Page 1

Ferm BV • P.O. Box 30159 • 8003 CD Zwolle • The Netherlands • www.ferm.com 0507-12.1

UK Subject to change

D Änderungen vorbehalten

NL Wijzigingen voorbehouden

F Sous réserve de modifications

E Reservado el derecho de modificaciones

técnicas

P Reservado o direito a modificações

I Con reserva di modifiche

S Ändringar förbehålles

SF Pidätämme oikeuden muutoksiin

N Rett till endringer forbeholdes

DK Ret til ændringer forbeholdes

www.ferm.com

UK

D

NL

F

E

P

I

S

SF

N

DK

USERS MANUAL 03

GEBRAUCHSANWEISUNG 06

GEBRUIKSAANWIJZING 09

MODE D’EMPLOI 12

MANUAL DE INSTRUCCIONES 15

ISTRUÇÕN A USAR 18

MANUALE UTILIZZATI 21

BRUKSANVISNING 24

KÄYTTÖOHJE 27

BRUKSANVISNING 30

BRUGERVEJLEDNING 33

Art.nr. AGM1024

FAG-230/2000K

Page 2

Ferm 39

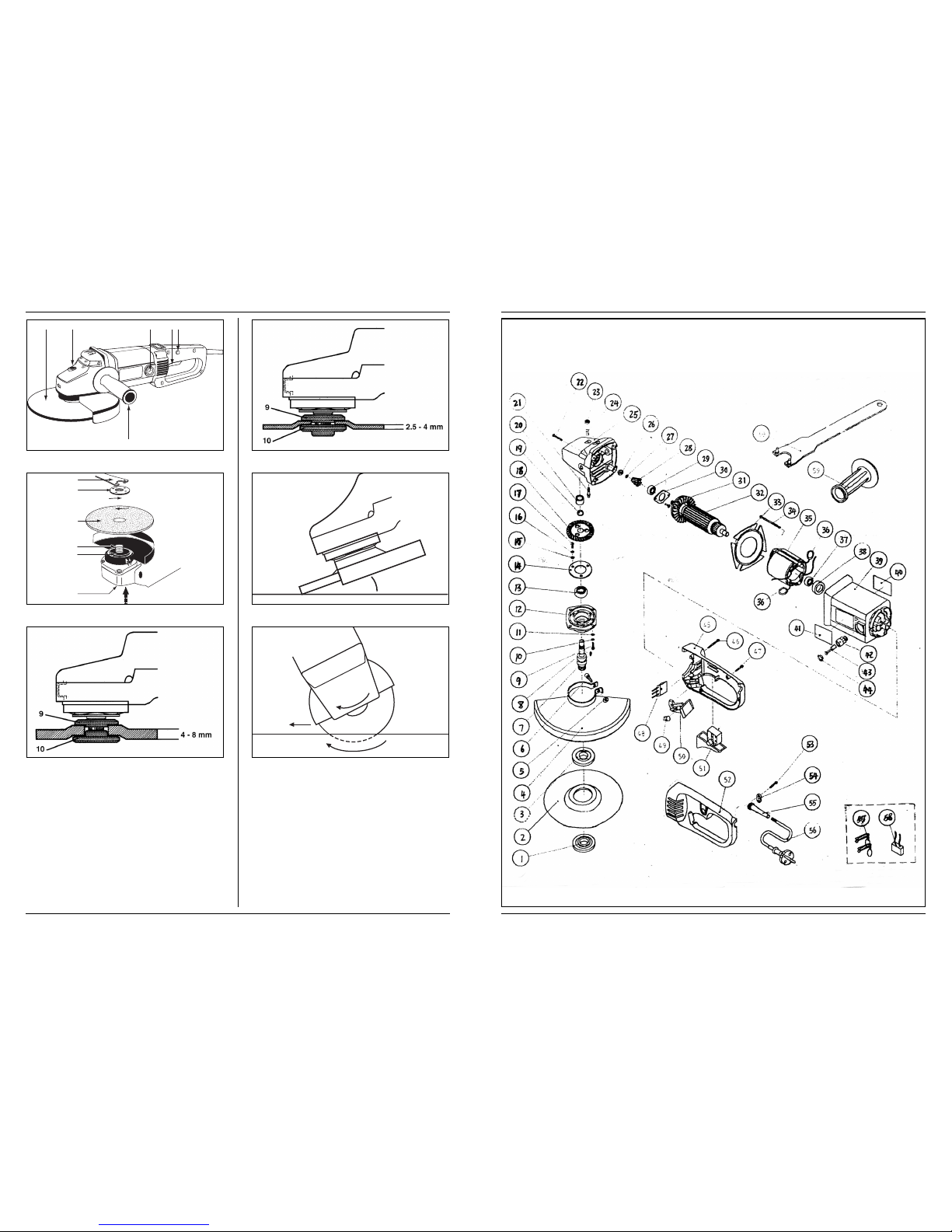

EXPLODED VIEW

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

30 - 40

o

+

11

12

7

9

6

5

453 2 1 6

2 Ferm

Page 3

38 Ferm

SPARE PARTS LIST FAG 230/2000K

REF.NR. DESCRIPTION FERM NR.

01 FLANGE INSIDE 406940

03 FLANGE OUTSIDE 406941

04 WHEEL COVER 406942

18 SPINDLE GEAR 406943

28 PINION GEAR 406944

32 ROTOR 406945

35 STATOR 406946

42 BRUSH HOLDER 406947

43 CARBON BRUSH SET (2 PCS) 406948

44 BRUSH CAP 406949

51 SWITCH 406950

59 SIDE HANDLE 406877

60 SPANNER 406814

THE NUMBERS IN THE FOLLOWING TEXT

CORRESPOND WITH THE PICTURES AT PAGE 2

ANGLE GRINDER

CONTENTS:

1. Machine data

2. Safety instructions

3. Assembly

4. Use

5. Service & maintenance

1. MACHINE DATA

INTRODUCTION

This machine is developed for grinding and roughing of

metal and stone.

PACKAGE CONTENTS

1 Angle grinder

1 Side handle

1 Spanner

2 Cut off grinding wheels

1 Set carbon brushes

1 Instruction manual

1 Safety instructions

1 Warranty card

TECHNICAL SPECIFICATION

FEATURES

Fig.1

1. on/off switch

2. screw-on lid carbon brush (both sides)

3. spindle lock

4. grinding disc

5. side handle

6. lock-off button

2. SAFETY INSTRUCTIONS

EXPLANATION OF SYMBOLS

In this manual and/or on the machine the following

symbols are used:

In accordance with essential applicable safety

standards of European directives

Class II machine – Double insulation – You don’t

need any earthed plug.

Denotes risk of personal injury, loss of life or

damage to the tool in case of non-observance of

the instructions in this manual.

Indicates electrical shock hazard.

Risk of fire

Keep bystanders away

Remove the plug from the mains

Wear safety glasses and ear protection

Wear protective gloves

Read instructions carefully

Faulty and/or discarded electrical or electronic

apparatus have to be collected at the appropriate

recycling locations.

SAFETY INSTRUCTIONS

When using electric machines always observe the

safety regulations applicable in your country to

reduce the risk of fire, electric shock and personal

injury. Read the following safety instructions and

also the enclosed safety instructions. Keep these

instructions in a safe place!

• Check that the maximum speed indicated on the

grinding disc corresponds to the maximum speed of

the machine. The speed of the machine must not

exceed the value on the grinding disc.

• Make sure that the dimensions of the grinding disc

correspond to the specifications of the machine.

• Make sure that the grinding disc has been mounted

and fastened properly. Do not use reducing rings or

adapters to make the grinding disc fit properly.

• Treat and store grinding discs in conformance with

the supplier’s instructions.

• Do not use the machine for grinding workpieces with

a maximum thickness exceeding the maximum

grinding depth of the grinding disc.

• Do not use grinding discs for deburring.

• When grinding discs have to be mounted on the

thread of the spindle, make sure that the spindle has

sufficient thread. Make sure that the spindle is

sufficiently protected and does not touch the

grinding surface.

Voltage | 230 V~

Frequency | 50 Hz

Power input | 2000 W

No-load speed | 6000/min

Disc diameter | 230 mm

Spindle dimension | M 14

Weight | 4,9 kg

Lpa (sound pressure) | 97,9 dB (A)

Lwa (sound power) | 110,9 dB (A)

Vibration value | 3,2 m/s

2

Ferm 3

Page 4

Ferm 37

• Before use, inspect the grinding disc for any damage.

Do not use grinding discs which are crack-ed, ripped

or otherwise damaged.

• Before use, let the machine run idle for 30 seconds.

Immediately switch off the machine in case of

abnormal vibrations or occurrence of another

defect. Carefully inspect the machine and grinding

disc before switching the machine on again.

• Make sure that sparks do not put people into danger

or that they contact highly flammable substances.

• Make sure that the workpiece is sufficiently

supported or clamped. Keep your hands away from

the surface to be cut.

• Always wear safety goggles and hearing protection. If

desired or required also use another kind of

protection like for example an apron or helmet.

• Ensure that mounted wheels and points are fitted in

accordance with the manufacturer’s instructions.

• Ensure that blotters are used when they are

provided with the bonded abrasive product and

when they are required.

• If a guard is supplied with the tool never use the tool

without such a guard.

• For tools intended to be fitted with threaded hole

wheel, ensure that the thread in the wheel is long

enough to accept the spindle length.

• Ensure that ventilation openings are kept clear when

working in dusty conditions. If it should become

nessesary to clear dust, first disconnect the tool

from the mains supply (use non metallic objects) and

avoid damaging internal parts.

• Though poor conditions of the electrical mains,

shortly voltage drops can appear when starting the

equipment. This can influence other equipment (eq.

blinking of a lamp). If the mains-impedance Zmax

<0.348 Ohm, such disturbances are not expected.

(In case of need, you may contact your local supply

authority for further information.

3. ASSEMBLY

Prior to mounting an accessory always unplug the

tool.

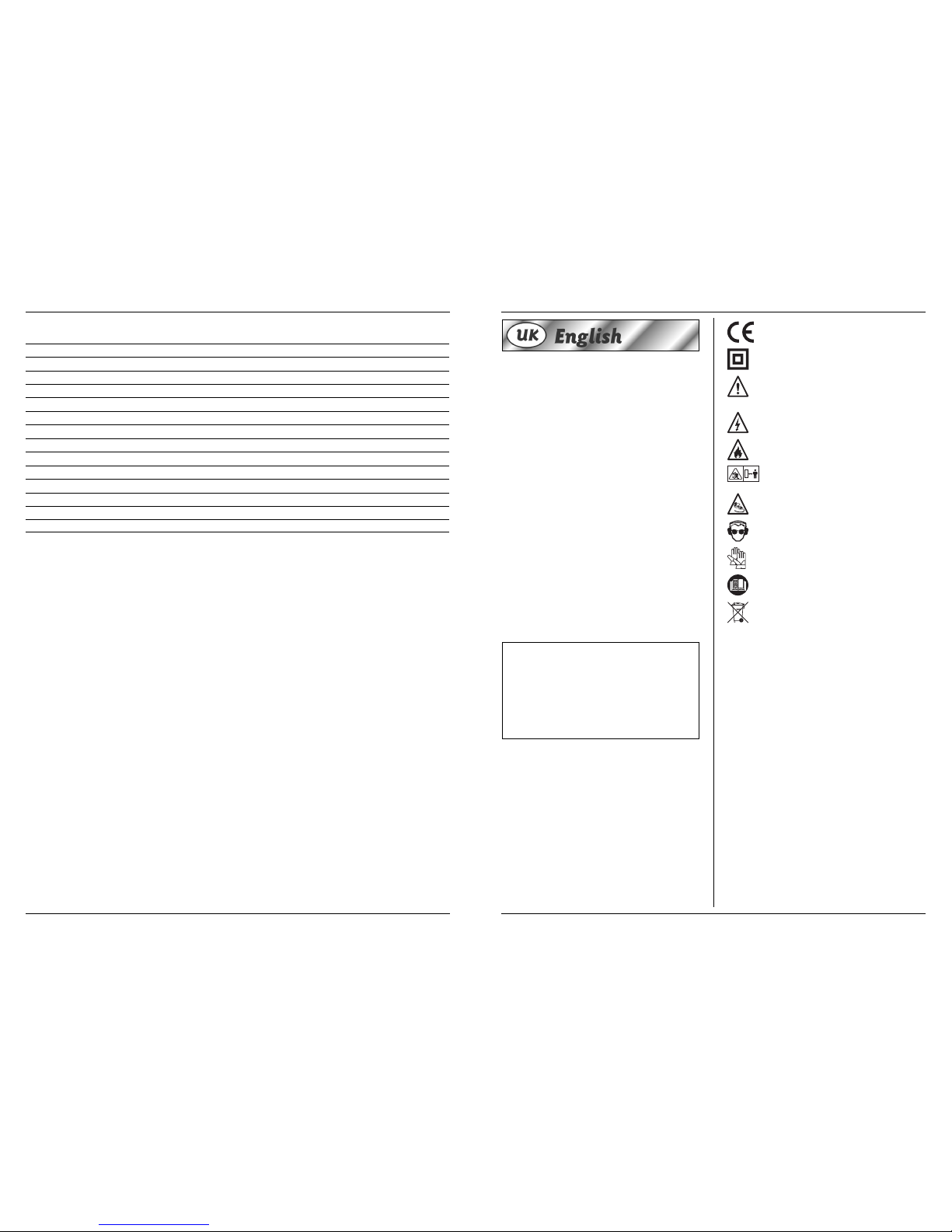

MOUNTING A GRINDING DISC.

Fig 2

Use grinding discs of the correct dimension. Use fibre

reinforced grinding discs only. The grinding disc must

not touch the edge of the guard.

• Press the spindle lock (6) and turn the spindle (9)

until it engages in the lock. Keep the spindle lock

pressed during this procedure.

• Remove the flange nut (12) from the spindle using the

spanner (11).

• Position the grinding disc (7) on the flange (5).

• Place the flange nut on the spindle an tighten it using

the spanner.

• Release the spindle lock and check that the spindle is

unlocked by rotating it.

MOUNTING THE SIDE HANDLE

Fig 1

The side handle can be used for both left-hand and righthand control.

• Fasten the side handle (Fig. 5) for left-hand operation

on the right-hand side of the machine.

• Fasten the side handle for right-hand operation on

the left-hand side of the machine.

• Fasten the side handle for upright working at the top

of the machine.

Make sure that the side handle is fastened

properly and cannot loosen unexpectedly.

MOUNTING GRINDING DISCS AND

ROUGHING DISCS

Fig. 3 and 4 show how to mount the flange (10) when

using thick (4 – 8 mm) and thin (2,5 – 4 mm) discs.

4. USE

SPECIAL ATTENTION WHEN STARTING

THE MACHINE

• Clamp the workpiece and make sure that the

workpiece cannot slide from under the machine

during the cutting activities.

• When working with the machine, always hold it firmly

with both hands and provide for a secure stance.

• Always direct the cable to the rear away from the

machine.

• Insert the mains plug only when the machine is

switched off.

• Apply the machine to the workpiece only when

switched on

Never use the machine for grinding magnesium

workpieces.

SWITCHING ON AND OFF

• This machine is equipped with a safety switch.

• Start the machine by pressing the “lock off” button

(to disengrage the switch) and switch on the

machine.

Before start working, the machine must be run

according to the max. speed.

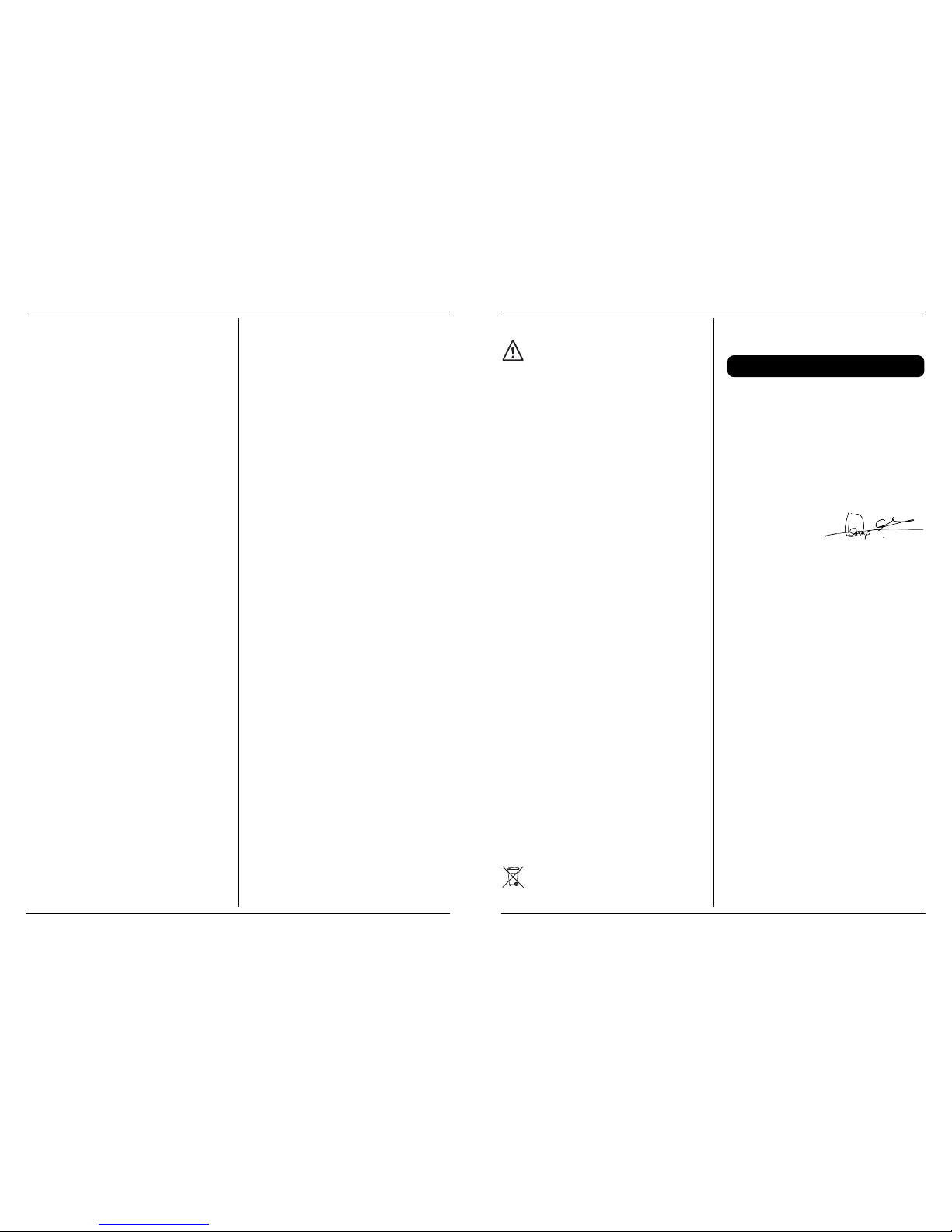

OPERATION

• Hold the machine firmly and move it against the

workpiece. Move the grinding disc evenly across the

workpiece.

• Move the machine during roughing under an angle of

30º - 40º across the workpiece (fig. 5).

Never use grinding discs for roughing!

• The machine must always work opposite to the

direction of rotation. Therefore, never move the

machine in the other direction! Otherwise, the

danger exists of it being pushed uncontrolled out of

the cut (fig. 6).

• Inspect the grinding disc regularly. Worn discs have a

negative effect on efficiency of the machine. Replace

the grinding disc on time.

• Do not put the machine down when the motor is still

running. Do not place the machine on a dusty

surface. Dust particles may enter the mechanism.

4 Ferm

Page 5

36 Ferm

• Always switch off the machine first before removing

the plug from the wall socket.

Never use the spindle lock to stop the motor.

TROUBLESHOOTING

1. Machine fails to operate:

• Power turned off

• (Extension) cable damaged

2. The elektromotor hardly reaches maximum

speed:

• The extension cable is too thin and/or too long

• The mains voltage is lower than 230 V

3. Machine overheats:

• Air vents are blocked. Clean them with a dry cloth.

• The machine has been overloaded. Use the machine

for the purpose it is made for.

4. Excessive sparking or elektromotor runs

irregular.

• There’s dirt inside the motor or the carbon brushes

are worn. Replace the carbon brushes or bring the

machine to a specialized repair centre.

5. SERVICE & MAINTENANCE

MAINTENANCE

Make sure that the plug is removed from the mains when

carrying out maintenance work on the motor.

The Ferm machines have been designed to operate over

a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon

proper machine care and regular cleaning.

CLEANING

Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt. If the dirt does not come off use a soft

cloth moistened with soapy water. Never use solvents

such as petrol, alcohol, ammonia water, etc. These

solvents may damage the plastic parts.

LUBRICATION

The machine requires no additional lubrication.

FAULTS

Should a fault occur, e.g. after wear of a part, please

contact the service address on the warranty card. In the

back of this manual you find an exploded view showing

the parts that can be ordered.

ENVIRONMENT

To prevent damage during transport, the appliance is

delivered in a solid packaging which consists largely of

reusable material. Therefore please make use of options

for recycling the packaging.

Faulty and/or discarded electrical or electronic

apparatus have to be collected at the appropriate

recycling locations.

WARRANTY

The warranty conditions can be found on the separately

enclosed warranty card.

We declare under our sole responsibility that this

product is in conformity with the following standards or

standardized documents

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

in accordance with the regulations.

98/37/EEC, 73/23/EEC

89/336/EEC

from 01-06-2005

ZWOLLE NL

W. Kamphof

Quality department

CE

ı

DECLARATION OF CONFORMITY

(UK)

Ferm 5

Page 6

Placér ikke maskinen på en støvet overflade.

Støvpartikler kan komme i kontakt med mekanikken.

• Sluk altid maskinen før du fjerner stikket fra

stikkontakten.

Anvend aldrig aksellåsen til stoppe motoren med.

HJÆLP

1. Maskinen fungere ikke:

• Strømmen er slukket

• (Forlænger) ledning er beskadiget

2. Den elektroniske motor når ikke op til

maksimumhastighed:

• Forlængerledningen er for tynd og/eller for lang

• Strømforsyningen er lavere end 230 V

3. Maskinen overophedes:

• Udluftningskanaler er blokeret. Rengør dem med en

tør klud.

• Maskinen er blevet overbelastet. Anvend kun

maskinen til det den er beregnet til.

4. Usædvanlig mange gnister, eller den

elektroniske motor køre uregelmæssigt.

• Der er snavs inde i motoren, eller kulbørsterne er

nedslidte. Udskift kulbørsterne eller aflevér

maskinen til et særligt reparationscenter.

5. SERVICE & VEDLIGEHOLDELSE

VEDLIGEHOLDELSE

Sørg for, at stikket til maskinen er taget ud af

stikkontakten, når der skal udføres vedligeholdelse på

motoren.

Ferm maskiner er blevet konstrueret, så de kan arbejde i

længere perioder med et minimum af vedligeholdelse.

Korrekt vedligeholdelse og rengøring af maskinen er en

forudsætning for lang tids tilfredsstillende brug.

RENGØRING

Kappen omkring motoren skal rengøres med en blød

klud, helst hver gang maskinen har været brugt.

Ventilationsrillerne skal holdes fri for støv og snavs. Hvis

snavset ikke vil gå af, bruges en blød klud vredet op i

sæbevand. Der må ikke bruges opløsningsmidler som

f.eks. benzin, sprit, salmiakspiritus o.l. Sådanne

opløsningsmidler kan beskadige dele af plastic.

SMØRING

Maskinen skal ikke smøres.

FEJL

Skulle en fejl opstå, f.eks. pga. slidtage af en enhed,

kontakt venligst serviceadressen på garantibeviset. På

bagsiden af denne manual finder du en tegning med alle

dele, der kan bestilles.

MILJØ

For at undgå transportbeskadigelse leveres maskinen i

en solid emballage. Emballagen er så vidt muligt lavet af

genbrugsmateriale. Genbrug derfor emballagen.

Defekte og/eller kasserede elektriske eller

elektroniske maskiner skal afleveres på en

genbrugsplads.

GARANTI

Garantibetingelser er beskrevet på det separat vedlagte

garantibevis.

Vi erklærer herved, udelukkende på eget ansvar, at dette

produkt opfylder følgende standarder eller

standardiserede dokumenter

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

i henhold til følgende direktiver:

98/37/EØF, 73/23/EØF

89/336/EØF

01-06-2005

ZWOLLE NL

W. Kamphof

Quality department

CE

ı

KONFORMITETSERKLÆRING

(DK)

Ferm 35

DIE NUMMERN IM NACHFOLGENDEN TEXT

KORRESPONDIEREN MIT DEN ABBILDUNGEN

AUF SEITE 2

WINKELSCHLEIFER

INHALT

1. Gerätedaten

2. Sicherheitshinweise

3. Wartungs- und Verschleißteile

4. Bedienung

5. Wartung und Pflege

1. GERÄTEDATEN

EINFÜHRUNG

Dieses Gerät wurde zum Schruppen und Schlichten von

Metall- und Steinoberflächen entwickelt.

LIEFERUMFANG

1 Winkelschleifer

1 Seitengriff

1 Schraubenschlüssel

2 Trennscheibe

1 Satz Kohlebürsten

1 Bedienungsanleitung

1 Sicherheitsvorschriften

1 Garantiekarte

TECHNISCHE DATEN

TEILEBEZEICHNUNG

Abb.1

1 Ein-/Aus-Schalter

2 Schraubdeckel Kohlebürste (Beidseitig)

3 Spindelarretierung

4 Schleifscheibe

5 Seitengriff

6. “Lock-off” Knopf

2. SICHERHEIT

ERLÄUTERUNG DER SYMBOLE

In dieser Anleitung und/oder auf dem Gerät werden

folgende Symbole verwendet:

Übereinstimmung mit den jeweils maßgeblichen

EU-Sicherheitsrichtlinien

Gerät der Schutzklasse II – schutzisoliert – kein

Schutzkontakt erforderlich

Lebens- und Verletzungsgefahr und Gefahr von

Beschädigungen am Gerät bei Nichteinhaltung der

Sicherheitsvorschriften in dieser Anleitung.

Elektroschockgefahr.

Brandgefahr

Umstehende fernhalten

Stecker aus der Netzsteckdose ziehen

Schutzbrille und Gehörschutz tragen

Schutzhandschuhe tragen

Anweisungen sorgfältig lesen

Schadhafte und/oder entsorgte elektrische oder

elektronische Geräte müssen an den dafür

vorgesehenen Recycling-Stellen abgegeben werden.

SICHERHEITSVORSCHRIFTEN

Beachten beim Benutzen von Elektromaschinen

immer die örtlichen Sicherheitsvor-schriften

bezüglich Feuerrisiko, Elektroschock und

Verletzung. Lesen Sie außer den folgenden

Hinweisen ebenfalls die Sicherheitsvorschriften im

einschlägigen Sonderteil.

Die Hinweise müssen sicher aufbewahrt werden!

• Überprüfen Sie, ob die Höchstdrehzahl, die auf der

Schleifscheibe angegeben ist, mit der

Höchstdrehzahl der Maschine übereinstimmt. Die

Drehzahl der Maschine darf nicht höher sein als der

Wert auf der Schleifscheibe.

• Achten Sie darauf, daß die Abmessungen der

Schleifscheibe mit den Angaben der Maschine

übereinstimmen.

• Achten Sie darauf, daß die Schleifscheibe richtig

montiert und ordnungsgemäß festgesetzt wurde.

Verwenden Sie keine Reduzierringe oder Adapter,

um die Schleifscheibe passend zu machen.

• Behandeln und lagern Sie Schleifscheiben gemäß den

Vorschriften des Lieferanten.

• Verwenden Sie die Maschine nicht, um Werkstücke

durchzuschleifen, die dicker sind als die maximale

Schleiftiefe der Schleifscheibe.

• Verwenden Sie keine Schleifscheiben für

Abgratarbeiten.

Spannung | 230 V~

Frequenz | 50 Hz

Eingangsspannung | 2000 W

Leerlaufdrehzahl | 6000/min

Schleifscheibe ø | 230 mm

Schleifspindelgewinde | M 14

Gewicht | 4,9 kg

Lpa (Schalldruckpegel) | 97,9 dB(A)

Lwa (Schallleistungspegel) | 110,9 dB(A)

Vibrationswert | 3,2 m/s

2

6 Ferm

Page 7

Forvis dig om, at spindlen er godt afskærmet og ikke

kan komme i kontakt med slibeoverfladen.

• Inden anvendelse skal slibeskiven kontrolleres for

eventuelle skader. Brug ikke revne eller brudte

slibeskiver eller sådanne skiver, der på anden måde

er beskadiget.

• Lad maskinen køre ubelastet i 30 sekunder inden

brug. Sluk øjeblikkeligt for maskinen, når den

begynder at vibrere for meget eller når der opstår en

anden defekt. Kontrollér maskinen og slibeskiven

omhyggeligt, før du igen tænder for maskinen.

• Sørg for, at den eventuelle gnistregn fra slibeskiven

ikke er til fare for mennesker og at den ikke kommer i

kontakt med letantændelige stoffer.

• Sørg for, at arbejdsemnet understøttes tilstrækkeligt

eller at det klemmes ind. Hold hænderne væk fra

slibeoverfladen.

• Bær altid sikkerhedsbriller og høreværn. Brug om

ønsket eller om nødvendigt andre

beskyttelsesmidler såsom et forklæde eller en hjelm.

• Kontrollér, at hjul og punkter er monteret i

overensstemmelse med producentens anvisninger.

• Kontrollér, at der bruges filtre, når de leveres med

den bundne slibeskive, og når det er påkrævet.

• Hvis værktøjet leveres med afskærmning, må det

ikke benyttes uden brug af denne afskærmning.

• Ved anvendelse af værktøjer, der skal påmonteres

gevindskårne hjul, skal det kontrolleres, at gevindet i

hjulet er langt nok til spindlen.

• Kontrollér, at ventilationsåbningerne holdes fri ved

arbejde under støvede forhold. Hvis det er

nødvendigt at rengøre for støv, skal maskinen først

afbrydes fra forsyningsnettet (brug ikke

metalobjekter). Undgå at beskadige indvendige dele.

• Hvis der er fejl på ledningsnettet, kan der ske

spændingsfald ved start af udstyret. Det kan påvirke

andet udstyr (f.eks. en lampe, der blinker). Hvis

netimpedansen Zmaks. < 0,348 Ohm, forventes der

ikke sådanne forstyrrelser. Yderligere oplysninger

fås ved henvendelse til det lokale elforsyningsselskab.

3. SAMLING

Før montering af tilbehør skal værktøjet altid være

strømafbrudt

MONTERING AF SIDEHÅNDGREBET

Fig 2

Anvend slibeskiver med den rette størrelse. Anvend

udelukkende fiberforstærkede slibeskiver. Slibeskiven

må ikke komme i kontakt med beskyttelseskappens

kant.

• Tryk aksellåsen (6) ind, og drej akslen (9) til denne

falder i låsen. Hold aksellåsen indtrykt, sålænge De

følger denne procedure.

• Fjern flangemøtrikken (12) fra akslen ved hjælp af

klampernøglen (11).

• Placér slibeskiven (7) på flangen (5).

• Skru flangemøtrikken på akslen igen og drej den fast

ved hjælp af klampernøglen.

• Kontrollér, at spærreanordningen er frigjort ved at

dreje på akslen og slip herved aksellåsen.

MONTAGE AF SIDEHÅNDGREB

Fig 1

Sidehåndgrebet er egnet til såvel venstrehåndet som

højrehåndet betjening.

• Ved venstrehåndet betjening drejes sidehåndgrebet

(Fig. 5) i optagelsen på maskinens højre side.

• Ved højrehåndet betjening drejes sidehåndgrebet i

optagelsen på maskinens venstre side.

• Ved vertikale arbejder drejes sidehåndgrebet i

optagelsen på maskinens overkant.

Sørg for, at sidehåndgrebet sidder godt fast og ikke

uventet kan rystes løs

MONTERING AF SLIBESKIVER OG

SKÆRESKIVER

Fig. 3 og 4 demonstrerer montering af flangen (10), når

der anvendes tykke (4 – 8 mm) og tynde (2.5 – 4 mm)

skiver.

4. ANVENDELSE

SÆRLIGE FORHOLDSREGLER VED START

AF MASKINEN

• Fastgør arbejdsstykket, og sørg for at arbejdsstykket

ikke glider ind under maskinen under betjening.

• Når der arbejdes med maskinen skal den altid holdes

med et fast greb med begge hænder, og du bør stå på

et sikkert underlag.

• Hold altid ledningen bort, væk fra maskinen.

• Indsæt kun strømledningen når maskinen er slukket.

• Maskine og arbejdsstykke bør ikke komme i kontakt,

når maskinen er slukket.

Anvend aldrig maskinen til at slibe arbejdsstykker i

magnesium.

IND/UDKOBLING

• Denne maskine er udstyret med en sikkerhedsafbryder.

• Maskinen startes ved at trykke på knappen "udløs" (for at

udløse afbryderen) og starte maskinen

.

Når maskinen har nået det maksimale omdrejningstal, kan den skubbes frem over arbejdsemnet

BETJENING

• Hold maskinen med et fast greb, og fjern denne fra

arbejdsstykket. Bevæg slibeskiven med ens

bevægelser over arbejdsstykket.

• Bevæg maskinen under slibning med en vinkel på 30º 40º tværs over arbejdsstykket (fig.5).

Anvend aldrig slibeskiven til grovhugning!

• Maskinen skal altid arbejde modsat

rotationsretningen. Træk derfor ikke maskinen i den

modsatte retning! Ellers kan den skubbes tilbage, væk

fra snittet, ude af kontrol

• Efterse ofte slibeskiven. Nedslidte skiver har en

negativ virkning på maskinens effektivitet. Udskift

slibeskiven i god tid.

• Stil ikke maskinen ned når motoren stadig køre.

34 Ferm

• Sorgen Sie dafür, daß bei Verwendung von

Schleifscheiben, die auf dem Gewinde der Spindel

befestigt wird, die Spindel genügend Gewinde hat.

Sorgen Sie dafür, daß die Spindel ausreichend

geschützt ist und die Schleifoberfläche nicht berührt.

• Überprüfen Sie die Schleifscheibe vor Benutzung auf

eventuelle Beschädigungen. Verwenden Sie keine

Schleifscheiben, die geborsten, gerissen oder anders

beschädigt sind.

• Lassen Sie die Maschine vor Inbetriebnahme 30

Sekunden lang unbelastet laufen. Schalten Sie die

Maschine sofort aus, wenn diese deutlich zu zittern

anfängt oder wenn ein anderer Defekt auftritt.

Überprüfen Sie die Maschine und Schleifscheibe

gründlich, bevor Sie die Maschine erneut einschalten.

• Sorgen Sie dafür, daß ein eventueller Funkenregen

keine Gefahr für Personen bildet oder in Richtung

von leicht entflammbaren Substanzen spritzt.

• Sorgen Sie dafür, daß das Werkstück ausreichend

unterstützt oder eingeklemmt wird. Bleiben Sie mit

den Händen von der Schleiffläche fern.

• Tragen Sie immer eine Schutzbrille und einen

Hörschutz. Benutzen Sie, falls erforderlich oder

gewünscht, andere Schutzkleidung, wie z.B. eine

Schürze oder einen Helm.

• Befestigen Sie Scheiben und sonstige Einzelteile

gemäß den Vorschriften des Herstellers.

• Verwenden Sie falls erforderlich Fließpapier, wenn

diese mit den Schleifmitteln mitgeliefert worden sind.

• Verwenden Sie immer eine Sicherheitsvorrichtung,

wenn diese mit dem Gerät mitgeliefert worden ist.

• Bei Werkzeugen, die mit einer Lochscheibe mit

Gewinde ausgerüstet werden, muss das Gewinde in

der Bohrung für die Spindellänge lang genug sein.

• Achten Sie darauf, dass Lüftungsöffnungen bei der

Arbeit in staubiger Umge-bung nicht verschmutzt

sind. Bevor Sie Lüftungsöffnungen reinigen, ziehen

Sie den Netzstecker. Verwenden Sie zum Reinigen

keine Metallgegenstände, vermeiden Sie die

Beschädigung von Innenteilen.

• Bei einem schwachen Stromnetz kann es beim

Einschalten der Anlage zur Span-nungsabsenkung

kommen. Dies kann sich auf andere Geräte

auswirken (beispielsweise Blinken einer

Anzeigelampe). Solche Störungen sind

ausgeschlossen, wenn die Netzimpedanz Zmax <

0,348 Ohm beträgt. Im Zweifelsfall fragen Sie bei

Ihrem Ver-sorgungsbetrieb nach.

3. MONTAGE

Vor Befestigung von Zubehör muss immer der

Stecker des Werkzeugs gezogen werden.

EINSETZEN EINER SCHLEIFSCHEIBE

Abb.2

Arbeiten Sie mit Schleifscheiben mit den richtigen

Abmessungen. Benutzen Sie nur glasfaserverstärkte

Schleifscheiben. Die Schleifscheibe darf den Rand der

Schutzkappe nicht berühren.

• Drücken Sie die Spindelverriegelung (6) und drehen

Sie die Spindel (9) bis diese einrastet. Halten Sie die

Verriegelung gedrückt, solange Sie hiermit tätig sind.

• Lösen Sie mit Hilfe des Spannschlüssels (11) die

Flanschmutter (12) vom Spindel.

• Setzen Sie die Schleifscheibe (7) auf die Flansche (5).

• Drehen Sie die Flanschmutter zurück auf die Spindel

und ziehen Sie sie anschließend mit dem

Spannschlüssel an.

• Lassen Sie die Spindelverriegelung los und

überprüfen Sie, ob die Verriegelung aufgehoben

wurde, indem Sie an der Spindel drehen.

MONTIEREN DES SEITENGRIFFS

Abb.1

Der Seitengriff eignet sich für links- und rechtshändige

Bedienung.

• Drehen Sie zwecks linkshändige Bedienung den

Seitengriff (Abb. 5) in die Aufnahme rechts der

Maschine.

• Drehen Sie zwecks rechtshändige Bedienung den

Seitengriff in die Aufnahme links der Maschine.

• Drehen Sie zwecks vertikaler Arbeiten den

Seitengriff in die Aufnahme oben in der Maschine.

Achten Sie auf einen festen Sitz des Seitengriffs,

damit dieser sich durch Vibration nicht unerwartet

löst.

EINSETZEN VON SCHLEIF- UND

SCHRUPPSCHEIBEN

In Abb. 3 und 4 ist dargestellt, wie der Flansch (10) bei

Verwendung von dicken (4–8 mm) und dünnen (2,5–4

mm) Scheiben angebracht wird.

4. GEBRAUCH

VORSICHTSMAßNAHMEN BEIM STARTEN

DES GERÄTS

• Das Werkstück immer festklemmen, sodass es

während der Arbeit nicht unter dem Gerät weg

schieben kann.

• Beim Arbeiten das Gerät immer mit beiden Händen

gut festhalten und für einen sicheren Stand sorgen.

• Das Kabel immer nach hinten vom Gerät weg führen.

• Den Netzstecker nur bei ausgeschaltetem Gerät

einstecken.

• Das Gerät nur dann auf dem Werkstück ansetzen,

wenn es eingeschaltet ist.

Das Gerät darf nie zum Schleifen von

Werkstücken aus Magnesium verwendet werden.

EIN- UND AUSSCHALTEN

•

Diese Maschine ist mit einem Sicherheitsschalter

ausgerüstet.

• Starten Sie die Maschine, indem Sie den "lock-off"-Knopf

betätigen (hierdurch wird der Schalter entsichert) und die

Maschine einschalten.

Warten Sie mit dem Schleifen bis die Maschine das

normale Tempo erreicht hat.

BEDIENUNG

• Das Gerät gut festhalten und gegen das Werkstück

bewegen. Die Schleifscheibe gleichmäßig über die

Werkstückoberfläche bewegen.

Ferm 7

Page 8

TALLENE I DEN FØLGENDE TEKST

KORRESPONDERER MED AFBILDNINGERNE PÅ

SIDE 2

VINKELSLIBER

INDHOLD:

1. Maskindata

2. Sikkerhedsforskrifter

3. Samling

4. Anvendelse

5. Service & vedligeholdelse

1. MASKINDATA

INDLEDNING

Denne maskine er udviklet til at skære og slibe i metal og

sten.

PAKKEINDHOLD

1 Skærebrænder

1 Sidehåndgreb

1 Skruenøgle

2 Skæringsvinkelsliber

1 Sæt kulbørster

1 Instruktionsmanual

1 Sikkerhedsinstruktioner

1 Garantibevis

TEKNISKE SPECIFIKATIONER

PRODUKTINFORMATION

Fig. 1

1. ænd/sluk-kontakt

2. gevindsokkel kulbørste (begge sider)

3. aksellås

4. slibeskive

5. sidehåndgreb

6. knappen "udløs"

2. SIKKERHEDSINSTRUKTIONER

SYMBOLFORKLARING

I denne brugervejledninge og/eller på maskinen

anvendes der følgende piktogrammer:

I overensstemmelse med grundlæggende

sikkerhedsstandarder i de europæiske direktiver.

Klasse II maskine – Dobbelt isolering – Du behøver

ingen jordforbindelsestik.

Betegnelse for risiko for personskader, dødsfald

eller beskadigelse af værktøjet i tilfælde af at du er

uopmærksom på instruktioner i denne manual.

indikerer farer for elektrisk stød

Brandfare

hold tilstedeværende på afstand.

Fjern stikket fra kontakten.

Bær beskyttelsesbriller og høreværn

Bær beskyttelseshandsker

Læs instruktionerne omhyggeligt

Defekte og/eller kasserede elektriske eller

elektroniske maskiner skal afleveres på en

genbrugsplads.

SIKKERHEDSFORSKRIFTER

Ved anvendelse af elektriske maskiner skal man altid

følge de lokalt gældende sikkerhedsforskrifter i

forbindelse med brandfare, fare for elektrisk stød og

legemensbeskadigelse. Læs udover de nedenstående

instruktioner også sikkerhedsforskrifterne i den

separat vedlagte sikkerhedsfolder.

Bevar instruktionerne godt!

• Kontrollér, at det maksimale omdrejningstal, der er

angivet på slibeskiven, stemmer overens med

maskinens maksimale omdrejningstal. Maskinens

omdrejningstal må ikke være højere end den på

slibeskiven angivne værdi.

• Vær opmærksom på, at slibeskivens mål stemmer

overens med maskinens specifikationer.

• Vær opmærksom på, at slibeskiven er monteret

rigtigt og ordentligt spændt fast. Brug ikke

reduktionsringe eller adaptere for at få en slibeskive

til at passe.

• Brug og opbevar slibeskiver i henhold til

leverandørens anvisninger.

• Brug ikke maskinen til gennemslibning af

arbejdsemner med en tykkelse, der er større end

skæreskivens maksimale slibedybde.

• Brug ikke skæreskiver til afgratning.

• Ved anvendelse af slibeskiver, der fastspændes på

spindlens gevind, skal der sørges for at spindlen har

et tilstrækkeligt stort gevind.

Spænding | 230 V~

Frekvens | 50 Hz

Optaget effekt | 2000 W

Ubelastet hastighed | 6000/min

Skive diameter | 230 mm

Akseldimension | M 14

Vægt | 4,9 kg

Lpa (Lydtryk) | 97,9 dB (A)

Lwa (Lydevne) | 110,9 dB (A)

Vibrationsværdi | 3,2 m/s

2

Ferm 33

• Zum Schruppen das Gerät in einem Winkel von 30º

bis 40º über das Werkstück führen (Abb. 5).

Nie eine Schleifscheibe zum Schruppen

verwenden!

• Das Gerät muss immer gegen die Drehrichtung

arbeiten. Deshalb mit dem Gerät nicht in die andere

Richtung fahren! Sonst besteht die Gefahr, dass es

unkontrolliert aus dem Schnitt gedrückt wird (Abb.

6).

• Die Schleifscheibe muss regelmäßig überprüft

werden. Verschlissene Scheiben beeinträchtigen die

Wirkung des Werkzeugs. Die Schleifscheibe

rechtzeitig auswechseln.

• Bei laufendem Motor darf das Gerät nie abgelegt

werden. Das Gerät nicht auf eine staubige

Oberfläche legen, da sonst Staubpartikel in die

Mechanik eindringen können.

• Ehe der Stecker aus der Steckdose gezogen wird,

muss das Gerät ausgeschaltet werden.

Der Motor darf nie mittels der Spindelarretierung

angehalten werden.

FEHLERBEHEBUNG

1. Das Gerät funktioniert nicht:

• Der Strom ist ausgeschaltet

• Beschädigtes (Verlängerungs-) Kabel

2. De Elektromotor erreicht die maximale

Drehzahl kaum:

• Zu dünnes und/oder zu langes Verlängerungskabel

• Netzspannung von weniger als 230 V

3. Das Gerät wird überhitzt:

• Verstopfte Lüftungsschlitze, Schlitze mit einem

trockenen Tuch reinigen

• Überlastung des Geräts, das Gerät nur wie

vorgesehen gebrauchen

4. Zu viel Funkenbildung oder unregelmäßig

laufender Elektromotor

• Verschmutzungen im Motor oder verschlissene

Kohlebürsten, die Kohlebürsten auswechseln oder

das Gerät bei einer Fachwerkstatt zur Reparatur

geben

5. SERVICE UND WARTUNG

WARTUNG

Vergewissern Sie sich, dass der Netzstecker gezogen ist,

während Sie Wartungsarbeiten am Motor ausführen.

Die Ferm-Geräte wurden für Langzeitbetrieb bei

minimaler Wartung konstruiert. Ihr nachhaltig

zufriedenstellender Betrieb hängt von der richtigen

Gerätepflege und von regelmäßiger Reinigung ab.

REINIGUNG

Reinigen Sie das Gerätegehäuse regelmäßig mit einem

weichen Tuch, vorzugsweise nach jeder Benutzung.

Halten Sie die Belüftungsschlitze frei von Staub und

Schmutz.

Lässt sich der Schmutz so nicht entfernen, verwenden

Sie ein weiches, mit Seifenwasser befeuchtetes Tuch.

Verwenden Sie niemals Lösungsmittel wie Benzin,

Alkohol, Ammoniakwasser usw. Diese Lösungsmittel

können die Kunststoffteile beschädigen.

SCHMIERUNG

Das Gerät erfordert keine zusätzliche Schmierung.

FEHLER

Sollte beispielsweise nach Abnutzung eines Teils ein

Fehler auftreten, dann setzen Sie sich bitte mit der auf

der Garantiekarte angegebenen Serviceadresse in

Verbindung. Im hinteren Teil dieser Anleitung befindet

sich eine ausführliche Übersicht über die Teile, die

bestellt werden können.

UMWELT

Um Transportschäden zu verhindern, wird die Maschine

in einer soliden Verpackung geliefert. Die Verpackung

besteht weitgehend aus verwertbarem Material.

Benutzen Sie also die Möglichkeit zum Recyclen der

Verpackung.

Schadhafte und/oder entsorgte elektrische oder

elektronische Geräte müssen an den dafür

vorgesehenen Recycling-Stellen abgegeben werden.

GARANTIE

Die Garantiebedingungen finden Sie auf der lose

beigefügten Garantiekarte.

Wir erklären unsere alleinige Verantwortung, dass

dieses Produkt konform den nachstehenden Standards

oder standardisierten Dokumenten ist.

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

Gemäß den Vorschriften.

98/37/EWG, 73/23/EWG

89/336/EWG

vom 01-06-2005

ZWOLLE NL

W. Kamphof

Quality Department

CE

ı

KONFORMITÄTSERKLÄRUNG

(D)

8 Ferm

Page 9

FEILSØKING

1. Maskinen går ikke:

• Maskinen er slått av

• Ledning eller skjøteledning er skadet

2. Elektromotoren oppnår ikke full hastighet:

• Skjøteledningen er for tynn eller for lang

• Strømspenningen er lavere enn 230 V

3. Maskinen blir for varm:

• Lufteventilene er blokkert. Rengjør dem med en tørr

klut.

• Maskinen er overbelastet. Bruk maskinen bare til det

den er beregnet for.

4. Alt for mye gnister, eller elektromotoren går

ujevnt

• Det er skitt i motoren, eller så er kullbørstene utslitt.

Skift kullbørstene eller lever maskinen hos et

spesialisert reparasjonsverksted.

5. SERVICE OG VEDLIKEHOLD

VEDLIKEHOLD

Trekk støpselet ut av stikkontakten når det skal utføres

vedlikehold på motoren.

Maskinene fra Ferm er konstruert for å kunne brukes

over lang tid med minimalt vedlikehold. For å oppnå

tilfredsstillende resultater over lang tid, er det viktig å

stelle maskinen riktig og rengjøre den regelmessig.

RENGJØRING

Rengjør maskinens ytterside regelmessig med en myk

fille - helst hver gang den er brukt. Hold

ventilasjonsåpningene frie for støv og skitt. Hvis det er

vanskelig å fjerne skitt, kan man bruke en myk fille som er

fuktet med såpevann. Bruk aldri løsemidler som bensin,

alkohol, ammoniakkvann, etc. Disse løsemidlene kan

ødelegge plastdelene.

SMØRING

Maskinen trenger ikke ekstra smøring.

FEIL

Hvis det oppstår feil som følge av for eksempel utslitte

deler, skal du kontakte serviceadressen på

garantikortet. Bakerst i denne bruksanvisningen finner

du en splittegning som viser deler som kan bestilles.

MILJØ

For å unngå transportskader leveres maskinen i solid

emballasje. Emballasjen er i den grad dette er mulig

fremstilt av resirkulerbart materiale. Benytt derfor

anledningen til å resirkulere emballasjen.

Defekte og/eller kasserte elektriske eller

elektroniske apparater må avhendes ved egnete

returpunkter.

GARANTI

Garantibetingelsene gjengis på det vedlagte, separate

garantikortet.

Vi erklærer på eget ansvar at dette produktet er i

samsvar med følgende standarder eller standardiserte

dokumenter.

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

i samsvar med bestemmelsene.

98/37/EEC, 73/23/EEC

89/336/EEC

fra 01-06-2005

ZWOLLE NL

W. Kamphof

Kvalitetsavdelingen

CE

ı

ERKLÆRING AV ANSVARSFORHOLD

(N)

32 Ferm

DE NUMMERS IN DE NU VOLGENDE TEKST

VERWIJZEN NAAR DE AFBEELDINGEN OP

PAGINA 2

HAAKSE SLIJPER

INHOUDSOPGAVE:

1. Machine gegevens

2. Veiligheid

3. Montage accessoires

4. Bediening

5. Service & Onderhoud

1. MACHINE GEGEVENS

INTRODUCTIE

Deze machine is gemaakt voor het doorslijpen en

afbramen van metaal en steen.

INHOUD VAN DE VERPAKKING

1 Haakse slijper

1 Zijhandgreep

1 Spansleutel

1 Set koolborstels

2 Doorslijpschijven

1 Gebruiksaanwijzing

1 Veiligheidskatern

1 Garantiekaart

TECHNISCHE SPECIFICATIE

BENAMING ONDERDELEN

Fig.1

1. aan/uit-schakelaar

2. schroefdeksel koolborstel (aan weerskanten)

3. spindelblokkeerknop

4. slijpschijf

5. zijhandgreep

6. “lock-off” knop

2. VEILIGHEID

VERKLARING VAN DE SYMBOLEN

In deze handleiding en/of op deze machine worden de

volgende symbolen gebruikt:

CE Conform de Europese toepasselijke standaards

op het gebied van veiligheid

De machine is dubbel geïsoleerd overeenkomstig

EN50144; een aardedraad is daarom niet nodig

Gevaar voor lichamelijk letsel of materiele schade

Gevaar: elektrische spanning

Brandgevaar

Houd omstanders op afstand

Neem de stekker uit het stopcontact

Draag een veiligheidsbril en gehoorbescherming

Draag veiligheidshandschoenen

Lees de instructies

Defecte en/of afgedankte elektrische of

elektronische gereedschappen dienen ter

verwerking te worden aangeboden aan een

daarvoor verantwoordelijke instantie.

VEILIGHEIDSVOORSCHRIFTEN

Neem bij het gebruik van elektrische machines altijd

de plaatselijk geldende veiligheidsvoorschriften in

acht in verband met brandgevaar, gevaar voor

elektrische schokken en lichamelijk letsel. Lees

behalve onderstaande instructies ook de

veiligheidsvoorschriften in het apart bijgevoegde

veiligheidskatern door.

Bewaar de instructies zorgvuldig!

• Controleer of het maximum toerental dat op de

slijpschijf staat aangegeven, overeenkomt met het

maximum toerental van de machine. Het toerental

van de machine mag niet hoger zijn dan de waarde op

de slijpschijf.

• Let op dat de afmetingen van de slijpschijf

overeenkomen met de specificaties van de machine.

• Let op dat de slijpschijf juist is gemonteerd en naar

behoren is vastgezet. Gebruik geen ver-loopringen

of adapters om een slijpschijf passend te maken.

• Behandel en bewaar slijpschijven volgens de

voorschriften van de leverancier.

• Gebruik de machine niet voor het doorslijpen van

werkstukken met een dikte die groter is dan de

maximale slijpdiepte van de doorslijpschijf.

• Gebruik geen doorslijpschijven voor

afbraamwerkzaamheden.

Spanning | 230 V~

Frequentie | 50 Hz

Opgenomen vermogen | 2000 W

Toerental onbelast | 6000/min

Schijfdiameter | 230 mm

Spindelmaat | M 14

Gewicht | 4,9 kg

Lpa (geluidsdruk) | 97,9 dB (A)

Lwa (geluidsvermogen) | 110,9 dB (A)

Vibratiewaarde | 3,2 m/s

2

Ferm 9

Page 10

• La maskinen gå i 30 sekunder uten belastning før den

tas i bruk. Slå av maskinen øyeblikkelig hvis den

begynner å vibrere unaturlig mye eller hvis det viser

seg at den er defekt på en annen måte. Kontroller

maskinen og slipeskiva grundig før du starter

maskinen på nytt.

• Pass på at det eventuelle gnistregnet ikke kan være til

fare for mennesker i nærheten og at gnistregnet ikke

spruter i retning av lett antennelige stoffer.

• Pass på at arbeidsstykket er tilstrekkelig godt støttet

opp eller klemt fast. Hold hendene borte fra den

flaten som skal slipes.

• Bruk alltid vernebriller og hørselsvern. Bruk gjerne

annet verneutstyr også, som for eksempel

verneforkle eller hjelm, og alltid når det er påkrevet.

• Pass på at monterte slipeskiver og •hoder er festet i

samsvar med produsentens instruksjoner.

• Pass på at festeskiver brukes når slike festeskiver

følger med slipeproduktene og når det ellers kreves.

• Hvis verktøyet leveres med vernehette, må

verktøyet aldri brukes uten denne vernehetten.

• For verktøy som bruker slipeskiver som festes med

gjenger, må du passe på at gjengene i skiven er så

lange at hele spindelen skrus inn.

• Pass på at ventilasjonsåpningene ikke blokkeres når

verktøyet brukes på steder med mye støv. Hvis

verktøyet må rengjøres for støv, må verktøyet først

kobles fra strømnettet. Ikke bruk metalliske

objekter til å rengjøre verktøyet, og unngå å skade

interne deler.

• Hvis strømnettet er i dårlig forfatning, kan det oppstå

kortvarige spenningsfall når vinkelsliperen startes.

Dette kan virke inn på annet utstyr (for eksempel kan

lamper blinke). Hvis nettimpedansen er mindre enn

0,348 ohm, skal det vanligvis ikke oppstå slike

forstyrrelser. (Hør med din lokale forhandler hvis du

har behov for mer informasjon).

3. MONTERING

Trekk alltid ut støpslet før du monterer tilbehør.

MONTERING AV SIDEHÅNDTAKET

Fig 2

Bruk slipeskiver med riktig størrelse. Bruk kun

fiberforsterkede slipeskiver. Slipeskiven må ikke komme

i kontakt med kanten av vernehetten.

• Trykk inn spindellåsen (6) og vri spindelen (9) til

denne faller i låsen. Hold spindellåsen inntrykket så

lenge denne prosedyren følges.

• Fjern flensmutteren (12) fra spindelen ved hjelp av

spennøkkelen (11).

• Plasser slipeskiven (7) på flensen (5).

• Skru flensmutteren på spindelen igjen og stram den

med spennøkkelen.

• Løsne spindellåsen og kontroller om sperringen er

opphevet ved dreie på spindelen.

MONTERING AV SIDEHÅNDTAKET

Fig 1

Sidehåndtaket er egnet til både venstre- og

høyrehåndsbruk.

• Ved venstrehåndsbruk skrus sidehåndtaket (Fig. 5) i

åpningen på høyre side av maskinen.

• Ved høyrehåndsbruk skrus sidehåndtaket i åpningen

på venstre side av maskinen.

• For vertikal arbeide skrus sidehåndtaket i åpningen

på oversiden av maskinen.

Sørg for at sidehåndtaket sitter godt fast slik at det

ikke uventet kan ristes løs.

SETTE PÅ SLIPE- OG FRESESKIVER

Figur 3 og 4 viser montering av flensen (10) ved bruk av

tykk (4-8 mm) og tynn (2,5-4 mm) skive.

4. BETJENING

VÆR OPPMERKSOM PÅ DETTE NÅR

MASKINEN STARTES:

• Spenn fast arbeidsstykket og forsikre deg om at det

ikke kan skli fram under arbeidet.

• Hold maskinen godt fast med begge hender og innta

en trygg arbeidsstilling.

• Legg alltid ledningen bakover og bort fra maskinen.

• Maskinen må være avslått når du setter inn støpslet.

• Maskinen må være slått på når du legger an mot

arbeidsstykket.

Bruk aldri maskinen til sliping av magnesium.

INN-/UTKOPLING

• Denne maskinen har en sikkerhetsbryter.

• Start maskinen ved å trykke på knappen "slå av lås" (for å

frigjøre bryteren) og slå maskinen på.

Når apparatet har nådd det høyeste turtallet, kan

du skyve det over arbeidsstykket.

BRUK

• Hold maskinen godt fast, og beveg den mot

arbeidsstykket. Før slipeskiven jevnt over

arbeidsstykket.

• Ved fresing beveges maskinen over arbeidsstykket

med en vinkel på 30º-40º (fig. 5).

Bruk aldri slipeskiver til fresing!

• Maskinen må alltid føres i retning mot

rotasjonsretningen. Før aldri maskinen med

rotasjonsretningen! Da oppstår fare for at den

skyves ukontrollert ut av sporet (fig. 6).

• Undersøk slipeskiven regelmessig. Slitte skiver

reduserer maskinens effektivitet. Skift slipeskive i tide.

• Sett ikke fra deg maskinen mens motoren går. Sett

ikke maskinen på en støvete overflate. Støv kan

trenge inn i mekanismen.

• Slå alltid av maskinen før du trekker ut støpslet fra

stikkontakten.

Bruk aldri spindellåsen til å stoppe motoren.

Ferm 31

• Zorg bij gebruik van slijpschijven die op het

schroefdraad van de spindel worden bevestigd dat de

spindel voldoende schroefdraad heeft. Zorg dat de

spindel voldoende beschermd is en niet in contact

komt met het slijpoppervlak.

• Inspecteer de slijpschijf voor gebruik op eventuele

beschadigingen. Gebruik geen slijpschijven die

gebarsten, gescheurd of anderszins beschadigd zijn.

• Laat voor gebruik de machine 30 seconden onbelast

draaien. Schakel de machine onmiddellijk uit als deze

aanzienlijk begint te trillen of als een ander defect

optreedt. Controleer de machine en slijpschijf

grondig voordat u de machine weer inschakelt.

• Zorg dat een eventuele vonkenregen geen gevaar

voor mensen oplevert of wegspat in de richting van

licht ontvlambare substanties.

• Zorg dat het werkstuk voldoende wordt

ondersteund of ingeklemd. Houd uw handen weg van

het te slijpen oppervlak.

• Draag altijd een veiligheidsbril en

gehoorbescherming. Gebruik desgewenst of indien

nodig andere bescherming, zoals bijvoorbeeld een

schort of een helm.

• Zie erop toe dat schijven en punten overeenkomstig

de instructies van de fabrikant worden gemonteerd.

• Zorg ervoor dat het vloeipapier wordt gebruikt als

dit bij het gelaagde schuurproduct wordt geleverd, of

als dit nodig is.

• Werk nooit zonder afschermkap, als deze bij een

apparaat meegeleverd wordt.

• Bij gereedschap voor schijven met schroefboringen,

dient de schroefdraad in de schijf voldoende lengte te

hebben om de as onder te kunnen brengen.

• Zorg ervoor dat bij het werken in een stoffige

omgeving de ventilatieopeningen vrij gehouden

worden. Trek eerst de stekker uit het stopcontact

als de stof verwijderd moet worden (gebruik geen

metalen voorwerpen). Voorkom hierbij

beschadiging van inwendige delen.

• Bij een slecht spanningsnet kunnen bij het starten van

de apparatuur korte spanningsvallen optreden. Dit

kan andere apparatuur beïnvloeden (bijv. een lamp

die gaat knipperen). Bij een impedantie van het net

Zmax < 0,348 Ohm kan men ervan uitgaan, dat

dergelijke verschijnselen zich niet voor zullen doen.

(Indien nodig kunt u voor nadere informatie contact

opnemen met uw plaatselijke energieleverancier).

3. MONTAGE VAN ACCESSOIRES

Zorg ervoor dat tijdens het monteren van

accessoires de machine is losgekoppeld van de

stroombron.

MONTEREN VAN EEN SLIJPSCHIJF

Fig 2

Gebruik slijpschijven van de juiste maat. Gebruik

uitsluitend vezelversterkte slijpschijven. De slijpschijf

mag niet met de rand van de beschermkap in contact

komen.

• Druk het spindelslot (6) in en draai aan de spindel (9)

tot deze in het slot valt. Houd het spindelslot

ingedrukt zolang u deze procedure volgt.

• Verwijder de flensmoer (12) van de spindel met

behulp van de spansleutel (11).

• Plaats de slijpschijf (7) op de flens (5).

• Schroef de flensmoer weer op de spindel en draai

hem vast met behulp van de spansleutel.

• Laat het spindelslot los en controleer of de

vergrendeling is opgeheven door aan de spindel te

draaien.

MONTEREN VAN DE ZIJHANDGREEP

Fig 1

De zijhandgreep is geschikt voor zowel links- als

rechtshandige bediening.

• Draai voor linkshandige bediening de zijhandgreep in

de opname aan de rechterkant van de machine (Fig

5).

• Draai voor rechtshandige bediening de zijhandgreep

in de opname aan de linkerkant van de machine.

• Draai voor verticale werkzaamheden de

zijhandgreep in de opname aan de bovenkant van de

machine.

Zorg dat de zijhandgreep goed vast zit en niet

onverwachts kan lostrillen.

MONTEREN VAN DUNNE SLIJPSCHIJVEN EN

AFBRAAMSCHIJVEN

Afb. 3 en 4 laten zien hoe de flens (10) gemonteerd dient

te worden bij dikke (4 - 8 mm) en dunne (2,5 - 4 mm)

schijven.

4. BEDIENING

AANDACHTSPUNTEN VOOR HET

INSCHAKELEN

• Klem het werkstuk vast of zorg ervoor dat het

tijdens de werkzaamheden niet onder de machine

kan wegglijden.

• Houd het netsnoer altijd uit de buurt van bewegende

delen.

• Houd de machine los van het werkstuk wanneer u de

machine in- of uitschakelt. De slijpschijf kan het

werkstuk beschadigen.

• Laat de machine volledig op toeren komen voordat u

de machine gebruikt.

Gebruik de machine niet voor het slijpen van

magnesium werkstukken.

IN- EN UITSCHAKELEN

• De machine is uitgerust met een veiligheidsschakelaar.

• De schakelaar van de machine moet eerst worden

ontgrendeld door de “lock-off” knop in te drukken.

Laat de machine volledig op toeren komen voordat

u de machine gebruikt.

WERKEN MET DE MACHINE

• Houd de machine stevig vast en druk deze tegen het

werkstuk aan. Beweeg de slijpschijf gelijkmatig over

het werkstuk.

• Beweeg de machine tijdens het afbramen onder een

hoek van 30º - 40º over het werkstuk (fig. 5).

10 Ferm

Page 11

TALLENE I FØLGENDE TEKST VISER TIL BILDENE

PÅ SIDE 2

VINKELSLIPER

INNHOLD:

1. Maskinopplysninger

2. Sikkerhetsinstruksjoner

3. Montering

4. Betjening

5. Service og vedlikehold

1. MASKINOPPLYSNINGER

INNLEDNING

Denne maskinen er beregnet for sliping og fresing av

metall og stein.

PAKKENS INNHOLD

1 Vinkelsliper

1 Sidehåndtak

1 Spennøkkel

2 Slipehjul for skjæring

1 Ett sett kullbørster

1 Bruksanvisning

1 Sikkerhetsinstruksjoner

1 Garantikort

TEKNISKE SPESIFIKASJONER

FUNKSJONER

Fig. 1

1. på-/av-bryter

2. skrudeksel for kullbørster (på begge sider)

3. spindellås

4 slipeskive

5. sidehåndtak

6. “slå av lås” bryter

2. SIKKERHETSINSTRUKSJONER

FORKLARING AV SYMBOLENE

Disse symbolene brukes i denne bruksanvisningen eller

på maskinen:

I overensstemmelse med viktige, aktuelle

sikkerhetsstandarder i EU

Class II-maskin – Dobbeltisolert – Krever ikke

jordet støpsel.

Angir fare for personskade, livsfare eller skade på

maskinen hvis instruksjonene i denne

bruksanvisningen ikke følges.

Fare for elektrisk støt.

Brannfare

Hold personer unna

Trekk støpslet ut av stikkontakten

Bruk vernebriller og hørselsvern

Bruk vernehansker

Les instruksjonene nøye

Defekte og/eller kasserte elektriske eller

elektroniske apparater må avhendes ved egnete

returpunkter.

SIKKERHETSFORSKRIFTER

Overhold ved bruk av elektriske maskiner alltid de

lokale sikkerhetsforskriftene. Dette for å unngå

brannfare, fare for elektrisk støt og personskade.

Les i tillegg til nedenstående instrukser også

sikkerhetsforskriftene i det vedlagte separate

sikkerhetsheftet. Ta godt vare på instruksene!

• Kontroller om det maksimale turtallet, som er angitt

på slipeskiva, stemmer overens med maskinens

maksimale turtall. Maskinens turtall må ikke

overstige slipeskivas maksimale turtall.

• Pass på at slipeskivas dimensjoner stemmer overens

med maskinens spesifikasjoner.

• Pass på at slipeskiva er montert korrekt og at den er

festet skikkelig. Bruk aldri noen form for foringer

eller adaptere for å få ei slipeskive til å passe.

• Slipeskivene må behandles og oppbevares ifølge

leverandørens egne forskrifter.

• Ikke bruk maskinen til å kappe arbeidsstykker som er

tykkere enn kappeskivas maksimale slipedybde.

• Ikke bruk kappeskiver til vanlige slipeoppgaver.

• Se til at det er tilstrekkelig med gjenger på spindelen

når du bruker slipeskiver som festes ved å skrus inn

på spindelgjengene. Pass på at spindelen er

tilstrekkelig beskyttet og ikke kan komme i kontakt

med slipeflaten.

• Kontroller slipeskivene for eventuelle skader før

bruk. Ikke bruk slipeskiver som er sprukket,

opprevet eller skadet på annen måte.

Spenning | 230 V~

Frekvens | 50 Hz

Opptatt effekt | 2000 W

Turtall, ubelastet | 6000/minutt

Skivediameter | 230 mm

Spindelstørrelse | M 14

Vekt | 4,9 kg

Lpa (lydtrykk) | 97,9 dB (A)

Lwa (lydeffekt) | 110,9 dB (A)

Vibrasjonsverdi | 3,2 m/s

2

30 Ferm

Gebruik nooit doorslijpschijven voor

afbraamwerkzaamheden!

• Belangrijk is de richting van de

doorslijpwerkzaamheden. De machine moet altijd

tegenlopend werken. Beweeg de machine daarom

niet in de andere richting. Anders bestaat het gevaar

dat de machine ongecontroleerd uit de snede wordt

geduwd (fig.6).

• Inspecteer regelmatig de slijpschijf. Versleten

slijpschijven hebben een negatief effect op de

efficiency van de machine. Vervang de slijpschijf op

tijd.

• Leg de machine pas neer wanneer de motor volledig

is uitgedraaid. Leg de machine niet weg op een

stoffige ondergrond. Stofdeeltjes kunnen het

mechaniek binnendringen.

• Schakel na beëindiging van de werkzaamheden altijd

eerst de machine uit voordat u de stekker uit het

stopcontact trekt.

Gebruik nooit het spindelslot om de motor tot

stilstand te brengen.

STORINGEN

1. De motor slaat niet aan

• De stekker zit niet in het stopcontact.

• Het snoer is onderbroken.

2. De elektromotor bereikt moeilijk het

maximum toerental

• De verlengkabel is te dun en/of te lang

• De netspanning is lager dan 230 V

3. De machine wordt overmatig warm

• De ventilatiesleuven zijn verstopt. Maak ze schoon

met een droge doek.

• De machine wordt te zwaar belast. Gebruik de

machine waarvoor hij geschikt is.

4. Overmatig vonken of onregelmatig lopen van

de elektromotor.

• Dit duidt meestal op aanwezigheid van vuil in de

motor of op versleten koolborstels

• Vervang de koolborstels of bied de machine aan bij

uw Ferm-dealer.

5. SERVICE & ONDERHOUD

ONDERHOUD

Zorg er altijd eerst voor dat de stekker uit het

stopcontact is verwijderd, voordat u met de

onderhoudswerkzaamheden begint.

De machines van Ferm zijn ontworpen om gedurende

lange tijd probleemloos te functioneren met een

minimum aan onderhoud. Door de machine regelmatig

te reinigen en op de juiste wijze te behandelen, draagt u

bij aan een lange levensduur van uw machine.

REINIGEN

Reinig de machinebehuizing regelmatig met een zachte

doek, bij voorkeur iedere keer na gebruik. Gebruik bij

hardnekkig vuil een zachte doek bevochtigd met

zeepwater. Gebruik geen oplosmiddelen als benzine,

alcohol, ammonia, etc. Dergelijke stoffen beschadigen

de kunststof onderdelen.

SMEREN

De machine heeft geen extra smering nodig.

STORINGEN

Wanneer er zich een storing voordoet, bijvoorbeeld bij

slijtage van een onderdeel, neem dan contact op met het

onderhoudsadres op de garantiekaart. Achter in deze

handleiding ziet u een opengewerkte afbeelding van de

onderdelen die besteld kunnen worden.

MILIEU

Om transportbeschadiging te voorkomen, wordt de

machine in een stevige verpakking geleverd. De

verpakking is zo veel mogelijk gemaakt van recyclebaar

materiaal. Maak daarom gebruik van de mogelijkheid om

de verpakking te recyclen.

Defecte en/of afgedankte elektrische of

elektronische gereedschappen dienen ter

verwerking te worden aangeboden aan een daarvoor

verantwoordelijke instantie.

GARANTIE

Lees voor de garantievoorwaarden de garantiekaart

achter in deze gebruiksaanwijzing.

Wij verklaren dat dit product

voldoet aan de volgende

normen of normatieve documenten

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

overeenkomstig de bepalingen in de richtlijnen

98/37/EEG, 73/23/EEG

89/336/EEG

van 01-06-2005

ZWOLLE NL

W. Kamphof

Quality department

CE

ı

CONFORMITEITSVERKLARING

(NL)

Ferm 11

Page 12

• Kytke virta ensin koneesta pois, ennen kuin irrotat

pistokkeen pistorasiasta.

Älä koskaan pysäytä moottoria karalukon avulla.

VIANETSINTÄ

1. Kone ei toimi:

• Virtaa ei ole kytketty

• (Jatko-) johto on vaurioitunut

2. Moottori ei saavuta täyttä kierrosnopeutta:

• Jatkojohto on liian ohut/pitkä

• Verkkojännite on alle 230 V

3. Kone kuumenee liikaa:

• Tuuletusaukot ovat tukossa. Puhdista aukot kuivalla

kankaalla.

• Moottori on ylikuormittunut. Käytä konetta vain sen

käyttötarkoituksiin.

4. Moottori kipinöi tai käy epätasaisesti.

• Moottori on likaantunut tai hiiliharjat ovat kuluneet.

Vaihda hiiliharjat tai vie kone huoltoon.

5. KUNNOSSAPITO JA

KORJAUKSET

KUNNOSSAPITO

Kun huollat moottoria, varmista että pistotulppa on

irrotettu pistorasiasta.

Ferm-laitteet on suunniteltu toimimaan pitkän aikaa

mahdollisimman vähällä huollolla. Jotta laite toimisi

jatkuvasti hyvin, sitä on hoidettava hyvin ja se on

puhdistettava säännöllisesti.

PUHDISTUS

Pyyhi laitteen ulkopinta säännöllisesti, mieluiten joka

käyttökerran jälkeen, pehmeällä liinalla. Pidä

ilmanvaihtoaukot pölyttöminä ja puhtaina. Jos lika ei

irtoa muuten, pyyhi pehmeällä, saippuaveteen

kostutetulla liinalla. Älä käytä puhdistukseen bensiiniä,

alkoholia, ammoniakkia tai muita liuotteita. Ne voivat

vahingoittaa muoviosia.

VOITELU

Laite ei tarvitse lisävoitelua.

VIAT

Jos kone vikaantuu esimerkiksi osan kulumisen johdosta,

ota yhteys takuukortin huoltopisteeseen. Tämän

käyttöoppaan takasivulla on hajotuskuva, jossa on

lueteltu tilattavissa olevat osat.

YMPÄRISTÖ

Kuljetusvaurioiden välttämiseksi kone on pakattu

tukevaan laatikkoon. Tämä pakkaus on mahdollisimman

ympäristöystävällinen. Kierrätä se.

Vioittuneet tai käytöstä poistettavat sähkölaitteet

on toimitettava asianmukaiseen

kierrätyspisteeseen.

TAKUU

Takuuehdot ilmenevät erillisestä takuukortista, joka

toimitetaan laitteen mukana.

Vakuutamme omalla vastuullamme, että tämä tuote on

seuraavien standardien tai standardoitujen

dokumenttien mukainen.

EN 50144-1, EN50144-2-3,

EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

määräysten mukainen.

98/37/EEC, 73/23/EEC,

89/336/EEC

Voimassa 01-06-2005

ZWOLLE NL

W. Kamphof

Laadunvalvontaosasto

CE

ı

TODISTUS STANDARDINMUKAISUUDESTA

(SF)

Ferm 29

LES CHIFFRES DU TEXTE SUIVANT

CORRESPONDENT AUX ILLUSTRATIONS PAGE 2

MEULEUSE D’ANGLE

TABLE DES MATIERES :

1. Spécifications de la machine

2. Consignes de sécurité

3. Montage

4. Utilisation

5. Service & maintenance

1. SPECIFICATIONS DE LA

MACHINE

INTRODUCTION

Cette machine est destinée au meulage et dégrossissage

de métaux et pierres.

CONTENU DE L’EMBALLAGE

1 Meuleuse d’angle

1 Poignée latérale

1 Clé de serrage

2 Meules à tronçonner

1 Paire de balais en carbone

1 Manuel d’instructions

1 Consignes de sécurité

1 Carte de garantie

SPÉCIFICATIONS TECHNIQUES

CARACTÉRISTIQUES

Image 1

1. bouton marche/arrêt

2. couvercle à vis des charbons (des deux côtés)

3. dispositif de blocage de l’arbre

4. meule

5. poignée latérale

6. bouton “lock-off”

2. CONSIGNES DE SECURITE

EXPLICATION DES SYMBOLES

Les symboles suivants sont utilisés dans ce mode

d’emploi et/ou sur la machine :

CE Conformément aux normes Européennes

applicables relatives à la sécurité

Machine de la classe II – Double isolation – vous

n’avez pas besoin d’une prise avec mise à terre.

Indique un risque de blessures, un danger mortel

ou un risque d’endommagement de l’outil en cas

du non-respect des consignes de ce mode d’emploi.

Indique un risque de décharges électriques

Risque d’incendie

Gardez des tiers à distance

Retirez la fiche mâle du secteur

Portez des lunettes de sécurité et des protège-ouïe

Portez des gants de protection

Lisez attentivement les instructions

Tout équipement électronique ou électrique

défectueux dont vous vous seriez débarrassé doit

être déposé aux points de recyclage appropriés.

CONSIGNES DE SÉCURITÉ

Lors d’utilisation de machines électriques, observez

les consignes de sécurité locales en vigueur en

matière de risque d’incendie, de chocs électriques et

de lésion corporelle. En plus des instructions cidessous, lisez entièrement les consignes de sécurité

contenues dans le cahier de sécurité fourni à part.

Conservez soigneusement ces instructions!

• Vérifiez si la vitesse maximale mentionnée sur la

meule correspond à la vitesse maximale de la

machine. La vitesse de la machine ne doit pas

dépasser la valeur indiquée sur la meule.

• Veillez à ce que les dimensions de la meule

correspondent aux spécifications de la machine.

• Assurez-vous que la meule est correctement

montée et convenablement fixée. N’utilisez jamais

des bagues de réduction ou des adaptateurs pour

ajuster la meule.

• Manipulez et conservez les meules conformément

aux instructions du fournisseur.

• N’utilisez pas la machine pour tronçonner des pièces

dont l’épaisseur est supérieure à la profondeur de

meulage maximale du disque de tronçonnage.

• N’utilisez pas de disques de tronçonnage pour des

travaux d’ébarbage.

Tension | 230 V~

Fréquence | 50 Hz

Courant d’alimentation | 2000 W

Régime à vide | 6000/min

Diamètre de la meule | 230 mm

Dimension de l’arbre | M 14

Poids | 4,9 kg

Niveau de pression acoustique | 97,9 dB(A)

Niveau de puissance acoustique | 110,9 dB(A)

Valeur des vibrations | 3,2 m/s

2

12 Ferm

Page 13

Älä käytä murtuneita, revenneitä tai muutoin

vahingoittuneita hiomalaikkoja.

• Käytä konetta kuormittamattomana 30 sekuntia

ennen sen käyttöönottoa. Katkaise koneen virta

välittömästi, jos se alkaa täristä huomattavasti, tai jos

siinä ilmenee jokin muu vika. Tarkasta kone ja

hiomalaikka huolellisesti ennen kuin käynnistät

koneen uudelleen.

• Varmista, ettei mahdollinen kipinöinti aiheuta

henkilövahinkoja tai roisku helposti syttyviä aineita

kohti.

• Varmista, että työstettävä kappale on riittävästi

tuettuna tai puristettuna. Pidä kädet loitolla

hiottavasta pinnasta.

• Käytä aina suojalaseja ja kuulosuojaimia. Käytä

halutessasi tai tarvittaessa myös muita

suojavarusteita, esimerkiksi esiliinaa tai kypärää.

• Varmista, että pyörät ja terät on kiinnitetty

valmistajan ohjeiden mukaisesti.

• Varmista, että hiovan tuotteen kanssa mahdollisesti

toimitetut välilevyt ovat tarvittaessa käytössä.

• Jos työkalun mukana on toimitettu suojus, älä käytä

laitetta ilman suojusta.

• Jos työkalu on tarkoitettu kiinnitettäväksi pyörään,

jossa on kierteitetty reikä, varmista, että pyörän

kierre on riittävän pitkä karan pituuteen nähden.

• Varmista, että ilma-aukot pysyvät puhtaina, kun

työskentelet pölyisissä tiloissa. Jos pölyn

poistaminen on tarpeen, irrota työkalu ensin

verkkovirrasta (älä käytä tähän metallisia välineitä)

äläkä vahingoita laitteen sisäosia.

• Sähköverkon heikko kunto voi aiheuttaa jännitteen

lyhytaikaisen alenemisen laitteen

käynnistysvaiheessa. Tämä voi vaikuttaa muihin

laitteisiin (esimerkiksi valaisimen lamppu voi vilkkua).

Jos sähköverkon impedanssi Zmax <0.348 ohmia,

häiriöitä ei todennäköisesti esiinny. (Pyydä

tarvittaessa lisätietoja paikalliselta sähkölaitokselta.)

3. ASENNUS

Irrota pistoke aina ensin pisrasiasta ennen

lisälaitteiden kiinnitystä.

SIVUKAHVAN KIINNITTÄMINEN

Kuva 2

Käytä oikeankokoisia hiomalaikkoja. Käytä ainoastaan

kuituvahvisteisia hiomalaikkoja. Hiomalaik•ka ei saa

koskettaa teräsuojuksen reunaa.

• Paina karalukko (6) sisään ja kierrä karaa (9), kunnes

se putoaa lukkoon. Pidä karalukkoa koko ajan

painettuna.

• Irrota karan laippamutteri (12) kiristysavaimen (11)

avulla.

• Aseta hiomalaikka (7) laipan (5) päälle.

• Kierrä laippamutteri takaisin karaan ja kiristä se

kiristysavaimen avulla.

• Päästä karalukko auki ja tarkista, että lukitus on auki

kääntämällä karaa.

SIVUKAHVAN ASENTAMINEN

Kuva 1

Sivukahva on tarkoitettu sekä oikea- että vasenkätiseen

käyttöön.

• Vasenkätistä käyttöä varten kierrä sivukahva (Kuva

5) koneen oikeassa reunassa olevaan aukkoon.

• Oikeakätistä käyttöä varten kierrä sivukahva koneen

vasemmassa reunassa olevaan aukkoon.

• Pystysuorissa töissä kierrä sivukahva koneen

yläpuolella olevaan tilaan.

Varmista että sivukahva on kunnolla kiinni ja ettei

se voi irrota vahingossa.

HIOMA- JA ROUHINTALAIKKOJEN

KIINNITYS

Kuvissa 3 ja 4 esitetään, kuinka laippa(10) kiinnitetään

käytettäessä paksuja (4 – 8 mm) ja ohuita (2,5 – 4 mm)

laikkoja.

4. KÄYTTÖ

KONEEN KÄYNNISTYKSESSÄ

HUOMIOITAVAA

• Purista työstettävä kappale kiinni ja varmista, ettei

kappale pääse liikkumaan työstämisen aikana.

• Pidä koneesta tukevasti kiinni molemmin käsin

vakaassa asennossa.

• Varmista, että sähköjohto on aina poispäin koneesta.

• Kytke pistoke pistorasiaan vain, kun koneessa ei ole

virtaa kytkettynä.

• Paina kone työstettävää kappaletta vasten vasta sen

jälkeen kun kone on käynnissä

Älä käytä hiomakonetta magnesiumia sisältävien

kappaleiden hiomiseen.

KÄYNNISTYS JA SAMMUTTAMINEN

• Tämä kone on varustettu turvakytkimellä.

• Käynnistä kone painamalla "lock off"-painiketta (kytkimen

vapauttamiseksi) ja kytkemällä koneeseen virta.

Odota, kunnes laite saavuttaa täyden

pyörimisnopeutensa ja työnnä johto eteenpäin.

TOIMINTA

• Pidä koneesta tukevasti kiinni ja paina sitä

työstettävää kappaletta vasten. Liikuta hiomalaikkaa

tasaisesti työstettävän kappaleen pinnalla.

• Liikuta konetta karhennettaessa noin 30 - 40º

kulmassa työstettävään kappaleeseen nähden (kuva

5).

Älä käytä hiontalaikkaa rouhintaan.

• Liikuta konetta aina pyörimissuuntaa vastaan. Älä

koskaan liikuta konetta toiseen suuntaan. Muutoin

vaarana on, että kone ryntää hallitsemattomasti

leikkuukohdasta (kuva 6).

• Tarkasta säännöllisesti hiomalaikan kunto. Kuluneet

laikat heikentävät koneen tehokkuutta. Vaihda

kulunut laikka ajoissa.

• Laske kulmahiomakone käsistäsi vasta, kun moottori

on pysähtynyt kokonaan. Älä laske konetta pölyiselle

alustalle. Pölyhiukkaset voivat päästä koneen

mekaanisiin osiin.

28 Ferm

• En cas d’usage de meules fixées sur le filetage de

l’arbre, veillez à ce que cet arbre ait d’un filet

suffisant. Assurez-vous que l’arbre est suffisamment

protégé et ne vient pas au contact de la surface à

meuler.

• Avant de l’utiliser, examiner la meule quant à la

présence d’éventuels endommagements. N’utilisez

pas de meules fendues, fissurées ou autrement

endommagées.

• Avant d’utiliser la machine, faites la tourner à vide

pendant 30 secondes. Éteignez immédiatement la

machine si elle se met à vibrer beaucoup ou si un

autre défaut apparaît. Vérifiez soigneusement l’état

de la machine et de la meule avant de rallumer la

machine.

• Assurez-vous qu’une éventuelle gerbe d’étincelles

ne présente aucun danger pour les personnes ni

qu’elle saute en direction de matières hautement

inflammables.

• Veillez à ce que la pièce à ouvrer est suffisamment

soutenue ou bloquée. Tenez vos mains éloignées de

la surface à meuler.

• Portez toujours des lunettes de sécurité et un

système de protection auditive. Utilisez si vous le

désirez, ou si c’est nécessaire, un autre moyen de

protection comme un tablier ou un casque par

exemple.

• Assurez-vous que les disques et les parties actives

sont montés conformément aux instructions du

fabricant.

• Veillez à utiliser les buvards livrés avec les parties

abrasives, le cas échéant.

• Si une garde de protection est livrée avec l’appareil,

utilisez-la systématiquement.

• Pour les outils à visser sur le disque, assurez-vous

que la profondeur du pas de vis du disque et la

longueur de la broche sont identiques.

• Lorsque l’appareil dégage de la poussière au cours de

son utilisation, assurez-vous que les trous d’aération

ne sont pas obturés. Pour les dépoussiérer,

débranchez d’abord l’appareil du secteur, nettoyezle à l’aide d’un objet non métallique en prenant garde

de ne pas endommager les pièces situées à

l’intérieur.

• Selon l’état de votre installation électrique, de brèves

baisses de tension électrique peuvent se produire

lors de la mise en marche de l’appareil. Elles peuvent

se manifester sur d’autres appareils électriques (ex. :

clignotement d’une ampoule). Ces baisses de tension

seront évitées, si le Zmax du rapport installation

électrique/impédance est inférieur à 0,348 ohm.

(pour de plus amples informations, veuillez vous

adresser à votre agence EDF locale).

3. MONTAGE

Débranchez toujours l’outil avant d’assembler un

accessoire.

MONTAGE DE LA POIGNÉE LATÉRALE

Image 2

Employez des meules de dimension correcte. Utilisez

exclusivement des meules armées de fibres. La meule ne

doit pas venir au contact du bord du carter de protection.

• Enfoncez le dispositif de blocage de l’arbre (6) et

tournez l’arbre (9) jusqu’à ce qu’il tombe dans le

dispositif de blocage. Maintenez le dispositif de

blocage de l’arbre enfoncé aussi longtemps que vous

suivez cette procédure.

• Retirez l’écrou de bride (12) de l’arbre à l’aide de la

clé de serrage (11).

• Placez la meule (7) sur la bride (5).

• Revissez l’écrou de bride sur l’arbre puis serrez-le à

l’aide de la clé de serrage.

• Détachez le dispositif de blocage de l’arbre et vérifiez

si le verrouillage est supprimé en serrant l’arbre.

MONTAGE DE LA POIGNÉE LATÉRALE

Image 1

La poignée latérale est appropriée pour être utilisée

aussi bien de la main gauche que de la main droite.

• Pour l’utilisation avec la main gauche, tournez la

poignée latérale (Fig. 5) dans le dispositif de prise

situé à droite de la machine.

• Pour l’utilisation avec la main droite, tournez la

poignée latérale dans le dispositif de prise situé à

gauche de la machine.

• Pour les travaux en verticale, tournez la poignée

latérale dans le dispositif de prise en haut de la

machine.

Veillez à ce que la poignée latérale soit bien fixée et

ne puisse pas se détacher subitement l’effet des

vibrations.

ASSEMBLAGE DES DISQUES DE MEULAGE

ET DÉGROSSISSAGE

Les images 3 et 4 montrent l’assemblage de la bride (10) à

l’aide de disques épais (4 – 8 mm) et mince (2,5 – 4 mm).

4. UTILISATION

VIGILANCE PARTICULIÈRE EN

DÉMARRANT LA MACHINE

• Fixez la pièce à façonner au moyen d’un étau de sorte

qu’elle ne puisse pas glisser de la position sous la

machine durant le travail.

• Tenez toujours la machine fermement avec les deux

mains en travaillant et mettez-vous en position

stable.

• Le câble doit toujours être orienté vers l’arrière, en

partant de la machine.

• Insérez la fiche mâle dans la prise du secteur

uniquement avec la machine hors tension.

• Mettez la machine en marche avant de l’appliquer sur

la pièce à façonner .

N’utilisez point la machine pour meuler des pièces

en aluminium.

MISE EN MARCHE ET ARRÊT

• Prenez soin que la meuleuse angulaire soit toujours en

ralenti (sans charge) si vous branchez ou coupez.

• Avant de mettre en marche la machine, appuyez sur la

touche "débloquer" (pour le déblocage de l'interrupteur)

et branchez la machine.

Ferm 13

Page 14

SEURAAVAN TEKSTIN NUMEROT VASTAAVAT

SIVULLA 2 OLEVIEN KUVIEN NUMEROITA

KULMAHIOMAKONE

SISÄLTÖ:

1. Koneen tiedot

2. Turvaohjeet

3. Asennus

4. Käyttö

5. Huoltotoimet

1. KONEEN TIEDOT

JOHDANTO

Tämä kone on tarkoitettu metallin ja kiven hiontaan ja

rouhintaan.

PAKKAUKSEN SISÄLTÖ

1 Kulmahiomakone

1 Sivukahva

1 Kiintoavain

2 Katkaisulaikat

1 Hiiliharjasarja

1 Käyttöopas

1 Turvaohjeet

1 Takuukortti

TEKNISET TIEDOT

VARUSTEET

Kuva 1

1. virtakytkin

2. hiiliharjan kierrekansi (molemmilla puolilla)

3. karalukko

4. hiomalaikka

5. sivukahva

6. “lock off"-painiketta

2. TURVAOHJEET

SYMBOLIEN SELITYKSET

Tässä käyttöoppaassa ja koneessa käytetään seuraavia

symboleita:

Soveltuvien EU-direktiivien

turvallisuusstandardien mukainen

Luokan II kone – kaksoiseristetty – maadoitettua

pistorasiaa ei tarvita.

Osoittaa loukkaantumisvaaran, hengenvaaran tai

työkalun vaurioitumisriskin, jos tämän oppaan

ohjeita ei noudateta.