Page 1

Installation guide / Montageanleitung / Инструкции по монтажу

N105/R09/(22.01.15)

FLOOR HEATING FILM

FUSSBODENFOLIE

Пленка для теплого пола

Page 2

2 3

Page 3

ECOFILM SET – Floor Heating Film

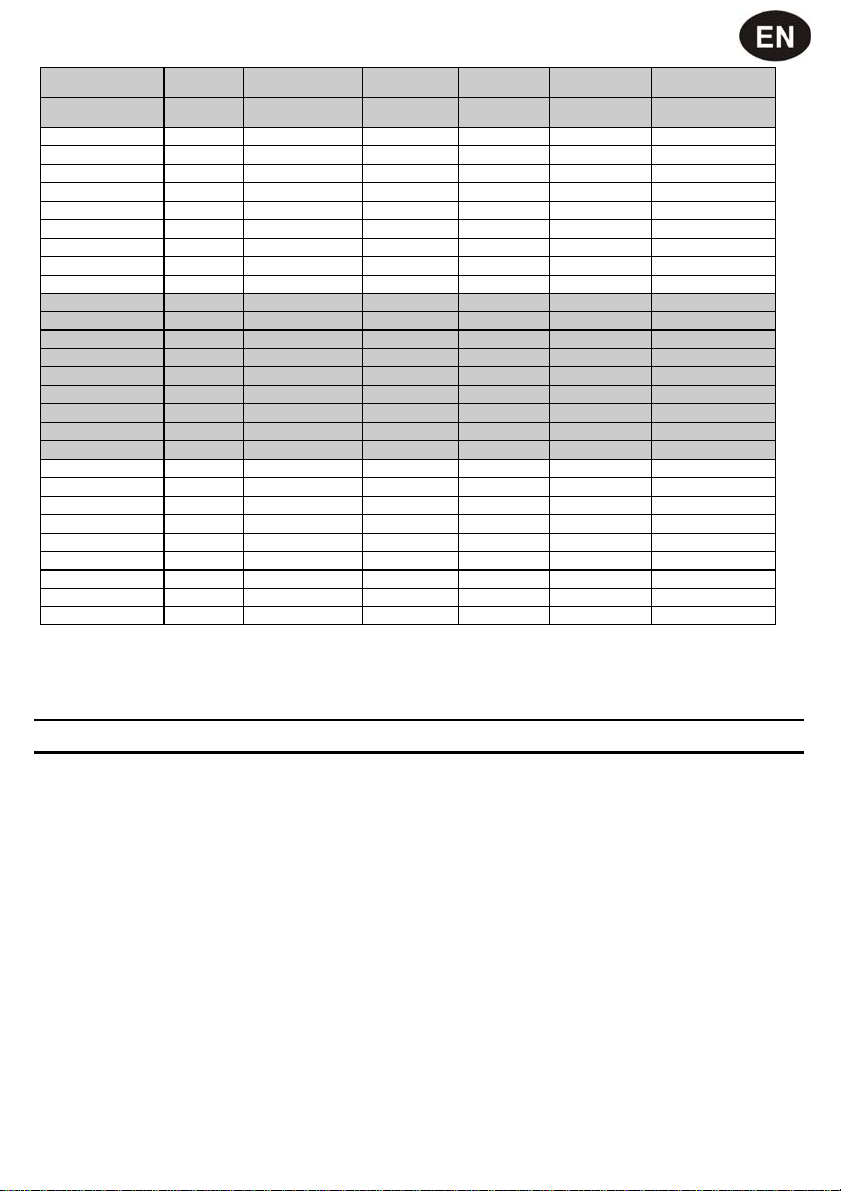

ECOFILM SET Total output Length of film strip Resistance Total film width Active heating film

TYPE [W] [m] [Ω] [m] width [m]

Eset 60 - 0,6x1,5m/ 50W 50 1,5 1058 0,6 0,55

Eset 60 - 0,6x2m / 66W 66 2 801,5 0,6 0,55

Eset 60 - 0,6x2,5m/ 83W 83 2,5 637,3 0,6 0,55

Eset 60 - 0,6x3m/ 99W 99 3 534,3 0,6 0,55

Eset 60 - 0,6x4m/ 132W 132 4 400,8 0,6 0,55

Eset 60 - 0,6x5m/ 165W 165 5 320,6 0,6 0,55

Eset 60 - 0,6x6m/ 198W 198 6 267,2 0,6 0,55

Eset 60 - 0,6x8m/ 264W 264 8 200,4 0,6 0,55

Eset 60 - 0,6x10m/330W 330 10 160,3 0,6 0,55

Eset 80 - 0,6x1,5m/ 66W 66 1,5 801,5 0,6 0,55

Eset 80 - 0,6x2m/ 88W 88 2 601,1 0,6 0,55

Eset 80 - 0,6x2,5m/ 110W 110 2,5 480,9 0,6 0,55

Eset 80 - 0,6x3m/ 132W 132 3 400,8 0,6 0,55

Eset 80 - 0,6x4m/ 176W 176 4 300,6 0,6 0,55

Eset 80 - 0,6x5m/ 220W 220 5 240,5 0,6 0,55

Eset 80 - 0,6x6m/ 264W 264 6 200,4 0,6 0,55

Eset 80 - 0,6x8m/ 352W 352 8 150,3 0,6 0,55

Eset 80 - 0,6x10m/ 440W 440 10 120,2 0,6 0,55

Eset 80 - 1,0x1,5m/ 117W 117 1,5 452,1 1 0,97

Eset 80 - 1,0x2m/ 156W 156 2 339,1 1 0,97

Eset 80 - 1,0x2,5m/ 195W 195 2,5 271,3 1 0,97

Eset 80 - 1,0x3m/ 234W 234 3 226,1 1 0,97

Eset 80 - 1,0x4m/ 312W 312 4 169,6 1 0,97

Eset 80 - 1,0x5m/ 390W 390 5 135,6 1 0,97

Eset 80 - 1,0x6m/ 468W 468 6 113 1 0,97

Eset 80 - 1,0x8m/ 624W 624 8 84,8 1 0,97

Eset 80 - 1,0x10m/ 780W 780 10 67,8 1 0,97

• The heating film includes two SK AV connecting cables 1.5 mm

• 230 Volts

1. Installation Conditions

Supply density

[W/m2]

60

60

60

60

60

60

60

60

60

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

2

, 5 m long

• Other use of the heating foil or other placement of the heating foil

than is mentioned in these instructions can be hazardous to health

and life or can cause material damage. Warranty conditions do not

apply to such use.

• The heating foil is designed for dry- process laying; it isn’t glued but

it must be fixed to prevent moving/slipping beyond the nonheating

edges.

• The heating film must not be installed on irregular surfaces. The

heating film must be protected against damage during installation

(e.g. damage of insulation with sharp objects, walking in unsuitable

footwear etc.). It is only possible to walk in shoes with a soft sole on

the heating film placed on a flat and smooth surface.

Page 4

• The installation (turning off, control) must enable electrical discon-

nection of the heating film in all poles. The minimum distance of disconnected contacts must be 3 mm. Supply circuits must be always

fitted with a protective switch with actuating current ≤30 mA.

• Heating foils musn’t be laid in layers, overlap each other or touch

other parts at any other location than at the non- heating edges.

The non- heating edges may overlap. Heating films must always be

secured against shifting.

• Lower and upper surfaces of the heating films are not distinguished,

but it is convenient to lay a wider part of their connection points

(plastic covers) downwards.

• Water insulation preventing water (humidity) penetration under the

heating film must be made under the floor construction—we recommend to lay water insulation in two mutually perpendicular layers

with joint overlaps.

• Heating films musn’t be installed at a temperature of lower than 3 °

C and they musn’t be exposed to temperatures of higher than 80 °C

on a long- term basis. The minimum bend radius of the heating foil

is 35mm and creasing must be prevented.

• Do not lay the heating film under fixtures and objects impeding heat

removal (e.g. furniture).

• Heating films mustn’t be covered on a long- term basis by a floor

covering or other objects of which the thermal resistance (R) is

higher than 0.15 m

• Lay moisture stop of PE foil min 0.2 mm thick on the heating film

2

K/W.

with min. 5 cm overlaps to protect the heating film against wetness.

• Heating foils must not be installed in close proximity to aluminium

foils, foils containing metals or on constructions with high humidity.

• Eset is not to be installed in rooms with higher humidity (bathrooms,

laundry rooms etc.)

• The supplier must inform other suppliers, owners and if possible,

also the user that no penetrating objects, such as e.g. nails, screws

or drills must be used in the area where heating foils are installed.

• A sheet of paper with information about the heating system must be

permanently kept in the switch box of the heating system and

passed on to any new owner or tenant.

• Heating foils are intended for glued laminate and wooden floors that

are fitted with lining strips around their perimeter to prevent unqualified disassembly of the floor covering.

4

Page 5

• The heating foil is manufactured according to the requirements of

the standard EN 60335-2-96 and it must be installed according to

the valid National Standards.

• The EN 50559 standards requirements must be met. El. installation

must be in accordance with national regulations.

• The covering of Ecofilm heating foil with 0.1 mm-thick polyester foil

or 0.2 mm polyethylene foil fulfils the requirements of the EN 603351 standard for class II structures, and the EN 60335-2-96 standard

for the installation of heating units in the floor or ceiling.

• The user must be instructed by the supplier regarding the installa-

tion of floor heating.

This fact is stated on a label which comes with the product and

must be glued into the switchboard: this label also informs readers

that the making of openings is prohibited, as is covering the floor

with furnishings or fittings without leaving at least a 4 cm gap between the floor and the bottom surface.

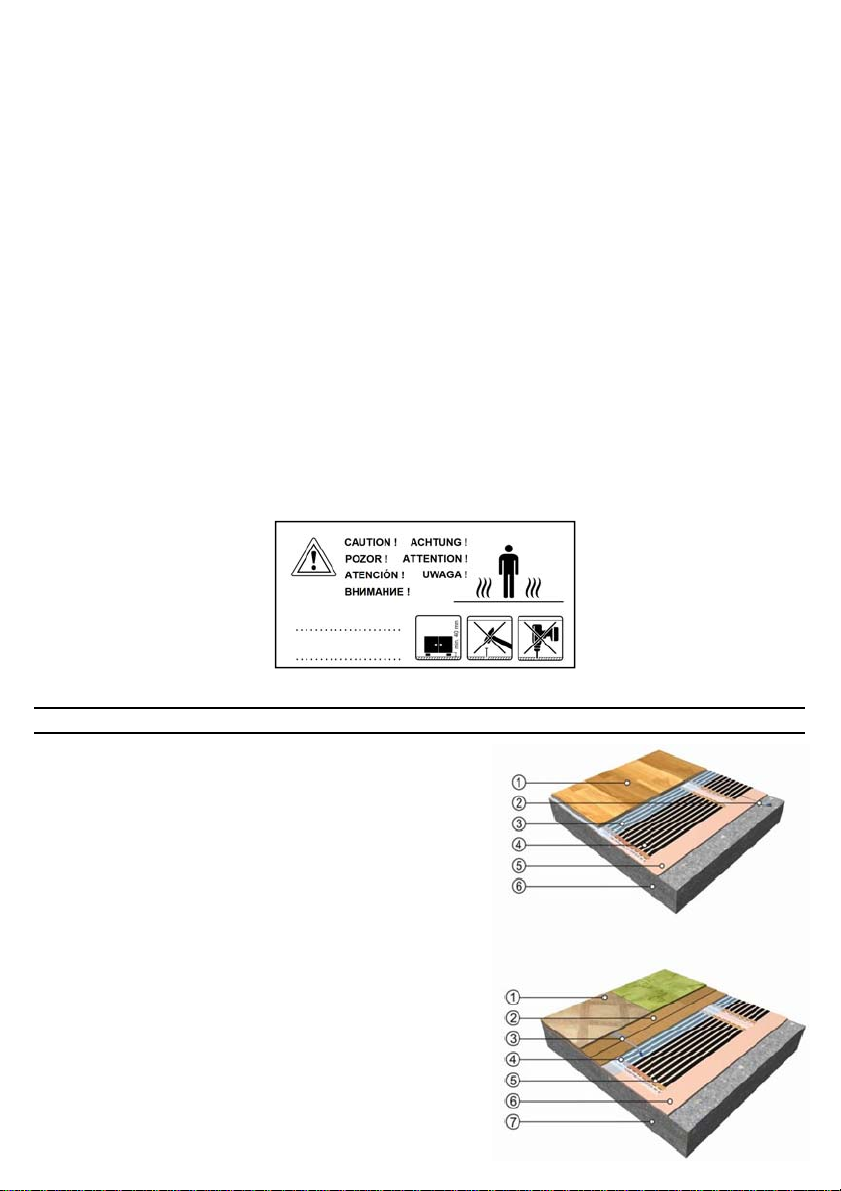

2. Floor Section – Direct Heating System

I. FLOATING FLOOR

BASE – CONCRETE, CETRIS ETC.

1 - three-layer wooden or laminate floating floor

2 - floor (limitation) probe in a groove

3 - PE foil covering, min. 0.2 mm thick

4 - ECOFILM® floor heating foil

5 - insulation underlay from extruded polystyrene

6 - base – concrete, anhydrite, original floor etc.

II. Under a carpet or PVC

1 - wear layer (PVC, carpet)

2 - HEAT-PAK 7 mm two-layer glued underlay

3 - floor (limitation) probe in the groove (embedded)

4 - PE foil covering, min. 0.2 mm thick

5 - ECOFILM® fl oor heating foil

6 - insulation underlay from extruded polystyrene

7 - base – original floor, concrete anhydrite, etc.

5

Page 6

3. Subfloor Quality

• The subfloor surface must be suitably flat, without any juts, bumps or depressions. It can be made from

concrete or other construction materials that can support sufficient loads.

• The subfloor humidity must not exceed 2% (approx. 60% relative humidity). If moisture can penetrate the

subfloor, you must, before you start your work, insulate the subfloor against moisture well.

4. How to Prepare the Heating Film

• Cut the heating film with scissors, if necessary, to the required length in the marked cutting place - cut the

film in the centre of a cutting strip!!

• Insulate uncovered edges of copper tapes with insulating stickers included in the set (or with a suitable

insulating tape in case you lose the stickers).

• The integrity of the heating film cannot be disturbed in any way (hole etc.).

• Nails, clips and other fixtures may only go through the film on longitudinal sides, at least 11 mm from live

parts of the film (copper bus). Should it be necessary to cut off the longitudinal edges, the minimum distance of 11 mm must be also observed.

5. How to Lay and Connect the Heating Film

• Before laying the heating film, lay out a damping layer (Starlon).

• In the places where you expect to place connection points (plastic covers) and in the places where con-

ductors lead to the connection box, you need to make a groove for sinking them into the subfloor or the

damping layer (connection points—wider parts of covers face downwards).

• Never lay the strips of the heating film in such a way that heating surfaces overlap. You can fix the strips in

place using an adhesive tape. Never lay the heating film across expansion joints or under fixed room furnishings. It is prohibited to step on the heating film without a suitable subfloor or in an unsuitable footwear.

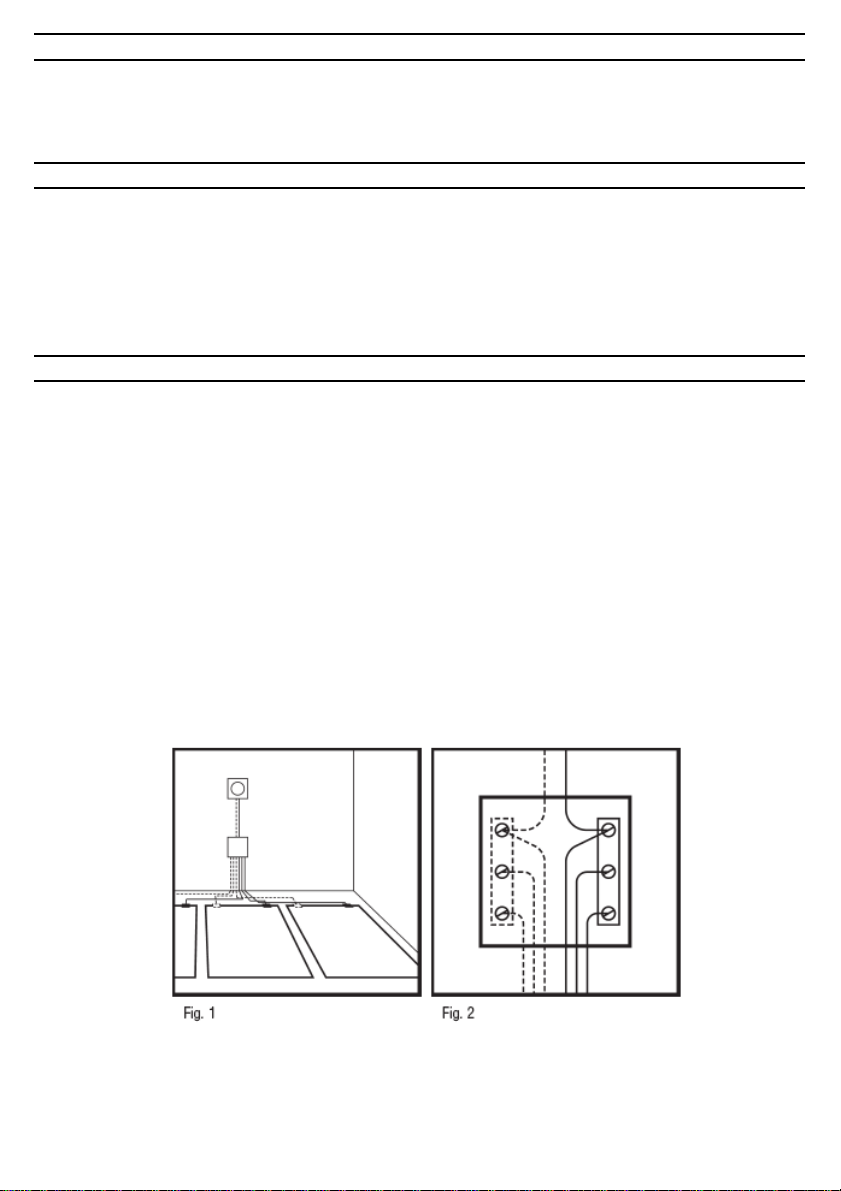

• Connect conductors to a connection box (see fig. 1 and 2) or directly to a thermostat.

• Once you have laid all strips, check the resistance of individual strips with an ohmmeter (before laying a

floor covering) and verify the values according to the table on the introductory page—a deviation must be

within +5% to –10% (in case of cutting the film, the values must be recalculated). Enter the measured data

in the Warranty Certificate. Draw the position of individual strips, conductors and connection points in the

Warranty Certificate as well.

• Lay out the PE foil at least 0.2 mm thick upon the whole floor surface. The individual strips must overlap by

at least 5 cm. Pull the overlaps up along the circumferential walls, connect with the PE foil of insulation

and place in the floor level.

6

Page 7

5.1 Connection of foil pieces within a floor

For the connection of several pieces of Ecofilm foil, 5-conductor WAGO connectors can be used. One connector can connect four heating films via one pole. You need 2 connectors for the connection of 4 pieces of

foil. If more connectors are used, connect them in series; the current passing through the connector must not

exceed 20A. The connectors are to be placed under the floor covering, into grooves which have been prepared in advance, outside the heating film.

Number of connectors for sets:

2 connectors – 2 to 4 sets

4 connectors – 5 to 7 sets

6 connectors – 8 to 10 sets

8 connectors – 11 to 13 sets

Installation procedure:

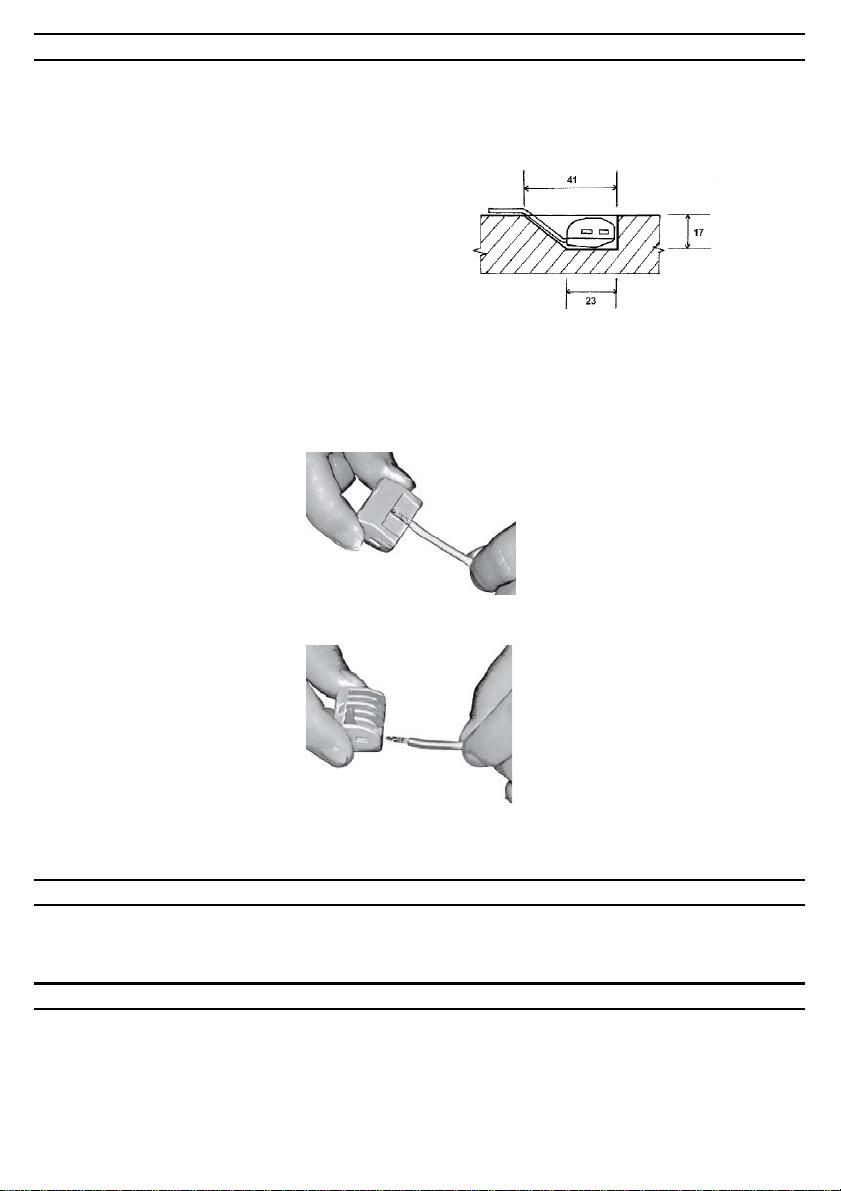

1. Lay out the heating films and stretch the conductors to the place of connection.

2. Cut out a groove in the floor as shown in the picture.

3. Remove the insulation from the conductor to a length of 9–10 mm.

4. Lift the orange lever, insert the conductors into the openings and pull the lever back again.

5. Place the connector into the groove; see the picture in point 2.

6. How to Lay a Floor Covering

• Lay a floor covering in accordance with the manufacturer's technical conditions and instructions.

7. Final Measuring

• Measure the resistance of individual circuits again and measure leakage current with an ohmmeter and

enter the data in the Warranty Certificate. The completed Warranty Certificate and this Installation Guide

must be handed over to an owner (user)!

7

Page 8

8. Start-up Operation

• The ECOFILM heating system can be started without a start-up operation in case it has not been installed

on concrete or similar construction material.

• Observe the following start-up operation when the system is installed on concrete:

DAY Setting

1. 15 °C

2. 18 °C

3.–5. 20 °C

6.–8. 25 °C

• After this start-up, switch off the heating system. When it cools down, switch on a normal operation mode.

9. Control

• Thermostats with a floor probe installed in the heating part of the floor, with at least 30 cm within the

heated area, must be used for the thermal regulation of rooms heated using heating foils.

• Place a floor probe of a thermostat as near the floor surface as possible, but right under the heating foil,

into a groove, when a laminated floor is installed.

• The radius of the bend of the conduit between the wall and the floor must be executed in such a way that

the probe can be exchanged if needed! The recommended minimum bend radius is 6 cm.

• The thermostat must be set to the mode: Room + floor temperature limit or Floor. The maximum allowed

floor temperature setting is 27°C.

10. Examples of suitable materials and floors

Examples of suitable materials and floors:

• ALLOC – Havel floating floors

• MAGNUM – www.magnumparket.cz

• Laminate floors, by Egger – http://www.egger.com,

• JUNCKERS wooden floors – HEMAX Trading s.r.o., http://www.junckers.cz

• Wooden and laminate floors – ABH design, http://www.abhdesign.cz

• Wooden and laminate floors – AB Parket STUDIO, http://www.abparket.cz

• Wooden and laminate floors – APIA s.r.o., http://www.parkety.com

• Floor wholesale, installation company – TOOM, http://www.toom.cz

• Mirel – www.mirel.cz

11. Warranty, Complaints

The supplier of the ECOFILM heating film provides a warranty period of 10 years for the product’s functionality, beginning from the date of its installation that is confirmed in the certificate of warranty (installation must

be made at latest within 6 months from the date of purchase), provided that:

1. The installation and the way of using must correspond to the Guide.

2. The completed and confirmed Warranty Certificate with all necessary data must be submitted.

3. The delivery note or the invoice issued at the moment when the product was bought must be submitted.

4. The product has not been damaged by its user or any third party.

The claims procedure: http://www.fenixgroup.eu

Please, throw paper packaging of the product to separated waste.

Protect the environment!

8

Page 9

ECOFILM SET – Fußbodenfolie

ECOFILM SET

TYP

Eset 60 - 0,6x1,5m/ 50W 50 1,5 60 1058 0,6 0,55

Eset 60 - 0,6x2m / 66W 66 2 60 801,5 0,6 0,55

Eset 60 - 0,6x2,5m/ 83W 83 2,5 60 637,3 0,6 0,55

Eset 60 - 0,6x3m/ 99W 99 3 60 534,3 0,6 0,55

Eset 60 - 0,6x4m/ 132W 132 4 60 400,8 0,6 0,55

Eset 60 - 0,6x5m/ 165W 165 5 60 320,6 0,6 0,55

Eset 60 - 0,6x6m/ 198W 198 6 60 267,2 0,6 0,55

Eset 60 - 0,6x8m/ 264W 264 8 60 200,4 0,6 0,55

Eset 60 - 0,6x10m/330W 330 10 60 160,3 0,6 0,55

Eset 80 - 0,6x1,5m/ 66W 66 1,5 80 801,5 0,6 0,55

Eset 80 - 0,6x2m/ 88W 88 2 80 601,1 0,6 0,55

Eset 80 - 0,6x2,5m/ 110W 110 2,5 80 480,9 0,6 0,55

Eset 80 - 0,6x3m/ 132W 132 3 80 400,8 0,6 0,55

Eset 80 - 0,6x4m/ 176W 176 4 80 300,6 0,6 0,55

Eset 80 - 0,6x5m/ 220W 220 5 80 240,5 0,6 0,55

Eset 80 - 0,6x6m/ 264W 264 6 80 200,4 0,6 0,55

Eset 80 - 0,6x8m/ 352W 352 8 80 150,3 0,6 0,55

Eset 80 - 0,6x10m/ 440W 440 10 80 120,2 0,6 0,55

Eset 80 - 1,0x1,5m/ 117W 117 1,5 80 452,1 1 0,97

Eset 80 - 1,0x2m/ 156W 156 2 80 339,1 1 0,97

Eset 80 - 1,0x2,5m/ 195W 195 2,5 80 271,3 1 0,97

Eset 80 - 1,0x3m/ 234W 234 3 80 226,1 1 0,97

Eset 80 - 1,0x4m/ 312W 312 4 80 169,6 1 0,97

Eset 80 - 1,0x5m/ 390W 390 5 80 135,6 1 0,97

Eset 80 - 1,0x6m/ 468W 468 6 80 113 1 0,97

Eset 80 - 1,0x8m/ 624W 624 8 80 84,8 1 0,97

Eset 80 - 1,0x10m/ 780W 780 10 80 67,8 1 0,97

GESAMTLEISTUNG

[W]

• Ein Folienbestandteil ist der Anschlussleiter SK AV 1,5 mm

• Versorgung Ecofilm Set 230 V

LÄNGE DER

FOLIENBAHN

[m]

Flächenanschlusswert

2

[W/m

]

2

von 2×5 m

Widerstand

[Ω]

Gesamtbreite

der Folie

[m]

Aktive Heizbreite

der Folie

[m]

1. Installationsbedingungen

• Jede andere Verwendung der Heizfolie oder andere Verlegung der

Heizfolie, als in dieser Anleitung angeführt ist, kann lebensgefährlich und gesundheitsgefährdend sein oder kann die Materialschäden verursachen. Auf solche Verwendung erstrecken sich die Garantiebedingungen nicht.

• Die Heizfolie ist für die Verlegung mit trockenem Bauprozess be-

stimmt, sie wird nicht geklebt, jedoch muss sie gegen Verschiebung / Abrutschen auf den nicht heizenden Rändern fixiert sein.

9

Page 10

• Die Heizfolie kann nicht auf den unebenen Oberflächen installiert

werden. Die Heizfolie ist vor der Beschädigung während der Montage (z.B. Beschädigung der Isolierung mit scharfen Gegenständen,

durch Begehen in ungeeigneten Schuhen usw.) zu schützen. Die

Heizfolie ist begehbar, falls die Schuhe weiche Sohlen haben und

die Folie auf einer ebenen und glatten Oberfläche gelegt ist.

• Die Installationsweise (Ausschaltung, Regelung) muss ermöglichen,

die Folie in allen Polen elektrisch abzuschalten. Der Abstand von

geöffneten Kontakten muss mindestens 3 mm sein. Die Speisekreise sind immer mit einem Fehlerstromschutzschalter mit dem nominalen Ansprechstrom von ≤30 mA auszustatten.

• Die Heizfolien können nicht geschichtet werden, weder können sie

übereinander liegen oder andere Teile als nicht heizende Ränder

berühren. Die nicht heizenden Teile können übereinander liegen.

Immer ist es nötig, die Heizfolie gegen Verschiebung zu befestigen.

• Bei den Heizfolien sind die oberen und unteren Flächen nicht be-

stimmt, es ist doch geeignet, sie mit dem breiteren Teil des Anschlusspunktes (Kunststoffdeckprofil) nach unten legen.

• Unter die Fußbodenkonstruktion ist eine Hydroisolierung zu legen,

die die Wassereindringung (Feuchtigkeitseindringung) unter die

Heizfolie verhindert. Es wird empfohlen, sie in zwei zueinander

senkrechten Schichten mit Überlappungen von Fugen zu verlegen.

• Die Heizfolien können bei der Temperatur unter 3 °C nicht installiert

werden und langfristig können sie den

• 80°C übersteigenden Temperaturen nicht ausgesetzt werden. Der

minimale Biegehalbmesser der Heizfolie ist 35 mm und es ist ihre

Zusammendrückung zu verhindern.

• Die Heizfolie kann unter fest eingebaute Ausstattung des Zimmers

und unter die die Wärmeabführung verhindernde Gegenstände

(z.B. Möbel mit Sockel, usw.) nicht verlegt werden.

• Die Heizfolien können nicht langfristig mit Fußbodenbelag oder an-

deren Gegenständen, deren Wärmewiderstand (R) 0,15 m

• Auf die Heizfolie ist eine Dampfsperre – PE Folie mit der Stärke von

2

K/W.

min. 0,2 mm und mit Überlappungen von min. 5 cm – wie Fuchtigkeitsschutz zu legen.

10

Page 11

• Die Heizfolien dürfen nicht in der Nähe von Aluminiumfolien, metall-

haltigen Folien oder auf den Konstruktionen mit erhöhter Feuchtigkeit installiert sein.

• Eset ist in den Räumen mit erhöhter Feuchtigkeit (Badezimmer,

Wachräume, usw.) nicht zu installieren.

• Der Lieferant muss andere Lieferanten, Besitzer und falls möglich

auch Benutzer darauf hinweisen, dass auf der Fläche, wo die Heizfolien installiert sind, keine durchdringende Mittel, wie z.B. Nägel,

Schrauben, Bohrer, verwendet werden können.

• In der Schalttafel des Heizsystems muss sich immer ein Blatt mit

Informationen über das Heizsystem befinden, das bei Änderung des

Besitzers oder Mieters immer zu übergeben ist.

• Die Heizfolien sind für geklebte Laminat- und Holzfußböden be-

stimmt, welche an ihrem Umfang mit Leisten vor unsachgemäßer

Demontage des Belags geschützt sind.

• Die Heizfolie wird gemäß den Anforderungen der Norm EN 60335-2

-96 hergestellt und muss gemäß den gültigen Normen installiert

werden.

• Die Installation muss den Normen EN 50559 und allen nationalen

Vorschriften entsprechen.

• Bei Deckung der Heizfolie Ecofilm mit Polyesterfolie mit einer Stär-

ke von 0,1 mm oder mit PE-Folie mit einer Stärke von 0,2 mm ist

die Anforderung der Norm EN 60335-1 für die Konstruktionen der

Klasse II und der Norm EN 60335-2-96 für Installierung der Heizeinheit in Fußboden und Decke erfüllt.

• Der Benutzer muss durch den Lieferanten über die Installierung der

elektrischen Fußbodenheizung unterwiesen sein.

Im Schaltschrank muss ein Schild, Bestandteil der Verpackung, geklebt sein, das auf diese Tatsache hinweist und die Information enthält, dass es verboten ist, Öffnungen zu machen und Fußboden mit

Einrichtungsgenständen zu decken, bei denen die Mindestlücke von

4 cm zwischen dem Fußboden und der unteren Fläche nicht gesichert ist.

11

Page 12

2. Fußbodenschnitt – Heizung mit direkter Beheizung

I. SCHWIMMFUSSBODEN

UNTERGRUND BETON, CETRIS, USW.

1 Dreischichtiger, schwimmend verlegter Holz- oder

Laminatfußboden

2 Fußbodenfühler (Begrenzungsfühler) in Nute

3 PE Deckfolie, Stärke min. 0,2mm

4 Fußbodenheizfolie ECOFILM®

5 Isolierunterlage aus extrudiertem Polystyrol

6 Untergrund – Beton, Anhydrid, ursprünglicher Fußboden,

usw.

II. Unter Teppich oder PVC

1 Begehschicht (PVC, Teppich)

2 Zweischichtige geklebte Unterlage HEAT-PAK 7 mm

3 Fußbodenfühler (Begrenzungsfühler) in Nute (verkittet)

4 PE Deckfolie, Stärke min. 0,2 mm

5 Fußbodenheizfolie ECOFILM

®

6 Isolierunterlage aus extrudiertem Polystyrol

7 Untergrund – ursprünglicher Fußboden, Beton, Anhydrid,

usw.

3. Qualität des Untergrunds

• Der Untergrund muss entsprechend eben, ohne Vorsprünge, Beulen oder Vertiefungen sein. Er kann aus

Beton oder aus anderen, ausreichend tragbaren Materialen sein.

• Die Feuchtigkeit des Untergrunds kann 2% (ca. 60% der relativen Feuchtigkeit) nicht überschreiten. Kann

die Feuchtigkeit in den Untergrund eindringen, ist es nötig, voraus eine hochwertige Feuchtigkeitsisolierung zu machen.

4. Vorbereitung der Heizfolie

• Im Bedarfsfall die Heizfolie mit Schere an die verlangte Länge in der gekennzeichneten Schnittstelle ab-

schneiden – dabei ist darauf zu achten, dass der Schnitt in der Mitte der Schnittbahn führt!!

• Nach dem Abschneiden der Heizfolie sind die Kanten der abgedeckten Kupferbänder mit Isolieraufkleber

zu isolieren, die sich im Umfang der Lieferung befinden. (Falls sie verloren wurden, mit einem geeigneten

Isolierband).

• Die Kompaktheit der Heizfolie kann keineswegs (Loch, usw.) beschädigt sein.

• Nägel, Schellen und weitere Befestigungsmittel können die Folie nur in den Längsseiten durchgehen, die

von den lebhaften Teilen der Folie (Kupfersammelleitungen) mindestens 11 mm entfernt sind. Ist es nötig,

diese Längsseiten abzuschneiden, ist es ebenfalls nötig, den Abstand von mindestens 11 mm zu respektieren.

12

Page 13

5. Verlegung und Anschluss der Heizfolie

• Vor der Verlegung ist die Fußbodenfläche mit einer Dämpfungsschicht (Starlon) zu belegen.

• In den Stellen, wo die Anschlusspunkte (Kunststoffprofile) gelegt sind, und in den Stellen, wo die Leiter zur

Dose führen, ist es nötig, vorher eine Entlastung – Nur für ihre Einsenkung in den Untergrund oder in die

Dämpfungsschicht – zu machen (Anschlussstellen – die Deckprofile sind mit ihrem breiteren Teil nach

unten orientiert).

• Die Bahnen der Heizfolie sind mit ihren Heizflächen übereinander nicht zu legen. Es ist geeignet, sie ge-

gen Verschiebung zu befestigen – z.B. mit einem Klebeband. Die Heizfolie ist grundsätzlich über Dehnungsfugen und unter stationäre Ausstattung nicht zu legen. Es ist verboten, die Folien ohne geeignete

Unterlage und in ungeeigneten Schuhen zu begehen.

• Die Leiter sind in die elektrische Dose (vgl. Bild 1 und 2) oder direkt in den Thermostat anzuschließen.

Nach der Verlegung der Bahnen mit Ohmmeter (vor der Verlegung des Fußbodenbelags) einzelne Bahnen messen und die Werte gemäß der na der Titelseite angeführten Tabelle kontrollieren – die Abweichung muss sich in der Toleranz von + 5% bis –10% befinden (falls die Folie verkürzt wurde, ist es nötig,

diese Werte umzurechnen). Die gemessenen Angaben sind in den Garantieschein zu bemerken. In den

Garantieschein sind ebenso die Positionen von Bahnen und Leitern, einschließlich ihrer Anschlussstelle,

zu bemerken.

• Eine PE Folie von mindestens 0,2 mm mit Überlappungen von 5 cm verlegen. Die auf dem Umfang verti-

kal hinaufgezogenen Überlappungen sind mit der PE Folie der unteren Isolierung zu verbinden, falten und

in die Ebene des Fußbodens zu legen.

5.1 Verbindung der Heizfolie im Fußboden

Zur Verbindung mehrerer Ecofilm-Heizfolien können 5 – Leitungsklemmen WAGO – verwendet werden. Mit

einer Klemme können vier Heizfolien mit einem Pol verbunden werden. Zur Verbindung von 4 Stück Folien

sind 2 Klemmen erforderlich. Werden mehrere Klemmen verwendet, verbinden Sie die Klemmen serienweise; der die Klemme durchgehende Strom darf 20A nicht überschreiten. Die Klemmen werden in die vorher

vorbereiteten Nuten unter den Fußbodenbelag – außerhalb der Heizfolien – eingelegt.

Anzahl der Klemmen pro Sätze:

2 Klemmen – 2 bis 4 Sätze

4 Klemmen – 5 bis 7 Sätze

6 Klemmen – 8 bis 10 Sätze

8 Klemmen – 11 bis 13 Sätze

13

Page 14

Montageablauf:

1. Heizfolien verlegen und die Verbindungsleiter zur Anschlussstelle führen.

2. Im Fußboden eine Nut laut Abbildung aushauen.

3. Die Versorgungsleitungen in der Länge 9–10 mm abisolieren.

4. Den orangefarbenen Hebel auskippen, die Leitungen in die Öffnungen einstecken und den Hebel wieder

einkippen.

5. Die Klemme in die Nut einlegen – siehe Abbildung im Punkt 2.

6. Verlegung des Endfußbodenbelags

• Er ist in Übereinstimmung mit den technischen Bedingungen und der Herstelleranleitung zu verlegen.

7. Schlussmessung

• Wieder die Messung mit Ohmmeter (Widerstand) + Messung des Übergangsstroms realisieren und in den

Garantieschein anführen. Den ausgefüllten Garantieschein sowie diese Anleitung ist dem Besitzer

(Benutzer) zu übergeben!

8. Anlaufbetrieb des Fußbodens

• Die Heizung ECOFILM kann ohne Anlaufbetrieb in Betrieb gesetzt werden, falls sie nicht auf dem Beton

oder einem ähnlichen Baumaterial installiert ist.

• Nach der Installierung auf Beton ist folgender Anlauf zu respektieren:

• Nach diesem Anlauf die Heizung abschalten und nach Abkühlung in den üblichen Betrieb einschalten.

TAG Einstellung

1. 15 °C

2. 18 °C

3.–5. 20 °C

6.–8. 25 °C

14

Page 15

9. Regelung

• Zur Temperaturregelung in Räumen, die mit Heizfolie beheizt werden, müssen Thermostate mit einem

Fußbodenfühler verwendet werden; der Fühler muss mind. 30 cm vom Rand der Heizfläche entfernt sein.

• Die Fußbodensonde des Thermostates ist möglichst nah der Fußbodenoberfläche zu installieren, aber bei

der Verlegung unter Laminatfußboden erfolgt es unmittelbar unter die Heizfolie in die ausgehöhlte Nut.

• Das Leerrohr ist am Übergang Wand-Boden so abzuwinkeln, dass der Fühler ggf. ausgetauscht werden

kann. Der Radius soll mindestens 6 cm betragen.

• Am Thermostat ist die Betriebsart „Raum + Fußbodentemperatur“ oder „Fußboden“ zu wählen. Die

höchstzulässige Einstellung der Fußbodentemperatur ist 27°C.

10. Beispiele der geeigneten Materialien und Fußböden

Beispiele der geeigneten Materialien und Fußböden:

• Schwimmfußböden ALLOC – Havel – Podlahové centrum (Fußbodenzentrum), http://www.havelpc.cz/

• MAGNUM – www.magnumparket.cz

• Laminatböden der Fa. Egger – http://www.egger.com/, http://www.step–style.cz/

• Holzböden JUNCKERS – HEMAX Trading s.r.o., http://www.junckers.cz/

• Holz- und Laminatböden – ABH design, http://www.abhdesign.cz/

• Holz- und Laminatböden – AB Parket STUDIO, http://www.abparket.cz/

• Holz- und Laminatböden – APIA s.r.o., http://www.parkety.com/

• Großhandel mit Bodenbelägen, Montagefirma – Fa. TOOM, http://www.toom.cz/

• Mirel – www.mirel.cz

11. Garantie, Reklamationen

Der Lieferant der Heizfolie ECOFILM gewährt auf ihre Funktionsfähigkeit die Garantie für die Dauer von

10 Jahre ab dem Tag der im Garantieschein bestätigten Installierung (die Installierung ist höchstens

innerhalb von 6 Monaten ab dem Tag des Verkaufs durchzuführen), falls:

1. Die Installation sowie Anwendung müssen in Übereinstimmung mit der Anleitung sein.

2. Der in allen verlangten Angaben ausgefüllte und bestätigte Garantieschein ist vorzulegen.

3. Es ist der Lieferschein oder die bei dem Verkauf des Erzeugnisses ausgestellte Rechnung vorzulegen.

4. Das Erzeugnis wurde vom Benutzer oder einem Dritten nicht beschädigt.

Die Reklamationsordnung ist auch auf http://www.fenixgroup.eu zu finden.

Denken Sie auch an die Umwelt!

Die Papierverpackungen des Erzeugnisses gehören in sortierte Abfälle.

15

Page 16

ECOFILM SET – Пленка для теплого пола

ECOFILM SET

тип

Eset 60 - 0,6x1,5m/ 50W 50 1,5 1058 0,6 0,55

Eset 60 - 0,6x2m / 66W 66 2 801,5 0,6 0,55

Eset 60 - 0,6x2,5m/ 83W 83 2,5 637,3 0,6 0,55

Eset 60 - 0,6x3m/ 99W 99 3 534,3 0,6 0,55

Eset 60 - 0,6x4m/ 132W 132 4 400,8 0,6 0,55

Eset 60 - 0,6x5m/ 165W 165 5 320,6 0,6 0,55

Eset 60 - 0,6x6m/ 198W 198 6 267,2 0,6 0,55

Eset 60 - 0,6x8m/ 264W 264 8 200,4 0,6 0,55

Eset 60 - 0,6x10m/330W 330 10 160,3 0,6 0,55

Eset 80 - 0,6x1,5m/ 66W 66 1,5 801,5 0,6 0,55

Eset 80 - 0,6x2m/ 88W 88 2 601,1 0,6 0,55

Eset 80 - 0,6x2,5m/ 110W 110 2,5 480,9 0,6 0,55

Eset 80 - 0,6x3m/ 132W 132 3 400,8 0,6 0,55

Eset 80 - 0,6x4m/ 176W 176 4 300,6 0,6 0,55

Eset 80 - 0,6x5m/ 220W 220 5 240,5 0,6 0,55

Eset 80 - 0,6x6m/ 264W 264 6 200,4 0,6 0,55

Eset 80 - 0,6x8m/ 352W 352 8 150,3 0,6 0,55

Eset 80 - 0,6x10m/ 440W 440 10 120,2 0,6 0,55

Eset 80 - 1,0x1,5m/ 117W 117 1,5 452,1 1 0,97

Eset 80 - 1,0x2m/ 156W 156 2 339,1 1 0,97

Eset 80 - 1,0x2,5m/ 195W 195 2,5 271,3 1 0,97

Eset 80 - 1,0x3m/ 234W 234 3 226,1 1 0,97

Eset 80 - 1,0x4m/ 312W 312 4 169,6 1 0,97

Eset 80 - 1,0x5m/ 390W 390 5 135,6 1 0,97

Eset 80 - 1,0x6m/ 468W 468 6 113 1 0,97

Eset 80 - 1,0x8m/ 624W 624 8 84,8 1 0,97

Eset 80 - 1,0x10m/ 780W 780 10 67,8 1 0,97

Общая

мощность

[Вт] [M] [Ω] [M] [M]

Длина рулона

пленки

Плоскостная

мощность

[Вт/м2]

60

60

60

60

60

60

60

60

60

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

Cоп-

ротивление

Общая ширина

пленки

Активная нагреват-

ширина пленки

•

С пленкой поставляется 2х5 м присоединительный провод SK AV 1,5 мм2

•

Питание Ecofilm Set 230 В

1. Условия для укладки

•

Иной способ применения нагревательной плёнки или иной способ укладки

нагревательной плёнки, в противоречие приведенным в настоящих инструкциях,

могут оказаться опасными для жизни и здоровья людей или привести к

материальному ущербу. На такой способ эксплуатации гарантийные обязательства

не распространяются.

•

Нагревательная плёнка рассчитана на укладку сухим способом, без применения

клея, однако, ее необходимо зафиксировать за ненагревательные края для

предупреждения смещения/сползания.

16

Page 17

•

Нагревательную пленку не разрешается укладывать на неподготовленную

поверхность. Нагревательную пленку при монтаже следует предохранять от

повреждений (например, повреждения изоляции острыми предметами,

неподходящей обувью и т.п.). По нагревательной пленке можно ходить только в

обуви с мягкой подошвой при условии, что пленка лежит на ровной и гладкой

поверхности.

•

Проводка (выключение, регуляция) должна быть сделана таким образом, чтобы

пленку от электричества можно было отсекать на всех полях, расстояние между

расцепленными контактами должно быть как минимум 3 мм. Питающие цепи

должны быть обязательно оборудованы токовым предохранителем с

номинальным током расцепления ≤30 мА.

•

Нагревательную плёнку не разрешается укладывать слоями, полосы не должны

перекрывать друг друга или соприкасаться другими частями, кроме

ненагревательного края. Перекрывание ненагревательных краем допускается. В

любом случае при укладке полосы следует зафиксировать, чтобы нагревательная

плёнка не сместилась.

•

У нагревательной пленки не имеется точно определенная верхняя или нижняя

сторона, однако лучше, когда снизу оказывается более широкоя часть

присоединительного места (пластмассовая крышка) .

•

Под конструкцией полового настила должна быть сделана гидроизоляция, которая

не позволит воде (сырости) проникать под нагревательную пленку, гидроизоляцию

рекомендуем класть в два слоя, перпендикулярно друг к другу с перекрытием

швов.

•

Производить монтаж нагревательной плёнки при температуре ниже плюс 3 °C не

разрешается, также недопусимо долговременное действие на пленку температур

свыше 80°C. Минимальный радиус изгиба нагревательной пленки 35м; нельзя

допускать сминания пленки.

•

Пленку ECOFILM не разрешается класть непосредственно на горючее основание;

нагревательную пленку не кладите и под стабильно установленное оборудование

помещения и предметы, мешающие отходу тепла (например, мебель с цоколем и

под.).

•

Нагревательные плёнки не разрешается на продолжительное время закрывать

покрытием для полов или другими предметами, термическое сопротивление (R)

превышает 0,15м2K/Вт .

•

На нагревательную пленку следует положить паронепроницаемую ПЭ пленку толщиной мин.0,2 мм, выдающуюся по сторонам примерно по мин. 5 см для

предохранения от сырости.

17

Page 18

•

Нагревательную пленку не разрешается укладывать поблизости от алюминия

пленок, пленок, содержащих металлы, и на конструкции с повышенной

влажностью.

•

Eset не устанавливаться в помещениях с повышенной влажностью (ванные

комнаты, прачечные и под.).

•

Основной поставщик должен предупредить остальных поставщиков, владельцев,

по возможности и пользователей, что на площади, на которую предстоит

укладывать нагревательную плёнку, не разрешается применять никакие

проникающие предметы, например, гвозди, шурупы и сверла

•

В распредщите нагревательной системы должен постоянно храниться лист с

информацией, касающейся нагревательной системы, который в случае изменения

хозяина или арендатора необходимо передать.

•

Нагревательные пленки предназначены для клееных ламинатных и деревянных

полов, зафиксированных по периметру планками с целью предупреждения

неправильной разборки настила.

•

Нагревательные плёнки производятся согласно требований стандарта ЭН 60335-296 и их монтаж должен выполняться в соответствии с действующими

национальными стандарта.

•

При установке необходимо соблюдать требования стандарта ЭН 50559.

Электропроводка должна быть выполнена в соответствии с национальными

предписаниями.

•

Требование стандарта EN 60335-1 по конструкциям класса II и стандарта EN

60335-2-96, касающегося устройства нагревательного блока в полу или потолке,

удовлетворяется путем закрывания нагревательной пленки Ecofilm полиэфирной

пленкой толщ. 0,1мм или полиэтиленовой пленкой толщ. 0,2мм.

•

Поставщик обязан проинструктировать пользователя о способе установки теплого

пола.

В распределительный шкаф необходимо вклеить табличку, которая находится

среди предметов, входящих в упаковку. Текст таблички должен нести информацию

о наличии теплого пола, в тексте должно быть предусмотрено запрещение

просверливать отверстия, закрывать пол предметами оборудования, не

имеющими ножки, т.е. между полом и нижней плоскостью, например, мебели

должен быть промежуток не менее 4см.

18

Page 19

2. Пол в разрезе – прямое отопление

I. ПЛАВАЮЩИЙ ПОЛ

ПОДСТИЛАЮЩИЙ СЛОЙ БЕТОН, CETRIS И ПОД.

1 - Трехслойный деревянный или пластиковый “плавающий“ пол

2 - Напольный (лимитирующий) зонд в канавке

3 - Защитная ПЭ пленка толщ. мин. 0,2мм

4 - Напольная нагревательная пленка ECOFILM

5 - Изолирующая прокладка из экструдированного полистирола

6 - Основание - бетон, ангидрит, старый пол и т.

II. Под ковёр или ПВХ

1 - Верхний слой (ПВХ, ковер)

2 - Двухслойная клеенная прокладка HEAT-PAK 7мм

3 - Напольный (лимитирующий) зонд в канавке (заделана мастикой)

4 - Защитная ПЭ пленка толщ. мин. 0,2мм

5 - Напольная нагревательная пленка ECOFILM

6 - Изолирующая прокладка из экструдированного полистирола

7 - Основание - бетон, ангидрит, старый пол и т.д.

3. Качество подстилающего слоя

•

Подстилающий слой должен быть надлежащим образом ровный, без выступов, вздутий или углублений. Может быть из бетона

или другого материала с достаточной грузоподъемностью.

•

Не допускается, чтобы влажность подстилающего слоя превышала 2 % (около 60 % относительной влажности). Если имеется

реальная опасность, что в подстилающий слой будет проникать сырость, надо заранее предусмотреть качественную

гидроизоляцию.

4. Подготовка нагревательной пленки

•

Нагревательную пленку, если требуется, отрежьте ножницами на соответствующую длину в отмеченном для отрезания месте.

Старайтесь разрез вести по центру разрезной полосы!

•

Отрезав нагревательную пленку, надо изолировать грани обнаженных медных полос при помощи изоляционной самоклеящейся

ленты, которая прилагается к каждой партии поставки (если потеряете, можно использовать подходящую изоленту).

•

Ничто не должно нарушать целостность нагревательной пленки (отверстия и пр.).

•

Гвозди, скобы и другие фиксирующие элементы должны проходить сквозь пленку только на ее продольных сторонах на

расстоянии не менее 11 мм от токоведущих частей пленки (медной сборной шины). Если продольные стороны придется

отрезать, следует также сохранять расстояние как минимум 11 мм.

д.

19

Page 20

5. Укладка и присоединение нагревательной пленки

•

Перед укладкой нагревательной пленки на плоскость пола положите амортизирующий слой (Starlon).

•

В местах нахождения присоединительных узлов (пластмассовых крышек) и в местах, где ведут провода в направлении к

коробке, надо заранее предусмотреть разгрузку: шлиц для их утопления в основание или амортизирующий слой

(присоединительные узлы – крышки более широкой стороной повернуты вниз).

•

Не допускается, чтобы полосы нагревательной пленки взаимно перекрывались нагревательными поверхностями. Полосы лучше

зафиксировать, чтобы не сдвинулись с места, например, при помощи клеящейся ленты. Запрещается класть нагревательную

пленку на температурные (расширительные) швы под стабильно установленное оборудование. Строго запрещается наступать

на пленку, лежащую на неподходящем основании, и в неподходящей обуви.

•

Провода присоединяются в электрокоробке (см. рисунок 1 и 2) или прямо к термостату

•

Положив полосы, при помощи омметра измерьте (еще до укладки полового покрытия) отдельные полосы и свертесь по таблице

с первой страницы, допускается отклонение в пределах от +5 % до –10 % (если пленку укорачиваете, значения надо

пересчитать). Полученные при измерении показания запишите в гарантийный паспорт. В гарантийный паспорт надо также

зарисовать и расположение полос и проводов

•

Положите ПЭ пленку толщиной не менее 0,2 мм с выдающимися по 5 см краями. Выдающиеся края, свисающие вертикально по

периметру, надо соединить с ПЭ пленкой нижней изоляции, перегнуть и разложить по плоскости пола (по краям).

, включая места присоединения.

5.1 Соединение пленки в полу

Для соединения нескольких кусков пленки Ecofilm можно использовать 5-проводные зажимы WAGO. Один зажим способен одним

полем объединить четыре нагревательные пленки. Для соединения четырех кусков пленки необходимо 2 зажима. В случае

применения большего количества муфт, соедините их по последовательной схеме. Ток, протекающий через муфту, не должен

превышать 20А. Муфты вставляются в заранее подготовленные шлицы под

Количество муфт в комплекте:

2 муфты – 2–4 комплекта

4 муфты – 5–7 комплектов

6 муфт – 8–10 комплектов

8 муфт – 11–13 комплектов

настилом пола, за пределами нагревательной пленки.

20

Page 21

Последовательность монтажа:

1. Положите все куски нагревательной пленки, соединительные провода подведите к месту подключения.

2. Вырубите в полу шлиц, как показано на рисунке.

3. С отрезка питающего провода длиной 9 – 10 мм снимите изоляцию.

4. Откиньте оранжевый рычажок, вставьте провода в отверстие и рычажок снова защелкните.

5. Муфту вставьте в шлиц, см. рисунок в

пункте 2.

6. Укладка окончательного полового покрытия

•

Материал укладывается в соответствии с техническими условиями и по инструкциям изготовителя полового покрытия

7. Заключительные проверки

•

Для контроля снова воспользуйтесь омметром (Cопротивление) + для измерения тока утечки и запишите показания в

гарантийный паспорт. Заполненный гарантийный паспорт и настоящие инструкции должны быть вручены владельцу

(пользователю) !

8. Пуско-наладочная эксплуатация теплого пола

•

Теплый пол из нагревательной пленки ECOFILM может быть запущен в эксплуатацию без режима «обкатки» при условии, что

пленка не положена на бетон или подобный строительный материал.

•

При укладке на бетон соблюдайте такую последовательность запуска:

день

1. 15 °C

2. 18 °C

3.–5. 20 °C

6.–8. 25 °C

Настраиваемая

температура

21

Page 22

9. Регулирование

•

Для регуляции температуры в помещениях, отапливаемых нагревательными контурами/матами, применяют термостаты с

напольным зондом, установленным в нагревательной части пола, на расстоянии как минимум 30см на нагревательной

плоскости.

•

Напольный датчик термостата устанавливаем как можно ближе к поверхности пола, однако в случае настила из слоистого

пластика это значит, что будет лежать вплотную под нагревательной пленкой в углубленном шлице.

•

Радиус изгиба инсталляционной трубки между стеной и полом должен быть рассчитан так, чтобы при необходимости можно

было зонд заменить! Рекомендуемый минимальный радиус изгиба 6см.

•

Термостат необходимо настроить в режиме: Комната + предел температуры пола или Пол. Максимальная допустимая настройка

температуры пола 27°C.

10. Примеры подходящих материалов и настилов для пола

•

Плавающий пол «ALLOC – Havel – Центр настилов для полов», http://www.havelpc.cz/

•

Ламинатный пол фирма «Egger» – http://www.egger.com/, http://www.step-style.cz/

•

Деревянные полы ООО «JUNCKERS – HEMAX Trading», http://www.junckers.cz/

•

Деревянные и ламинатные полы – ABH design, http://www.abhdesign.cz/

•

Деревянные и ламинатные полы – AB Parket STUDIO, http://www.abparket.cz/

•

Деревянные и ламинатные полы – ООО «APIA», http://www.parkety.com/

•

Оптовый магазин настилов для полов, фирма «TOOM», http://www.toom.cz/

•

Mirel – www.mirel.cz

11. Гарантия, рекламации

•

Поставщик нагревательной пленки ECOFILM дает гарантию на ее функции на срок 10 лет по условиям рекламационного

порядка. Гарантийный срок начинается со дня инсталляции, но не позднее 6 месяцев от даты продажи (полный текст

рекламационного порядка найдете на сайте www.fenixgroup.eu).

1) Инстралляция и способ эксплуатации должны соответствовать инструкциям.

2) Необходимо предъявить заполненный и подтвержденный гарантийный паспорт по

3) Необходимо предъявить накладную или фактуру, выписанные при покупке товара.

4) Изделие не было повреждено пользователем или третьим лицом.

Думайте и о жизненной среде!

Бумажную упаковку от изделия сдавайте как вторсырье.

всем требуемым статьям.

22

Page 23

23 24

Page 24

This Installation Guide is intended for a supplier, owner and user of the heating foil. In case of of an owner/user, this Installation Guide must

be submitted to a new owner/user together with a duly completed Warranty Certificate.

Diese Anleitung ist für die Lieferanten, Besitzer und Benutzer der Heizfolie bestimmt, und falls sich der Besitzer ändert, ist die Anleitung dem

Nachfolger zusammen mit dem vollkommen ausgefüllten Garantieschein zu übergeben.

Настоящие инструкции предназначены поставщикам, владельцам и пользователям нагревательной пленки, а в случае изменения

владельца /пользователя/ должны быть переданы преемнику вместе с надлежащим образом заполненным гарантийным паспортом.

Jaroslava Ježka 1338/18a, 790 01 Jeseník

Fenix s.r.o.

tel.: +420 584 495 442, fax: +420 584 495 431

e-mail: fenix@fenixgroup.cz , http://www.fenixgroup.eu

Fenix Trading s.r.o.

Slezská 2, 790 01 Jeseník

tel.: +420 584 495 304, fax: +420 584 495 303

e-mail: fenix@fenixgroup.cz , http://www.fenixgroup.eu

Loading...

Loading...