CPX-terminal

Electrical interface

CPX-CP-4-FB

CPI System

Desciription

Installing and

commissioning CPI

systems

Electronics

Description

CPX-CP interface

539294

en 1211b

[761481]

Contents and general instructions

Original de.......................................

Edition en 1211b..................................

Designation P.BE-CPX-CP-EN.........................

Order no. 539294..................................

© (Festo AG & Co. KG, D-73726 Esslingen, Federal Republic of

Germany, 2012)

Internet: http://www.festo.com

E-Mail: service_international@festo.com

The reproduction, distribution and utilization of this document

as well as the communication of its contents to others without

express authorization is prohibited. Offenders will be held

liable for the payment of damages. All rights reserved in the

event of the grant of a patent, utility module or design.

Festo P.BE-CPX-CP-EN en 1211b

I

Contents and general instructions

PROFIBUS®,PROFIBUS-DP®,INTERBUS®, DeviceNet®, CC-Link®,TORX®are registered

trademarks of the respective trademark owners in certain countries.

II

Festo P.BE-CPX-CP-EN en 1211b

Contents and general instructions

Contents

Designated use VI........................................................

Target group VII..........................................................

Service VII...............................................................

Important user instructions VIII..............................................

Notesontheuseofthismanual X...........................................

1. System summary – CPI system 1-1...................................

1.1 Overview of the CPI system 1-3.......................................

1.1.1 Method of operation of the CPI/CP system 1-6...................

1.1.2 Variants and extension rules for the CPI-/CP system 1-9...........

1.1.3 Assigned I/Os of the CPI/CP modules 1-12.......................

1.2 CPI system with the CPX-CP interface 1-13...............................

1.2.1 Address range of the CPI system with the CPX-CP interface 1-14......

1.2.2 Address assignment 1-15.....................................

2. Installation 2-1...................................................

2.1 General instructions on installation 2-3................................

2.2 CPI connections 2-6................................................

2.2.1 Permissible CPI/CP modules and string lengths dependent

on the CPI cables 2-7........................................

2.2.2 Connecting CP strings 2-9....................................

2.3 Connecting the power supply 2-10.....................................

2.3.1 Power supply 2-11...........................................

2.3.2 Ascertaining the current consumption 2-12.......................

2.3.3 Power supply arrangement – formation of power zones 2-16........

2.4 Complying with protection class IP65/IP67 2-19..........................

Festo P.BE-CPX-CP-EN en 1211b

III

Contents and general instructions

3. Commissioning 3-1................................................

3.1 Procedure for commissioning 3-3.....................................

3.2 Prepare the CPI system for commissioning 3-4..........................

3.2.1 Checking the CP strings 3-4..................................

3.2.2 Saving the string assignment 3-5..............................

3.3 Switching-on reaction of the CPI system 3-8.............................

3.4 Reaction of the CPI system to faults in operation 3-10......................

3.4.1 Eliminating assignment faults 3-10..............................

3.4.2 Replacing CPI/CP modules 3-11................................

3.4.3 Replacing CPI/CP modules during operation 3-12.................

3.5 Notes on operation 3-15..............................................

3.5.1 Factory default mark from version 22 3-16.......................

3.6 Parametrizing 3-17..................................................

3.7 Commissioning functions with the handheld 3-27.........................

3.7.1 Menu commands of the CPX-CP interface on the Handheld 3-28......

3.7.2 Representation of the CPI/CP modules 3-29......................

3.7.3 Displaying the string assignment 3-30...........................

3.7.4 Observing signal states (monitoring) 3-31........................

3.7.5 Parametrizing with the Handheld 3-33...........................

4. Diagnosis and error treatment 4-1....................................

4.1 Overview of diagnostic possibilities 4-3................................

4.2 Diagnosis via LEDs 4-4..............................................

4.2.1 Normal operating status 4-6..................................

4.2.2 CPI system-specific LEDs 4-7..................................

4.2.3 CP string-specific LEDs 4-9...................................

4.3 Error messages of the CPX-CP interface 4-12.............................

4.4 Diagnostics via the CPX-FEC or CPX bus node 4-16........................

4.4.1 Status bits of the CPX terminal 4-16.............................

4.4.2 I/O diagnostic interface and diagnostic memory 4-17..............

4.5 Diagnostic functions with the Handheld 4-21.............................

4.6 Error handling and parameterisation 4-22...............................

IV

Festo P.BE-CPX-CP-EN en 1211b

Contents and general instructions

A. Technical appendix A-1.............................................

A.1 Technical specifications of CPX-CP interface, type CPX-CP-4-FB A-3..........

A.2 Accessories A-4....................................................

A.3 Displaying CPI/CP module-specific information with the Handheld A-5.......

A.4 Address assignment of the CP valve terminals and CPI/CP modules A-6......

A.5 Parametrizing with the FST software (CPX-FEC) A-8.......................

A.6 Permissible CPI/CP modules and string lengths dependent on the

CPI cables A-10.....................................................

B. CPX-CP interface with Interbus field bus node B-1.......................

B.1 Addressing with Interbus B-3.........................................

B.1.1 Address range with Interbus field bus nodes B-3.................

B.1.2 Address assignment with Interbus field bus nodes B-3............

B.2 Diagnosing with Interbus B-7.........................................

C. Appendix C-1.....................................................

Festo P.BE-CPX-CP-EN en 1211b

V

Contents and general instructions

VI

Festo P.BE-CPX-CP-EN en 1211b

Contents and general instructions

Designated use

The CPX-CP interface described in this description has been

designed exclusively for use in combination with CPX

terminals from Festo. The designated CP modules from Festo

(CP valve terminals and CPI I/O modules) can be connected

to the CPX-CP interface. The CPX terminal and the connected

CPI modules are only to be used as follows:

–asintended

– without unauthorised modifications

– in excellent technical condition.

If standard ancillary components, such as sensors and actuators, are connected, the specified limits for pressures, temperatures, electrical data, torques, etc. must be complied with.

Comply with the legal rules and regulations and standards,

rules of the testing organisations and insurance companies

and national specifications applicable for the location.

Warning

•

Only use PELV circuits in accordance with

IEC/EN 60204-1 (protective extra-low voltage, PELV)

for the electrical power supply.

•

Also observe the general requirements for PELV circuits

in accordance with IEC EN 60204-1.

•

Use only voltage sources that guarantee reliable

electrical isolation of the operating voltage according to

IEC DIN EN 60204-1.

Festo P.BE-CPX-CP-EN en 1211b

VII

Contents and general instructions

Ranges of application and certifications

The products fulfil the requirements of EU directives and bear

the CE certification.

Standards and test values, which the products must comply

with and fulfil, can be found in the technical appendix section.

The product-relevant EU directives can be found in the declaration of conformity.

Certificates and declarations of conformity for these products

can be found at www.festo.com.

Target group

Service

This description is intended exclusively for technicians

trained in control and automation technology, who have

experience in installation, commissioning, programming and

diagnostics of programmable logic controllers (PLC) and

fieldbus systems/networks.

Please consult your local Festo repair service if you have any

technical problems.

VIII

Festo P.BE-CPX-CP-EN en 1211b

Contents and general instructions

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which may occur if the product is not used correctly. These

instructions are marked (Warning, Caution, etc.), printed on a

shaded background and marked additionally with a pictogram. A distinction is made between the followi ng danger

warnings:

Warning

This means that failure to observe this instruction may

result in serious personal injury or damage to property.

Caution

This means that failure to observe this instruction may

result in personal injury or damage to property.

Note

This means that failure to observe this instruction may

result in damage to property.

The following pictogram marks passages in the text which

describe activities with electrostatically sensitive components.

Festo P.BE-CPX-CP-EN en 1211b

Electrostatically sensitive components may be damaged if

they are not handled correctly.

IX

Contents and general instructions

Marking special information

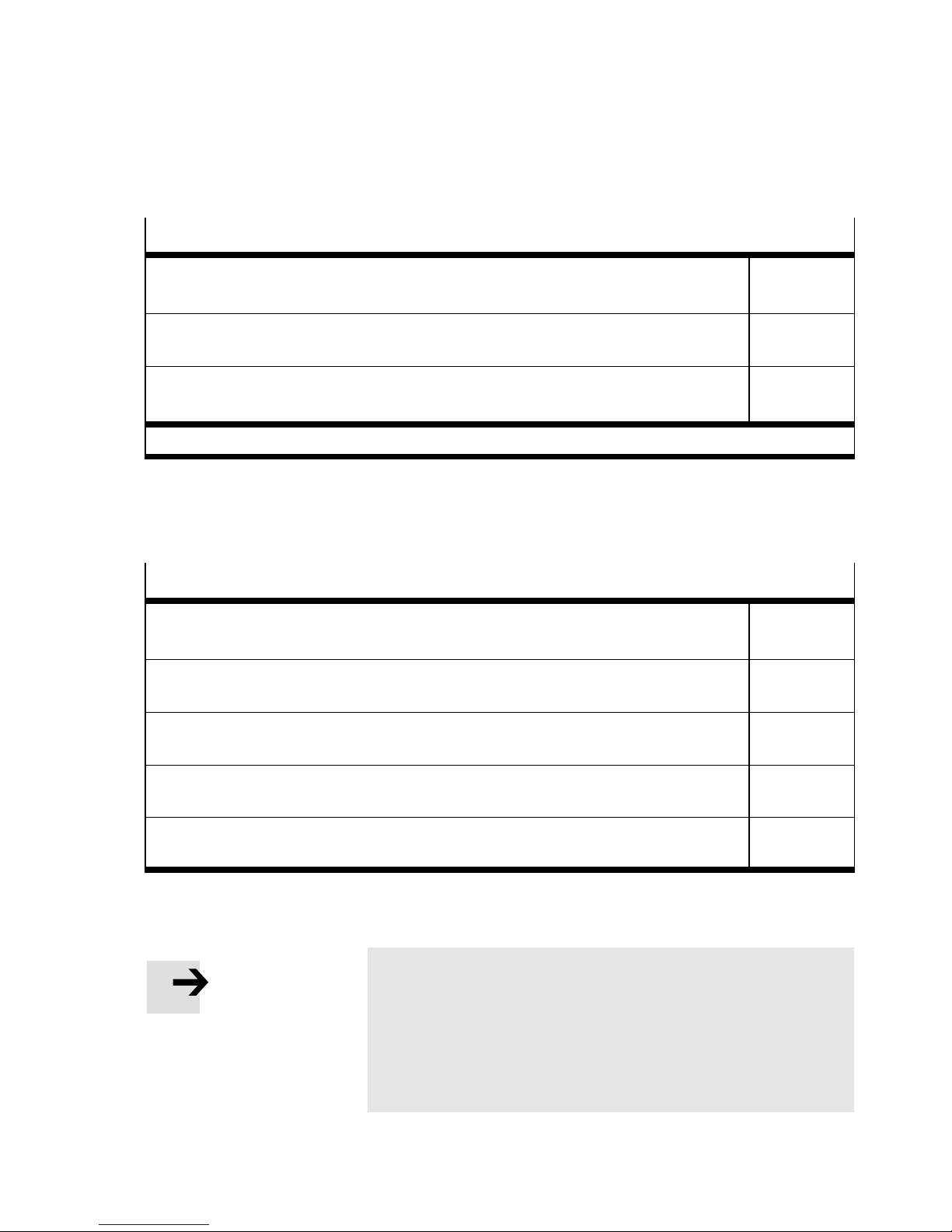

The following pictograms mark passages in the text

containing special information.

Pictograms

Information:

Recommendations, tips and references to other sources of

information.

Accessories:

Information on necessary or sensible accessories for the

Festo product.

Environment:

Information on environment-friendly use of Festo products.

Text markings

•

Bullet points denote activities that may be carried out in

any sequence desired.

1. Figures denote activities which must be carried out in the

numerical order specified.

– Hyphens indicate general activities.

X

Festo P.BE-CPX-CP-EN en 1211b

Contents and general instructions

Notes on the use of this manual

This manual contains specific information on the method of

operation, and on fitting, installing and commissioning the

CPX-CP interface.

Special information on commissioning, programming and

diagnostics of a CPX terminal with the CPX fieldbus node or

CPX-FEC used can be found in the relevant description.

General basic information on the method of operation, on

fitting, installing and commissioning CPX terminals can be

found in the CPX system manual.

An overview of the structure of the CPX terminal user

documentation is contained in the CPX system description.

www.festo.com Support portal: search term “CPX

system description”

Festo P.BE-CPX-CP-EN en 1211b

XI

Contents and general instructions

Information on the CPI modules and the valve terminals with

a CPI connection can be found in the manual for the relevant

module. An overview is shown in Tab. 0/1.

Version

CP modules,

Electronics

description

Modules

with

CP

connection,

Electronics

description

Description

Pneumatics

Title Contents

“CPI-CL modules, CPI-EL

modules”

Type P.BE-CPX-EA-CL...

“CPV Direct”

Type P.BE-CP-DI...

“CDVI ...”

Type P.BE-CDVI-DN-...

“CPA-SC / CPV-SC ...”

Type P.BE-CPASCCPVSC-...

“CPV valve terminal”

Type P.BE-CPV-...

“CPA valve terminals”

Type P.BE-CPA-...

Mounting, installation and commissioning of CP

input and output modules, type CP-...-CL and

CPI-…-EL

Instructions on mounting, installation,

commissioning and diagnostics for the

corresponding CPV valve terminal with direct

link

Instructions on mounting, installation,

commissioning and diagnostics of the CDVI with

fieldbus direct link “DeviceNet”

Instructions on mounting, installation,

commissioning and diagnostics of the CPV-SC

or CPA-SC valve terminal with fieldbus direct

link for PROFIBUS DP or DeviceNet.

Mounting, installation, c ommissioning,

servicing and conversion of the CPV pneumatics

(type 10)

Mounting, installation, c ommissioning,

servicing and conversion of the CPA pneumatics

(type 12)

“MPA valve terminal”

Type P.BE-MPA-...

Tab. 0/1: Descriptions for CP I/O modules and CP valve terminals from Festo

XII

Mounting, installation, c ommissioning,

servicing and conversion of the CPA pneumatics

(type 32)

Festo P.BE-CPX-CP-EN en 1211b

Contents and general instructions

The following product-specific terms and abbreviations are

used in this manual:

Term/abbreviation

CP cable Special cable for connecting the various CPI/CP modules in a CP string.

CP functionality Supports the CP protocol without extended functions

CP module Collective term for modules without extended functions which can be in-

CP string CPI or CP modules which are connected by CPI/CP cable to the CPX-CP

CP valve terminal CPV valve terminal (type 10) or CPA valve terminal ( type 12), each with CP

CP system Complete electrical installation system consisting of a CP master with one

CPI cable Special cable for connecting the various CPI/CP modules in a CP string.

CPI connection Socket or plug on the CPI modules which allows the modules to be connec-

Meaning

Colour: black, type KVI-CP1-... and type KVI-CP2-...

tegrated into a CPI/CP system.

interface. For reasons of simplicity, only the term “CP string” is used, even

if it has CPI functions.

connection (also regarded as CP modules). Basic electric unit, black.

or more CP strings. The system consists of CP modules (without extended

functions).

Colour: white, type KVI-CP3-. ..

ted using the CPI or CP cable.

CPI field bus interface Term for a CPI capable interface with field bus connection (e.g.

CPI field bus module Defined combination of a CPX field bus node and a CPX-CP interface.

CPI functionality Supports the CPI protocol with extended functions

CPI module Collective term for modules with extended functions which can be integ-

CPI system Also: “CPI installation system”

Tab. 0/2: Specific terms and abbreviations

Festo P.BE-CPX-CP-EN en 1211b

combination of CPX field bus node and CPX-CP interface (CPI field bus

module) or CPV with CPI string extension (CPV Direct)).

connects a CPI system with a field bus.

rated into a CPI/CP system.

Complete electrical installation system consisting of a CP master with one

or more CP strings. The system consists of CPI/CP modules with and

without extended functions. The system need not consist exc lusively of CPI

modules.

XIII

Contents and general instructions

Term/abbreviation Meaning

CPX-CP interface CPX module with 4 CP strings for connecting CPI/CP modules and CP valve

terminalstotheCPXterminal.

CPX modules Collective term for the various modules which can be integrated into a CPX

terminal.

CPX terminal Complete system comprising CPX modules with or without pneumatics

Extended functions – Additional options in string assignment:

Up to 4 modules per string with a maximum of 32 inputs and 32 outputs.

Without extended functions, only 1 output and 1 input module is possible.

– Revised data communication:

Inputs report change in status when data arrive or a diagnostic message

is present. Message is queried specifically. Additionally, the system

monitors the participants for TimeOut.

Without extended functions, the system, queries information from the

stations cyclically (so-called polling).

Fieldbus node s Provide the connection to spe cific fieldbuses. Tra nsmit control signals to

the connected modules and monitor their operational ability.

I Digital input

I/O modules Collective term for the modules which provide digital inputs and outputs

(e.g., CPX I/O modules, CPI input modules and CPI output modules)

I/Os Digital inputs and outputs

Input module Input module

O Digital output

Output module Output module

String allocation Type and sequence of the CPI/CP modules connected to one or mo r e CP

strings.

Tab. 0/3: Specific terms and abbreviations

XIV

Festo P.BE-CPX-CP-EN en 1211b

System summary – CPI system

Chapter 1

System summary – CPI system

Festo P.BE-CPX-CP-EN en 1211b

1-1

1. System summary – CPI system

Contents

1. System summary – CPI system 1-1...................................

1.1 Overview of the CPI system 1-3.......................................

1.1.1 Method of operation of the CPI/CP system 1-6...................

1.1.2 Variants and extension rules for the CPI-/CP system 1-9...........

1.1.3 Assigned I/Os of the CPI/CP modules 1-12.......................

1.2 CPI system with the CPX-CP interface 1-13...............................

1.2.1 Address range of the CPI system with the CPX-CP interface 1-14......

1.2.2 Address assignment 1-15.....................................

1-2

Festo P.BE-CPX-CP-EN en 1211b

1. System summary – CPI system

1.1 Overview of the CPI system

Festo can assist you in solving your automation task at the

machine level with the aid of valve terminals. Due to its

modular structure, the CPI system from Festo enables you to

integrate valve terminals and I/O modules optimally in your

machines and systems.

1

CPX terminal with

CP interface as CP

master

2

CP modules

3

CP string

12

3

4

4

CP input module

5

CPV valve terminal

6

CPA valve terminal

7

CP string exclusively

with CPI modules

(modules with extended functions)

Fig. 1/1: Example 1 for design of a CPI system

Note

Observe that only products from Festo can be connected.

5

4

6

7

Festo P.BE-CPX-CP-EN en 1211b

1-3

1. System summary – CPI system

3

2

1

CPI fieldbus node

1

2

MPA-CPI valve terminal

3

CPV-CPI valve terminal

4

CP-CL module

5

CP-EL module

Fig. 1/2: Example 2 for design of a CPI system

45

1-4

Festo P.BE-CPX-CP-EN en 1211b

1. System summary – CPI system

A CPI system consists of individual modules which are connected to each other by means of CPI cables. In this way it is

possible to decentralise the configuration of the CPI modules.

The compact CP valve terminals and I/O modules can be

mounted very close to the cylinders to be controlled. This

enables short compressed air lines to be used.

System losses can be minimized if short compressed air

tubing is used and the times required for pressurising and

exhausting the tubing can be reduced.

This enables smaller valves with sufficient flow to be used,

thereby helping to reduce costs.

Festo P.BE-CPX-CP-EN en 1211b

1-5

1. System summary – CPI system

1.1.1 Method of operation of the CPI/CP system

CPI/CP systems are composed of the following modules:

Modules

CPI/CP master Special CP fieldbus nodes and CP

Function

interfaces are available for the various fieldbuses.

– As electrical modules are an in-

tegral part of a CPX terminal or a

modular valve terminal (CPX-CP

interface/CPI interface).

– Provide the connection to specif-

ic fieldbuses (CPI node, CPV direct)

– These offer connections for up to

four strings to which I/O modules and CP valve terminals are

connected.

– They transmit control signals to

the c onnected modules and

monitor their functioning

1-6

CPV/CPV-SC valve terminals

with CPI connection

– These provide different valve

functions via valve sub-bases for

controlling pneumatic actuators

– Relay plates, pressure zone sep-

aration plates and blanking

plates can also be integrated

Tab. 1/1: Overview of the CPI modules - Part 1

Festo P.BE-CPX-CP-EN en 1211b

1. System summary – CPI system

Modules Function

MPA valve terminals

with CPI connection

CP-/CPI input modules (type CL, EL, RL)

CP-/CPI output

modules (type CL,

EL, RL)

– These provide different valve functions

via valves for controlling pneumatic actuators.

– Provide inputs for connecting sensors

and thus enable, for example, cylinder

positions to be interrogated

– These provide universally effective elec-

tric outputs for controlling low-current

consuming devices (in addition, valves,

lamps, etc.)

Festo P.BE-CPX-CP-EN en 1211b

Tab. 1/2: Overview of CPI modules - part 2

1-7

1. System summary – CPI system

123

In the capacity of CPI master, each CPX-CP interface controls

data transfer to a wide variety of controller systems in a CPX

terminal. In principle, several CPX-CP interfaces can be used

in a CPX terminal.

1

Field bus (incoming)

2

Field bus (continuing)

3

CPI master

(CPX-CP interface)

4

CP string

5

CP input module

6

CP valve terminal

7

Sensor

8

Cylinder

9

CP output module

Fig. 1/3: Method of operation of the CPI system

4

5

6

7

8

9

Cable lengths The complete length of cable on a string must not exceed

1-8

I/O data exchange between the CPX terminal and the modules

connected to the CPX-CP interface takes place constantly via

the CPX-CP interface.

10 m.

Festo P.BE-CPX-CP-EN en 1211b

1. System summary – CPI system

1.1.2 Variants and extension rules for the CPI-/CP system

Modules can be divided into two groups:

– CPI modules (extended functions)

– CP modules (no extended functions)

Tab. 1/3 shows the number of supported modules and rules

dependent on the type of the master and the CPI/CP modules.

Rules and properties

CPI system – Max. 4 modules on the CP string

– Max. 32 inputs and 32 outputs per CP string

CPI modules – There is an incoming and continuing interface on all CPI modules and valve

terminals

– Any sequence of the CPI modules/valve terminals within the CP string

CP modules – There is an incoming and continuing interface on CP output modules and CP

valve terminals

– Only incoming interface at CP input modules. They can therefore only be

placed at the end of a CP string.

CPI/CP master The CPX-CP interface and the CPV Direct are CPI masters.

A mixture of CPI/CP modules is possible on CPI masters:

– Only one CP input module is possible at the end of a string

– Per CP string, only one CP valve terminal

– “Unused” locations on the CP string can be “filled” with CPI modules2).

1)

Without extended functions2)With extended functions

1)

or one CP output module

1)

Tab. 1/3: Rules for extending the CPI system

Festo P.BE-CPX-CP-EN en 1211b

Note

Independent of the type of CPI/CP modules, not more than

32 inputs and 32 outputs may be connected (sum of all

modules on a CP string).

That is, a CP string can be extended with a maximum of 2

CP valve terminals with extended functions, since they

always occupy 16 output addresses.

1-9

1. System summary – CPI system

CP master

VT / O I

VT / O

I

VT / O: CP valve terminal or

CP output module

I: CP input module

Fig. 1/4: Example: Setting up a CP system

(without extended functions)

All CPI modules (with extended functions) can also be connected to CP masters (without extended functions) as shown

in Fig. 1/4.

1-10

Festo P.BE-CPX-CP-EN en 1211b

1. System summary – CPI system

CPI master

CPI master

CP (O) CPI (I/O)

CPI (I/O)

CPI (I/O)

CPI (I/O)

CP (O)

CPI (I/O)

CPI (I/O)

CPI (I/O)

CPI (I/O) CPI (I/O)

CPI (I/O)

CP (O)

CPI (I/O)CPI (I/O)

CPI (I/O)

CPI (I/O)

CPI (I/O)

CPI (I/O)

CP (O)

CP (I)

CP (I)CP (O) CPI (I/O)

Grey: CPI (with extended functions)

CP (I): CP input module

CP (O): CP output module or CP valve terminal

CPI (I/O): CPI input or output module (with extended functions) or CP valve terminal

with CPI ability (for valve terminals: max. 2 possible)

Rules:

CP: For the CP master, the rules remain valid.

CPI: Max. 32 inputs and 32 outputs per string, max. 4 modules per string

Max. 1 CP output module or 1 CP valve terminal

Max. 1 CP input module always at the end of the string

Max. 2 valve terminals with CPI functions per string

Fig. 1/5: Example: expansion of a CPI/CP system

Festo P.BE-CPX-CP-EN en 1211b

CPI (I/O) CPI (I/O)

CPI (I/O)

CP (O)

CPI (I/O)

CP (O)

CP (I)

CP (I)

1-11

1. System summary – CPI system

1.1.3 Assigned I/Os of the CPI/CP modules

Tab. 1/4 provides an overview of the assigned addresses for

the various CPI/CP modules (status at November 2012).

CPI modules

Kind Type Extended

functions

CPI/CP valve terminals

CPI/CP input modules

CPV..-GE-FB-4

CPV..-GE-FB-4/6/6

CPV..-GE-FB-6

CPV..-GE-FB-8

CPA10/14-IFB-CP

CPI-MPA-S

CP-E08-M8-CL

CP-E08-M12-CL

CP-E16-KL-CL

CP-E16-M12-EL

CP-E16-M8-EL

CP-E32-M8-EL

CP-E16-M8

CP-E16N-M8

CP-E16-M8-Z

CP-E16-M12x2-5POL

CP-E16N-M12x2

CP-E16-KL-IP20-Z

No

Yes

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

Assigned I/Os

at CPI masters

(with extended

functions)

– 16 O

8I

8I

16 I

16 I

16 I

32 I

16 I

16 I

16 I

16 I

16 I

16 I

1)

16 O

16 O

16 O

2)

–

–

–

–

–

–

–

–

–

–

–

–

at CP masters

(without extended functions)

– 16 O

16 O

16 O

16 O

16 O

2)

16 I

16 I

16 I

16 I

16 I

3

–

16 I

16 I

16 I

16 I

16 I

16 I

)

–

–

–

–

–

3)

–

–

–

–

–

–

–

CPI/CP output modules

CP-A04-M12-CL

CP-A08-M12-EL-Z

CP-A08-M12-5POL

CP-A08N-M12

1)

Assignment dependent on equipment. CPV..-GE-FB-4/6/6 dynamically occupies 8 or 16 outputs

2)

Assignment depe ndent on equipment. CPI-MPA dynamically occupies 8, 16, 24 or 32 outputs

3)

No function on CP master

Tab. 1/4: Assigned I/Os of the CPI/CP modules

1-12

Yes

Yes

No

No

–

–

–

–

8O

8O

16 O

16 O

Festo P.BE-CPX-CP-EN en 1211b

–

–

–

–

16 O

16 O

16 O

16 O

1. System summary – CPI system

1.2 CPI system with the CPX-CP interface

The CPX-CP interface supports CPI systems with extended

functions. CPI systems with CP modules with extended

functions are distinguished by the following features:

– moreI/Osperstringarepossible(max.32I/32O)

– up to 4 CPI/CP modules are possible

– modules can be in any order.

The CPX-CP interface, in the capacity of technology module

(also termed function module), assigns I/O addresses in the

CPX terminal. The number of addresses assigned depends

on:

– the field bus node or FEC used and the operating mode of

the CPX terminal,

– the saved configuration (string assignment).

Address assignment is carried out as follows:

Field bus node/FEC

CPX field bus node with Remote I/O

operating mode, e.g.:

–

CPX-FB11, DeviceNet

–

CPX-FB13, PROFIBUS

–

CPX-FB14, CANopen

–

CPX-FB23, CC-Link

CPX front end controller with Stand Alone

or Remote Controller operating mode:

–

CPX-FEC

CPX field bus node for Interbus with

operating mode Remote I/O, e.g.:

–

CPX-FB6

Addressing see

Section 1.2.2

Section B.1.1

Festo P.BE-CPX-CP-EN en 1211b

Tab. 1/5: Addressing

1-13

1. System summary – CPI system

1.2.1 Address range of the CPI system with the CPX-CP interface

Size of the assigned address range

The following rules apply to the address range occupied by

the CPX-CP interface ( Tab. 1/6):

– The size of the assigned address range depends on the

number of the last string used.

– The assignment for inputs is independent of the assign-

ment for outputs.

– Each string on the CP interface has an address range of

32 bits for inputs and 32 bits for outputs at its disposal.

Unused address range Unused address range is reserved for extensions.

Last string used

No string assigned 0I No module with inputs

String 1

1

2

3

4

Assigned address range Assigned address range

Inputs Description Outputs Description

0O No module with

connected.

32 I At least one input

module on string 1.

No input modules on

strings 2 to 4.

32 O At least one output

outputs connected.

module on string 1.

No output modules on

strings 2 to 4.

String 2

String 3

String 4

1

2

3

4

1

2

3

4

1

2

3

4

64 I At least one input

96 I At least one input

128 I At least one input

Tab. 1/6: Assigned address range

1-14

module on string 2.

No input modules on

strings 3 and 4.

module on string 3.

No input modules on

string 4.

module on string 4.

64 O At least one output

module on string 2.

No output modules on

strings 3 and 4.

96 O At least one output

module on string 3.

No output modules on

string 4.

128 O At least one output

module on string 4.

Festo P.BE-CPX-CP-EN en 1211b

1. System summary – CPI system

1.2.2 Address assignment

The assignment of the addresses of the CPI/CP modules

depends on the CPX field bus node or CPX-FEC used. The

following representation applies to the field bus nodes (e.g.

CPX-FB13) as well as for the Front End Controller CPX-FEC, but

not for Interbus field bus nodes. The assignment for Interbus

field bus nodes (e.g. CPX-FB6) can be found in appendix B.1.

Address assignment of the individual modules takes places

according to the following rules:

– A CP interface provides four strings with a total of

128 input addresses and 128 output addresses.

– A used string occupies 32 input addresses and 32 output

addresses.

– The addresses are assigned fixed to the individual CP

strings and CPI modules in ascending order.

String

Input addresses Output addresses

number

1 I0 ... I31 O0 ... O31

2 I32 ... I63 O32 ... O63

3 I64 ... I95 O64 ... O95

4 I96 ... I127 O96 ... O127

– Address assignment of the individual modules is there-

fore determined by the string to which they are connected

and by the number of I/Os the existing modules occupy

on the string.

Festo P.BE-CPX-CP-EN en 1211b

– Unused address range (due to modules not being

available) remains reserved for later CPI extensions.

The diagram below shows as an example the address

assignment of a CPI system.

1-15

1. System summary – CPI system

PROFIBUS addresses starting at input/output word 45 are

used. The CPX-CP interface thus occupies 12 bytes of input

addresses and 16 bytes of output addresses.

I/O mapping

Idata Odata

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Byte 9

Byte 10

Byte 11

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Byte 9

Byte 10

Byte 11

Byte 12

Byte 13

Byte 14

Byte 15

Module 0

L1

8I

Module 0

I45.0 ... I45.7 O45.0 ... O45.7 O46.0 ... O46.7 O47.0 ... O47.7

L2

16O

Module 4

Obyte4

Obyte5

O49.0 ... O49.7

O50.0 ... O50.7 ...

L3

16O

Module 8

Obyte8 Ibyte8

Obyte9

O53.0 ... O53.7

O54.0 ... O54.7

L4

8O

Module 12

Obyte12

O57.0 ... O57.7

Module 1 Module 2 Module 3String

8O

Module 1

Obyte0Ibyte0

8O

Module 2

Obyte1

16I

Module 5

Ibyte4

Ibyte5

I49.0 ... I49.7

I50.0 ... I50.7

8I

Module 9

I53.0 ... I53.7

8O

Module 13

Obyte13 Obyte14 Obyte15

O58.0 ... O58.7 O59.0 ... O59.7

(Module 6) (Module7)

16O

Module 10

Obyte10 Ibyte9

Obyte11

O55.0 ... O55.7

O56.0 ... O56.7

8O

Module 14

8O

Module 3

Obyte2

16I

Module 11

Ibyte10

I54.0 ... I54.7

I55.0 ... I55.7

8O

Module 15

O60.0 ... O60.7

used

reserved

Fig. 1/6: Address assignment of a CPI system, example

1-16

The address assignment (method of counting, sequence of

the I/Os) within the individual CP valve terminals and CPI/CP

modules can be found in the relevant description for the

module.

Overview of the address assignments Appendix A.4.

Festo P.BE-CPX-CP-EN en 1211b

Installation

Chapter 2

Installation

Festo P.BE-CPX-CP-EN en 1211b

2-1

2. Installation

Contents

2. Installation 2-1...................................................

2.1 General instructions on installation 2-3................................

2.2 CPI connections 2-6................................................

2.2.1 Permissible CPI/CP modules and string lengths dependent

on the CPI cables 2-7........................................

2.2.2 Connecting CP strings 2-9....................................

2.3 Connecting the power supply 2-10.....................................

2.3.1 Power supply 2-11...........................................

2.3.2 Ascertaining the current consumption 2-12.......................

2.3.3 Power supply arrangement – formation of power zones 2-16........

2.4 Complying with protection class IP65/IP67 2-19..........................

2-2

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

2.1 General instructions on installation

Warning

Accidental movements of the connected actuators and

loose tubing can cause injury to persons and/or damage

to property.

Before carrying out mounting, installation and maintenance work, switch off the following:

– Compressed air supply

– Operating voltage supply for the electronics/sensors

– Load voltage supply for the outputs/valves.

Caution

Electrostatically sensitive components!

• D o not therefore touch the contacts of the components.

• Observe the regulations for handling electrostatically

sensitive components.

You will then prevent the electronics from being damaged.

Note

Handle all modules and components with great care. Pay

particular attention to the following:

– The specified torques must be complied with.

For information on mounting the CPX terminal CPX system

description (P.BE-CPX-SYS-..).

Festo P.BE-CPX-CP-EN en 1211b

2-3

2. Installation

1

CPI system and

CP string-specific

status LEDs

2

CPI connections

X1 … X4

3

Identification plates

(accessories)

Electrical connecting and display elements

The following connecting and display elements can be found

on the CPX-CP interface:

4

L1

PS

L2

PL

L3

RN

L4

X1

X2

1

2

4

Save key

X3

X4

3

Fig. 2/1: Connecting and display elements on the CPX-CP interface

Dismantling and fitting

The CPX-CP interface is mounted in an interlinking block of

the CPX terminal ( Fig. 2/2).

Dismantling Dismantle the CPX-CP interface as follows:

1. Loosen the four screws with a Torx screwdriver size T10.

2. Pull the CPX-CP interface carefully and without tilting

away from the contact rails of the manifold block.

2-4

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

1

Screws, tightening

torque 0.9 … 1.1 Nm

2

CPX-CP interface

1

3

Contact rails

4

Interlinking block

(any, here with additional power supply

as an example)

3

Fig. 2/2: Dismantling/fitting the CPX-CP interface

Fitting Fit the CPX-CP interface as follows:

1. Place the CPX-CP interface in the manifold block. Make

sure that the grooves with the terminals for electrical

contact on the bottom of the CPX-CP interface lie directly

above the contact rails.

2. Press the CPX-CP interface carefully and without tilting as

far as possible into the manifold block.

2

4

Festo P.BE-CPX-CP-EN en 1211b

3. Tighten the screws at first only by hand. Place the screws

so that the self-cutting threads can be used.

4. Tighten the screws with a Torx screwdriver size T10 with

torque 0.9 ... 1.1 Nm.

2-5

2. Installation

2.2 CPI connections

Note

Operative malfunction due to impermissible cabling.

•

For connecting the CPI/CP modules to the CP string,

use only the special CPI/CP cables from Festo

( www.festo.com/catalogue).

•

Observe that the total cable length on a string must not

exceed 10 m.

•

Dependent on the CPI/CP modules and CPI/CP cables

used as well as the current consumption, the

permissible modules and string length per CP st ring may

be limited ( section 2.2.1).

•

Observe the maximum permissible current consumption

per CP string, ( section 2.3.2).

In this way, you can avoid:

– Errors in data exchange between the CPX-CP interface

and the connected modules.

2-6

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

2.2.1 Permissible CPI/CP modules and string lengths dependent on the

CPI cables

Use for CPI systems the special CPI cables type KVI-CP-3-...

(colour white).

Note

When using the CPI cable type KVI-CP-3-… (colour white)

the following restriction applies, dependent on the modules used and the current consumption:

– The maximum permissible string length of 10 m may be

limited further. An overview shows Tab. 2/1 and

Tab. 2/2.

Note

When using the CPI cable Type KVI-CP-1-… or

KVI-CP-2-... (colour black) additional restrictions apply

for the string length and max. current consumption

( Appendix A.6).

Festo recommends the use of CP cable

type KVI-CP-3-… (colour white).

Tip:

PlaceCPvalveterminalsorCPoutputmodulesasthefirst

module on the string if possible.

Festo P.BE-CPX-CP-EN en 1211b

2-7

2. Installation

CP string without

CPI output module

with maximum one

CP valve terminal

type

CPV10-.../CPA10-... 0.5 A . .. 1.5 A 10 m 10 m 10 m

CPV14-.../CPA14-... 0.5 A ... 1.5 A 10 m 10 m 10 m

CPV18-...

1)

Maximum sensor supply current used section 2.3.2, Tab. 2/5

2)

Nominal voltage or undervoltage of -10 %, 16 valve solenoid coils s witched simultaneously (high

current phase)

3)

Maximum undervoltage of -15 %, 8 valve solenoid coils switched simultan eously (high current

phase)

4)

Maximum undervoltage of -15 %, 16 valve solenoid coils switched simultaneously (high current

phase)

5)

Valve terminal installed at each string beginning

6)

Valve terminal installed at each string end

Maximum sensor

current con-

Maximum string length with CP cable, type

KVI-CP-3-...

sumption of the

U

CPI modules on

the CP string

0.5 A 10 m 10 m 10 m

1.0 A 10 m 10 m 10 m

1.5 A 10 m 10 m 10 m

1)

= 21.6 ... 24 V;

VAL

16 valves

2)

U

= 20.4 V;

VAL

8 valves

U

3)

VAL

16 valves

8m

5m

= 20.4 V;

5)

6)

5)

6)

4)

Tab. 2/1: Permissible string lengths with CP cables, type KVI-CP-3- dependent on the CP

valve terminal used and the sensor current consumption

CP string without CP valve

terminal with maximum of

one CPI output module type

CP-A04-M12-CL 0,5 A 10 m

CP-A08...-M12-... 1,5 A 10 m

1)

Maximum sensor supply current used section 2.3.2, Tab. 2/5

Tab. 2/2: Permissible string lengths with CP cables, type KVI-CP-3- dependent on the CPI

output module used and the sensor current consumption

2-8

Maximum sensor current

consumption of the CPI

modules on the CP string

Maximum string length

with CP cable, type KVI-

1)

CP3-...

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

2.2.2 Connecting CP strings

CP connections There are four CPI connections for the CP strings on the

CPX-CP interface (X1 ... X4).

CPI/CP modules can be connected to each CPI connection

according to the rules described in section 1.2 .

Connecting CP modules

1. Check which address range is intended for the CPI/CP

module ( section 1.2).

2. Connect the modules with the CPI/CP cables to the string

which makes this address range available.

3. Fasten the plug and socket of the CPI/CP cable with the

union nut. In this way the electrical contact is guaranteed.

4. Use the identification labels (type IBS 6x10 or IBS 9x20)

to indicate the string to which the module is connected.

In this way you can avoid confusion during later repair

and maintenance work.

Festo P.BE-CPX-CP-EN en 1211b

2-9

2. Installation

2.3 Connecting the power supply

Take the following aspects into consideration when installing

a CPI system with the CPX-CP interface:

– Power supply ( section 2.3.1)

– Current consumption ( section 2.3.2)

– Formation of power zones ( section 2.3.3).

Note

It is imperative that you observe the notes in section 2.3.3

when forming power zones in the CPX terminal by means

of several manifold blocks with power supply.

Recommendation:

• Provide the load voltage for the valve coils and, if necessary, for the outputs separately if you wish to implem ent

an EMERGENCY STOP function.

Note

Check whether pressure switch-off is also necessary for an

EMERGENCY STOP function on your machine/system.

Note

Observe the notes on earthing the CPI/CP modules in the

manual for the relevant module.

2-10

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

2.3.1 Power supply

The power supply for the CPI system with the CPX-CP

interface is provided via the following connections on the

CPX terminal (manifold blocks with power supply):

Manifold block

type CPX-EV-S... (U

Manifold block

type CPX-EV-V... or

CPX-EV-S... (U

VAL

)

EL/SEN

The power supply for the following is provided via the oper-

)

ating voltage supply for the electronics/sensors (U

EL/SEN

the CPX terminal:

– the internal electronics of the CPX- CP interface

– the internal electronics of all the CPI modules connected

– the 24 V sensor supply of the inputs of the CPI input

modules connected.

The power supply for the following is provided via the load

supply for the valves (U

)oftheCPXterminal:

VAL

– the 24 V supply for the CP valve terminals and CPI/CP

output modules (output modules without load supply

connection).

Note

Malfunctioning due to power supply outside the tolerance

The module with the lowest tolerance always determines

the permitted voltage tolerances.

)of

Festo P.BE-CPX-CP-EN en 1211b

If the CPX-CP interface is used, special tolerances according to Tab. 2/3 must be observed for the load supply for

the valves (U

Load supply for valves (U

CPX-CP interface 20,4 ... 26.4 V

1)

If midi/maxi pneumatics are also supplied via the load supply for

the valves: 21.6 ... 26.4 V

) of the CPX-CP interface.

VAL

) Tolerance

VAL

1)

Tab. 2/3: Permitted voltage tolerance

2-11

2. Installation

2.3.2 Ascertaining the current consumption

The current consumption of a CPÎ system depends on the

number and type of the CPI modules connected.

Recommendation:

• Use a closed-loop controlled power unit.

• When selecting the power unit, check that it has sufficient

output. Calculate the total current consumption, if

necessary.

Calculation Tab. 2/5 and Tab. 2/7 show how to calculate the total current

consumption for a CPI system. Please refer to the relevant

technical specifications for the current consumption of the

CP valve terminals and the CPI/CP modules.

Note

Select a power unit which provides sufficient output for

later extensions to the CPI system.

If you are using CP output modules with a separa te load

voltage connection, take into account the appropriate current

consumption when selecting a power unit.

Observe the notes on selecting the power unit in the

CPX system manual.

2-12

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

Note

Operative malfunctions due to the maximum permitted

current consumption on a CP string being exceeded.

•

Make sure that the current consumption of all the modules in a CP string does not exceed the maximu m permissible value of 1.6 A.

•

Observe that the sensor current consumption from

U

EL/SEN

can be additionally restricted dependent on the

string assignment, string length and the CPI/CP cables

used section 2.2.1.

Festo P.BE-CPX-CP-EN en 1211b

2-13

2. Installation

Current consumption on CP string x of U

EL/SEN

of the CPX terminal

Current consumption for internal electronics of all the CPI/CP modules connected

(number of CPI/CP modules x 0.035 A)

Current consumption of all sensors connected to the CPI/CP input modules

(max. 1.5 A)

2)

1)

+ _____ A

Internal current consumption per input channel of the CPI/CP input modules

(number of all inputs x 0.01 A)

+ _____ A

Sum of current consumption on string x (max. 1.6 A)

= _____ A

1)

Refer to manufacturer's specifications

2)

Dependent on the string assignment, string length and the CPI/CP cables used, section 2.2.1

Tab. 2/4: Current consumption of U

Total current consumption of U

EL/SEN

EL/SEN

of the CPX terminal per CP string

of the CPX terminal

_____ A

Sum of current consumption on CP string 1 of Tab. 2/4

Sum of current consumption on CP string 2 of Tab. 2/4

Sum of current consumption on CP string 3 of Tab. 2/4

Sum of current consumption on CP string 4 of Tab. 2/4

Total current consumption of

Tab. 2/5: Total current consumption of U

U

EL/SEN

of the CPX terminal

EL/SEN

_____ A

+ _____ A

+ _____ A

+ _____ A

= _____ A

of the CPX terminal

2-14

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

Current consumption on CP string x of U

Current consumption of all simultaneously energized valve coils of the CP valve

terminals

Load current of all simultaneously activated ouputs of the CPI output modules

without load voltage connection

Sum of current consumption on string x (max. 1.6 A)

1)

Current consumption dependent on valve type ( Technical data of the valves)

1)

Tab. 2/6: Current consumption from U

Total current consumption of U

Sum of current consumption on CP string 1 as per Tab. 2/6

Sum of current consumption on CP string 2 as per Tab. 2/6

of the CPX terminal

VAL

of the CPX terminal

VAL

of the CPX terminal per CP string

VAL

_____ A

+ _____ A

= _____ A

_____ A

+ _____ A

Sum of current consumption on CP string 3 as per Tab. 2/6

Sum of current consumption on CP string 4 as per Tab. 2/6

Total current consumption of

Tab. 2/7: Current consumption of U

U

of the CPX terminal

VAL

of the CPX terminal

VAL

Note

The 24 V supply of the CP valve terminals and of the

CPI/CP output modules (output modules without load

supply connection) takes place within the CPX-CP interface

through a shared cable.

•

Observe that currents in a shared cable add up.

+ _____ A

+ _____ A

= _____ A

Festo P.BE-CPX-CP-EN en 1211b

2-15

2. Installation

2.3.3 Power supply arrangement – formation of power zones

The modular power supply arrangement of the CPX terminal

facilitates the formation of power zones.

Please note the following:

The internal electronics of the CPI/CP I/O modules are supplied from the operating voltage supply for ele ctronics/

sensors (U

The CP valve terminals and the CPI/CP output modules are

provided with load supply by the load supply for the valves

(U

).

VAL

EL/SEN

).

Note

The CPX-CP interface connects the internal contact rails

0U

EL/SEN

and 0 U

of the CPX terminal.

VAL

– As a result, the electrical isolation of the operating

voltage supply for electronics/sensors (U

EL/SEN

)ofthe

CPX terminal and of the load voltage valves supplying

the CPX-CP interface (U

) CPX-CP interface cancel each

VAL

other out.

– Complete electrical isolation (all poles) o f the valve sup-

ply of the CP valve terminals, even in conjunction with

CPX valve supply of type CPX-EV-V, is therefore not possible.

Note

The CPX-CP interface must be supplied via the same

potential (common power unit) as the operating power

supply for the electronics/sensors (U

EL/SEN

)ofthe

CPX terminal (see also Fig. 2/3).

2-16

Basic information on the power supply arrangement of the

CPX terminal can be found in the CPX system description.

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

Example CPX terminal with CP interface + system

supply and 2 additional power supplies for valves

In the example ( Fig. 2/3) the CPX-CP interface and therefore the CP valve terminals and CPI/CP output modules

without load voltage connection are supplied via the valve

supply 2 . The CP valve terminals can only be switched off at

asinglepole!

The MPA pneumatics are supplied via the valve supply 3

(only permitted with MPA electronic modules type

VMPA..-FB-EMG-...). The MPA pneumatics can be switched off

at all poles.

Festo P.BE-CPX-CP-EN en 1211b

2-17

2. Installation

0V

24V

0V

24V

0V

24V

FE

VAL

VAL

OUT

OUT

EL/SEN

EL/SEN

1

8DI

12 3 4 12 3 412 3 4

2

3

4

8DI4DO CP-I

MPA

8O 8O

3

1

Interlinking block with system supply

2

Interlinking block with additional power supply for valves (supplies CPX-CP

interface)

3

Interlinking block with CP interface; connects internally at module level the

rails 0 U

4

Interlinking block with additional power supply for valves (supplies MPA p neu-

EL/SEN

and 0 U

VAL

matics)

Fig. 2/3: Separate power supply for CPX-CP interface and MPA pneumatics (example)

2-18

Festo P.BE-CPX-CP-EN en 1211b

2. Installation

2.4 Complying with protection class IP65/IP67

Note

To comply with protection class IP65/IP67:

• Seal unused CPI/CP connections and the Save key with

the appropriate protective caps.

If CPI/CP connections are not used, seal them with a protective cap, type FLANSCHDOSE, S712 (included in delivery).

You will then comply with protection class IP65/IP67.

Festo P.BE-CPX-CP-EN en 1211b

2-19

2. Installation

2-20

Festo P.BE-CPX-CP-EN en 1211b

Commissioning

Chapter 3

Commissioning

Festo P.BE-CPX-CP-EN en 1211b

3-1

3. Commissioning

Contents

3. Commissioning 3-1................................................

3.1 Procedure for commissioning 3-3.....................................

3.2 Prepare the CPI system for commissioning 3-4..........................

3.2.1 Checking the CP strings 3-4..................................

3.2.2 Saving the string assignment 3-5..............................

3.3 Switching-on reaction of the CPI system 3-8.............................

3.4 Reaction of the CPI system to faults in operation 3-10......................

3.4.1 Eliminating assignment faults 3-10..............................

3.4.2 Replacing CPI/CP modules 3-11................................

3.4.3 Replacing CPI/CP modules during operation 3-12.................

3.5 Notes on operation 3-15..............................................

3.5.1 Factory default mark from version 22 3-16.......................

3.6 Parametrizing 3-17..................................................

3.7 Commissioning functions with the handheld 3-27.........................

3.7.1 Menu commands of the CPX-CP interface on the Handheld 3-28......

3.7.2 Representation of the CPI/CP modules 3-29......................

3.7.3 Displaying the string assignment 3-30...........................

3.7.4 Observing signal states (monitoring) 3-31........................

3.7.5 Parametrizing with the Handheld 3-33...........................

3-2

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

3.1 Procedure for commissioning

In order to avoid connecting and addressing errors, you

should carry out commissioning in steps as follows. Proceed

as follows:

1. Check the CP strings ( section 3.2.1).

2. Save the string assignment of the CPI system

( section 3.2.2).

3. Check the saved string assignment

( sections 3.3 and 3.4)

4. If required: Parameterise the CPX-CP interface and CPI

modules ( section 3.6).

5. Check the address assignment (if necessary, without any

connected actuators by LED) Description for the CPX

fieldbus node or CPX-FEC.

6. Commission the total system Description for the CPX

fieldbus node or CPX-FEC.

Festo P.BE-CPX-CP-EN en 1211b

3-3

3. Commissioning

3.2 Prepare the CPI system for commissioning

Note

Do not yet connect the CPX terminal to a higher-order

controller for preparing commissioning.

You will thus avoid addressing faults which may occur in

various field bus systems when address ranges are

modified during operation.

3.2.1 Checking the CP strings

Preparations Before commissioning a CPX terminal with CPX-CP interface,

you should first prepare each individual CPI system for commissioning.

Proceedasfollows:

1. Check the pneumatic tubing connections of the

connected CP valve terminals with the help of the manual

override ( pneumatics description).

2. Check the complete electric circuitry of the CP system.

3. Save the current string assignment of th e CPI system as

the set assignment, as described in section 3.2.2.

3-4

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

3.2.2 Saving the string assignment

Warning

Undesired modification of input and output addresses.

Be very careful if the string assignment of your CPI system

is modified at a later stage:

• After saving the string assignment, check the address

assignments of your CPI system before starting user

programs.

You can thereby avoid:

– addressing faults with incorrectly fitted CPI modules.

String allocation The CPX-CP interface saves the type and sequence of the

connected CPI modules for every string ( chapter 1). This

is also termed string assignment.

The saved string assignment allows the CPX-CP interface to

avoid errors in connecting, and thus addressing errors. It

checks automatically to see if the current string assignment

is the same as the saved assignment. A distinction is made

here between the following test phases:

– Testing during the start-up phase ( section 3.3)

– Testing during operation ( section 3.4).

After the switch on procedure, the status LEDs indicate the

operating status and correct function of the bus node and the

fieldbus communication. If the status LEDs on all the CPI/CP

modules light up, the CPI system is prepared for configuration.

You can find out which indicator displays the normal operating status in the user documentation of the respective CPI

module. Different procedures are necessary for configuration

of the various fieldbus nodes or the FEC.

Festo P.BE-CPX-CP-EN en 1211b

Explanations on this can be found in the manual for the CPX

field bus node or the CPX-FEC.

3-5

3. Commissioning

Saving the string

assignment

The desired string assignment is generated and saved for

commissioning. In this way the appropriate addresses are

assigned to the connected CPI modules.

Save the string assignments as follows:

1. Leave the power supply of the CPX terminal switched off

for the time being.

2. Check that each of the CPI/CP modules is connected to

the string which provides the address range intended

( chapter 1).

3. Check that the CPI cables are fastened properly with the

union nut.

4. Switch on the power supply of the CPX terminal and, if

necessary, of the CPI/CP modules with load voltage connection.

On the CPX-CP interface, the LEDs of strings (L1 ... L4), to

which CP modules have been connected or for which the

string assignment has been modified, will flash.

5. Use a small screwdriver or similar to press the Save key

for at least 1 s ( section 2.1).

This will save the current string assignment as the target

string assignment in the CPX-CP interface.

The LEDs of strings (L1 ... L4), with which the connected

CPI/CP modules have been recognised, no longer flash.

ThestatusLEDsofalltherecognizedCPI/CPmodules

light up. Wait some seconds before continuing with the

next step.

6. Switch off the power supply for the CPX terminal. Wait

some seconds. Then switch it back on again.

The current string assignment is now available in the

fieldbus node or the CPX-FEC.

7. Depending on the CPX field bus node or CPX-FEC being

used, the modified address range of the CPX-CP interface

must be accepted:

3-6

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

CPX field bus node /

CPX-FEC

CPX fieldbus node

or CPX-FEC with operating

mode Remote I/O

CPX-FEC with Stand Alone or

Remote Controller operating

mode

How to accept the address range

System parameter “System start” [System start]:

“System start with default p arameterisation and up-to-date CPX

expansion” [default parameters], (factory setting):

– The revised address range of the CPX-CP interface is automatic-

ally accepted.

“System start with saved param eterisation and saved CPX expansion” [saved parameters]:

1. Change “System start ...” system parameter to “... default

parameterisation ...” .

2. Switch off the power supply of the CPX terminal then switch it

on again. The address range of the CPX-CP interface will then

be accepted.

3. If necessary, you can restore the desired parameterisation.

•

To accept the address range of the CPX-CP interface, you must

save the actual configuration as the set configuration (actualsetpoint comparison). Information on this can be found in the

manual for the CPX-FEC or software package FST 4.1.

Tab. 3/1: Saving the string assignment and accepting the address range

Note

After saving the string assignment, check the address

assignments of your CPI system before starting user

programs.

Festo P.BE-CPX-CP-EN en 1211b

3-7

3. Commissioning

3.3 Switching-on reaction of the CPI system

When the power supply is switched on, the CPX-CP interface

ascertains automatically the current string assignment. It

ascertains one after the other which CPI modules are connected to the relevant string.

If the current assignment is the same as the saved assignment, the CPX-CP interface will switch automatically to the

ready status.

The RN LED of the CPX-CP interface as well as the status LEDs

on the connected CPI/CP modules light up ( Fig. 3/1).

If the current assignment is not the same as the saved assignment, the string LEDs (L1 ... L4) of the relevant string will

flash on the CPX-CP interface. In this case the CPI system is

not ready to operate.

You then have the following possibilities of restoring the

readiness to operate:

– Eliminate assignment errors manually or replace

individual CPI modules ( section 3.4)

– Save the current assignment as the set assignment

( section 3.2.2).

Detailed notes on diagnosing the CPX-CP interface using the

LEDs can be found in section 4.2.

3-8

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

Switch on power supply

“CP configuration error”; error LED flashes;

string LED on

String 1 ... 4:

Record module types

No

Save key

pressed?

Ye

s

Save string allocation

No

ment saved?

String allocation?

“CP configuration

error”; error LED

flashes; string LEDs on

String assign-

Yes

String 1 ... 4: Record

module types

No

Module types:

Set = Actual?

Yes

“CP configuration

error”; error LED

flashes; string LEDs off

Switch power supply

on/off

Initial start-up Modification/extension Normal operation

Fig. 3/1: Switching-on reaction of the CPI system

Festo P.BE-CPX-CP-EN en 1211b

CPI system ready to

operate (permanent

I/O update)

3-9

3. Commissioning

3.4 Reaction of the CPI system to faults in operation

If there is a fault on a CP string during operation, e.g. by

cable fracture etc., this will be indicated by the relevant string

LED (L1 ... L4) flashing or lighting up. on the CPX-CP interface.

The status LED on the relevant module goes out. All modules

working without faults remain ready to operate.

Detailed notes on diagnosing the CPX-CP interface using the

LEDs can be found in section 4.2.

3.4.1 Eliminating assignment faults

In order to eliminate assignment or connection faults of the

CP system:

1. Switch off the power supply for the CPX terminal.

2. Restore the saved assignment by connecting the

appropriate CPI/CP modules with the CXP-CP interface

again.

3. Switch on the power supply for the CPX term inal again.

3-10

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

3.4.2 Replacing CPI/CP modules

Replacement possibilities Only one defective CPI/CP module can be replaced with a

CPI/CP module of the sa me type without the need to save

the string assignment again.

Note

Replacing a CPI/CP module with a CPI/CP module of a different type or replacing several CPI/CP modules will require a new commissioning and new saving of the string

assignment ( section 3.2).

In order to replace a single CP module, proceed as follows:

1. Stop the process controller P LC/Master

2. Switch off the power supply for the CPX terminal.

3. In the case of CPI/CP output modules and CP valve

terminals on the CP string concerned:

Switch off the following sources of energy:

– the compressed air supply for the CP valve terminal

– the o perating voltage supply for the CPI/CP output

module.

4. Disconnect all connecting cables and, if necessary, also

the tubing.

5. Connect all connecting cables and, if necessary, the

tubing with the identically constructed new module.

6. Now connect the new module ofthesametypeto the

same string.

Festo P.BE-CPX-CP-EN en 1211b

7. In the case of CPI/CP output modules and CP valve

terminals:

Switch on the operating voltage supply or the

compressed air supply again.

8. Switch on the power supply for the CPX term inal again.

9. Check the addresses of the CPI system.

3-11

3. Commissioning

3.4.3 Replacing CPI/CP modules during operation

In special cases, a single CPI/CP module can be replace d

during operation with a CPI module of the same type.

In rare cases, the replacement can produce a short circuit

report for the string. Restart the system if there is a short

circuit report.

Warning

Undesired modification of I/O states.

• Check whether the design of your machine/system

permits replacement of modules during operation.

Warning

Undesired modification of input and output addresses.

Be very careful if the string assignment of your CPI system

is modified at a later stage:

• Make sure that modules are not sepa rated from a string

and subsequently connected to another string during

operation. Use the identification labels (type IBS 6x10 or

IBS9x20) in order to identify modules clearly.

You can thereby avoid:

– modified input and output addresses of the modules.

The CPX-CP interface will recognise replacement with a different type of module (e.g., O module replaced with a valve terminal or CP-E16-M8 replaced with CP-E16-M12x2) as a string

assignment fault. In this case, therefore, readiness to operate

is not restored to the relevant module during operation.

Recommendation:

When replacing CPI/CP modules, always switch off the power

supply if possible ( section 3.4.2).

3-12

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

If the design of your machine/system makes it necessary to

replace a CPI/CP module during operation, you should

proceed as follows:

1. In the case of CPI/CP output modules and CP valve

terminals on the CP string concerned:

Switch off the following sources of energy where

applicable:

– the compressed air supply to the valve terminal

– the o perating voltage supply to the output module.

2. Disconnect all connecting cables and, if necessary, also

the tubing.

3. Connect all connecting cables and, if necessary, the

tubing with the identically constructed new module.

4. Now connect the new module ofthesametypeto the

same string.

5. In the case of CPI/CP output modules and CP valve

terminals:

Switch on the operating voltage supply or the

compressed air supply again.

You can thus restore the defective connection during

operation, or replace the defective module without impairing

operation of the modules in the other strings. When the

connection is restored again or replaced, the readiness to

operate will be taken up with the appropriate module

automatically.

Festo P.BE-CPX-CP-EN en 1211b

3-13

3. Commissioning

Restriction in recognising the string assignment

Specific modifications to the string assignment cannot be

recognised during operation:

– CPI/CP modules or entire strings which are connected to

the previously unassigned string 2 instead of string 1 or

vice versa. This also applies to strings 3 and 4, respectively.

However, these modules will retain their previous addresses

until the power supply is switched off and then on again.

Note

Modifications to the string assignment will be recognised

reliably after the power has been switched on.

Recommendation:

• If possible, switch the power supply off and t hen on

again after performing conversion work on the

CP strings, provided that your system permits this.

Note

After saving the string assignment, check the address

assignments of your CPI system before starting user

programs.

You can thereby avoid:

– addressing faults with incorrectly fitted CPI/CP modules.

3-14

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

3.5 Notes on operation

Warning

Undesired activation of actuators!

An incorrect status of the valves and outputs can lead to

dangerous situations.

• M ake sure that valves and outputs are put into a safe

state when faults occur.

Note

Please note the following if the outputs of a valve terminal

are reset after master stop, field bus interruption or fault:

– Single-solenoid valves move to the basic position.

– Double-solenoid valves remain in the current position.

– Mid-position valves move to the mid-position (depend-

ing on valve type: pressurized, exhausted or blocked).

Warning

Undesired modification of input and output addresses.

Be very careful if the string assignment of your CPI system

is modified at a later stage:

• Make sure that modules are not separated from one

string and accidentally connected to another. Use the

identification labels (type IBS 6x10 or IBS9x20) in order

to identify modules clearly.

• After saving the string assignment, check the address

assignments of your CPI system before starting user

programs.

You can thereby avoid:

– modified input and output addresses of the modules.

Festo P.BE-CPX-CP-EN en 1211b

3-15

3. Commissioning

3.5.1 Factory default mark from version 22

Note

If defective data segments are discovered on an EEPROM

during switch on, they are overwritten with default values.

The CPI will then cancel the switch-on procedure and display the error through the LEDs. ( chapter 4.2) The error

number 205 is returned via the C-bus.

3-16

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

3.6 Parametrizing

The reaction of the CPI system with the CPX-CP interface can

be parametrized.

– Module parameter ( Tab. 3/2):

Activates or deactivates error monitoring for the total

CPX-CP interface (overview).

– Channel-specific module parameters ( Tab. 3/3):

Activates or deactivates error monitoring for individual

CPI modules.

Further information on parametrizing can be found in the

system manual and in the manual for the CPX field bus node

or the CPX-FEC.

Function number

4828 + m * 64 + 0 Monitoring CPX module – CPX-CP interface

4828 + m * 64 + 6 Monitoring CPX module – CPX-CP interface and CPI modules

1)

m = module number (counting from left to right, beginning with 0)

1)

Module parameter – CPX-CP interface and CPI/CP modules

Tab. 3/2: Overview – module parameters

Function number

4828 + m * 64 + 8 ... 11 Monitoring CPI module string 1, module 0 ... 3

4828 + m * 64 + 12 ... 15 Monitoring CPI module string 2, module 0 ... 3

4828 + m * 64 + 16 ... 19 Monitoring CPI module string 3, module 0 ... 3

4828 + m * 64 + 20 ... 23 Monitoring CPI module string 4, module 0 ... 3

2)

–

2)

–

2)

–

1)

Channel-specific module parameters – CPI/CP modules

Fail safe channel x

Idle mode channel x

Force channel x

1)

m = module number (counting from left to right, beginning with 0)

2)

Access is protocol-specific (description of fieldbus node or FEC)

Tab. 3/3: Overview – channel-specific module parameters (specific to strings and/or

modules)

Festo P.BE-CPX-CP-EN en 1211b

3-17

3. Commissioning

Parameter assignment

Parametrisation of the CPX-CP interface applies only to certain CPI/CP modules. An overview shows Tab. 3/4.

CPI module type

Parameter SCS SCO CP diag. Vout Vval Vsen Vsen, Vout, Vval SCS; SCO

Bit no. 0 1 0 1 2 3 4 0 1

Valve terminals

CPV..-GE-FB-...

CPA..-…

MPA-…

CP input modules

CP-E16-M8 (-Z)

CP-E16N-M8

CP-E16-12-5-POL

CP-E16N-M12

CP-E16-KL-IP20

CP output modules

CP-A08-M12-5-POL

CP-A08N-M12

CPX-CP module parameter

(CPX-CP interface / CPI/CP modules)

Par. byte 0

Fig. 3/2

-

x

-

-

-

-

-

-

-

-

x

-

-

-

-

-

x

x

Parameter byte 6

Fig. 3/3

x

x

x

x

x

x

x

x

x

x

x

-

x

-

x

x

x

-

x

-

x

-

x

-

x

-

x

x

x

x

x

x

x

-

-

-

-

-

-

-

Channel-specific param.

(CPI/CP modules)

Parameter byte 8 ... 23

Fig. 3/4

-

x

x

x

x

x

x

-

-

x

x

x

x

x

x

x

x

x

x

-

x

-

-

-

-

-

x

x

CL input modules

CP-E08-M12-CL

CP-E08-M8-CL

CP-E08-KL-CL

CL output module

CP-A04-M12-CL

EL input modules

CP-E16-M12-EL

CP-E16-M8-EL

CP-E32-M8-EL

EL output module

CP-A08-M12-EL-Z

x

x

x

- x x x x - - x x

- - x x - - x - x

- x x x x - - x x

-

-

-

Tab. 3/4: Module-related paramete r assignment

3-18

x

x

x

x

-

x

-

x

-

-

-

-

x

x

x

x

x

x

Festo P.BE-CPX-CP-EN en 1211b

x

x

x

3. Commissioning

Fig. 3/2: Parameterisation byte 0

Festo P.BE-CPX-CP-EN en 1211b

3-19

3. Commissioning

Fig. 3/3: Parameterisation byte 6

3-20

Festo P.BE-CPX-CP-EN en 1211b

3. Commissioning

Fig. 3/4: Parameterisation bytes 8 … 32

Festo P.BE-CPX-CP-EN en 1211b

3-21

3. Commissioning

Description of the module parameters