Compact Performance

Electronics Manual

CPV valve terminal

with direct

connection

Type

CPV...-GE-CO3-8

Field bus protocol:

–CANopen

Manual

548744

en 1201a

[762118]

Contents and general instructions

Original de.......................................

Edition en 1201a..................................

Designation P.BE-CPV-CO3-EN........................

Order no. 548744..................................

© (Festo AG & Co. KG, D-73726 Esslingen, Germany, 2012)

Internet: http://www.festo.com

E-Mail: service_international@festo.com

The reproduction, distribution and utilization of this document as well as the comunication of its contents to others

without express authorization is prohibited. Offenders will

be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility module

or design.

Festo P.BE-CPV-CO3-EN en 1201a

I

Contents and general instructions

TORX® is a registered trade name of CAMCAR TEXTRON INC.,

Rockford,Ill.,USA

II

Festo P.BE-CPV-CO3-EN en 1201a

Contents and general instructions

Contents

Intended use VI..........................................................

Target group VII..........................................................

Service VII...............................................................

Notes on the use of this manual VII...........................................

Important user instructions VIII..............................................

1. Installation 1-1...................................................

1.1 General notes on installation 1-3......................................

1.2 Setting the CPV Direct 1-5...........................................

1.2.1 Overview of setting the CPV Direct 1-5..........................

1.2.2 Setting the CANopen bus address (node ID) 1-7..................

1.2.3 Setting the baud rate 1-8....................................

1.2.4 Setting the configuration mode 1-9............................

1.2.5 Recognizing the CPI extension with the SAVE button 1-9...........

1.2.6 Help table for setting the bus address 1-9.......................

1.3 Connecting to the field bus 1-14.......................................

1.3.1 Field bus cable 1-14..........................................

1.3.2 Field bus baud rate and field bus length 1-15.....................

1.3.3 Information on connecting the field bus 1-16.....................

1.3.4 Field bus interface 1-18.......................................

1.3.5 Field bus plug from Festo 1-19.................................

1.3.6 Further connection possibilities for the field bus with adapters 1-21..

1.4 Bus termination with terminating resistors 1-24..........................

1.4.1 Install a terminating resistor using the adapters 1-24...............

1.5 Power supply 1-25..................................................

1.5.1 Cable for power supply 1-25...................................

1.5.2 Selecting the power unit 1-27.................................

1.5.3 Connecting the power supply 1-29..............................

1.6 Extending the CPV Direct 1-33.........................................

1.6.1 Rules for extending the CPI system 1-35.........................

1.7 Preparing the CPI system for commissioning 1-38.........................

1.7.1 Checking the CP strings 1-38..................................

Festo P.BE-CPV-CO3-EN en 1201a

III

Contents and general instructions

1.7.2 Saving the string assignment 1-39..............................

1.8 Switching-on reaction of the CPI system 1-41.............................

1.9 Reaction of the CPI system to faults in operation 1-43......................

1.9.1 Eliminating assignment faults 1-43..............................

1.9.2 Replacing CPI/CP modules 1-44................................

2. Commissioning 2-1................................................

2.1 Preparing the CPV valve terminal for commissioning 2-3..................

2.1.1 Switching on the operating voltages 2-3........................

2.1.2 Address assignment of the CPV valve terminal 2-4................

2.1.3 Address assignment of CPI/CP modules 2-6.....................

2.1.4 Address assignment for tool change configuration 2-7.............

2.2 CommissioningonaCANopenmaster 2-7..............................

2.2.1 General information on CANopen 2-8...........................

2.3 Overview 2-9......................................................

2.3.1 Brief overview of the scope of functions 2-9.....................

2.3.2 Overview Object directory 2-10................................

2.3.3 Switch-on behaviour of the CPV Direct 2-11......................

2.3.4 Default Identifier distribution 2-1 3..............................

2.3.5 Reaction to network communication faults 2-14...................

2.3.6 Manufacturer Specific Condition Monitoring 2-15..................

2.3.7 Module parameters 2-15......................................

2.4 Tool change configuration 2-16........................................

2.4.1 Example of the tool change configuration 2-18....................

2.5 Overview of parametrizing 2-19........................................

2.6 Further information 2-19.............................................

3. Diagnosis and error treatment 3-1....................................

3.1 Diagnosis via LEDs 3-3..............................................

3.1.1 Normal operating status 3-4..................................

3.1.2 Fault diagnosis with the LEDs 3-5..............................

3.1.3 Status display of the valve solenoid coils 3-9....................

3.2 Diagnosis via the field bus 3-10........................................

3.2.1 Composition of the Emergency Message 3-11.....................

IV

Festo P.BE-CPV-CO3-EN en 1201a

Contents and general instructions

3.3 Overview of diagnostic objects 3-17....................................

3.4 Short circuit/overload 3-18...........................................

3.4.1 Output module 3-18.........................................

3.4.2 Sensor supply on one input module 3-19........................

A. Technical appendix and accessories A-1...............................

A.1 Technical specifications A-3..........................................

A.2 Product codes A-5..................................................

A.3 Accessories A-6....................................................

B. Object directories B-1..............................................

B.1 Object directories B-3...............................................

B.1.1 Overview Object directory B-3................................

B.1.2 Communication profile B-4...................................

B.1.3 Digital CP inputs (Transmit PDO 1) B-10..........................

B.1.4 Digital CP outputs (Receive PDO 1) B-12.........................

B.1.5 Manufacturer Specific Condition Monitoring B-15..................

B.1.6 Module configuration B-21....................................

C. Exa mples C-1.....................................................

C.1 Examples: Communication sequence C-3...............................

C.1.1 Example 1: Start CANopen network (operational mode) C-3........

C.1.2 Example 2: Set output C-3....................................

C.1.3 Example 3: Start “Node guard” monitoring C-4...................

C.1.4 Example 4: Load objects C-5..................................

C.1.5 Example 5: Write objects C-6.................................

C.2 Example: Parametrizing with the program “CANsetter” C-7................

D. Index D-1.........................................................

Festo P.BE-CPV-CO3-EN en 1201a

V

Contents and general instructions

Intended use

The CPV valve terminal with field bus direct connection

(CPV Direct) described in this manual is intended exclusively

for use as a slave on the CANopen field bus.

Thevalveterminalmayonlybeusedasfollows:

– as designated in industrial applications.

– without any modifications by the user . Only the conver-

sions or modifications described in the documentation

supplied with the product are permitted.

– in faultless technical condition.

The maximum values specified for pressures, temperatures,

electrical data, torques etc. must be observed.

If additional commercially-available components such as

sensors and actuators are connected, the specified limits for

pressures, temperatures, electrical data, torques, etc. must

not be exceeded.

Please comply with national and local safety laws and

regulations.

If implementing an emergency stop function, note the

measures listed in section 1.5.3.

VI

Festo P.BE-CPV-CO3-EN en 1201a

Contents and general instructions

Target group

This manual is intended exclusively for technicians trained in

control and automation technology who have experience in

installing, commissioning, programming and diagnosing

slaves on the CANopen.

Service

Please consult your local Festo repair service if you have

any technical problems.

Notes on the use of this manual

This manual contains specific information on installing,

commissioning, programming and diagnosing CPV valve

terminals with direct connection for CANopen.

Informationonthepneumaticscanbefoundinthe

“Pneumatics manual, P.BE-CDV-...”

Festo P.BE-CPV-CO3-EN en 1201a

VII

Contents and general instructions

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which may occur if the product is not used correctly. These

instructions are marked (Warning, Caution, etc.), printed on a

shaded background and marked additionally with a pictogram. A distinction is made between the following danger

warnings:

Warning

This means that failure to observe this instruction may

result in serious personal injury or damage to property.

Caution

This means that failure to observe this instruction may

result in personal injury or damage to property.

Note

This means that failure to observe this instruction may

result in damage to property.

The following pictogram marks passages in the text which

describe activities with electrostatically sensitive components.

Electrostatically sensitive components may be damaged if

they are not handled correctly.

VIII

Festo P.BE-CPV-CO3-EN en 1201a

Contents and general instructions

Marking special information

The following pictograms mark passages in the text

containing special information.

Pictograms

Information:

Recommendations, tips and references to other sources of

information.

Accessories:

Information on necessary or sensible accessories for the

Festo product.

Environment:

Information on environment-friendly use of Festo products.

Text mark ings

• The bullet indicates activities which may be carried out in

any order.

1. Figures denote activities which must be carried out in the

numerical order specified.

– Hyphens indicate general activities.

Festo P.BE-CPV-CO3-EN en 1201a

IX

Contents and general instructions

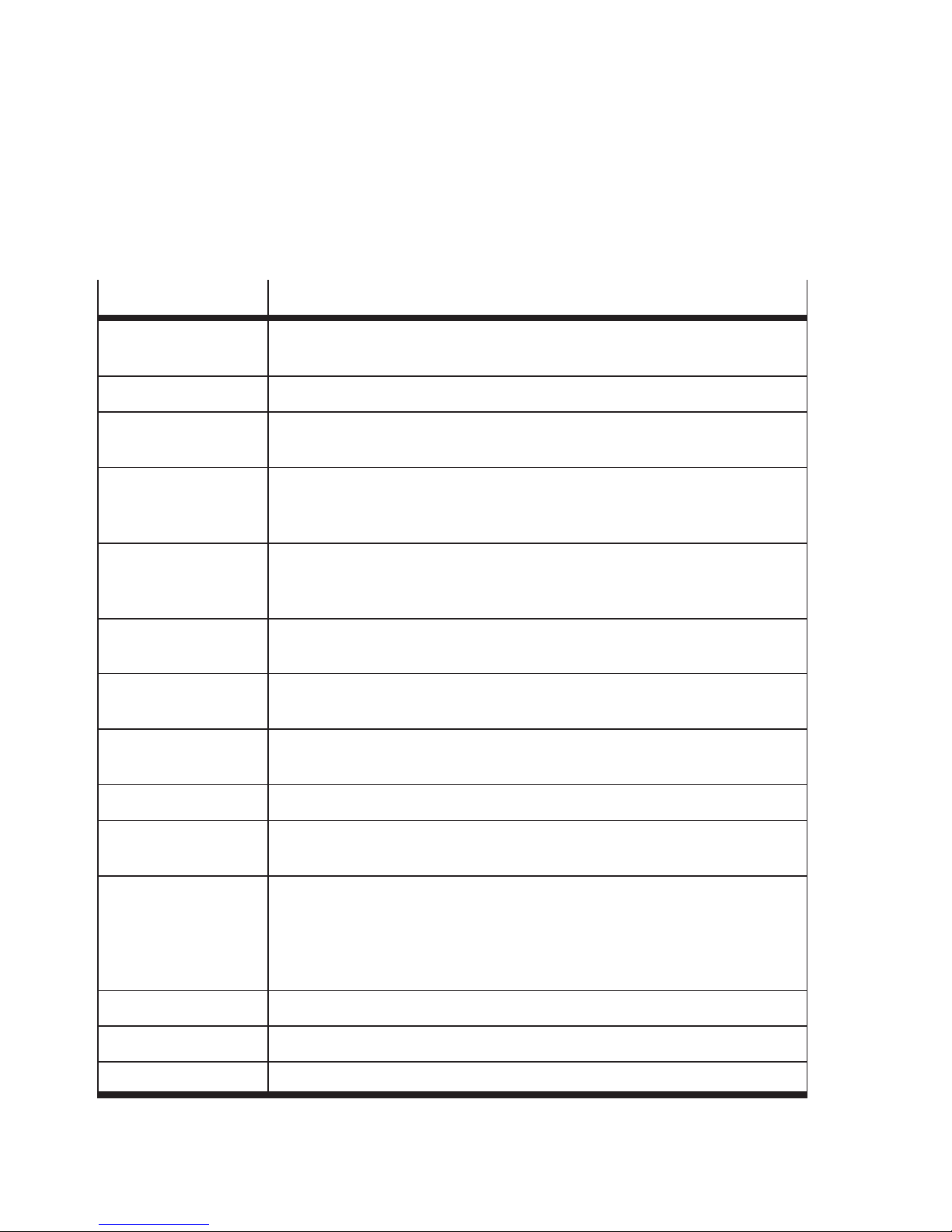

The following product-specific terms and abbreviations are

used in this manual:

Term/abbreviation

CP cable Special cable for connecting the various CPI/CP modules in a CP string.

CP function Supports the CP protocol without extended functions

CP module Common term for modules without extended functions which can be

CP string CPIorCPmoduleswhichareconnectedbyCPI/CPcableandwhichare

CP system Complete electrical installation system consisting of a CP master with one

CP valve terminal CPV valve terminal (type 10) or CPA valve terminal (type 12), each with

CPI cable Special cable for connecting the various CPI/CP modules in a CP string.

CPI connection Socket or plug on the CPI modules which allows the modules to be

Meaning

Colour: black, type KVI-CP1-... and type KVI-CP2-...

incorporated in a CPI/CP system.

connected to the CPX-CP interface. For reasons of simplicity, only the term

“CP string” is used, even if it has CPI functionality.

or more CP strings. The system consists of CP modules (without extended

functions).

CP connection (also regarded as CP modules). Basic electric unit, black.

Colour: white, type KVI-CP3-...

connected using the CPI or CP cable.

CPI function Supports the CPI protocol with extended functions

CPI module Common term for modules with extended functions which can be

incorporated in a CPI/CP system.

CPI system Also: “CPI installation system”

Complete electrical installation system consisting of a CP master with one

or more CP strings. The system consists of CPI/CP modules with and

without extended functions. The system need not consist exclusively of

CPI modules.

CPV Direct CPV valve terminal with field bus direct connection

I Digital input

I/Os Digital inputs and outputs

X

Festo P.BE-CPV-CO3-EN en 1201a

Contents and general instructions

T erm/abbreviation Meaning

I/O modules Collective term for the modules which provide digital inputs and o u tputs

(e.g., CPX I/O modules, CPI input modules a nd CPI output modules).

ID Identifier

Input module Input module

O Digital output

Output module Output module

SC/O Short circuit/overload

String assignment Type and order of the CPI/CP modules connected to one or more CP strings.

Tab. 0/1: Product-specific terms and abbreviations

Festo P.BE-CPV-CO3-EN en 1201a

XI

Contents and general instructions

XII

Festo P.BE-CPV-CO3-EN en 1201a

Installation

Chapter 1

Installation

1-1Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

Contents

1. Installation 1-1...................................................

1.1 General notes on installation 1-3......................................

1.2 Setting the CPV Direct 1-5...........................................

1.2.1 Overview of setting the CPV Direct 1-5..........................

1.2.2 Setting the CANopen bus address (node ID) 1-7..................

1.2.3 Setting the baud rate 1-8....................................

1.2.4 Setting the configuration mode 1-9............................

1.2.5 Recognizing the CPI extension with the SAVE button 1-9...........

1.2.6 Help table for setting the bus address 1-9.......................

1.3 Connecting to the field bus 1-14.......................................

1.3.1 Field bus cable 1-14..........................................

1.3.2 Field bus baud rate and field bus length 1-15.....................

1.3.3 Information on connecting the field bus 1-16.....................

1.3.4 Field bus interface 1-18.......................................

1.3.5 Field bus plug from Festo 1-19.................................

1.3.6 Further connection possibilities for the field bus with adapters 1-21..

1.4 Bus termination with terminating resistors 1-24..........................

1.4.1 Install a terminating resistor using the adapters 1-24...............

1.5 Power supply 1-25..................................................

1.5.1 Cable for power supply 1-25...................................

1.5.2 Selecting the power unit 1-27.................................

1.5.3 Connecting the power supply 1-29..............................

1.6 Extending the CPV Direct 1-33.........................................

1.6.1 Rules for extending the CPI system 1-35.........................

1.7 Preparing the CPI system for commissioning 1-38.........................

1.7.1 Checking the CP strings 1-38..................................

1.7.2 Saving the string assignment 1-39..............................

1.8 Switching-on reaction of the CPI system 1-41.............................

1.9 Reaction of the CPI system to faults in operation 1-43......................

1.9.1 Eliminating assignment faults 1-43..............................

1.9.2 Replacing CPI/CP modules 1-44................................

1-2

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.1 General notes on installation

Warning

Sudden unexpected movement of the connected actuators

and uncontrolled movements of loose tubing can cause

injury to human beings or damage to property.

Before carrying out installation and maintenance work,

switch off the following:

– the compressed air supply

– the operating voltage supply for the internal logics

– the load voltage supply to the valves.

You will thereby avoid undefined switching states of the

electronic components.

Caution

The electronic components may be damaged if they are

not handled correctly.

– Observe the handling specifications for electrostatically

sensitive components.

– Do not touch the electrical contacts of the components.

Festo P.BE-CPV-CO3-EN en 1201a

1-3

1. Installation

Electrical connecting and display elements

6

1

2

3

1 Field bus connection

(9-pin Sub-D plug)

5

4

4 Switching status displays of the valve

coils (yellow LED, see section 3.1)

2 Connection for voltage supply

(M12 plug, 4-pin, see section 1.5)

3 Status LEDs (see section 3.1)

– module/network status (MNS)

– operating voltage for electronics (PS)

– load voltage (PL)

–faultP

Fig. 1/1: Connecting and display elements on the CPV Direct

1-4

5 CPI extension connection

(see section 1.6)

6 Switch cover (removable) for

DIL switches and the SAVE button

(see section 1.2)

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.2 Setting the CPV Direct

1.2.1 Overview of setting the CPV Direct

The CPV Direct can be set by means of 2 DIL switches

situated under the switch cover.

The SAVE button for recognizing the CPI extension is also

situated under the switch over.

Festo P.BE-CPV-CO3-EN en 1201a

Fig. 1/2: Removing/ fitting the switch cover

1-5

1. Installation

1

2

3

4

1 2-element DIL switch, switch elements 1 … 2 for setting

the CANopen baud rate

2 SAVE button for the CPI system

3 8-element DIL switch, switch elements 1 … 7 node ID for

setting the CANopen bus address

4 8-element DIL switch, switch element 8 for setting the

string configuration (tool change configuration)

Fig. 1/3: DIL switches and the SAVE button

Procedure

1. Switch off the operating voltage.

2. Unscrew the screws in the switch cover and remove the

cover.

3. Setting the DIL switch:

4. If you have connected CPI/CP modules to the CPI exten-

5. Replace the switch cover, check that the seal is seated

1-6

– setting the baud rate on the 2-element DIL switch,

– bus address and tool change configuration on the

8-element DIL switch.

sion connection: read the procedure for configuring the

CPI/CP modules in section 1.6.

correctly and tighten the fastening screws by hand.

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

Note

The fitting position of the switch cover is clearly marked by

means of a recess in the housing.

Make sure that the seal is seated correctly.

1.2.2 Setting the CANopen bus address (node ID)

You can set the C ANopen bus address (binary coded) with

switch elements 1 … 7 of the 8-element DIL switch.

The following bus addresses are permitted:

Protocol

Address designation Permitted

bus addresses

CANopen Bus address 0; …; 127

Tab. 1/1: Permitted bus address for CANopen

Note

Bus addresses may only be assigned once per field

bus line.

Help tables for setting the bus address can be found in

section 1.2.6.

Festo P.BE-CPV-CO3-EN en 1201a

1-7

1. Installation

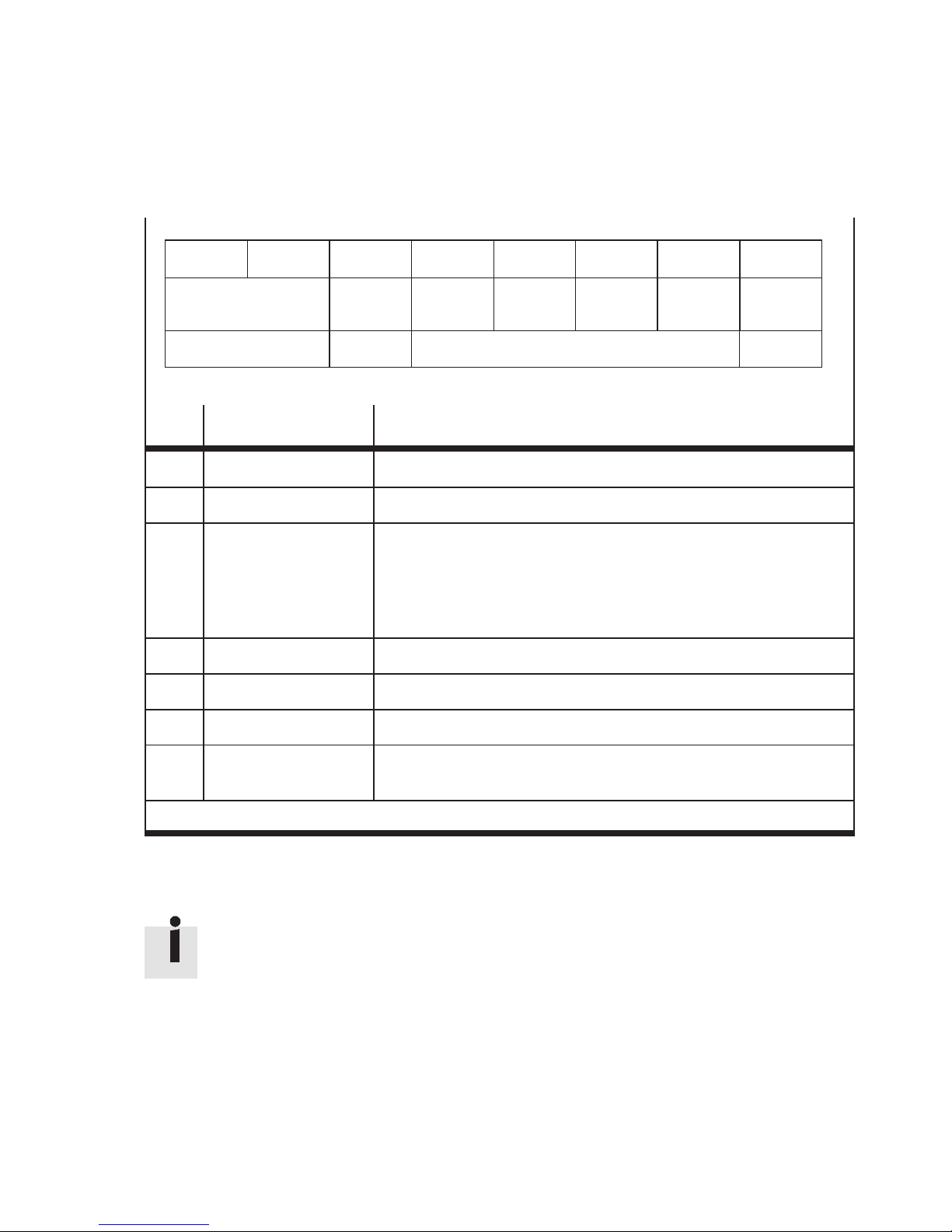

Examples for setting the CANopen bus address

Set bus address

05 20+22=1+4=

38 21+22+25=

Tab. 1/2: Examples of set bus addresses (binary coded)

Recommendation:

Assign the bus addresses in ascending order. Assign the bus

addresses to suit the machine structure of your system.

1.2.3 Setting the baud rate

You can set the baud rate with switch elements 1 and 2 of the

2-element DIL switch.

Position of the switch elements

5

2+4+32=

38

Tab. 1/3: Setting the baud rate

1-8

Baud rate

125 kBaud DIL 1.1 = off

250 kBaud DIL 1.1 = on

500 kBaud DIL 1.1 = off

1000 kBaud DIL 1.1 = on

Position of the switch elements

DIL 1.2 = off

DIL 1.2 = off

DIL 1.2 = on

DIL 1.2 = on

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.2.4 Setting the configuration mode

You can set the string configuration with switch element 8 of

the 8-element DIL switch.

String configuration

Normal mode DIL 2.8 = off

Tool change

configuration

Position of the switch elements

Tab. 1/4: Setting the string configuration on the 8-element

DIL switch

1.2.5 Recognizing the CPI extension with the SAVE button

When the SAVE button is pressed, the CPI/CP modules connected to the CPI extension connection will be recognized

automatically. This can only take place in normal mode.

1. Prepare to connect the CPV Direct to the power supply

(see section 1.5).

DIL 2.8 = on

1.2.6 Help table for setting the bus address

Festo P.BE-CPV-CO3-EN en 1201a

2. Carry out the CPI extension according to the sections 1.6

“Extending the CPV Direct” and 1.7 “Preparing the

CPI system for commissioning”.

In the tool change configuration, pressing the SAVE button is

not necessary. Please refer here to section 2.4.

On the following pages you will find an overview on setting

the bus address.

1-9

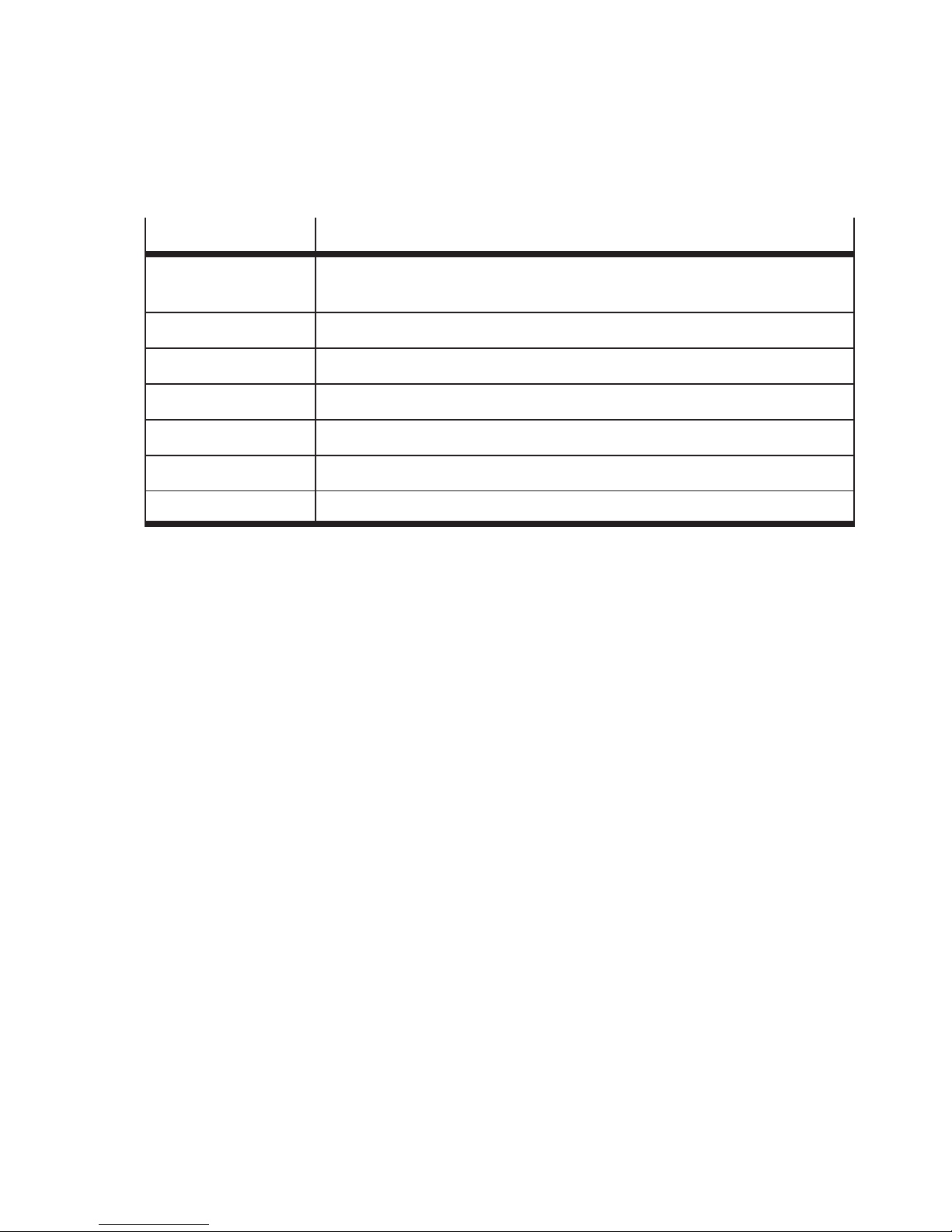

1. Installation

Bus

address

0

1

2

3

4

5

6

7

1 2 3 4 5 6 7 8

not permitted

ON

OFF OFF OFF OFF OF F OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF OFF OF F

OFF OFF OFF OFF OF F

ON

OFF OFF OFF OFF

ON

OFF

ON ON

OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF OFF

Bus

address

16

17

18

19

20

21

22

23

1 2 3 4 5 6 7 8

ON

OFF OFF OFF OFF

ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF

OFF OFF

ON

ON

OFF

ON ON

OFF

OFF

OFF

OFF

OFF OFF

ON

OFF OFF

ON

OFF OFF

ON

OFF OFF

ON

OFF OFF

ON

OFF OFF

ON

OFF OFF

ON

OFF OFF

8

9

10

11

12

13

14

15

ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF

ON ON ON ON

ON

ON

OFF

ON

OFF

ON ON

ON ON

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

24

25

26

27

28

29

30

31

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON ON

OFF

ON ON ON ON ON

ON ON

ON ON

ON ON

OFF

ON ON

OFF

ON ON ON

ON ON ON

Tab. 1/5: Setting bus addresses 0 … 31: Position of the DIL switch elements

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

1-10

Festo P.BE-CPV-CO3-EN en 1201a

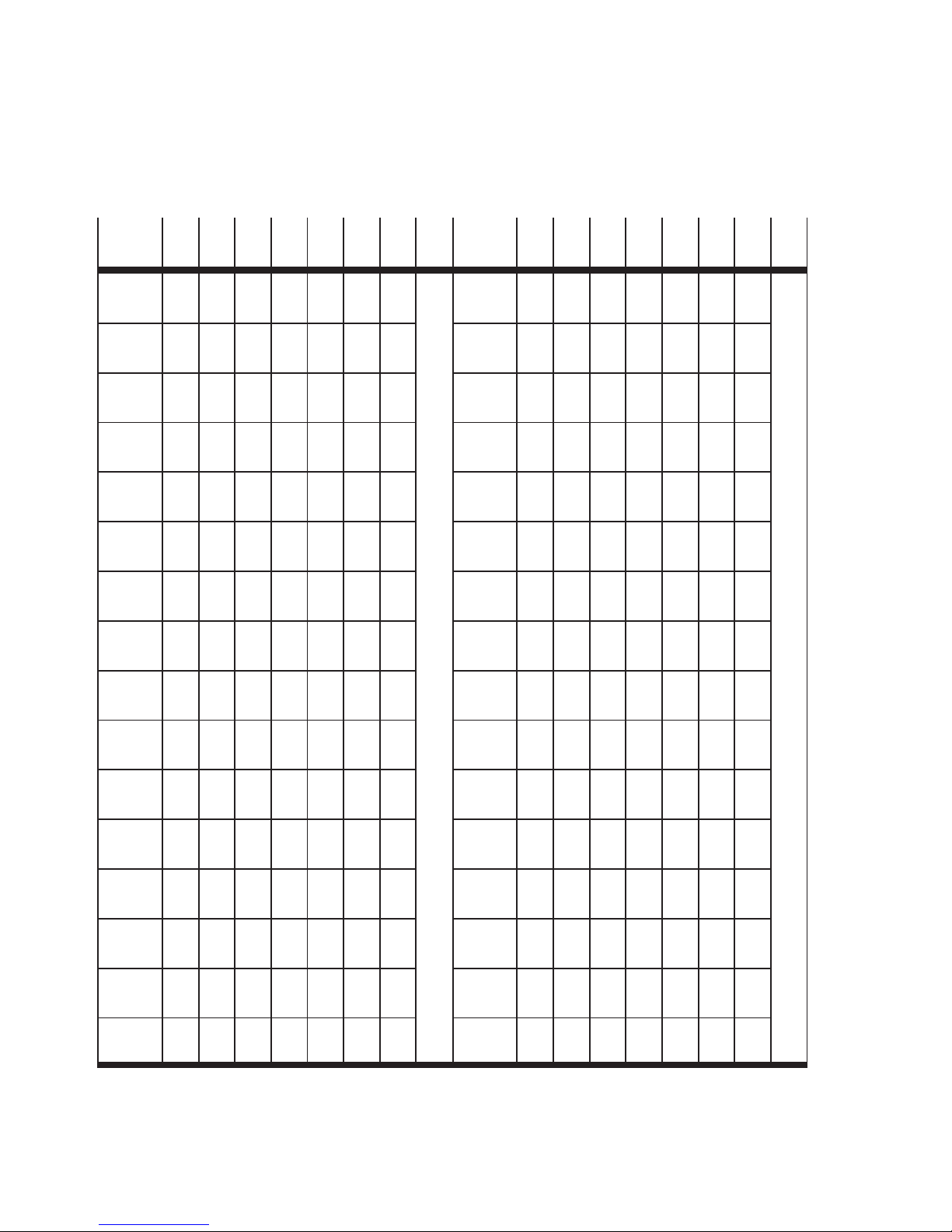

1. Installation

Bus

address

32

33

34

35

36

37

38

39

1 2 3 4 5 6 7 8

ON

OFF OFF OFF OFF OF F

ON

OFF OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF

OFF OFF OFF

ON

ON

OFF

ON ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Bus

address

48

49

50

51

52

53

54

55

1 2 3 4 5 6 7 8

ON ON

OFF OFF OFF OFF

ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF

OFF OFF

ON

ON

OFF

ON ON

OFF

OFF

OFF

OFF

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

40

41

42

43

44

45

46

47

ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF

ON ON ON ON

ON

ON

OFF

ON

OFF

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

56

57

58

59

60

61

62

63

ON ON ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON ON ON

OFF

ON ON ON ON ON ON

ON ON ON

ON ON ON

OFF

ON ON ON

OFF

ON ON ON ON

ON ON ON ON

Tab. 1/6: Setting bus addresses 32 … 63: Position of the DIL switch elements

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Festo P.BE-CPV-CO3-EN en 1201a

1-11

1. Installation

Bus

address

64

65

66

67

68

69

70

71

1 2 3 4 5 6 7 8

ON

OFF OFF OFF OFF OF F OFF

ON

OFF OFF OFF OFF OF F

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF OFF

OFF OFF OFF OFF

ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

ON

ON

ON

ON

ON

ON

ON

Bus

address

80

81

82

83

84

85

86

87

1 2 3 4 5 6 7 8

OFF OFF OFF OFF

ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF

OFF OFF

ON

ON

OFF

ON ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

72

73

74

75

76

77

78

79

ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF

ON ON ON ON

ON

ON

OFF

ON

OFF

ON ON

ON ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

ON

ON

ON

ON

ON

ON

ON

ON

88

89

90

91

92

93

94

95

ON ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON ON

OFF

ON ON ON ON ON

ON ON

ON ON

OFF

ON ON

OFF

ON ON ON

ON ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Tab. 1/7: Setting bus addresses 64 … 95: Position of the DIL switch elements

ON

ON

ON

ON

ON

ON

ON

ON

1-12

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

Bus

address

96

97

98

99

100

101

102

103

1 2 3 4 5 6 7 8

ON ON

OFF OFF OFF OFF OF F

ON

OFF OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF OFF

OFF OFF OFF

ON

ON

OFF

ON ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

Bus

address

112

113

114

115

116

117

118

119

1 2 3 4 5 6 7 8

ON ON ON

OFF

OFF OFF OFF

ON

OFF OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF OFF

OFF OFF

ON

ON

OFF

ON ON

ON ON ON

ON ON ON

ON ON ON

ON ON ON

OFF

ON ON ON

OFF

ON ON ON

OFF

ON ON ON

OFF

104

105

106

107

108

109

110

111

ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON

OFF

ON ON ON ON

ON

ON

OFF

ON

OFF

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

120

121

122

123

124

125

126

127

ON ON ON ON

OFF OFF OFF

ON

OFF OFF

ON

OFF

ON ON

OFF OFF

ON

OFF

ON ON ON ON ON ON

OFF

ON ON ON ON ON ON ON

ON ON ON ON

ON ON ON ON

OFF

ON ON ON ON

OFF

ON ON ON ON ON

ON ON ON ON ON

Tab. 1/8: Setting bus addresses 96 … 127: Position of the DIL switch elements

Festo P.BE-CPV-CO3-EN en 1201a

1-13

1. Installation

1.3 Connecting to the field bus

1.3.1 Field bus cable

Note

If installation has not been carried out correctly and if high

baud rates are used, data transmission errors may occur

as a result of signal reflections and attenuations.

Causes of the transmission faults can be:

– missing or incorrect terminating resistor

– incorrect screening/shield connection

– branch lines too long

– transmission over long distances

– unsuitable cables.

Observe the cable specifications. Refer to your controller

manual for information on the type of cable to be used.

Use a twisted, screened 4-core cable for connecting the field

bus. The bus interface is supplied with power via the field bus

cable.

If the Festo field bus plug is used, a cable diameter of

5…8mmor7…10mmispermitted.

Note

If the valve terminal is fitted into a moving part of a

machine, the field bus cable on the moving part must be

provided with strain relief. Note the relevant regulations in:

IEC/DIN EN 60204-1.

1-14

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.3.2 Field bus baud rate and field bus length

The maximum permitted field bus length depends on the

baud rate used. Detailed information can be found in the

manuals for your control system.

The maximum permitted length of the branch line depends on

the total length of the branch lines and the baud rate.

Note

• Refer to the manuals for your control system or bus

interface in order to ascertain which T-adapter you

should use and the maximum branch line length which

is permitted for your controller.

• Take into account also the sum of the branch line lengths

when calculating the maximum permitted length of the

field bus cable.

Information on setting the baud rate can be found in

section 1.2.3.

Festo P.BE-CPV-CO3-EN en 1201a

1-15

1. Installation

1.3.3 Information on connecting the field bus

The field bus interface on the CPV Direct serves for providing

and continuing the field bus cable. The feld bus connection

can be exchanged and has been designed as:

– a 9-pin Sub-D plug

– an M12 adapter

– a screw terminal adapter.

Caution

• Make sure the polarity is correct when you connect the

field bus interface and the power supply for the bus

interface/internal logics.

• Connect the screening/shield.

Note

Bus slaves have different tolerances in respect of the interface supply, depending on the manufacturer. Note this

when planning the bus length and placing the power unit.

The following tolerance of the bus interface supply applies to

the CPV Direct (pin 9 on the Sub-D plug or pin 2 on the M12

adapter and pin 5 on the screw terminal adapter):

V

= 30.0 V

max

V

= 11.0 V

min

Recommendation:

Avoid long distances between the bus interfaces/logic supply

and the CPV Direct. Place the power unit approximately in the

centre of the bus.

1-16

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

You can implement a T-adapter with the Festo field bus plug

(see figure).

6

5

4

1

2

3

1 Field bus

2 Power supply

3 Screening/shield

Fig. 1/4: Structure of the bus interface and example of connection

Festo P.BE-CPV-CO3-EN en 1201a

4 T-adapter (T-tap)

5 Branch line

6 Field bus plug with T-adapter function

1-17

1. Installation

1.3.4 Field bus interface

There is 9-pin Sub-D plug on the top of the valve terminal for

connecting the CPV Direct to the field bus. This connection

serves for the incoming and continuing field bus cables. You

can connect the CPV Direct with the field bus plug from Festo

type FBS-SUB-9-BU-2x5POL-B.

Note

Note that only the Festo field bus plug guarantees

compliance with protection class IP65.

Before using field bus plugs from other manufacturers:

• Replace the two flat screws by bolts (part no. 340 960).

Pin

CANopen Description Field bus plug from

Festo (IP65)

1

2

3

4

5

6

7

8

9

n.c.

CAN_L

0 V bus

n.c.

CAN screening/shield

GND optional

CAN_H

n.c.

24 V bus

51

96

(view of connection on the CPV Direct)

not connected

CAN Bus Low

Power supply to the bus interface

not connected

Capacitive connection to housing

–

CAN Bus High

not connected

Power supply to the bus interface

–

A/L

GND

–

Clamping strap

–

B/H

–

V+

T ab. 1/9: Pin assignment of the field bus interface on the CPV Direct

1-18

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

Note

The screening connection at pin 5 of the field bus interface

of the CPV Direct is connected capacitively with the housing inside the valve terminal. This prevents equalizing currents from flowing via the screening of the field bus cable

(Fig. 1/5).

1 Capacitive

connection

2 Housing

1

2

Fig. 1/5: Screening connection within the CPV Direct

1.3.5 Field bus plug from Festo

Note

Use a protective cap or blanking plug to seal unused connections. You will then comply with protection class IP65.

• Observe the fitting instructions for the field bus plug.

51

96

Festo P.BE-CPV-CO3-EN en 1201a

You can connect the CPV valve terminal easily to the field bus

with the field bus plug from Festo (FBS-SUB-9-BU-2x5POL-B).

You can disconnect the plug from the node without interrupting the bus cable (T-TAP function).

Note

The clamp strap in the Festo field bus plug is connected

only capacitively internally with the metal housing of the

Sub-D plug. This prevents equalizing currents from flowing

via the screening of the field bus cable (Fig. 1/6).

1-19

1. Installation

• Clamp the screening of the field bus cable under the

clamp strap in the field bus plug. T he “SLD” terminal in

the fieldbus plug is optional.

1 Hinged cover with

display window

2 Clamp strap for

screening/shield

connection

3 Protective cap if

connection is not

used

4 Field bus

continuing (OUT)

5 Field bus

incoming (IN)

6 Only connected

capacitively

21

Bus in

GND

V+

H

L

56

SLD

Bus out

GND

SLD

V+

H

L

3

4

Fig. 1/6: Field bus plug from Festo type FBS-SUB-9-BU-2x5POL-B

1-20

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.3.6 Further connection possibilities for the field bus with adapters

Caution

• Make sure the polarity is correct when you connect the

field bus interface and the power supply for the bus

interface/internal logics.

• Connect the screening/shield.

There are further possibilities of connecting the CPV Direct by

means of adapters. The adapters must be ordered separately

from Festo:

– M12 adapter 5-pin (protection class IP65)

type FBA-2-M12-5POL

– screw terminal adapter 5-pin (protection class IP20)

type FBA-1-SL-5POL

Festo P.BE-CPV-CO3-EN en 1201a

1-21

1. Installation

M12 adapter (IP65)

Order this connection from Festo (type FBA-2-M12-5POL). The

bus is connected via a 5-pin M12 socket with PG9 screw connector. Use the second connection socket for the continuation

of the field bus.

Note

Use blanking plugs to seal unused connections. You will

then comply with protection class IP65.

Order this connection from Festo (type FBA-2-M12-5POL).

M12 adapter

2

3

4

In Out

Bus In

151

5

Bus Out

2

3

4

Protective cap or plug with bus termination

resistor if connection is not used.

Pin no.

1. Screening/shield

2. 24 V DC bus (max. 4 A)

3. 0 V bus

4. CAN_H

5. CAN_L

T ab. 1/10: Pin assignment of the field bus interface (adapter for M12 connection 5-pin)

You can disconnect the M12 adapter from the CPV Direct

without interrupting the bus cable (T-TAP function). Bus In

and Bus Out are connected together with an M12 connector

(see Fig. 1/4).

1-22

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

Screw terminaladapter (IP20)

With this adapter the bus can be connected to a 2x5-pin

terminal strip. Use the second row of connections for the

continuing field bus.

The maximum permitted current at the terminals is 4 A.

Use cables with a cross sectional area of min. 0.34 mm

Order this connection from Festo (type FBA-1-SL-5POL)

together with the terminal strip type FBSD-KL-2x5POL.

2

.

Screw terminal adapter

12 345

Pin no.

1. 0 V bus

2. CAN_L

3. Screening/shield

4. CAN_H

5. 24 V DC bus (max. 4 A)

2x5-pin terminal strip

T ab. 1/11: Pin assignment of the field bus interface

(screw terminal adapter 5-pin)

If you connect the field bus via the terminal strip type

FBSD-KL-2x5POL from Festo, you can implement a T-adapter

function.

Festo P.BE-CPV-CO3-EN en 1201a

Alternatively, you can use ready made bus cables from other

manufacturers (see also appendix A, Accessories).

1-23

1. Installation

1.4 Bus termination with terminating resistors

Note

Always use a bus termination at both ends of the field bus.

This also applies if the CPV Direct is at the end of the field

bus.

If you use T-adapters, install the terminating resistor at the

unused output of the T-adapter.

Recommendation:

Fit a resistor (120 Ω, 0.25 W, see following fig.) for the bus

termination in the Festo field bus plug.

1 Protective cap

12

2 Resistor for bus

connection

(120 Ω, 0.25 W)

GND

GND

SLD

V+

H

L

SLD

V+

H

L

Fig. 1/7: Bus termination with resistor in the field bus plug from Festo

1.4.1 Install a terminating resistor using the adapters

IftheCPVvalveterminaltobeconnectedisattheendofthe

field bus, a terminating resistor (120 Ω, 0.25 W) must be

fitted in the field bus socket.

V+

GND

SLD

H

L

• Connect the terminating resistor between the cores for

1-24

CAN_H and CAN_L.

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.5 Power supply

1.5.1 Cable for power supply

• Use a power supply cable with sufficient cross-sectional

area.

• Avoid long distances between the power unit and the

CPV valve terminal. Long cables reduce the voltage

supplied by the power unit.

• If necessary calculate the suitable cross-sectional area

and the maximum permitted cable length.

The power supply connection is in the form of a plug. The pin

assignment of the plug can be found on the following pages.

UseplugsfromtheFestorangeforconnectingthepowersupply in accordance with the outer diameter of the cables used

(see appendix A.3).

Festo P.BE-CPV-CO3-EN en 1201a

1-25

1. Installation

1 Cable

2 Strain relief

3 Housing

4 Connecting part

1

2

3

4

Fig. 1/8: Individual socket parts and cable routing

Preparing When you have selected suitable cables, connect them as

follows (Fig. 1/8):

1. Open the socket: To do this loosen the centre knurled nut.

2. Open the strain relief on the rear of the housing and pull

the cable through.

3. Remove 5 mm of the insulation from the end of the cable

and fit core end sleeves.

4. Connect the conductors.

5. Replace the connecting part on the housing of the socket

and screw it tight. Pull the cable back so that there are no

loops inside the housing.

6. Tighten the strain relief.

1-26

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.5.2 Selecting the power unit

Warning

• In order to provide the electric power supply, use only

PELV circuits as per IEC/DIN EN 60204-1 (Protective

Extra-Low Voltage, PELV).

T ake into account also the general requirements for

PELV circuits as per IEC/DIN EN 60204-1.

• Use only power packs which guarantee reliable electri-

cal isolation of the operating voltage as per IEC/DIN

EN 60204-1.

By the use of PELV power units, protection against electric

shock (protection against direct and indirect contact) is

guaranteed in accordance with IEC/DIN EN 60204-1

(electrical equipment of machines, general requirements).

The current requirement of a CPI/CP system depends on the

number of CPI/CP modules and valve coils.

Recommendation:

• Use closed-loop controlled power units.

• When selecting the power unit, check that it provides

sufficient output. If necessary, calculate the total current

requirement according to the following table.

Festo P.BE-CPV-CO3-EN en 1201a

1-27

1. Installation

Total current

consumption

The table below shows how to calculate the total current

consumption of a CPI/CP system. The values specified have

been rounded up.

Current consumption of the CP

Sums

electronics (pin 1)

CPV Direct max. 100 mA

CPV valve terminal max. 40 mA

CPA valve terminal 20 mA

CPI/CP input module max. 40 mA

Sensors see manufacturer

specifications

CPI/CP output module max. 40 mA

Carry forward = ______ mA

Current consumption of the valve supply

(pin 2)

Current consumption of

all simultaneously

energized valve coils

1)

Current consumption depends on the valve type

(see Technical specifications of the valves)

1)

__ x ____ mA = ______ mA

Tab. 1/12: Calculating the total current consumption

1-28

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.5.3 Connecting the power supply

Warning

If the valve terminal is supplied with load voltage via an

output of a “safety I/O module”, switch-on test pulses of

the “safety I/O module” may lead to unexpected reactions

of the valve terminal.

• Make sure that switch-on test pulses are reliably

suppressed or switched off.

Current consumption depends on the type of valve terminal.

Please refer to the “Pneumatics Manual, P.BE-CPV-...” and the

previous section for the values.

• Connect the power supply to the 4-pin M12 plug

(Fig. 1/1).

• Observe the tolerance when connecting the 24 V load

voltage at pin 2: 20.4 … 26.4 V DC. Check the 24 V operating voltage of the valves whilst the system is operating.

Caution

Protect the load voltage of the CPV valve coils with a

max. 2 A external fuse.

In this way you can avoid functional damage to the

CPV Direct in the event of a short circuit.

Festo P.BE-CPV-CO3-EN en 1201a

1-29

1. Installation

Note

Check your EMERGENCY STOP circuit in order to ascertain

the measures necessary for switching your machine/system into a safe state in the event of an EMERGENCY STOP.

– Switching off the load voltage for the valves and output

modules in the secondary circuit of the power unit.

– Switching off the compressed air supply for the valve

terminal.

Duetoenergystoredintheinputcircuitryofvalveterminals, there may be a delayed reaction of the valves when

the load voltage is switched off.

T ake this into consideration, e.g. as follows:

– by using an input signal in the controller for checking

whether the load voltage has been switched off.

– by blocking the control signal for the valves by locking

the output signal with the input signal “Load voltage”.

Pin assignment of the power supply connection

1

Pin assignment

1

1: 24 V DC operating voltage for the electronics

(and inputs, with modules connected to the

extension connection)

2: 24 V DC load voltage for the valves (max. 2 A)

3: 0 V

4: Earth/ground connection

Fig. 1/9: Pin assignment of the power supply connection

1-30

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

Potential equalization

The CPV valve terminal has 2 earth connections for potential

equalization:

– on the power supply connection

–ontheendplate.

Note

• Always connect the earth potential to pin 4 of the power

supply connection.

• Connect the earth connection of the end plate with low

impedance (short cable with large cross-sectional area)

to the earth potential.

• By means of low-impedance connections, make sure

that the housing of the valve terminal and the earth connection at pin 4 have the same potential and that there

are no equalizing currents.

Inthisway,youwillavoidinterferencecausedbyelectromagnetic influences.

Festo P.BE-CPV-CO3-EN en 1201a

1-31

1. Installation

3124

0V

2A

24 V

2A

12 432

PE

1

2 Potential equalization

3 The load voltage can be switched off separately and

external fuses

4 Earth connection at pin 4 designed for 3 A

Fig. 1/10: Example of connection with PELV power supply

unit and potential equalization

2

1-32

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.6 Extending the CPV Direct

This section is only relevant for you if you wish to connect

CPI/CP modules to the CPI extension connection.

1

1 CPI extension connection

Fig. 1/11: CPI extension connection

The rules for CPI systems apply for extending the CPV Direct

(see section 1.6.1).

You can connect the following CPI/CP modules to the

CPI extension connection:

– CP input and output modules

– CPI input and output modules (with extended functions)

– CPV-SC with CPI connection

– CPV/CPA valve terminals with and without extended

functions.

Festo P.BE-CPV-CO3-EN en 1201a

1-33

1. Installation

Caution

The maximum cable length between the CPV Direct and the

last CPI/CP module must not exceed 10 m.

The CP connecting cables must have special electrical

properties. Therefore always use Festo CP connecting

cables.

Ready-to-use CP connecting cables are available from Festo.

These are available in various lengths and designs.

} www .festo.com/catalogue

Seal unused CPI/CP connections of your

CPI/CP system with the relevant seal

provided. In this way you will comply

with protection class IP65.

1-34

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.6.1 Rules for extending the CPI system

The CPI system supports a different number of modules per

CP string, depending on the type of CP master and on the

CPI/CP modules connected.

TheCPVDirectisaCPImaster.

Modules can be placed in two different groups:

– CPI modules (with extended functions)

– CP modules (without extended functions)

Rules and properties

CPI system – Max. 4 modules on the CP string

– Max. 32 inputs and 32 outputs (per CP string)

– The sequence of the modules within the CP string is optional

CPI master A mixture of CPI/CP modules is possible on CPI masters:

– Only one CP input module is possible at the end of a string

– Only one CP valve terminal

– “Unused” locations on the CP string can be “filled” with CPI modules

CPI modules Modules always have an Incoming and continuing interface on all CPI modules

(input modules, output modules) and valve terminals with CPI connection.

1)

with extended functions

2)

without extended functions

2)

or one CP output module2)is possible per CP string.

1)

.

T ab . 1/13: Rules for extending the CPI system

Festo P.BE-CPV-CO3-EN en 1201a

1-35

1. Installation

CPI master

Note

Irrespective of the type of CPI/CP modules, not more than

32 inputs and 32 outputs may be connected (sum of all

modules on a CP string).

This means that a CP string can be extended by maximum

2 CP valve terminals with CPI ability, as CP valve terminals

always occupy 16 output addresses.

X X

X X I

X X I

X VI/O

X: Any CPI module or CP valve terminal with CPI ability

(max. 2 valve terminals possible)

I: CP input module

VI/O: CP valve terminal or CP output module

grey: CPI modules/valve terminals with extended functions

XX

X

Fig. 1/12: Examples of extending a CPI system

1-36

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

CP string without

CPI output module

with max. one

CP valve terminal

type

CPV10-.../CPA10-...

CPV14-.../CPA14-...

CPV18-...

1)

Maximum sensor supply current used

2)

Rated voltage or undervoltage of -10 %, 16 valve solenoid coils switched simultaneously

(high current phase)

3)

Rated voltage or undervoltage of -15 %, 8 valve solenoid coils switched simultaneously

(high current phase)

4)

Rated voltage or undervoltage of -15 %, 16 valve solenoid coils switched simultaneously

(high current phase)

5)

Valve terminal installed in each case at start of string

6)

Valve terminal installed in each case at end of string

Maximum

sensor current

Maximum string length with CPI cable,

type KVI-CP-3-...

consumption of

V

the CPI modules

on the CP string

0.5 ... 1.5 A 10 m 10 m 10 m

0.5 ... 1.5 A 10 m 10 m 10 m

0.5 A 10 m 10 m 10 m

1.0 A 10 m 10 m 10 m

1.5 A 10 m 10 m 10 m

1)

= 21.6 ... 24 V

val

16 valves

2)

V

= 20.4 V

val

8valves

3)

V

= 20.4 V

val

16 valves

5)

6)

8m

5)

6)

5m

4)

Tab. 1/14: Permitted string lengths with CPI cables, type KVI-CP-3-... depending on the

CP valve terminal used and on the sensor current consumption

CP string without CP valve

terminal, with a maximum of

one CPI output module, type

CP-A04-M12-CL 0.5 A 10 m

CP-A08...-M12-... 1.5 A 10 m

1)

Maximum sensor supply current used

Tab. 1/15: Permitted string lengths with CP cables, type KVI-CP-3-... depending on the

CPI output module used and on the sensor current consumption

Festo P.BE-CPV-CO3-EN en 1201a

Maximum sensor current

consumption of the CPI

modules on the CP string

Maximum string length

with CP cable, type

1)

KVI-CP-3-...

1-37

1. Installation

1.7 Preparing the CPI system for commissioning

This section is only relevant for you if you have connected

CPI/CP modules to the CPI extension connection.

Note

Do not yet connect the CPV Direct to a higher-order

controller for preparing commissioning.

You will thus avoid addressing faults which may occur in

variousfieldbussystemswhenaddressrangesaremodified during operation.

1.7.1 Checking the CP strings

Preparations Before commissioning a CPV Direct with CPI extensions,

you should first prepare each individual CPI system for

commissioning.

Proceed as follows:

1. Check the pneumatic tubing of the valve terminals with

the aid of the manual override (see pneumatics manual).

2. Check the complete electric circuitry of the CPI system.

3. Save the current string assignment of the CPI system as

the nominal assignment, as described in section 1.7.2.

1-38

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.7.2 Saving the string assignment

Warning

Be very careful if the string assignment of your CPI system

is modified at a later stage:

• After saving the string assignment, check the address

assignments of your CPI system before starting user

programs.

You will then avoid addressing faults in the case of incorrectly fitted CPI/CP modules.

String assignment The CPV Direct saves the type and the sequence of the

connected CPI/CP modules for the CP string (string

assignment).

The saved string assignment enables the CPV Direct to avoid

faults in connecting, and thus addresssing. It checks automatically to see if the current string assignment is the same

as the saved assignment. A distinction is made here between

the following test phases:

– testing during the start-up phase (see section 1.8)

– testing during operation (see section 1.9).

When the status LEDs on all the CPI/CP modules light up, the

CPI system is prepared for commissioning. You can now commission the CPI system.

Festo P.BE-CPV-CO3-EN en 1201a

1-39

1. Installation

Saving the string

assignment

The desired string assignment is generated and saved for

commissioning. In this way the connected CPI/CP modules

are assigned with the relevant addresses.

Save the string assignment as follows:

1. Leave the power supply for the CPV Direct switched off

for the time being.

2. Make sure that the CPI cables are fastened properly with

the union nut.

3. Switch on the power supply for the CPV Direct and, if

necessary, for the CPI/CP modules with load voltage

connection.

The fault LED P on the CPV Direct will flash if CPI/CP

modules are connected or if the string assignment is

modified.

4. Use a small screwdriver or similar tool to press the SAVE

button for at least 1 s (see Fig. 1/3).

This will save the current string assignment as the

nominal string assignment in the CPV Direct.

The fault LED Pno longer flashes.

The status LEDs of all the recognized CPI/CP modules

light up.

1-40

Note

After saving the string assignment, check the address

assignments of your CPI system before starting user

programs.

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.8 Switching-on reaction of the CPI system

When the power supply is switched on, the CPV Direct

ascertains automatically the current string assignment. It also

ascertains which CPI/CP modules are connected to the string

extension.

Ifthecurrentassignmentisthesameasthesaved

assignment, the CPV Direct will switch automatically to the

ready-to-operate status.

The PS/PL LEDs of the CPV Direct as well as the status LEDs

on the connected CPI/CP modules light up.

If the current assignment is not the same as the saved

assignment, the fault LED P on the CPV Direct will flash.

In this case the CPI system is not ready to operate.

You then have the following possibilities of restoring the

readiness to operate:

– Eliminate assignment faults manually or replace

individual CPI modules (see section 1.9).

– Save the current assignment as the nominal assignment

(see section 1.7.2).

Detailed instructions on diagnosing the CPV Direct using the

LEDs can be found in section 3.1.

Festo P.BE-CPV-CO3-EN en 1201a

1-41

1. Installation

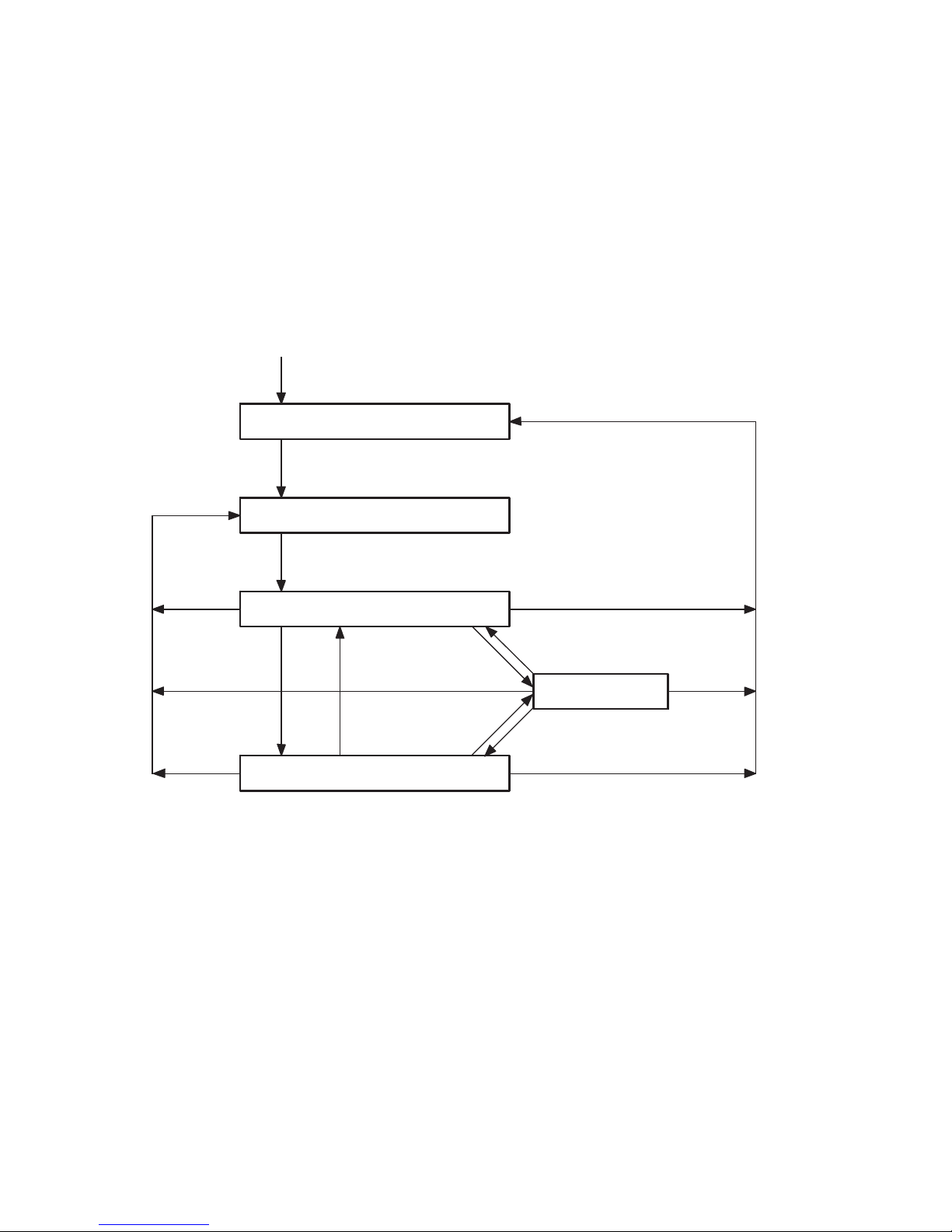

Switch on the power

supply

CP string: Register

module types

“CP configuration fault”

Fault LED P flashes

No

Save button

pressed?

Yes

String assignment

save

Fault LED P out

No

Module types:

Set = Actual?

Yes

First commissioning

(commissioning with

modified configuration)

Fig. 1/13: Switching-on reaction of the CPI system

1-42

CPI system ready to

operate (permanent

I/O update)

Normal operation

Festo P.BE-CPV-CO3-EN en 1201a

1. Installation

1.9 ReactionoftheCPIsystemtofaultsinoperation

Warning

Undesired activation of actuators

An incorrect status of the valves and outputs can lead to

dangerous situations.

• Make sure that valves and outputs are put into a safe

state when faults occur.

If there is a fault on the CP string during operation, e g. due

to cable fracture, this will be displayed on the CPV Direct by

the diagnostic LED of the string extension (P). The status LED

on the relevant module goes out. All modules working without faults remain ready to operate.

Detailed instructions on diagnosing the CPV Direct using the

LEDs can be found in section 3.1.

1.9.1 Eliminating assignment faults

In order to eliminate assignment or connection faults of the

CPI system:

1. Switch off the power supply for the CPV Direct.

2. Restore the saved assignment by connecting the

appropriate CPI/CP modules with the CPV Direct again.

3. Switch on the power supply for the CPV Direct again.

Festo P.BE-CPV-CO3-EN en 1201a

1-43

1. Installation

1.9.2 Replacing CPI/CP modules

Note

Replacing a CPI/CP module with a CPI/CP module of a

different type or replacing several CPI/CP modules will

require new commissioning and new saving of the string

assignment (see section 1.7).

In order to replace an individual module, proceed as follows:

1. Switch off the power supply for the CPV Direct.

2. In the case of CPI/CP output modules and valve terminals

on the CP string concerned:

Switch off the following sources of energy:

– the compressed air supply to the valve terminal

– the operating voltage supply for the CPI/CP output

module.

3. Disconnect all connecting cables and, if necessary, also

the tubing.

4. Connect all the cables and, if applicable, the tubing with

the new module ofthesametype.

5. Now connect the new module ofthesametypeto the

same string.

6. In the case of CPI/CP output modules and CP valve

terminals:

Switch on the operating voltage supply or the

compressed air supply again.

7. Switch on the power supply for the CPV Direct again.

8. Check the addresses of the CPI system.

1-44

Festo P.BE-CPV-CO3-EN en 1201a

Commissioning

Chapter 2

Commissioning

2-1Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

Contents

2. Commissioning 2-1................................................

2.1 Preparing the CPV valve terminal for commissioning 2-3..................

2.1.1 Switching on the operating voltages 2-3........................

2.1.2 Address assignment of the CPV valve terminal 2-4................

2.1.3 Address assignment of CPI/CP modules 2-6.....................

2.1.4 Address assignment for tool change configuration 2-7.............

2.2 CommissioningonaCANopenmaster 2-7..............................

2.2.1 General information on CANopen 2-8...........................

2.3 Overview 2-9......................................................

2.3.1 Brief overview of the scope of functions 2-9.....................

2.3.2 Overview Object directory 2-10................................

2.3.3 Switch-on behaviour of the CPV Direct 2-11......................

2.3.4 Default Identifier distribution 2-1 3..............................

2.3.5 Reaction to network communication faults 2-14...................

2.3.6 Manufacturer Specific Condition Monitoring 2-15..................

2.3.7 Module parameters 2-15......................................

2.4 Tool change configuration 2-16........................................

2.4.1 Example of the tool change configuration 2-18....................

2.5 Overview of parametrizing 2-19........................................

2.6 Further information 2-19.............................................

2-2

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

2.1 Preparing the CPV valve terminal for commissioning

2.1.1 Switching on the operating voltages

Note

Please observe the switching-on instructions in the manual

foryourPLCcontroller.

• Before switching on, make sure that the field bus has

been configured completely and correctly as specified.

Observe the following points before switching on the power

supply:

Common supply Provide a common power supply for the control system and

all field bus slaves via a central power unit or a central switch.

Separate supply If the control system and the field bus slaves have separate

power supplies, the devices must be switched on in the following sequence:

1. the operating voltage supply for all field bus slaves

2. the operating voltage supply for the controller.

Festo P.BE-CPV-CO3-EN en 1201a

2-3

2. Commissioning

2.1.2 Address assignment of the CPV valve terminal

The CPV valve terminal with field bus direct connection always occupies 16 output addresses, irrespective of the

number of valve solenoid coils fitted on it. This enables the

CPV valve terminal to be extended at a later date without the

need to shift the addresses.

The following diagram shows the addressing sequence of the

individual CPV valve plates.

6-7

8-9

10-11

12-13

14-15

0-1

4-5

2-3

Fig. 2/1: Address assignment of the CPV Direct

– A valve location on the CPV valve terminal always

occupies 2 addresses, even if it is fitted with a blanking

plate or pressure separation plate. If a valve location is

fitted with a double-solenoid valve, the following applies:

– pilot solenoid 14 occupies the lower-value address;

– pilot solenoid 12 occupies the higher-value address.

With single-solenoid valves the higher-value address

remains unused.

2-4

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

– The address assignment on the CPV valve terminal is from

left to right and on the individual valve locations from the

front to the rear.

15

Numbers of

the outputs

01234567891011121314

Byte 0 Byte 1

Bit 3Bit 2

Bit 5Bit 4

Bit 0 Bit 1

Bit 1Bit 0

Bit 3Bit 2

Bit 5Bit 4

Bit 7Bit 6

Bit 6 Bit 7

Fig. 2/2: Address assignment of the CPV valve terminal

(outputs) with examples for byte 0 and byte 1

Festo P.BE-CPV-CO3-EN en 1201a

2-5

2. Commissioning

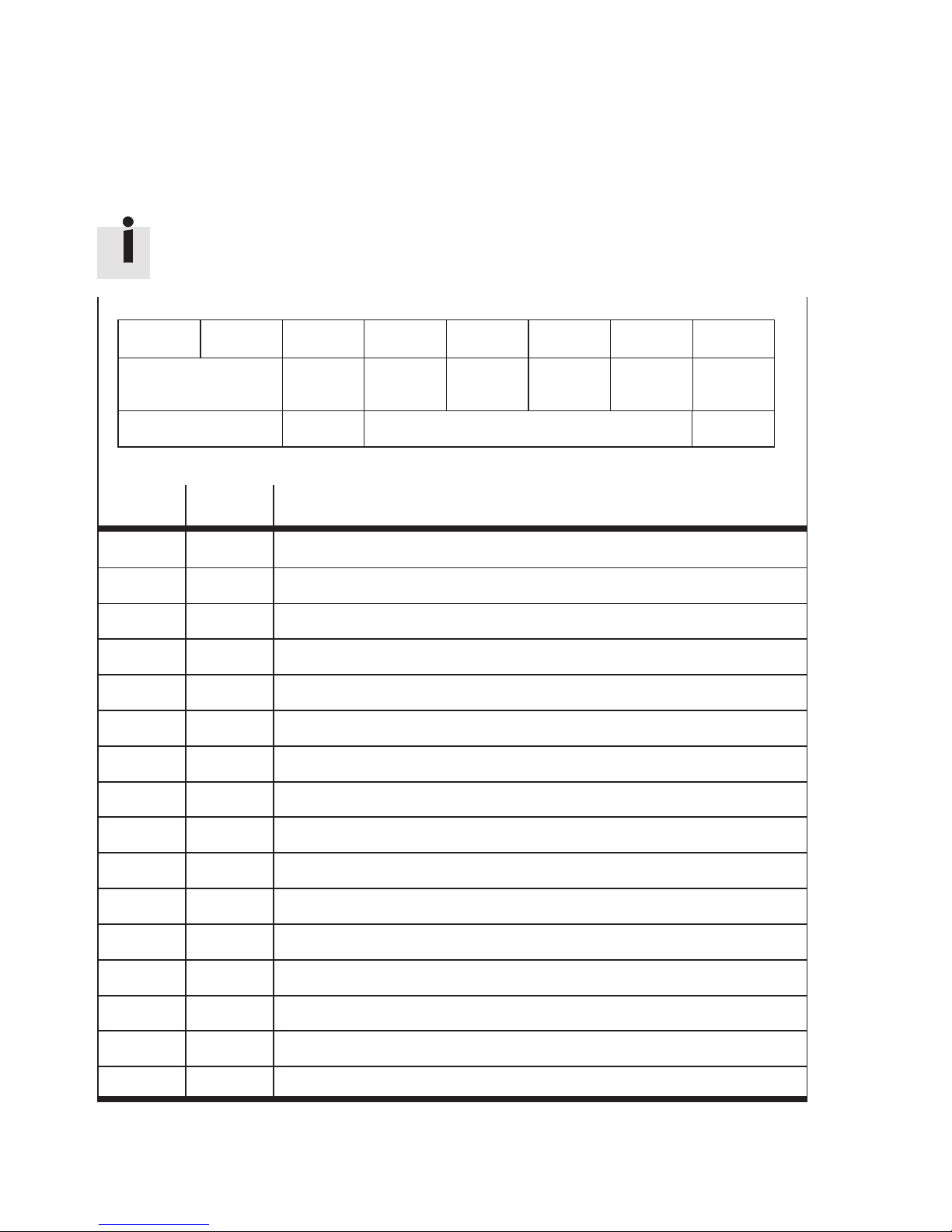

2.1.3 Address assignment of CPI/CP modules

Tab. 2/1 provides an overview of the assigned addresses for

the various CPI/CP modules (as at 2011).

CPI/CP modules

Type CPI-capable

CPI/CP input modules CP-E08-M8-CL

CP-E08-M12-CL

CP-E16-KL-CL

CP-E08-M12-E L

CP-E16-M8-EL

CP-E32-M8-EL

CP-E16-M8

CP-E16N-M8

CP-E16-M8-Z

CP-E16-M12x2-5POL

CP-E16N-M12x2

CP-E16-KL-IP20-Z

CPI/CP output modules

CP-A04-M12-CL

CP-A08-M12-E L-Z

CP-A08-M12-5POL

CP-A08N-M12

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

Yes

Yes

No

No

Assigned I/O on

CPV-CO3-...

1)

CPI masters

I O

8I

8I

16 I

16 I

16 I

32 I

16 I

16 I

16 I

16 I

16 I

16 I

–

–

–

–

1)

–

–

–

–

–

–

–

–

–

–

–

–

8O

8O

16 O

16 O

CPI/CP valve terminals

1)

with extended functions

Further CPI modules and CPI-capable valve terminals in preparation.

CPV...-CPI

CPV-SC-CPI

CPV...-GE-FB-4

CPV...-GE-FB-6

CPV...-GE-FB-8

CPA10/14-IFB-CP

T ab . 2/1: Assigned I/Os of the CPI/CP modules

2-6

Yes

Yes

No

No

No

No

– 16 O

16 O

16 O

16 O

16 O

16 O

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

2.1.4 Address assignment for tool change configuration

Further information on the tool change configuration can be

found in section 2.4.

2.2 CommissioningonaCANopenmaster

This section describes the configuration and addressing of a

CPV valve terminal on a CANopen interface or CANopen

master.

The following standard specifications have been taken into

account:

CANopen specifications (standard regulations)

DS 201

DS 207

DS 301, 4.02 The Draft Standard 301 is based on the CAL c ommunication profile.

DS 401, V2.1 The Draft Standard 401 defines th e device profiles for input and output

CAN Application Layer CAL

modules within CANopen.

In order to understand this section, you should be familiar

with CANopen and the specifications DS 301 and DS 401.

Festo P.BE-CPV-CO3-EN en 1201a

2-7

2. Commissioning

2.2.1 General information on CANopen

CANopen devices have an object directory which makes all

important slave parameters accessible in a standardized

manner. A CANopen system is configured mainly by access to

the object directory of the individual slaves. The access

mechanism is provided by Service Data Objects (SDO).

There are two different communication mechanisms in a

CANopen system.

The P

rocess Data Objects (PDO) serve for the fast transfer of

processing data and are transmitted by simple CAN messages without protocol overhead. Process Data Objects can be

transmitted event-controlled, synchronous to a system pulse

sequence or on demand.

The S

ervice Data Objects (SDO) form a point-to-point connec-

tion and permit access to every entry in the object directory

of a node.

2-8

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

2.3 Overview

2.3.1 Brief overview of the scope of functions

– Module states and boot-up as per Communication Profile

DS 301

– A Service Data Object for read and write access to the

object directory

– A Process Data Object for access to digital outputs

– A Process Data Object for access to digital inputs

– Emergency telegram for fault message to the master

– Node guarding / Heart beat

– Default setting of all identifiers as per DS 301 and the

node address (predefined connection set)

– Variable mapping

Festo P.BE-CPV-CO3-EN en 1201a

2-9

2. Commissioning

2.3.2 Overview Object directory

The following table provides an overview of the implemented

objects of the CPV-CO3:

Index (hex)

Objects See

section

1000 … 1200 Communication part of the object

directory

1400 Communication parameters for

Receive PDO (outputs)

1600 Mapping parameters for Receive PDO

(outputs)

1800 Communication parameters for

Transmit PDO (inputs)

1A00 Mapping parameters for Transmit PDO

(inputs)

3000 … 3050 Manufacturer Specific,

Condition Counter

3100 Manufacturer Spe cific, Module Identity B.1.6

3200 Manufacturer Specific ,

Module Diagnosis

B.1.2

B.1.4

B.1.3

B.1.5

2-10

3300 Manufacturer Specific ,

Module Parameter

6000 Input Array B.1.3

6200 Output Array B.1.4

6206 Fault Mode Array for the outputs

6207 Fault State Array for the outputs

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

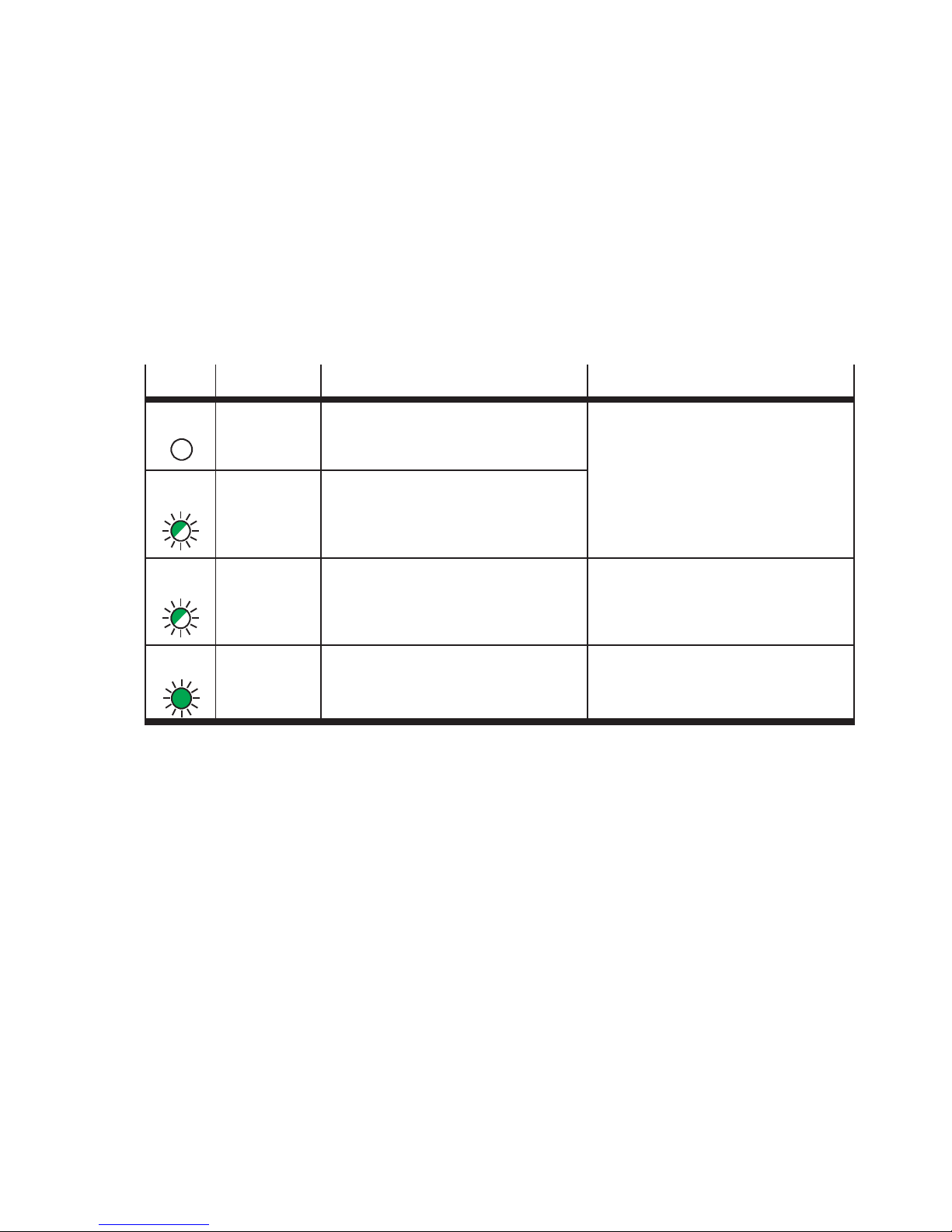

2.3.3 Switch-on behaviour of the CPV Direct

The following diagram shows the status transitions of the

CPV Direct:

Power on

Hardware initialization

0

0

5

Communication initialization

4

00

Pre-operational

2

1

2

3

Stopped

3

1

Operational

Fig. 2/3: Status transitions of the CPV Direct (description see next page)

Festo P.BE-CPV-CO3-EN en 1201a

2-11

2. Commissioning

0

Description of the status transitions

Status

transition

0

1

2

3

Description Command

Specifier (CS)

Operational

mode

Pre-operational

mode

Stopped mode 02

01

H

Start_Remote_

Node_Indication

80

H

Enter_Pre_

Operation_

State_Indication

H

Stop_Node_

Indication

Function

Automatic boot up after Power On

Starts the CPV valve terminal in operational

mode:

– SDO transmission valid

– PDO transmission (outputs active)

– Node guarding / Heart beat valid

(Node guard response: Toggle + 05

CPV valve terminal in pre-operational mode:

– SDO transmission valid

– PDO transmission invalid (outputs assume

fault status

*)

)

– Node guarding / Heart beat valid

(Node guard response: Toggle + 7F

CPV valve terminal in stopped mode:

– SDO transmission invalid

– PDO transmission invalid (outputs assume

fault status

*)

)

– Node guarding / Heart beat valid

(Node guard response: Toggle + 04

)

H

)

H

)

H

4

Resetting the

communication

functions

5

Module reset

including

application

*)

only after the transition from operational mode to stopped or pre-operational mode

2-12

82

H

Reset_

Communication_

Indication

81

H

Reset_Node_

Indication

Resetting the communication functions:

– Outputs are reset

– Communication parameters are reset

(Index 1000

… 1FFFh)

h

Module reset including application:

– Outputs are reset

– SDO re-initialized, modified values are reset

(Index 1000

… 6207h)

h

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

2.3.4 Default Identifier distribution

The following table shows the identifier distribution:

Broadcast objects

Object name

Object designation ValuerangeoftheCOBidentifier

with the CPV Direct

SYNC 128

080

D

H

Peer-to-Peer objects

Object

Object designation ValuerangeoftheCOBidentifier

with the CPV Direct

EMERGENCY For procedures wit h high

priority,e.g.undervoltage

Send PDO PDO1 (Tx), inputs 385D… 511

Receive PDO PDO1 (Rx), valves/outputs 513D… 639

Transmit SDO SDO1 (Tx) 1409D… 1535

129D… 255

081

181

201

581

0FF

H

H

H

H

1FF

27F

5FF

D

H

*)

D

H

D

H

D

H

Receive SDO SDO1 (Rx) 1537D… 1663

Node guarding /

Heart beat

*)

The value depends on the bus address, e.g.: PDO1 (Tx) = 384D + bus address

Festo P.BE-CPV-CO3-EN en 1201a

601

H

67F

Guarding 1793D… 1919

701

H

77F

D

H

D

H

2-13

2. Commissioning

2.3.5 Reaction to network communication faults

You can parametrize the reaction of the valves and any existing outputs if a fault occurs. All valves/outputs are reset as

standard when the following faults and operating states occur

as soon as Node guard, Heart beat are activated via the configuration:

– Communication faults (Node guard, Heart beat)

– Transitio n from operational to pre-operational or stopped

The status of the valves/outputs can be modified via indices

6206 and 6207 (Default Output Mode, Error State Output)

(see section B.1.4).

The general reaction of the valve terminal to faults (communication faults, faults on the input or output module and faults

on the CPI/CP string) can be parametrized via Index 1029.

Default setting via Index 1029 (see section B.1):

– Communication faults as well as input/output faults lead

to the pre-operational status.

– CPI/CP faults remain in the current status.

Warning

• Make sure that valves and outputs are reset when the

faults named occur.

Dangerous situations may arise if the valves and outputs

are not reset.

Note here the example C.1.3. in the appendix.

2-14

Festo P.BE-CPV-CO3-EN en 1201a

2. Commissioning

Note

Pleasenotethefollowingiftheoutputsareresetafter

PLC stop, field bus interruption or fault:

– Single-solenoid valves move to the basic position.

– Double-solenoid valves remain in the current position.

– Mid-position valves move to the mid-position (depend-

ing on valve type: pressurized, exhausted or blocked).

2.3.6 Manufacturer Specific Condition Monitoring

Examples see section B.1.5.

2.3.7 Module parameters

Further information on the module parameters see

CPI system description CP-B E-CPX-CP-...

Festo P.BE-CPV-CO3-EN en 1201a

2-15

2. Commissioning

2.4 Tool change configuration

With the string configuration in the tool change configuration,

you can commission modules on the CPI extension connection without a new configuration. In the tool change configuration, pressing the SAVE button is not necessary.