Page 1

cod. -- — 11/2010 (Rev. 00)

ECONCEPT SOLAR ST

INSTRUCTIONS FOR USE, INSTALLATION AND MAINTENANCE

Page 2

ECONCEPT SOLAR ST

2 EN

B

Declaration of conformity

Manufacturer: FERROLI S.p.A.

Address: Via Ritonda 78/a 37047 San Bonifacio VR Italy

declares that this unit complies with the following EU directives:

• Gas Appliance Directive 2009/142

• Efficiency Directive 92/42

• Low Voltage Directive 73/23 (amended by 93/68)

• Electromagnetic Compatibility Directive 89/336 (amended by 93/68)

President and Legal Representative

Cav. del Lavoro

Dante Ferroli

B

This symbol indicates "Caution" and is placed next to all safety warnings. Strictly follow

these instructions in order to avoid danger and damage to persons, animals and things.

A

This symbols calls attention to a note or important notice.

cod. -- - 11/2010 (Rev. 00)

• Carefully read the warnings in this instruction booklet since they provide important information on safe

installation, use and maintenance.

• This instruction booklet is an integral part of the

product and must be carefully kept by the user for future reference.

• If the unit is sold or transferred to another owner or if

it is to be moved, always make sure that the booklet

accompanies the boiler so that it can be consulted

by the new owner and/or installer.

• Installation and maintenance must be carried out by

professionally qualified personnel, according to current regulations and the manufacturer's instructions.

• Incorrect installation or poor maintenance can cause

damage or physical injury. The manufacturer declines any responsibility for damage caused by errors in installation and use or by failure to follow the

manufacturer's instructions.

• Before carrying out any cleaning or maintenance operation, disconnect the unit from the electrical power supply using the switch and/or the special cut-off devices.

• In case the unit breaks down and/or functions poorly,

deactivate it, do not make any attempt to repair it or

directly intervene. Contact professionally qualified

personnel. Any repair/replacement of products must

only be carried out by qualified professional personnel using exclusively genuine parts. Failure to comply with the above could affect the safety of the unit.

• Periodical maintenance carried out by qualified personnel

is essential for guaranteeing good operation of the unit.

• This unit must only be used for the purpose for which

it was designed. Any other use is considered improper and therefore hazardous.

• After removing the packing, check the integrity of the

contents. Packing materials must not be left within the

reach of children as they are potentially hazardous.

• In case of doubt do not use the unit, and contact the

supplier.

• The images shown in this manual are a simplified

representation of the product. In this representation

there may be slight, unimportant differences with the

supplied product.

Page 3

ECONCEPT SOLAR ST

3

cod. -- - 11/2010 (Rev. 00)

1 Operating instructions ............................................................................................................ 4

1.1 Introduction............................................................................................................................................. 4

1.2 Control panel ..........................................................................................................................................5

1.3 Lighting and turning off........................................................................................................................... 7

1.4 Adjustments............................................................................................................................................ 8

2 Installation .............................................................................................................................. 13

2.1 General Instructions .............................................................................................................................13

2.2 Place of installation ............................................................................................................................. 13

2.3 Plumbing connections ..........................................................................................................................13

2.4 Gas connection .................................................................................................................................... 14

2.5 Electrical connections........................................................................................................................... 15

2.6 Fume ducts........................................................................................................................................... 16

2.7 Condensate drain connection...............................................................................................................20

3 Service and maintenance......................................................................................................21

3.1 Adjustments.......................................................................................................................................... 21

3.2 Starting ................................................................................................................................................. 22

3.3 Maintenance......................................................................................................................................... 26

3.4 Trouble shooting................................................................................................................................... 27

4 Technical data and characteristics ...................................................................................... 29

4.1 Dimensions and connections ...............................................................................................................29

4.2 General view and main components ....................................................................................................30

4.3 Water circuit .........................................................................................................................................31

4.4 Technical data table .............................................................................................................................33

4.5 Diagrams ..............................................................................................................................................34

4.6 Wiring diagram .....................................................................................................................................36

4.7 DBM29 (ECOTRONIC tech) - Solar Controller ....................................................................................38

4.8 FZ4B low temperature zone card .........................................................................................................47

Page 4

ECONCEPT SOLAR ST

4 EN

cod. -- - 11/2010 (Rev. 00)

1. Operating instructions

1.1 Introduction

Thank you for choosing ECONCEPT SOLAR ST, a floor-standing boiler with incorporated solar hot water tankFERROLI featuring advanced design, cutting-edge technology, high reliability and quality construction . Please read this

manual carefully since it provides important information on safe installation, use and maintenance

ECONCEPT SOLAR ST is a high-efficiency, low emissions, sealed chamber premix condensing heat generator for

heating and hot water production, running on natural gas or LPG and equipped with a microprocessor control system.

The boiler shell consists of an aluminium lamellar exchanger and a ceramic premix burner equipped with electronic

ignition and ionisation flame control, modulating speed fan and modulating gas valve.

The boiler is arranged for connection to one or more solar collectors, which are used for domestic hot water production

. In fact, the unit has a special, incorporated stratified solar hot water tank and an advanced circuit with variable-speed

solar pump , for maximising the saving obtainable from a solar panel system.

Regarding the production of hot water for heating, ECONCEPT SOLAR ST it is fitted standard with a double internal

circulation, enabling the simultaneous and independent management of two heating zones: a low temperature zone

(floor system) and a high temperature zone (radiators, towel warmers, etc.).

Page 5

ECONCEPT SOLAR ST

5EN

cod. -- - 11/2010 (Rev. 00)

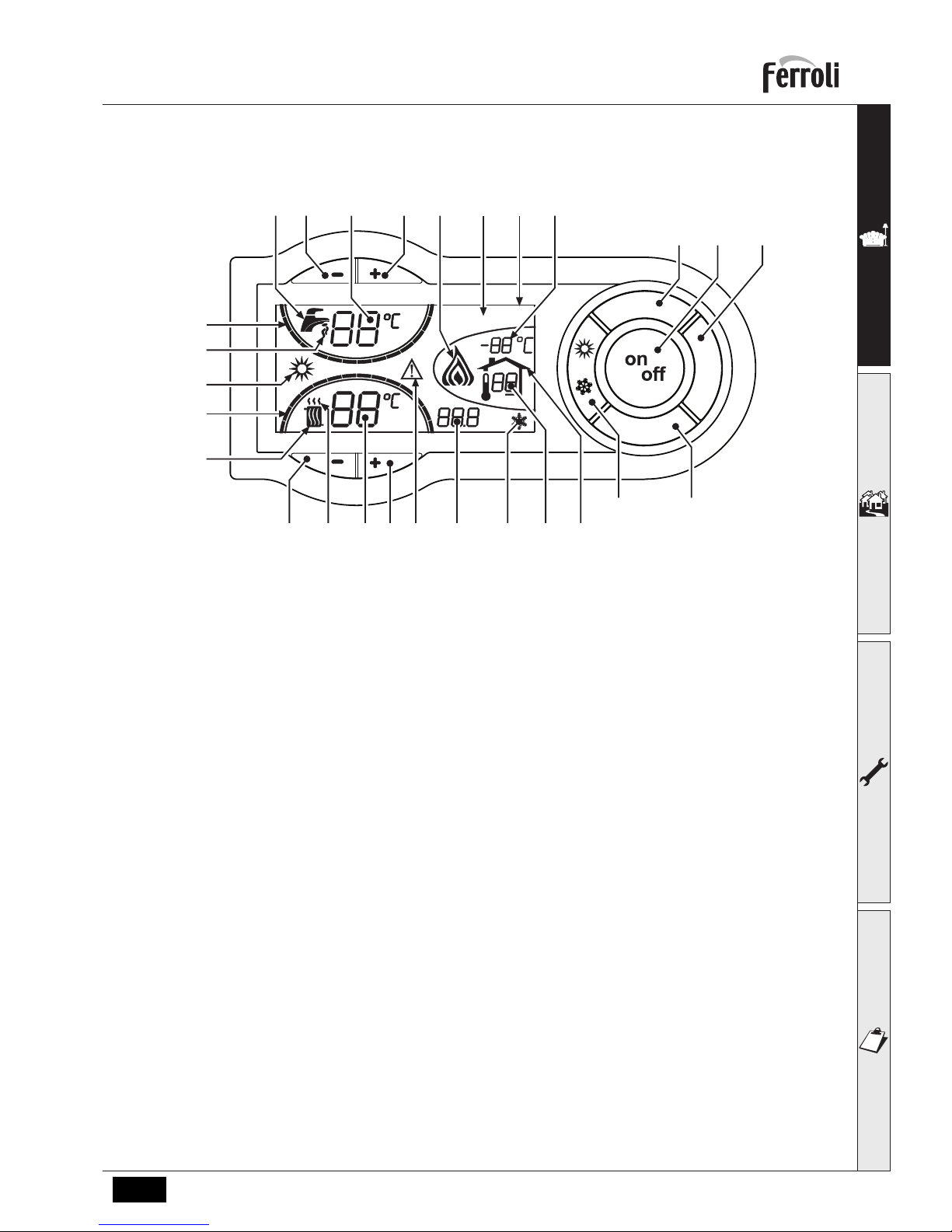

1.2 Control panel

fig. 1 - Control panel

Key

1 = DHW temperature setting decrease button

2 = DHW temperature setting increase button

3 = Heating system temperature setting decrease

button (high temperature zone)

4 = Heating system temperature setting increase

button (high temperature zone)

5 = Display

6 = Summer / Winter mode selection button

7 = Economy / Comfort mode selection button

8 = Reset button

9 = Unit On / Off button

10 = "Sliding Temperature" menu button (high tem-

perature zone)

11 = Set DHW temperature reached

12 = DHW symbol

13 = DHW mode

14 = DHW outlet temperature / setting (flashing dur-

ing "Exchanger protection" function)

15 = Eco (Economy) or Comfort mode

16 = External sensor temperature (with optional ex-

ternal probe)

17 = Appears on connecting the external Probe or the

Remote Timer Control (optionals)

18 = Room temperature (with optional Remote Timer

Control - low temperature zone)

19 = Burner lit and actual power (flashing during

"Flame protection" function)

20 = Antifreeze operation

21 = Heating system pressure

22 = Fault

23 = Heating delivery temperature / setting - high

temperature zone (flashing during “Exchanger

protection” function )

24 = Heating symbol

25 = Heating mode

26 = Set heating delivery temperature reached

27 = Summer mode

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

ecomfort

bar

5

7910

21

86

43

12 14

11

13

15 16

17182021222325

24

26

27

19

Page 6

ECONCEPT SOLAR ST

6 EN

cod. -- - 11/2010 (Rev. 00)

Indication during operation

Heating

A heating demand (generated by the Room Thermostat or Remote Timer Control) is indicated by flashing of the hot air

above the radiator (details 24 and 25 - fig. 1).

The display (detail 23 - fig. 1) shows the actual heating delivery temperature and, during heating standby time, the message "d2".

The heating graduation marks (detail 26 - fig. 1) light up as the heating sensor temperature reaches the set value.

fig. 2

Domestic hot water (DHW)

A hot water tank heating demand is indicated by flashing of the hot water under the tap (details 12 and 13 - fig. 1).

The display (detail 14 - fig. 1) shows the actual hot water outlet temperature and, during DHW standby time, the message "d1".

The DHW graduation marks (detail 11 - fig. 1) light up as the hot water tank sensor temperature reaches the set value.

fig. 3

Exclude hot water tank (economy)

Hot water tank temperature maintaining/heating can be excluded by the user. If excluded, domestic hot water will only

be delivered by the solar circuit; the latter is managed by the controller DBM29 whose specifications are given in

cap. 4.7 "DBM29 (ECOTRONIC tech) - Solar Controller".

When hot water tank heating is activated (default setting), the COMFORT symbol (detail 15 - fig. 1) is activated on the

display, and when off, the ECO symbol (detail 15 - fig. 1) is activated on the display.

The hot water tank can be deactivated by the user (ECO mode ) by pressing the economy/comfort button (detail 7 fig. 1). To activate the COMFORT mode, press theeconomy/comfort button (detail 7 - fig. 1) again.

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

bar

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

comfort

bar

comfort

Page 7

ECONCEPT SOLAR ST

7EN

cod. -- - 11/2010 (Rev. 00)

1.3 Lighting and turning off

Boiler not electrically powered

fig. 4 - Boiler not powered

B

The antifreeze system does not work when the power and/or gas to the unit are turned off. To avoid damage

caused by freezing during long idle periods in winter, it is advisable to drain all the water from the boiler, DHW

circuit and system; or drain just the DHW circuit and add a suitable antifreeze to the heating system, complying

with that prescribed in sec. 2.3.

Boiler lighting

Switch on the power to the unit.

fig. 5 - Boiler ignition

• For the following 180 seconds the display will show FH which identifies the heating system air venting cycle.

• During the first 5 seconds the display will also show the card software version.

• Open the gas cock ahead of the boiler.

• When the message FH disappears, the boiler is ready to operate automatically whenever domestic hot water is

drawn or in case of a room thermostat demand.

Turning the boiler off

Press the button (detail 9 - fig. 1) for 1 second.

fig. 6 - Turning the boiler off

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

Page 8

ECONCEPT SOLAR ST

8 EN

cod. -- - 11/2010 (Rev. 00)

When the boiler is turned off, the electronic board is still powered.

Domestic hot water and heating operation are disabled. The antifreeze system remains activated.

To re-light the boiler, press the button (detail 9 fig. 1) again for 1 second.

fig. 7

The boiler will be immediately ready to operate whenever domestic hot water is drawn or in case of a room thermostat demand.

1.4 Adjustments

Summer/Winter Switchover

Press the button (part 6 - fig. 1) for 1 second.

fig. 8

The display will activate the Summer symbol (part 27 - fig. 1): the boiler will deliver tap water only. The antifreeze system

stays on.

To turn off Summer mode, press button (part 6 - fig. 1) again for 1 second.

Heating temperature adjustment (high temperature zone)

Use the heating buttons (details 3 and 4 -

fig. 1

) to adjust the temperature from a min. of 20°C to a max. of 90°C.

fig. 9

This temperature becomes the maximum system delivery temperature also for the low temperature zone. Do not set a

lower value than that of “Heating temperature adjustment (low temperature zone)”:

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

Page 9

ECONCEPT SOLAR ST

9EN

cod. -- - 11/2010 (Rev. 00)

Heating temperature adjustment (low temperature zone)

With optional remote timer control installed

Use the "Heating temperature adjustment" button (see relevant manual) to adjust the temperature from a min. of 10°C

to a max. of 40°C.

Without optional remote timer control installed

The heating temperature adjustment for the low temperature zone is fixed at 40°C.

This setting must only be modified by qualified Personnel.

Room temperature adjustment

Room temperature adjustment of the high temperature zone can only be managed by a room thermostat; whereas room

temperature adjustment of the low temperature can be managed by a room thermostat or a remote timer control.

Room temperature adjustment (with optional room thermostat)

Using the room thermostat, set the temperature required in the rooms. If the room thermostat is not present, the boiler

will keep the system at the set system delivery set point temperature.

Room temperature adjustment (with optional remote timer control)

Using the remote timer control, set the required temperature in the rooms. The boiler will adjust the system water according

to the required room temperature. For operation with remote timer control, refer to the relevant instruction manual.

Domestic hot water (DHW) temperature adjustment

Use the DHW buttons (details 1 and 2 - fig. 1) to adjust the temperature from a min. of 10°C to a max. of 65°C.

fig. 10

Sliding temperature

When the optional external probe is installed, the control panel display (detail 5 - fig. 1) shows the actual outside temperature read by the probe. The boiler control system works with "Sliding Temperature". In this mode, the heating system temperature is controlled according to the outside weather conditions in order to ensure high comfort and energy

saving throughout the year. In particular, as the outside temperature increases, the system delivery temperature is decreased according to a specific "compensation curve".

With the Sliding Temperature adjustment, the temperature set with the heating buttons (details 3 and 4 - fig. 1) becomes

the maximum system delivery temperature (high and low temperature zone). It is advisable to set a maximum value to

allow system adjustment throughout its useful operating range.

The boiler must be adjusted at the time of installation by qualified personnel. Adjustments can in any case be made by

the user to improve comfort .

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

Page 10

ECONCEPT SOLAR ST

10 EN

cod. -- - 11/2010 (Rev. 00)

Compensation curve and curve offset - High Temperature Zone

Press the button (detail 10 - fig. 1) once to display the actual compensation curve (fig. 11), which can be modified

with the DHW buttons (details 1 and 2 - fig. 1).

Adjust the required curve from 1 to 10 according to the characteristic (fig. 13).

By setting the curve to 0, sliding temperature adjustment is disabled.

fig. 11 - Compensation curve

Press the heating buttons (details 3 and 4 - fig. 1) to access parallel curve offset (fig. 14), modifiable with the

DHW buttons (details 1 and 2 - fig. 1).

fig. 12 - Parallel curve shift

Press the button (detail 10 - fig. 1) again to exit parallel curve adjustment mode.

Compensation curve and curve offset - Low Temperature Zone with optional Remote Timer Control

connected

Refer to the relevant instruction manual.

Compensation curve and curve offset - Low Temperature Zone without optional Remote Timer Control connected

Press the ECONOMY/COMFORT button (detail 7 - fig. 1) for 10 seconds; parameter o01 or the actual compensation

curve is displayed, which can be modified with the DHW buttons (details 1 and 2 - fig. 1).

Adjust the required curve from 1 to 10 according to the characteristic (fig. 13). By setting the curve to 0, sliding temperature adjustment is disabled.

Press the heating button (detail 4 - fig. 1) to access parameter o02 or parallel curve offset (fig. 14), modifiable with the

DHW buttons (details 1 and 2 - fig. 1).

Press the ECONOMY/COMFORT button (detail 7 - fig. 1) again for 10 seconds to exit parallel curve adjustment mode .

Page 11

ECONCEPT SOLAR ST

11EN

cod. -- - 11/2010 (Rev. 00)

References for Compensation curve and curve offset

If the room temperature is lower than the required value, it is advisable to set a higher order curve and vice versa. Proceed by increasing or decreasing in steps of one and check the result in the room.

fig. 13 - Compensation curves

fig. 14 - Example of parallel compensation curve shift

Adjustments from remote timer control (for Low Temperature Zone only)

A

If the Remote Timer Control (optional) is connected to the boiler, the above adjustments are managed according to that given in table 1. Also, the control panel display (detail 5 - fig. 1) shows the actual room temperature

read by the Remote Timer Control.

Table. 1

DHW temperature adjustment Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

Eco/Comfort selection On disabling DHW from the Remote Timer Control menu, the boiler selects

the Economy mode. In this condition, the ECONOMY/COMFORT button

(detail 7 - fig. 1) on the boiler panel is disabled .

On enabling DHW from the Remote Timer Control menu, the boiler selects

the Comfort mode. In this condition , one of the two modes can be selected

with the ECONOMY/COMFORT button (detail 7 - fig. 1) on the boiler panel .

20

30

40

50

60

70

80

90

85

20 10 0 -10 -20

1

2

3

4

5

68910 7

20

30

40

50

60

70

80

90

85

20 10 0 -10 -20

1

2

3

4

5

6

8910

7

20 10 0 -10 -20

20

30

40

50

60

70

80

90

85

1

2

3

4

568910 7

OFFSET = 20 OFFSET = 40

Page 12

ECONCEPT SOLAR ST

12 EN

cod. -- - 11/2010 (Rev. 00)

System water pressure adjustment

The filling pressure with system cold, read on the boiler water gauge, must be approx. 1.0 bar. If the system pressure

falls to values below minimum, the boiler card will activate fault F37 (fig. 15).

fig. 15 - Low system pressure fault

Operate the filling cock (detail 1 - fig. 16) and bring the system pressure to a value above 1.0 bar.

At the bottom of the boiler there is a pressure gauge (detail 2 - fig. 16) to show the pressure even when there is no power

supply.

fig. 16 - Filling cock

A

Once the system pressure is restored, the boiler will activate the 180-second air venting cycle indicated on the

display by FH.

At the end of the operation always close the filling cock (detail 1 - fig. 16)

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

Page 13

ECONCEPT SOLAR ST

13EN

cod. -- - 11/2010 (Rev. 00)

2. Installation

2.1 General Instructions

BOILER INSTALLATION MUST ONLY BE PERFORMED BY QUALIFIED PERSONNEL, IN ACCORDANCE WITH ALL THE

INSTRUCTIONS GIVEN IN THIS TECHNICAL MANUAL, THE PROVISIONS OF CURRENT LAW, THE PRESCRIPTIONS

OF NATIONAL STANDARDS AND LOCAL REGULATIONS AND THE RULES OF PROPER WORKMANSHIP

2.2 Place of installation

The combustion circuit is sealed with respect to the place of installation, therefore the unit can be installed in any room.

However, the place of installation must be sufficiently ventilated to prevent the creation of dangerous conditions in case

of even small gas leaks. This safety standard is required by EEC Directive no. 90/396 for all gas units, including those

with sealed chamber.

Therefore the place of installation must be free of dust, flammable materials or objects, or corrosive gases. The room

must be dry and not subject to freezing.

A

If the unit is enclosed in a cabinet or mounted alongside, a space must be provided for removing the casing

and for normal maintenance operations

2.3 Plumbing connections

Important

The heating capacity of the unit must be previously established by calculating the building's heat requirement according

to the current regulations. The system must be provided with all the components for correct and regular operation. It is

advisable to install shutoff valves between the boiler and heating system allowing the boiler to be isolated from the system if necessary.

B

The safety valve outlet must be connected to a funnel or collection pipe to prevent water spurting onto the floor

in case of overpressure in the heating circuit. Otherwise, if the discharge valve cuts in and floods the room,

the boiler manufacturer cannot be held liable.

Do not use the water system pipes to earth electrical appliances.

Before installation, carefully wash all the pipes of the system to remove any residuals or impurities that could affect proper operation of the unit.

B

Also, a filter must be installed on the system return piping to prevent impurities or sludge from the system clogging and damaging the heat generators.

The filter must be installed when replacing generators in existing systems. The manufacturer declines any liability for damage caused to the generator by failure to install or inadequate installation of this filter.

Carry out the relevant connections according to the diagram in sec. 4.1and the symbols given on the unit.

The unit has an internal double circulation, which enables the management of two heating zones: a low temperature

zone (floor system) and a high temperature zone (radiators, towel warmers,etc.).

Solar system

The unit has a specific internal circuit for connection to one or more external solar collectors. The internal circuit of

ECONCEPT SOLAR ST comprises: stratified solar hot water tank with solar coil, flow limiter, filling unit, solar safety

valve, variable-speed pump and solar expansion tank. Make the corresponding connections , respecting the instructions

given below.

• It is best to use steel or copper pipes in the solar circuit. Given the high temperatures the heat transfer fluid can

reach, the use of plastic pipes , e.g. in PE or similar materials, is not allowed. Deformation or breakage of the pipes

can cause a general system failure !

• The widths of the pipes must be correctly sized . In particular, too large a size slows the system speed and reduces

its efficiency . To minimise pressure loss in the solar circuit, the speed of flow in the copper pipe must not exceed

1.5 m/s. For ideal transmission of heat, for the collectors a nominal flow of 40 l/h for every m2 of gross collector area

is necessary .

• All the components of the system must be sized in order to ensure an even volumetric flow rate with the required

nominal flow rate .

• The pipes outside the boiler must be provided with adequate thermal protection to prevent excessive heat loss. In

particular, in case if pipes laid outdoors, use insulation resistant to atmospheric agents , UV rays and bird damage.

Page 14

ECONCEPT SOLAR ST

14 EN

cod. -- - 11/2010 (Rev. 00)

• The solar circuit must be perfectly tight. Check all the joins between pipes and correct execution of any welds. Use

pressure fittings only of the thermal resistance guaranteed by their manufacturer is equal to 200ºC.

• The presence of air in the solar circuit considerably affects its efficiency . It is necessary to install venting devices in

the highest points of the solar circuit (e.g. at the tops of the columns) and make sure the system is completely vented

after commissioning and after every maintenance operation . The delivery and return pipes must be installed with

adequate slopes towards the vents, avoiding the creation of air pockets. Automatic or manual devices (recommended) can be used as venting devices. The venting devices must be resistant to temperatures up to 150°C. If the system is not working and the automatic venting devices are not blocked, steam can come out . Therefore the automatic

venting devices must be blocked while the system is working.

• The solar circuit must be filled with suitable heat transfer fluid, specific for solar systems. Recommended products:

"FERSOL LT" or "FERSOL ULTRA LT" which provide adequate antifreeze protection for temperatures to -12°C and

-25°C respectively. In general, choose the type of fluid according to the outside temperature in relation to the heating

system in the place of installation . Add approx. 7°C to this temperature (e.g. -5°C) as a safety factor : therefore in

the above example, the antifreeze protection of "FERSOL LT" fluid will suffice. FERSOL premixed solar fluid contains non-toxic propylene glycols and corrosion inhibitors thermostable to 300°C (peak temperature limit condition

reachable for very short periods).

• For solar system filling and venting operations, refer to sec. 3.2. For periodical fluid and maintenance checking operations, refer tosec. 3.3.

System water charcteristics

In the presence of water harder than 25° Fr (1°F = 10ppm CaCO3), the use of suitably treated water is advisable in order

to avoid possible scaling in the boiler. The treatment must not in any case reduce the hardness to values below 15°F

(Decree 236/88 for uses of water intended for human consumption). Water treatment is indispensable in the case of

very large systems or with frequent replenishing of water in the system. If partial or total emptying of the system becomes necessary in these cases, it is advisable to refill it with treated water.

Antifreeze system, antifreeze fluids, additives and inhibitors

The boiler is equipped with an antifreeze system that turns on the boiler in heating mode when the system delivery water

temperature falls under 6°C. The device will not come on if the electricity and/or gas supply to the unit are cut off. If it

becomes necessary, it is permissible to use antifreeze fluid, additives and inhibitors only if the manufacturer of these

fluids or additives guarantees they are suitable for this use and cause no damage to the heat exchanger or other components and/or materials of the boiler unit and system. It is prohibited to use generic antifreeze fluid, additives or inhibitors that are not expressly suited for use in heating systems and compatible with the materials of the boiler unit and

system.

2.4 Gas connection

B

Before making the connection, ensure that the unit is arranged for operation with the type of fuel available and

carefully clean all the pipes of the gas system to remove any residues that could affect good functioning of the

boiler.

The gas must be connected to the relative connector (see fig. 33) in conformity with current standards, with rigid metal

pipes or with continuous flexible s/steel wall tubing, placing a gas cock between the system and the boiler. Make sure

that all the gas connections are tight. The capacity of the gas meter must be sufficient for the simultaneous use of all

equipment connected to it. The diameter of the gas pipe leaving the boiler does not determine the diameter of the pipe

between the unit and the meter; it must be chosen according to its length and loss of head, in conformity with current

standards.

B

Do not use the gas pipes to earth electrical appliances.

Page 15

ECONCEPT SOLAR ST

15EN

cod. -- - 11/2010 (Rev. 00)

2.5 Electrical connections

Connection to the electrical grid

B

The unit's electrical safety is only guaranteed when correctly connected to an efficient earthing system executed according to current safety standards. Have the efficiency and suitability of the earthing system checked

by professionally qualified personnel. The manufacturer is not responsible for any damage caused by failure

to earth the system. Also make sure that the electrical system is adequate for the maximum power absorbed

by the unit, as specified on the boiler dataplate.

The boiler is prewired and provided with a Y-cable and plug for connection to the electricity line. The connections to the

grid must be made with a permanent connection and equipped with a bipolar switch whose contacts have a minimum

opening of at least 3 mm, interposing fuses of max. 3A between the boiler and the line. It is important to respect the

polarities (LINE: brown wire / NEUTRAL: blue wire / EARTH: yellow-green wire) in making connections to the electrical

line. During installation or when changing the power cable, the earth wire must be left 2 cm longer than the others.

B

The user must never change the unit's power cable. If the cable gets damaged, switch off the unit and have it

changed solely by professionally qualified personnel. If changing the electric power cable, use solely “HAR

H05 VV-F” 3x0.75 mm2 cable with a maximum outside diameter of 8 mm.

Solar collector temperature probe

The unit is provided with a temperature probe for positioning on the circuit at the outlet of the last collector .The probe

must be connected to the controller after carrying out the solar circuit filling operations described in sec. 2.3. The controller is located on the left side on the back of the electrical box. The probe must be connected to terminals 5 and 6,

removing the resistances (to be kept for future use).

Room thermostat (optional)

B

CAUTION: The room thermostat must have clean contacts. CONNECTING 230 V. TO THE TERMINALS OF

THE ROOM THERMOSTAT WILL IRREPARABLY DAMAGE THE ELECTRONIC CARD.

When connecting a remote timer control or a timer switch, do not take the power supply for these devices from

their cut-out contacts. Their power supply must be taken with a direct connection from the mains or with batteries, depending on the kind of device.

External probe (optional)

Connect the probe to its respective terminals. The maximum permissible length for the boiler - external probe connection electrical cable is 50 m. A normal 2-wire cable can be used. The external probe should preferably be installed on

the North, North-West wall or that facing the largest area of living room. The probe must never be exposed to the early

morning sun or, insofar as possible, direct sunlight; protect it if necessary. In any case, the probe must not be installed

near windows, doors, ventilation openings, flues or heat sources that could affect the reading.

fig. 17 - External probe positioning not recommended

Page 16

ECONCEPT SOLAR ST

16 EN

cod. -- - 11/2010 (Rev. 00)

Accessing the electrical terminal block

Follow the instructions given in fig. 18 to access the electrical connections terminal block. The layout of the terminals

for the various connections is given in the wiring diagram in fig. 36.

fig. 18 - Accessing the terminal block

2.6 Fume ducts

The unit is a "C-type" with sealed chamber and forced draught ; the air inlet and fume outlet must be connected to one

of the following extraction/suction systems. The unit is approved to work with all the Cxy flue configurations specified

on the dataplate (some configurations are given by way of example in this section). Some configurations may be expressly limited or not permitted by law, standards or local regulations. Before proceeding with installation, check and

carefully observe the above-mentioned prescriptions. Also comply with the provisions on the positioning of wall and/or

roof terminals and the minimum distances from windows, walls, ventilation openings, etc.

B

This C-type unit must be installed using the fume suction and exhaust ducts supplied by the manufacturer in

accordance with UNI-CIG 7129/92. Failure to use them automatically invalidates every warranty and relieves

the manufacturer of any liability.

A

For fume exhaust pipes longer than 1 metre, during installation take in account the natural expansion of the

materials when the boiler is working.

To prevent deformations, leave an expansion space of approx. 2 ÷ 4 mm for every metre of pipe.

fig. 19 - Expansion

2 ÷ 4 mm

Page 17

ECONCEPT SOLAR ST

17EN

cod. -- - 11/2010 (Rev. 00)

Connection with coaxial pipes

fig. 20 - Examples of connection with coaxial pipes ( = Air / = Fumes)

For coaxial connection, fit the unit with one of the following starting accessories. For the wall hole dimensions, refer to

sec. 4.1. Any horizontal sections of the fume exhaust must be kept sloping slightly towards the boiler, to prevent any

condensate from flowing back towards the outside and causing dripping.

fig. 21 - Starting accessory for coaxial ducts

Before proceeding with installation, check with table 2 that the maximum permissible length is not exceeded, bearing in

mind that every coaxial bend gives rise to the reduction indicated in the table. For example, a Ø 60/100 duct comprising

a 90° bend + 1 horizontal metre has a total equivalent length of 2 metres.

Table. 2 - Max. length coaxial ducts

ECONCEPT SOLAR ST 18 ECONCEPT SOLAR ST 25

Coaxial 60/100 Coaxial 80/125 Coaxial 60/100 Coaxial 80/125

Max. permissible length 6 m 16 m 5 m 15 m

Reduction factor 90° bend 1 m 0.5 m 1 m 0.5 m

Reduction factor 45° bend 0.5 m 0.25 m 0.5 m 0.25 m

C

13

C

13

C

33

C

33

C

33

C

13

Ø 100

Ø 60

120

142

Ø 80

Ø 127

120

147

Ø 100

Ø 60

041002X0 041006X0 041001X0

Page 18

ECONCEPT SOLAR ST

18 EN

cod. -- - 11/2010 (Rev. 00)

Connection with separate pipes

fig. 22 - Examples of connection with separate pipes ( = Air / = Fumes)

For connection of the separate ducts, fit the unit with the following starting accessory:

fig. 23 - Starting accessory (code 041039X0) for separate ducts

Before proceeding with installation, make sure the maximum permissible length has not been exceeded, by means of

a simple calculation:

1. Establish the layout of the system of split flues, including accessories and outlet terminals.

2. Consult the table 4 and identify the losses in m

eq

(equivalent metres) of every component, according to the instal-

lation position.

3. Check that the sum total of losses is less than or equal to the maximum permissible length in table 3.

Table. 3 - Max. length separate ducts

Separate ducts

ECONCEPT SOLAR ST 18 ECONCEPT SOLAR ST 25

Max. permissible length 80 m

eq

75 m

eq

C

53

C

33

C

53

B

23

C

13

Ø 81Ø 81

65

87

65

Page 19

ECONCEPT SOLAR ST

19EN

cod. -- - 11/2010 (Rev. 00)

Table. 4 - Accessories

Connection to collective flues

fig. 24 - Examples of connection to flues ( = Air / = Fumes)

If you are then going to connect the ECONCEPT SOLAR ST boiler to a collective flue or a single flue with natural

draught, the flue must be expressly designed by professionally qualified technical personnel in conformity with the current standards and be suitable for airtight chamber units equipped with a fan.

In particular, flues must have the following characteristics:

• Be sized according to the method of calculation stated in the current standards.

• Be airtight to the products of combustion, resistant to the fumes and heat and waterproof for the condensate.

• Have a circular or quadrangular cross-section, with a vertical progression and with no constrictions.

• Have the ducts conveying the hot fumes adequately distanced or isolated from combustible materials.

• Be connected to just one unit per floor.

• Be connected to just one type of unit (or all and only forced draught units or all and only natural draught units).

• Have no mechanical suction devices in the main ducts.

• Be at a lower pressure, all along their length, under conditions of stationary operation.

• Have at their base a collection chamber for solid materials or condensation equipped with a metal door with an airtight closure.

Losses in m

eq

Air

inlet

Fume exhaust

Vertical Horizontal

Ø 80 PIPE 1 m M/F 1KWMA83W 1.0 1.6 2.0

BEND 45° M/F 1KWMA65W 1.2 1.8

90° M/F 1KWMA01W 1.5 2.0

PIPE SECTION with test point 1KWMA70W 0.3 0.3

TERMINAL air, wall 1KWMA85A 2.0 -

fumes, wall with antiwind 1KWMA86A - 5.0

FLUE Split air/fumes 80/80 1KWMA84U - 12.0

C

83

C

43

C

43

Page 20

ECONCEPT SOLAR ST

20 EN

cod. -- - 11/2010 (Rev. 00)

2.7 Condensate drain connection

The boiler is equipped with an internal trap to drain condensate. Fit the inspection union A and flexible tube B, pressing

it in for approx. 3 cm and securing it with a clamp. Fill the trap with approx. 0.5 l. of water and connect the flexible tube

to the drainage system.

fig. 25

Page 21

ECONCEPT SOLAR ST

21EN

cod. -- - 11/2010 (Rev. 00)

3. Service and maintenance

All adjustment, conversion, commissioning and maintenance operations described below must only be carried out by Qualified Personnel (meeting the professional technical requirements prescribed by current regulations) such as those of the

Local After-Sales Technical Service.

FERROLI declines any liability for damage and/or injury caused by unqualified and unauthorised persons tampering with

the unit.

3.1 Adjustments

Gas conversion

The unit can operate on natural gas or LPG and is factory-set for use with one of these two gases, as clearly shown on

the packing and on the dataplate. Whenever a gas different from that for which the unit is arranged has to be used, a

conversion kit will be required, proceeding as follows:

1. Remove the casing.

2. Open the sealed chamber.

3. Replace the nozzle A inserted in the mixer, with that contained in the conversion kit.

4. Reassemble and check the tightness of the connection.

5. Apply the label, contained in the conversion kit, near the dataplate.

6. Refit the sealed chamber and casing.

7. Modify the parameter for the type of gas:

• put the boiler in standby mode

• press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds. the display shows "P01" flashing.

• Press the DHW buttons fig. 1 (details 1 and 2 - ) to set parameter 00 (for natural gas) or 01 (for LPG ).

• press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds.

• the boiler will return to standby mode

8. Check the working pressure.

9. Using a combustion analyser connected to the boiler fume outlet, check that the CO

2

content in the fumes, with the

boiler operating at max. and min. power, matches that given in the technical data table for the corresponding type

of gas.

fig. 26 - Gas nozzle replacement

A

Page 22

ECONCEPT SOLAR ST

22 EN

cod. -- - 11/2010 (Rev. 00)

TEST mode activation

Press the heating buttons (details fig. 13 and 4 - ) together for 5 seconds to activate the TEST mode. The boiler lights

at the maximum heating power set as described in the following section.

The heating symbol (detail 24 - fig. 1) and DHW symbol (detail 12 - fig. 1) flash on the display; the heating power and

actual flame current value (uA x 10) will be displayed alongside.

fig. 27 - TEST mode (heating power = 100%)

Press the heating buttons (details 3 and 4 - fig. 1) to increase or decrease the power (min.=0%, max.=100%).

Press the DHW button "-" (detail 1 - fig. 1) and boiler power is immediately adjusted to min. (0%). Press the DHW button

"+" (detail 2 - fig. 1) and boiler power is immediately adjusted to max. (100%).

If the TEST mode is activated and enough hot water is drawn to activate the DHW mode, the boiler remains in TEST

mode but the 3-way valve goes to DHW.

To deactivate the TEST mode, repeat the activation sequence.

The TEST mode is automatically disabled in any case after 15 minutes or on stopping of hot water drawing (in case of

drawing of hot water enough to activate DHW mode).

Heating power adjustment

To adjust the heating power, switch the boiler to TEST mode (see sec. 3.1). Press the heating buttons (details 3 and 4

- fig. 1) to increase or decrease the power (min. = 00 - max. = 100). Press the RESET button within 5 seconds and the

max. power will remain that just set. Exit TEST mode (see sec. 3.1).

3.2 Starting

Before lighting the boiler

• Open any on-off valves between the boiler and the systems.

• Check the tightness of the gas system, proceeding with caution and using a soap and water solution to detect any

leaks in connections.

• Check correct prefilling of the expansion tank (ref. sec. 4.4).

• Fill the water system and make sure all air contained in the boiler and the system has been vented, by opening the

air vent valve on the boiler and any vent valves on the system.

• Fill the condensate trap and check correct connection of the condensate elimination system.

• Make sure there are no water leaks in the system, DHW circuits, connections or boiler.

• Check correct connection of the electrical system and efficiency of the earthing system

• Make sure the gas pressure value for heating is that required.

• Make sure there are no flammable liquids or materials in the immediate vicinity of the boiler

Checks during operation

• Turn the unit on as described in sec. 1.3.

• Make sure the fuel circuit and water systems are tight.

• Check the efficiency of the flue and air-fume ducts while the boiler is working.

• Check the correct tightness and functionality of the condensate elimination system and trap.

• Make sure the water is circulating properly between the boiler and the systems.

• Make sure the gas valve modulates correctly in the heating and domestic hot water production phases.

e

c

o

c

o

m

f

o

r

t

m

o

d

e

r

e

s

e

t

eco

bar

Page 23

ECONCEPT SOLAR ST

23EN

cod. -- - 11/2010 (Rev. 00)

• Check proper boiler lighting by doing several tests, turning it on and off with the room thermostat or remote control.

• Using a combustion analyser connected to the boiler fume outlet, check that the CO2 content in the fumes, with the boiler

operating at max. and min. output, corresponds to that given in the technical data table for the corresponding type of gas.

• Make sure the fuel consumption indicated on the meter matches that given in the technical data table on sec. 4.4.

• Check the correct programming of the parameters and carry out any necessary customization (compensation curve,

power, temperatures, etc.).

Solar circuit

The solar circuit is managed by the Controller DBM29 whose specifications are given in cap. 4.7 "DBM29 (ECOTRONIC

tech) - Solar Controller".

To start the solar system it is necessary to use the special filling pump and carry out the following procedure , respecting

the order of steps described below. Do this when the collectors are cold, i.e. in the morning or evening. If this is not

possible, protect the panels with covers that opaque to the sun's rays.

fig. 28 - Solar circuit

Key

1 Filling cock

7 Pressure gauge

9 Filters

10 Container

11 Drain cock

12 Flow limiter

16 Pump

17 Vent

10

9

7

16

17

1

12

11

Mandata solare

Ritorno solare

Page 24

ECONCEPT SOLAR ST

24 EN

cod. -- - 11/2010 (Rev. 00)

1. Solar circuit tightness test

Open the venting device in the solar collector circuit (ref. 17 - fig. 28).

Remove the boiler casing front panels. Open the solar circuit filling cock (ref. 1 - fig. 28) and drain cock (ref. 11 - fig. 28) .

Fit a hose from the cock (ref. 11) to the container (ref. 10 - fig. 28) and from the pump (ref. 16 - fig. 28) to the cock (ref. 1).

fig. 29 - Closed

fig. 30 - Open

Turn the flow limiter (ref. 12 - ) adjuster screw to the horizontal position (fig. 29), which closes itfig. 28.

Pump the heat transfer fluid into the circuit with the filling pump (ref. 16), until it comes out the drain cock (ref. 11 - fig.28)

Maintain the circulation of the fluid, venting the system through the vent of the collectors (ref. 17 - fig. 28).

After venting, close the drain cock (11) and the venting device (ref. 17).

Bring the pressure to 4.5 bar and close the cock (ref. 1 - fig. 28).

Wait a few minutes, visually checking the unions and welds and recheck the pressure, which must remain stable on

the pressure gauge (ref. 7 - fig. 28).

Eliminate any leaks detected and, if necessary, do another tightness check with solar heat transfer fluid.

2. Flushing the solar circuit

Keeping the system filled and the flow limiter screw (12) in the horizontal position (closed), connect a filter (9) on the

drain pipe connected to the cock (11)

Open the cock (11) and cock (1), depressurising the solar circuit

Check the closing of the system venting device (17)

Using the pump (16), pump the solar heat transfer fluid from the container (10) in the solar circuit, for about 10-15 minutes (depending on the length of the system pipes)

Check the filter (9) and clean it if necessary.

3. Filling the solar circuit

Check the solar expansion tank prefilling pressure (ref. 308 - fig. 34), which should be approx. 0.3-0.5 bar below the

filling pressure (final) so that, even cold, the tank membrane is under some tension (recommended value: 1.5 bar).

Close the cock(11) and fill the solar circuit, pressurising it .

If a pressure of 2 bar (recommended value cold for systems with a height difference of up to 15 metres between the

highest point of the solar collector and the expansion tank) is reached, also close the cock (1) and turn the flow limiter

screw (12) to the upright position (open).

Disconnect the hoses and the filling pump from the cocks ref. 1 and ref. 11 of fig. 28.

4. Solar circuit venting

• Activate mode FH (see specifications in cap. 4.7 "DBM29 (ECOTRONIC tech) - Solar Controller").

• The solar pump will start operating in continuous mode.

• Open the system vent and ensure complete venting .

• Deactivate mode FH (see specifications in cap. 4.7 "DBM29 (ECOTRONIC tech) - Solar Controller").

• The pressure gauge should indicate 1.5 - 2 bar in the circuit. If necessary, pressurise again by repeating the above steps.

L/min

12

L/min

12

Page 25

ECONCEPT SOLAR ST

25EN

cod. -- - 11/2010 (Rev. 00)

5. Adjusting the flow limiter

ECONCEPT SOLAR ST is equipped with a variable-speed solar pump controlled by an advanced control system, which

optimises the flow rate in the solar circuit according to working conditions and heat demands.

For correct operation, the flow rate in the solar circuit must be preset during commissioning, by means of the flow limiter,

(fig. 31) to a value of 2 l/min per panel.

fig. 31 - Flow limiter

Activate the “Flow limiter adjustment” mode (see specifications in

cap. 4.7 "DBM29 (ECOTRONIC tech) - Solar Controller"

).

Using an adjusting wrench (9 mm), operate on the control of the limiter (4 - fig. 31) and adjust the flow rate.

Deactivate the “Flow limiter adjustment” mode (see specifications in

cap. 4.7 "DBM29 (ECOTRONIC tech) - Solar Controller"

).

6. Solar collector temperature sensor

To connect the solar collector sensor it is necessary to disconnect the resistance “A” from the terminals on the cable

“PT1000”. Then connect the solar collector probe “311” to the same terminals.

fig. 32 - Solar collector sensor connection

L/min

12

10

8

6

4

2

4

A

M

B

PT 1000

M

B

PT 1000

A

311

Page 26

ECONCEPT SOLAR ST

26 EN

cod. -- - 11/2010 (Rev. 00)

3.3 Maintenance

Periodical check

To ensure proper operation of the unit over time, have qualified personnel carry out a yearly check, providing for the

following:

• The control and safety devices (gas valve, flowmeter, thermostats, etc.) must function correctly.

• The fume exhaust circuit must be perfectly efficient.

(Sealed chamber boiler: fan, pressure switch, etc. - The sealed chamber must be tight: seals, cable glands, etc.)

(Open chamber boiler: anti-backflow device, fume thermostat, etc.)

• The air/fume terminal and ducts must be free of obstructions and leaks

• The burner and exchanger must be clean and free of deposits. For cleaning do not use chemical products or wire

brushes.

• The electrode must be free of scale and properly positioned.

• The gas and water systems must be tight.

• The water pressure in the cold water system must be approx. 1 bar; otherwise bring it to that value.

• The circulating pump must not be blocked.

• The expansion tank must be filled.

• The gas flowrate and pressure must match that given in the respective tables.

A

The boiler casing, control panel and aesthetic parts can be cleaned with a soft damp cloth, if necessary

soaked in soapy water. Do not use any abrasive detergents and solvents.

Solar circuit

Make sure to periodically check the condition and pressure of the fluid in the system when cold, at least once every 23 years, if possible at the end of the most critical period in relation to the risk of prolonged stagnation of the fluid in the

collectors (overheating of the fluid due to maximum insolation with system idle/not used: e.g. the check should be carried out immediately after the summer holidays).

If FERSOL solar fluid is used, the condition of the fluid, or protection stability , is visually indicated by its pink/purple colour

and a change to a different colour (colourless) indicates deterioration to a minimum protection level .At this point, change

all the fluid or in any case check that the pH is not below 8 , in which case change the fluid so as to avoid problems.

Do not dilute the fluid with water or other fluids. When necessary, top up only with the same product.

Do not use in systems executed with materials that are not compatible with moderately alkaline liquids (PH 8 - 10).

Information regarding disposal: The fluid is not considered hazardous for the health and the environment, nevertheless

it must not be disposed of or diluted in potable waters (e.g. ground waters) or water for food products.

Page 27

ECONCEPT SOLAR ST

27EN

cod. -- - 11/2010 (Rev. 00)

3.4 Trouble shooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault, the display will flash together

with the fault symbol (detail 22 - fig. 1) indicating the fault code (detail 21 - fig. 1).

There are faults that cause permanent shutdown (marked with the letter "A"): to restore operation just press the RESET

button (detail 8 - fig. 1) for 1 second or RESET on the optional remote timer control if installed; if the boiler fails to start,

it is necessary to first eliminate the fault.

Other faults (marked with the letter "F") cause temporary shutdowns that are automatically reset as soon as the value

returns within the boiler's normal working range.

List of faults DBM05C boiler card

Table. 5 - List of faults

Fault

code

Fault Possible cause Cure

A01 The burner fails to light

No gas

Check the regular gas flow to the boiler and that the air has

been eliminated from the pipes

Detection/ignition electrode fault

Check the wiring of the electrode and that it is correctly

positioned and free of any deposits

Faulty gas valve Check the gas valve and replace it if necessary

Insufficient gas supply pressure Check the gas supply pressure

Trap clogged Check the trap and clean it if necessary

A02

Flame present signal with

burner off

Electrode fault Check the ionisation electrode wiring

Card fault Check the card

A03

Overtemperature protection

activation

Heating sensor damaged

Check the correct positioning and operation of the heating

sensor

No water circulation in the system Check the circulating pump

Air in the system Vent the system

A04 Fume extraction duct safety

device activation

Fault F07 generated 3 times in the last 24

hours

See fault F07

A05 Fan protection activation

Fault F15 generated for 1 hour

(consecutive)

See fault F15

A06

No flame after ignition stage

(6 times in 4 min.)

Ionisation electrode fault Check the position of the ionisation electrode and replace it if

necessary

Flame unstable Check the burner

Gas valve Offset fault Check the Offset adjustment at minimum power

air/fume ducts blocked

Remove the obstruction from the flue, fume extraction and air

inlet ducts and terminals

Trap clogged Check the trap and clean it if necessary

F07 High fume temperature

Flue partially obstructed or insufficient

Check the efficiency of the flue, fume extraction ducts and

outlet terminal

Fume sensor position Check correct positioning and operation of the fume sensor

F10 Delivery sensor 1 fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F11 Return sensor fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F12 DHW sensor fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F13 Fume sensor fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F14 Delivery sensor 2 fault

Sensor damaged

Check the wiring or replace the sensorWiring shorted

Wiring disconnected

F15 Fan fault

No 230V power supply Check the 3-pin connector wiring

Tachometric signal interrupted Check the 5-pin connector wiring

Fan damaged Check the fan

Page 28

ECONCEPT SOLAR ST

28 EN

cod. -- - 11/2010 (Rev. 00)

List of faults DBM29 solar card

Low temperature zone card fault FZ4B

The controller indicates the boiler operating mode and its faults through the incorporated display: "St" means Standby

(no demand in progress), "CH" means that the zone controller requests the boiler for activation of heating mode, "DH"

means Domestic Hot Water production. The fault codes are given below:

The fault codes are also displayed in the corresponding menu of the Remote Control during normal operation.

F21 Incorrect system water pressure

The pressure is reaching the maximum

value

Check the system

Check the safety valve

Check the expansion tank

A26 System protection activation Fault F40 generated 3 times in the last hour See fault F40

F34 Supply voltage under 170V Electric mains trouble Check the electrical system

F35 Faulty mains frequency Electric mains trouble Check the electrical system

F37 Incorrect system water pressure

Pressure too low Fill the system

Sensor damaged Check the sensor

F39 External probe fault

Probe damaged or wiring shorted Check the wiring or replace the sensor

Probe disconnected after activating the

sliding temperature

Reconnect the external probe or disable the sliding

temperature

F40 Incorrect system water pressure Pressure too high

Check the system

Check the safety valve

Check the expansion tank

A41 Sensor positioning Delivery sensor disconnected from the pipe Check correct positioning and operation of the heating sensor

F42 Heating sensor fault Sensor damaged Replace the sensor

F47

System water pressure sensor

fault

Wiring disconnected Check the wiring

Fault

code

Possible cause Cure

F82 Regulator configuration fault Only with Parameter P26=1, Stand alone

F83 Solar Collector PT1000 sensor

The sensor fault, understood as a short circuit or open circuit, causes deactivation of the

Solar Pump and shutter closing. The protection is immediately deactivated on eliminating the

fault.

To signal this fault, the symbol S3 will be deactivated, whereas the Fault symbol and the

backlight will start flashing.

F84 Solar Collector Return NTC sensor

The sensor fault, understood as a short circuit or open circuit, causes deactivation of the

Solar Pump . The protection is immediately deactivated on eliminating the fault.

To signal this fault, the symbol S4 will be deactivated, whereas the Fault symbol and the

backlight will start flashing.

F85 Boiler card communication fault

Only with Parameter P26=0, Communicating

The fault, understood as no communication with the boiler card for 60 consecutive seconds,

causes deactivation of the Solar Pump and shutter closing. The protection is immediately

deactivated on eliminating the fault.

F87 Protection for no circulation

Only with Parameter P25<>0, Operation without flowmeter

This fault is activated when, with the Solar Pump activated, the card does not detect flow in

the solar circuit for 10 consecutive minutes. The fault causes deactivation of the Solar Pump.

After checking and eliminating the fault , the protection can be removed, activating and deactivating the OFF mode.

Fault

code

Possible cause Cure

F70 NTC sensor fault (T1) With circuit / contact open

F71 NTC sensor fault (T2) With circuit / contact open

F72 NTC sensor fault (T3) With circuit / contact open

F73 NTC sensor fault (T4) With circuit / contact open

F74 Communication with boiler card not present

F75 Communication with Remote Control (RT1) not present (Only with Remote Control connected)

F76 Communication with Remote Control (RT2) not present (Only with Remote Control connected)

F77 Communication with Remote Control (RT3) not present (Only with Remote Control connected)

Fault

code

Fault Possible cause Cure

Page 29

ECONCEPT SOLAR ST

29EN

cod. -- - 11/2010 (Rev. 00)

4. Technical data and characteristics

4.1 Dimensions and connections

fig. 33 - Dimensions and connections

7 Gas inlet

8 Cold water inlet

10 System delivery

11 System return

192 Recirculation

320 Low temperature delivery

321 Low temperature return

323 Mixed DHW outlet

327 Solar system delivery

328 Solar system return

1057

180 120

221

600

180 120

221

120 180

Mod. 18 Mod. 25

600

1800

47

110

904857 68

415541

44

54

45

327 - Ø 3/4

328 - Ø 3/4

321 - Ø 3/4

11 - Ø 3/4

8 -

Ø 3/4

7 - Ø 1/2

192 - Ø 3/4

10 - Ø 3/4

323 - Ø 3/4

320 - Ø 3/4

Page 30

ECONCEPT SOLAR ST

30 EN

cod. -- - 11/2010 (Rev. 00)

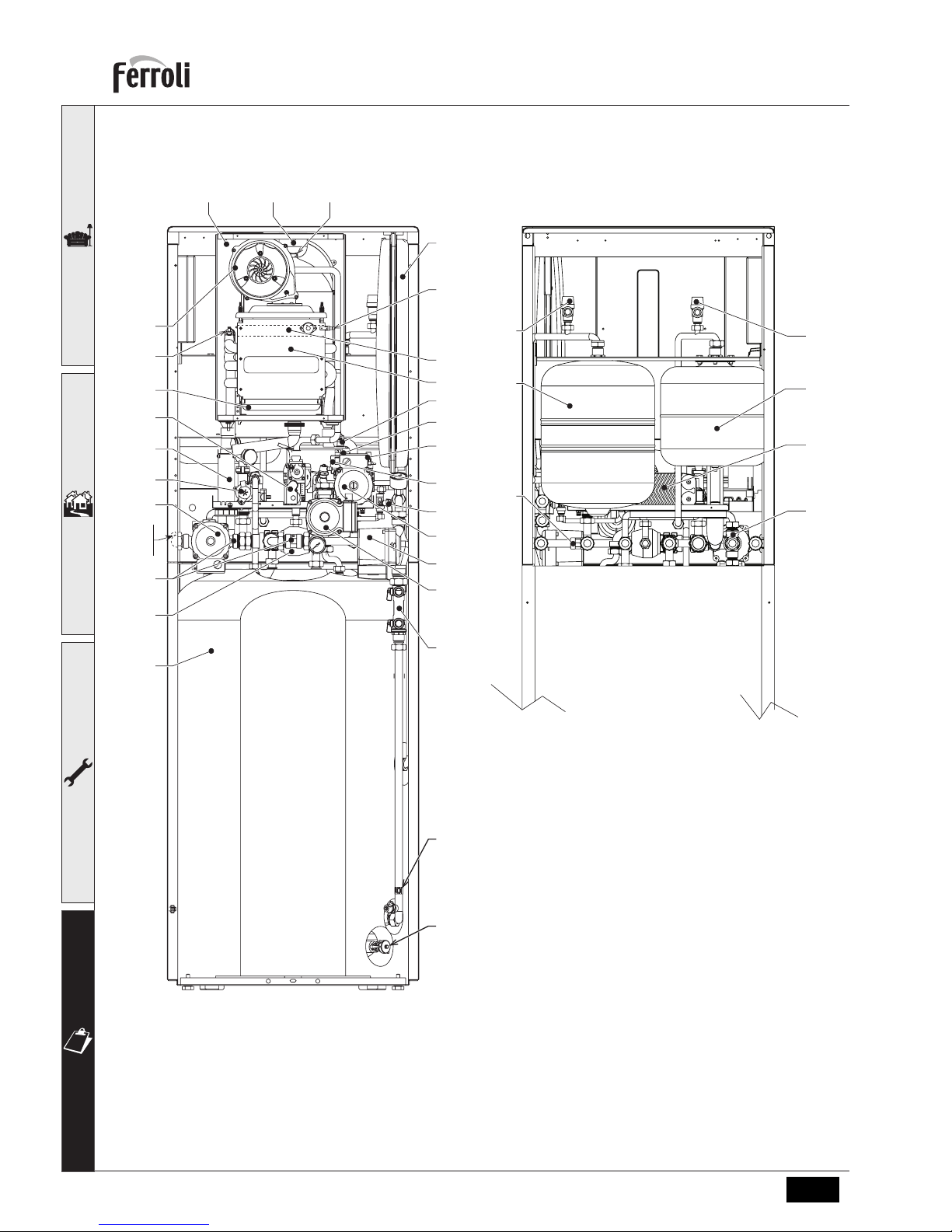

4.2 General view and main components

fig. 34 - Main components

5 29 191

56

82

188

22

161

14a

36

246

32

95

196

278

16

193

44

194

179

14b

14c

318a

315a

180

74

310

130

312

308

40

316

314

233

186

179

317a

319a

Page 31

ECONCEPT SOLAR ST

31EN

cod. -- - 11/2010 (Rev. 00)

4.3 Water circuit

fig. 35 - Water circuit

56

44

14a

32

11

10

7

95

241

246

36

186

161

278

16

196

145

179

179

194

193

154

97

191

233

155

130

311

309

310

Valvola regolazione

portata

314

313

180

321

316

315a

317a

319a

320

318a

40

322

323

8

179

14b

308

179

145

326

74

Indicatore di portata

14c

312

Page 32

ECONCEPT SOLAR ST

32 EN

cod. -- - 11/2010 (Rev. 00)

Key fig. 34-35-36

5 Sealed chamber

7 Gas inlet

8 Cold water inlet

10 System delivery

11 System return

14a Safety valve

14b Safety valve

14c Safety valve

16 Fan

22 Burner

29 Fume outlet manifold

32 Heating circulating pump

36 Automatic air vent

40 DHW expansion tank

44 Gas valve

56 Expansion tank

72 Room thermostat (not supplied)

72a Low temperature zone room thermostat (not

supplied)

74 System filling cock

82 Detection electrode

95 Diverter valve

97 Magnesium anode

130 Hot water tank circulating pump

138 External probe (not supplied)

139a Low temperature zone remote timer control (not

supplied)

145 Pressure gauge

154 Condensate outlet

155 Hot water tank temperature probe

161 Condensing heat exchanger

179 Non-return valve

180 Hot water tank

186 Return sensor

188 Ignition electrode

191 Fume temperature sensor

193 Trap

194 Exchanger

196 Condensate tray

233 Hot water tank drain cock

241 Bypass

246 Pressure transducer

256 Modulating heating circulating pump signal

278 Double sensor (Safety + Heating)

308 Solar expansion tank

309 Solar system filling cock

310 Solar system circulating pump

311 Collector temperature sensor

312 Flowmeter unit

313 Solar system drain cock

314 Solar return sensor

315a

Low temperature mixing valve

A = BROWN: FZ4B (9) - VALVE (6)

B = BLUE: FZ4B (10) - VALVE (2)

C = BLACK: FZ4B (11) - VALVE (3)

316 DHW mixing valve

317a Low temperature safety thermostat

318a Low temperature circulating pump

319a Low temperature modulation sensor

320 Low temperature delivery

321 Low temperature return

322 DHW recirculation return

323 Mixed DHW outlet

326 Solar system venting cock

Page 33

ECONCEPT SOLAR ST

33EN

cod. -- - 11/2010 (Rev. 00)

4.4 Technical data table

ECONCEPT SOLAR

ST 18

ECONCEPT SOLAR

ST 25

Data Unit Value Value

Max. heating capacity kW 18 25.2 (Q)

Min. heating capacity kW 3 5.3 (Q)

Max. Heat Output in heating (80/60°C) kW 17.7 24.6 (P)

Min. Heat Output in heating (80/60°C) kW 2.9 5.2 (P)

Max. Heat Output in heating (50/30°C) kW 19 26.6

Min. Heat Output in heating (50/30°C) kW 3.2 5.7

Max. heating capacity in hot water production kW 18 27

Min. heating capacity in hot water production kW 3 5.3

Max. Heat Output in hot water production kW 17.7 26.5

Min. Heat Output in hot water production kW 2.9 5.2

Efficiency Pmax (80-60°C) % 98.3 98.3

Efficiency Pmin (80-60°C) % 97.3 97.3

Efficiency Pmax (50-30°C) % 105.4 105.4

Efficiency Pmin (50-30°C) % 107.2 107.2

Efficiency 30% % 109.1 109.1

Efficiency class Directive 92/42 EEC NOx emission class - 5 5 (NOx)

Gas supply pressure G20 mbar 20 20

Max. gas delivery G20

m

3

/h

1.9 2.86

Min. gas delivery G20

m

3

/h

0.32 0.56

Gas supply pressure G31 mbar 37 37

Max. gas delivery G31 kg/h 1.41 2.11

Min. gas delivery G31 kg/h 0.23 0.41

Max. working pressure in heating bar 3 3 (PMS)

Min. working pressure in heating bar 0.8 0.8

Max. heating temperature °C 95 95 (tmax)

Heating water content litres 1 1.5

Heating expansion tank capacity litres 8 8

Heating expansion tank prefilling pressure bar 1 1

Max. working pressure in hot water production bar 9 9 (PMW)

Min. working pressure in hot water production bar 0.25 0.25

Hot water content litres 180 180

DHW circuit expansion tank capacity litres 12 12

DHW circuit expansion tank prefilling pressure bar 3 3

DHW flow rate 't 30°C

(flow rate obtained without supply of solar circuit)

l/

10min

230 260

DHW flow rate 't 30°C

(flow rate obtained without supply of solar circuit)

l/h 650 890 (D)

Solar expansion tank capacity litres 18 18

Protection rating IP X5D X5D

Power supply voltage V/Hz 230V/50Hz 230V/50Hz

Electrical power input W 280 280

Electrical power input in hot water production W 180 180

Empty weight kg 120 125

Type of unit C13-C23-C33-C43-C53-C63-C83-B23-B33

PIN CE 0461BT0920 0063BR3161

Page 34

ECONCEPT SOLAR ST

34 EN

cod. -- - 11/2010 (Rev. 00)

4.5 Diagrams

High Temperature zone circulating pumps Head/Pressure loss (ECONCEPT SOLAR ST 18)

A Boiler pressure losses

1 - 2 - 3 Circulating pump speed

Low Temperature zone circulating pumps Head/Pressure loss (ECONCEPT SOLAR ST 18)

B Boiler pressure losses

1 - 2 - 3 Circulating pump speed

0

1

2

3

4

5

6

7

0 500 1.000 1.500 2.000

Q [l/h]

H [m H

2

O]

A

3

2

1

0

1

2

3

4

5

6

7

0 500 1.000 1.500 2.000

Q [l/h]

H [m H

2

O]

B

3

2

1

Page 35

ECONCEPT SOLAR ST

35EN

cod. -- - 11/2010 (Rev. 00)

High Temperature zone circulating pumps Head/Pressure loss (ECONCEPT SOLAR ST 25)

A Boiler pressure losses

1 - 2 - 3 Circulating pump speed

Low Temperature zone circulating pumps Head/Pressure loss (ECONCEPT SOLAR ST 25)

B Boiler pressure losses

1 - 2 - 3 Circulating pump speed

0

1

2

3

4

5

6

7

0 500 1.000 1.500 2.000

Q [l/h]

H [m H

2

O]

3

2

1

A

0

1

2

3

4

5

6

7

0 500 1.000 1.500 2.000

Q [l/h]

H [m H

2

O]

B

3

2

1

Page 36

ECONCEPT SOLAR ST

36 EN

cod. -- - 11/2010 (Rev. 00)

4.6 Wiring diagram

fig. 36 - Wiring diagram

72 A

95

155

191

16

186

188

82

T°T°

278

139 A

138

DBM05D

DSP05

256

310

314

319a

318a

317a

DBM29

FZ4B

72

311

3.9 KOhm

32

16

44

NL

230V

50Hz

130

246

GND

OUT

+5V

123456

MODULDIRECT SENSOR

78

MIX

12345678910111213141516 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

315a

AB C

123456789101112

1110987654321

32121

Page 37

ECONCEPT SOLAR ST

37EN

cod. -- - 11/2010 (Rev. 00)

A

Attention: Before connecting the collector temperature sensor, remove the resistance between terminals 5

and 6 of controller DBM29.

A

Attention: Before connecting the room thermostat on the direct zone, remove the jumper on the terminal

block .

A

Attention: The boiler is arranged for operation with room thermostat on the low temperature zone. On connecting the remote timer control it will be necessary to configure the controller FZ4B. To do this, press the

AUTOCFG button (see fig. 37) until all the LEDs of theFZ4B card flash. The boiler will then be ready to operate

with remote timer control on the low temperature.

To reconnect the room thermostat in place of the remote timer control, carry out the above procedure again,

bringing the room thermostat to demand status (voltage-free contact).

fig. 37 - Controller FZ4B

AUTOCFG

OK

-

+

FZ4B

Page 38

ECONCEPT SOLAR ST

38 EN

cod. -- - 11/2010 (Rev. 00)

4.7 DBM29 (ECOTRONIC tech) - Solar Controller

User interface

fig. 38

1 Activated: solar collector temperature sufficient for exchange, normal operation

Flashing: solar collector cold recognition

2 Activated: solar collector antifreeze function

3 Activated: shutter closed for hot water tank max. temperature reached

Deactivated: shutter open, normal operation

4 Activated: solar collector temperature ok, normal operation

Flashing: solar collector cooling on

5 Solar circulating pump on

6 Boiler in DHW mode

7 Boiler in heating mode

8 Solar card fault

9 Boiler burner on

11 Upper hot water tank / solar collector return temperature

12 Hot water tank / solar collector temperature

13 Activated: Solar collector temperature ok, normal operation

Deactivated: solar collector temperature sensor fault

Flashing: solar collector limit temperature function

14 Activated: solar collector return temperature ok, normal operation

Deactivated: solar collector return temperature sensor fault

15 Activated: boiler hot water tank temperature correct, normal operation

Flashing: hot water tank cooling function

16 Actual solar circulating pump speed (A=Min., E=Max.)

21 Solar collector temperature sensor info

22 Solar collector return temperature sensor info

23 Activated: excess heat elimination/supplementary heating demand

Deactivated: no excess heat elimination/supplementary heating demand

A ON/OFF / Enter button

B Parameter selection button

C Parameter selection button

D Service menu access / information button

12

11

23167

13

AB CD

1

2

3

4

14

5

15

621 22 9

8

Page 39

ECONCEPT SOLAR ST

39EN

cod. -- - 11/2010 (Rev. 00)

Lighting

Whenever the power to the regulator is switched on, the display activates all the symbols for 2 seconds; in the next 5

seconds, the display will show the regulator software version.

Standby mode

After the lighting stage, if there are no faults and/or higher priority demands, the regulator goes to standby mode. The

following information is displayed:

• Standby: temperature of Solar Collector PT1000 sensor S3 with range 1¸175°C, the symbol S3 will be lit up; tem-

perature of Solar collector Return NTC sensor S4 with range 1¸125°C, the symbol S4 will be lit up.

• Press the Info button for 1 second and the regulator returns to standby mode.

Operation

Solar Circulating Pump activation

If the temperature of the Hot Water Tank Sensor is lower than the Tank max. temperature parameter value (Installer

parameter, default value equal to 60°C) and if the difference (positive) between the temperature of Solar Collector Sensor S3 and the temperature of the Hot Water Tank Sensor is higher than or equal to the Activation temperature differential parameter value (Installer parameter, default value equal to 6°C) then the ECOTRONIC tech regulator activates

the Solar Circulating Pump .

To signal this mode, the Solar Circulating Pump symbol will be lit up.

Solar Circulating Pump modulation

When the Solar Circulating Pump is working and the Solar Circulating Pump Operation parameter (Installer parameter,

default value equal to 0=On/Off ) is set to 1, the modulation algorithm is: