Page 1

FG

,

cod. 3540I950 — 06/2007 (Rev. 00)

INSTRUCTIONS FOR USE, INSTALLATION AND MAINTENANCE

INSTRUCTIONS D'UTILISATION, D'INSTALLATION ET D'ENTRETIEN

KULLANMA, KURULUM VE BAKøM TALIMATLARø

Page 2

FG

B

• Carefully read the warnings in this instruction booklet since they provide important information on safe

installation, use and maintenance.

• This instruction booklet is an integral part of the

product and must be carefully kept by the user for future reference.

• If the unit is sold or transferred to another owner or if

it is to be moved, always make sure that the booklet

accompanies the boiler so that it can be consulted

by the new owner and/or installer.

• Installation and maintenance must be carried out by

professionally qualified personnel, according to current regulations and the manufacturer's instructions.

• Incorrect installation or poor maintenance can cause

damage or physical injury. The manufacturer declines any responsibility for damage caused by errors in installation and use or by failure to follow the

manufacturer's instructions.

• Before carrying out any cleaning or maintenance operation, disconnect the unit from the electrical power

supply using the switch and/or the special cut-off devices.

• In case the unit breaks down and/or functions poorly,

deactivate it, do not make any attempt to repair it or

directly intervene. Contact professionally qualified

personnel. Any repair/replacement of products must

only be carried out by qualified professional personnel using exclusively genuine parts. Failure to comply with the above could affect the safety of the unit.

• Periodical maintenance carried out by qualified personnel is essential for guaranteeing good operation

of the unit.

• This unit must only be used for the purpose for which

it was designed. Any other use is considered improper and therefore hazardous.

• After removing the packing, check the integrity of the

contents. Packing materials must not be left within

the reach of children as they are potentially hazardous.

• In case of doubt do not use the unit, and contact the

supplier.

• The images shown in this manual are a simplified

representation of the product. In this representation

there may be slight, unimportant differences with the

supplied product.

B

A

This symbol indicates "Caution" and is placed next to all safety warnings. Strictly follow

these instructions in order to avoid danger and damage to persons, animals and things.

This symbols calls attention to a note or important notice.

Declaration of conformity

Manufacturer: FERROLI S.p.A.

Address: Via Ritonda 78/a 37047 San Bonifacio VR Italy

declares that this unit complies with the following EU directives:

• Low Voltage Directive 73/23 (amended by 93/68)

• Electromagnetic Compatibility Directive 89/336 (amended by 93/68)

President and Legal Representative

Cav. del Lavoro

Dante Ferroli

2 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 3

FG

1 Operating instructions ............................................................................................................4

1.1 Introduction.............................................................................................................................................4

1.2 Control panel .......................................................................................................................................... 4

1.3 Lighting and shutdown ........................................................................................................................... 5

1.4 Adjustments............................................................................................................................................6

2 Installation................................................................................................................................ 8

2.1 General Instructions ...............................................................................................................................8

2.2 Place of installation ................................................................................................................................8

2.3 Plumbing connections ............................................................................................................................8

2.4 Safety coil connection (optional) ............................................................................................................9

2.5 Electrical connections........................................................................................................................... 10

2.6 Connection to the flue .......................................................................................................................... 11

3 Service and maintenance......................................................................................................12

3.1 Adjustments.......................................................................................................................................... 12

3.2 Startup.................................................................................................................................................. 12

3.3 Maintenance......................................................................................................................................... 12

3.4 Troubleshooting.................................................................................................................................... 14

4 Technical data and characteristics ...................................................................................... 15

4.1 Dimensions, connections and main components .................................................................................15

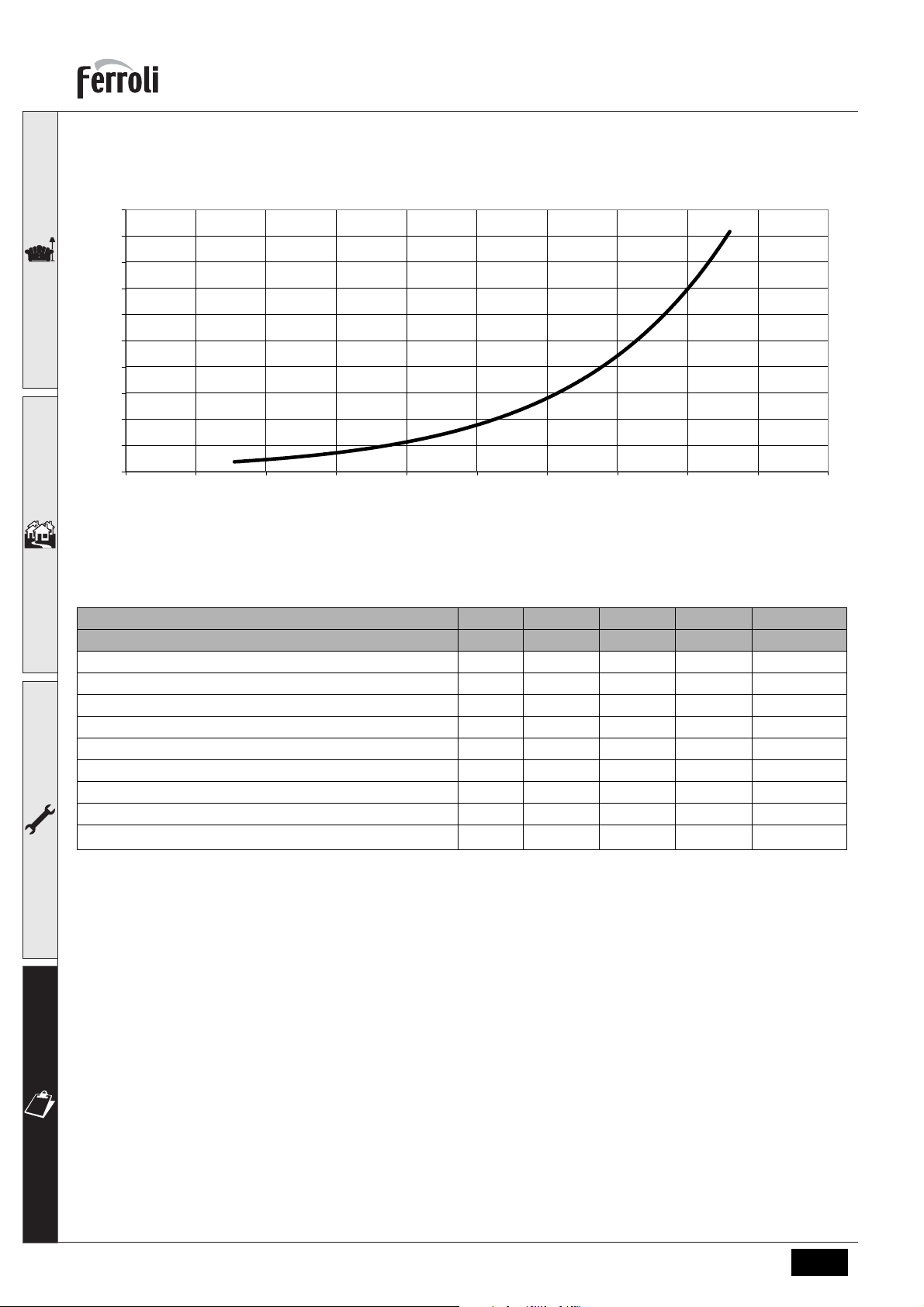

4.2 Pressure loss........................................................................................................................................16

4.3 Technical data table .............................................................................................................................16

4.4 Wiring diagram .....................................................................................................................................17

,

cod. 3540I950 - 06/2007 (Rev. 00)

3

Page 4

FG

1. Operating instructions

1.1 Introduction

Dear Customer,

Thank you for choosing a FERROLI boiler featuring advanced design, cutting-edge technology, high reliability and qual-

ity construction. Please read this manual carefully since it provides important information on safe installation, use and

maintenance.

FG is a wood-burning steel boiler, with total gasification. It exploits the principle of reverse flame combustion, with gradual burning of the wood, to the advantage long operation times before refuelling. In fact, thanks to a variable-speed fan

located at the back of the boiler, combustion occurs in a negative pressure. the lit wood, placed in a holder above a

special grill, develops a particular type of combustion which, thanks to the high temperature determined by a balanced

supply of primary combustion air from above and secondary air injected through the separation grill, turns the cellulose

into simpler compounds that burn in the underlying combustion chamber with a flame similar to that of natural gas, with

efficiencies exceeding 85%. In the wood loading stage the fan is activated when the door is opened, thus preventing

smoke from escaping.

The outer casing consists of painted steel panels, insulated internally with mineral wood to ensure optimum insulation

of the boiler body. A safety exchanger for eliminating the excess heat can be installed by request.

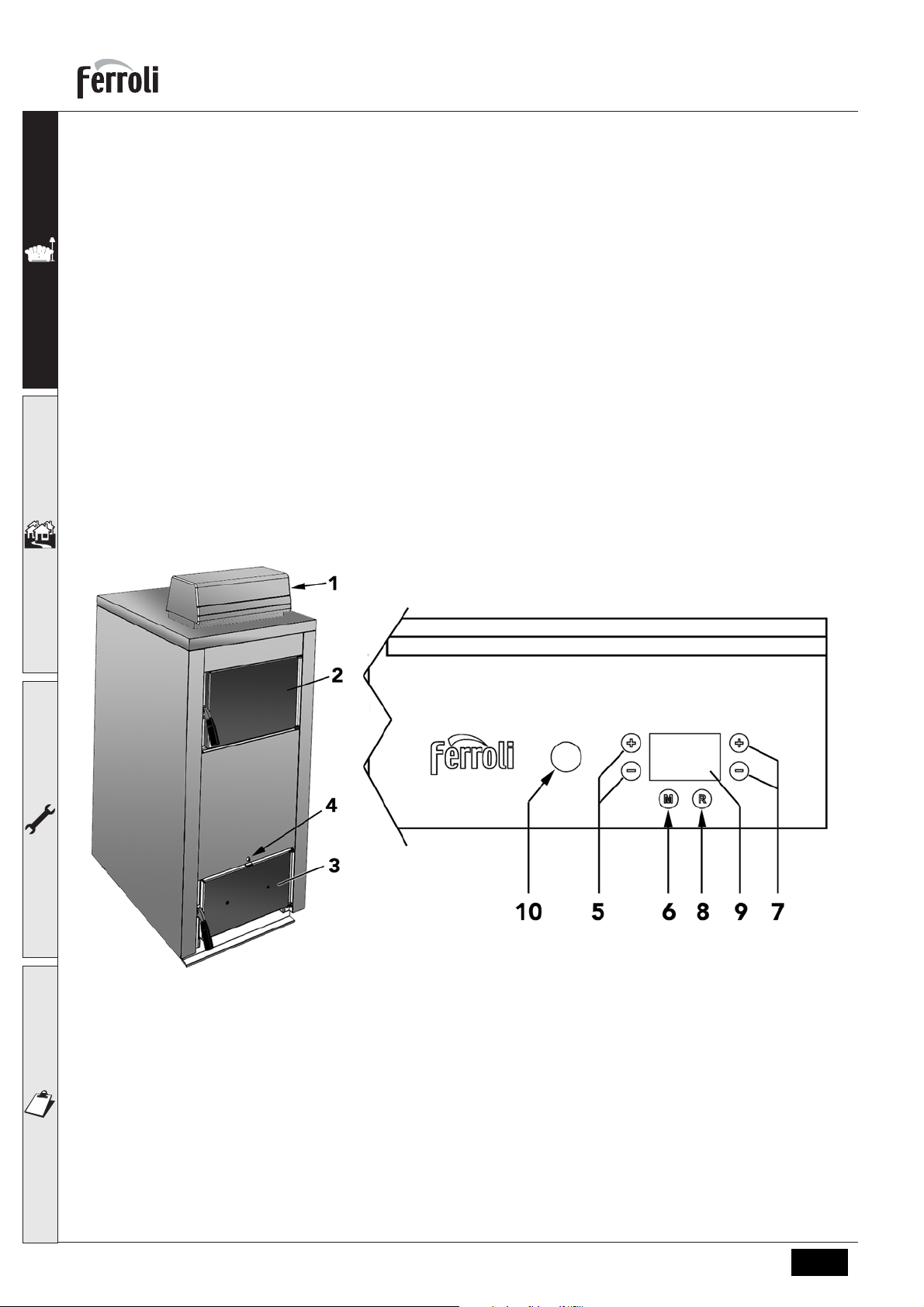

1.2 Control panel

fig. 1 - Control panel

Key

1 Control panel

2 Wood loading door

3 Combustion chamber/ash compartment door

4 Combustion air adjustment

5 Heating temperature adjustment + - buttons

During operation, the display shows the system delivery temperature.

4 GB

cod. 3540I950 - 06/2007 (Rev. 00)

6 Button M, Summer/Winter "Mode" changeover

7 Parameter editing + - buttons

8 Button R, configuration menu access

9 Display

10 Lighting switch

Page 5

FG

1.3 Lighting and shutdown

Fuel

The boiler must only operate with normal and untreated wood. The logs can be 50 cm long for models FG30 and FG40,

and 70 cm for model FG50. Pressed fuels and briquettes can also be used, provided they are entirely of wood.

The burning of waste, plastic or liquids can create dangerous burnt gases with risk of poisoning, death or ex-

B

• Only use the specified fuels.

• In the presence of risk of explosion, fire, burnt gases or fumes, put the boiler out of service.

• The boiler must only be operated by adults who are familiar with the boiler instructions and its operation.

• The user is only authorised to start the boiler, set the heating temperature, put it out of service and clean it.

• Keep unsupervised children away from the boiler when it is operating.

• Do not burn liquids or use them to increase boiler performance.

• Only use non-flammable agents to clean the surface of the boiler.

• Do not place flammable objects on or near the boiler.

• Do not place flammable materials in the boiler installation compartment (e.g. wood, paper, petroleum, gas oil).

Wood is an extremely heterogeneous fuel for type, moisture content, shape and size. Boiler heating efficiency depends

on the type of wood used and its moisture content, as well as the method of loading and size of the fuel. Excellent quality

woods are oak, ash, beech, maple and fruit trees except cherry; chestnut and birch are good quality; lime, poplar and

willow are of adequate quality. Resiniferous woods are generally mediocre fuels. The higher the moisture-content, the

lower the heating power. The use of fuels that are not dry causes losses of efficiency. Use logs dried outdoors and in

the natural state (stored for 2 years with max. moisture content 20%).

plosion.

Boiler lighting

• Open the bottom door and remove any ash present in the combustion chamber. Close the bottom door.

• Switch on the power to the unit. Turn the switch to ON.

• Open the top door. Place some paper and kindling on the burner plate.

• Light the fuel and add some slightly larger pieces of wood.

• Close the door and wait for a first bed of embers to form.

• Open the top door slowly to allow the fan to suck the smoke accumulated in the firewood holder.

• Spread the embers evenly on the burner plate, using a poker.

• Load wood when the bed of embers has formed on the main stone.

Loading wood

• Proceed with loading wood which must be 50 cm long for models FG30 and FG40, and approx. 70 cm for model

FG50.

• Since regular falling of the wood is essential for good combustion, make sure that the length of the pieces of wood

introduced, their shape and method of loading do not hinder it. The pieces must be arranged lengthwise and horizontally. No pieces must be inclined or placed sideways.

• Consume the wood as much as possible before loading more.

• New loading can be carried out when the bed of embers in the holder is approx. 5 cm deep.

• Open the top loading door slowly.

• Arrange the new load of wood in the same way as previously described.

- Pieces that are too long do not fall regularly, causing empty spaces in the wood holder, with the formation of

B

unburnt wood areas.

- Pieces that are too short cause uneven air passages, with a decrease in power and efficiency.

- Always open the top door slowly, in order to avoid puffs and the creation of smoke.

- Never open the bottom door during operation.

- During loading avoid keeping the top door open for long periods.

- In case of operation with reduced performance, low temperature distilled gases can form, with risk of poisoning if breathed.

- If dense smoke can be seen, do not breathe it.

- Make sure the installation room is well-ventilated.

- Clean the boiler and gas exhaust ducts as prescribed.

cod. 3540I950 - 06/2007 (Rev. 00)

5GB

Page 6

FG

Boiler shutdown

To shut down the boiler, allow all the fuel to be burned.

Shutdown for short periods

For short shutdown periods, turn the lighting switch to OFF after the fuel has finished and the boiler has cooled.

• Clean the loading door support surfaces and the loading compartment.

• Remove the ashes and clean the combustion chamber.

• Close the ash compartment door and the loading door.

Shutdown for long periods

To put the boiler out of service for long periods (e.g. at the end of the cold season), carefully clean the boiler to prevent

corrosion.

To avoid damage caused by freezing during long idle periods in winter, it is advisable to drain all water from

B

the boiler, or add a suitable antifreeze to the heating system, in compliance with that prescribed in sec. 2.3.

1.4 Adjustments

Summer/Winter changeover

Press the button to activate Summer/Winter changeover.

Heating temperature setting

Operate the buttons and (detail 5 fig. 1) to set the system delivery temperature.

The control system regulates the fan air delivery and therefore the speed of combustion for reaching and maintaining

the set temperature.

At too low boiler water temperatures tar forms inside the boiler, and at temperatures below 65 °C condensate

B

forms in the combustion chamber.

Frequent operation below 65 °C causes a big reduction in the boiler's useful life.

Make sure the boiler water temperature remains constantly between 80 - 90 °C.

6 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 7

FG

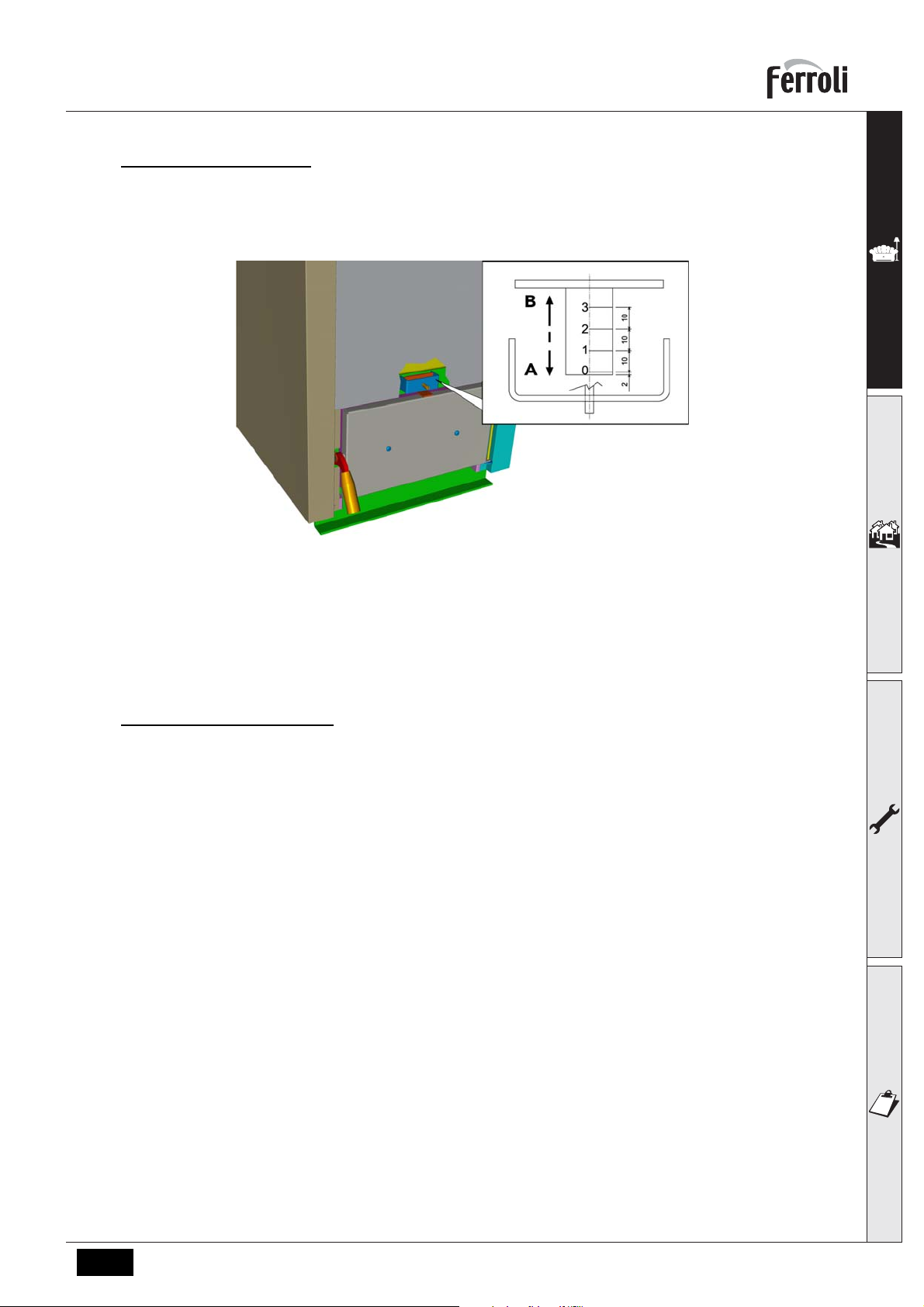

Secondary air adjustment

The smoke extractor fan located on the back of the boiler supplies the primary combustion air. The boiler is equipped

with a factory-set secondary air adjustment device, which must be checked with the aid of a combustion analyser in the

first lighting stage. The adjustment screw can subsequently be used to adapt the supply of secondary air according to

the quality and type of fuel.

fig. 2 - Secondary air adjustment

A Open

B Closed

• Large, wet are hard to burn wood: close 1 notch.

• Dry and very flammable wood: open 1 notch or more.

• If the boiler tends to puff due to very wet fuel, close it gradually.

System pressure adjustment

Periodically check that the system is full of water. These checks must be carried out cold, checking the expansion tanks

(open types must have water at the initial level, whereas in closed types the pressure must be equal to or higher than

the initial prefilling pressure).

cod. 3540I950 - 06/2007 (Rev. 00)

7GB

Page 8

FG

2. Installation

2.1 General Instructions

BOILER INSTALLATION MUST ONLY BE PERFORMED BY QUALIFIED PERSONNEL, IN ACCORDANCE WITH

ALL THE INSTRUCTIONS GIVEN IN THIS TECHNICAL MANUAL, THE PROVISIONS OF CURRENT LAW, THE PRESCRIPTIONS OF NATIONAL AND LOCAL STANDARDS AND THE RULES OF PROPER WORKMANSHIP.

2.2 Place of installation

The boiler must be installed in a special room with ventilation openings towards the outside in conformity with current

regulations. If there are several burners or extractors that can work together in the same room, the ventilation openings

must be sized for simultaneous operation of all the units. The place of installation must be free of flammable objects or

materials, corrosive gases, volatile substances or dusts that can be sucked by the fan. The room must be dry and not

exposed to rain, snow or frost.

A

2.3 Plumbing connections

Ensure enough space around the unit for removing the casing and for normal servicing operations. In particular, make sure there is enough space in the front part of the boiler for loading the fuel.

The heating capacity of the unit must be previously established by calculating the building's heat requirement according

to current regulations. The system must be provided with all the components for correct and regular operation. It is advisable to install on-off valves between the boiler and heating system allowing the boiler to be isolated from the system

if necessary.

The safety valve outlet must be connected to a funnel or collection pipe to prevent water spurting onto the floor

B

Before installation, carefully wash all the pipes of the system to remove residuals or impurities that could affect correct

operation of the unit.

Carry out the relevant connections according to the diagram in cap. 4 "Technical data and characteristics" and the symbols given on the unit.

Characteristics of the water system

In the presence of water harder than 25° Fr (1°F = 10ppm CaCO3), use suitably treated water in order to avoid possible

scaling in the boiler. Treatment must not reduce the hardness to values below 15°F (Decree 236/88 for uses of water

intended for human consumption). Treatment of the water used is indispensable in case of very large systems or with

frequent introduction of replenishing water in the system.

Antifreeze system, antifreeze fluids, additives and inhibitors

If necessary, antifreeze fluids, additives and inhibitors can be used only if the manufacturer of these products guarantees that they are suitable for this use and do not cause damage to the boiler exchanger or other components and/or

materials of the unit and system. Do not use antifreeze fluids, additives or inhibitors that are not specific for use in heating systems and not compatible with the boiler materials and system.

in case of overpressure in the heating circuit. Otherwise, if the drain valve is activated and floods the room,

the boiler manufacturer cannot be held liable.

Do not use the water system pipes to earth electrical appliances.

8 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 9

FG

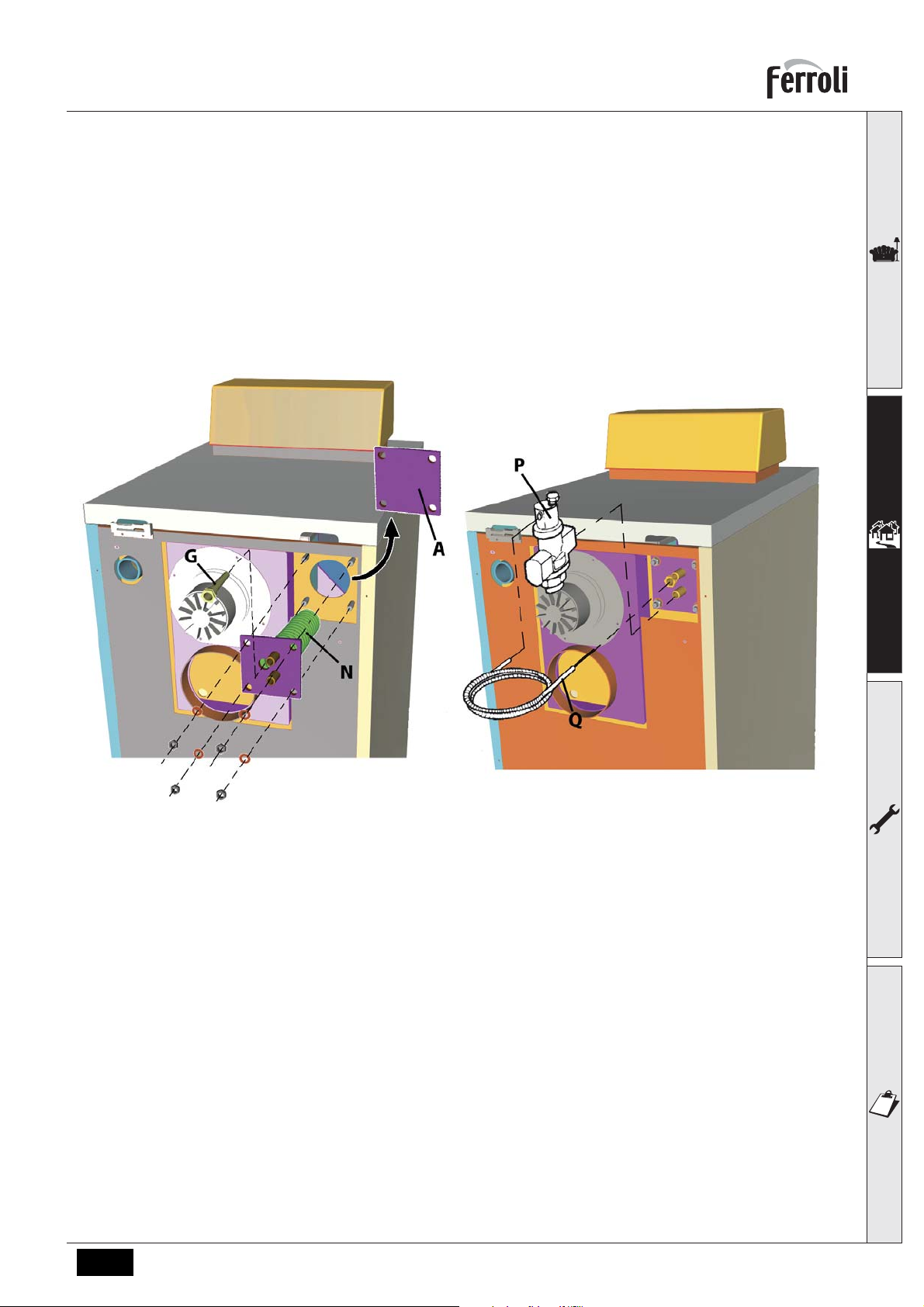

2.4 Safety coil connection (optional)

An external (cooling circuit) safety heat exchanger (optional) can be supplied together with the boiler.

In countries where Standard EN 303-5 is applied, the boiler must have a system enabling a safety outlet for the excess

heat without additional energy. In this way the maximum boiler water temperature will not exceed 100 °C (overheating

protection).

The minimum cooling water supply pressure must be 2.0 bar. A flowrate of at least 10 l/min. must be available.

• Remove the flange “A” located at the back of the boiler.

• Install the coil “N”, fixing it with the 4 bolts.

• Fit the safety valve "P" on the outlet of the coil "N", respecting the direction of the arrow. Insert the valve probe "Q"

in the special sheath "G". Connect the water inlet directly to the safety coil. Connect the valve outlet.

fig. 3 - Safety heat exchanger connection

cod. 3540I950 - 06/2007 (Rev. 00)

9GB

Page 10

FG

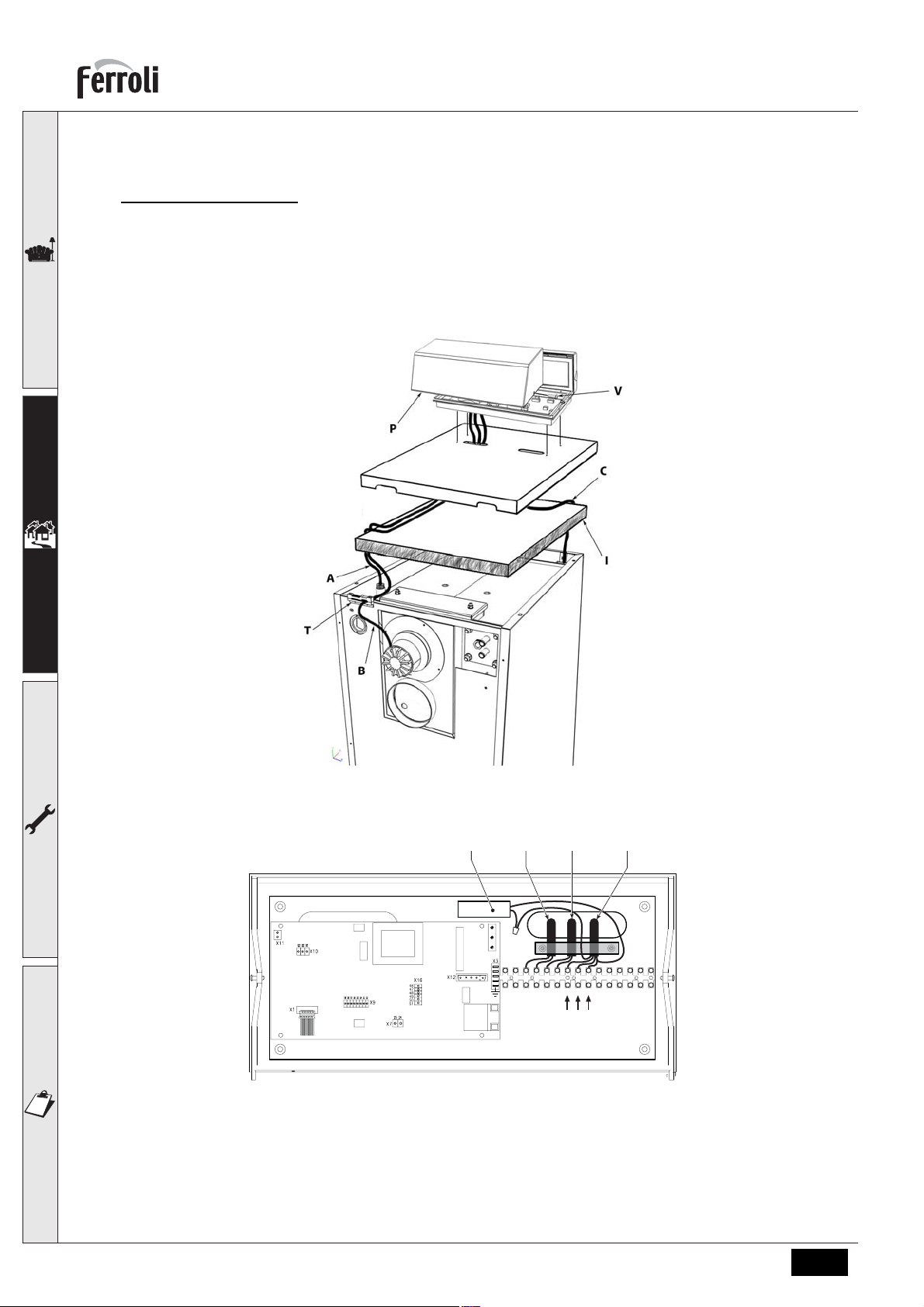

2.5 Electrical connections

Fitting the control panel

1. Remove the control panel cover "P" by undoing the two side screws "V".

2. Arrange the cables of the fan "B", the sensor "A" and the door microswitch "C" as shown in fig. 4

3. Connect the fan cable to the terminal block, respecting the colours indicated in fig. 5 and fix the condenser"R" with

the special adhesive clamp.

4. Connect the cable of the microswitch "C" to the terminals as shown in fig. 5.

5. Insert the probe "A" in the special pocket.

C Condenser

16 Fan

34 Heating temperature sensor

296 Door microswitch

fig. 4 - Fitting the control panel

R

fig. 5 - Connection to the terminal block

34 296 16

14131211109876543

Blu

Giallo/Verde

Nero/Bianco

10 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 11

FG

Connection to the electrical grid

The unit's electrical safety is only guaranteed when correctly connected to an efficient earthing system exe-

B

The boiler is prewired and provided with a Y-cable and plug for connection to the electricity line. The connections to the

grid must be made with a permanent connection and equipped with a bipolar switch whose contacts have a minimum

opening of at least 3 mm, interposing fuses of max. 3A between the boiler and the line. It is important to respect the

polarities (LINE: brown wire / NEUTRAL: blue wire / EARTH: yellow-green wire) in making connections to the electrical

line. During installation or when changing the power cable, the earth wire must be left 2 cm longer than the others.

B

2.6 Connection to the flue

The unit must be connected to a flue designed and built in compliance with current regulations. The pipe between the

boiler and flue must be made from material suitable for the purpose, i.e. heat and corrosion resistant. Ensure the seal

at the joints and insulate the entire pipe between boiler and flue, to prevent the formation of condensate.

cuted according to current safety standards. Have the efficiency and suitability of the earthing system checked

by professionally qualified personnel. The manufacturer is not responsible for any damage caused by failure

to earth the system. Also make sure that the electrical system is adequate for the maximum power absorbed

by the unit, as specified on the boiler dataplate.

The user must never change the unit's power cable. If the cable gets damaged, switch off the unit and have it

changed solely by professionally qualified personnel. If changing the electric power cable, use solely “HAR

H05 VV-F” 3x0.75 mm2 cable with a maximum outside diameter of 8 mm.

cod. 3540I950 - 06/2007 (Rev. 00)

11GB

Page 12

FG

3. Service and maintenance

All adjustment, conversion, startup and periodical checking operations described below must only be carried out by Qualified Personnel (meeting the professional technical requirements prescribed by current regulations).

FERROLI declines any liability for damage and/or injury caused by unqualified and unauthorised people tampering with the

unit.

3.1 Adjustments

Secondary air adjustment

During the startup stage it is advisable to check the setting of the secondary air adjustment device.

Light the boiler and carry out first loading with the same type of fuel to be used by the end-user.

Wait for the boiler to stabilise.

Using a combustion analyser check the CO in the fumes. If the CO content is > 0.5% gradually open the regulator until

obtaining a CO value of < 0.5%.

N.B.: opening the secondary air regulator of the boiler too much can result in uneven combustion (tendency to

"puff"). In this case close the regulator by 1/2 - 1 notch.

3.2 Startup

Checks to be made at first lighting, and after all maintenance operations that involved disconnecting from the

B

Before lighting the boiler

• Open any on-off valves between the boiler and the systems.

• Check correct prefilling of the expansion tank

• Fill the water system and make sure that all air contained in the boiler and the system has been vented.

• Make sure there are no water leaks in the system, connections or boiler.

• Check correct connection of the electrical system and efficiency of the earthing system

• Make sure there are no flammable liquids or materials in the immediate vicinity of the boiler

Checks during operation

• Turn the unit on as described in sec. 1.3.

• Check the seal of the water systems.

• Check the efficiency of the flue and air-fume ducts while the boiler is working.

• Check that the water is circulating properly between the boiler and the systems.

• Check the seal of the wood loading and combustion chamber doors.

• Check combustion and correct setting of the secondary air control device.

systems or operations on safety devices or parts of the boiler.

3.3 Maintenance

Warnings

- Before carrying out any maintenance make sure to disconnect the power to the boiler and wait until it is at

B

room temperature.

- Never drain (even partially) the water from the system, unless absolutely necessary.

- Do not clean the boiler and/or its parts with easily flammable substances (e.g. petrol, alcohol, etc.).

- Do not leave containers with flammable substances in the room where the boiler is installed.

- Do not clean the heating system with boiler operating.

- Use tube brushes and vacuum aspirators for cleaning; if rags are used, make sure they are not left inside

the boiler.

12 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 13

FG

Routine maintenance

Soot and ash on the inside walls of the boiler and on the refractory bricks reduces the transfer of heat. However, during

the operation of a boiler with wood gasification less ash is produced than during heating with conventional boilers.

Remove the ash from the combustion chamber every 1-2 days, and in any case before it is full, so as to leave sufficient

space for combustion.

If the ash is still hot, use protective gloves.

B

Carry out thorough cleaning at least once a week:

• Open the loading door and brush the combustion residuals in the ash compartment through the opening between

• Clean the inside walls of the combustion chamber with a brush

• Remove the loose soot and ash from the combustion chamber.

• Check perfect door closure seal. Also make sure there is no tar or condensate dripping from the smokebox.

Put the ash in a non-flammable container provided with a lid.

the burner plates.

Do not clean the burner plates with a wire brush, as they may become damaged.

B

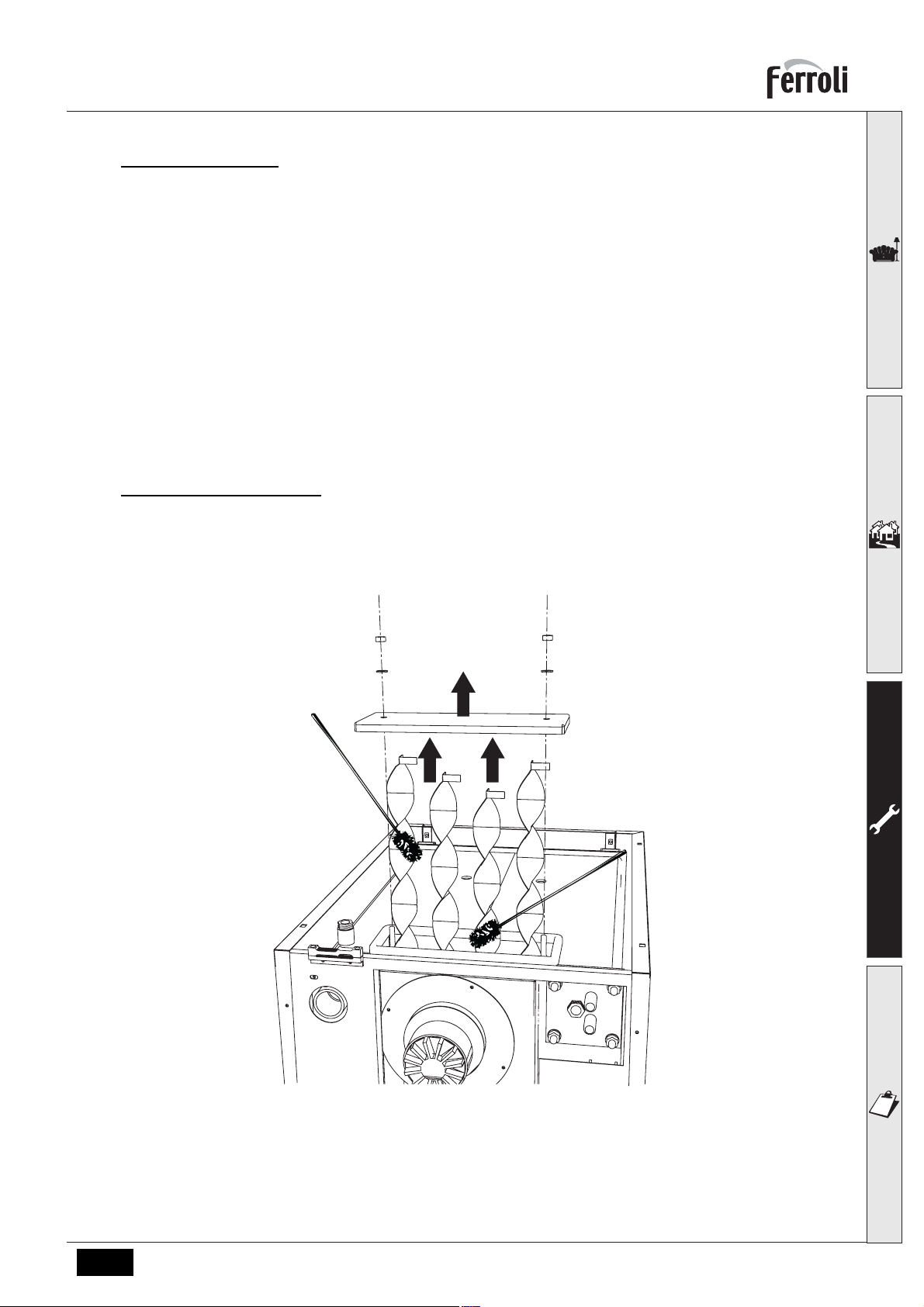

Extraordinary maintenance

Clean the fume ducts once a month:

• Remove the top cover of the casing

• Open the inspection door at the back of the boiler (see fig. 6).

• Remove the turbulators and clean the fume ducts with a tube brush.

fig. 6 - Fume duct cleaning

cod. 3540I950 - 06/2007 (Rev. 00)

13GB

Page 14

FG

Periodical check

To ensure correct operation of the unit over time, have qualified personnel carry out a yearly check, providing for the

following:

• Check and if necessary clean the boiler and fume ducts as indicated in the previous paragraph.

• Remove the fume extractor and clean the fan.

• Check the conditions of the burner plates.

• Check the seal of the ash compartment and loading door; replace the gasket if necessary.

• The control and safety devices must work properly.

• The fume exhaust circuit must be perfectly efficient.

• The exhaust pipes and terminals must be free of obstructions and leaks

• The burner and exchanger must be clean and free of deposits. For possible cleaning do not use chemical products

or wire brushes.

• The water pressure in the system when cold must be approx. 1 bar; otherwise bring it to that value.

• The circulating pump must not be blocked.

• The expansion tank must be filled.

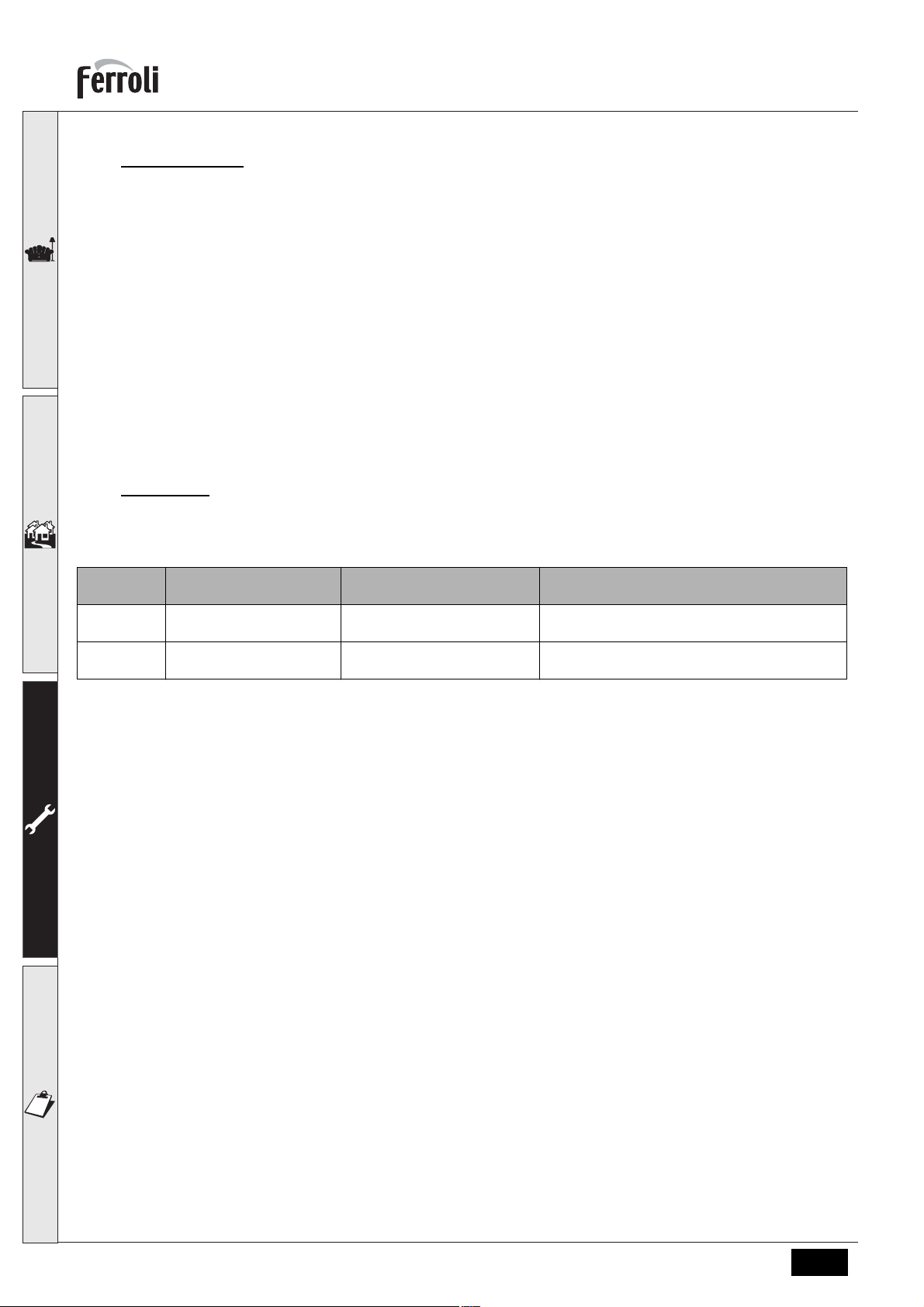

3.4 Troubleshooting

Diagnostics

In case of operation anomalies or problems, the display flashes and a fault identification code appears.

Table. 1 - Fault list

Fault

code

E05

E06

Fault Possible cause Cure

Heating temperature sensor

fault

Heating temperature sensor

fault

Sensor damaged or short

circuited

Sensor damaged or wiring disconnected

Check the wiring or replace the sensor

Check the wiring or replace the sensor

14 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 15

FG

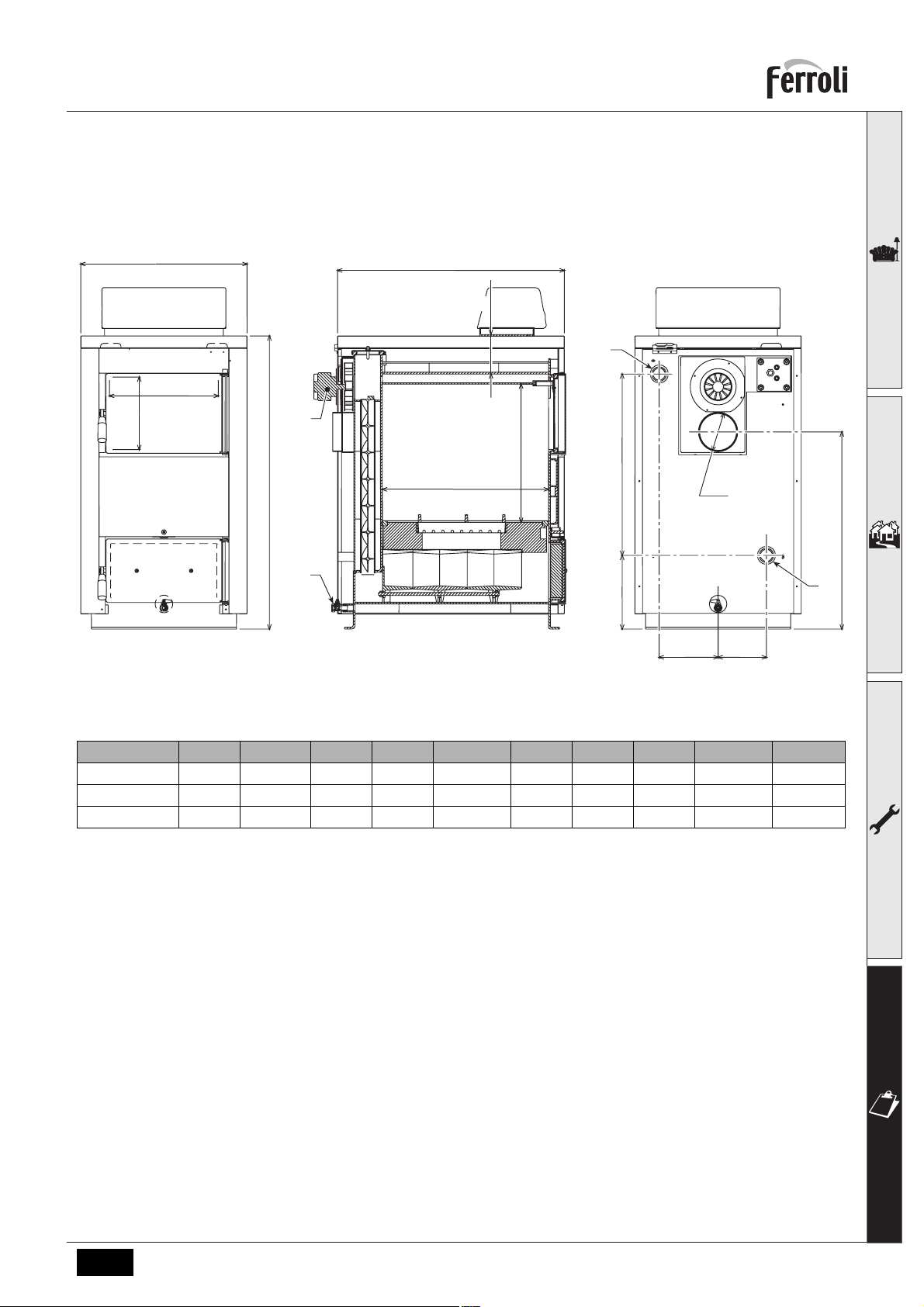

4. Technical data and characteristics

4.1 Dimensions, connections and main components

240

A

360

C

86

16

E

B

275

fig. 7 - Dimensions, connections and main components

D

10

F244

L

I

11

GH

Model A B C D E F G H I L (Ø)

Fg 30 550 970 750 550 457.7 600 195 160 652.5 130

Fg 40 550 1150 750 550 637.5 780 195 160 812 150

Fg 50 600 1150 930 730 627.5 780 220 185 812 150

Key

10 System delivery

11 System return

16 Fan

275 System water drain

cod. 3540I950 - 06/2007 (Rev. 00)

15GB

Page 16

FG

4.2 Pressure loss

20

18

16

14

12

10

mbar

8

6

4

2

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

portata lt/h

4.3 Technical data table

Unit Value Value Value

Model FG 30 FG 40 FG 50

Max. heating capacity kW 34.9 46.2 57.5 (Q)

Min. heating capacity kW 16.9 22.3 27.8 (Q)

Max. heat output in heating kW 30 40 50 (P)

Min. heat output in heating kW 15 20 25 (P)

Efficiency Pmax % 86 86.5 87

Efficiency Pmin % 89 89.5 90

Working pressure in heating bar 3 3 3 (PMS)

Empty weight kg 185 220 286

3

Combustion chamber volume

dm

100 140 200

16 GB

cod. 3540I950 - 06/2007 (Rev. 00)

Page 17

FG

4.4 Wiring diagram

N

93 92 91

16

34

72

296

32

230V

N

50Hz

L

34567891011121314 N L

98

59 58 57 56 55 54 53 52

N

CP24

16 Fan

32 Heating circulating pump

72 Room thermostat (not supplied)

34 Heating temperature sensor

296 Door microswitch

X16

MLC23.01

fig. 8 - Wiring diagram

X12

N

5 4 3 2 1

cod. 3540I950 - 06/2007 (Rev. 00)

17GB

Page 18

FG

B

• Lire attentivement les avertissements contenus

dans le présent livret fournissant des indications importantes pour la sécurité de l'installation, son utilisation et son entretien.

• Le manuel d'instructions fait partie intégrante du pro-

duit et en constitue un composant essentiel que l'utilisateur aura soin de garder afin de pouvoir le

consulter par la suite.

• En cas de vente ou de cession de l'appareil à un au-

tre propriétaire ou d'un déménagement, s'assurer

que le manuel accompagne dans tous les cas la

chaudière de manière à pouvoir être consulté en tout

temps par le nouveau propriétaire et/ou installateur.

• L’installation et l'entretien doivent être effectués con-

formément aux normes en vigueur, selon les instructions du constructeur et par un personnel

professionnel qualifié.

• Une installation incorrecte ou un entretien impropre

peuvent entraîner des dommages à des personnes,

à des animaux ou à des choses. Le constructeur

n'assume aucune responsabilité pour les dommages causés par des erreurs d'installation et d'utilisation et, dans tous les cas, en cas de non observation

des instructions qu'il a fournies.

• Avant d'effectuer toute opération de nettoyage ou

d'entretien, isoler l'appareil du réseau d'alimentation

électrique en actionnant l'interrupteur de l'installation et/ou au moyen des dispositifs d'isolement

prévus.

• Désactiver l'appareil en cas de panne et/ou de mauvais fonctionnement en s'abstenant de toute tentative de réparation ou d'intervention directe.

S'adresser uniquement à un personnel professionnel qualifié. Les éventuelles réparations ou remplacements de composants devront être effectués

uniquement par du personnel professionnel qualifié

en n'utilisant que des pièces de rechange d'origine.

La non observation de ce qui précède compromet

les conditions de sécurité de l'appareil.

• Pour garantir le bon fonctionnement de l'appareil, il

est indispensable de faire effectuer l'entretien périodique uniquement par du personnel professionnel

qualifié.

• Cet appareil ne peut servir que dans le cadre des utilisations pour lesquelles il a été conçu. Tout autre

usage sera considéré comme impropre et dès lors

dangereux.

• Après avoir retiré l'emballage, s'assurer du bon état

du contenu. Les éléments du conditionnement ne

peuvent être laissés à la portée des enfants étant

donné qu'ils pourraient être la source potentielle de

dangers.

• En cas de doute, ne pas utiliser l'appareil et s'adresser au fournisseur.

• Les images contenues dans ce manuel ne sont

qu'une représentation simplifiée du produit. Cette représentation peut présenter de légères différences,

non significatives, par rapport au produit.

Ce symbole signifie “Attention” et est mis en regard de toutes les annonces relatives à

B

A

la sécurité. Ces prescriptions sont à respecter scrupuleusement pour éviter tous risques

causés à des personnes, animaux et objets.

Ce symbole attire l'attention sur une note ou un avertissement important

Déclaration de conformité

Le constructeur : FERROLI S.p.A.

Adresse: Via Ritonda 78/a 37047 San Bonifacio VR

déclare que cet appareil est conforme aux directives CEE ci-dessous:

• Directive basse tension 73/23 (modifiée 93/68)

• Directive Compatibilité Electromagnétique 89/336 (modifiée 93/68)

Président et fondé de pouvoirs

Cav. du travail

Dante Ferroli

18 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 19

FG

1 Instructions d'utilisation ....................................................................................................... 20

1.1 Introduction........................................................................................................................................... 20

1.2 Tableau des commandes .....................................................................................................................20

1.3 Allumage et extinction ..........................................................................................................................21

1.4 Réglages .............................................................................................................................................. 22

2 Installation.............................................................................................................................. 24

2.1 Dispositions générales .........................................................................................................................24

2.2 Emplacement ....................................................................................................................................... 24

2.3 Raccordements hydrauliques...............................................................................................................24

2.4 Raccordement serpentin de sécurité (option) ......................................................................................25

2.5 Branchements électriques.................................................................................................................... 26

2.6 Raccordement au conduit de fumée ....................................................................................................27

3 Utilisation et entretien ........................................................................................................... 28

3.1 Réglages .............................................................................................................................................. 28

3.2 Mise en service ....................................................................................................................................28

3.3 Entretien ............................................................................................................................................... 28

3.4 Résolution des problèmes.................................................................................................................... 30

4 Caractéristiques et données techniques............................................................................. 31

4.1 Dimensions, raccords et composants principaux .................................................................................31

4.2 Perte de charge.................................................................................................................................... 32

4.3 Tableau des caractéristiques techniques .............................................................................................32

4.4 Schéma électrique................................................................................................................................ 33

,

cod. 3540I950 - 06/2007 (Rev. 00)

19

Page 20

FG

1. Instructions d'utilisation

1.1 Introduction

Cher Client,

Nous vous remercions d'avoir choisi FERROLI, une chaudière de conception avancée, de technologie d'avant-garde,

de fiabilité élevée et de haute qualité constructive. Lire attentivement les instructions contenues dans la présente notice,

car elles fournissent des indications importantes concernant la sécurité d'installation, l'utilisation et l'entretien de l'appareil.

FG Il s'agit d'une chaudière en acier fonctionnant au bois, à gazéification totale. Elle utilise le principe de la combustion

à flamme inverse qui permet une consommation graduelle du bois, avec en conséquence une plus longue autonomie.

En effet, grâce à un ventilateur à vitesse variable, positionné dans la partie arrière de la chaudière, la combustion s'effectue en dépression ; le bois allumé, situé dans un magasin au-dessus d'une grille spéciale, développe une forme particulière de combustion qui, grâce à la tempéture élevée déterminée par l'apport équilibré de l'air comburant primaire

par le haut et secondaire injecté à travers la grille de séparation, transforme la cellulose en composés plus simples qui

brûlent dans la chambre de combustion sous-jacente, avec une flamme similaire à celle du méthane, et des rendements

supérieurs à 85%. En phase de chargement du bois, à l'ouverture de la porte, le ventilateur est activé pour éviter la

sortie de la fumée.

L'habillage extérieur est constitué par des panneaux en acier peints, isolés internement avec de la laine minérale pour

garantir une excellente isolation du corps de la chaudière. Sur demande, un échangeur de sécurité peut être installé

pour l'élimination de la chaleur en excès.

1.2 Tableau des commandes

fig. 1 - Tableau de contrôle

Légende

1 Tableau des commandes

2 Porte de chargement bois

3 Porte logement cendre/chambre de combustion

4 Réglage de l'air comburant

5 Touches + - réglage température chauffage

Durant le fonctionnement, l'afficheur visualise la température de refoulement installation.

20 FR

cod. 3540I950 - 06/2007 (Rev. 00)

6 Touche M, "Mode" commutation Eté/Hiver

7 Touches + - modification paramètres

8 Touche R, accès menu configuration

9 Afficheur

10 Interrupteur d'allumage

Page 21

FG

1.3 Allumage et extinction

Combustible

La chaudière ne doit fonctionner qu'avec du boîs à l'état naturel et non traité. La longueur des morceaux de bois peut

être de 50 cm pour les modèles FG30 et FG40, 70 cm pour le modèle FG50. Il est également possible d'utiliser des

combustibles pressés et en briques à condition qu'entièrement en bois.

La combustion de déchets, plastique ou liquides, peut créer la formation de gaz brûlés dangereux avec risque

B

• Utiliser exclusivement les combustibles indiqués.

• En présence de danger d'explosion, incendie, gaz brûlés ou exhalations, mettre la chaudière hors service.

• La chaudière ne doit être utilisée que par des personnes adultes, à connaissance des instructions et du fonctionne-

• L'utilisateur est autorisé à mettre la chaudière en marche, à introdure la température de chauffage, à éteindre la

• Empêcher aux enfants de s'approcher de la chaudière lorsqu'elle est en marche.

• Ne pas donner feu à des liquides ni en utiliser pour augmenter les performances de la chaudière.

• Nettoyer la surface de la chaudière avec des produits non inflammables.

• Ne pas poser d'objets inflammables sur la chaudière ni à proximité.

• Ne pas déposer de matériaux inflammabes dans le logement d'installation de la chaudière (par exemple bois, pa-

Le bois est un combustible extrêmement hétérogène du point de vue de son essence, degré d'humidité, forme et dimensions. Le rendement thermique de la chaudière est influencé par le type de bois utilisé et par son degré d'humidité,

outre la modalité de chargement et la dimension des morceaux de combustible. Les bois de meilleure qualité sont le

chêne, le frêne, le hêtre, l'érable et les arbres fruitiers sauf le cerisier, le châtaignier et le bouleau de qualité discrète, le

tilleul, le peuplier et le saule de qualité suffisante. En général, les résineux sont des combustibles médiocres. Le pouvoir

calorifique diminue avec l'augmentation de l'humidité du bois. L'emploi de combustibles humides provoque des pertes

de rendement. Utiliser du bois en bûches séché en plein air et à l'état naturel (stocké pendant 2 ans avec humidité maximum de 20%).

d'empoisonnement, mort ou explosion.

ment de la chaudière.

chaudière et à la nettoyer.

pier, pétrole, gasoil).

Allumage de la chaudière

• Ouvrir la porte inférieure et enlever la cendre éventuelle présente dans la chambre de combustion. Refermer la porte

inférieure.

• Fournir l'alimentation électrique à l'appareil. Mettre l'interrupteur d'allumage sur la position ON.

• Ouvrir la porte supérieure. Poser sur la plaque du brûleur un peu de papier et du bois fin et sec.

• Allumer le combustible et ajouter quelques morceaux de bois de dimensions légèrement supérieures.

• Fermer la porte et attendre la formation d'un premier lit de braises.

• Ouvrir lentement la porte supérieure pour permettre au ventilateur d'aspirer les fumées s'étant accumulées dans le

magasin bois.

• Distribuer uniformément les braises sur la plaque du brûleur en utilisant un pique-feu.

• Après avoir réalisé le lit de braises sur la pierre principale, on peut procéder au chargement du bois.

Chargement du bois

• Charger la chaudière avec des morceaux de bois de 50 cm de long pour les modèles FG30 et FG40, et d'environ

70 cm pour le modèle FG50.

• Etant donné que, pour une bonne combustion, il est indispensable qu'il y ait une descente uniforme du bois, il est

nécessaire d'assurer que la longueur des morceaux introduits, leur forme et le mode de chargement n'empêchent

pas la descente régulière du combustible. Les morceaux doivent être disposés longitudinalement et horizontalement. Aucun morceau ne doit être incliné ou mis de travers.

• Avant d'effectuer une nouveau chargement de bois, consommer le plus possible le précédent.

• Le nouveau chargement ne pourra être effectué que lorsque le lit de braises dans le magasin sera réduit à une

épaisseur d'environ 5 cm.

• Ouvrir lentement la porte supérieure de chargement.

• Disposer le nouveau chargement de bois de la manière indiquée précédemment.

cod. 3540I950 - 06/2007 (Rev. 00)

21FR

Page 22

FG

- Les morceaux trop longs ne tombent pas régulièrement en provoquant des vides dans le magasin à bois,

B

Extinction de la chaudière

Pour éteindre la chaudière, laisser brûler tout le combustible.

Extinction pendant de brèves périodes

Pour des périodes brèves d'extinction, une fois le combustible terminé et la chaudière refroidie, mettre l'interrupteur de

mise en marche sur OFF.

• Nettoyer les surfaces d'appui de la porte de chargement et le logement de chargement.

• Enlever la cendre et nettoyer la chambre de combustion.

• Fermer la porte du logement cendre et la porte de chargement.

avec formation de zones de bois non brûlé.

- Les morceaux trop courts provoquent des passages d'air non réguliers, avec baisse de puissance et de rendement.

- Ouvrir la porte supérieure toujours lentement, afin d'éviter les bouffées de chaleur et les formations de fumée.

- Durant le fonctionnement, il est interdit d'ouvrir la porte inférieure.

- Lors de la phase de chargement, éviter de tenir la porte supérieure ouverte pendant trop longtemps.

- En cas de fonctionnement avec performances réduites, des gaz distillés à basse température peuvent se

former et, s'ils sont respirés, ils peuvent provoquer un empoisonnement par la fumée.

- Si une fumée dense est visible, ne pas la respirer.

- Bien aérer le local d'installation de la chaudière.

- Nettoyer la chaudière et les voies d'évacuation des gaz comme prescrit.

Arrêt pour de longues périodes

Pour mettre la chaudière hors service pendant une longue période (par ex. à la fin de la période froide), nettoyer la chaudière avec soin pour éviter les corrosions.

Si l'appareil est destiné à rester inutilisé pour une longue période en hiver, afin d'éviter les dommages causés

B

par le gel, il est conseillé, soit de vider toute l'eau contenue dans la chaudière, soit de verser l'antigel approprié

dans l'installation de chauffage, en respectant les prescriptions du sez. 2.3.

1.4 Réglages

Commutation Eté/Hiver

Appuyer sur la touche pour activer la commutation Eté/Hiver.

Réglage de la température de chauffage

Agir sur les touches et (rep. 5 fig. 1) pour introduire la température de départ installation.

Le système de contrôle règle le débit d'air du ventilateur et donc la vitesse de combustion pour atteindre et conserver

la température introduite.

Avec des températures de l'eau de chaudière trop basses, on crée du goudron à l'intérieur de la chaudière ;

B

à des températures inférieures à 65 °C, on crée de l'eau de condensation dans la chambre de combustion.

Un fonctionnement fréquent à une température inférieure à 65 °C provoque une forte diminution de la durée

de vie de la chaudière.

Faites attention à ce que la température de l'eau en chaudière reste constamment entre 80 - 90 °C.

22 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 23

FG

Réglage de l'air secondaire

Le ventilateur d'extraction des fumées situé sur le côté arrière de la chaudière effectue l'alimentation d'air comburant

primaire. La chaudière est équipée d'un dispositif de réglage de l'air secondaire, pré-étalonné en usine, qui doit être

vérifié en phase de premier allumage à l'aide d'un analyseur de combustion. Il est possible l'intervenir par la suite sur

la vis de réglage pour adapter l'apport d'air secondaire selon la variation de la qualité et du type de combustible.

fig. 2 - Réglage de l'air secondaire

A Ouvert

B Fermé

• Bois gros humide de combustion difficile : fermer d'une encoche.

• Bois sec très inflammable : ouvrir d'une encoche ou plus.

• Lorque la chaudière tend à souffler, à cause de combustible excessivement humide, fermer progressivement.

Réglage de la pression de l'installation

Contrôler périodiquement que l'installation est pleine d'eau. Ces contrôles doivent être effectués à froid, en vérifiant les

vases d'expansion qui, si de type ouvert, doivent avoir l'eau au niveau initial, si de type fermé, doivent avoir une pression

égale à celle de pré-chargement de départ.

cod. 3540I950 - 06/2007 (Rev. 00)

23FR

Page 24

FG

2. Installation

2.1 Dispositions générales

L'INSTALLATION DE LA CHAUDIÈRE DOIT ÊTRE EFFECTUÉE CONFORMÉMENT AUX TEXTES RÉGLEMENTAIRES ET RÈGLES DE L'ART EN VIGUEUR, SUIVANT LES INSTRUCTIONS DU CONSTRUCTEUR ET PAR UN PROFESSIONNEL QUALIFIÉ.

2.2 Emplacement

La chaudière doit être installée dans un local approprié, muni d'ouvertures d'aération vers l'extérieur en conformité avec

les normes en vigueur. En présence de plusieurs brûleurs ou aspirateurs dans le même local qui fonctionnent simultanément, les ouvertures d'aération doivent être dimensionnées pour le fonctionnement de tous les appareils. Le lieu

d'installation doit être exempt de tous objets ou matériaux inflammables, gaz corrosifs, poussières et substances volatiles qui peuvent être aspirés par le ventilateur. Le local d'installation du brûleur doit en outre être sec et à l'abri de la

pluie, de la neige et du gel.

A

Un espace suffisant pour le démontage de l'habillage et pour les opérations d'entretien normales doit être

prévu autour de l'appareil. En particulier, vérifier que, dans la partie avant de la chaudière, il y ait un espace

suffisant pour le chargement du combustible.

2.3 Raccordements hydrauliques

La capacité thermique de l'appareil sera préalablement définie à l'aide d'un calcul des besoins caloriques de l'édifice,

conformément aux normes en vigueur. L'installation doit comprendre tous les accessoires requis pour garantir un fonctionnement correct et régulier. Il est conseillé d'installer entre la chaudière et le circuit, des vannes darrêt permettant,

au besoin, d'isoler la chaudière de l'installation.

L'évacuation de la soupape de sûreté doit être raccordée à un entonnoir d'écoulement, ou à une tuyauterie de

B

Avant l'installation, laver soigneusement toutes les tuyauteries de l'installation afin d'éliminer toutes les impuretés ou

résidus risquant de compromettre le bon fonctionnement de l'appareil.

Effectuer les raccordements aux raccords prévus, comme indiqué au cap. 4 "Caractéristiques et données techniques"

et conformément aux plaques des pictogrammes apposées sur l'appareil.

Caractéristiques de l'eau de l'installation

En présence d'une eau ayant un degré de dureté supérieur à 25° Fr (1°F = 10ppm CaCO3), il est recommandé d'utiliser

une eau spécialement traitée afin d'éviter toute incrustation éventuelle dans la chaudière. Le traitement ne doit pas

réduire la dureté à des valeurs inférieures à 15°F (DPR 236/88, utilisation de l'eau destinée à la consommation humaine). Le traitement de l'eau utilisée s'impose également dans le cas de circuits d'installation très étendus ou d'appoints

fréquents d'eau dans l'installation.

Système antigel, produits antigel, additifs et inhibiteurs

Si nécessaire, il est possible d'utiliser des liquides antigel, des additifs et des inhibiteurs, seulement et exclusivement

si le producteur de ces liquides ou additifs fournit une garantie qui assure que ses produits sont appropriés à l'utilisation

et ne provoquent pas de dommages à l'échangeur de la chaudière ou à d'autres composants et/ou matériaux de la

chaudière et de l'installation. Il est interdit d'utiliser des liquides antigel, des additifs et des inhibiteurs non spécifiquement prévus pour l'utilisation dans des circuits thermiques et compatibles avec les matériaux composant la chaudière

et le circuit.

récupération, pour éviter le dégorgement d'eau au sol en cas de surpression dans le circuit de chauffage. Dans

le cas de non-respect de la règle ci-dessus, le fabricant de la chaudière ne sera pas retenu responsable si la

soupape de sûreté devait intervenir et donc provoquer l'inondation de la pièce ou du local.

Ne pas utiliser les tuyauteries hydrauliques comme mise à la terre de votre installation électrique ou d'appareils électriques.

24 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 25

FG

2.4 Raccordement serpentin de sécurité (option)

Avec les chaudières, il est possible de recevoir un échangeur thermique (en option) de sécurité extérieur (circuit de refroidissement).

Dans les pays qui appliquent la norme EN 303-5, la chaudière doit disposer d'une installation permettant une sortie sûre

de la chaleur en excès, sans énergie complémentaire. De cette manière, la température maximum de l'eau de la chaudière ne dépassera pas les 100 °C (protection anti-surchauffe).

La pression minimum d'alimentation de l'eau de refroidissement doit être de 2,0 bars. Un débit en volume d'au moins

10 l/min doit être disponible.

• Enlever la flasque “A” située dans la partie arrière de la chaudière.

• Monter le serpentin “N” en le fixant avec les 4 boulons.

• Monter la soupape de sûreté "P" sur la sortie du serpentin "N" en respectant le sens indiqué par la flèche. Insérer

la sonde "Q" de la soupape dans la gaine spéciale "G". Relier l'entrée de l'eau directement sur le serpentin de sécurité. Relier la sortie à la soupape.

fig. 3 - Raccordement de l'échangeur thermique de sécurité

cod. 3540I950 - 06/2007 (Rev. 00)

25FR

Page 26

FG

2.5 Branchements électriques

Montage panneau de commandes

1. Enlever le couvercle du panneau de commandes "P" en dévissant les deux vis latérales "V".

2. Amener les câbles du ventilateur "B", de la sonde "A" et du micro-interrupteur porte "C" comme indiqué sur fig. 4

3. Relier le câble ventilateur au bornier en respectant les couleurs indiquées sur fig. 5 et fixer le condenseur "R" avec

le collier adhésif spécial.

4. Relier le câble du micro-interrupteur "C" aux bornes comme indiqué sur fig. 5.

5. Insérer la sonde "A" dans le puits spécial.

fig. 4 - Montage panneau de commandes

C Condenseur

16 Ventilateur

34 Capteur de température chauffage

296 Micro-interrupteur porte

R

fig. 5 - Raccordement au bornier

34 296 16

14131211109876543

Blu

Giallo/Verde

Nero/Bianco

26 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 27

FG

Raccordement au réseau électrique

La sécurité électrique de l'appareil ne peut être assurée que lorsque celui-ci est correctement raccordé à un

B

La chaudière est précâblée; le câble de raccordement au réseau électrique est de type "Y" sans fiche. Les connexions

au réseau électrique doivent être réalisées par raccordement fixe et dotées d'un interrupteur bipolaire avec une distance

entre les contacts d'ouverture d'au moins 3 mm, en interposant des fusibles de 3A maximum entre la chaudière et la

ligne. Il est important de respecter la polarité (LIGNE: câble marron / NEUTRE: câble bleu / TERRE: câble jaune-vert)

dans les raccordements au réseau électrique. Lors de l'installation ou du remplacement du câble d'alimentation, la longueur du conducteur de terre doit être de 2 cm plus longue des autres.

B

2.6 Raccordement au conduit de fumée

L’appareil peut être raccordé à une cheminée conçue et construite conformément aux normes en vigueur. Le conduit

entre la chaudière et la cheminée doit être en matériau adapté à cette fonction, c'est-à-dire qu'il doit résister à la chaleur

et à la corrosion. Il est recommandé de soigner l'étanchéité dans les points de jonction et de calorifuger toute la conduite

entre la chaudière et la cheminé, pour éviter la formation d'eau de condensation.

dispositif de mise à la terre efficace conformément aux normes électriques en vigueur. Faire vérifier par un

professionnel qualifié l'efficacité et la conformité du dispositif de mise à la terre. Le constructeur ne saur être

tenu pour responsable des dommages éventuels découlant de l'absence de connexion de mise à la terre efficace. Faire vérifier que l'installation électrique est adaptée à la puissance maximale absorbée par l'appareil,

indiquée sur la plaque signalétique de la chaudière.

Le câble d'alimentation de l'appareil ne doit pas être remplacé par l'utilisateur. En cas d'endommagement du

câble, éteindre l'appareil et confier exclusivement son remplacement à un professionnel qualifié. En cas de

remplacement du câble d'alimentation, utiliser exclusivement un câble "HAR H05 VV-F" 3x0,75 mm2 avec

diamètre extérieur de 8 mm maximum.

cod. 3540I950 - 06/2007 (Rev. 00)

27FR

Page 28

FG

3. Utilisation et entretien

Toutes les opérations de réglage, de mise en service et celles de contrôle périodique décrites ci-après doivent être effectuées par un professionnel qualifié (conformément aux textes réglementaires et règles de l'art en vigueur).

FERROLI Toute responsabilité contractuelle et extracontractuelle du constructeur est exclue pour les dommages causés

par des erreurs dans l'installation et l'utilisation et, dans tous les cas, par le non-respect des instructions fournies par le

constructeur.

3.1 Réglages

Réglage air secondaire

En phase de mise en service, il est opportun de vérifier l'étalonnage du dispositif de réglage de l'air secondaire.

Allumer la chaudière et effectuer le premier chargement avec le même combustible que celui qu'utilisera l'utilisateur

final pour alimenter la chaudière.

Attendre que la chaudière soit stable.

A l'aide d'un analyseur de combustion, vérifier la teneur en CO dans les fumées. Si le contenu en CO est > 0.5%, ouvrir

progressivement le régulateur jusqu'à l'obtention d'une valeur de CO < 0.5%.

N.B.: En ouvrant excessivement le régulateur de l'air secondaire, la chaudière peut avoir une combustion irrégulière

(tendance à “souffler”). Dans ce cas, fermer le régulateur de 1/2 encoche - 1 encoche.

3.2 Mise en service

Vérifications à effectuer au premier allumage et après toutes les opérations d'entretien ayant occasionné des

B

Avant d'allumer la chaudière

• Ouvrir les vannes d'arrêt éventuelles montées entre la chaudière et l'installation.

• Vérifier le prégonflage du vase d'expansion

• Remplir les tuyauteries et assurer l'évacuation complète de l'air dans la chaudière et les installations.

• Vérifier l'absence de fuites d'eau dans l'installation, dans les branchements ou dans la chaudière.

• Vérifier le raccordement de l'installation électrique et l'efficacité de fonctionnement de la mise à la terre.

• Vérifier l'absence de stockage de liquides ou de matériaux inflammables à proximité de la chaudière.

Vérifications en cours de fonctionnement

• Allumer l'appareil ainsi qu'il est décrit sez. 1.3.

• Vérifier l'étanchéité des circuits de l'eau.

• Contrôler l'efficacité de la cheminée et des conduits d'air/fumées pendant le fonctionnement de la chaudière.

• Vérifier que la circulation d'eau entre la chaudière et l'installation s'effectue correctement.

• Vérifier l'étanchéité des portes de chargement bois et de la chambre de combustion.

• Vérifier la combustion et l'étalonnage correct du dispositif de réglage de l'air secondaire.

débranchements des installations ou des interventions sur des dispositifs de sécurité ou parties de la chaudière.

3.3 Entretien

Avertissements

- Avant de procéder à n'importe quelle opération d'entretien, il est indispensable de déconnecter la chaudière

B

et d'attendre qu'elle retourne à la température ambiante.

- Ne jamais décharger l'eau de l'installation, même si partiellement, si ce n'est pour des raisons absolument

exceptionnelles.

- Ne pas nettoyer la chaudière et/ou ses parties avec des substances facilement inflammables (ex. essence,

alcool, etc.).

- Ne pas laisser de récipients de substances inflammables dans la pièce où est installée la chaudière.

- Ne pas effectuer le nettoyage de la centrale thermique avec la chaudière en marche.

- Pour le nettoyage, utiliser des goupillons et des aspirateurs ; si l'on utilise des chiffons, vérifier qu'ils ne sont

pas laissés à l'intérieur de la chaudière.

28 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 29

FG

Entretien courant

Le dépôt de suie et cendre sur les parois internes de la chaudière et sur les briques réfractaires réduit la transmission

de la chaleur. Toutefois, durant son fonctionnement, la chaudière à gazéification de bois produit moins de cendre que

la chaudière traditionnelle de chauffage.

Enlever la cendre de la chambre de combustion tous les 1-2 jours et dans tous les cas, avant qu'elle ne se remplisse

complètement, afin de laisser assez d'espace pour la combustion.

Si la cendre est encore chaude, enfiler des gants de protection.

B

Au moins une fois par semaine, effectuer un nettoyage soigné :

• Ouvrir la porte de chargement et balayer les restes de la combustion du logement cendres à travers la fente pré-

• Nettoyer les parois internes de la chambre de combustion avec une brosse.

• Eliminer la suie et la cendre de la chambre de combustion.

• Contrôler l'étanchéité parfaite de la fermeture de la porte. En outre, vérifier l'absence de coulées de goudron ou de

Transférer la cendre dans un récipient non inflammable muni de couvercle.

sente entre les plaques du brûleur.

condensation de la chambre fumée.

Ne pas nettoyer les plaques du brûleur avec une brosse métallique car elles pourraient s'endommager.

B

Entretien extraordinaire

Une fois par mois, effectuer le nettoyage des passages fumée :

• Enlever le couvercle supérieur de l'habillage

• Ouvrir la porte d'inspection située dans la partie arrière de la chaudière (voir fig. 6).

• Extraire les turbulateurs et, à l'aide d'un goupillon, nettoyer les passages fumée.

fig. 6 - Nettoyage passages fumée

cod. 3540I950 - 06/2007 (Rev. 00)

29FR

Page 30

FG

Contrôle périodique

Pour un fonctionnement correct durable de l'appareil, il est nécessaire de faire effectuer par un professionnel qualifié

un contrôle annuel qui prévoit les opérations suivantes :

• Contrôler et, si nécessaire, nettoyer la chaudière et les passages fumée comme indiqué au paragraphe précédent.

• Démonter le ventilateur d'extraction fumées et nettoyer l'hélice.

• Vérifier les conditions des plaques du brûleur.

• Vérifier l'étanchéité de la porte de chargement et du logement cendres ; si nécessaire, remplacer le joint.

• Les dispositifs de commande et de sécurité doivent fonctionner correctement.

• Le circuit d'évacuation des fumées doit être parfaitement efficace.

• Les conduits de fumée doivent être libres de tout obstacle et ne pas présenter de fuites.

• Le brûleur et l'échangeur doivent être en parfait état de propreté et détartrés. Pour le nettoyage, ne pas utiliser de

produits chimiques ni de brosses en acier.

• La pression de l'eau dans l'installation à froid doit être d'environ 1 bar ; si ce n'est pas le cas, ramener la pression à

cette valeur.

• La pompe de circulation ne doit pas être bloquée.

• Le vase d'expansion doit être gonflé.

3.4 Résolution des problèmes

Diagnostic

En cas d'anomalies ou de problèmes de fonctionnement, l'afficheur clignote et le code de l'anomalie apparaît.

Tableau 1 - Liste des anomalies

Code

anomalie

E05

E06

Anomalie Causes probables Solution

Anomalie au capteur de

température chauffage

Anomalie au capteur de

température chauffage

Capteur endommagé ou en

court-circuit

Capteur endommagé ou

câblage interrompu

Contrôler le câblage ou remplacer le capteur

Contrôler le câblage ou remplacer le capteur

30 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 31

FG

4. Caractéristiques et données techniques

4.1 Dimensions, raccords et composants principaux

240

A

360

C

86

16

E

B

275

fig. 7 - Dimensions, raccords et composants principaux

D

10

F244

L

I

11

GH

Modèle A B C D E F G H I L (Ø)

Fg 30 550 970 750 550 457.7 600 195 160 652.5 130

Fg 40 550 1150 750 550 637.5 780 195 160 812 150

Fg 50 600 1150 930 730 627.5 780 220 185 812 150

Légende

10 Départ installation

11 Retour installation

16 Ventilateur

275 Evacuation eau installation

cod. 3540I950 - 06/2007 (Rev. 00)

31FR

Page 32

FG

4.2 Perte de charge

20

18

16

14

12

10

mbar

8

6

4

2

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

portata lt/h

4.3 Tableau des caractéristiques techniques

Unité Valeur Valeur Valeur

Modèle FG 30 FG 40 FG 50

Capacité thermique maxi kW 34.9 46.2 57.5 (Q)

Capacité thermique mini kW 16.9 22.3 27.8 (Q)

Puissance thermique maxi chauffage kW 30 40 50 (P)

Puissance thermique mini chauffage kW 15 20 25 (P)

Rendement Pmax % 86 86.5 87

Rendement Pmin % 89 89.5 90

Pression d’exercice chauffage bars 3 3 3 (PMS)

Poids à vide kg 185 220 286

3

Volume chambre de combustion

dm

100 140 200

32 FR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 33

FG

4.4 Schéma électrique

N

93 92 91

16

34

72

296

32

230V

N

50Hz

L

34567891011121314 N L

98

59 58 57 56 55 54 53 52

N

CP24

16 Ventilateur

32 Circulateur circuit chauffage

72 Thermostat d'ambiance (non fourni)

34 Capteur de température chauffage

296 Micro-interrupteur porte

X16

MLC23.01

fig. 8 - Schéma électrique

X12

N

5 4 3 2 1

cod. 3540I950 - 06/2007 (Rev. 00)

33FR

Page 34

FG

B

• Bu kullanım talimatı kitapçı÷ında yer alan uyarıları

dikkatlice okuyunuz. Bu uyarılar, emniyetli kurulum

(yerleútirme), kullanım ve bakım hakkında önemli bilgiler vermektedir.

• Bu kullanma kitapçı÷ı, bu ürünün tamamlayıcı ve te-

mel parçası olup kullanıcı tarafından ileride müracaat edilmek üzere özenle saklanmalıdır.

•E÷er bu ünite bir baúka kiúiye satılır ya da aktarılırsa

ya da e÷er bu üniteyi taúır ya da bırakırsanız, bu kullanım kitapçı÷ının üniteye eúlik etmesini sa÷layınız,

böylelikle yeni sahibi ve/veya kuranı tarafından bu

bilgilere müracaat edilebilir.

• Kurulum ve bakı

ra ve de imalatçının talimatları uygun úekilde gerçekleútirilmeli ve mesleki açıdan kalifiye bir personel

tarafından yerine getirilmelidir.

• Hatalı kurulum ya da yetersiz bakım; insanlara,

hayvanlara ya da nesnelere zarar verebilir. ømalatçı

(üretici), imalatçı tarafından sa÷lanan talimatlara

uyulmamasından ve de uygulamadaki hatalardan

kaynaklanan hasarlara karúı hiçbir sorumluluk kabul

etmemektedir.

• Herhangi bir temizlik ya da bakım iúlemlerini yerine

getirmeden önce, sistem sivicini ve/veya karúı gelen

açma kapama aygıtlarını kullanarak, cihazın úebeke

güç kayna÷ı ba÷lantısını kesiniz.

m iúlemleri; yürürlükteki standartla-

• Cihazda arızaların meydana gelmesi ve/veya yetersiz çalıúması durumunda, cihaz kapatılmalıdır.

Cihazı, tamir etmeye kalkıúmayın

olarak kalifiye personel ile temasa geçiniz. Ürünlerin

herhangi bir onarım-de÷iútirme iúlemi, sadece mesleki olarak kalifiye personel tarafından ve sadece

orijinal parçalar kullanılarak yerine getirilmelidir.

Yukarıda yer alan koúula uygun hareket edilmemesi,

ünitenin emniyetini tehlikeye sokabilir.

• Ünitenin iyi úekilde çalıúmasını garanti altına almak

için, bir kalifiye personel tarafından periyodik bir

bakımının yapılması gereklidir.

• Bu cihaz, sadece özel olarak tasarlanmıú oldu

amaçlar için kullanılmalıdır. Bunun dıúındaki herhangi bir kullanım, yanlıú ve bu nedenle tehlikeli

olarak de÷erlendirilir.

• Ambalajını çıkardıktan sonra, içindekilerin tam olup

olmadı÷ını kontrol ediniz. Ambalaj parçaları, olası

tehlike kayna÷ı oldu÷undan, çocukları

yerlerde bırakılmamalıdır.

• ùüphe durumunda, cihazı kullanmayınız ve de

sa÷layıcıya dönünüz.

• Bu kılavuzda yer alan resimler, ürün hakkında basit

bir sunum yapmak amacıyla verilmiútir. Bu verilmekte olan sunumlar ile temin edilen ürün arasında bazı

ufak tefek ve önemsiz farklılıklar olabilir.

ız. Sadece mesleki

÷u

n eriúebilece÷i

Bu sembol “Uyari” isareti olup güvenlikle ilgili tüm uyarilarin yanina konmustur. Insanla-

B

A

ra, hayvanlara ve nesnelere bir zarara gelmesini önlemek için bu tip kurallara tam olarak

uyulmalidir.

Bu sembol, bir bilgi ya da önemli bir uyariyi dikkate getirir.

Uygunluk beyani

ømalatçi: FERROLI S.p.A.

Adres: Via Ritonda 78/a 37047 San Bonifacio VR

bu cihazin; asagida yer alan AET(EEC) yönergelerine uygunluk içinde oldugunu beyan etmektedir:

• Yönerge 73/23, Düsük Voltaj (93/68 nolu direktifle degisiklige ugratildi)

• 89/336 Elektromanyetik Uygunluk Yönetmeligi (93/68 ile degisiklik yapilmistir)

Baskan ve yasal temsilci

øú. Dep.

Dante Ferroli

34 TR

cod. 3540I950 - 06/2007 (Rev. 00)

Page 35

FG

1 Kullanma talimatları...............................................................................................................36

1.1 Giriú ...................................................................................................................................................... 36

1.2 Komut paneli ........................................................................................................................................ 36

1.3 Açma ve kapatma................................................................................................................................. 37

1.4 Ayarlamalar ..........................................................................................................................................38

2 Kurulum ..................................................................................................................................40

2.1 Genel talimatlar ....................................................................................................................................40

2.2 Kurulum yeri .........................................................................................................................................40

2.3 Su ba÷lantıları ......................................................................................................................................40

2.4 Spiral emniyet ba÷lantısı (opsiyonel) ................................................................................................... 41

2.5 Elektrik ba÷lantıları............................................................................................................................... 42

2.6 Bacaya ba÷lantı....................................................................................................................................43

3 Servis ve bakım......................................................................................................................44

3.1 Ayarlamalar ..........................................................................................................................................44

3.2 Servise alma......................................................................................................................................... 44

3.3 Bakım ...................................................................................................................................................44

3.4 Sorunların giderilmesi........................................................................................................................... 46

4 Özellikler ve Teknik Veriler ................................................................................................... 47

4.1 Boyutlar, ba÷lantılar ve ana bileúenler ................................................................................................. 47

4.2 Yük kaybı.............................................................................................................................................. 48

4.3 Teknik veriler tablosu ........................................................................................................................... 48

4.4 Elektrik úeması .....................................................................................................................................49

,

cod. 3540I950 - 06/2007 (Rev. 00)

35

Page 36

FG

1. Kullanma talimatları

1.1 Giriú

Sayın Müúteri,

Geliúmiú tasarım, en son teknoloji, yüksek güvenilirlik ve de kaliteli yapım içeren, duvara monte FERROLI kombiyi

seçti÷iniz için teúekkür ederiz. Bu kullanım talimatı kitapçı÷ında yer alan uyarıları dikkatlice okuyunuz, çünkü bunlar emniyetli kurulum (yerleútirme), kullanım ve bakım hakkında önemli bilgiler vermektedir.

FG Bu, odunla çalıúan bir tam gazlandırmalı çelik kombidir. Odunun yavaú tüketilmesini ve dolayısıyla uzun süre

ba÷ımsız çalıúma avantajını sa÷layan ters alevli yanma ilkesinden faydalanır. Kombinin arka kısmında bulunan

de÷iúken hızlı vantilatör sayesinde yanma düúük basınçta olur; Özel bir ızgara üzerine yerleútirilmiú depoda yanan

odun, yukarıdan gelen birincil yanma havası akıúının ve ayırma ızgarasından geçirilerek enjekte edilen ikincil dengeli

yanma havası akıúının belirledi÷i yüksek sıcaklık sayesinde, selülozu yanma odasında metanınkine benzer bir alevle

%85'ten daha yüksek bir verimle yanabilecek daha basit bileúiklere dönüútüren özel bir yanma úekli üretir. Odun yükleme aúamasında, kapa÷ın açılması esnasında dumanın dıúarıya çıkmasını önlemek için fan devreye girer.

Dıú muhafaza, kombi gövdesinin optimum izolasyonunu sa÷lamak için cilalı, yalıtkan, içi mineral yünlü çelik panellerden

yapılmıútır. østek üzerine aúırı sıcaklı÷ı azaltmak için bir emniyet eúanjörü de yerleú

1.2 Komut paneli

tirilebilir.

úek. 1 - Kontrol paneli

Açıklamalar

1 Komut paneli

2 Odun yükleme kapısı

3 Kül odası/yanma odası kapısı

4 Yanma havası ayarı

5 Isıtma sıcaklı÷ı ayarlama (+ -) tuúları

Çalıúma esnasında gösterge sistem çıkıú sıcaklı÷ını görüntüler

36 TR

cod. 3540I950 - 06/2007 (Rev. 00)

6 M tuúu, Yaz/Kıú ayarı de÷iútirme "Modu"

7 Parametreleri de÷iútirme (+ -) tuúları

8 Konfigürasyon menüsüne eriúim tuúu (R)

9 Gösterge

10 Çalıútırma sivici

Page 37

FG

1.3 Açma ve kapatma

Yakıt

Kombi sadece do÷al ve iúlenmemiú odun ile çalıútırılmalıdır. Kütük uzunlukları FG30 ve FG40 modelleri için 50 cm,

FG50 modeli için 70 cm olabilir. Tamamen ahúap oldukları takdirde presli ve kalıplanmıú yakıtlar da kullanılabilirler.

Plastik veya sıvı atıkların yakılması zehirlenme, ölüm veya patlamaya yol açabilecek zehirli yanıcı gazların or-

B

• Sadece belirtilen yakıtları kullanınız.

• Patlama, yanıcı gaz veya kaçak tehlikesi bulunması durumunda kombiyi servis dıúı bırakınız.

• Kombi sadece çalıútırma talimatlarını bilen yetiúkin kiúiler tarafından çalıútırılmalıdır.

• Kullanıcının sadece, kombiyi çalıútırma, ısıtma sıcaklı÷ını

• Çocukların kontrolünüz dıúında kombiye yaklaúmalarını engelleyiniz.

• Kombi ayarlarını yükseltmek için sıvılar yakmayınız ya da kullanmayınız.

• Kombi yüzeyini sadece yanmaz maddelerle temizleyiniz.

• Kombi üzerine ya da yakınına yanıcı nesneler koymayınız.

• Kombinin kurulum odasına yanıcı materyaller koymayınız (örn. odun, ka÷ıt, benzin, mazot).

Yapısı, nemlilik derecesi, úekli ve boyutları itibariyle odun heterojen bir yakıttır. Kombinin sıcaklık randımanı kullanılan

odun tipinden, nemlilik derecesinden bunun yanında yakıtın yüklenme ve parçalanma úeklinden etkilenir. Optimum kalitedeki odunlar meúe, diúbudak, kayın, akçaa÷aç ve viúne dıúındaki meyve a÷açlarının odunlarıdır, iyi kalitedeki odunlar kestane, huú a÷acı odunları, yeterli kalitedekiler ıhlamur, kavak ve sö÷üt a÷acı odunlarıdır. Reçineli a÷açlar vasat

yakıtlardır. Odunun nemlilik derecesi arttıkça ısıl güç düúer. Nemli yakıtların kullanılması randıman kaybına yol açar.

Odunu do÷al koúullarda güneúte kurutulmuú kütükler halinde kullanınız (2 yıl süresince maksimum %20 nem koúulunda

depolanmıú).

taya çıkmasına neden olabilir.

ayarlama, kombiyi servis dıúı bırakma ve temizleme yetki-

si vardır.

Kombinin yakılması

• Alt kapa÷ı açınız ve yanma odasında bulunması muhtemel külleri temizleyiniz. Alt kapa÷ı tekrar kapatınız.

• Cihazın elektrik beslemesini açınız. Ateúleme sivicini ON pozisyonuna getiriniz.

•Üst kapa÷ı açınız. Brülör tablasına bir miktar ka÷ıt ile kuru ve ince odun koyunuz.

• Yakınız ve biraz daha büyük ebatlarda birkaç odun parçası daha ekleyiniz.

• Kapıyı kapatınız ve ilk kor yata÷ı oluúana kadar bekleyiniz.

• Odun deposunda biriken dumanın fan tarafından çekilmesini sa÷lamak için üst kapıyı yavaúça açınız.

• Korları bir ocak süngüsü yardımıyla tabla üzerinde eúit úekilde da÷ıtınız.

•Ana taú üzerinde kor yata÷ı oluútuktan sonra odun yüklemesi yapınız.

Odun yükleme

• FG30 ve FG40 modelleri için 50 cm ve FG50 modeli için 70 cm uzunlukta olacak úekilde odun yükleyiniz.

• øyi bir yanma sonucu için odunun eúit seviyede alçalması gerekti÷inden konulan parçaların uzunluklarının, biçimlerinin ve yüklenme úekillerinin yakıtın eúit seviyede inmesini engellemedi÷inden emin olunuz. Parçalar yatay veya