FARGO electronic Color ID Card Printer II User Manual

Operating Instructions

970922-510343-(02)

Color ID Card Printer II

© Copyright 1997 All rights reserved.

Notices

The information in this document is subject to change

without notice.

NO WARRANTY OF ANY KIND IS MADE WITH

REGARD TO THIS MATERIAL, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

No liability is assumed for errors contained herein or for

incidental damages in connection with the furnishing,

performance, or use of this material.

This document contains proprietary information which

is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced,

or translated into another language without prior

written consent.

Patent Pending

Trademark Acknowledgements

IBM is a registered trademark of International Business

Machines Corporation. Windows is a trademark of

Microsoft Corporation. All other trademarks are the

property of their respective owners.

Printing History

Edition 1.2, #970922

© Copyright 1997 All rights reserved.

iii

For Users in the United States:

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio

or television reception, which can be determined by

turning the equipment off and on, the user is

encouraged to try to correct the interference by one or

more of the following measures:

■

Re-orient or relocate the receiving antenna.

■

Increase the separation between the equipment

and receiver.

■

Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

■

Consult the dealer or an experienced radio/TV

technician for help.

Use of a shielded cable is required to comply with the

Class A limits of Part 15 of the FCC Rules.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate and/or obtain warranty service for

this equipment.

For Users in Canada:

This digital apparatus does not exceed the Class A

limits for radio noise for digital apparatus set out on the

Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique nÕemet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la class A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

iv

Table of

Contents

Section 1: Introduction

A. How Your Color ID Card Printer

Works .............................................................1

B. Special Features ...........................................1

Section 2: Safety Precautions...........................3

Section 3: Getting Started

A. Choosing a Good Location ......................12

B. About Moisture Condensation ................12

C. Unpacking and Inspection .......................12

D. Identifying the Parts .................................13

Section 4: Ribbons and Cards

A. About Ribbons ...........................................15

B. Loading Ribbon into the Printer ..............17

C. About Cards................................................18

D. Loading Cards into the Printer ................20

Section 5: Card Laminating

A. About the PrinterÕs Laminator.................21

B. About Overlaminates ................................22

C. Loading the Overlaminate into

the Printer....................................................23

Section 6: Hooking Up the Printer

A. Applying Power ........................................25

B. Running the Self Test ................................25

C. Connecting the Color ID Card

Printer to Your Computer .........................26

Section 7: Installing and Using the Color ID

Card Printer Driver

A. Installing the Windows

Printer Driver .............................................28

B. Installing the 32-Bit Print Spooler for

Windows 95 ................................................30

C. Setting Up the Windows

Printer Driver .............................................32

D. Printing a Card ..........................................40

Section 8: Maintenance

A. Supplies Required .....................................41

B. Standard Printhead Cleaning...................42

C. Expanded Printhead Cleaning ................42

D. Cleaning the PrinterÕs Case .....................43

E. Cleaning the Inside of the Printer ...........43

F. Clearing a Card Jam ..................................43

G. Clearing a Ribbon Jam ..............................44

H. Cleaning the Card Feed Rollers ..............44

I. Cleaning the Drive Roller .........................45

J. Maintaining the Cleaning Rollers............46

v

Section 9: Mechanical Adjustments

A. Adjusting the Card Input Guides............47

B. Adjusting the Internal Card Guide..........47

C. Adjusting the Card Separator Flap..........49

D. Adjusting the Laminator...........................51

Section 10: Troubleshooting .........................53

Section 11: Technical Specifications...........58

Appendix A: Magnetic Stripe Encoding

Module

A. Introduction ................................................59

B. Track Locations...........................................60

C. Sending Track Information .......................60

Appendix B: Interfacing Information

A. Introduction ................................................62

B. Centronics-type Parallel Interface ...........62

Index .................................................................63

vi

1

The Color ID Card Printer utilizes dye-sublimation

printing technology to achieve its direct-to-card

photo-quality output. Dye-sublimation is a process

which uses a dye-based ribbon roll that is

partitioned by a number of consecutive color

panels. The panels are grouped in a repeating

series of four separate colors, Yellow, Magenta,

Cyan, and Black (YMCK), along the entire length

of the ribbon. The ID Card Printer always prints

the yellow panel first, followed by the magenta

panel, the cyan panel, and finally the black panel.

If applicable, the fifth clear overlay panel will

always follow the black panel.

As the ribbon and card pass simultaneously

beneath the printhead, the hundreds of thermal

elements within the printhead heat the dyes on the

ribbon. When these dyes are heated, they vaporize

and diffuse into the surface of the card. By varying

the heat intensity of each thermal element within

the printhead, it is possible for each transferred dot

of color to vary in hue, thus blending one color into

the next. The result? Continuous-tone, photorealistic color images.

The Color ID Card Printer will print from any IBMPC

¨

or compatible running Windowsª 3.1x or

Windows 95. This means that you can use the

printer with virtually any software package

running under Windows without any special setup or configuration beyond the initial installation

of the specific software driver and interface cable.

Data is sent to the Color ID Card Printer in a bitmapped, rasterized format so your computer,

along with the printer driver software, will do

almost all of the complex Raster Image Processing

(ÒRIPÓ) work; therefore, the faster your computer,

the faster the image will be RIPÕd and sent to the

printer.

A. How Your

Color ID Card

Printer Works

1

Introduction

Congratulations

on your purchase

of the Color ID

Card Printer. This

printer has been

designed to

provide you with

stunning, photoquality color

output on a

variety of

different card

sizes and

thicknesses. It

offers many

features which

easily allow you

to create full-color

photo ID cards

complete with

high resolution

graphics, text, bar

codes, and even a

clear or

holographic

overlaminate.

B. Special

Features

Your Color ID Card Printer has many distinct

advantages over other color ID card printers. Its

100 card capacity card hopper allows for automatic

card feeding which reduces the time and personnel

required to create a photo ID card. In addition, the

Color ID Card Printer offers:

■

Automatic, dual-sided printing in color or

monochrome

■

Simultaneous dye-sublimation/resin thermal

transfer printing capability for printing

continuous-tone photos and crisp, readable bar

codes

■

Thermal transfer film or polyester chip

overlaminate capabilities

■

Optional magnetic stripe or smart card encoding

capabilities

■

A fast print speed of just 30 seconds/full color

card

■

Fast, 32-bit print spooler for Windows 95

■

Dual-sided card cleaning system

■

Upgradable memory (2MB maximum)

■

Optional color matching software

■

Optional Ethernet network support

And best of all, operation of the printer is simple

and straight forward. Please refer to the remainder

of this manual for instructions on setting up and

printing with your new Color ID Card Printer.

2

2

Safety

Precautions

Before operating the

unit, please read the

following safety

precautions carefully.

3

Warnings

CAUTION!

TO PREVENT FIRE OR SHOCK HAZARD,

DO NOT EXPOSE THE UNIT TO RAIN OR

MOISTURE. TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE

FRONT, TOP OR BACK PANELS. NO USERSERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE

PERSONNEL.

■

Operate the unit only on 110-120 VAC, 50/60 Hz.

For printers that have been shipped outside of

the United States and Canada, operate the unit

only on 220-240 VAC, 50/60 Hz. If you have any

doubt as to whether you have a unit with the

correct voltage rating for your countryÕs power

supply, DO NOT ATTEMPT TO USE THE

UNIT. Contact your dealer or the factory.

■

Stop operation immediately if any liquid or solid

object should fall into the cabinet. Unplug the

unit and have it checked by qualified service

personnel.

■

Do not disassemble the cabinet. Refer servicing

only to qualified personnel.

■

Service personnel: parts of this device may be

damaged if exposed to static electrical discharges

generated by various means, such as walking on

a carpeted floor. To avoid potential damage,

always wear an appropriate personal grounding

device, such as a wrist strap (w/ integral resistor)

connected to an ESD ground. Or, at a minimum,

make positive contact with the bare metal chassis

of the printer with your hand prior to touching

any internal electrical components.

1

Sicherheitsmaßnahmen

4

Machen Sie sich vor

Inbetriebnahme des

Geräts mit den

Sicherheitsmaßnahmen

gründlich vertraut.

Sicherheitshinweise

VORSICHT!

ZUR VERHÜTUNG VON FEUERGEFAHR

ODER ELEKTRISCHEN SCHLÄGEN DAS

GERÄT VOR REGEN ODER FEUCHTIGKEIT

SCHÜTZEN. UM DIE GEFAHR VON

STROMSCHLÄGEN ZU VERHINDERN,

OBERE, SEITLICHE UND HINTERE

ABDECKUNG NICHT ABNEHMEN. DAS

GERÄT ENTHÄLT KEINE TEILE, DIE VOM

BENUTZER GEWARTET WERDEN KÖNNEN.

WARTUNGSARBEITEN DÜRFEN NUR VON

QUALIFIZIERTEM FACHPERSONAL

DURCHGEFÜHRT WERDEN.

■

Das GerŠt nur mit 120 V 50/60 Hz Wechselstrom

betreiben. Drucker, die au§erhalb der USA und

Kanada verwendet werden, nur mit 220/240 V

50/60 Hz Wechselstrom betreiben. Wenn Sie

nicht sicher sind, ob Ihr GerŠt mit der Spannung

des šrtlichen Stromnetzes arbeitet, DAS GERÄT

NICHT IN BETRIEB NEHMEN. Wenden Sie

sich an Ihren HŠndler oder den Hersteller des

GerŠts.

■

Den Betrieb sofort unterbrechen, wenn ein

Gegenstand in das GehŠuse gefallen oder

FlŸssigkeit eingedrungen ist. Den Netzstecker

ziehen und das GerŠt von qualifiziertem

Wartungspersonal ŸberprŸfen lassen.

■

Keine GehŠuseteile abnehmen. Wartungsarbeiten

nur von qualifiziertem Fachpersonal

durchfŸhren lassen.

5

1

Consignes

de sécurité

Avant d’utiliser

l’appareil, prière de

lire attentivement les

consignes de sécurité

suivantes.

Avertissements

ATTENTION!

POUR EVITER TOUT RISQUE D’INCENDIE

OU D’ELECTROCUTION, NE PAS EXPOSER

L’APPAREIL A LA PLUIE OU A L’HUMIDITE.

POUR EVITER TOUTE DECHARGE

ELECTRIQUE, NE PAS RETIRER LES

PANNEAUX AVANT, SUPERIEUR OU

ARRIERE. NE PAS TENTER DE REPARER

SOI-MEME LES PIECES A L’INTERIEUR DE

L’APPAREIL. CONFIER L’ENTRETIEN DE

L’APPAREIL A UN PERSONNEL QUALIFIE.

■

Faire fonctionner lÕappareil uniquement sur

courant alternatif de 110/120 V, 50 ou 60 Hz. Les

imprimantes expŽdiŽes en-dehors des Etats-Unis

et du Canada fonctionnent uniquement sur

courant alternatif de 220/240 V, 50 or 60 Hz. En

cas de doute sur la compatibilitŽ entre la tension

nominale de lÕappareil et le courant du pays

dÕutilisation, NE PAS TENTER D’UTILISER

L’APPAREIL. Contacter le revendeur ou lÕusine.

■

Arr•ter immŽdiatement le fonctionnement si un

liquide ou un solide venait ˆ sÕinfiltrer ˆ

lÕintŽrieur de lÕarmoire. DŽbrancher lÕappareil et

le faire vŽrifier par un personnel qualifiŽ.

■

Ne pas dŽmonter lÕappareil. Confier lÕentretien

de lÕappareil ˆ un personnel qualifiŽ.

1

Precauciones

de seguridad

Antes de operar la

unidad, haga el favor

de leer detenidamente

las siguientes

precauciones de

seguridad.

6

Advertencias

¡PRECAUCION!

PARA EVITAR PELIGROS DE INCENDIO O

CHOQUE ELECTRICO, NO EXPONGA LA

UNIDAD A LA LLUVIA NI A LA HUMEDAD.

PARA REDUCIR EL RIESGO DE CHOQUE

ELECTRICO, NO QUITE LOS PANELES

FRONTALES, SUPERIORES, LATERALES NI

DE FONDO. EL INTERIOR NO TIENE PIEZAS

REPARABLES POR EL USUARIO. PARA

SERVICIO DE REPARACION Y

MANTENIMIENTO SOLICITE LA ATENCION

DE UN TECNICO DE SERVICIO

AUTORIZADO.

■

Opere la unidad s—lo a 110-120 VAC, 50/60 Hz.

Para las impresoras enviadas fuera de los Estados

Unidos y Canad‡, opere la unidad s—lo a 220-240

VAC, 50/60 Hz. Si no est‡ seguro que la unidad

que tiene es compatible al voltaje de la corriente

elŽctrica de su pa’s, NO INTENTE USAR LA

UNIDAD. Llame al representante de ventas o a

la f‡brica.

■

Detenga la operaci—n inmediatamente si algœn

l’quido u objeto s—lido cayera en el armario.

Desenchufe la unidad y h‡gala revisar por un

tŽcnico de servicio autorizado.

■

No desarme el armario. Para servicio de

mantenimiento, solicite la atenci—n de un tŽcnico

autorizado.

Prima di dare inizio al

funzionamento

dell’unità, siete

pregati di leggere

attentamente le

seguenti precauzioni

di sicurezza.

1

Precauzioni

per la

Sicurezza

7

Avvertenze

ATTENZIONE!

ONDE EVITARE IL PERICOLO DI INCENDIO

O SCOSSA ELETTRICA, NON ESPORRE

L’UNITÀ ALLA PIOGGIA OD UMIDITÀ.

EVITARE DI RIMUOVERE I PANNELLI

ANTERIORE, SUPERIORE, O POSTERIORE

PER RIDURRE IL RISCHIO DI SCOSSA

ELETTRICA. LA MANUTENZIONE DELLE

PARTI INTERNE DELL’UNITÀ NON É DI

COMPETENZA DELL’UTENTE. AI FINI

DELLA RIPARAZIONE RIVOLGERSI AL

PERSONALE DI COMPETENZA.

■

Negli Stati Uniti e Canada lÕunitˆ funziona solo

con alimentazione a 110-120 VAC, 50/60 Hz. Le

stampanti destinate ad altri paesi funzionano

solo con alimentazione a 220/240 VAC, 50/60 Hz.

Qualora non abbiate la certezza che il

trasformatore e la spina di cui disponete siano

quelli adeguati allÕalimentazione erogata nel

vostro paese, NON USARE L’UNITÀ. Rivolgersi

piuttosto al rivenditore o la fabbrica del luogo.

■

Arrestare immediatamento il funzionamento

dellÕunitˆ qualora si verifichi un versamento di

liquido o la caduta di un oggetto solido al suo

interno. Staccare la spina e rivolgersi al personale

di assistenza qualificato.

■

Non smontare la struttura dellÕalloggiamento. Le

riparazioni vanno effettuate solo dal personale di

competenza.

1

Precauções

de

Segurança

Antes de operar esta

unidade, leia

cuidadosamente as

seguintes precauções

de segurança.

Advertências

CUIDADO!

PARA EVITAR PERIGO DE CHOQUES

ELÉTRICOS OU INCÊNDIO, NÃO EXPONHA

A UNIDADE À CHUVA OU UMIDADE. PARA

REDUZIR O RISCO DE CHOQUES

ELÉTRICOS, NÃO REMOVA OS PAINÉIS

DIANTEIRO, SUPERIOR OU TRASEIRO.

NENHUMA PEÇA NO INTERIOR DESTA

UNIDADE PODE SER CONSERTADA PELO

USUÁRIO. PEÇA ASSISTÊNCIA AO PESSOAL

DE MANUTENÇÃO QUALIFICADO.

■

Opere esta unidade somente em 110-120 VAC,

50/60 Hz. As impressoras enviadas para fora dos

Estados Unidos ou Canad‡ devem ser operadas

somente em 220-240 VAC, 50/60 Hz. Se voc• n‹o

souber se a sua unidade tem a voltagem correta

para o sistema elŽtrico do seu pais, NÃO TENTE

USAR ESTA UNIDADE. Entre em contato com

seu revendedor ou com a f‡brica.

■

Pare imediatamente a opera•‹o se qualquer

l’quido ou objeto s—lido cair no gabinete.

Desligue a unidade da tomada e leve-a ao pessoal

de manuten•‹o qualificado.

■

N‹o desmonte o gabinete. Pe•a assist•ncia

somente ao pessoal qualificado.

8

9

Chinese or Japanese to be

keylined here

10

Chinese or Japanese to be

keylined here

11

Arabic to be keylined here

3

Getting

Started

12

A. Choosing a

Good Location

Place the unit in a location with adequate air

circulation to prevent internal heat build up.

1. Use the dimensions specified in Section 11 as a

guideline for the minimum clearances to the unit.

NOTE

Allow for adequate clearance above the unit to

accommodate the height of the unit with its covers open.

2. Do not install unit (a) near heat sources such as

radiators or air ducts, or (b) in a place subject to

direct sun-light, excessive dust, mechanical

vibration or shock.

B. About

Moisture

Condensation

If the unit is brought directly from a cold to a

warm location, or is placed in a very damp room,

moisture may condense inside the unit. Should this

occur, print quality may not be optimum. Leave

the unit turned OFF in a warm, dry room for

several hours before using. This will allow the

moisture to evaporate.

C. Unpacking and

Inspection

While unpacking your printer, inspect the carton to

ensure that no damage has occurred during

shipping. Make sure that all supplied accessories

are included with your unit. The following items

should be included with your Color ID Card

Printer:

■

Printer

■

Power Cord

■

Cleaning Roller

■

Printer Driver Diskette (3.5Ó)

■

32-bit Print Spooler Software; for use in

Windows 95 only

■

Warranty Statement and Registration Card

■

This manual and other printed information

Save the carton and packing materials. They will

come in handy when transporting the unit or

shipping it for service.

13

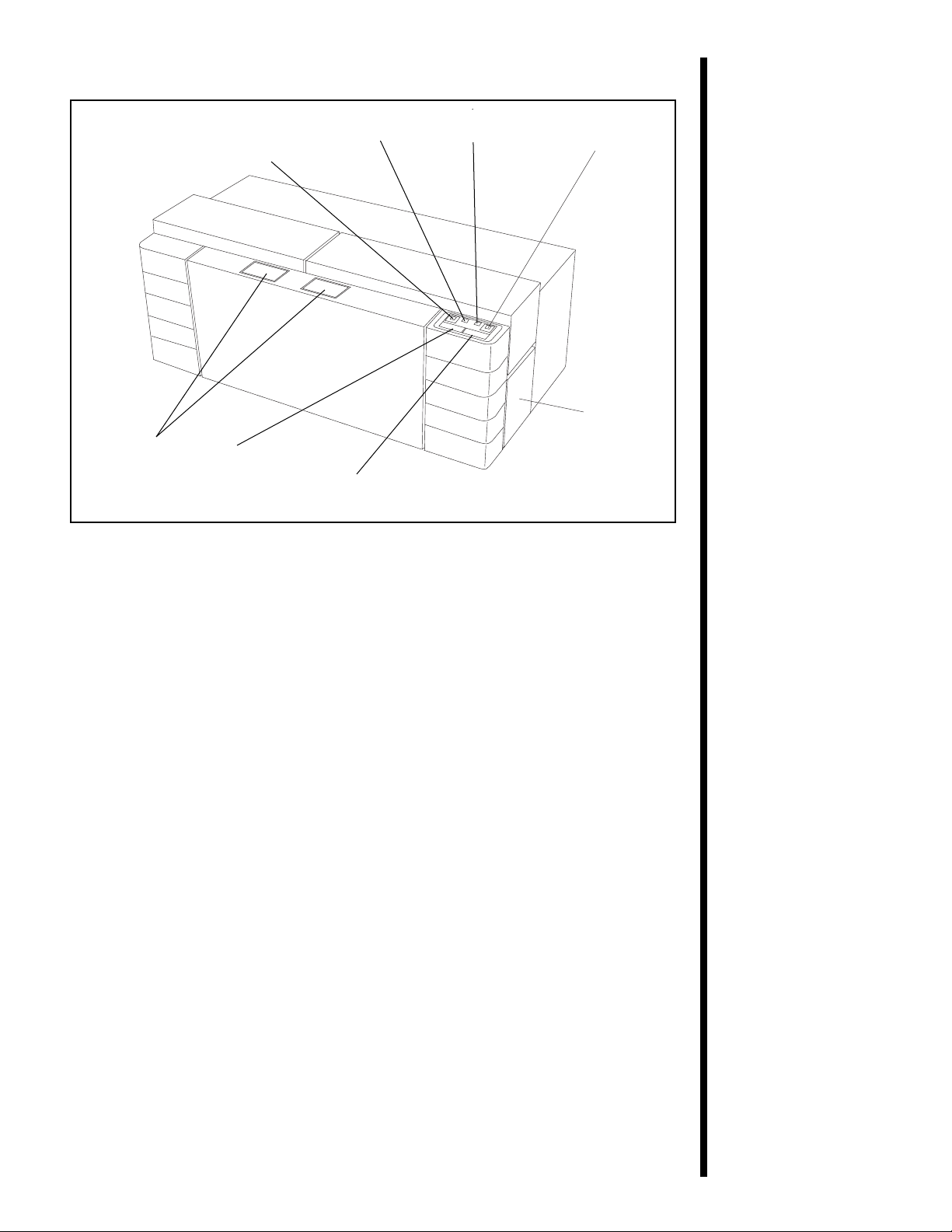

Cover

Release

Buttons

on/cancel

Card

Hopper

Door

clean/ribbon

on-line

Button

on/cancel

Button

laminator

LED

on-line

LED

D. Identifying

the Parts

1. This illustration shows all of the control

buttons and the LED indicator lights found on the

front of the Color ID Card Printer. The laminator

light indicates the current status of the printerÕs

built-in laminator. When the light is flashing, the

laminator is either heating up or cooling down.

When the light is solid, the laminator has reached

and is maintaining its target temperature.

The on/cancel button signifies that the printer

power is ON and also serves to cancel the current

print job and reset the printer for the next print job.

This button also ejects any cards left within the

printer after a print job is canceled.

The on-line button takes the printer on and offline. The printer must have the on-line light

illuminated in order to print. When flashing, the

on-line light also serves to indicate a print error

condition. Such conditions are discussed in

Section 10 of this manual.

The clean/ribbon light illuminates when your

ribbon supply is getting low. The light will

illuminate when approximately 10-20 prints are left

on the ribbon. The clean/ribbon light also serves as

a reminder that the printer should be cleaned

during every ribbon change (about every 250

prints) according to the steps in this manualÕs

Maintenance Section.

14

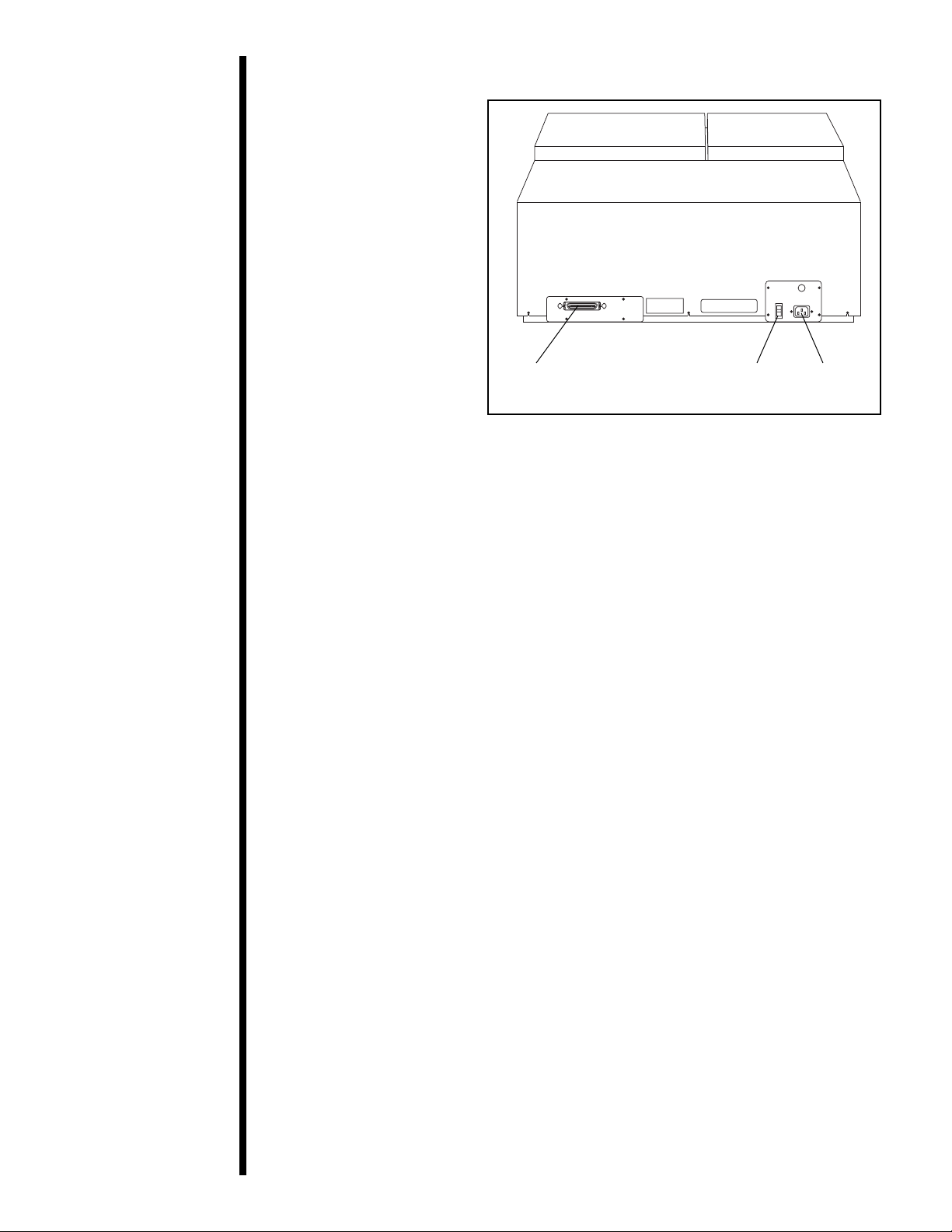

2. This illustration

shows the input ports

found on the rear panel

of the printer. For

complete instructions

about each of these

features, see later

sections of this manual.

Power

Input

Port

Parallel

Interface

Power

Switch

15

4

Ribbons and

Cards

The Color ID Card Printer has the following ribbon

types available for printing:

■

Standard Resin Black (K) ribbon with no clear

overlay panel (produces 1,000 prints)

■

A variety of Colored Resin ribbons with no clear

overlay panel (produce 1,000 prints)

■

Premium Resin Black (K) ribbon with no clear

overlay panel (produces 1,000 prints)

■

A gold Metallic Resin ribbon with no clear overlay

panel (produces 1,000 prints)

■

Dye-Sublimation Black (BO) ribbon with a clear

overlay panel (produces 500 prints)

■

Full-Color (YMCBO) ribbon with a dyesublimation black panel and a clear overlay panel

(produces 250 prints)

■

Full-Color (YMCKO) ribbon with a resin black

panel and a clear overlay panel (produces 250

prints)

■

Full-Color (YMCKOK) ribbon with 2 resin black

panels and a clear overlay panel (produces 250

prints)

■

Full-Color (YMCKK) ribbon with 2 resin black

panels and NO clear overlay panel (produces 250

prints)

The ribbons which have a clear overlay panel (O)

will print an ID card and place a clear, protective

overlay over the cardÕs printable area. Be sure that

the Overlay option within the printer driver setup

window is selected when printing with these ribbons

unless you intend to utilize the printer's built-in

laminator. When applying the PolyGuard

overlaminate, do not apply the ribbonÕs clear overlay

panel since it will interfere with the transfer of the

overlaminate material. When applying the film

overlaminate, the ribbonÕs clear overlay should be

applied on top of the overlaminate. See Section 5-B

for further overlaminate information. See Section

7-B for instructions on enabling or disabling the

printerÕs Overlay option.

All color or monochrome dye-sublimation cards must have

either a printed overlay or a chip or film overlaminate

applied to them. If neither of these types of protective

coatings are applied, your card's dye-sublimation image

will quickly begin to wear or fade. Cards printed solely

with monochrome resin text, bar codes, or images do not

require any type of protective overlay or overlaminate.

A. About

Ribbons

NOTE

16

The ribbons which utilize a resin black (K), are

intended for printing bar codes onto cards which

can be read by both infra-red and visible light bar

code scanners. Bar codes printed with a dyesublimation black (B) can only be read by a visible

light bar code scanner.

The black monochrome-only resin ribbons (K) are

available in both a premium and standard quality.

The premium resin black ribbon provides

maximum durability and is ideal for applications

such as access control where cards are repeatedly

swiped through a magnetic stripe reader. The

standard resin black ribbon provides high

durability ideal for most general purpose ID card

applications.

In addition to a standard black resin ribbon, several

other standard resin ribbons are also available in a

variety of spot colors including blue, green, red,

and metallic gold. All monochrome resin ribbons

provide 1,000 prints. Bar codes printed with the

blue and green ribbons can be read by both infrared and visible light bar code scanners. Bar codes

printed with the metallic gold ribbon can only be

read by an infra-red bar code scanner. Bar codes

printed with the red ribbon are NOT readable.

The Full-Color YMCKK ribbon is intended to be

used for dual-sided printing. By supplying two

resin black panels, this ribbon lets you print fullcolor on one side and monochrome resin black on

the other, without wasting an entirely new set of

ribbon panels for the monochrome side. Since no

overlay panel is included, this ribbon must be used

in conjunction with the printerÕs overlaminate

function. If you do not wish to use the

overlaminate function, another Full-Color

YMCKOK ribbon is available which also includes a

clear overlay panel. When printing with either of

these ribbons, no overlaminate is necessary for the

monochrome resin black side.

Watches, rings, bracelets, and other jewelry can damage

the printhead if accidentally bumped against it. For best

results, remove such items before installing or removing

ribbons.

IMPORTANT!

Loading...

Loading...