Page 1

Ferm BV • P.O. Box 30159 • 8003 CD Zwolle • NL • www.ferm.com 0407-30.1

UK Subject to change

D Änderungen vorbehalten

NL Wijzigingen voorbehouden

F Sous réserve de modifications

E Reservado el derecho de modificaciones

técnicas

P Reservado o direito a modificações

I Con reserva di modifiche

S Ändringar förbehålles

SF Pidätämme oikeuden muutoksiin

N Rett till endringer forbeholdes

DK Ret til ændringer forbeholdes

www.ferm.com

UK

D

NL

F

E

I

S

SF

N

DK

USERS MANUAL 04

GEBRAUCHSANWEISUNG 07

GEBRUIKSAANWIJZING 11

MODE D’EMPLOI 14

MANUAL DE INSTRUCCIONES 18

MANUALE UTILIZZATI 21

BRUKSANVISNING 25

KÄYTTÖOHJE 28

BRUKSANVISNING 32

BRUGERVEJLEDNING 35

Art.nr. BJM1006

FBJ-710P

Page 2

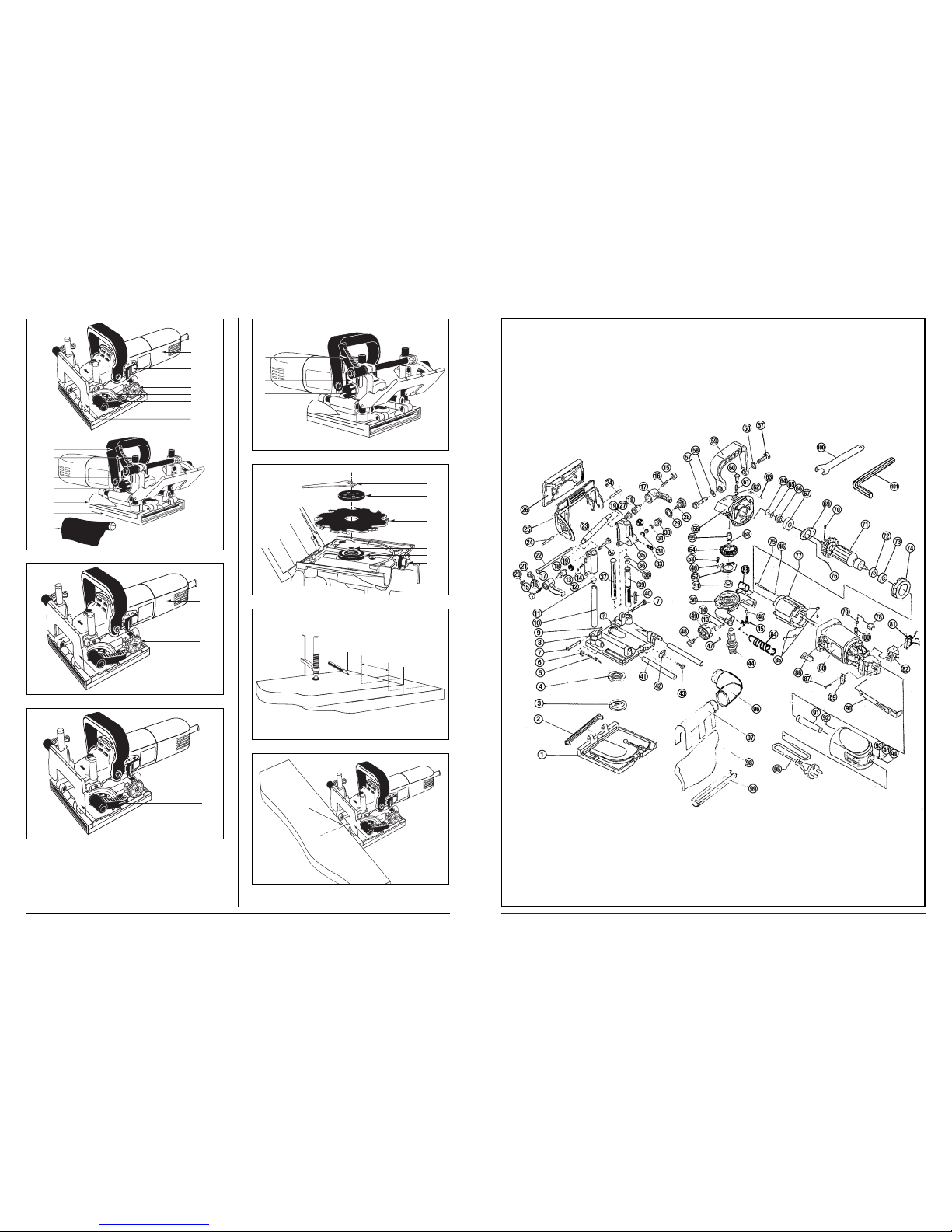

Fig.A

Fig.B

Fig.C

Fig.D

Fig.E

Fig.F

Fig.G

10 - 15 cm

19

18

21

20

17

16

20

9

11

10

4

8

7

15

A

20

9

2

11

10

13

14

12

3

7

15

1

6

8

4

2 Ferm

Ferm 43

EXPLODED VIEW

Page 3

42 Ferm

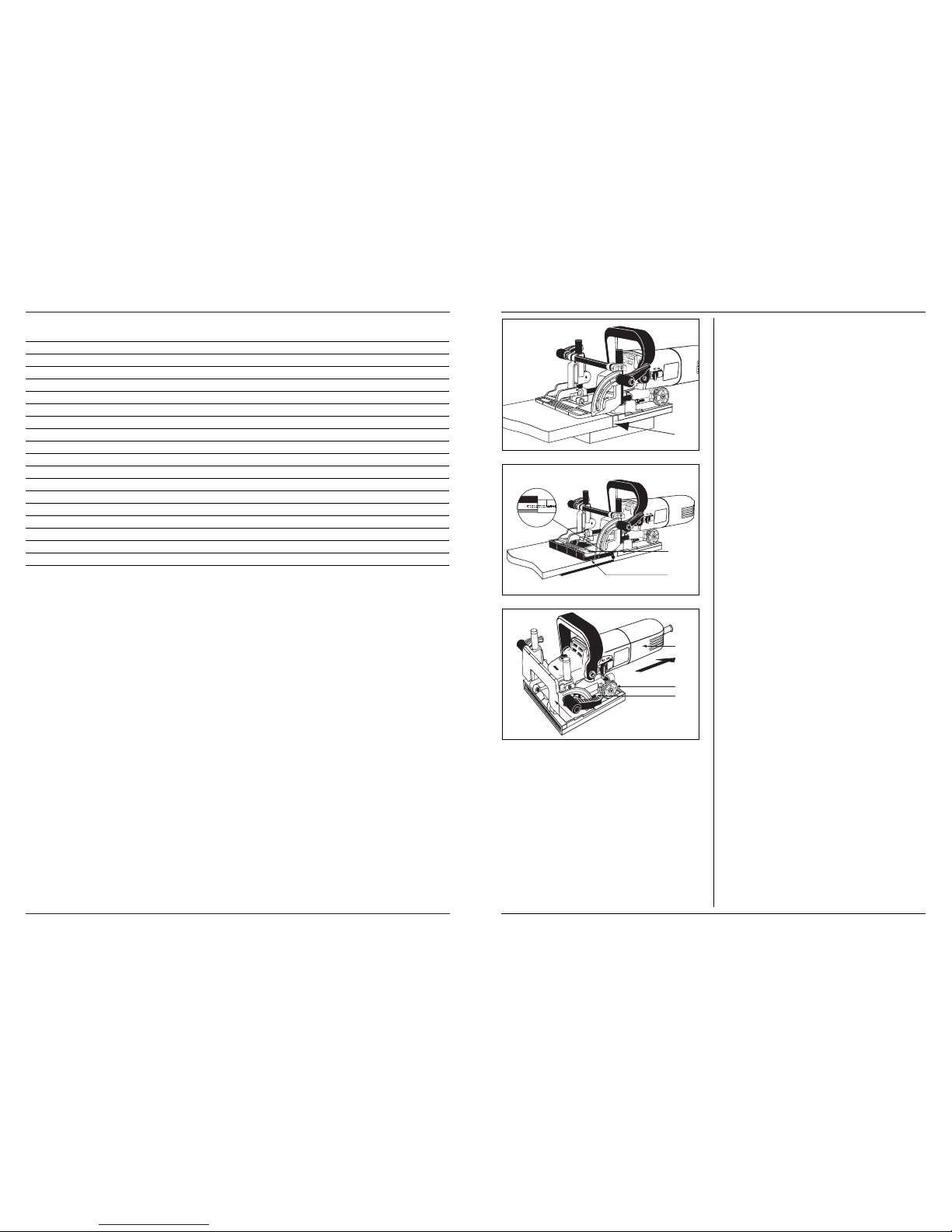

Fig.H

Fig.I

Fig.J

7

15

A

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

4

5

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

l

l

l

l

|

Ferm 3

SPARE PARTS LIST FBJ-710

REF NR DESCRIPTION FERM NR

407650 UPPER FLANGE 003

407651 LOWER FLANGE 004

407652 STOPPED PIN + NUT 005 + 006

407653 LOCKING KNOB COMPLETE 015 - 019

407655 ADJUSTING KNOB 028

407658 SPINDLE GEAR 054

407659 HANDLE 059

407660 PINION GEAR 066

406059 ROTOR 071

406060 STATOR 077

406061 CARBON BRUSH SET 079

406062 CARBON BRUSH HOLDER 080

406063 SWITCH 082

406064 SWITCH ACTUATOR 086

406065 PULL-ROD FOR SWITCH 090

407661 DUST BAG COMPLETE 096 - 099

407662 WRENCH 100

Page 4

BISCUIT JOINTER

THE NUMBERS IN THE FOLLOWING TEXT

CORRESPOND WITH THE PICTURES AT PAGE 2

& 3

TECHNICAL SPECIFICATIONS

PACKAGE CONTENTS

The package contains:

1 Biscuit Jointer

1 Saw blade

1 Wrench

1 Adjustment plate

1 Allen wrench

1 Dust collection bag

1 Instruction manual

1 Safety instructions

1 Guarantee card

Check the machine, loose parts and accessories for

transport damage.

PRODUCT INFORMATION

Fig.A

The FBJ-710 Biscuit Jointer is suitable for cutting grooves

for biscuit dowel joints in solid wood, plywood,

chipboard, fibre board, plexiglass and artificial marble.

1. On/off switch

2. Auxiliary handle

3. Spindle lock

4. Angle stop

6. Scale for the fence angle

7. Cutting depth adjustment knob

8. Clamping lever for angle adjustment

9. Clamping lever for height adjustment

10. Knob for height adjustment

11. Scale for the height adjustment

12. Base plate

13. Dust bag connection

14. Dust bag

15. Motor base

SAFETY INSTRUCTIONS

The following symbols are used throughout this manual:

Denotes risk of personal injury, loss of life or

damage to the tool in case of non-observance of

the instructions in this manual.

Denotes risk of electric shock.

Carefully read this manual before using the machine.

Make sure that you know how the machine functions and

how to operate it. Maintain the machine in accordance

with the instructions to make sure it functions properly.

Keep this manual and the enclosed documentation with

the machine.

ELECTRIC SAFETY

Always check that the power supply corresponds to

the voltage on the rating plate.

Your machine is double insulated in accordance

with EN 50144; therefore no earth wire is

required.

Replacing cables or plugs

Immediately throw away old cables or plugs when they

have been replaced by new ones. It is dangerous to insert

the plug of a loose cable in the wall socket.

Using extension cables

Only use an approved extension cable suitable for the

power input of the machine. The minimum cable size is

1.5 mm2. When using a cable reel always unwind the reel

completely.

SPECIAL SAFETY PRECAUTIONS

• Sawdust and splinters must not be removed while

the machine is running.

• Do not use cutting discs or circular saw blades in the

machine.

• Protect saw blades against shocks and impacts.

• Only use properly sharpened blades, otherwise

increased cutting forces will shatter the work piece.

• Before use, inspect the saw blade for any damage. Do

not use saw blades which are cracked, ripped or

otherwise damaged.

• Make sure that the work piece is sufficiently

supported or clamped. Keep your hands away from

the surface to be cut.

• Use the machine only with the auxiliary handle

• When saw blades have to be mounted on the thread

of the spindle, make sure that the spindle has

sufficient thread.

• Make sure that the saw blade has been mounted and

fastened properly. Do not use reducing rings or

adapters to make the saw blade fit properly.

• Apply the machine to the work piece only when the

machine is switched on.

• When working with the machine always hold the

machine firmly with both hands and provide for a

secure stance.

• Persons under 16 years of age are not permitted to

operate this machine.

Voltage | 230 V~

Frequency | 50 Hz

Power input | 710 W

No-load speed | 11000/min

Disc diameter | 100 mm

Blade bore diameter | 20+22 mm

Max. cutting depth | 18 mm

Fence adjustment | 0 - 90°

Spindle dimension | M10

Weight | 3.0 kg

Lpa (sound pressure) | 89.6 dB(A)

Lwa (sound power level) | 102.6 dB(A)

Vibration value | 1.9 m/s

2

4 Ferm Ferm 41

Page 5

• Always wear safety goggles and hearing protection. If

desired or required also use another protection for

example an apron or helmet.

• Always disconnect the plug from the socket before

carry out any work on the machine. Only plug-in

when the machine is switched off.

• Keep mains lead clear from working range of the

machine. Always lead the cable away behind you.

• Do not stop the blade by hand after switching off.

• The base plate must not be clamped down while the

blade is extended. Lowering and raising the blade

must be a smooth operation.

ADJUSTING THE MACHINE

ADJUSTING THE CUTTING DEPTH

Fig.B

• Move the motor base (15) as far as possible

backwards.

• Set the cutting depth by turning the cutting depth

adjustment knob (7).

• Move the motor base forwards and check if the pin

(A) will fall in the notch of the adjustment knob.

The following table shows the relationship of the

markings on the adjustment knob to cutting depth,

thickness of material and associated biscuit dowel:

Marking Thickness Biscuit Cutting

of material Dowel depth in mm

0 8-12 mm No. 0 8.0

10 12-15 mm No. 10 10.0

20 > 15 mm No. 20 12.3

S-Simplex 13.0

D-Duplex 14.7

Max. - - 18.0

ADJUSTING THE CUTTING ANGLE

Fig. C

• The cutting angle can be set by unlocking the

clamping lever (8) and put the angle stop (4) in the

required angle.

• Should the clamping lever be in the way when

working with the tool, then pull the clamping lever

out and fasten it in a different position without

changing the cutting angle.

ADJUSTING THE HEIGHT

Fig. D

• The correct height can be set by unlocking the

clamping lever (9) and turning the knob for the height

adjustment (10) to the desired height with aid of the

scale (11).

• The height must corresponds to half of the material

thickness of the working piece, the groove for the

biscuit dowel must always be in the middle of the

working piece.

• Should the clamping lever be in the way when

working with the tool, then pull the clamping lever

out and fasten it in a different position without

changing the height.

MOUNTING ACCESSORIES

Disconnect the plug from the main socket

MOUNTING SAW BLADE

Fig. E

• Loosen the allen screw (16) with the supplied allen

wrench and open the top of the base plate

• Press the spindle lock and turn the spindle (17) until it

engages in the lock. Keep the spindle lock pressed

during this procedure.

• Remove the flange nut (18) from the spindle using the

wrench (19).

• Position the saw blade (20) on the flange (21).

• Place the flange nut (18) on the spindle (17) and

tighten it with the wrench.

• The flange nut has two sides. One for sawblades with

bore 20 mm and the otherside for sawblades with

bore 22 mm.

Take care that the flange nut will be placed with the

correct side on the spindle.

• Release the spindle lock and check that the spindle is

unlocked by rotating it.

• Close the top of the base plate and fasten the allen

screw (16) with the supplied allen wrench.

Make sure that the top of the base plate is securely

closed before operating the machine.

MOUNTING DUST BAG

Fig. A

For dust extraction the dust bag (14) can be used.

Insert the dust bag (14) into the vacuuming connection

(13). Empty the dust bag regularly so that the vacuuming

performance remains intact.

OPERATION

SWITCHING ON AND OFF

Never use the spindle lock while the machine is

working.

• To switch the machine on slide the on/off switch

forwards.

• To switch the machine off, depress the on/off switch,

the switch will automatically move to the ‘off’

position.

Never use the spindle lock to stop the motor.

MARKING THE WORKPIECES

Fig. F

Before starting with the Biscuit Jointer the workpieces

must be marked as following:

• Place the two workpieces, which must be connected,

on top of each other.

• Fasten the workpieces and mark the center of the

groove.

• The space between two grooves should be 10-15

cm, this doesn’t concerns for smaller workpieces.

Smaller workpieces don’t have to be marked.

Ferm 540 Ferm

Page 6

Ferm 39

POSITIONING OF THE MACHINE

Based on the size of the workpieces the machine can be

positioned in several ways.

LARGE WORKPIECES

Fig. G

• Place the machine near the workpiece.

• The middle of the base plate (this point is marked on

the base plate) must facing the centre of the groove in

the workpiece (see marking the workpiece).

SMALL WORKPIECES

Fig. H

• Place the machine near the workpiece.

• The side of the machine must be facing the side of the

workpiece.

WORKPIECESTHINNER THAN 16 MM

Fig. I

• Place the machine near the workpiece.

• Place the adjustment plate (5) on the angle stop (4).

• Take care for setting the height, the groove for the

biscuit dowel must be in the middle of the workpiece.

For workpieces thinner than 16mm it is not possible to

make the groove for the biscuit dowel in the middle of

the workpiece without the aid of the adjustment plate.

SAWING GROOVES

• Move the motor base backward.

• Place the machine near the workpiece.

• Position the machine (see positioning of the

machine)

• Hold the machine with both hands and switch the

machine on.

• Push the motor base carefully forward as far as

possible.

• Move the motor base backward and switch the

machine off.

JOINING THE WORKPIECES

When the grooves in both workpieces have been made

the workpieces can be joined together:

• Put glue in both grooves.

• Place the biscuit dowel in the groove of one

workpiece.

• Place the other workpiece on the biscuit dowel.

• Fasten the workpieces and wait till the glue is dry.

CHECKING THE CUTTING DEPTH

Fig. J

Always check the cutting depth after mounting a

saw blade:

• Disconnect the plug from the socket.

• Move the motor base (15) as far as possible backwards.

• Set the cutting depth in the maximum position by

turning the depth adjustment knob (7).

• Move the motor base forwards till the pin (A) will fall

in the notch of the adjustment knob (7).

Turn the saw blade till one tooth of the saw blade is in

the front position.

• Measure the distance from the side of the base plate

to the tooth of the saw blade

• Check if the distance is 18 mm. the maximum

position is 18 mm.

SETTING THE CUTTING DEPTH

When the cutting depth is not correct, it can be adjusted

as following:

• Move the motor base (15) as far as possible

backwards.

• Loosen the pin (A).

• Set the cutting depth by turning the screw, the screw

is positioned at the back of the pin (A).

• Repeat the procedure till the cutting depth is correct

• Fasten the pin (A).

MAINTENANCE

Make sure that the machine is not live and

unplugged when carrying out maintenance work

on the motor.

The Ferm machines have been designed to operate over

along period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon

proper machine care and regular cleaning.

Cleaning

Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt. If the dirt does not come off use a soft

cloth moistened with soapy water. Never use Solvents

such as petrol, alcohol, ammonia water, etc. These

solvents may damage the plastic parts. Keep the moving

parts of the machine clean, like the guiding pillars, the

mechanism of the heigt adjustment and angle

adjustment, to ensure good working.

Lubrication

The machine requires no additional lubrication.

Faults

Should a fault occur, e.g. after wear of a part, please

contact your local Ferm dealer.

In the back of this manual you find an exploded view

showing the parts that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during

transport, it is delivered in a sturdy packaging. Most of

the packaging materials can be recycled. Take these

materials to the appropriate recycling locations.

6 Ferm

Page 7

GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

We declare under our sole responsibility that this

product is in conformity with the following standards or

standardized documents

EN60475-1, EN60475-2-5, EN55014-1,

EN-55014-2, EN61000-3-2, EN61000-3-3

in accordance with the regulations.

98/37EEC

73/23EEC

89/336EEC

from 01-03-2004

ZWOLLE NL

W. Kamphof

Quality department

BISCUIT JOINTER

DIE NUMMERN IM NACHFOLGENDEN TEXT

KORRESPONDIEREN MIT DEN ABBILDUNGEN

AUF SEITE 2 & 3

TECHNICAL DATEN

INHALT DER VERPACKUNG

Die Verpackung enthält:

1 Schattenfugenfräse

1 Scheibenfräser

1 Schraubenschlüssel

1 Einstellplatte

1 Innensechskantschlüssel

1 Staubsack

1 Betriebsanleitung

1 Sicherheitsheft

1 Garantiekarte

Überprüfen Sie die Maschine, lose Teile und Zubehör auf

Transportschäden.

PRODUKT INFORMATION

Abb.A

Die Schattenfugenfräse FBJ-710 ist bestimmt zum Fräsen

von Nuten für Schattenfugenverbindungen in

Massivholz, Sperrholz, Spannplatten, Faserplatten und

Kunstmarmor.

1. Ein-Aus-Schalter

2. Handgriff

3. Spindelarretierung

4. Parallelanschlag

6 Skala für den Parallelanschlag

7. Knopf zur Einstellung der Schnitttiefe

8. Klemmhebel für die Winkeleinstellung

9. Klemmhebel für die Höheneinstellung

10. Knopf zur Höheneinstellung

11. Skala zur Höheneinstellung

12. Grundplatte

13. Spanauswurf

14. Staubsack

15. Antriebsmotor

Netzspannung | 230 V~

Netzfrequenz | 50 Hz

Nennaufnahmeleistung | 710 W

Nullastdrehzahl | 11000 U/min

Scheibenfräserdurchmesser | 100 mm

Scheibenfräserbohrung | 20 mm/22 mm

Maximale Schnitttiefe | 18 mm

Anschlagwinkel | 0 – 90°

Spindelgewinde | M10

Gewicht | 3,0 kg

Schalldruck (Lpa) | 89.6 dB(A)

Schallleistungspegel (Lwa) | 102.6 dB(A)

Schwingungswert (aw) | 1.9 m/s

2

CE

ı

DECLARATION OF CONFORMITY

(UK)

Ferm 7

INDSTILLING AF FRÆSEDYBDE

Når fræsedybden ikke er korrekt, kan den justeres på

følgende måde.

• Flyt motorhuset (15) så langt tilbage som muligt.

• Løsn stiften (A).

• Indstil fræsedybden ved at dreje på skruen, som er

bagved stiften (A).

• Gentag dette, indtil fræsedybden er korrekt.

• Sæt stiften (A) fast.

VEDLIGEHOLDELSE

Sørg for, at maskinen ikke er strømførende, og at

stikket er trukket ud, når motoren vedligeholdes.

Maskinerne fra Ferm er udviklet til at fungere længe uden

problemer med et minimum af vedligeholdelse. Ved at

rengøre maskinen regelmæssigt og behandle den

korrekt, bidrager De til en længere levetid for maskinen.

Rengøring

Rengør regelmæssigt maskinkappen med en blød klud,

helst efter hvert brug. Sørg for at ventilationshullerne er

fri for støv og snavs.

Brug en blød klud, der er vædet i sæbevand til at fjerne

hårdnakket snavs. Brug ingen opløsningsmidler, så som

benzin, alkohol, ammoniak, osv. Den slags stoffer

beskadiger kunststofdelene.

Smøring

Maskinen behøver ingen ekstra smøring.

Fejl

Kontakt Deres Ferm-forhandler, hvis der opstår fejl som

følge af slitage af en del. Bagerst i denne brugsanvisning

finder De en reservedelstegning med de reservedele,

der kan bestilles.

MILJØ

For at undgå transportbeskadigelse leveres maskinen i

en solid emballage. Emballagen er så vidt muligt lavet af

genbrugsmateriale. Genbrug derfor emballagen.

Når de udskifter Deres maskinen bør De tage den gamle

maskine med til Deres lokale Ferm-forhandler. Der vil

maskinen blive bearbejdet på miljøvenlig vis.

GARANTI

Læs det separat vedlagte garantikort for

garantibetingelserne.

Vi erklærer herved, udelukkende på eget ansvar, at dette

produkt opfylder følgende standarder eller

standardiserede dokumenter

EN60475-1, EN60475-2-5, EN55014-1,

EN-55014-2, EN61000-3-2, EN61000-3-3

i henhold til følgende direktiver:

98/37EEC

73/23EEC

89/336EEC

01-03-2004

ZWOLLE NL

W. Kamphof

Quality department

CE

ı

KONFORMITETSERKLÆRING

(DK)

38 Ferm

Page 8

MONTERING AF TILBEHØR

Tag stikket ud af stikkontakten.

MONTERING AF SAVKLINGE

Fig. E

• Løsn unbrakoskruen (16) ved hjælp af den

medfølgende unbrakonøgle, og løft låget til

bundpladen.

• Tryk på spindellåsen, og drej spindlen (17), til den går

ind i låsen. Hold spindellåsen trykket ned under

denne procedure.

• Afmonter flangemøtrikken (18) på spindlen ved

hjælp af skruenøglen (19).

• Anbring savklingen (20) på flangen (21).

• Anbring flangemøtrikken (18) på spindlen (17), og

stram den med skruenøglen.

• Flangemøtrikken har to sider. En side til savklinger

med en huldiameter på 20 mm og den anden side til

savklinger med en huldiameter på 22 mm.

Kontroller, at flangemøtrikken er anbragt med den

korrekte side mod spindlen.

• Udløs spindellåsen og kontroller, at spindlen ikke er

låst ved at dreje den.

• Luk låget på bundpladen, og fastgør unbrakoskruen

(16) med unbrakonøglen.

Kontroller, at toppen på bundpladen er lukket, før

maskinen tændes.

MONTERING AF STØVPOSE

Fig. A

Støvposen (14) kan bruges til støvudsugning.

Tilslut støvposen (14) til støvudsugningsforbindelsen

(13). Tøm regelmæssigt støvposen.

BRUG AF MASKINEN

TÆND OG SLUK

Brug kun spindellåsen, når maskinen er tændt.

• Skub tænd-sluk-knappen frem for at tænde

maskinen.

• Tryk på tænd-sluk-knappen igen for at slukke

maskinen, og knappen vil automatisk stille sig på

"sluk".

Brug aldrig spindellåsen til at slukke for motoren.

MARKERING AF ARBEJDSEMNERNE

Fig. F

Før skyggefugefræseren tændes, skal arbejdsemnerne

markeres på følgende måde:

• Anbring de to arbejdsemner, som skal forbindes,

oven på hinanden.

• Fastgør arbejdsemnerne, og marker midten af

fugespalten.

• Afstanden mellem to fugespalter bør være 10-15 cm.

Dette gælder dog ikke for mindre arbejdsemner,

som ikke skal markeres.

ANBRINGELSE AF MASKINEN

Afhængig af arbejdsemnernes størrelse, kan maskinen

anbringes på flere måder.

STØRRE ARBEJDSEMNER

Fig. G

• Anbring maskinen tæt på arbejdsemnet.

• Midten af bundpladen (er markeret på bundpladen)

skal vende mod midten af arbejdsemnets fugespalte

(se markering af arbejdsemnerne).

MINDRE ARBEJDSEMNER

Fig. H

• Anbring maskinen tæt på arbejdsemnet.

• Maskinens side skal vende mod arbejdsemnets side.

ARBEJDSEMNER SMALLERE END 16 MM

Fig. I

• Anbring maskinen tæt på arbejdsemnet.

• Anbring justeringspladen (5) på vinkelstoppet (4).

• Sørg for, at skyggefugen til dyvlen er i midten af

arbejdsemnet.

Hvis arbejdsemnerne er smallere end 16 mm, kan

skyggefugen til dyvlen kun laves i midten af arbejdsemnet

ved brug af justeringspladen.

SAVNING AF FUGESPALTER

• Flyt motorhuset tilbage.

• Anbring maskinen tæt på arbejdsemnet.

• Anbring maskinen (se anbringelse af maskinen)

• Hold maskinen med begge hænder, og tænd den.

• Skub forsigtigt motorhuset så langt frem som muligt.

• Træk motorhuset tilbage, og sluk for maskinen.

SAMLING AF ARBEJDSEMNER

Når fugespalterne i begge arbejdsemner er lavet, kan

arbejdsemnerne samles:

• Put lim i begge fugespalter.

• Anbring dyvlen i et af arbejdsemnernes fugespalter.

• Anbring det andet arbejdsemne på dyvlen.

• Fastgør arbejdsemnerne, og vent til limen er tør.

KONTROL AF FRÆSEDYBDE

Fig. J

Kontroller altid fræsedybden, efter savklingen er

monteret:

• Tag stikket ud af stikkontakten.

• Træk motorhuset (15) så langt tilbage som muligt.

• Indstil fræsedybden på den maksimale position ved at

dreje knappen til justering af fræsedybden (7).

• Flyt motorhuset frem, indtil stiften (A) glider ind i

hakket på justeringsknappen.

Drej savklingen, indtil en af savklingens tænder er i

forreste position.

• Mål afstanden mellem bundpladens side og

savklingens tand.

• Kontroller, at afstanden er 18 mm. Den maksimale

position er 18 mm.

Ferm 37

SICHERHEITSVORSCHRIFTEN

In dieser Betriebsanleitung erscheinen folgende

Piktogramme:

Verweist auf Verletzungsgefahr, Gefahr für Leben

und mögliche Beschädigung der Maschine, falls die

Anweisungen in dieser Betriebsanleitung nicht befolgt werden.

Deutet das Vorhandensein elektrischer Spannung

an.

Lesen Sie diese Betriebsanleitung aufmerksam, bevor Sie

die Maschine in Betrieb nehmen. Machen Sie sich

vertraut mit der Funktionsweise und der Bedienung.

Warten Sie die Maschine entsprechend den

Anweisungen, damit sie immer einwandfrei funktioniert.

Die Betriebsanleitung und die dazugehörende

Dokumentation müssen in der Nähe der Maschine

aufbewahrt werden.

ELEKTRISCHE SICHERHEIT

Überprüfen Sie immer, ob Ihre Netzspannung der

des Typenschilds entspricht.

Die Maschine ist nach EN 50144 doppelisoliert;

daher ist Erdung nicht erforderlich.

Austauschen von Kabeln oder Steckern

Entsorgen Sie alte Kabel oder Stecker, unmittelbar

nachdem Sie durch neue ersetzt sind. Das Anschließen

eines Steckers eines losen Kabels an eine Steckdose ist

gefährlich.

Verwendung von Verlängerungskabeln

Benutzen Sie nur ein genehmigtes Verlängerungskabel,

das der Maschinenleistung entspricht. Die Ader müssen

einen Mindestquerschnitt von 1,5 mm2haben. Befindet

das Kabel sich auf einem Haspel. muß es völlig abgerollt

werden.

SPEZIELE SICHERHEITSVORSCHRIFTEN

• Sägestaub und Späne brauchen beim Betrieb der

Maschine nicht entfernt zu werden.

• Benutzen Sie mit der Maschine keine Trennscheiben

oder Kreissägeblätter.

• Schützen Sie Scheibenfräser gegen Stoß und Schlag.

• Verwenden Sie nur unbeschädigte, scharfe Scheiben,

da anderenfalls das Werkstück splittern könnte.

• Inspizieren Sie vor dem Beginn der Arbeit den

Scheibenfräser auf Beschädigungen. Verwenden Sie

keine verbogenen, gerissenen oder sonst wie

beschädigten Scheiben.

• Achten Sie darauf, dass das Werkstück sorgfältig

aufliegt und eingespannt ist. Halten Sie Ihre Hände

von der Bearbeitungsstelle fern.

• Halten Sie die Fräse nur am Handgriff.

• Vergewissern Sie sich, dass beim Anbringen eines

Scheibenfräsers auf der Antriebsspindel ausreichend Gewindegänge vorhanden sind.

• Achten Sie darauf, dass der Scheibenfräser sorgfältig

fest sitzt. Verwenden Sie beim Anbringen eines

Scheibenfräsers keine Unterlegscheiben oder

sonstigen Hilfsmittel, um den Sitz zu verbessern.

• Bewegen Sie den Scheibenfräser nur bei

eingeschalteter Maschine auf das Werkstück zu.

• Halten und führen Sie die Maschine bei der Arbeit

immer mit zwei Händen und sorgen Sie selbst für

einen festen Stand.

• Personen unter 16 Jahren dürfen die Maschine nicht

bedienen.

• Tragen Sie bei der Arbeit eine Sicherheitsbrille und

einen Gehörschutz. Falls erforderlich tragen Sie auch

andere Schutzmittel, beispielsweise eine Schürze

und einen Schutzhelm.

• Vor allen Arbeiten am Gerät müssen Sie den

Netzstecker ziehen. Stecken Sie den Netzstecker

nur bei ausgeschalteter Maschine ein.

• Halten Sie das Anschlusskabel fern von der

Arbeitsstelle; führen Sie es immer hinter Ihnen längs.

• Bremsen Sie den Scheibenfräser nach dem

Ausschalten nicht mit der Hand ab.

• Bei offen liegendem Scheibenfräser darf die

Grundplatte nicht festgeklemmt sein. Das Auf- und

Abbewegen der Scheibe muss leicht gehen.

EINSTELLUNG DER MASCHINE

EINSTELLUNG DER SCHNITTIEFE

Abb. B

• Ziehen Sie den Antriebsmotor (15) so weit wie

möglich zurück.

• Stellen Sie die gewünschte Schnitttiefe mit dem

Knopf zur Einstellung der Schnitttiefe (7) ein.

• Schieben Sie den Motor nach vorne und prüfen Sie,

ob der Zapfen (A) in die Kerbe des Einstell-knopfes

einrastet.

Die folgende Tabelle gibt die Beziehung der

Markierungen a Einstellknopf zur Schnitttiefe, zur

Material-stärke und des betreffenden Schattendübels an:

Markierung Material- Schatten- Schnitttiefe

Stärke dübel in mm

0 8-12 mm No. 0 8.0

10 12-15 mm No. 10 10.0

20 > 15 mm No. 20 12.3

S-Simplex 13.0

D-Duplex 14.7

Max. - - 18.0

EINSTELLUNG DES SCHNITTWINKELS

Abb. C

• Zum Einstellen des Schnittwinkels lösen Sie den

Arretierhebel (8) und stellen den Parallelanschlag (4)

in die gewünschte Lage.

• Sollte der Arretierhebel beim Fräsen im Wege sein,

ziehen Sie ihn heraus und setzen ihn in einer anderen

Stellung ein, ohne den Schnittwinkel zu ändern.

EINSTELLUNG DER HÖHE

Abb. D

• Zum Einstellen der richtigen Höhe lösen Sie den

Arretierhebel (9) und drehen den Höheneinstellknopf (10) mithilfe der Skala (11) in die gewünschte

Höhe.

8 Ferm

Page 9

• Die Höhe muss die halbe Randflächenhöhe des

Werkstücks betragen. Die Nut für den Schatten-dübel

muss immer in der Mitte des Werkstückrands liegen.

• Sollte der Arretierhebel beim Fräsen im Wege sein,

ziehen Sie ihn heraus und setzen ihn in einer anderen

Stellung fest, ohne die Höhe zu ändern.

MONTAGEZUBEHÖR

Lösen Sie den Stift von der Grundplatte

EINSETZEN DES SCHEIBENFRÄSERS (Abb. E)

• Lösen Sie die Innensechskantschraube (16) mit dem

mitgelieferten Innensechskantschlüssel und öffnen

Sie die Abdeckhaube der Grundplatte.

• Drücken Sie die Spindelarretierung und drehen Sie

die Antriebsspindel (17), bis sie einrastet.

Halten Sie die Spindelarretierung während der

ganzen Zeit gedrückt.

• Entfernen Sie mit dem Schraubenschlüssel (19) den

Spannflansch (18) von der Antriebsspindel.

• Legen Sie den Scheibenfräser (20) auf die

Distanzbuchse (21).

• Bringen Sie den Spannflansch (18) wieder an der

Antriebsspindel (17) an und drehen Sie mit dem

Schraubenschlüssel fest.

• Der Spannflansch hat zwei Seiten, eine für

Scheibenfräser mit einer Mittelbohrung von 20 mm

und eine für Scheibenfräser mit 22 mm

Mittelbohrung.

Achten Sie darauf, dass Sie den Spannflansch mit der

richtigen Seite auf der Antriebsspindel an-bringen.

• Lassen Sie die Spindelarretierung los und prüfen Sie

durch Drehen der Antriebsspindel, dass sie nicht

mehr blockiert ist.

• Schließen Sie die Grundplattenabdeckhaube wieder

und drehen Sie die Innensechskantschraube mit dem

Innensechskantschlüssel wieder fest.

Vergewissern Sie sich vor Beginn der Arbeit, dass

die Grundplatte ordnungsgemäß geschlossen ist.

ANBRINGEN DES STAUBSACKS

Abb. A

Zum Auffangen der Frässpäne kann der Staubsack

verwendet werden.

Setzen Sie den Staubsack (14) in den Spanauswurf (13)

ein. Entleeren Sie den Staubbeutel regelmäßig, um eine

einwandfreie Funktion zu gewährleisten.

ARBEITEN MIT DER

SCHATTENFUGENFRÄSE

EIN- UND AUSSCHALTEN.

Benutzen Sie die Spindelarretierung niemals bei

laufendem Motor

• Zum Einschalten des Motors schieben Sie den EinAus-Schalter nach vorne.

• Zum Ausschalten drücken Sie den Ein-Aus-Schalter,

wodurch er von selbst in die Ausstellung

zurückspringt.

Benutzen Sie die Spindelarretierung nicht zum

Anhalten des Motors.

ANREIßEN DES WERKSTÜCKS

Abb. F

Bevor Sie mit der Schattenfugenfräse zu arbeiten

beginnen, muss das Werkstück folgendermaßen angerissen werden:

• Legen Sie die beiden Stücke, die verbunden werden

sollen, flach gegeneinander.

• Spannen Sie die beiden Stücke ein und zeichnen Sie

die Mitte der Nut an.

• Der Abstand zwischen zwei Nuten muss 10-15 cm

betragen. Dies gilt nicht für kleinere Werkstücke,

diese brauchen nicht angerissen zu werden.

ANSETZEN DER MASCHINE

Je nach der Größe der Werkstücke kann die Maschine

auf verschiedene Arten angesetzt werden.

GROßE WERKSTÜCKE

Abb. G

• Stellen Sie die Maschine nahe an das Werkstück.

• Die Mittenmarkierung an der Grundplatte muss der

angezeichneten Mitte der neuen Nut gegenüberliegen.

KLEINE WERKSTÜCKE

Abb. H

• Stellen Sie die Maschine nahe an das Werk stück.

• Die Arbeitsseite der Maschine muss am Werkstück

anliegen.

WERKSTÜCKE DÜNNER ALS 16 MM

Abb. I

• Stellen Sie die Maschine nahe an das Werkstück.

• Legen Sie die Einstellplatte (5) auf den

Parallelanschlag (4).

• Stellen Sie die Höhe sorgfältig ein; die Nut für den

Schattendübel muss genau in der Randmitte des

Werkstücks liegen.

Für weniger als 16 mm dicke Werkstücke kann die Nut

für den Schattendübel nicht ohne die Hilfe der

Einstellplatte genau in der Randmitte des Werkstücks

hergestellt werden.

FRÄSEN EINER NUT

• Ziehen Sie den Motor zurück.

• Stellen Sie die Maschine nahe an das Werkstück.

• Setzen Sie die Maschine an (siehe oben: 'Ansetzen

der Maschine').

• Halten Sie die Maschine mit beiden Händen fest und

schalten Sie sie ein.

• Drücken Sie die Grundplatte langsam so weit, wie es

geht, nach vorne.

• Ziehen Sie die Grundplatte zurück und schalten Sie

die Maschine aus (Schalter drücken).

VERBINDEN DER WERKSTÜCKE

Nachdem in beiden Werkstücken eine Nut angebracht

worden ist, können sie miteinander verbunden werden.

Ferm 9

SIKKERHEDSFORSKRIFTER

I denne brugsanvisning anvendes de følgende

piktogrammer:

Angiver risiko for legemensbeskadigelse, livsfare

eller maskinskade, hvis instruktionerne i denne

brugsanvisning tilsidesættes.

Angiver elektrisk spænding.

Læs denne brugsanvisning godt igennem før maskinen

tages i brug. Sørg for at De kender maskinens funktion og

betjening. Vedligehold maskinen i følge instruktionerne,

for at maskinen altid kan fungere optimalt. Bevar denne

brugsanvisning og den vedlagte dokumentation til

maskinen.

ELEKTRISK SIKKERHED

Kontroller altid om netspændingen svarer til

værdien på typeskiltet.

Maskinen er dobbeltisoleret i henhold til EN

50144; det er derfor ikke nødvendigt med en

jordledning.

Ved udskiftning af ledninger og stik

Kasser gamle ledninger og stik, så snart de er skiftet ud

med nye. Det er farligt at sætte et stik fra en løs ledning i

en stikkontakt.

Ved brug af forlængerledninger

Brug udelukkende godkendte forlængerledninger, der

er beregnede til maskinens effekt. Lederne skal have et

gennemsnit på mindst 1,5 mm2. Hvis forlængerledningen

sidder på en tromle, rulles ledningen helt af.

SÆRLIGE

SIKKERHEDSFORANSTALTNINGER

• Savsmuld og flis må ikke fjernes, mens maskinen er i

drift.

• Brug ikke skæreskiver eller runde savklinger i

maskinen.

• Beskyt savklingerne mod stød.

• Brug kun klinger, som er korrekt slebet, ellers

ødelægges arbejdsemnet.

• Kontroller savklingen for skader før brug. Brug ikke

revnede eller på anden måde ødelagte savklinger.

• Kontroller, at arbejdsemnet er tilstrækkeligt

understøttet eller fastspændt. Hold hænderne væk

fra den overflade, der skal skæres i.

• Maskinen må kun bruges sammen med

hjælpehåndtaget.

• Ved montering af savklinger på spindlens gevind

kontrolleres det, at gevindet passer i længden.

• Kontroller, at savklingen er korrekt monteret og

fastspændt. Der må ikke anvendes reduktionsringe

eller tilpasningsstykker for at få klingen til at passe

korrekt.

• Anbring først maskinen på arbejdsemnet, når

maskinen er tændt.

• Hold altid maskinen med begge hænder, og sørg for

sikker fodstilling under arbejdet.

• Personer under 16 år må ikke betjene maskinen.

• Brug altid beskyttelsesbriller og høreværn. Der kan

også benyttes andet beskyttelsesudstyr, f.eks.

beskyttelsesforklæde eller hjelm.

• Tag altid stikket ud af kontakten, før der udføres

arbejde på maskinen. Sæt altid stikket i, når maskinen

er slukket.

• Sørg for, at hovedledningen holdes væk fra

maskinens arbejdsområde. Hold altid kablet bag dig.

• Stop ikke savklingen med hånden, efter at maskinen

er slukket.

• Bundpladen må ikke fastspændes, mens klingen

stikker frem. Klingen skal hæves og sænkes jævnt.

JUSTERING AF MASKINE

JUSTERING AF FRÆSEDYBDE

Fig. B

• Flyt motorhuset (15) så langt tilbage som muligt.

• Indstil fræsedybden ved at dreje knappen til justering

af fræsedybden (7).

• Flyt motorhuset frem og kontroller, at stiften (A)

glider ind i hakket på justeringsknappen.

Nedenstående tabel angiver forholdet mellem

markeringerne på justeringsknappen og fræsedybde,

materialetykkelse og den tilknyttede dyvel:

Markering Materiale- Dyvel Fræse-

tykkelse dybde i mm

0 8-12 mm No. 0 8.0

10 12-15 mm No. 10 10.0

20 > 15 mm No. 20 12.3

S- Simplex 13.0

D- Duplex 14.7

Max. - - 18.0

JUSTERING AF FRÆSEVINKEL

Fig. C

• Fræsevinklen kan indstilles ved at låse spændearmen

op (8) og indstille vinkelstoppet (4) i den krævede

vinkel.

• Hvis spændearmen er i vejen, når der arbejdes med

værktøjet, trækkes spændearmen ud og fastgøres i

en anden position uden at ændre fræsevinklen.

HØJDEJUSTERING

Fig. D

• Den korrekte højde indstilles ved at låse

spændearmen op (9) og dreje knappen til justering af

højde (10) til den ønskede højde ved hjælp af skalaen

(11).

• Højden skal svare til halvdelen af arbejdsemnets

tykkelse, og skyggefugen til dyvlen skal altid være i

midten af arbejdsemnet.

• Hvis spændearmen er i vejen, når der arbejdes med

værktøjet, trækkes spændearmen ud og fastgøres i

en anden position uden at ændre højden.

36 Ferm

Page 10

GARANTI

Garantibetingelsene er å finne på det vedlagte

garantikortet.

Vi erklærer på eget ansvar at dette produktet er i

samsvar med følgende standarder eller standardiserte

dokumenter.

EN60475-1, EN60475-2-5, EN55014-1,

EN-55014-2, EN61000-3-2, EN61000-3-3

i samsvar med bestemmelsene.

98/37EEC

73/23EEC

89/336EEC

fra 01-03-2004

ZWOLLE NL

W. Kamphof

Kvalitetsavdelingen

VINKELSLIBER

TALLENE I DEN FØLGENDE TEKST

KORRESPONDERER MED AFBILDNINGERNE PÅ

SIDE 2 & 3.

TEKNISKE SPECIFIKATIONER

EMBALLAGENS INDHOLD

Kassen indeholder:

1 Skyggefugefræser

1 Savklinge

1 Skruenøgle

1 Justeringsplade

1 Unbrakonøgle

1 Støvpose

1 Brugsanvisning

1 Sikkerhedsfolder

1 Garantikort

Kontroller maskinen, løsdele og tilbehør for

transportskade.

PRODUKTINFORMATION

Fig. A

FBJ-710 skyggefugefræser er velegnet til at fræse

skyggefuger til dyvelsamlinger i massivt træ, krydsfiner,

spånplader, fiberplader, plexiglas og kunstigt marmor.

1. Tænd-sluk-knap

2. Hjælpehåndtag

3. Spindellås

4. Vinkelstop

6. Skala til vinkelanslag

7. Knap til justering af fræsedybde

8. Spændearm til vinkeljustering

9. Spændearm til højdejustering

10. Knap til højdejustering

11 Skala til højdejustering

12. Bundplade

13. Tilslutning til støvpose

14. Støvpose

15. Motorhus

Spænding | 230 V~

Frekvens | 50 Hz

Indgangseffekt | 710 W

Tomgangshastighed | 11.000/min.

Skivens diameter | 100 mm

Klingens huldiameter | 20+22 mm

Maksimal fræsedybde | 18 mm

Justering af anslag | 0-90°

Spindelstørrelse | M10

Vægt | 3.0 kg

Lpa (lydtryk) | 89.6 dB(A)

Lwa (lydeffekt) | 102.6 dB(A)

Vibrationsværdi | 1.9 m/s

2

CE

ı

ERKLÆRING AV ANSVARSFORHOLD

(N)

Ferm 35

• Bringen Sie in beiden Nuten Klebstoff an.

• Setzen sie in eine der beiden Nuten einen

Schattendübel ein.

• Schieben Sie das andere Werkstück über den Dübel

• Spannen Sie die Werkstücke ein und warten sie auf

das Aushärten des Klebstoffs.

PRÜFEN DER SCHNITTIEFE

Abb. J

Prüfen Sie nach dem Einsetzen eine Scheibenfräsers

immer die Schnitttiefe:

• Ziehen Sie den Netzstecker.

• Ziehen Sie den Motor (15) so weit wie möglich

zurück.

• Stellen Sie mit dem Tiefeneinstellknopf (7) die

größtmögliche Schnitttiefe ein.

• Bewegen Sie den Motor nach vorne, bis der Stift (A)

in die Nut des Einstellknopfes (7) einrastet.

Drehen Sie die Scheibe, bis ein Zahn der Scheibe

nach vorne gerichtet ist.

• Messen Sie den Abstand von der Zahnspitze bis zur

Grundplatte.

• Prüfen Sie, ob der Abstand 18 mm beträgt, wenn er

18 mm betragen soll.

EINSTELLEN DER SCHNITTIEFE

Wenn die Schnitttiefe neu eingestellt werden soll,

handeln Sie folgendermaßen:

• Ziehen Sie den Motor (15) so weit wie möglich

zurück.

• Lösen Sie den Stift (A).

• Stellen Sie durch Drehen der Schraube in der

Rückseite des Stiftes (A) die Tiefe neu ein.

• Wiederholen Sie die Einstellung, bis die Schnitttiefe

richtig ist.

• Arretieren Sie den Stift (A).

WARTUNG

Bei der Ausführung von Wartungsarbeiten muss

die Maschine außer Betrieb und der Netzstecker

gezogen sein.

Die Maschinen von Ferm sind entworfen, um während

einer langen Zeit problemlos und mit minimaler

Wartung zu funktionieren. Sie Verlängern die

Lebensdauer, indem Sie die Maschine regelmäßig

reinigen und fachgerecht behandeln.

Reinigen

Reinigen Sie das Maschinengehäuse regelmäßig mit

einem weichen Tuch, vorzugsweise nach jedem Einsatz.

Halten Sie die Lüfterschlitze frei von Staub und Schmutz

Entfernen Sie hartnäckigen Schmutz mit einem weichen

Tuch, angefeuchtet mit Seifenwasser. Verwenden Sie

keine Lösungsmittel wie Benzin, Alkohol, Ammonia,

usw. Derartige Stoffe beschädigen die Kunststoffteile.

Schmieren

Die Maschine braucht keine zusätzliche Schmierung.

Störungen

Wenden Sie sich in Störungsfällen, z.B. durch Verschleiß

eines Teils, an Ihren örtlichen Ferm-Vertragshändler.

Am Ende dieser Betriebsanleitung finden Sie eine

Zeichnung der erhältlichen Ersatzteile.

UMWELT

Um Transportschäden zu verhinderen, wird die

Maschine in einer soliden Verpackung geliefert. Die

Verpackung besteht weitgehend aus verwertbarem

Material. Benutzen Sie also die Möglichkeit zum

Recyclen der Verpackung.

Bringen Sie bei Ersatz die alten Maschinen zu Ihren

örtlichen Ferm-Vertagshändler. Er wird sich um eine

umweltfreundliche Verarbeitung ïhrer alten Maschine

bemühen.

GARANTIE

Lesen Sie die Garantiebedingungen auf der separat

beigefügten Garantiekarte.

Wir erklären unsere alleinige Verantwortung, dass

dieses Produkt konform den nachstehenden Standards

oder standardisierten Dokumenten ist.

EN60475-1, EN60475-2-5, EN55014-1,

EN-55014-2, EN61000-3-2, EN61000-3-3

Gemäß den Vorschriften.

98/37EEC

73/23EEC

89/336EEC

vom 01-03-2004

ZWOLLE NL

W. Kamphof

Quality Department

CE

ı

KONFORMITÄTSERKLÄRUNG

(D)

10 Ferm

Page 11

LAMELLENFREES

DE NUMMERS IN DE NU VOLGENDE TEKST

VERWIJZEN NAAR DE AFBEELDINGEN OP

PAGINA 2 & 3.

TECHNISCHE SPECIFICATIES

INHOUD VAN DE VERPAKKING

De verpakking bevat:

1 Lamellenfrees

1 Freesblad

1 Sleutel

1 Afstelplaat

1 Inbussleutel

1 Stofzak

1 Gebruiksaanwijzing

1 Veiligheidskatern

1 Garantiekaart

Controleer de machine, losse onderdelen en

accessoires op transportschade.

PRODUCT INFORMATIE

Fig. A

De FBJ-710 lamellenfrees is geschikt voor het frezen van

sleuven voor lamello’s in massief hout, multiplex,

spaanplaat, vezelplaat, plexiglas of gipsmarmer

1. Aan-/uitschakelaar

2. Bijgeleverde handgreep

3. Asvergrendeling

4. Hoekstop

6. Schaal voor geleiderhoek

7. Afstelknop freesdiepte

8. Klem voor hoekafstelling

9. Klem voor hoogteafstelling

10. Knop voor hoogteafstelling

11 Schaal voor hoogteafstelling

12. Bodemplaat

13. Aansluiting voor stofzak

14. Stofzak

15. Motorvoet

VEILIGHEIDSVOORSCHRIFTEN

In deze gebruiksaanwijzing worden de volgende

pictogrammen gebruikt:

Duidt op mogelijk lichamelijk letsel, levensgevaar

of kans op beschadiging van de machine indien de

instructies in deze gebruiksaanwijzing worden genegeerd.

Geeft elektrische spanning aan.

Lees deze gebruiksaanwijzing aandachtig door voor u de

machine in gebruik neemt. Zorg dat u kennis heeft van de

werking van de machine en op de hoogte bent van de

bediening. Onderhoud de machine volgens de

instructies opdat deze altijd goed functioneert. Bewaar

deze gebruiksaanwijzing en de bijgevoegde

documentatie bij de machine.

ELEKTRISCHE VEILIGHEID

Controleer altijd of uw netspanning overeenkomt

met de waarde op het typeplaatje van de machine.

De machine is dubbel geïsoleerd overeenkomstig

EN 50144; een aardedraad is daarom niet nodig.

Bij vervanging van snoeren of stekkers

Gooi oude snoeren of stekkers direct weg zodra ze

door nieuwe exemplaren zijn vervangen. Het is

gevaarlijk om de stekker van een los snoer in het

stopcontact te steken.

Bij gebruik van verlengsnoeren

Gebruik uitsluitend een goedgekeurd verlengsnoer, dat

geschikt is voor het vermogen van de machine. De aders

moeten een doorsnede hebben van minimaal 1,5 mm2.

Wanneer het verlengsnoer op een haspel zit, rol het

snoer dan helemaal af.

SPECIALE VEILIGHEIDSMAATREGELEN

• Verwijder nooit zaagsel of splinters bij een draaiende

machine.

• Gebruik geen snijschijven of cirkelzaagbladen in de

machine.

• Voorkom schokken of stoten van de freesbladen.

• Gebruik alleen scherpe bladen; als u dit niet doet,

kunt u uw werkstuk verbrijzelen.

• Controleer voordat u begint uw freesblad op

beschadigingen. Gebruik geen freesbladen die

barsten, scheuren of andere beschadigingen

vertonen.

• Het werkstuk moet goed ondersteund of

vastgeklemd zijn. Kom niet met uw handen in de

buurt van het te frezen oppervlak.

• Werk altijd met de bijgeleverde handgreep.

• Zorg voor voldoende schroefdraad, als een

freesblad op de schroefdraad van de as gemonteerd

moet worden.

• Het freesblad dient correct gemonteerd en goed

vastgezet te worden. Gebruik geen verloopringen of

passtukken om een freesblad passend te krijgen.

Spanning | 230 V~

Frequentie | 50 Hz

Opgenomen vermogen | 710 W

Onbelast toerental | 11000 omw/min

Schijfdiameter | 100 mm

Boringdiameter freesblad | 20+22 mm

Max. freesdiepte | 18 mm

Afstelling geleider | 0 - 90°

Afmeting as | M10

Gewicht | 3,0 kg

Lpa (geluidsdruk) | 89.6 dB(A)

Lwa (geluidsenergieniveau) | 102.6 dB(A)

Trillingsniveau | 1.9 m/s

2

Ferm 11

PLASSERING AV MASKINEN

Maskinen kan plasseres på flere måter, avhengig av

lamellenes størrelse.

STORE LAMELLER

Fig. G

• Plasser maskinen nær lamellen.

• Midten av bunnplaten (dette er merket av på

bunnplaten) skal peke mot midten av sporet på

lamellen (se Merking av lamellene).

SMÅ LAMELLER

Fig. H

• Plasser maskinen nær lamellen.

• Siden på maskinen skal vende mot siden på lamellen.

LAMELLER TYNNERE ENN 16MM

Fig. I

• Plasser maskinen nær lamellen.

• Sett justeringsplaten (5) på vinkelsperren (4).

• Sørg for å stille inn korrekt høyde. Sporet for

lamellskjøten skal være midt på lamellen.

På lameller som er tynnere enn 16 mm, er det ikke mulig

å lage sporet for lamellskjøten midt på lamellen uten å

bruke justeringsplaten.

SAGE SPOR

• Trekk motordelen bakover.

• Plasser maskinen nær lamellen.

• Plasser maskinen i ønsket stilling (se Plassering av

maskinen).

• Hold maskinen med begge hender, og slå på

maskinen.

• Skyv forsiktig motordelen så langt frem som mulig.

• Trekk motordelen bakover, og slå av maskinen.

FESTE LAMELLENE TIL HVERANDRE.

Når du har laget spor i begge lamellene, kan du feste dem

til hverandre:

• Ha lim i begge sporene.

• Plasser lamellskjøten i sporet på den ene lamellen.

• Plasser den andre lamellen på lamellskjøten.

• Sett lamellene i klemme, og vent til limet har tørket.

KONTROLLERE SKJÆREDYBDEN

Fig. J

Husk alltid å kontrollere skjæredybden når du har

montert et sagblad:

• Trekk støpselet ut av stikkontakten.

• Trekk motordelen (15) så langt bakover som mulig.

• Still inn maksimal skjæredybde ved å vri på

justeringsknotten for skjæredybde (7).

• Skyv motordelen frem til tappen (A) låses i hakket på

justeringsknotten (7).

Drei på sagbladet til en av tennene på bladet er i

frontposisjon.

• Mål avstanden fra siden av bunnplaten til tannen på

sagbladet.

• Kontroller om avstanden er 18 mm. Maksimal

innstilling er 18 mm.

STILLE INN SKJÆREDYBDE

Hvis skjæredybden ikke er riktig, stiller du den inn på

følgende måte:

• Trekk motordelen (15) så langt bakover som mulig.

• Frigjør tappen (A).

• Still inn skjæredybden ved å vri på skruen som er

plassert bak tappen (A).

• Gjenta denne prosedyren til du har oppnådd ønsket

skjæredybde.

• Lås tappen (A) på plass.

VEDLIKEHOLD

Kontroller at maskinen ikke er tilkoblet en

strømkilde når det skal utføres vedlikeholdsarbeid

på motoren.

Maskinene fra Ferm er konstruert slik at de kan fungere

uten problemer med et minimum av vedlikehold. Hvis

maskinen rengjøres regelmessig og behandles på riktig

måte, bidrar dette til å gi maskinen en lang levetid.

Rengjøring

Rengjør maskinhuset regelmessig med en myk klut, helst

etter hver bruk. Sørg for at ventilasjonsåpningene er fri

for støv og skitt. Hardnakket skitt fjernes med en myk

klut som er fuktet med såpevann. Bruk ikke løsemidler

som bensin, alkohol, ammoniakk o.kl. Slike stoffer

skader kunststoffdelene.

Smøring

Maskinen trenger ikke ekstra smøring.

Feil

Hvis det skulle opptre en feil som følge av f.eks. slitasje på

en del, må man ta kontakt med den lokale Fermforhandleren.

Bakerst i denne bruksanvisningen finnes det en

deltegning med de deler som kan bestilles.

MILJØ

For å unngå transportskader leveres maskinen i solid

emballasje. Emballasjen er i den grad dette er mulig

fremstilt av resirkulerbart materiale. Benytt derfor

anledningen til å resirkulere emballasjen.

34 Ferm

Page 12

• Bruk alltid vernebriller og hørselsvern. Annet

beskyttelsesutstyr, som arbeidsforkle eller hjelm,

kan også brukes hvis det er ønskelig eller påkrevd.

• Trekk alltid støpselet ut av stikkontakten før det skal

utføres vedlikeholdsarbeid på maskinen. Maskinen

må være slått av når støpselet settes inn i

stikkontakten.

• Påse at strømledningen ligger utenfor maskinens

arbeidsområde. La ledningen ligge bak deg når du

arbeider med maskinen.

• Forsøk aldri å stoppe sagbladet med hendene etter at

maskinen er slått av.

• Bunnplaten må ikke klemmes ned når bladet er

trukket ut. Bladet skal senkes og heves med en myk

bevegelse.

JUSTERE MASKINEN

JUSTERE SKJÆREDYBDE

Fig. B

• Trekk motordelen (15) så langt bakover som mulig.

• Still inn skjæredybden ved hjelp av knotten for

justering av skjæredybde (7).

• Skyv motordelen forover, og kontroller at tappen

(A) låses i hakket på justeringsknotten.

Tabellen nedenfor viser forholdet mellom merkene på

justeringsknotten og skjæredybde, lamelltykkelse og

aktuell lamellskjøt:

Merke Lamell- Lamell- Skjære-

tykkelse skjøt dybde i mm.

0 8-12 mm No. 0 8.0

10 12-15 mm No. 10 10.0

20 > 15 mm No. 20 12.3

S- Simplex 13.0

D- Duplex 14.7

Max. - - 18.0

JUSTERE SKJÆREVINKEL

Fig. C

• Juster skjærevinkelen ved å frigjøre klemmearmen

(8) og sette vinkelsperren (4) i ønsket vinkel.

• Hvis klemmearmen er i veien når du bruker

maskinen, kan du trekke den ut og feste den i en

annen posisjon uten å forandre skjærevinkel.

JUSTERE HØYDE

Fig. D

• Still inn ønsket høyde ved å frigjøre klemmearmen

(9) og vri knotten for høydejustering (10) til ønsket

høyde ved hjelp av skalaen (11).

• Skjærehøyden skal være halvparten av

lamelltykkelsen, og sporet for lamellskjøten skal

alltid være midt på lamellen.

• Hvis klemmearmen er i veien når du bruker

maskinen, kan du trekke den ut og feste den i en

annen posisjon uten å forandre høyden.

MONTERE TILLEGGSUTSTYR

Trekk støpselet ut av stikkontakten.

MONTERE SAGBLADET

Fig. E

• Løsne sekskantskruen (16) ved hjelp av

sekskantnøkkelen som fulgte med maskinen, og åpne

lokket til bunnplaten.

• Trykk på spindellåsen, og vri spindelen (17) til den

låses på plass. Hold spindellåsen trykket ned under

denne prosedyren.

• Fjern flensmutteren (18) fra spindelen ved hjelp av

skrunøkkelen (19).

• Plasser sagbladet (20) på flensen (21).

• Sett flensmutteren (18) tilbake på spindelen (17), og

stram til ved hjelp av skrunøkkelen.

• Flensmutteren har to sider. Den ene er beregnet på

sagblader med en borediameter på 20 mm, og den

andre på sagblader med en borediameter på 22 mm.

Påse at du setter flensmutteren på spindelen med

riktig borediameterside opp.

• Frigjør spindellåsen, og kontroller at spindelen er

frigjort ved å snurre på den.

• Lukk igjen lokket på bunnplaten, og fest

sekskantskruen (16) ved hjelp av sekskantnøkkelen.

Kontroller at lokket på bunnplaten er skikkelig

festet før du starter maskinen.

MONTERE STØVPOSEN

Fig. A

Du bruker støvposen (14) til støvoppsamling.

Sett støvposen (14) inn i vakuuminntaket (13). Tøm

støvposen med jevne mellomrom for optimal

vakuumfunksjon.

BRUK AV MASKINEN

SLÅ MASKINEN AV OG PÅ.

Bruk aldri spindellåsen før maskinen er startet.

• Skyv av/på-bryteren fremover for å slå på maskinen.

• Trykk på av/på-bryteren for å slå av maskinen.

Bryteren går automatisk tilbake til "av"-posisjon.

Forsøk aldri å stoppe motoren ved hjelp av

spindellåsen.

MERKING AV LAMELLENE

Fig. F

Før du starter lamellfresen, må lamellene merkes på

følgende måte:

• Plasser de to lamellene, som må være koblet til

hverandre, oppå hverandre.

• Fest lamellene, og merk midten av sporet.

• Avstanden mellom spor skal være 10-15 cm. Dette

gjelder ikke for mindre lameller – de trenger ikke å

merkes.

Ferm 33

• Plaats de machine alleen tegen een werkstuk als hij

ingeschakeld is .

• Houd de machine altijd stevig met beide handen vast

en neem daarbij een stabiele houding aan.

• Personen jonger dan 16 jaar mogen niet met deze

machine werken.

• Draag altijd een veiligheidsbril en

gehoorbescherming. Gebruik zonodig of indien

gewenst ook andere beschermende middelen, zoals

een schort of een helm.

• Haal altijd de stekker uit het stopcontact voordat u

aan het apparaat zelf werkzaamheden uit gaat

voeren. Steek de stekker alleen in het stopcontact als

de machine uitgeschakeld is.

• Houd het netsnoer altijd weg van het werkgebied van

de machine. Laat de kabel altijd achter u langs lopen.

• Probeer nadat u de machine uitgeschakeld hebt,

nooit het blad met de hand te stoppen.

• De bodemplaat mag nooit bij een uitstekend

freesblad vastgeklemd worden. Het blad dient

gemakkelijk omhoog en omlaag te kunnen bewegen.

HET AFSTELLEN VAN DE

MACHINE

HET AFSTELLEN VAN DE FREESDIEPTE

Fig. B

• Breng de voet van de motor (15) zover mogelijk naar

achteren.

• Stel de freesdiepte met de betreffende afstelknop (7) in.

• Breng de motorvoet naar voren en controleer of de

pen (A) in de inkeping van de afstelknop valt.

De volgende tabel geeft het verband aan tussen de

markeringen op de afstelknop en de freesdiepte,

materiaaldikte en bijbehorende lamello:

Markering Dikte Lamello Freesdiepte

materiaal in mm

0 8-12 mm No. 0 8.0

10 12-15 mm No. 10 10.0

20 > 15 mm No. 20 12.3

S-Simplex 13.0

D-Duplex 14.7

Max. - - 18.0

HET AFSTELLEN VAN DE FREESHOEK

Fig. C

• De freeshoek kan ingesteld worden door klem (8)

los te maken en de hoekstop (4) in de gewenste hoek

te plaatsen.

• Als de klem tijdens het werken met het apparaat in

de weg zou zitten, kunt u deze lostrekken en weer in

een andere positie terugplaatsen, zonder de

freeshoek te veranderen.

HOOGTEAFSTELLING

Fig. D

• De juiste hoogte kunt u instellen, door de

betreffende klem (9) los te maken en de knop voor

hoogte-instelling (10) met behulp van de schaal (11)

naar de gewenste hoogte te verdraaien.

• De hoogte moet overeenkomen met de helft van de

materiaaldikte van het werkstuk. De sleuf voor de

lamello moet zich altijd in het midden van het

werkstuk bevinden.

• Mocht de klem tijdens het werken met het apparaat

in de weg zitten, trek deze dan los en plaats hem weer

terug in een andere positie, zonder de hoogte te

veranderen.

MONTAGETOEBEHOREN

Haal de stekker uit het stopcontact.

MONTAGE VAN HET FREESBLAD

Fig. E

• Draai de inbusbout (16) met de meegeleverde

inbussleutel los en open de bovenkant van de

bodemplaat.

• Druk de asvergrendeling in en verdraai de as (17)

totdat deze in de vergrendeling valt. Houd de

asvergrendeling tijdens deze procedure aangedrukt.

• Verwijder met sleutel (19) de flensmoer (18) van de

as.

• Plaats het freesblad (20) op de flens (21).

• Plaats de flensmoer (18) terug op de as (17) en draai

deze met de sleutel vast.

• De flensmoer is dubbelzijdig, de ene zijde is voor

freesbladen met boringen van 20 mm en de andere

zijde voor freesbladen met boringen van 22 mm.

Let erop dat de flensmoer altijd met de juiste zijde op

de as wordt geplaatst.

• Maak de asvergrendeling los en controleer of de as

vrij kan draaien.

• Sluit de bovenkant van de bodemplaat en draai de

inbusbouten (16) met de meegeleverde inbussleutel

vast.

Let erop dat de bovenkant van de bodemplaat

stevig gesloten is voordat u met de machine gaat

werken.

MONTAGE VAN DE STOFZAK (

Fig. A

U kunt de stofzak (14) gebruiken voor het afzuigen van

stof. Breng de stofzak (14) in de afzuigaansluiting (13)

aan. Maak de stofzak regelmatig leeg, zodat de

vacuümwerking blijft functioneren.

GEBRUIK

AAN- EN UITSCHAKELEN.

Gebruik de asvergrendeling nooit bij een draaiende

machine.

• Schuif de aan-/uitschakelaar naar voren om de

machine in te schakelen.

• Als u de machine uit wilt zetten, hoeft u de

aan/uitschakelaar alleen maar in te drukken, waarna

de schakelaar automatisch naar de uitstand schuift.

Probeer de motor nooit met de asvergrendeling te

stoppen.

12 Ferm

Page 13

HET AFTEKENEN VAN HET WERKSTUK

Fig. F

Teken het werkstuk als volgt af, voordat u met de

lamellenfrees begint:

• Plaats de beide werkstukken die aan elkaar

gekoppeld moeten worden, bovenop elkaar.

• Maak de werkstukken vast en markeer het midden

van de sleuf.

• De ruimte tussen twee sleuven dient 10-15 cm te

bedragen. Dit geldt niet bij kleinere werkstukken;

deze hoeven niet gemarkeerd te worden.

POSTIONEREN VAN DE MACHINE

Afhankelijk van de grootte van de werkstukken, kan de

machine op verschillende manieren gepositioneerd

worden.

GROTE WERKSTUKKEN

Fig. G

• Plaats de machine in de buurt van het werkstuk.

• Het midden van de bodemplaat (zie de markering op

de bodemplaat) moet tegenover het midden van de

sleuf in het werkstuk komen (zie de markering op het

werkstuk).

KLEINE WERKSTUKKEN

Fig. H

• Plaats de machine in de buurt van het werkstuk.

• De zijkant van de machine moet gelijk komen met de

zijkant van het werkstuk.

WERKSTUKKEN DUNNER DAN 16 MM

Fig. I

• Plaats de machine in de buurt van het werkstuk.

• Plaats de afstelplaat (5) op de hoekstop (4).

• Stel de hoogte zorgvuldig in. De sleuf voor de lamello

moet in het midden van het werkstuk komen.

Bij werkstukken die dunner zijn dan 16 mm is het niet

mogelijk zonder afstelplaat de sleuf voor de lamello in

het middel van het werkstuk te krijgen.

HET FREZEN VAN SLEUVEN

• Breng de voet van de motor naar achteren.

• Plaats de machine in de buurt van het werkstuk.

• Breng de machine in positie (zie het positioneren van

de machine).

• Houd de machine met beide handen vast en schakel

de machine aan.

• Duw de bodem van de machine voorzichtig zo ver

mogelijk naar voren.

• Duw de voet van de motor weer naar achteren en

schakel de machine uit.

DE WERKSTUKKEN AAN ELKAAR

KOPPELEN

Als in beide werkstukken de sleuven zijn aangebracht,

kunnen deze aan elkaar gekoppeld worden:

• Breng in beide sleuven lijm aan.

• Plaats de lamello in de sleuf van één van de

werkstukken.

• Schuif het andere werkstuk op deze lamello.

• Maak de werkstukken vast en laat de lijm drogen.

HET CONTROLEREN VAN DE

FREESDIEPTE

Fig. J

Als u een nieuw freesblad monteert, dient u altijd de

freesdiepte te controleren:

• Haal de stekker uit het stopcontact.

• Breng de voet van de motor (15) zover mogelijk naar

achteren.

• Stel de freesdiepte met de afstelknop voor de

freesdiepte (7) in op de maximale positie.

• Breng de motorvoet naar voren, totdat de pen (A) in

de inkeping van de afstelknop (7) valt.

• Verdraai het zaagblad totdat zich aan de voorkant

een tand bevindt.

• Meet de afstand van de zijde van de bodemplaat tot

de tand van het freesblad.

• Controleer of deze 18 mm is, wat met de maximale

diepte overeenkomt.

HET BIJSTELLEN VAN DE FREESDIEPTE

Als de freesdiepte niet correct is, kan deze als volgt

worden bijgesteld:

• Breng de voet van de motor (15) zover mogelijk naar

achteren.

• Maak de pen (A) los.

• Stel de freesdiepte in door de schroef die zich aan de

achterkant van pen (A) bevindt, te verdraaien.

• Herhaal deze procedure totdat de freesdiepte

correct is.

• Maak pen (A) weer vast.

ONDERHOUD

Let erop dat er geen spanning op de machine staat

en de stekker uit het stopcontact is, voordat u met

onderhoud aan de motor gaat beginnen.

De machines van Ferm zijn ontworpen om gedurende

lange tijd probleemloos te functioneren met een

minimum aan onderhoud. Door de machine regelmatig

te reinigen en op de juiste wijze te behandelen, draagt u

bij aan een hoge levensduur van uw machine.

Reinigen

Reinig de machine-behuizing regel matig met een zachte

doek, bij voorkeur iedere keer na gebruik. Zorg dat de

ventilatiesleuven vrij van stof en vuil zijn.

Gebruik bij hardnekkig vuil een zachte doek bevochtigd

met zeepwater. Gebruik geen oplosmiddelen als

benzine, alcohol, ammonia, etc. Dergelijke stoffen

beschadigen de kunststof onderdelen.

Smeren

De machine heeft geen extra smering nodig.

Storingen

Indien zich een storing voordoet als gevolg van

bijvoorbeeld slijtage van een onderdeel, neem dan

contact op met uw plaatselijke Ferm-dealer.

Achterin deze gebruiksaanwijzing vindt u een

onderdelentekening met de na te bestellen onderdelen.

Ferm 13

LAMELLFRES

TALLENE I FØLGENDE TEKST VISER TIL BILDENE

PÅ SIDE 2 & 3.

TEKNISKE SPESIFIKASJONER

PAKKENS INNHOLD

Pakken inneholder:

1 Lamellfres

1 Sagblad

1 Skrunøkkel

1 Justeringsplate

1 Sekskantnøkkel

1 Støvpose

1 Bruksanvisning

1 Sikkerhetshefte

1 Garantikort

Kontroller at maskinen, løse deler og tilbehør ikke har

fått transportskader.

PRODUKTINFORMASJON

Fig. A

FBJ-710 lamellfres er beregnet på skjæring av spor for

lamellskjøter i heltre, kryssfiner, kartong, fiberplater,

pleksiglass og kunstig marmor .

1. Av/på-bryter

2. Håndtak

3. Spindellås

4. Vinkelsperre

6. Skala for verneskjermvinkel

7. Justeringsknott for skjæredybde

8. Klemmearm for vinkeljustering

9. Klemmearm for høydejustering

10. Knott for høydejustering

11 Skala for høydejustering

12. Bunnplate

13. Feste for støvpose

14. Støvpose

15. Motordel

SIKKERHETSFORSKRIFTER

I denne bruksanvisningen benyttes følgende symboler:

Henviser til mulig personskade, livsfare eller fare

for skader på maskinen hvis instruksene i denne

bruksanvisningen ikke overholdes.

Viser til elektrisk spenning.

Les denne bruksanvisningen nøye før maskinen tas i

bruk. Sørg for å vite hvordan maskinen virker og

hvordan den skal betjenes. Vedlikehold maskinen i

henhold til instruksene, slik at den alltid virker som den

skal. Oppbevar denne bruksanvisningen og den vedlagte

dokumentasjonen ved maskinen.

ELEKTRISK SIKKERHET

Kontroller alltid om nettspenningen er i

overensstemmelse med verdien på typeskiltet.

Maskinen er dobbelt isolert i henhold til EN

50144; det er derfor ikke nødvendig med

jordledning.

Utskifting av ledninger og støpsler

Kast gamle ledninger og støpsler så snart de har blitt

erstattet av nye. Det er farlig å stikke støpselet på en løs

ledning i stikkontakter.

Bruk av skjøteledninger

Bruk utelukkende en godkjent skjøteledning som er

egnet til maskinens effekt. Ledningene må ha et

tverrsnitt på minst 1,5 mm2. Hvis skjøteledningen sitter

på en rull, må den rulles helt ut.

SPESIELLE SIKKERHETSFORHOLDSREGLER

• Sagflis og spon må ikke fjernes underveis mens du

bruker maskinen.

• Bruk ikke skjæreskiver eller sirkelsagblad i maskinen.

• Beskytt sagbladene mot støt og slag.

• Bruk alltid skarpe blader slik at lamellen ikke skades

som følge av for stor skjærekraft.

• Kontroller at sagbladet ikke er skadet før bruk. Bruk

ikke sagblad som har sprekker eller rifter eller andre

skader.

• Sørg for at lamellen er tilstrekkelig støttet eller

festet. Hold hendene borte fra overflaten som skal

skjæres.

• Hold alltid i håndtaket under bruk av maskinen.

• Ved montering av sagbladet på spindelen må du påse

at det er nok gjenger på spindelen.

• Kontroller at sagbladet er korrekt montert og sitter

godt fast. Reduksjonsring eller adapter må ikke

brukes til å feste sagbladet.

• Maskinen må kun brukes på lamellen når den er slått

på.

• Hold maskinen godt fast med begge hender under

bruk, og sørg for at du står støtt.

• Personer under 16 år må ikke bruke denne

maskinen.

Spenning | 230 V~

Frekvens | 50 Hz

Inngangseffekt | 710 W

Tomgangshastighet | 11 000/min

Skivediameter | 100 mm

Bladets borediameter | 20 + 22 mm

Maks. skjæredybde | 18 mm

Verneskjermjustering | 0-90°

Spindeldimensjoner | M10

Vekt | 3.0 kg

Lydtrykk | 89.6 dB (A)

Lydstyrkenivå | 102.6 dB (A)

Vibrasjonsverdi | 1.9 m/s

2

32 Ferm

Page 14

• Mittaa etäisyys tukilevyn sivusta sahanterän

hampaaseen.

• Varmista, että etäisyys on 18 mm. Suurin

mahdollinen asetus on 18 mm.

LEIKKAUSSYYVYYDEN SÄÄTÄMINEN.

Jos leikkaussyvyys ei ole oikea, sitä voidaan säätää

seuraavasti:

• Siirrä moottoriosa (15) ääriasentoonsa taaksepäin.

• Irrota tappi (A).

• Määritä leikkaussyvyys kiertämällä ruuvia. Ruuvi on

tapin (A) takana.

• Toista, kunnes leikkaussyvyys on haluttu.

• Kiinnitä tappi (A).

HOITO

Varmista, että koneessa ei ole virtaa ja että se on

irrotettu virtalähteestä, kun huollat moottoria.

Ferm-koneet on suunniteltu toimimaan pitkään ja

mahdollisimman pienellä huoltotarpeella. Puhdistamalla

ja käyttämällä sitä oikealla tavalla voit itsekin vaikuttaa

koneen käyttöikään.

Puhdistaminen

Puhdista koneen ulkopinta säännöllisesti pehmeällä

kankaalla. Parasta olisi puhdistaa se jokaisen

käyttökerran jälkeen. Pidä koneen jäähdytysaukot

puhtaina. Jos lika on pinttynyt, voit käyttää

saippuavedellä kostutettua kangaspalaa. Älä kuitenkaan

käytä liuottimia kuten bensiiniä, alkoholia, ammoniakkia

jne, koska ne vahingoittavat koneen muoviosia.

Voitelu

Konetta ei tarvitse voidella.

Häiriöt

Jos koneen toiminnassa ilmenee häiriö esim. jonkin osan

kulumisen johdosta, ota yhteyttä lähimpään Fermjälleenmyyjään. Näiden käyttöohjeiden lopusta löydät

kokoonpanopiirustuksen ja varaosalistan..

YMPÄRISTÖ

Kuljetusvaurioiden välttämiseksi kone on pakattu

tukevaan laatikkoon. Tämä pakkaus on mahdollisimman

ympäristöystävällinen. Kierrätä se.

Jos vaihdat koneen uuteen, voit viedä vanhan koneen

Ferm-jälleenmyyjällesi, joka huolehtii

ympäristöystävällisestä jätehuollosta.

TAKUU

Lue takuuehdot koneen mukaan liitetystä takuukortista.

Vakuutamme omalla vastuullamme, että tämä tuote on

seuraavien standardien tai standardoitujen

dokumenttien mukainen.

EN60475-1, EN60475-2-5, EN55014-1,

EN-55014-2, EN61000-3-2, EN61000-3-3

määräysten mukainen.

98/37EEC

73/23EEC

89/336EEC

Voimassa 01-03-2004

ZWOLLE NL

W. Kamphof

Laadunvalvontaosasto

CE

ı

TODISTUS STANDARDINMUKAISUUDESTA

(SF)

Ferm 31

MILIEU

Om transportbeschadiging te voorkomen, wordt de

machine in een stevige verpakking geleverd. De

verpakking is zo veel mogelijk gemaakt van recyclebaar

materiaal. Maak daarom gebruik van de mogelijkheid om

de verpakking te recyclen.

Breng oude machines wanneer u ze vervangt naar uw

plaatselijke Ferm-dealer. Daar zal de machine op

milieuvriendelijke wijze worden verwerkt.

GARANTIE

Lees voor de garantievoorwaarden de apart bijgevoegde

garantiekaart.

Wij verklaren dat dit product

voldoet aan de volgende

normen of normatieve documenten

EN60475-1, EN60475-2-5, EN55014-1,

EN-55014-2, EN61000-3-2, EN61000-3-3

overeenkomstig de bepalingen in de richtlijnen

98/37EEC

73/23EEC

89/336EEC

van 01-03-2004

ZWOLLE NL

W. Kamphof

Quality department

LAMELLEUSE

LES CHIFFRES DU TEXTE SUIVANT

CORRESPONDENT AUX ILLUSTRATIONS PAGE

2 & 3.

CARACTERISTIQUES TECHNIQUES

CONTENU DE L’EMBALLAGE

L’emballage contient :

1 Fraiseuse à rainurer

1 Lame de scie

1 Clé plate

1 Plaque de réglage

1 Clé coudée six pans

1 Sac collecteur de sciure

1 Mode d’emploi

1 Cahier de sécurité

1 Certificat de garantie

Vérifiez si la machine, les pièces détachées et les

accessoires n’ont pas été endommagés au transport.

INFORMATIONS PRODUIT

Fig. A

La fraiseuse à rainurer FBJ-710 est conçue pour creuser

des rainures pour montages à lamelles d'assemblage

dans le bois massif, le contre-plaqué, les panneaux de

particules, les panneaux de fibres, le Plexiglas et le

marbre artificiel.

1. Commutateur Marche/Arrêt

2. Poignée auxiliaire

3. Verrou de la broche

4. Butée d'angle

6. Echelle pour angle de la protection

7. Molette de réglage de profondeur de coupe

8. Levier de blocage pour réglage d'angle

9. Levier de blocage pour réglage de la hauteur

10. Molette de réglage de la hauteur

11 Echelle pour réglage de la hauteur

12. Embase

13. Raccord pour sac à sciure

14. Sac à sciure

15. Bloc moteur

Tension | 230 V~

Fréquence | 50 Hz

Puissance d'entrée | 710 W

Vitesse à vide | 11 000 tr/min

Diamètre du disque | 100 mm

Diamètre de l'alésage de lame | 20+22 mm

Profondeur de coupe maximale | 18 mm

Réglage de la protection | 0 – 90°

Dimension de la broche | M10

Poids | 3,0 kg

Pression sonore | 89.6 dB(A)

Niveau de puissance sonore | 102.6 dB(A)

Vibrations | 1.9 m/s

2

CE

ı

CONFORMITEITSVERKLARING

(NL)

14 Ferm

Page 15

CONSIGNES DE SÉCURITÉ

Dans ce mode d’emploi, il est fait usage des

pictogrammes suivants:

Indique un éventuel risque de lésion corporelle, un

danger de mort ou un risque d’endommagement

de la machine si les instructions de ce mode d’emploi ne sont

pas respectées.

Indique la présence de tension électrique.

Risque d’incendie.

Lisez attentivement ce mode d’emploi avant d’utiliser la

machine. Assurez-vous d’avoir bien pris connaissance du

fonctionnement de la machine et de son utilisation.

Entretenez la machine conformément aux instructions

afin qu’elle fonctionne toujours correctement.

Conservez ce mode d’emploi et la documentation jointe

à proximité de la machine.

SÉCURITÉ ÉLECTRIQUE

Vérifiez toujours si la tension de votre réseau

correspond à la valeur mentionnée sur la plaque

signalétique.

La machine est doublement isolée conformément

à la norme EN 50144 ; un fil de mise à la terre n’est

pas donc pas nécessaire.

En cas de changement de câbles ou de fiches

Jetez immédiatement les câbles ou fiches usagés dès

qu’ils sont remplacés par de nouveaux exemplaires. Il est

dangereux de brancher la fiche d’un câble défait dans une

prise de courant.

En cas d’emploi de câbles prolongateurs

Employez exclusivement un câble prolongateur

homologué, dont l’usage est approprié pour la puissance

de la machine. Les fils conducteurs doivent avoir une

section minimale de 1,5 mm

2

. Si le câble prolongateur se

trouve dans un dévidoir, déroulez entièrement le câble.

CONSIGNES DE SECURITE SPECIALES

• Ne retirez pas la sciure et les éclats de bois tant que la

machine fonctionne.

• N'utilisez pas de disques de coupe ni de lames de scie

circulaire dans la machine.

• Protégez les lames de scie contre les chocs et les

impacts.

• N'utilisez que des lames correctement affûtées,

sinon l'augmentation des forces de coupe fera

éclater la pièce à travailler.

• Avant utilisation, inspectez la lame pour détecter

toute détérioration éventuelle. N'utilisez pas de

lames fissurées, fendues ou endommagées de

quelque manière que ce soit.

• Assurez-vous que la pièce à travailler est

correctement soutenue ou fixée. Gardez les mains

éloignées de la surface à couper.

• N'utilisez la machine qu'avec la poignée auxiliaire.

• Lorsque des lames de scie doivent être montées sur

le filetage de la broche, assurez-vous que la broche

possède un filetage suffisant.

• Assurez-vous que la lame a été montée et serrée

correctement. N'utilisez pas de bagues de réduction,

ni d'adaptateurs pour installer la lame correctement.

• N'appliquez la machine sur la pièce à travailler

qu'après avoir mis la machine en marche.

• Lorsque vous travaillez avec la machine, tenez-la

toujours fermement des deux mains et adoptez une

position sûre.

• L'utilisation de cette machine est interdite aux

personnes de moins de 16 ans.

• Portez toujours des lunettes de protection et un

casque antibruit. Au besoin, utilisez également une

autre protection comme un tablier ou un casque, par

exemple.

• Débranchez toujours le cordon d'alimentation avant

de procéder à toute intervention sur la machine ellemême. Avant de brancher le cordon d'alimentation,

assurez-vous que la machine est en position Arrêt.