Page 1

Pro-LX Laminating Card

Printer/Encoder User Guide (Rev.

4.0)

Part Number: L000700

Page 2

RESTRICTED USE ONLY Fargo Electronics, Inc.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 4.0), property of FARGO

Electronics, Incorporated

Copyright 2002, 2003, 2004, 2005, 2006 by FARGO Electronics, Incorporated. All rights

reserved. Printed in the United States of America. Exclusive permission is granted to

authorized resellers of FARGO products to reproduce and distribute this copyrighted

document to authorized FARGO customers, who have signed a “no disclosure agreement”

regarding the restricted, proprietary use of said document.

The revision number for this document will be updated to reflect changes, corrections,

updates, and enhancements to this document.

Revision Control

Date Document Title

Number

Revision 4.0 15 September 2003 Pro-LX Laminating Card Printer/Encoder

User Guide (Rev. 4.0)

These reference documents were thoroughly reviewed to provide FARGO with professional

and international standards, requirements, guidelines, and models for our technical, training,

and user documentation. At all times, the Copyright Protection Notice for each document

was adhered to within our FARGO documentation process. This reference to other

documents does not imply that FARGO is an ISO-certified company at this time.

ANSI/ISO/ASQ Q9001-2000 American National Standard, (sub-title) Quality Management

Systems - Requirements (published by the American Society of Quality, Quality Press,

P.O. Box 3005, Milwaukee, Wisconsin 53201-3005)

The ASQ ISO 9000:2000 Handbook (editors, Charles A. Cianfrani, Joseph J. Tsiakals,

and John E. West; Second Edition; published by the American Society of Quality, Quality

Press, 600 N. Plankinton Avenue, Milwaukee, Wisconsin 53203)

Juran's Quality Handbook (editors, Joseph M. Juran and A. Blanton Godfrey; Fifth

Edition, McGraw-Hill)

Any questions regarding changes, corrections, updates, or enhancements to this document

should be forwarded to:

FARGO Electronics, Incorporated

Support Services

6533 Flying Cloud Drive

Eden Prairie, MN 55344 (USA)

(952) 941-9470

(800) 459-5636

FAX: (952) 941-7836

www.fargo.com

E-mail: sales@fargo.com

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 2

Page 3

RESTRICTED USE ONLY Fargo Electronics, Inc.

How to use the manual

The Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 4.0) is, in fact, the

troubleshooting and field service manual for the entire Pro-LX Card Printer. The manual is

designed to provide installers and technicians with quick, efficient lookup of related

procedures, components, and terms. The manual can be used effectively in either soft or

hard copy, depending on the preference of the installer or technician.

Manual Description

Sequence of Operations,

Glossary of Terms, and

Technical/Functional

Specifications (hyper-linked)

Table of Contents (hyperlinked)

Troubleshooting,

Replacement, Removal,

Diagnostic, and Navigation

Procedures (in hyper-linked

Sections)

Cross-Referencing (hyperlinked)

Comprehensive Index

(hyper-linked)

You can go directly to the Sequence of Operations,

Glossary of Terms, Technical Specifications, and

Functional Specifications to learn how to use the

processes, procedures, functions, and windows for the

Pro-LX Laminating Card Printer/Encoder within concise,

correlative tables.

You can use the automated Table of Contents to quickly

locate, for example, an error message, a procedure, the

index, or an appendix.

You can go directly to Specifications (Section 1), General

Troubleshooting (Section 2), Printer Adjustments (Section

3), Parts Replacement (Section 4), Printer Packing

(Section 5), and Board Level Diagnostics (Section 6) to

find troubleshooting, removal, and replacement

procedures. The section titles are always labeled

according to their function for consistent usage.

You can use the cross-referencing links to quickly locate,

for example, an error message or a procedure.

You can use the COMPREHENSIVE INDEX to quickly

locate information on the Pro-LX Laminating Card

Printer/Encoder, relating to a specification, a procedural

step, a window or screen, a component, a term, a qualifier,

or a related feature to this printer.

Appendices You can use Appendix A and B to locate information

relating to engineering drawings and technical updates,

which are specific to the Pro-LX Laminating Card

Printer/Encoder.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 3

Page 4

RESTRICTED USE ONLY Fargo Electronics, Inc.

Safety Messages (review carefully)

Symbol Critical Instructions for Safety purposes

Danger:

Caution:

Failure to follow these installation guidelines can result in death or

serious injury.

Information that raises potential safety issues is indicated by a warning

symbol (as shown to the below).

To prevent personal injury, refer to the following safety messages

before performing an operation preceded by this symbol.

To prevent personal injury, always remove the power cord prior to

performing repair procedures, unless otherwise specified.

To prevent personal injury, make sure only qualified personnel

perform these procedures.

This device is electrostatically sensitive. It may be damaged if

exposed to static electricity discharges.

Information that raises potential electrostatic safety issues is indicated

by a warning symbol (as shown to the below).

To prevent equipment or media damage, refer to the following

safety messages before performing an operation preceded by this

symbol.

To prevent equipment or media damage, observe all established

Electrostatic Discharge (ESD) procedures while handling cables in

or near the Circuit Board and Printhead Assemblies.

To prevent equipment or media damage, always wear an

appropriate personal grounding device (e.g., a high quality wrist

strap grounded to avoid potential damage).

To prevent equipment or media damage, always remove the Pro-

LX Ribbon and Cards from the printer before making any repairs,

unless otherwise specified.

To prevent equipment or media damage, take jewelry off of

fingers and hands, as well as thoroughly clean hands to remove oil

and debris before working on the printer.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 4

Page 5

RESTRICTED USE ONLY Fargo Electronics, Inc.

13254

8

9

15

242526272829303132

30

30

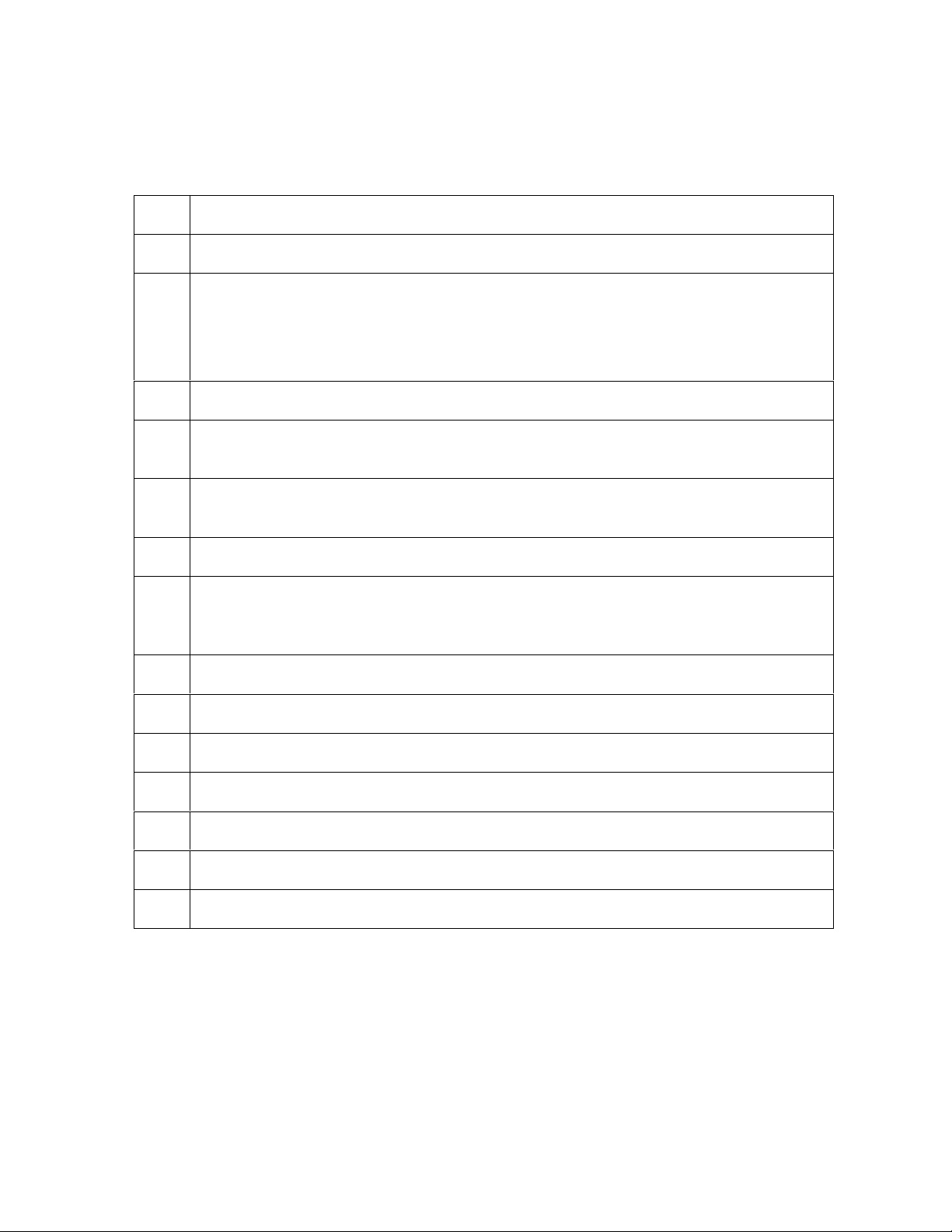

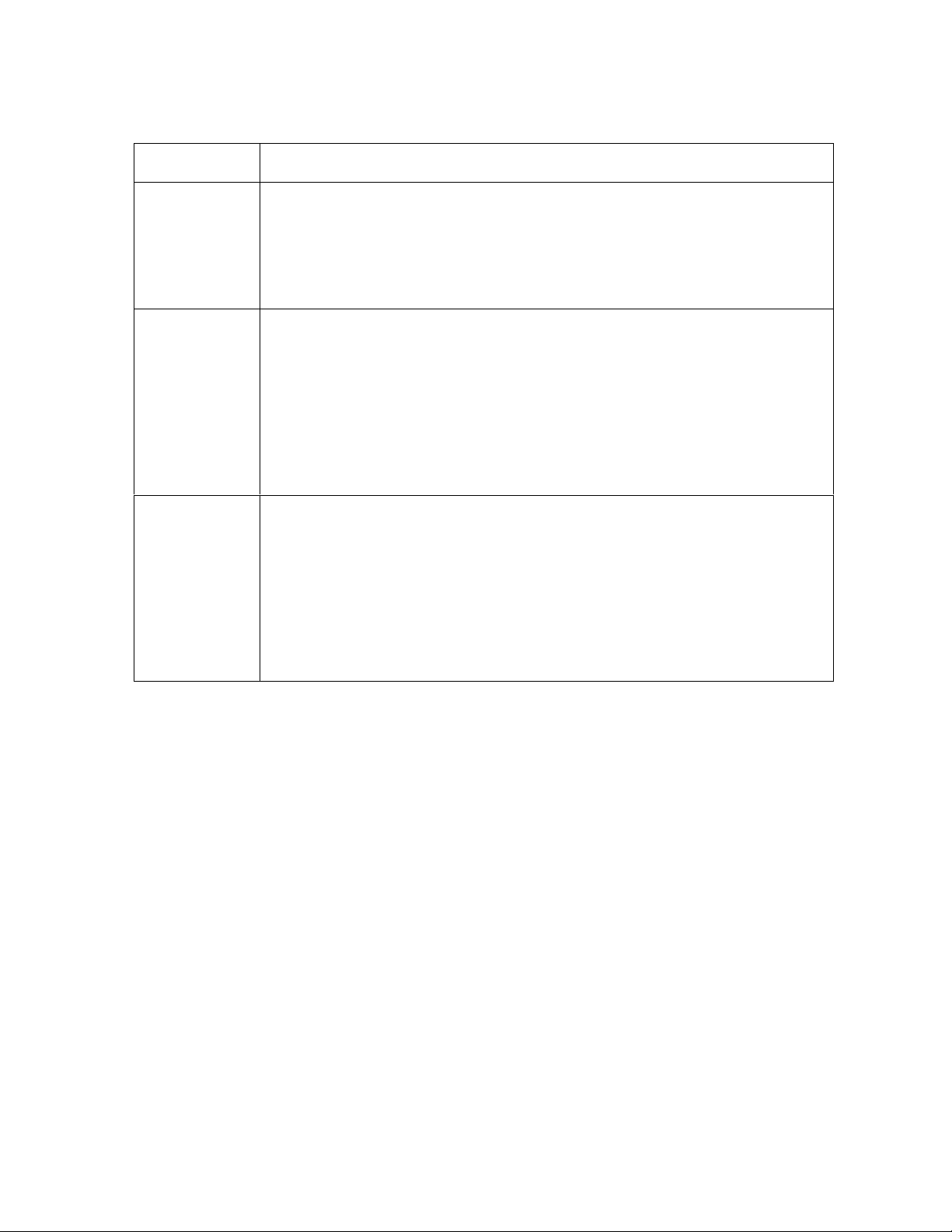

Pro-LX Laminating Card Printer/Encoder Overview

Reviewing Pro-LX Block Diagram

42

6

22

21

7

23

36

19

20

13

33

10

11

14

12

40

41

38

37

16

17

39

18

34

35

Motors Sensors Parts

1 Card Feed 8 Card Feed 25 Input Stack

2 Print Stepper 9 Print TOF (Top Of Form) 26 Card Feed Roller

3 Ribbon Drive 10 Ribbon Encoder Wheel 27 Cleaning Roller

4 Print Headlift 11 Ribbon Core ID 28 Cleaning Tape

5 Lamination Stepper 12 Ribbon Sensor 29 Print Platen

6 Lamination Drive 13 Head Lift 30 Print Drive Rollers

7 Lamination Headlift 14 Thermistor 31 Printhead

15 Print Cover Interlock 32 Print Encoder Wheel

16 Lamination TOF 33 Flipper Clutch

17 Flipper Home 34 Encode Section

18 Mag Feed TOF 35 Mag Drive Roller

19 Lam Encoder Wheel 36 Lam Encoder Wheel

20 Lam Core ID 37 Lam Platen Roller

21 Laminate Ribbon Sensor 38 Lam Drive Rollers

22 Lam Headlift 39 Flipper Drive Roller

23 Thermocouple 40 Lam Roller

24 Lam Cover Interlock 41 Flattener Roller

42 Printhead Cooling Fan

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 5

Page 6

RESTRICTED USE ONLY Fargo Electronics, Inc.

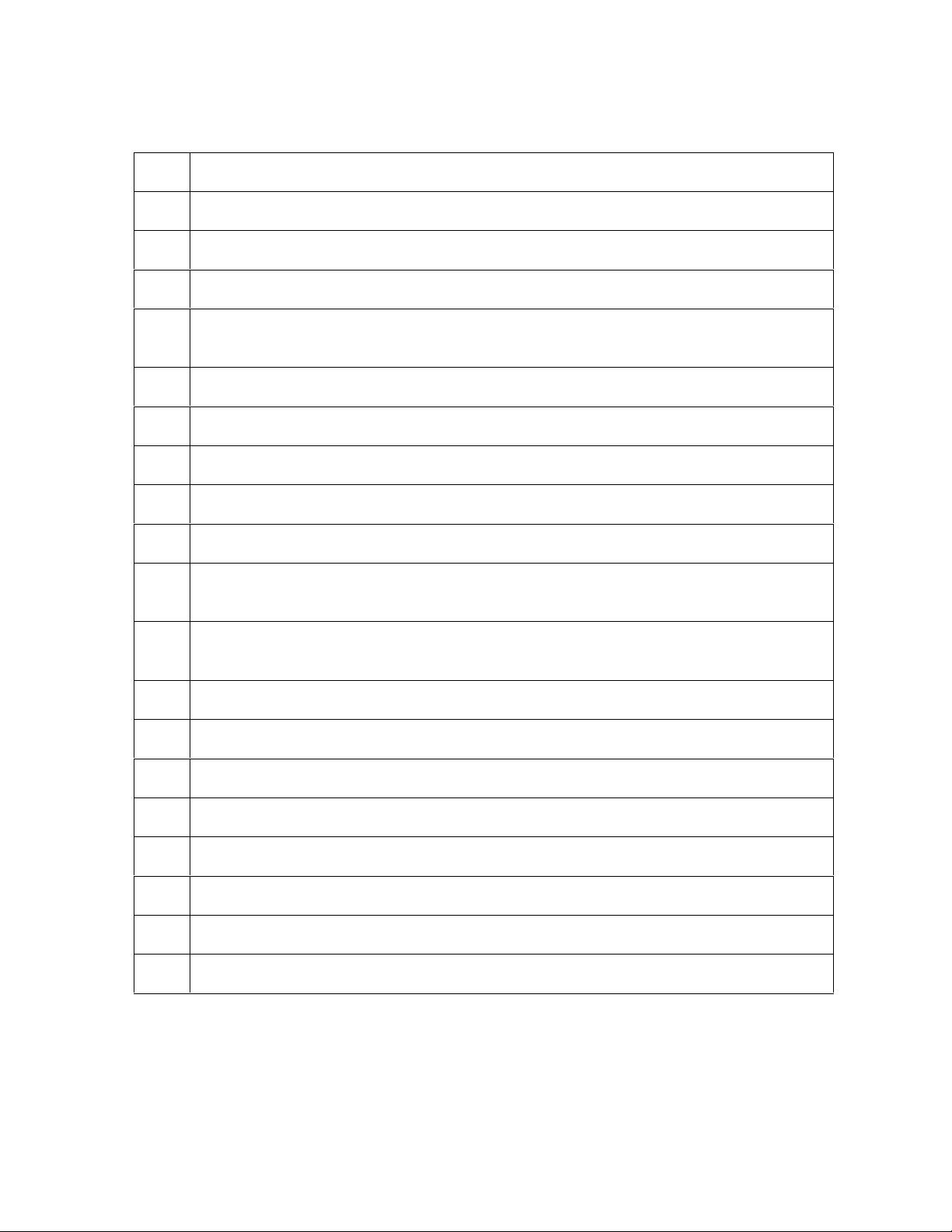

Reviewing Pro-LX Boot Up Sequence

Step Process

1 On Power up, print and the Lam Stepper Motor engage.

2 Print and Lamination Headlift Sensor checks for current open/closed state.

If either Sensor registers closed, the appropriate Headlift Motor engages until

Headlift Sensor detects open state.

3 Check SmartCard and Mag Sensors for presence of card.

If there is a card found in either location, the print and Lam Stepper Motors engage

to back the card out onto the flipper table.

4 Print TOF, Card Detection and LAM TOF Sensors check for presence of card.

If any Sensor finds a card, the card is fed onto the flipper table. The flipper table

then rotates and ejects the card into the reject bin.

5 The Flipper Clutch activates.

6 The Lam Stepper Motor engages.

7 The Flipper Home Sensor detects the homing flag and the Flipper Table levels.

8 The Flipper Clutch disengages

9 The Lam Stepper Motor disengages.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 6

Page 7

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing Pro-LX Sequence of Operations

The following sequence describes a dual sided full color print job with magnetic encoding

and single sided Lamination.

Step Process

1 The File information is received from the PC

2 The Printer checks the installed Ribbon type stored in memory against the Ribbon

type command that was sent from the printer.

a. If Ribbon type does not match, a Wrong Ribbon Error is displayed on the

LCD.

3 The Card Input Motor and Print Stepper Motor engage.

4 The Card detection Sensor detects leading edge of card and disengages the card

input Motor.

5 The Print Stepper drives card to the Print TOF Sensor. The Print Stepper

disengages

6 The Print Ribbon drive engages.

7 The Print Ribbon Sensor looks for the color transition from Yellow to Magenta.

The Print Ribbon Encoder detects number of revolutions required to use an entire

color panel.

8 The Print Stepper Motor engages.

9 The Print TOF Sensor detects trailing edge of card.

10 The Print Stepper Motor queues card to the middle of the platen roller. All Stop

11 The Print Headlift Motor engages.

12 The Print Headlift Sensor detects closed state.

13 The Print Headlift Motor disengages.

14 The Print Stepper Motor engages.

Continued on the next page.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 7

Page 8

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing Pro-LX Sequence of Operations (continued)

Step Process

15 The Print Cover Sensor checks for a closed state.

16 The Ribbon Drive Motor engages.

17 The Image Data is burned by the printhead until image data is depleted. All Stop.

18 The Thermistor engages Printhead Cooling Fan to maintain proper operating

temperature.

19 The Headlift Motor engages.

20 The Print Headlift Sensor detects an open state.

21 The Print Headlift Motor disengages.

22 The Print Stepper Motor engages.

23 The Print Ribbon drive engages.

24 After the Ribbon advances a few encoder clicks, assume the Ribbon is free of

cards. All Stop.

25 Repeat steps 10 through 24 for the appropriate number of color and overlay

panels.

26 The Print and the Lamination Drive Stepper Motors engage.

27 The Lamination Card Sensor detects presence of card. All Stop.

28 The Lam Stepper engages.

29 The Card feeds back to the Flipper Table.

30 The Flipper Clutch engages

31 The Flipper Table rotates 180 degrees

32 The Flipper Table Clutch disengages. All Stop.

33 The Print and Lam Stepper Motors are activated.

Continued on the next page.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 8

Page 9

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing Pro-LX Sequence of Operations (continued)

Step Process

34 The card is fed past the Print TOF Sensor. All Stop.

35 The Flipper Table Clutch engages.

36 The Lamination Stepper engages.

37 The Flipper table rotates to level. All Stop.

38 Repeat steps 10 through 18 for appropriate number of color/overlay panels.

39 The Print and Lamination drive Stepper Motors engage.

40 The Lamination Card Sensor detects presence of card. All Stop.

41 The Lam Stepper engages.

42 The Card feeds back to the flipper table.

43 The Flipper Clutch engages

44 The Flipper Table rotates to encoding angle.

45 The Flipper Table Clutch disengages. All Stop.

46 The Print and Lamination Stepper Motors activate.

47 The Encoding TOF Sensor detects leading edge of card.

48 The Card feeds to below the magnetic encoder head. All Stop.

49 The Print and Lamination Stepper Motors are engaged.

50 The Magnetic Encoding Head is activated.

51 The Card feeds to the Encoding TOF Sensor. All Stop.

52 Repeat steps 40 through 45 for each verification pass.

53 The Card is fed onto the Flipper Table.

Continued on the next page.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 9

Page 10

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing Pro-LX Sequence of Operations (continued)

Step Process

54 The Flipper Clutch engages.

55 The Flipper table returns to level.

56 The Flipper Clutch disengages.

57 The Card feeds back to Print TOF Sensor then forward to the Lamination card

Sensor. All Stop.

58 The Laminate Ribbon Drive activates until Laminate Ribbon Sensor detects patch

mark.

At this time the Thermocouple is checking the temperature of the Laminate roller

and activating the heater core if needed.

59 The Lamination Stepper is activated.

60 The Card is fed to the platen roller. All Stop

61 The Lamination Cover Sensor checks for closed state.

62 The Headlift Motor engages.

63 The Headlift Sensor detects closed state.

64 The Headlift Motor disengages.

65 The Lamination Stepper Motor and Laminate Ribbon drive engage for the distance

of the card. All Stop.

66 The Headlift Motor engages.

67 The Headlift Sensor detects open state.

68 The Headlift Motor disengages.

69 The Lamination Stepper Motor is activated and card is fed out of the printer.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 10

Page 11

RESTRICTED USE ONLY Fargo Electronics, Inc.

Table of Contents

How to use the manual _________________________________________________________________3

Safety Messages (review carefully)________________________________________________________4

Pro-LX Laminating Card Printer/Encoder Overview __________________________________________5

Reviewing Pro-LX Block Diagram _____________________________________________________5

Reviewing Pro-LX Boot Up Sequence __________________________________________________6

Reviewing Pro-LX Sequence of Operations_______________________________________________7

Section 1: Specifications________________________________________________________ 15

Regulatory Compliances _______________________________________________________________15

Agency Listings______________________________________________________________________16

Technical Specifications _______________________________________________________________16

Functional Specifications ______________________________________________________________19

Printer Components: Top Cover to Power Port___________________________________________20

Printer Components: Centronics-Type Parallel Interface ___________________________________24

Printer Components: Print Ribbons ____________________________________________________25

Printer Components: Resin-Only Print Ribbons __________________________________________26

Printer Components: Dye-Sublimation-Only Print Ribbons _________________________________27

Printer Components: Blank Cards _____________________________________________________29

Reviewing the upgraded 81754 PVC Cards ______________________________________________31

Printer Components: Laminator ______________________________________________________33

Visual Security Solutions (Specifications) _________________________________________________34

VeriMarkTM Cards - 2-D holographic foil application _____________________________________34

Custom HoloMarkTM Cards _________________________________________________________34

Visual Security - Card Stock Part Numbers ______________________________________________34

Visual Security - Fargo Certified Overlaminates (Special Order in 50 quantity minimum)__________34

Visual Security Card Stock - Tolerances ________________________________________________35

VeriMarkTM - Application Specifications_______________________________________________35

HoloMarkTM and Custom HoloMarkTM - Application Specifications ________________________35

Section 2: General Troubleshooting______________________________________________ 36

LCD/SmartGuard Messages ____________________________________________________________36

Reviewing the Top Line LCD Messages ________________________________________________36

Reviewing the Bottom Line LCD Error / Status Messages __________________________________40

Communications Errors________________________________________________________________43

Resolving the Communication Errors___________________________________________________43

Card Feeding Errors __________________________________________________________________46

Resolving the Card Feeding Errors_____________________________________________________46

Resolving the Flipper Jam Error Message _______________________________________________48

Print Process Errors___________________________________________________________________49

Resolving the Headlift Error Message __________________________________________________49

Resolving the Cover Open Error Message _______________________________________________50

Resolving the Blank Output issues _____________________________________________________51

Card Jam Errors______________________________________________________________________53

Resolving the Card Jam: Print Error Message____________________________________________53

Resolving the Card Jam: Mag Error / Smart Error Message _________________________________54

Resolving the Card Jam: Lam Error Message ____________________________________________55

Resolving the Card Jam: Flip Error Message_____________________________________________56

Ribbon Errors _______________________________________________________________________57

Resolving the Lam Error/Out Error Message_____________________________________________57

Resolving the Skipping Ribbon Panel issues _____________________________________________59

Resolving the Wrong Ribbon error (being displayed incorrectly) _____________________________62

Resolving the Ribbon Low Message ___________________________________________________63

Resolving the Ribbon Breaking issues __________________________________________________64

Resolving the Lamination (not adhering to the card surface) problem__________________________67

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 11

Page 12

RESTRICTED USE ONLY Fargo Electronics, Inc.

Encoding Errors______________________________________________________________________69

Resolving the Mag Verify Error Message _______________________________________________69

Resolving data intended for the Magnetic Stripe (being printed on the card) problem _____________72

Diagnosing Image Problems ____________________________________________________________73

Resolving the Pixel Failure problems___________________________________________________73

Resolving the Card Surface Debris problems_____________________________________________74

Resolving the Incorrect Image Darkness problems ________________________________________75

Resolving the Ribbon Wrinkle problems ________________________________________________77

Resolving the Excessive Resin Printing problems _________________________________________79

Resolving the Incomplete Resin Printing problems ________________________________________81

Resolving the Image Placement problems _______________________________________________82

Resolving the Poor Image Quality problems _____________________________________________86

Running the Self Test _________________________________________________________________87

Running the Standard Self Test Print ___________________________________________________87

Reviewing the Main Circuit Board_____________________________________________________88

Using the DIP Switch (Self-test) ______________________________________________________89

Setting the DIP Switch Settings _______________________________________________________91

Running the 15-Shade Self Test _______________________________________________________92

Interfacing Information ________________________________________________________________93

Reviewing the Pin Assignments _______________________________________________________93

Reviewing the Centronics Parallel Pin Assignments _______________________________________94

Reviewing the Printer Timing Diagram _________________________________________________96

Reviewing the Printer Timing ________________________________________________________97

Section 3: Printer Adjustments__________________________________________________ 98

Safety Messages (review carefully)_______________________________________________________98

Using the Settings dialog box ___________________________________________________________99

Using the Image Darkness option_____________________________________________________100

Using the Image Placement option ____________________________________________________101

Using the Print Length option________________________________________________________102

Using the Magnetic Offset option_____________________________________________________103

Using the Flipper Offset option ______________________________________________________104

Using the Lamination Placement option________________________________________________105

Adjusting the Card Flattener_________________________________________________________107

Adjusting the Laminator____________________________________________________________109

Printer Driver Options________________________________________________________________111

Using the Calibrate tab _______________________________________________________________112

Using Image Position controls _______________________________________________________113

Using the Lamination Position control _________________________________________________115

Using the Sensors and Settings buttons ________________________________________________116

Using the Magnetic Encoding tab _______________________________________________________118

Using the Encoding Mode option _____________________________________________________120

Using the Coercivity option _________________________________________________________121

Using the Magnetic Track Selection option _____________________________________________121

Reviewing the Enable MLE Support checkbox __________________________________________123

Using the Magnetic Track Options____________________________________________________124

Using the Bit Density radio buttons ___________________________________________________125

Using the Character Size radio buttons_________________________________________________125

Using the ASCII Offset ____________________________________________________________126

Using the LRC Generation radio buttons _______________________________________________127

Using the Character Parity radio buttons _______________________________________________127

Using the Verification radio buttons___________________________________________________128

Using the Shift Data Left checkbox ___________________________________________________129

Using the Encode Before Print checkbox _______________________________________________129

Reviewing ISO Track Locations _____________________________________________________130

Sending Track Information__________________________________________________________131

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 12

Page 13

RESTRICTED USE ONLY Fargo Electronics, Inc.

Entering Track Information _________________________________________________________131

Reviewing Tracks 1, 2 and 3 (in table format) ___________________________________________132

Reviewing the Track Data Note ______________________________________________________132

Reviewing the ASCII Code and Character Table_________________________________________133

Using the Lamination tab _____________________________________________________________134

Selecting from the Lamination Side dropdown menu _____________________________________135

Selecting from the Lamination Type dropdown menu _____________________________________136

Selecting Lamination Dwell Time and Temperature ______________________________________138

Using the Overlay / Print Area tab ______________________________________________________139

Using the Overlay / Print Area dropdown menu _________________________________________140

Using the Overlay / Print Area _______________________________________________________141

Using Security Options (Visual Security Solutions)_______________________________________147

Selecting Orientation - Landscape under Card tab ________________________________________148

Selecting the Visual Security Solutions dropdown menu (A to D) ___________________________149

Selecting Orientation - Portfolio under Card tab _________________________________________150

Selecting the Visual Security Solutions dropdown menu (E to H)____________________________151

Selecting the VeriMark radio button __________________________________________________152

Selecting the HoloMark radio button __________________________________________________153

Reviewing the Custom VeriMark Card (Custom Graphic in a 2D foil) ________________________154

Reviewing the Custom HoloMark Card (Custom Graphic in a 2D foil) _______________________155

Using SmartShield Area dropdown menu ______________________________________________156

Using the Image Color tab_____________________________________________________________157

Using the K Panel Resin tab _________________________________________________________159

Selecting from the Print All Black With K Panel options __________________________________160

Selecting the Full Card option _______________________________________________________161

Selecting the Defined Area(s) option __________________________________________________162

Selecting the Undefined Area(s) option ________________________________________________163

Using the Defined Area(s) function ___________________________________________________164

Using the Device Options tab __________________________________________________________173

Selecting the Ribbon Type __________________________________________________________174

Selecting from the Color Matching options _____________________________________________175

Selecting from the Resin Dither dropdown menu_________________________________________176

Selecting the Print Both Sides checkbox _______________________________________________177

Selecting the Split 1 Set of Ribbon Panels checkbox ______________________________________178

Using the Print Back Side First option _________________________________________________179

Selecting the Print Back Side Only checkbox ___________________________________________180

Selecting the Rotate Front 180 Degrees checkbox ________________________________________180

Selecting the Rotate Back 180 Degrees checkbox ________________________________________180

Selecting the Buffer Single Card checkbox _____________________________________________181

Selecting the Disable Printing checkbox _______________________________________________181

Selecting the Pause for Low Ribbon checkbox __________________________________________182

Using the Card tab___________________________________________________________________183

Selecting the Card Size_____________________________________________________________183

Selecting the Orientation ___________________________________________________________183

Determining the number of Copies____________________________________________________183

Clicking on the Test Print button _____________________________________________________183

Clicking on the About button ________________________________________________________184

Section 4: Cleaning___________________________________________________________ 185

Cleaning the Printhead _____________________________________________________________186

Cleaning the Card Feed Rollers ______________________________________________________187

Replacing the Cleaning Tape ________________________________________________________189

Cleaning the Platen Rollers _________________________________________________________191

Cleaning the Printer’s Exterior _______________________________________________________192

Cleaning the Printer’s Interior _______________________________________________________192

Cleaning the Magnetic Encoder ______________________________________________________193

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 13

Page 14

RESTRICTED USE ONLY Fargo Electronics, Inc.

Section 5: Packing the Pro-LX Card Printer______________________________________ 194

Section 6: Board Level Diagnostics ______________________________________________ 195

Board Errors _______________________________________________________________________195

Resolving the EE Memory Error _____________________________________________________195

Resolving the EE Checksum Error____________________________________________________195

Resolving the DRAM Memory Error__________________________________________________196

Sensor Testing______________________________________________________________________196

Reviewing the Sensor Location and Voltages ___________________________________________197

Reviewing the Motor Voltages (when active) ___________________________________________198

Section 7: Fargo Technical Support_____________________________________________ 199

Contacting Fargo Technical Support_____________________________________________________199

Reading the Serial Numbers on a Fargo printer ____________________________________________200

Finding out when a Fargo Card Printer was manufactured _________________________________200

Reviewing Example No. 1: Serial Number 80453289_____________________________________200

Reviewing Example No. 2: Serial Number A1280224 ____________________________________200

Section 8: Reviewing the Spare Parts List________________________________________ 201

Glossary of Terms ____________________________________________________________ 202

Index_______________________________________________________________________ 222

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 14

Page 15

RESTRICTED USE ONLY Fargo Electronics, Inc.

Section 1: Specifications

The purpose of this section is to provide the User with specific information on the Regulatory

Compliances, Agency Listings, Technical Specifications and Functional Specifications for the

Pro-LX Laminating Card Printer/Encoder (Rev. 3.0).

Regulatory Compliances

Term Description

CSA The Printer manufacturer has been authorized by UL to represent

the Card Printer as CSA Certified under CSA Standard 22.2.

File Number: E145118

FCC The Card Printer complies with the requirements in Part 15 of the

FCC rules for a Class B digital device. (Note: These

requirements are designed to provide reasonable protection

against harmful interference in a residential installation.)

If equipment operation in a residential area causes unacceptable

interference to radio and TV reception, the operator is required to

take whatever steps are necessary to correct the interference.

ITS-EMC The Card Printer has been tested and complies with EN55022

Class B: 1995 and EN82082-1: 1997 standards for EMI

emissions.

(Note: Based on the above testing, the Printer manufacturer

certifies that the Card Printer complies with all current EMC

directives of the European Community and has placed the CE

mark on the Card Printer.)

License Number: J99032510

TÜV-GS The Card Printer has been tested and complies with IEC950 and

bears the TÜV-GS mark.

License Number: S9971826

UL The Card Printer is listed under UL 1950 INFORMATION

TECHNOLOGY EQUIPMENT.

File Number: E145118, Volume 1, Section 15

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 15

Page 16

RESTRICTED USE ONLY Fargo Electronics, Inc.

Agency Listings

Term Description

Emissions

Standards

Safety

Standards

CE, FCC, CRC c1374, BSMI, ITS (EN 55022 Class B:1995, FCC

Class B, EN 82082-1:1997).

UL 1950, CSA C2.2 No.950-95 and TüV-GS (EN 60950 A1-A4, A11).

Technical Specifications

Term Description

Accepted

Standard Card

Size

Accepted Card

Thickness

Accepted Card

Types

Card Capacity 100 cards (30 mil).

Colors Up to 16.7 million colors and 256 shades per pixel.

CR-80: 3.375 in. x 2.125 in. (85.6mm x 54mm)

.020 in. (20 mil) to .040 in. (40 mil) (.508mm to 1.02mm).

PVC or Polyester cards with polished PVC finish

Dimensions 10.44 in. H x 24.79 in. W x 10.3 in. D (265mm x 630mm x 260mm).

Encoding

Options

Humidity 20% to 80% Non-Condensing.

Interface Centronics parallel, IEEE-1284 Compliant

Memory 4 MB RAM; expandable to 16 MB RAM.

Operating

Temperature

ISO Magnetic Stripe Encoding Module, dual high- and low-

coercivity, Tracks 1, 2 and 3

JIS II Magnetic Stripe Encoding Module

E-card Docking Station (required for 3rd party smart card encoding)

65ºF to 80ºF (18ºC to 27ºC).

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 16

Page 17

RESTRICTED USE ONLY Fargo Electronics, Inc.

Technical Specifications (continued)

Term Description

Overlaminate

Options

Thermal Transfer Overlaminate, .25 mil thick, 500 prints

PolyGuard Overlaminate, .6 mil thick, 250 prints

PolyGuard Overlaminate, 1.0 mil thick, 125 prints

All overlaminates available in either clear, holographic globe design or

custom holographic design; can also be optimized for use with smart

cards and Magnetic Stripes

Printing Method Dye Sublimation/Resin Thermal Printer

Printing

300 dpi (11.8 dots/mm).

Resolution

Print SpeedBatch Mode

8 seconds per card / 450 cards per hour (K)*

15 seconds per card / 240 cards per hour (BO)*

30 seconds per card / 120 cards per hour (YMCKO)*

30 seconds per card / 120 cards per hour (YMCK/lamination)

37 seconds per card / 97 cards per hour (YMCKK/lamination)

Print speed indicates an approximate batch print speed and is

measured from the time a card feeds into the Printer to the time it

ejects from the Printer.

Print speeds do not include the time needed for the PC to process the

image.

Process time is dependent on the size of the file, the CPU, amount of

RAM and the amount of available resources at the time of the print.

(Note: The single card print speeds will be slower than the batch print

speeds listed above since batch print speed is enhanced by the

Printer's multi-tasking capabilities when printing multiple cards in

succession.)

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 17

Page 18

RESTRICTED USE ONLY Fargo Electronics, Inc.

Technical Specifications (continued)

Term Description

Print Ribbon

Options

Full Color with resin black, YMCKO*, 250 prints

Full Color with two resin black panels, YMCKOK*, 250 prints

Full Color with resin black, no overlay panel, YMCKK*, 250 prints,

must be used with overlaminate

Dye-Sublimation black, BO*, 500 prints

Resin black, green, blue, red, white, silver, gold, scratch-off, 1000

prints

*Indicates the ribbon type and the number of ribbon panels printed

where Y=Yellow, M=Magenta, C=Cyan, K=Resin Black, O=Overlay,

B=Dye-Sublimation Black

Print Area CR-80 edge to edge (3.37”L x 2.11”W / 85.5mmL x 53.5mmW)

Supply Voltage 100 to 240 V ac.

Supply

50 Hz/60 Hz.

Frequency

Software Drivers Windows 95/ 98/ ME/ NT/ 2000/XP.

System

Requirements

IBM-PC or compatible. Windows 95/ 98/ ME/ NT/ 2000/XP. Pentium™

class 133 MHz computer with 32 MB of RAM or higher, 200 MB free

hard disk space or higher and ECP parallel port with DMA access.

Warranty Printer - One year; optional Extended Warranty Program (U.S. only)

Printhead - One year, unlimited pass with UltraCard cards

Weight 40 lbs. (18.2kg).

Kits, Adapters

and Cable

16MB RAM Upgrade Kit

Printer Cleaning Kit

Ethernet Interface Adapter (Windows only; required for stand-alone

networking of Printers)

USB-to-Parallel Interface Cable (Windows 98/ME/2000/XP only)

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 18

Page 19

RESTRICTED USE ONLY Fargo Electronics, Inc.

Functional Specifications

The Card Printer utilizes two different, yet closely related printing technologies to achieve its

remarkable direct-to-card print quality for dye-sublimation and resin thermal transfer. (Note:

The Card Printer will print from any IBM-PC® or compatible running Windows® 95/98/ME,

Windows NT 4.0, Windows 2000 or Windows XP.)

The following describes how each of these technologies works:

Function Description

DyeSublimation

Resin

Thermal

Transfer

Dye-Sublimation is the print method the Pro-LX Laminating Card

Printer/Encoder uses to produce smooth, continuous-tone, photographic

images. This process uses a dye-based ribbon roll that is partitioned by a

number of consecutive color panels.

The panels are grouped in a repeating series of these three process

colors along the entire length of the Print Ribbon: yellow, magenta and

cyan (YMC).

The Printer always prints the yellow panel (first), the magenta panel

(second) and the cyan panel (third).

As the Print Ribbon passes beneath the Printhead, thermal elements

within the Printhead heat the dyes on the ribbon. (Note: When these

dyes are heated, the dyes vaporize and diffuse into the surface of the

card. A separate pass is made for each of the three color panels on the

ribbon.)

By combining the colors of each panel and by varying the heat used to

transfer these colors, it is possible to print up to 16.7 million different

shades of color. This blends one color smoothly into the next, producing

photo-quality images with no dot pattern.

Resin Thermal Transfer is the print method the Printer uses to print sharp

black text and crisp bar codes that can be read by both infrared and visiblelight bar code scanners.

Like dye-sublimation, this process uses the same thermal Printhead to

transfer color to a card from a resin-only Print Ribbon or the resin black (K)

panel of a full color Print Ribbon.

The difference, however, is that solid dots of resin-based ink are

transferred and fused to the surface of the card to produce durable,

saturated printing.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 19

Page 20

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Top Cover to Power Port

Component Description

Print Top

Cover

Opens to allow access to the Printhead, Print Ribbon and card path.

(Note: This cover must be closed in order for the Printer to begin

printing.)

Lamination

Top Cover

Opens to allow access to the lamination roller, overlaminate and card

path. (Note: This cover must be closed in order for the Printer to begin

printing.)

Cover

Unlatches the Top Covers.

Release

Buttons

Printhead

Printer component that prints. (Note: This component is fragile and must

not be bumped or touched with anything other than a cleaning pen.)

Card

Cleaning

Cartridge

Automatically cleans cards for higher print quality. (Note: Replace the

Card Cleaning Tape within this assembly after every 1,500 cards or as

needed depending on the cleanliness of the card stock and the

environment in which the Printer is located. Replace this tape if the cards

start showing speckles or debris on the printed surface.)

LCD Display The LCD display shows the User the current status of the Printer. Since

the Printer's printing and laminating functions work independently, the top

line of the LCD reports the status of the printing functions, while the

bottom line reports the status of the laminating functions.

When the Printer is first powered ON, the Printer's startup screen will

appear displaying the current firmware version and the amount of

installed Printer memory (4MB or 16MB).

Once the Printer has finished its startup system check, it will then display

Printer Ready and Lam Ready to indicate that the Printer is ready for

operation. Lam Temp=XX% will display if the Printer's built-in laminator is

heating or cooling to its target temperature. When it reaches 100%,

lamination will begin.

During operation, the LCD will also indicate the specific ribbon panel

being printed, whether or not it is laminating and if any printing errors

have occurred.

On LED Light

Indicates the Printer power is either ON or OFF.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 20

Page 21

RESTRICTED USE ONLY Fargo Electronics, Inc.

Print Top Cover

Ready LED Light

Access Card Slot

Card Input Hopper

Rejection Card Hopper

Printer Components: Top Cover to Power Port (continued)

This table displays Printer components. Refer to the table in this section.

Printhead

Card Cleaning Cartridge

Lamination Top Cover

Cover Release

Buttons

Card Output Hopper

LCD Display

On LED Light

Pause/Resume

Button

On/Cancel

Button

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 21

Card Thickness

Adjustment Slide

Page 22

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Top Cover to Power Port (continued)

Component Description

Ready LED

Light

On/Cancel

Button

Pause/

Resume

Button

When ON, this light indicates the Printer is ready for operation. When

OFF, this light indicates the Printer is either OFF or paused and will not

operate.

If this light is flashing, a Printer error has occurred. (Note: Refer to the

Printer's LCD display for the specific type of error that occurred. See the

Interpreting LCD Messages for a complete description of all possible LCD

error prompts.

The On/Cancel button turns the Printer power ON and OFF. It also

serves to cancel the current print job and reset the Printer for the next

print job if an unrecoverable print error has occurred.

If a card is left within the Printer after a print job is canceled, it will

automatically be ejected when the Printer is turned back ON. (Note:

With the Top Cover(s) open, this button can also be used to manually

rotate the feed Rollers forward. This is helpful when cleaning the Printer

or if clearing jammed media.)

The Pause/Resume button allows the User to pause the Printer at any

time during operation. Note, however, that the Printer will always finish its

current task before pausing.

If the Pause/Resume button is pressed in the middle of printing the

magenta ribbon panel, the Printer will pause only after the entire magenta

panel has printed. (Note: The Ready LED Light will turn OFF when the

Printer is paused and ON again when operation is resumed. With the Top

Cover(s) open, this button can also be used to manually rotate the feed

Rollers backward. This is helpful when cleaning the Printer or if clearing

jammed media.)

Access Card

Slot

This is the slot in which a SmartGuard Access Card is inserted when

using the Printer's included SmartGuard Security Feature. (Note: This

unique option prevents the Printer from operating unless a custom

access card is inserted. It also allows the User to print custom

SmartShield Security Images which glow under ultraviolet light.)

Card Input

Load blank cards into this Hopper.

Hopper

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 22

Page 23

RESTRICTED USE ONLY Fargo Electronics, Inc.

Parallel Interface Port

Power Port

Printer Components: Top Cover to Power Port (continued)

Component Description

Card Thickness

Adjustment Slide

Card Output

Hopper

Rejection Card

Hopper

E-Card Docking

Station Port - For

Smart Card

Support

Parallel Interface

Port

Power Port Connects to the included power.

Adjusts the Printer to feed varying card thicknesses. See the

Resolving the Card Feeding Errors procedure in Section 2, page 46.

Stores printed cards; up to 100, 30 mil cards.

Stores cards that have not printed or encoded properly. Helps to

separate potential bad cards from a stack of good cards, which eject

into the Card Output Hopper. (Note: The Printer will automatically

eject cards into this Hopper if there is a printing error, encoding error

or if a card is left in the Printer after a print job is canceled or the

Printer restarted.)

Provided only if the Printer includes an optional E-Card Docking

Station. This is necessary for support of third party smart card

encoding features.

Connects to a Windows PC with a parallel cable.

E-Card Docking

Station Port

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 23

Page 24

RESTRICTED USE ONLY Fargo Electronics, Inc.

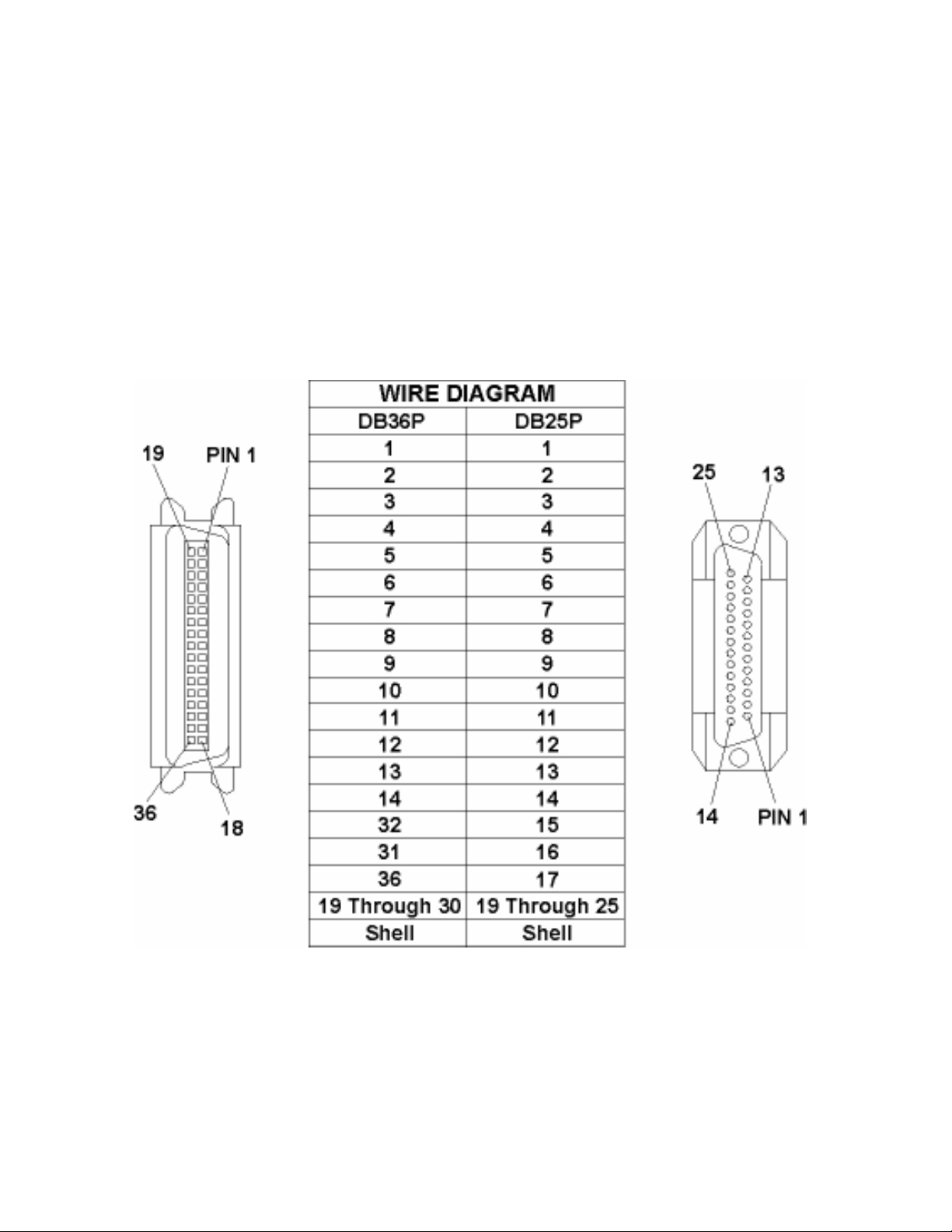

Printer Components: Centronics-Type Parallel Interface

The Card Printer is equipped with a standard 8-bit centronics-type parallel interface port. This

communication port is the means through which the Printer receives data from the computer.

This section describes the pin assignments and signal specifications for this port.

The Centronics-type parallel interface is the most widely used Printer interface due to its

simplicity, speed and standardization throughout the PC industry. The Printer's parallel

interface connector is a standard 36-pin Amp type with two metal-wire retaining clips and is

ECP (Extended Capabilities Port) compatible. It mates with a standard, bi-directional PC to

Printer parallel cable.

For best results, keep the interface cable to less than 6 feet in length.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 24

Page 25

RESTRICTED USE ONLY Fargo Electronics, Inc.

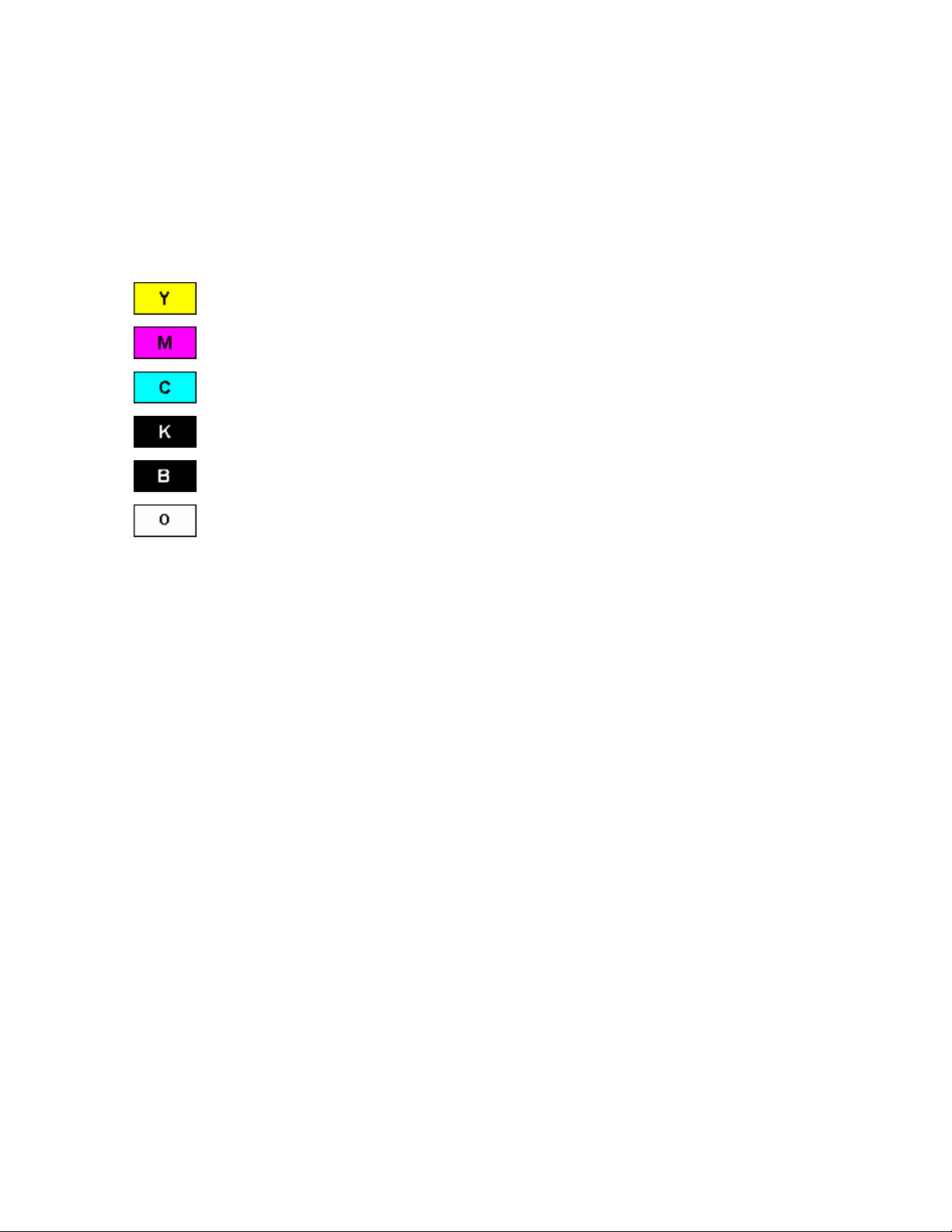

Printer Components: Print Ribbons

The Card Printer utilizes both dye-sublimation and/or resin thermal transfer methods to print

images directly onto blank cards. Since the dye-sublimation and the resin thermal transfer

print methods each provide their own unique benefits, Print Ribbons are available in resinonly, dye-sublimation-only and combination dye-sublimation/resin versions. (Note: A letter

code has been developed to indicate the type of ribbon panels found on each ribbon.)

This letter code is as follows:

= Dye-Sublimation Yellow Panel

= Dye-Sublimation Magenta Panel

= Dye-Sublimation Cyan Panel

= Resin Black Panel

= Dye-Sublimation Black Panel

= Clear Protective Overlay Panel

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 25

Page 26

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Resin-Only Print Ribbons

Resin-only Print Ribbons consist of a continuous roll of a single resin color. No protective

overlay panel (O) is provided since resin images do not require the protection of such an

overlay.

Type Description

Standard Resin Black

(K) (provides 1,000

prints)

Premium Resin Black

(K) (provides 1,000

prints)

Colored Resin

(provides 1,000 prints)

Metallic Resin

(provides 1,000 prints)

Scratch-Off Resin

(provides 1,000 prints)

This ribbon provides high resin durability ideal for most general

purpose monochrome ID card applications. Resin black bar

codes are readable by both infrared and visible-light bar codes

scanners.

This ribbon provides maximum resin durability ideal for

applications such as access control where cards are repeatedly

swiped through a Magnetic Stripe reader. Resin black bar codes

are readable by both infrared and visible-light bar codes

scanners.

Colored resin ribbons are available in different colors for

customizing or color coding resin-only ID cards.

Metallic resin ribbons are available for printing resin images with

a unique metallic sheen.

A scratch-off resin ribbon is available for printing over areas of a

pre-printed card in order to hide specific information such as a

personal identification number.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 26

Page 27

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Dye-Sublimation-Only Print Ribbons

A dye-sublimation-only Print Ribbon is available in a monochrome version. This ribbon

consists of dye-sublimation ribbon panels which alternate with a clear protective overlay (O)

panel. Dye-Sublimation images must have an overlay panel applied to them or they will

quickly begin to wear or fade.

Caution: All color or monochrome dye-sublimation images must have the ribbon's

clear overlay panel or an overlaminate applied to them. If a protective layer is not applied, the

card's dye-sublimation image will quickly begin to wear or fade. Cards printed solely with

monochrome resin text, bar codes or images do not require any type of protective overlay.

To apply the ribbon's clear overlay panel, select the Printer Driver’s Overlay / Print Area tab.

By default, the Printer Driver is setup to automatically apply the overlay panel for a selected a

ribbon type that provides an overlay (O) panel. To apply an overlaminate, select the

Lamination tab.

(Note: The Printer requires specialized Print Ribbons in order to function properly.)

Type Description

Dye-Sublimation

Black (BO)

(provides 500

prints)

Dye-Sublimationonly Print Ribbon

DyeSublimation/Resin

Print Ribbon

This ribbon provides a dye-sublimation black panel (B) along with an

overlay panel (O) and is used to print smooth, photo-quality black and

white photo ID cards. Dye-Sublimation bar codes are readable only by

visible-light bar codes scanners.

It is available in a monochrome version. This ribbon consists of dyesublimation ribbon panels which alternate with a clear protective

overlay (O) panel. Dye-Sublimation images must have an overlay panel

applied to them or they will quickly begin to wear or fade.

The Dye-Sublimation/resin Print Ribbon combines the yellow (Y),

magenta (M) and cyan (C) dye-sublimation panels with a resin black

(K) panel.

By combining both types of ribbon panels, this ribbon can be used to

print full-color, photo-quality images with the dye-sublimation panels

along with sharp, black text and bar codes with the resin black panel.

A clear overlay panel (O) is also included on most ribbons to protect the

dye-sublimation images. Dye-Sublimation images must have an overlay

panel or overlaminate applied to them or they will quickly begin to wear

or fade.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 27

Page 28

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Dye-Sublimation-Only Print Ribbons (continued)

Type Description

Full-Color

(YMCKO)

(provides 250

prints)

Full-Color

(YMCKOK)

(provides 250

prints)

Full-Color

(YMCKK)

(provides 250

prints)

This ribbon is used to print full-color photo ID cards along with resin black

text and bar codes. Both infrared and visible-light bar code scanners can

read bar codes printed with resin black.

An overlay panel (O) is included to protect the full-color dye-sublimation

printing.

This ribbon is used for dual-sided printing. By supplying two resin black

panels, this ribbon used to print full-color with resin black on one side and

resin black-only on the other, without wasting an entirely new set of

ribbon panels for the black-only side.

An overlay panel (O) is also included to protect the side of the card with

full-color dye-sublimation printing. No overlay is necessary for the resin

black-only side. Both infrared and visible-light bar code scanners can

read bar codes printed with resin black.

This ribbon is intended to be used for dual-sided printing. By supplying

two resin black panels, this ribbon lets you print full-color with resin black

on one side and resin black-only on the other, without wasting an entirely

new set of ribbon panels for the black-only side.

Since no overlay panel is included, this ribbon must be used in

conjunction with the Printer's overlaminate feature. No overlaminate is

necessary for the resin black-only side. Both infrared and visible-light bar

code scanners can read bar codes printed with resin black.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 28

Page 29

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Blank Cards

Caution: Never run cards with a contaminated, dull or uneven surface through the

Printer. Printing onto such cards will ultimately lead to poor print quality and will greatly

reduce the life of the Printhead. Always store the card stock in its original packaging or in a

clean, dust-free container. Do not print onto cards that have been dropped or soiled.

Printhead damage caused by contaminated or poor quality cards will automatically void the

Printhead's factory warranty.

Type Description

Card Size The Card Printer accepts standard CR-80 sized cards (3.375"L x 2.125"W /

85.6mmL x 54mmW) with a thickness of 30 mil (.030"/. 762mm).

Card

Design

Card

Surface

UltraCard

Stock

The Printer will print onto any card with a clean, level and polished PVC

surface.

Although the Printer is equipped with card cleaning Rollers, it is very important

to always print onto cards specifically designed for direct-to-card dyesublimation printing.

Suitable cards must have a polished PVC surface free of fingerprints, dust or

any other types of embedded contaminants. In addition, cards must have a

completely smooth, level surface in order for the Printer to achieve consistent

color coverage.

Certain types of Proximity cards have an uneven surface that will inhibit

consistent color transfer.

Certain types of smart card chips are raised slightly above the cards

surface which also results in poor color transfer.

UltraCard stock has a glossy PVC laminate on top and bottom and is optically

inspected to provide the scratch- and debris-reduced cards. Two types of

these cards are available: UltraCard and UltraCard III.

UltraCard stock has a PVC core and offers medium card durability.

UltraCard III stock has a 40% polyester core and offers high durability.

(Note: Both types of UltraCards produce printed images with a glossy, photoquality finish.)

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 29

Page 30

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Laminator

Danger: The Printer’s Lamination Roller can reach temperatures exceeding 350

degree F (175° C). Use extreme caution when operating the Laminator. Never touch the

Lamination Roller unless the Printer Power has been turned off for at least 20 to 30 minutes.

Type Description

Controls Both the Printer itself and the Printer’s software driver control the built-in

laminator.

Temperature Upon initial power up of the Printer, the bottom line of the LCD display will

read Lam Temp = X%. (Note: This indicates that the laminator is heating

up to its preset or default laminating temperature of approximately 300° F

(150° C). The percentage number indicates how close it is to achieving

100% temperature.)

Heating

Process

Temperature

Adjustment

New

Temperature

Setting

This heating process will generally take about 3 to 4 minutes before the

laminator is heated to the default temperature. (Note: Once the laminator

reaches 100% of its default temperature, the LCD display will change to

Lam Ready.)

(Note: The LCD display will read Lam Temp = X% whenever the laminator

is heating up or cooling down to the prescribed temperature. When the

Lam Temp = 100%, the target temperature has been reached and

lamination will begin.)

To change the temperature of the laminator, adjust its temperature through

the Lamination tab within the Printer Driver setup window. (Note: Once

adjusted, the new temperature settings will be sent down with the next print

job along with the rest of the Printer Driver information.)

Before printing begins, the laminator will automatically adjust itself to the

new temperature setting. (Note: This new temperature setting will remain

programmed within the Printer until it is once again changed within the

Printer Driver or until the Printer is turned OFF.)

Whenever the Printer is turned OFF, the laminator will automatically reset

itself and return to its default temperature the next time the Printer is turned

ON.

Press the On/Cancel button to disconnect the Printer's power cord both

serve to reset the laminator to its default temperature. The temperature

setting within the Printer Driver, however, will stay the same until it is

changed.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 30

Page 31

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the upgraded 81754 PVC Cards

The upgraded 81754 PVC cards are designed for a sharper card image quality and for

reduced debris and defects on Fargo Card Printers. Carefully read these detailed notes and

instructions before applying this information to your Fargo printer or printers.

Technician Note 1: The new card lot number starts at Lot # 2010104 with date codes

that started on 04/01/2003. The photo (below) shows a lot number that starts after Lot #

2010104, indicating a new card lot number. The card lot number and date can be read

on the bar code label attached to the shrink-wrapped stack of 100 cards, as shown

below. All new Fargo printers with a serial number (S/N) starting with A320 will have factory

settings for these new 81754 PVC cards.

Technician Note 2: Do not use the new 81754 PVC card stock with Fargo laminating

printers/encoders. This same guideline is used for the existing 81754 PVC card stock. Fargo

recommends using the UltraCard III stock with the Fargo laminating printers/encoders.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 31

Page 32

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the upgraded 81754 PVC Cards (continued)

Follow these two (2) instructions below:

1. Instruction for new 81754 PVC card stock: Increase the Printer Driver’s Dye-Sub

Intensity to print with the new 81754 PVC card stock on Fargo Card Printers (S/N A319

and older). See the chart provided below. See the appropriate Fargo service documents

for specific Printer Driver instructions.

Card New Printer (S/N A320 and

newer)

Old Printer (S/N A319 and

older)

New Card No Change Necessary Increase the Dye-Sub Intensity as

follows:

HDP®: N/A

Pro-LX/C25: 3 - 5 %

DTC500: 5 -10 %

C11/C16: 3 - 5 %

2. Instruction for existing 81754 PVC card stock: The Printer Driver’s Dye-Sub Intensity

setting may or may not need to be decreased to print existing card stock. See the chart

provided below. See the appropriate Fargo service documents for specific Printer Driver

instructions.

Technician Note 1: To control the brightness of the image, adjust the Dye-Sub

Intensity slide on the Image Color tab of the Printer Driver.

Technician Note 2: Moving the Dye-Sub Intensity slide to the left causes less heat

to be used in the printing process, thus generating a lighter print.

Card New Printer (S/N A320 and

Old Printer (S/N A319 and older)

newer)

Old Card Decrease the Dye-Sub Intensity

No Change Necessary

as follows:

HDP®: N/A

Pro-LX/C25: 3 - 5 %

DTC500: 5 - 10 %

C11/C16: 3 - 5 %

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 32

Page 33

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Laminator

The Printer's internal lamination system is used to choose between both a Thermal Transfer

Film overlaminate and a polyester patch overlaminate called PolyGuard™. The Thermal Film

overlaminate is a relatively thin material that covers a card edge-to-edge and provides a

medium level of ID card durability and security.

PolyGuard is a much thicker material that does not cover edge-to-edge, but provides an

extremely high level of ID card durability and security.

PolyGuard is available in either a 1.0 or .6 mil thickness and should always be used for

those applications requiring the highest degree of ID card durability and security.

PolyGuard and the Thermal Film overlaminates are available in either a clear or generic

"secure" holographic-type design. (Note: Custom holographic-type overlaminate designs

are also available with specific designs, patterns, logos and security features. Please

contact an authorized reseller for more information.)

Caution: If using the Thermal Transfer Film overlaminate, a variety of laminating

options are available within the Printer Driver. Refer to the Using the Lamination tab

description in Section 3, page 134, for complete details about these options.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 33

Page 34

RESTRICTED USE ONLY Fargo Electronics, Inc.

Visual Security Solutions (Specifications)

VeriMarkTM Cards - 2-D holographic foil application

VeriMarkTM Cards are a low cost, customized 2-D holographic foil application, that is made

in two steps.

The first step is to emboss a base foil 1.9 cm (L) x 1.3 cm (H) onto the surface of a blank

white card.

The second step is debossing a custom made dye into the surface of the base foil -

leaving a customized image, logo or text provided by the customer.

Two separate color foils are used to contrast the impression.

End Users will be able to choose between 8 different card placements (4 - landscape) and

(4-portrait) where the VeriMarkTM can be located. When its time to print through the driver,

the End User will select the location on their organizations card design around which no

printing and overlay will be placed.

Custom HoloMarkTM Cards

A Custom HoloMark TM Card is a three-dimensional holographic image transferred to metal

foil and embossed to blank cards. The image is customer specific and the program mirrors

our holographic laminates program with a couple exceptions.

Visual Security - Card Stock Part Numbers

All Visual Security Cards will be offered on the following Fargo Card Stocks only:

P/N# 81754 Ultra Card

P/N# 81762 Ultra Card III with hi-coercivity magnetic stripe

P/N# 81763 Ultra Card III

Visual Security - Fargo Certified Overlaminates (Special Order in 50

quantity minimum)

Part No. 82255: PolyGuard 1.0 mil for HoloMarkTM and VeriMarkTM Cards, Clear

Part No. 82256: PolyGuard 1.0 mil for HoloMarkTM and VeriMarkTM Cards, High

Resolution Globe design hologram with "Secure" micro-text

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 34

Page 35

RESTRICTED USE ONLY Fargo Electronics, Inc.

Visual Security Card Stock - Tolerances

Tolerance of base foil placement will equal +/- .010" from the nearest edges of the card

Tolerance of layered foil will equal +/- .010"

VeriMarkTM - Application Specifications

VeriMarkTM foils will cover a dimensional area of 1.9 cm length x 1.3 cm height. The

exclusive areas are as follows:

VeriMarkTM Card customers will be able to choose 1 of 8 pre-defined placements

(corners) via printer driver (4 positions) Landscape and (4 Positions) Portrait mode.

VeriMarkTM foil placement will not interfere with card punch slots .

Foil color base is silver; debossed impression is gold foil.

VeriMarkTM foil placement will be located 0.4 cm from the edges of the card except for

the top two locations on portrait orientation cards (positions E & F). The foil will be

located 0.9 cm from the top of the card and 0.4 cm from the sides of the card.

HoloMarkTM and Custom HoloMarkTM - Application Specifications

HoloMarkTM and Custom HoloMarkTM foils will cover a dimensional area of 1.5 cm x 1.5

cm. The exclusive areas are as follows:

HoloMarkTM and Custom HoloMarkTM card end-users will be able to choose 1 of 8 pre-

defined placements (corners) via printer driver (4 positions) Landscape and (4 positions)

Portrait mode.

HoloMarkTM foil placement will not interfere with card punch slots.

Foil Color options will be silver or gold.

Outside edge placement of Foil impression options on card will be 0.4 cm from edge of

card.

HoloMarkTM foil placement options will be at all four corners of card located 0.4 cm from

edge of card.

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 35

Page 36

RESTRICTED USE ONLY Fargo Electronics, Inc.

Section 2: General Troubleshooting

The purpose of this section is to provide the User with specific procedures relating to the

LCD/SmartGuard Messages, Communication Errors, Card Feeding Errors, Print Process

Errors, Card Jam Errors, Ribbon Errors, Encoding Errors, Diagnosing Image Problems,

Running the Self-Test and Interfacing Information for the Pro-LX Laminating Card

Printer/Encoder.

LCD/SmartGuard Messages

The LCD display shows the current status of the Printer. Refer to the cause and solution

tables in this section for all possible LCD messages. (Note: These tables display the LCD

messages in alphabetical order. If the LCD message is communicating an error or requires

an action, these tables will also offer a solution to what should be done.)

Reviewing the Top Line LCD Messages

Message Cause

Card Jam: Flip A card is jammed in the Flipper Table area of the Printer. See the

Clearing the Card Jam: Flip Error Message procedure in Section 2,

page 56.

Card Jam: Mag A card is jammed in the Mag Encoding module, beneath the Flipper

Table. See the Clearing the Card Jam: Mag Error / Smart Error

procedure in Section 2, page 54.

Card Jam: Print A card is jammed somewhere along the printing path, under the

Printer's top-right cover. See the Clearing Card Jam: Print Error

procedure in Section 2, page 53.

Card Jam: Smart A card is jammed in the smart card encoding module, beneath the

Card Flipping Mechanism. See the Clearing the Card Jam: Smart

Error procedure in Section 2, page 54.

Card Jam: Lam A card is jammed in the print station of the Printer. See the Clearing

the Card Jam: Lam Error procedure in Section 2, Page 55.

Card Out/Not Fed Either the Card Hopper is out of cards or the Printer is unable to feed

a card in from the Card Hopper. See the Clearing Card Jam Error

procedure in Section 2, page 53.

Clearing Jam Indicates error or jam is being cleared.

Feeding Card Indicates card is feeding properly.

Flipper Jam Card Flipping Mechanism is unable to rotate. See the Resolving the

Flipper Jam Error Message procedure in Section 2, page 48.

Continued on the next page

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 36

Page 37

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the Top Line LCD Messages (continued)

Message Cause

Flipping Card Indicates card is being flipped for backside printing.

Head-down Failed Printhead is unable to lower itself. See the Resolving the Headlift

Error Message procedure in Section 2, page 49.

Head-up Failed Printhead is unable to raise itself. See the Resolving the Headlift

Error Message procedure in Section 2, page 49.

Invalid Key Card The SmartGuard Access Card is invalid or is inserted backwards or

up side down. Appears only when using the SmartGuard Security

Feature. See the SmartGuard User’s Guide for more information.

Invalid Password An invalid SmartGuard password was entered. Appears only when

using the SmartGuard Security Feature. See the SmartGuard User’s

Guide for more information.

Key Card Ready Indicates SmartGuard or SmartShield data has successfully been

encoded onto the SmartGuard Access Card. Appears only when

using the SmartGuard Security Feature. See the SmartGuard User’s

Guide for more information.

Key Disabled Indicates the SmartGuard Security Feature has been disabled.

Appears only when using the SmartGuard Security Feature. See the

SmartGuard User’s Guide for more information.

Key Not Inserted Attempts are made to print without the SmartGuard Access Card

inserted. Appears only when using the SmartGuard Security

Feature. See the SmartGuard User’s Guide for more information.

Continued on the next page

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 37

Page 38

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the Top Line LCD Messages (continued)

Message Cause

Key Card Deleted Indicates the data on the SmartGuard Access Card was successfully

deleted. Appears only when using the SmartGuard Security Feature.

See the SmartGuard User’s Guide for more information.

Lam Error/Out

Error Message

Indicates a Lam Error/Out Error Message. See Resolving the Lam

Error/Out Error Message procedure in Section 2, page 57.

Low Ribbon/Clean Indicates the Print Ribbon will soon run out and that the Printer

should be cleaned.

Mag Encoding Indicates the Mag Stripe is being encoded.

Mag Verify Error The Mag Stripe was not encoded properly. See Resolving Mag

Verify Error Message Section 2, page 69.

Mag Verifying Indicates data on Mag Stripe is being verified.

No Shield Loaded Attempts are made to print with the Printer Driver's SmartShield

option selected (even though the optional SmartGuard Security

Feature is not used).

OR

If using the SmartGuard feature, the SmartShield image is not

encoded onto the SmartGuard Access Card (currently inserted into

the Printer).

See the SmartGuard User’s Guide for more information.

Print Cover Open Indicates that the top-right cover is not properly shut. If this appears

in error, see the Resolving Cover Open Error Message procedure in

Section 2, page 50.

Printer Ready Indicates the Printer is ready to print.

Printing Indicates the Printer is printing.

Continued on the next page

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 38

Page 39

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the Top Line LCD Messages (continued)

Message Cause

Rasterize Shield Indicates the Printer is loading the SmartShield security image from

the SmartGuard Access Card into its memory. Appears when a valid

access card containing a SmartShield image is first inserted into the

Printer.

(Note: If SmartShield image is named, the name will also appear

along with this message on the bottom line of the LCD Display.

Appears only when using the SmartGuard Security Feature.)

See the SmartGuard User’s Guide for more information.

Reading Key Data Indicates the Printer is reading the data from the SmartGuard

Access Card. Appears when a valid access card is first inserted into

the Printer. Appears only when using the SmartGuard Security

Feature.

See the SmartGuard User’s Guide for more information.

Rib Calib Failed

Error

Indicates that an attempt at calibrating the Ribbon Sensor through

the Printer Driver has failed. See the Resolving the Skipping Ribbon

Panel issues procedures in Section 2, page 59.

Ribbon Error/Out

Error

Indicates either the Print Ribbon is out or a ribbon error has

occurred. See Resolving Ribbon Low Error Message procedure in

Section 2, page 63.

Ribbon Jam/Out

Error

The Print Ribbon has become jammed in the Printer Rollers, it is

stuck to the surface of the card or it is out. See the Resolving the

Ribbon Breaking issues procedure in Section 2, page 64.

Ribbon Low Error

Message

Indicates either the ribbon is running low or is out. See Resolving

Ribbon Low Error Message procedure in Section 2, page 63.

Sensor Calibrate Indicates the Ribbon Sensor is calibrating. See the Resolving the

Skipping Ribbon Panel issues procedures in Section 2, page 59.

Continued on the next page

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 39

Page 40

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the Top Line LCD Messages (continued)

Message Cause

Smart Card Error Unable to encode smart card.

Smart Card Good Indicates smart card was successfully encoded.

Smart Encoding Indicates the Printer is writing or encoding data onto the SmartGuard

Access Card. Appears only when using the SmartGuard Security

Feature. See the SmartGuard User’s Guide for more information.

Writing Key Data Indicates the Printer is writing or encoding data onto the SmartGuard

Access Card. Appears only when using the SmartGuard Security

Feature. See the SmartGuard User’s Guide for more information.

Wrong Ribbon

Error

The wrong Print Ribbon is installed. See the Resolving the Wrong

Ribbon error (being displayed incorrectly) procedure in Section 2,

page 62.

Reviewing the Bottom Line LCD Error / Status Messages

Message Cause

Card Jam: Lam

Error

Clearing Jam Indicates error or jam is being cleared. See Card Jam Errors in

Lam Calib Failed An attempt at calibrating the Lamination Sensor through the Printer

Lam Cover Open The Lamination Top Cover is not properly shut. If this appears in

A card is jammed somewhere along the laminating path, under the

Printer's Lamination Top Cover. See the Resolving the Card Jam:

Lam Error procedure in Section 2, page 55.

Section 2, page 53.

Driver has failed. See the Resolving the Lam Error/Out Error

Message procedure in Section 2, page 57.

error, see the Resolving Cover Open Errors procedure in Section 2,

page 50.

Continued on the next page

Pro-LX Laminating Card Printer/Encoder User Guide (Rev. 5.0) 40

Page 41

RESTRICTED USE ONLY Fargo Electronics, Inc.

Reviewing the Bottom Line LCD Error / Status Messages (continued)

Message Cause