply the module identifiers – from left to right, corresponding to the physical order as installed in the CPX terminal – in your configuration program (e.g. Siemens SIMATIC

STEP 7, see section 2.7).

In graphically oriented configuration programs, the module

identifiers are typically found in a separate listing of all available hardware modules or field devices, e.g. in a module

folder or module catalogue.

Configuration

of the bus node

Electric modules

Tab. 2/1 shows the assigned address space of the bus node

in the Remote Controller operating mode.

Tab. 2/2 to Tab. 2/4 give an o verview of the assigned address

spaces of different electric modules and of the bus node in

the remote I/O operating mode.

The address assignment within the individual CPX modules

can be found in the associated descriptions, e.g. P.BE-CPXEA-... and P.BE-CPX-AX-...

Details on the CP interface can be found in the description for

the CP interface (P.BE-CPX-CP-...).

In the Remote Controller (RC) operating mode, only the

identifier of the bus node will be configured (see Tab. 2/1).

In the Remote I/O (RIO) operating mode, the identifiers of

the bus node (including diagnostics mode), the CPX modules and, if present, the pneumatics modules are configured

(see Tab. 2/2).

2-6

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

Electricmodules–busnode Module type Module

indicator

(Designation) (Name) Inputs Outputs

Remote Controller operating mode

with setting of data field size 8 byte I /

8byteO(see Tab. 1/4)

Remote Controller operating mode

with setting of data field size 16 byte I /

16 byte O (see Tab. 1/4)

1)

Module identifier in the operator un it or in the hardw are configuration of the programming software

Note.: In the operator unit, the bus n ode is designated with “FB33-RC ProfiNet I/O bus node” or

“FB34-RC ProfiNet RJ45 bus node” or “FB35-RC ProfiNet FOC bus node”

CPX-FB33

CPX-M-FB34

CPX-M-FB35

CPX-FB33

CPX-M-FB34

CPX-M-FB35

e.g. FB33-RC

ProfiNet I/O

bus node

e.g. FB33-RC

ProfiNet I/O

bus node

1)

1)

Allocated address

1)

space

8byte/

32 I

16 byte/

64 I

8byte/

32 O

16 byte/

64 O

Tab. 2/1: Address assi gnme n t o f th e bus no d e fo r th e Re mo te Controll er o pera t i ng mo de

Electricmodules–busnode

Module type Module

indicator

(Designation) (Name) Inputs Outputs

Allocated address

1)

space

Remote I/O operating mode

without diagnostic access or for setting the diagnostics mode via the

hardware configuration

(from Revision 21, see Tab. 1/2)

Remote I/O operating mode

with status bits [Status ]

Remote I/O operating mode

with I/O diagnostics interface

[System Table Interface, STI]

1)

Modul identifier in the operator unit or in the hardware configuration of the programming software

Note: In the operator unit, the bus node is designated with “FB33-RIO ProfiNet Remote I/O”

or “FB34-RIO ProfiNet RJ45 Remote I/O” or “FB35-RIO ProfiNet FOC Remote I/O”

2)

Diagnostics mode status bits occupies 16 I or 2 bytes of address space (8 I or 8 bits remain unused)

(independent of the diagnostics mode)

CPX-FB33

CPX-M-FB34

CPX-M-FB35

CPX-FB33

CPX-M-FB34

CPX-M-FB35

CPX-FB33

CPX-M-FB34

CPX-M-FB35

e.g. FB33-RIO

ProfiNet Re-

mote I/O

e.g. FB33-RIO

ProfiNet Re-

mote I/O

[Status]

e.g. FB33-RIO

ProfiNet Re-

mote I/O

[STI]

1)

1)

1)

– –

2byte/

8 (16) I

(8 bit

used)

2byte/

16 I

2)

–

2byte/

16 O

T ab. 2/2: Address assignment of the bus nodes for the Remote I/O operating mode

Festo P.BE-CPX-PNIO-EN en 1407c English

2-7

2. Commissioning

Electric modules Module type Module

indicator

Allocated address

1)

space

(Designation) (Name) Inputs Outputs

Digital 4-off input module CPX-4DE 4DI

Input module

Digital 8-off input module CPX-8DE 8DI

Input module

Digital 8-off input module

with channel diagnostics

CPX-8DE-D 8DI-D

Input module

Digital 8-off input module, n-switching: CPX-8NDE 8NDI

Input module

Digital 16 -off input module CPX-16DE 16DI

Input module

Digital 16 -off input module

with channel diagnostics

CPX-M-16DE-D16DI-D

Input module

Digital 4-off output module CPX-4DA 4DO

Output module

1byte/

4(8)I

1byte/

3)

–

–

8I

1byte/

–

8I

1byte/

–

8I

2byte/

–

16 I

2byte/

–

16 I

– 1byte/

4(8)O

2)

Digital 8-off output module CPX-8DA 8DO

Output module

Digital 8-off h igh-current output module

CPX-8DA-H 8DO-H

Output module

Digital multi I/O module CPX-8DE-8DA 8DI/8DO

Multi I/O mod-

– 1byte/

8O

– 1byte/

8O

1byte/

8I

1byte/

8O

ule

Analogue 2-off input module CPX-2AE-U-I 2AI

Analogue input

Analogue 2-off output module CPX-2AA-U-I 2AO

Analogue out-

2 wo r ds/

–

32 I

– 2 wo r ds/

32 O

put

1)

Module identifier in the operator un it or in the hardwar e configuration of the programming software

2)

4-off modules (CPX-4DE and CPX-4DA) occupy 8 I or 8 O or 1 byte of address space (4 I/O or 8 bits

of address space remain unused)

Tab. 2/3: Example of address assignment of electric CPX modules (overview; bus node

inRemoteI/Ooperatingmode)–Part1

2-8

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

Electric modules Module type Module

indicator

Allocated address

1)

space

(Designation) (Name) Inputs Outputs

Analogue 4-off input module

Analogue 4-off input module

(temperature module for RTD sensors)

Analogue 4-off input module

(temperature module for TC sensors)

2)

2)

2)

CPX-4AE-I 4AI-I

Analogue input

CPX-4AE-T 4AI-T

Analogue input

temp.

CPX-4AE-TC 4AI-TC

Analogue input

4 words/

64 I

2words

or

4 words/

32/64 I

4 words/

64 I

–

–

3)

–

temp.

Analogue 4-wa y input module

with pressure sensors

2)

(measuring range –1 ... +1 bar)

Analogue 4-wa y input module

with pressure sensors

2)

(measuring range 0 ... 10 bar)

CPX-4AEP-B2

CPX-4AEP-D10

4AI-P-B2

Analogue input

press.

4AI-P-D10

Analogue input

press.

4 words/

64 I

4 words/

64 I

–

–

CP interface

1)

Module identifier in the operator un it or in the hardw are configuration of the programming software

2)

No support for the additional function FSU

2)

CPX-CP-4-FB CPI

CP interface

Max.

8 wo r ds/

4)

128 I

Max.

8 wo r ds/

4)

128 O

Note

When using the module in FSU operation, fast running up of the CPX terminal and compliance of

the PROFINET specification with regard to FSU are not guaranteed.

3)

Number of inputs switchable between 2 and 4

4)

Address space assignment dependent on the string allocation (4 byte I or 4 byte O per string)

Tab. 2/4: Example of address assignment of electric CPX modules (overview; bus node

in Remote I/O operating mode) – Part 2

Festo P.BE-CPX-PNIO-EN en 1407c English

2-9

2. Commissioning

Pneumatic interfaces and pneumatic modules

Tab. 2/5 ... Tab. 2/7 provide an overview of the assigned address spaces of various pneumatic interfaces and modules.

Configuration

of the pneumatics (valves)

The valves are configured according to the pneumatic interface used:

– Valves of type 03 (Midi/Maxi), type 12 (CPA) and

type 44/45 (VTSA/VTSA-F or ISO):

For expansion of the valve side, only one configuration

process is required for the pneumatics interface. In the

pneumatic interface, the number of solenoid coils is set

using a DIL switch.

– Valves of type 32 and 33 (MPA-, MPA-F-, MPA-P- and

MPAF-P- or VPPM pneumatic modules):

From a technical point of view, the individual MPA pneumatic modules each represent an electric module for controlling the attached valves.

A configuration process is required for each pneumatic

module of type MPA... or VPPM:

2-10

Pneumatic modules of type MPA1 each occupy 1 byte

A or 8 outputs regardless of how many valves are attached to the pneumatic module.

Pneumatic modules of type MPA2 each occupy

1 byte O or 8 outputs, but only 4 bits are used.

Pneumatic modules of type MPA-P or MPAF-P each

occupy 2 byte I or 16 inputs.

Pneumatic modules of type VPPM each occupy 4

bytes of address space, i.e. 2 bytes I / 2 bytes O or 16 inputs and 16 outputs.

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

Pneumatic modules of type MPA-P or MPAF-P and VPPM

are among the analogue modules. Observe the sequence

of the modules in addressing or I/O mapping (see

Tab. 2/9).

Additional information on the pneumatics can be found in the

corresponding pneumatics descriptions Document overview “Descriptions of the CPX terminal” in the CPX system

description (P.BE-CPX-SYS...).

The descriptions for the pneumatic valve terminal (Midi/Maxi,

CPA, MPA and VTSA/VTSA-F or ISO) contain the address assignment within the pneumatic modules.

Information about pneumatic interfaces and pneumatic modules can be found in the descriptions of the input/output

modules P.BE-CPX-EA-… and P.BE-CPX-AX-...

Festo P.BE-CPX-PNIO-EN en 1407c English

2-11

2. Commissioning

Pneumatic interface for MPA/

MPA-F and related modules

Pneumatic interface for MPA or

MPA-F valves (type 32/33)

MPA1 pneumatic module

(type 32, 33): 1-8V..)

without galvanic isolation

MPA1 pneumatic module

(type 32, 33: 1-8V..)

with galvanic isolation

MPA2 pneumatic module

(type 32/33): 1-4V..)

without galvanic isolation

MPA2 pneumatic module

(type 32, 33: 1-4V..)

with galvanic isolation

Module type

(Designation of the

Module

indicator

Allocated address

1)

space

electronic module)

Inputs Outputs

VMPA-FB-EPL-... – – –

VMPA1-FB-EMS-8

[8DO]

VMPA1-FB-EMG-8

[8DO]

VMPA2-FB-EMS-4

[4DO]

VMPA2-FB-EMG-4

[4DO]

MPA1S

Valve module

MPA1G

Valve module

MPA2S

Valve module

MPA2G

Valve module

– 1byte/

– 1byte/

– 1byte/

– 1byte/

8O

8O

4(8)O

4(8)O

2)

2)

MPA1 pneumatic module

(type 32, 33): 1-8V..)

without galvanic isolation,

VMPA1-FB-EMSD2-8

[8DO]

MPA1S-D

Valve module

– 1byte/

8O

with diagnostic function D2

MPA1 pneumatic module

(type 32, 33: 1-8V..)

with galvanic isolation,

VMPA1-FB-EMGD2-8

[8DO]

MPA1G-D

Valve module

– 1byte/

8O

with diagnostic function D2

MPA2 pneumatic module

(type 32/33): 1-4V..)

without galvanic isolation,

VMPA2-FB-EMSD2-4

[4DO]

MPA2S-D

Valve module

– 1byte/

4(8)O

with diagnostic function D2

MPA2 pneumatic module

(type 32, 33: 1-4V..)

with galvanic isolation,

VMPA2-FB-EMGD2-4

[4DO]

MPA2G-D

Valve module

– 1byte/

4(8)O

with diagnostic function D2

1)

Module identifier in the operator un it or in the hardwar e configuration of the programming software

2)

4-off modules MPA2 always occupy 8 O (1 byte) of address space (4 O or 8 bits remain unused)

Tab. 2/5: Overview of CPX pneumatic interfaces and pneumatic modules (part 1)

2)

2)

2-12

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

Pneumatic interface for MPA/

MPA-F and related modules

Module type Module

indicator

Allocated address

1)

space

(Name) Inputs Outputs

VPPM proportional-pressure regulation valve (type 32; 2 bar, 6 bar,

10 bar, “not equipped” or vacant

position)

2) 3)

MPA-P Pressure sensor module

(measuring range 0 ... 10 bar)

VPPM-6...-1-...

[2AI/2AO]

2) 3)

VMPA...-FB-PS-...

[2AI-P]

VPPM

Proportional

valve ...

MPA-P

Analogue in-

1word/

16 I

1word/

16 I

1word/

16 O

–

put press.

MPAF-P pneumatic interface with

pressure sensor

2) 3) 4)

Measurement range 0 ... 10 bar)

1)

Module identifier in the operator un it or in the hardw are configuration of the programming software

2

) No support for the additional function FSU

VMPAF-FB-EPL-PS

[1AI-P]

MPAF-P

Analogue input press.

1word/

16 I

–

Note

When using the module in FSU operation, fast running up of the CPX terminal and compliance of

the PROFINET specification with regard to FSU are not guaranteed.

3)

Pneumatic m odules of type MPA-P or MPAF-P and VPPM are among the analogue modules:

Observe the sequence of the modules as part of addressing or in I/O mapping (see Tab. 2/9)

4)

MPAF-P is also called “end plate” with pressure sensor or pressure sensor plate

Tab. 2/6: Overview of CPX pneumatic interfaces and pneumatic modules (part 2)

Festo P.BE-CPX-PNIO-EN en 1407c English

2-13

2. Commissioning

Pneumatic interfaces for Midi/

Maxi,CPA,VTSA/VTSA-F(ISO)

Pneumatics interface for Midi/Maxi

valves (type 03) 1-..-..)

with setting:

– 1...8 solenoid coils

– 1...16 solenoid coils

– 1...24 solenoid coils

– 1…32 solenoid coils (26 effective)

Pneumatics interface for CPA valves

(type 12: 1-..-..)

with setting:

– 1...8 solenoid coils

– 1...16 solenoid coils

– 1…24 solenoid coils ( 22 effective)

Pneumatic interface for VTSA or

VTSA-F pneumatics (ISO, type

44/45: 1-..-..) with setting:

– 1...8 solenoid coils

– 1...16 solenoid coils

– 1...24 solenoid coils

– 1...32 solenoid coils

2)

2)

2)

Module type Module

(Name) Inputs Outputs

CPX-GP-03-4.0 TYPE 3

indicator

Allocated addre s s space

1)

–

Pneumatic interface

1byte/8O

2 byte/16 O

3 byte/24 O

4 byte/32 O

CPX-GP-CPA-10

CPX-GP-CPA-14

CPA 10/14

Pneumatic interface

–

1byte/8O

2 byte/16 O

3 byte/24 O

VABA-10S6-x1 VTSA pneu-

–

matic interface, ISO

plug-in or

TYPE 44 or

TYPE 45

3)

1byte/8O

2 byte/16 O

3 byte/24 O

4 byte/32 O

1)

Module identifier in the operator un it or in the hardwar e configuration of the programming software

2)

Setting with DI L switch in the pneumatic interface

3)

Display text (module identifier) dependent on the version of the operator unit

Tab. 2/7: Overview of CPX pneumatic interfaces and pneumatic modules (part 3)

2-14

Festo P.BE-CPX-PNIO-EN en 1407c English

2. Commissioning

Calculation of the address allocation

Use Tab. 2/8 to calculate the address assignment or number

of inputs and outputs of your CPX terminal.

Input/output modules and system diagnostics

1. Status bits or I/O diagnostics interface

2. Number of input modules CPX-4DE + __ x 8I

1)

Inputs Outputs

+ _____ I + _____ O

2)

+ _____ I

3. Number of input modules CPX-8DE, 8DE-D, -8NDE + _ _ x 8 I + _____ I

4. Number of input modules CPX-16DE, (M-)16DE-D + __ x 16I + _____ I

5. Number of output modules CPX-4DA + __ x 8O

2)

+ _____ O

6. Number of output modules CPX-8DA, 8DA-H + __ x 8 O + _____ O

7. Number of multi I/O modules CPX-8DE-8DA + __ x 8 I/O + _____ I + _____ O