Page 1

HDP 800 Series Card Printer/Encoders

Service Manual (Rev. 5.0)

• HDP820 (Dual-Sided Card Printer/Encoders)

• HDP820-LC (Dual-Sided Card Printer/Encoders)

• HDP825 (Dual-Sided Card Printer/Encoders)

• HDP825-LC (Dual-Sided Card Printer/Encoders)

Part Number: L000307

Page 2

RESTRICTED USE ONLY FARGO Electronic, Inc.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0), property of FARGO

Electronics, Incorporated

Copyright 2002, 2003, 2004, 2005, 2006 by FARGO Electronics, Incorporated. All rights

reserved. Printed in the United States of America. Exclusive permission is granted to

authorized resellers of FARGO products to reproduce and distribute this copyrighted document

to authorized FARGO customers, who have signed a “no disclosure agreement” regarding the

restricted, proprietary use of said document.

The revision number for this document will be updated to reflect changes, corrections, updates

and enhancements to this document.

Revision Control

Number

Revision 5.0 1 January 2004

These reference documents were thoroughly reviewed to provide FARGO with professional and

international standards, requirements, guidelines and models for our technical, training and user

documentation. At all times, the Copyright Protection Notice for each document was adhered to

within our FARGO documentation process. This reference to other documents does not imply

that FARGO is an ISO-certified company at this time.

• ANSI/ISO/ASQ Q9001-2000 American National Standard

Systems - Requirements (published by the American Society of Quality, Quality Press, P.O.

Box 3005, Milwaukee, Wisconsin 53201-3005)

• The ASQ ISO 9000:2000 Handbook

John E. West; Second Edition; published by the American Society of Quality, Quality Press,

600 N. Plankinton Avenue, Milwaukee, Wisconsin 53203)

• Juran's Quality Handbook

McGraw-Hill)

Any questions regarding changes, corrections, updates or enhancements to this document

should be forwarded to:

Date Document Title

HDP 800 Series Card Printer/Encoders

Service Manual (Rev. 5.0)

, (sub-title) Quality Management

(editors, Charles A. Cianfrani, Joseph J. Tsiakals and

(editors, Joseph M. Juran and A. Blanton Godfrey; Fifth Edition,

FARGO Electronics, Incorporated

Support Services

6533 Flying Cloud Drive

Eden Prairie, MN 55344 (USA)

(952) 941-9470

(800) 459-5636

FAX: (952) 941-7836

www.fargo.com

E-mail: sales@fargo.com

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

ii

Page 3

RESTRICTED USE ONLY FARGO Electronic, Inc.

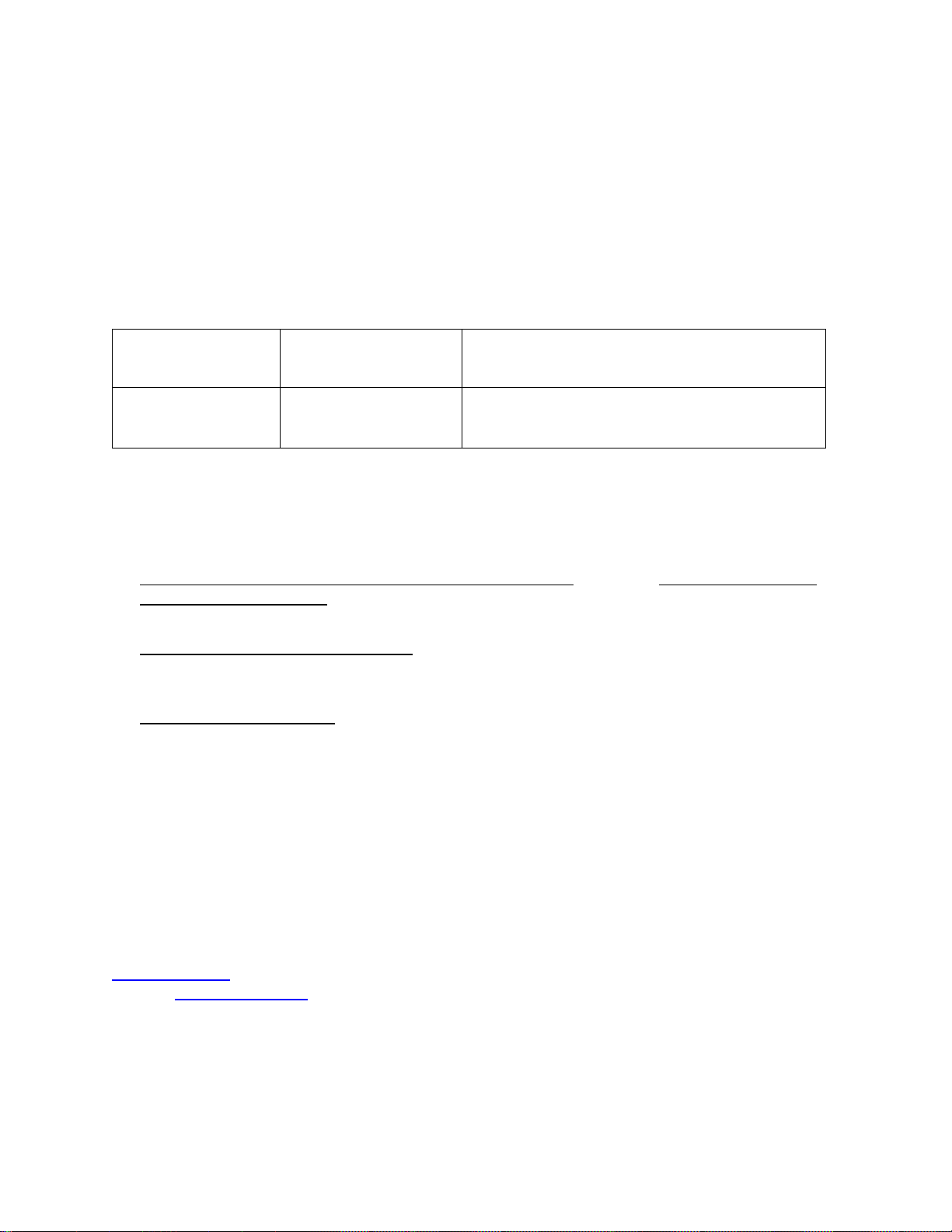

Reviewing the HDP800 Series Printers Overview table

HDP800 Series Input

Hoppers

HDP820 (Dual-Sided

Card Printer/Encoders)

HDP820-LC (DualSided Card

Printer/Encoders)

HDP825 (Dual-Sided

Card Printer/Encoders)

HDP825-LC (DualSided Card

Printer/Encoders)

1 250 CR-80,

1 250 CR-80,

2 200 CR-80 Optional Optional

2 200 CR-80 Optional Included

Card

Capacity

Accepted

Card Size

CR-90 &

CR-100

CR-90 &

CR-100

Encoding

Modules

Optional Optional

Optional Included

Lamination

Module

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

iii

Page 4

RESTRICTED USE ONLY FARGO Electronic, Inc.

How to use the manual

The HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) is designed to provide

installers and technicians with quick, efficient lookup of related procedures, components and

terms. The manual can be used effectively either in soft or hard copy, depending on the

preference of the installer or technician.

Manual Description

Sequence of Operations,

Glossary of Terms and

Technical/Functional

Specifications (hyper-linked)

Table of Contents (hyperlinked)

Troubleshooting,

Replacement, Removal,

Diagnostic and Navigation

Procedures (in hyper-linked

Sections)

Cross-Referencing (hyperlinked)

Comprehensive Index

(hyper-linked)

You can go directly to the Sequence of Operations,

Glossary of Terms, Technical Specifications and

Functional Specifications to learn how to use the

processes, procedures, functions and windows for the

HDP 800 Series Card Printer/Encoders within concise,

correlative tables.

You can use the Table of Contents to quickly locate an

error message, a procedure, the index or an appendix.

You can go directly to Specifications, General

Troubleshooting, Printer Adjustments, Parts Replacement,

Printer Packing, Board Level Diagnostics, LCD On-Line

Menu Navigation and Firmware Updates to find

troubleshooting, removal and replacement procedures.

The section titles are always labeled according to their

function for consistent usage.

You can use the cross-referencing links to quickly locate

an error message or a procedure.

You can use the Comprehensive Index to quickly locate

information on the HDP 800 Series card Printer, relating

to a specification, a procedural step, a window or screen, a

component, a term, a qualifier or a related feature to this

Printer.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

iv

Page 5

RESTRICTED USE ONLY FARGO Electronic, Inc.

Safety Messages (review carefully)

Symbol Critical Instructions for Safety purposes

Danger: Failure to follow these installation guidelines can result in death or

serious injury.

Information that raises potential safety issues is indicated by a warning

symbol (as shown to the below).

• To prevent personal injury, refer to the following safety messages

before performing an operation preceded by this symbol.

• To prevent personal injury, always remove the power cord prior to

performing repair procedures, unless otherwise specified.

• To prevent personal injury, make sure only qualified personnel

perform these procedures.

Caution: This device is electrostatically sensitive. It may be damaged if

exposed to static electricity discharges.

Information that raises potential electrostatic safety issues is indicated

by a warning symbol (as shown to the below).

• To prevent equipment or media damage, refer to the following

safety messages before performing an operation preceded by this

symbol.

• To prevent equipment or media damage, observe all established

Electrostatic Discharge (ESD) procedures while handling cables in

or near the Circuit Board and Printhead Assemblies.

• To prevent equipment or media damage, always wear an

appropriate personal grounding device (e.g., a high quality wrist

strap grounded to avoid potential damage).

• To prevent equipment or media damage, always remove the

Ribbon and Cards from the Printer before making any repairs,

unless otherwise specified.

• To prevent equipment or media damage, take jewelry off of

fingers and hands, as well as thoroughly clean hands to remove oil

and debris before working on the Printer.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

v

Page 6

RESTRICTED USE ONLY FARGO Electronic, Inc.

123

13

323334

35363738

44

454

6

4

7

49

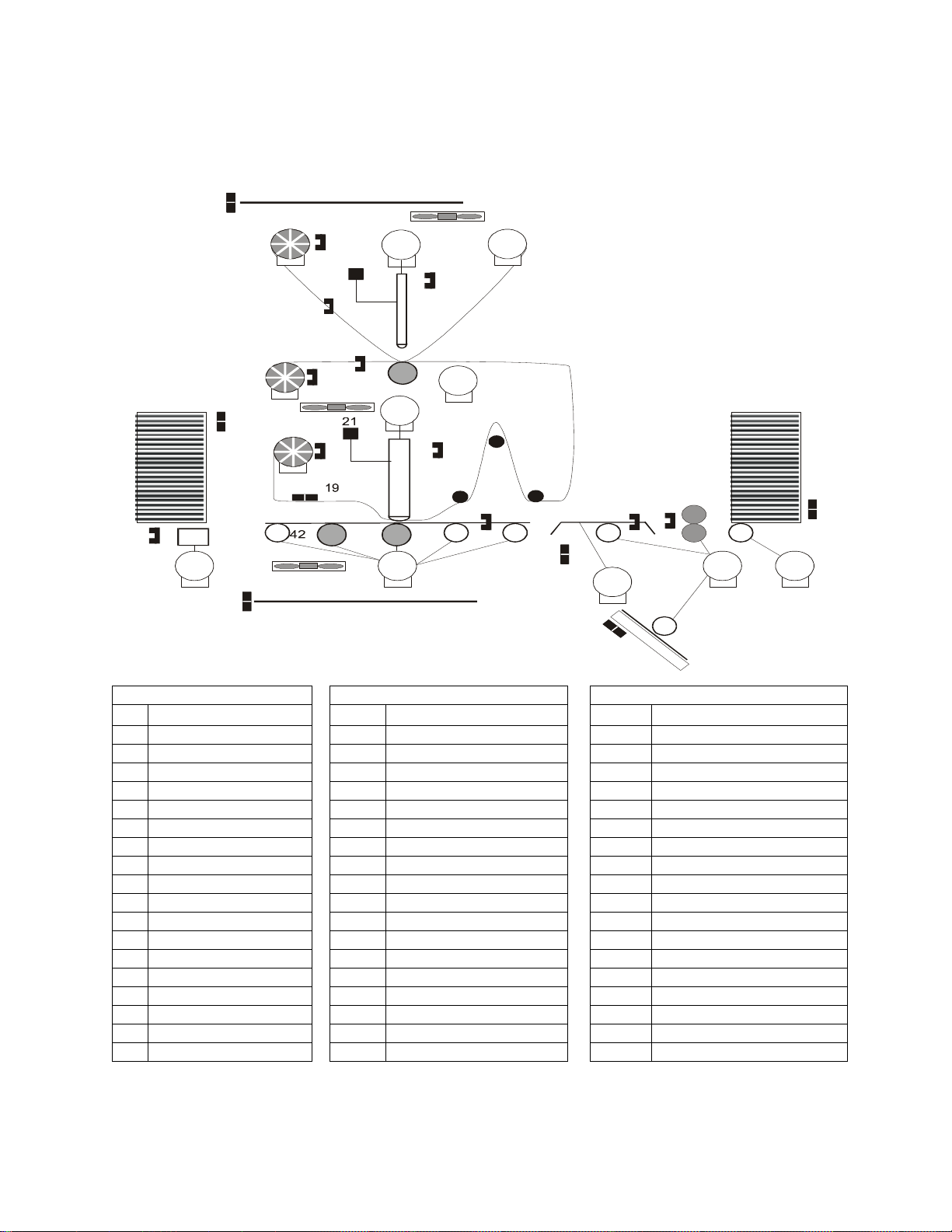

HDP 800 Series Card Printer/Encoders Overview

Reviewing the HDP 800 Series Block Diagram

30

9

25

2

7

24

11

26

10

7

29

5

0

28

12

8

31

43

20

22

39

18

5

14

15

17

16

23

4

8

4

1

6

33

40

4

Motors Sensors Parts

1 Card Input 13 Card Low 32 Card Input Roller

2 Card Feed Stepper 14 Card Detection 33 Cleaning Cartridge

3 Flipper Stepper 15 Flipper Table Card 34 Flipper Table Roller

4 Lamination Stepper 16 Encoding TOF 35 Flipper Table

5 Print Stepper 17 Flipper Home 36 Encoding Module

6 Lamination Headlift 18 Card TOF 37 Encoding Feed Roller

7 Film Supply 19 Lower Film 38 Card Feed Roller

8 Film Take Up 20 Film Take Up Encoder 39 Card Feed Roller

9 Ribbon Supply 21 Thermocouple 40 Platen Roller

10 Ribbon Take Up 22 Film Supply Encoder 41 Flattener Roller

11 Print Headlift 23 Upper Film 42 Card Feed Roller

12 Stacker Lift 24 Ribbon Sensor Array 43 Flattener Cooling Fan

25 Ribbon Encoder 44 Lamination Roller

26 Print Headlift 45 Transfer Platen Roller

27 Thermistor 46 Printhead

28 Stacker Lift 47 Printhead Cooling Fan

29 Stacker Full 48 Film Cooling Fan

30 Cover Interlock 49 Card Input Hopper

31 Release Lever 50 Card Output Stacker

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

vi

Page 7

RESTRICTED USE ONLY FARGO Electronic, Inc.

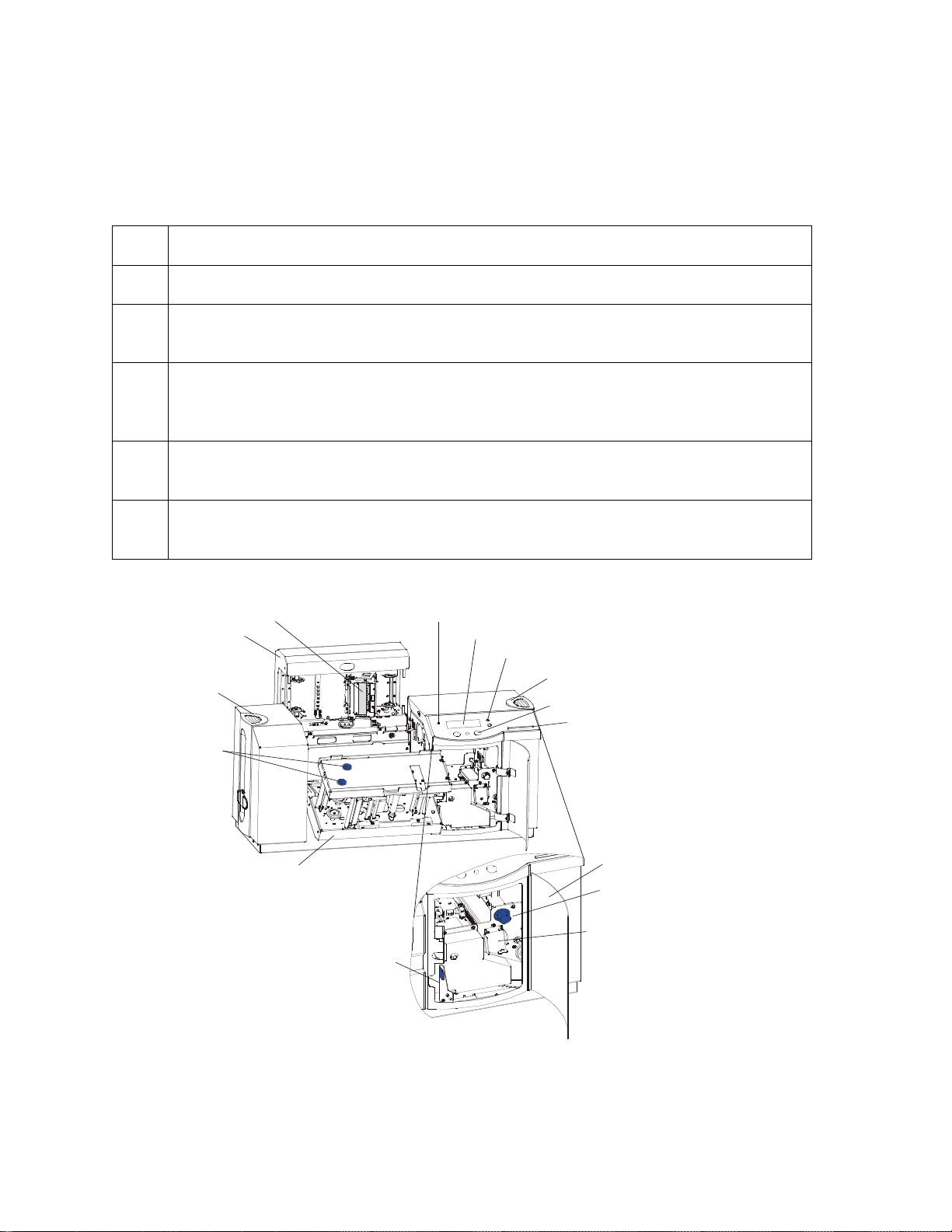

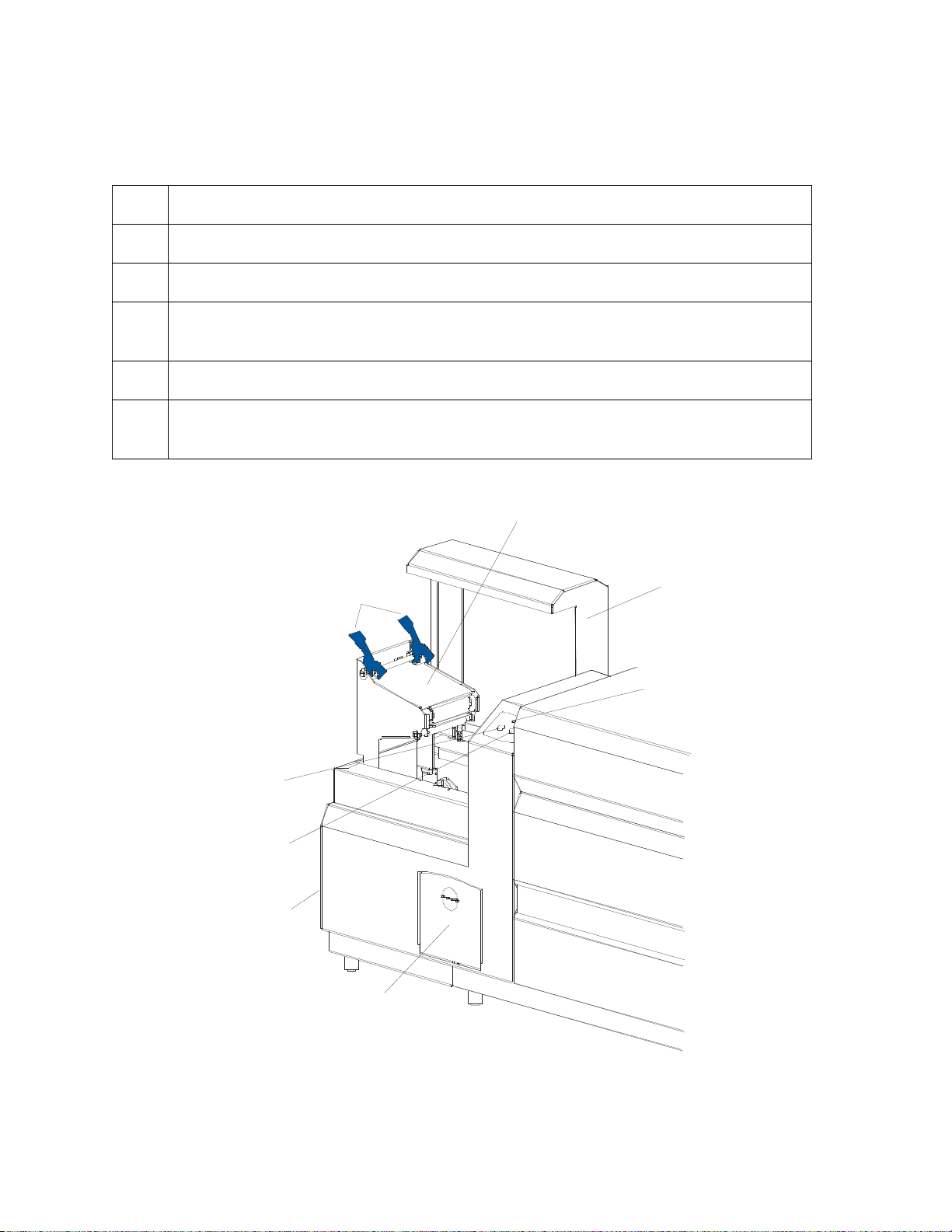

LCD Display

Softkey Buttons

Card Input Hopper

Front Access Door

Reviewing HDP 800 Series Card Printer - Sequence of Operations

The following sequence describes a dual sided full color print job with magnetic encoding. This

Printer also has an optional Card Stacker installed. (Note: The HDP825/825-LC Printers have

two (2) Card Input Hoppers that load 100 cards in each Hopper.)

Step

Process

1 The File information is received from the PC.

2 The Heater warms up and/or maintains the heat on the hot Roller using the

Thermocouple to help maintain the desired temp.

3 The Ribbon Drives turn ON and move until the correct panel is found by the Print

Ribbon Sensor array (5 reflective). All stop. (Note: The Print Ribbon Encoder is

active during this step.)

4 The Film Ribbon Drive turns ON until the Film is positioned with the Film alignment

Sensor. All stop. (Note: The Film Ribbon Encoder is active during this step.)

5 The Headlift Motor engages, moving the Printhead down until Headlift Sensor is

activated. All stop.

Continued on the next page

Print Station

Printhead

Card Output

Hopper

Film Tension

Knobs

LED Light

Scroll Buttons

Access

Card Slot

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

Transfer Station

Release Lever

Card Thickness

Adjustment Knob

Card Cleaning

Assembly

vii

Page 8

RESTRICTED USE ONLY FARGO Electronic, Inc.

Reviewing HDP 800 Series Card Printer - Sequence of Operations (cont.)

Step Process

5 The Fan turns ON as required to keep head cool.

6 The Ribbon Drives, Film Ribbon Drive and Stepper turn ON and the Printhead

burns the image data until the image data is depleted. All stop. (Note: The

Ribbon Encoders are active during this step.)

7 The Headlift Motor engages, moving the Printhead up until the Headlift Sensor is

activated. All stop.

8 The Ribbon Drives and Film Ribbon Drive advance until the Print Ribbon Encoder

sees acceleration at release. (Note: The Ribbon Encoders are active during this

step.)

9 The Ribbon Drives move until the Print Ribbon Position Sensor finds the next

panel. All Motors stop. (Note: The Ribbon Encoder is active during this step.)

10 The Film ribbon drive turns ON until the images portion of the Film is positioned

before the Printhead, using the Film Alignment Sensor. All stop. (Note: The

Ribbon Encoder is active during this step.)

11 The Headlift Motor engages, moving printhead down until the Headlift Sensor is

activated. All stop.

12 Ribbon Drive, Film Ribbon Drive and Stepper all turn ON and the Printhead burns

image data until the image data is depleted. All stop. (Note: The Ribbon

Encoders are active during this step.)

13 The Headlift Motor engages, moving the Printhead up until the Headlift Sensor is

activated. All stop.

14 The Ribbon Drive and Film Ribbon Drive engage until print ribbon encoder sees

acceleration at release. (Note: The Ribbon Encoders are active during this step.)

15 Repeat Steps 9 to 14 for the appropriate number of color/heat seal panels.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

viii

Page 9

RESTRICTED USE ONLY FARGO Electronic, Inc.

o create a slack region between the Printer and Laminator sections. All stop.

Reviewing HDP 800 Series Card Printer - Sequence of Operations (continued)

Step Process

16 The Ribbon Drives turn ON to advance the printed portion of the Film to a position

near the heated lam Roller using the Lamination Film Alignment Sensor.

The Ribbon Drive stays ON for a certain number of additional clicks after turns

OFF t

(Note: Ribbon encoders and dancer zero position switch are active during this

step.)

17 The Ribbon Drive is used with the Lamination Film Alignment Sensor to locate the

printed Film more precisely under the hot Roller. All stop.

18 This is simultaneous to Steps 1 to 17 and then Steps 19 to 24 will occur.

19 The DC Motor and Stepper Motor turn ON and run until a card is seen by the card

Sensor, which will cause the Card Input Motor to stop.

The Stepper will continue to run a certain number of steps to position the card on

the Flipper Table. All stop. Card Low Sensor will check for cards in Input Hopper.

20 Stepper will turn ON, causing the Flipper to turn to the magnetic angular position.

The Flag Sensor and counted steps are used to determine the angular position.

All stop.

21 Stepper will engage to drive the card past the Mag Card Sensor and the Mag

Head.

22 Stepper engages to drive the card to a centered position on the Flipper Table

using the Mag Card Sensor and a step count. All stop.

23 Stepper will turn ON, causing the Flipper to turn to the default (flat) position. The

Flat Sensor and counted steps are used to determine the angular position. All

stop.

24 Steppers engage to move the card OFF the Flipper and to a position near the hot

Roller, using Card Feed Sensors and a step count. All stop.

25 Stepper engages to move the card to a position directly under the hot Roller. The

Top of Form Sensor determines card edge and number of steps to position card.

All stop.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

ix

Page 10

RESTRICTED USE ONLY FARGO Electronic, Inc.

Reviewing HDP 800 Series Card Printer - Sequence of Operations (continued)

Step Process

26 If the heater is not at the required temperature yet, the job will pause.

27 The Headlift Motor turns ON to lower the hot Roller and will stop when the Headlift

Sensor is activated. All off.

28 The Stepper and Ribbon Drive engage to laminate the printed Film onto the card.

They will turn off after a given number of steps based on the position given by the

card Sensor. All stop. (Note: The Ribbon Encoder is active during this step.)

29 The Headlift Motor turns on to raise the hot Roller, stopping when the Headlift

Sensor is activated.

30 The Ribbon Drive and Stepper turn ON for a given number of clicks based on

ribbon encoder, until the ribbon is released.

31 The Stepper turns ON to move the card through the flattening section and into the

output hopper (based on steps from a known position). All stop.

32 The Heater and Thermocouple are maintained at a set temperature at all times

when the Printer is ON. The cooling fan is ON when the Printer is ON.

33 The Stacker Lift Motor engages until the Stacker Lift Sensor is activated.

34 The Stacker Full Sensor checks for presence of cards.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

x

Page 11

RESTRICTED USE ONLY FARGO Electronic, Inc.

Reviewing the HDP 800 Series Card

Printer/Encoders - Boot up Sequence

Step Process

1 The Card feed stepper turns ON (to check for a card on the Flipper table).

2 The Lam Headlift turns until the head up position is returned from the Headlift

Sensor).

3 The Film transfer take-up Motor turns ON to take up any slack in the dancer (and

runs until the Dancer Down Sensor is activated).

4 The Print Headlift turns until head up position is returned from Headlift Sensor.

5 The Print Ribbon moves forward until it finds the yellow panel, pauses, advances

to magenta, then backs up to yellow (the Ribbon Sensor detects marks on the

ribbon).

6 The Transfer Ribbon advances forward two panels from supply (advances until

the Print Film Sensor senses 2 marks on the Film).

7 The Transfer Ribbon advances forward one panel onto take up (advances until

the Transfer Film Sensor senses 1 mark on the Film)

8 The Transfer Ribbon advances forward one panel from supply (advances until

the Print Film Sensor senses 1 mark on the Film).

9 The Transfer Ribbon advances forward one panel onto take up (advances until

the transfer Film Sensor senses 1 mark on the Film).

10 The Transfer Ribbon reverses for one panel from take up (reverses until transfer

the Film Sensor senses 1 mark on the Film).

11 The Transfer Ribbon reverses for one panel onto supply (reverses until the Print

Film Sensor senses 1 mark on the Film).

12 The Transfer Ribbon reverses for one panel from take up (reverses until the

Transfer Film Sensor senses 1 mark up on the Film).

13 The Transfer Ribbon reverses for one panel onto supply (reverses until the Print

Film Sensor senses 1 mark on the Film).

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

xi

Page 12

RESTRICTED USE ONLY FARGO Electronic, Inc.

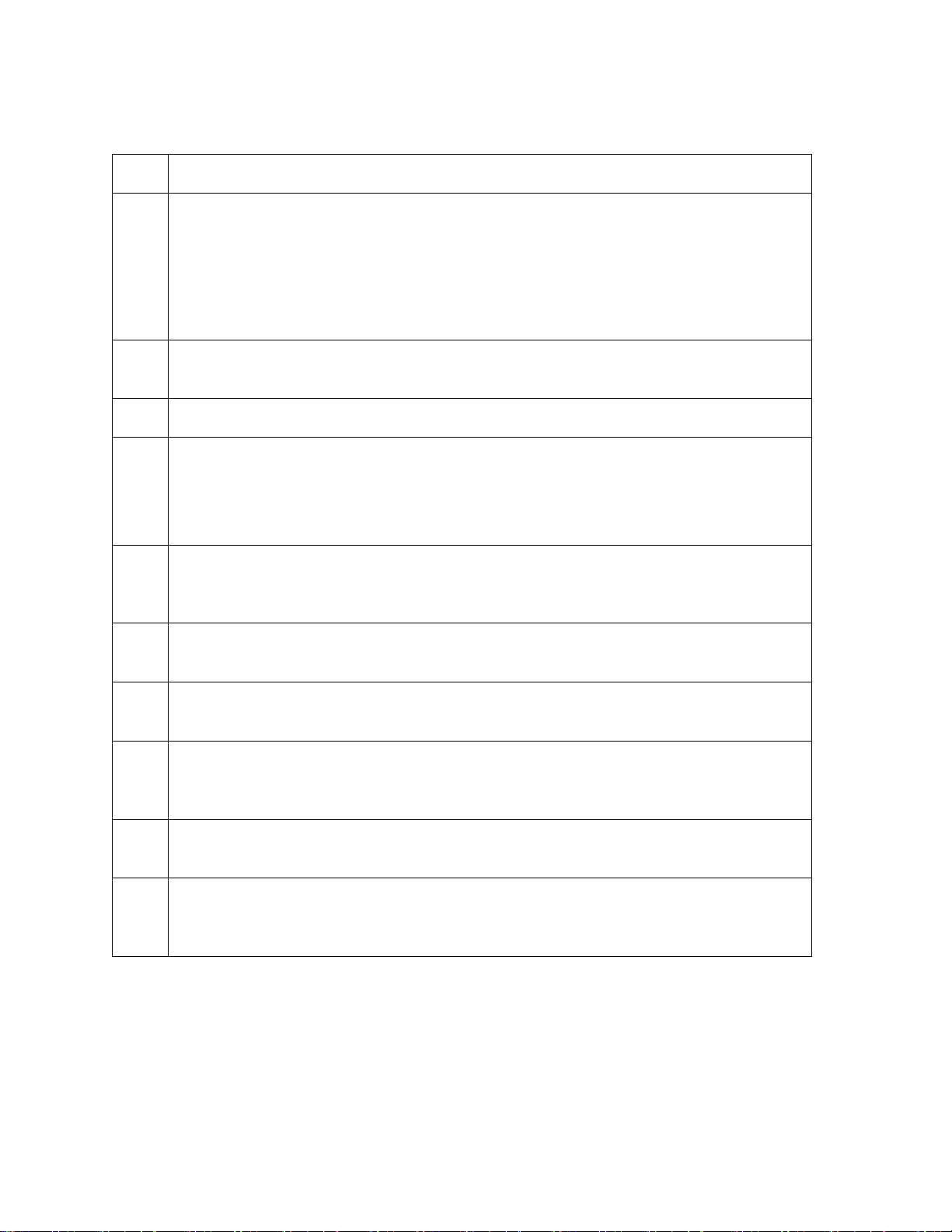

Lamination Station

Reviewing the Lamination Module Sequence of Operations

The LAM sequence of operations begins after printing has occurred with the Card Printer.

Step

Process

1 The card is fed onto the Lamination Module Flipper Table.

2 The card is fed to the Card Position Sensor.

3 The Lamination Ribbon Motor begins cycling until the Upper Lamination Sensor

detects the mark.

4 The Card Feed Motor activates to center the card on the Platen Roller.

5 The Lamination Roller Lift Motor cycles until the Lamination Roller Lift Sensor

detects state change.

Continued on the next page

Securing

Latches

Lamination

Top Cover

Cancel

Button

Resume

(pause) Button

Card Output

Hopper

Lamination

LED Light

Rejection

Card Hopper

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

xii

Page 13

RESTRICTED USE ONLY FARGO Electronic, Inc.

Reviewing the Lamination Module Sequence of Operations (continued)

Step Process

6 The Card Feed Motor and the Lamination Ribbon Motor activate for the length of

the card.

7 The Lamination Roller Lift Motor cycles until the Lamination Roller Lift Sensor

detects state change.

8 The card is fed back to the Flipper Table.

9 The Flipper Table Clutch engages.

10 The Flipper Table Motor activates until the Card is inverted based on the Flipper

offset setting.

11 The Flipper Table Clutch disengages.

12 The card is fed off the Flipper Table.

13 The Flipper Table Clutch engages.

14 The Flipper Table Motor activates until the Flipper Table is homed.

15 The Flipper Table Clutch disengages.

16 Repeat Steps 2 through 7.

17 The card is fed out of the Printer.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

xiii

Page 14

RESTRICTED USE ONLY FARGO Electronic, Inc.

Reviewing Lamination Module Boot up Sequence

Step Process

1 The Lamination Headlift turns until the head up position is returned from Headlift

Sensor.

2 The Lamination Ribbon Motor activates to determine the presence of a roll of

lamination.

3 The Lamination Flipper table homes itself.

4 The Card Sensor checks for the presence of a card and ejects it if found.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

xiv

Page 15

RESTRICTED USE ONLY Fargo Electronics, Inc.

Table of Contents

Section 1: Specifications _________________________________________________ 10

Reviewing the HDP800 Series Printers Overview table ________________________ 10

Regulatory Compliances ________________________________________________ 11

Agency Listings _______________________________________________________ 11

Technical Specifications ________________________________________________ 12

Functional Specifications________________________________________________ 16

Printer Components: Access Card Slot to Parallel Interface Port_______________ 17

Printer Components: LCD and Softkey Control Pad ________________________ 25

Printer Components: Centronics-Type Parallel Interface _____________________ 31

Printer Components: Print Ribbons _____________________________________ 32

Printer Components: Blank Cards_______________________________________ 33

Printer Components: Card Input Hopper (HDP820/820-LC) __________________ 34

Printer Components: Card Input Hopper (HDP825/825-LC) __________________ 35

Printer Components: Card Output Hopper ________________________________ 36

Printer Components: Lamination Roller __________________________________ 37

Reviewing the Card Lamination Module____________________________________ 38

Reviewing the Lamination Top Cover and Station __________________________ 39

Reviewing the Securing Latches and Lamination LED Light __________________ 40

Reviewing the Cancel button ___________________________________________ 41

Reviewing the Resume (pause) button____________________________________ 42

Reviewing the Rejection Card Hopper and Card Output Hopper _______________ 43

Reviewing the Module and Printer interaction _____________________________ 44

Reviewing the Module and LCD Display interaction ________________________ 45

Reviewing the Module’s Programmed Default Temperature __________________ 46

Reviewing the Laminator Temperature Adjustment _________________________ 47

Reviewing the Overlaminates ____________________________________________ 48

Reviewing the Thermal Transfer Film and PolyGuard Overlaminates ___________ 48

Reviewing the CR-90 or CR-100 Patch Size _______________________________ 49

Reviewing the Overlaminate Design _____________________________________ 49

Section 2: General Troubleshooting _______________________________________ 50

LCD/SmartGuard Messages______________________________________________ 50

Reviewing LCD Messages_____________________________________________ 50

Reviewing SmartGuard™ Error and Status Messages _______________________ 58

Communications Errors _________________________________________________ 60

Resolving the Communication Errors ____________________________________ 60

Firmware Errors _______________________________________________________ 63

Resolving the Upgrade Failed error ______________________________________ 63

Card Feeding Errors ____________________________________________________ 65

Resolving the Card Feeding problem (HDP820/820-LC) _____________________ 65

Resolving the Card Feeding Errors (HDP825/825-LC)_______________________ 68

Resolving the stalled Cards on or at the Feed Rollers ________________________ 71

Resolving the jammed Cards on the Flipper Table __________________________ 71

Resolving the Flipper Alignment Error Message____________________________ 72

Resolving the Cards being fed improperly off the Flipper Table _______________ 73

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

1

Page 16

RESTRICTED USE ONLY Fargo Electronics, Inc.

Resolving the Card Jam Error Message___________________________________ 74

Resolving the Card Jam: Lam Error Message______________________________ 75

Magnetic Encoding Errors _______________________________________________ 76

Resolving the No ENC Response Error Message ___________________________ 76

Resolving the No Magnetic Encoder Error Message_________________________ 76

Resolving the Failed Magnetic Encode Error Message _______________________ 77

Removing the Card jam in the Printer’s Magnetic Encoding Area ______________ 78

Resolving the Printer being unable to read Encoded Magnetic track Data problem _ 79

Resolving the magnetic stripe Data being printed on a Card problem ___________ 80

E-card Encoding Errors _________________________________________________ 81

Resolving the Job Mismatch error _______________________________________ 81

Removing the Card jam in the Printer’s Smart Card Encoding Area ____________ 82

Resolving the No Prox Encoder Error Message ____________________________ 83

Resolving the No Smart Encoder Error Message ___________________________ 83

Resolving the Failed Smart Encode Error Message__________________________ 84

Printing Process Errors__________________________________________________ 85

Resolving the Ribbon Alignment Error Message ___________________________ 85

Resolving the Print Ribbon Jam_________________________________________ 86

Resolving the Print Ribbon Error Message ________________________________ 86

Resolving the Print Ribbon Out Error Message_____________________________ 87

Resolving the Wrong Print Ribbon Error Message __________________________ 87

Resolving the Unknown Ribbon Type Error Message _______________________ 88

Resolving the Headlift Error Message ____________________________________ 88

Resolving the Printer pausing between Panels problem ______________________ 89

Resolving the Printhead Temp Error Message______________________________ 90

Resolving the Printer Open Error Message ________________________________ 90

Transfer Process Errors _________________________________________________ 91

Resolving the Upper and Lower Film errors _______________________________ 91

Resolving the Film Sensor errors________________________________________ 93

Resolving the Transfer Cooling error ____________________________________ 97

Resolving the Card Jam Error Message___________________________________ 98

Resolving the Temperature Timeout Error Message _________________________ 99

Resolving the Transfer Lift Error Message ________________________________ 99

Resolving the Output Stacker errors ____________________________________ 100

Card Lamination Errors ________________________________________________ 101

Resolving the Overlaminate Jam _______________________________________ 101

Resolving the Card Lamination Placement errors __________________________ 103

Resolving the Lam Error/Out Error Message _____________________________ 104

Resolving the Lamination (not adhering to the card surface) problem __________ 106

Diagnosing the Image Problems _________________________________________ 108

Resolving the Pixel failure problems ____________________________________ 108

Resolving the Card surface debris problems ______________________________ 110

Resolving the incorrect Image Darkness problems _________________________ 113

Resolving the Ribbon wrinkle problems _________________________________ 115

Resolving the excessive Resin Printing problems __________________________ 117

Resolving the incomplete Resin Printing problems_________________________ 118

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

2

Page 17

RESTRICTED USE ONLY Fargo Electronics, Inc.

Resolving the HDP Film wrinkle problems_______________________________ 119

Resolving the incomplete Transfer problems _____________________________ 121

Resolving an incomplete transfer on the leading edge problem _______________ 122

Resolving an incomplete transfer on the trailing edge problem _______________ 122

Resolving the Image Placement problems ________________________________ 123

Resolving the poor Image Quality problems ______________________________ 127

Resolving the Image washout on Film problems___________________________ 128

Resolving the Registration problems ____________________________________ 129

Resolving the Card Skewed Image problems _____________________________ 131

Printing a Test Image __________________________________________________ 132

Reviewing the Gray/Align YMC/K Self-Test _____________________________ 132

Reviewing the Color/Resin YMCK Self-Test _____________________________ 133

Reviewing the Color Bars YMC Self-Test _______________________________ 133

Reviewing the Card Count Self-Test ____________________________________ 134

Reviewing the Magnetic Test option ____________________________________ 134

Reviewing the Lamination Color/Resin YMCK+L Self-Test _________________ 135

Section 3: Card Lamination Module______________________________________ 136

Safety Messages (review carefully) _______________________________________ 136

Opening the Card Lamination Module __________________________________ 137

Loading the Overlaminate ____________________________________________ 140

Adjusting the Card Lamination Module ___________________________________ 143

Adjusting the Card Flattener __________________________________________ 143

Adjusting the Card Guide Rail_________________________________________ 145

Adjusting the Internal Card Guide ______________________________________ 149

Attaching the Card Lamination Module _________________________________ 152

Section 4: Printer Adjustments __________________________________________ 164

Safety Messages (review carefully) _______________________________________ 164

Adjusting the Card Size ________________________________________________ 165

Adjusting the Card Input Guide ________________________________________ 166

Adjusting the Card Stacker Output Guide ________________________________ 170

Adjusting the Internal Card Guide ______________________________________ 173

Adjusting the Card Thickness Knob ____________________________________ 176

Fine-Tuning the Card Separator Adjustment Assembly (D840995) ______________ 177

Printing on Alternate Card stocks ________________________________________ 178

Selecting the Right Cards and optimize the HDP Print Process _______________ 178

Selecting the Appropriate HDP Printer Driver settings ______________________ 179

Conducting the Tape Adhesion Test ____________________________________ 181

Printer Driver Options _________________________________________________ 184

Installing Printer Driver Updates _______________________________________ 184

Setting Up the Printer Driver ____________________________________________ 186

Setting up Windows 98SE/Windows Millennium __________________________ 186

Setting up Windows NT/Windows 2000/Windows XP______________________ 186

Using the Device Options tab ___________________________________________ 187

Adjusting the Ribbon Type ___________________________________________ 188

Adjusting the Film Type _____________________________________________ 189

Adjusting for the color matching _______________________________________ 190

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

3

Page 18

RESTRICTED USE ONLY Fargo Electronics, Inc.

Adjusting for the Resin Dither _________________________________________ 191

Using the Print Both Sides option ______________________________________ 192

Using the Split 1 Set of Ribbon Panels option_____________________________ 193

Using the Print Back Side First option___________________________________ 194

Using the Print on Back Side Only option________________________________ 195

Using the Rotate Front 180 Degrees or Rotate Back 180 Degrees options _______ 196

Using the Print in Single Card Mode option ______________________________ 197

Using the Link Card to Print Job option _________________________________ 198

Using the Disable Printing option ______________________________________ 199

Using the Image color tab ______________________________________________ 200

Using the Image Transfer tab____________________________________________ 204

Adjusting the Image Position controls ___________________________________ 205

Adjusting the Transfer Dwell Time and Temperature _______________________ 207

Adjusting the Flattener Temperature ____________________________________ 208

Using the K Panel Resin tab_____________________________________________ 209

Selecting the Full Card with the K Panel Resin tab_________________________ 210

Selecting the Defined Area(s) with the K Panel Resin tab ___________________ 211

Selecting the Undefined Area(s) with the K Panel Resin tab _________________ 212

Defining the Area to activate the Card Grid ______________________________ 213

Measuring the Total Card area_________________________________________ 214

Measuring the Area to be positioned on the Card __________________________ 215

Selecting the Print YMC under the K and Print K Only options_______________ 216

Using the Magnetic Encoding tab ________________________________________ 218

Using the Encoding Mode option ______________________________________ 219

Encoding the Mode/Coercivity/Magnetic Track Selection ___________________ 221

Reviewing the Magnetic Track Options _________________________________ 222

Reviewing the Enable MLE Support checkbox____________________________ 223

Reviewing the Verification options _____________________________________ 224

Reviewing the Shift Data Left _________________________________________ 225

Reviewing the ISO Track Locations ____________________________________ 226

Sending the Track Information ________________________________________ 227

Reviewing the Sample String__________________________________________ 228

Reviewing the ASCII Code and Character Table __________________________ 229

Using the Card tab ____________________________________________________ 230

Selecting the Card Size from CR-80, CR-90 or CR-100 _____________________ 231

Selecting the Custom Card Size________________________________________ 233

Selecting the Card Type______________________________________________ 234

Reviewing the Orientation ____________________________________________ 236

Specifying the Copies _______________________________________________ 236

Clicking on the About button__________________________________________ 237

Using the Lamination tab (only with Card Lamination Module) ________________ 238

Selecting the Lamination Position ______________________________________ 239

Selecting the Lamination Side _________________________________________ 240

Selecting the Lamination Type ________________________________________ 241

Adjusting the Transfer Dwell Time and Transfer Temperature________________ 242

Selecting the Sensors button and Defaults button __________________________ 242

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

4

Page 19

RESTRICTED USE ONLY Fargo Electronics, Inc.

Selecting the Sensors button and Defaults button __________________________ 243

Section 5: Cleaning ____________________________________________________ 244

Using the Required Supplies __________________________________________ 244

Safety Messages (review carefully) _______________________________________ 245

Cleaning inside the Printer____________________________________________ 246

Cleaning outside the Printer___________________________________________ 246

Cleaning the Printhead _______________________________________________ 247

Cleaning the Cleaning Rollers _________________________________________ 248

Cleaning the Card Feed Rollers ________________________________________ 252

Cleaning the Platen Rollers ___________________________________________ 256

Section 6: Parts Replacement____________________________________________ 258

Safety Messages (review carefully) _______________________________________ 259

Reviewing the Printer Components _______________________________________ 260

Reviewing the Input Hopper Components________________________________ 260

Reviewing the Print Module Components ________________________________ 263

Reviewing the Transfer Station Components _____________________________ 265

Reviewing the Base Module Components ________________________________ 266

Reviewing the Base Module Components ________________________________ 267

HDP Main Board Cable Connections Reference___________________________ 269

HDP Lamination Board Cable Connections Reference______________________ 270

HDP Lamination Module Board Cable Connections Reference _______________ 272

Cover Removal Procedures _____________________________________________ 273

Removing the Print Station cover (840361) ______________________________ 273

Removing the Front Transfer Cover (840362)_____________________________ 274

Removing the Mid Pulley Cover (D840166)______________________________ 275

Removing the Base Module cover (840363) ______________________________ 276

Removing the Card Input Hopper cover (840167) _________________________ 277

Removing the Card Output Hopper cover (840167) ________________________ 277

Removing the Back cover ____________________________________________ 278

Control Panel Assembly Components _____________________________________ 279

Replacing the Control Panel Assembly Components _______________________ 279

Printhead Assembly Components ________________________________________ 281

Replacing the Printhead (D840854)_____________________________________ 281

Replacing the Fan Assembly (D840986) _________________________________ 282

Replacing the Head Force Spring - 2 (840272) ____________________________ 283

Replacing the Ribbon Deflector (D840638) ______________________________ 284

Print Station Components replacement ____________________________________ 285

Replacing the Headlift Drive O-Rings (140212) ___________________________ 285

Replacing the Ribbon Drive O-Ring behind the Encoder Wheel (810492) ______ 286

Replacing the Ribbon Sensor Board Assembly (140407) ____________________ 287

Replacing the Encoder Wheel (810492) _________________________________ 288

Replacing the Ribbon Sensor Array Assembly (840108) ____________________ 289

Replacing the Ribbon Supply Motor Assembly (D840980) __________________ 290

Replacing the Ribbon Take-Up Motor Assembly (D840980) _________________ 291

Replacing the Headlift Motor Assembly (D840980)________________________ 292

Replacing the Ribbon Supply Encoder Sensor Assembly (D840982)___________ 293

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

5

Page 20

RESTRICTED USE ONLY Fargo Electronics, Inc.

Replacing the HDP 800 Series Ribbon Hub ______________________________ 294

Replacing the HDP 800 Series Ribbon Take up Roller Hubs _________________ 313

Replacing the HDP 800 Series Film Supply Hub __________________________ 315

Replacing the Headlift Sensor Assembly (D840983) _______________________ 322

Transfer Station Components Replacements ________________________________ 323

Replacing the Film Drive O-Rings (140212)______________________________ 323

Replacing the Film Drive Encoder Wheel - 2 (810492) _____________________ 324

Replacing the Stepper Motor Assembly (840123)__________________________ 325

Replacing the Supply Encoder Sensor Assembly (840135) __________________ 326

Replacing the Lamination Take-Up Encoder Sensor Assembly (840136) _______ 327

Replacing the Lower Film Sensor Assembly (840199) ______________________ 328

Replacing the Upper Film Sensor Assembly (D841023)_____________________ 329

Replacing the Print Platen Roller (D840811) _____________________________ 330

Replacing the Transfer Peel Off Bar Assembly (D840698) __________________ 331

Replacing the Transfer Station Assembly (D841083) _______________________ 332

Replacing the Lamination Assembly (D841085)___________________________ 334

Replacing the Transfer Lift Sensor (A000126) ____________________________ 336

Replacing the Transfer Lift Motor (D840173)_____________________________ 337

Base Module Components Replacements __________________________________ 338

Replacing the Drive Belt – Platen Roller to Card Feed Roller (220071)_________ 338

Replacing the Drive Belt – Card Feed Roller to Card Feed Roller (220082) _____ 339

Replacing the Stepper Motor Assembly (D841045) ________________________ 340

Replacing the Pinch Roller Spring Plate-Front Input Side (D840865) __________ 341

Replacing the Pinch Roller Spring Plate-Front Output Side (D840865) _________ 342

Replacing the Pinch Roller Spring Plate-Back Input Side (D840865) __________ 343

Replacing the Pinch Roller Spring Plate-Back Output Side (D840865) _________ 344

Replacing the Drive Pulley - Back - 2 (D850190)__________________________ 345

Replacing the Gear - Card Transport - 2 (760330) _________________________ 346

Replacing the Compound Gear (D841032) _______________________________ 347

Replacing the Base Module (D841082)__________________________________ 348

Card Input Hopper Components Replacements______________________________ 350

Replacing the Input Hopper (D841087)__________________________________ 350

Replacing the Separator Adjustment Assembly (D840995) __________________ 351

Replacing the Flipper Table Sensor Board Assembly (140407) _______________ 352

Replacing the Card Low Sensor Board Assembly (140407) __________________ 353

Replacing the Cleaning Roller Drive Idler Gear - 2 (760401)_________________ 354

Replacing the Card Feed Gear - 3 (810271) on the Flipper Table Encoder Feed Motor

(E000062)_________________________________________________________ 355

Replacing the Card Feed Shaft Gear on the Cleaning Roller Assembly (810271) _ 356

Replacing the Feed/Encoding Motor Assembly (E000062) __________________ 357

Replacing the Cleaning Roller Assembly (840102)_________________________ 358

Replacing the Flipper Table Position Motor (840124) ______________________ 359

Replacing the Card Feed Motor Assembly (D841105) ______________________ 360

Replacing the Flipper Table Card Sensor Assembly (D840625)_______________ 361

Replacing the Card Feed Sensor (D840624) ______________________________ 362

Replacing the Magnetic Encoder Head (840104) __________________________ 363

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

6

Page 21

RESTRICTED USE ONLY Fargo Electronics, Inc.

Replacing the Encoder Card Sensor (140407)_____________________________ 364

Power Assembly Components Replacements _______________________________ 365

Replacing the Power Switch (120011)___________________________________ 365

Replacing the Power Cord Receptacle (130067) ___________________________ 366

Replacing the Main Print Board (A000271) ______________________________ 367

Replacing the Lamination Board (140402) _______________________________ 368

Replacing the Power Supply (150240) __________________________________ 369

Output Stacker Components Replacements_________________________________ 370

Replacing the Output Stacker (D841079) ________________________________ 370

Replacing the Stacker Full Sensor (140407) ______________________________ 371

Replacing the Stacker Lift Motor (840130)_______________________________ 372

Card Lamination Module Component Replacements _________________________ 373

Replacing the Lamination Module Board Cover (D870151)__________________ 373

Replacing the Lamination Module Main Cover (D870159) __________________ 374

Replacing the Lamination Module Main Board (A000250) __________________ 375

Replacing the Lamination Module Arm Assembly (D870153)________________ 376

Replacing the Lamination Module Card Flipper Table Assembly (D870091) ____ 377

Replacing the Card Position Sensor Assembly (D870186) ___________________ 379

Replacing the Lamination Module Flipper Position Sensor (D870188) _________ 380

Replacing the Lamination Module Overlaminate Encoder Sensor (D870189) ____ 381

Replacing the Lamination Module Ribbon ID Sensor (820593) _______________ 382

Replacing the Lamination Module Overlaminate Sensor (D870241) ___________ 383

Replacing the Lamination Module Hopper Sensor Assembly (D870228) _______ 384

Replacing the Lamination Module Platen Motor (D870218) _________________ 386

Replacing the Lamination Module Flipper Table Motor (D870217) ___________ 388

Replacing the HDP820-LC/HDP825-LC Lamination Lid Hinge Bracket _______ 390

Adjusting the HDP820-LC/HDP825-LC Lamination Heat Shield Adjustment ___ 408

HDP820/HDP820-LC Magnetic and Smart Card Module Replacement___________ 414

Replacing the Magnetic/Smart Card Module______________________________ 418

Section 7: Packing the HDP800 Series Card Printer_________________________ 437

Section 8: Board Level Diagnostics _______________________________________ 438

Board Errors_________________________________________________________ 438

Resolving the EE Memory Error _______________________________________ 438

Resolving the EE Checksum Error _____________________________________ 438

Resolving the DRAM Memory Error ___________________________________ 439

Resolving the RAM Memory Error _____________________________________ 439

Resolving the FPGA Error____________________________________________ 439

Sensor Testing _______________________________________________________ 440

Reviewing the Sensor Location and Voltages _____________________________ 441

Reviewing the Sensor Layout on Ribbon Sensor array ______________________ 442

Reviewing the Sensor Location and Voltages for the Lamination Module_______ 443

Section 9: LCD On-Line Menu Navigation ________________________________ 444

Entering the LCD Menu and selecting an Option ____________________________ 444

Selecting from the HDP800 Series Menu Option Structure Tree ______________ 446

Reviewing the Printer Setup ____________________________________________ 447

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

7

Page 22

RESTRICTED USE ONLY Fargo Electronics, Inc.

Preparing to Adjust the Print Offset, Transfer TOF and Transfer EOF__________ 449

Aligning the Print Offset _____________________________________________ 450

Setting the Transfer TOF _____________________________________________ 452

Setting the Transfer EOF _____________________________________________ 454

Setting the Transfer EOF _____________________________________________ 455

Adjusting the Transfer Tension ________________________________________ 456

Adjusting the Film Drive _____________________________________________ 457

Adjusting the Ribbon Tension _________________________________________ 457

Adjusting the Ribbon Drive ___________________________________________ 458

Adjusting the Transfer Temperature ____________________________________ 458

Setting the Flattener Temperature ______________________________________ 459

Setting the Printhead Resistance _______________________________________ 459

Adjusting the Image Darkness _________________________________________ 460

Changing the Encoder Settings ________________________________________ 461

Setting the Magnetic TOF ____________________________________________ 462

Setting the Magnetic TOF ____________________________________________ 463

Adjusting the Flipper Offset___________________________________________ 464

Adjusting the Lamination Flipper Offset _________________________________ 464

Adjusting the LAM TOF and EOF _____________________________________ 465

Adjusting the Lamination Sensor Calibration _____________________________ 466

Adjusting the Lamination Temperature Setting____________________________ 466

Show the Error Count _______________________________________________ 466

Using the Show Card Count option _____________________________________ 467

System Upgrade (Firmware Upgrade) ___________________________________ 467

Section 10: Firmware Updates___________________________________________ 468

Firmware Updater Application Program ___________________________________ 468

Downloading Firmware Updates _________________________________________ 470

Updating the Printer's Firmware _________________________________________ 471

Updating the Main Firmware__________________________________________ 471

Updating the LCD Firmware __________________________________________ 474

Firmware Upgrades (as of 10/07/03) ______________________________________ 476

Section 11: Fargo Technical Support _____________________________________ 478

Contacting Fargo Technical Support ______________________________________ 478

Reading the Serial Numbers on a Fargo printer______________________________ 479

Finding out when a Fargo Card Printer was manufactured ___________________ 479

Reviewing Example No. 1: Serial Number 80453289 ______________________ 479

Reviewing Example No. 2: Serial Number A1280224______________________ 479

Section 12: Reviewing Spare Parts Lists___________________________________ 480

Reviewing Spare Parts List for HDP 800 Series Card Printer_________________ 480

Reviewing Spare Parts List for Card Lamination Module____________________ 494

Glossary of Terms _____________________________________________________ 502

Index ________________________________________________________________ 522

Appendix A: Engineering Drawings ______________________________________ 535

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

8

Page 23

RESTRICTED USE ONLY Fargo Electronics, Inc.

Appendix B: Technical Updates _________________________________________ 535

Appendix C: Miscellaneous _____________________________________________ 535

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

9

Page 24

RESTRICTED USE ONLY Fargo Electronics, Inc.

Section 1: Specifications

The purpose of this section is to provide the User with specific information on the Regulatory

Compliances, Agency Listings, Technical Specifications and Functional Specifications for the

HDP 800 Series Card Printer/Encoders.

Reviewing the HDP800 Series Printers Overview

table

HDP800 Series Input

Hoppers

HDP820 (Dual-Sided

Card Printer/Encoders)

HDP820-LC (DualSided Card

Printer/Encoders)

HDP825 (Dual-Sided

Card Printer/Encoders)

HDP825-LC (DualSided Card

Printer/Encoders)

1 250 CR-80,

1 250 CR-80,

2 200 CR-80 Optional Optional

2 200 CR-80 Optional Included

Card

Capacity

Accepted

Card Size

CR-90 &

CR-100

CR-90 &

CR-100

Encoding

Modules

Optional Optional

Optional Included

Lamination

Module

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

10

Page 25

RESTRICTED USE ONLY Fargo Electronics, Inc.

Regulatory Compliances

Term Description

CSA The Printer manufacturer has been authorized by UL to represent

the Card Printer as CSA Certified under CSA Standard 22.2.

File Number: E145118

FCC The Card Printer complies with the requirements in Part 15 of the

FCC rules for a Class B digital device. (Note: These requirements

are designed to provide reasonable protection against harmful

interference in a residential installation.)

If equipment operation in a residential area causes unacceptable

interference to radio and TV reception, the operator is required to

take whatever steps are necessary to correct the interference.

ITS-EMC The Card Printer has been tested and complies with EN55022

Class B: 1995 and EN82082-1: 1997 standards for EMI emissions.

(Note: Based on the above testing, the Printer manufacturer

certifies that the Card Printer complies with all current EMC

directives of the European Community and has placed the CE mark

on the Card Printer.)

License Number: J99032510

TÜV-GS The Card Printer has been tested and complies with IEC950 and

bears the TÜV-GS mark.

License Number: S9971826

UL The Card Printer is listed under UL 1950 INFORMATION

TECHNOLOGY EQUIPMENT.

File Number: E145118, Volume 1, Section 15

Agency Listings

Term Description

Emissions

Standards

CE, FCC, CRC c1374, BSMI, ITS (EN 55022 Class B:1995, FCC Class

B, EN 82082-1:1997).

Safety

Standards

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

UL 1950, CSA C2.2 No.950-95 and TüV-GS (EN 60950 A1-A4, A11).

11

Page 26

RESTRICTED USE ONLY Fargo Electronics, Inc.

Technical Specifications

Term Description

Accepted

Standard Card

Sizes

Accepted Card

Thickness

Accepted

Electronic Card

types

HDP820/820-LC:

• CR-80: 3.375 in. x 2.125 in. (85.6mm x 54mm) (corresponds to

ID1)

• CR-90: 3.63 in. x 2.37 in. (92mm x 60mm)

• CR-100: 3.88 in. x 2.63 in. (98.5mm x 67mm); laminate with CR-

90 or CR-100 size PolyGuard only if laminating with HDP800

Series-LC

HDP825/825-LC:

• CR-80: 3.375” L x 2.125” W/85.6mm L x 54mm W

.030 in. (30 mil) to .070 in. (70 mil) (.762mm to 1.778mm). (30 mil

maximum for CR-100 size cards)

(.030" to .040"/.762mm to 1.02mm if laminating with HDP800 SeriesLC; thicker cards are allowed to pass through the Lamination Module if

you choose to print-only)

HID Proximity Cards, MIFARE Contactless Smart Cards and Contact

Smart Cards

Accepted Card

Compositions

Colors Up to 16.7 million colors and 256 shades per Pixel.

Card Capacity

Dimensions

ABS, PVC, PET and PETG

HDP820/HDP820-LC: 250 cards (.030"/.762mm); auto or manual

feed

HDP825/HDP825-LC: 200 cards (.030"/.762mm) auto or manual feed

• HDP820/825: 15” H x 26.1” W x 14"D/381mm H x 663mm W x

356mmD

• HDP820-LC/825-LC: 15” H x 34.75” W x 14"D/381mm H x

883mm W x 356mmD

• LC Module: 14.2” H x 13” W x 10”D/362mm H x 330mm W x

254mmD

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

12

Page 27

RESTRICTED USE ONLY Fargo Electronics, Inc.

Technical Specifications (continued)

Term Description

Display User-friendly, SmartScreen LCD Control Panel; LED display on

Card Lamination Module.

Encoding Options

Fargo Certified

Supplies

HDP Film Options

• ISO Magnetic Stripe Encoding Module, dual high- and low-

coercivity, Tracks 1, 2 and 3

• JIS II Magnetic Stripe Encoding Module

• E-card Docking Station (required for all e-card options or 3rd

party smart card encoding)

• Contact Smart Card Encoder (ISO 7816), Parts 1-4; T=0 & T=1

• Contactless Smart Card Encoder (MIFARE

®

)

• Prox Card Encoder (HID read-only) (Note: Corporate Express

1000 Cards can be used with special order Weigand/ASCII

Converter)

Fargo Card Printer/Encoders require highly specialized media to

function properly. To maximize printed card quality and durability,

printhead life and printer/encoder reliability, use only Fargo Certified

Supplies, Fargo warranties are void, where not prohibited by law,

when non-Fargo Certified Supplies are used.

• Clear, 1,250 prints

• Standard Holographic

• Custom Holographic, special order

HDP Film Storage

77ºF (25ºC) or lower for no longer than 1.5 years.

Temperature

Humidity 20% to 80% Non-Condensing.

Input Hopper Card

Capacity

Interface

HDP820/HDP820-LC: 250 cards (.030"/.762mm)

HDP825/HDP825-LC: 200 cards (.030"/.762mm)

• Centronics parallel, IEEE-1284 Compliant

• Optional USB to Parallel Adaptor

• Interfacing information for E-card Options

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

Continued on the next page

13

Page 28

RESTRICTED USE ONLY Fargo Electronics, Inc.

Technical Specifications (continued)

Term Description

Maximum Accepted

(HDP825/825-LC only) 2.125 in. to 2.63 in. (54mm to 67mm).

Card Width Range

Maximum Accepted

3.375 in. to 3.88 in. (85.6mm to 98.5mm).

Card Length Range

Memory 8 MB RAM; expandable to 32 MB RAM.

Operating

65ºF to 80ºF (18ºC to 27ºC).

Temperature

Options The options are the 32MB RAM Upgrade Kit, Printer Cleaning Kit,

External Print Server (Windows only; required for stand-alone

networking of printer/encoders), Card Lamination Module and USBto-Parallel Interface Cable (Windows 98/Me/2000/XP only).

Output Hopper

Card Capacity

Overlaminate

Options (HDP800

Series-LC only)

100 cards (.030"/.762mm); 250 cards with optional Card Output

Stacker

All overlaminates are available in either clear, holographic globe

design or custom holographic design. They can also be optimized

for use with smart cards and Magnetic Stripes. PolyGuard available

in CR-80, CR-90 and CR-100 patch sizes. Here are the options:

• Thermal Transfer Overlaminate, .25 mil thick, 500 prints

• PolyGuard Overlaminate, .6 mil thick, 250 prints

• PolyGuard Overlaminate, 1.0 mil thick, 125 prints

Print Area Over-the-edge on all accepted standard card sizes (YMCKH ribbon

required for over-the-edge printing on CR-100 cards).

Print Method HDP Dye-Sublimation/Resin Thermal Transfer

Printing Method HDP™ Dye-Sublimation/Resin Thermal Transfer.

Printing Resolution Up to 16.7 million colors and 256 shades per Pixel.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

14

Page 29

RESTRICTED USE ONLY Fargo Electronics, Inc.

Technical Specifications (continued)

Term Description

Print Ribbon

Options

• Full color, YMC, 700 prints

• Full color with resin black, YMCK, 250 or 500 prints

• Full color with two resin black Panels, YMCKK, 400 prints

• Full color with resin black and heat seal Panel for difficult to print

surfaces, YMCKH, 400 prints; extra wide for over-the-edge

printing on CR-100 cards

All HDP ribbons utilize Fargo's exclusive RibbonTraq™ system for

maximum print quality, performance, reliability and ease of use.

Print Speed-Batch

Mode

• 35 seconds per card/112 cards per hour (YMC with transfer)

• 38 seconds per card/94 cards per hour (YMCK with transfer)

• 66 seconds per card/54 cards per hour (YMCKK with transfer)

• 40 seconds per card/90 cards per hour (YMCK/Lamination)*

• 72 seconds per card/50 cards per hour (YMCKK/Lamination)*

Resolution 300 dpi (11.8 dots/mm)

Software Drivers Windows 95/ 98/ ME/ NT/ 2000/XP.

Supply Voltage 100 to 240 VAC, 3.75A.

Supply Frequency 50 Hz/60 Hz.

System

Requirements

IBM-PC or compatible. Windows 95/ 98/ ME/ NT/ 2000/XP.

Pentium

™

class 133 MHz computer with 32 MB of RAM or higher,

200 MB free hard disk space or higher and ECP parallel port with

DMA access.

Warranty

Printer: One year; optional Extended Warranty Program (U.S.

only)

Printhead: Lifetime; unlimited pass

Weight

HDP820/825: 70 lbs. (31.8kg).

HDP820-LC/825-LC: 87 lbs./39.5kg

LC Module: 21 lbs./9.5 kg

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

15

Page 30

RESTRICTED USE ONLY Fargo Electronics, Inc.

Functional Specifications

The Card Printer utilizes two different, yet closely related printing technologies to achieve its

remarkable direct-to-card print quality for dye-sublimation and resin thermal transfer. The

Card Printer will print from any IBM-PC® or compatible running Windows® 98Se/Me,

Windows NT 4.0, Windows 2000 or Windows XP Pro.

The following describes how each of these technologies works:

Function Description

DyeSublimation

Dye-Sublimation is the print method the Card Printer uses to produce

smooth, continuous-tone images that look photographic. (Note: This

process uses a dye-based ribbon roll that is partitioned by a number of

consecutive color Panels.)

• Process colors: The Panels are grouped in a repeating Series of

three process colors - yellow, magenta and cyan (YMC), along the

entire length of the Print Ribbon.

• Panels: The Printer always prints the yellow Panel first, followed by

the magenta Panel and the cyan Panel.

• Printhead: As the Print Ribbon passes beneath the Printhead,

hundreds of thermal elements within the Printhead heat the dyes on the

ribbon. (Note: When these dyes are heated, they vaporize and diffuse

into the surface of the card. A separate pass is made for each of the

three color Panels on the ribbon.)

• color Shades: By combining the colors of each Panel and by varying

the heat used to transfer these colors, it is possible to print up to 16.7

million different shades of color. (Note: This blends one color smoothly

into the next, producing photo-quality images with absolutely no dot

pattern.)

• Dye-Diffusion Thermal Transfer: It is the process of heating a dye

suspended in a cellulous substrate until the dye can flow, diffusing into

the dye receptive surface of the card or InTM. This produces the image

in the surface of the card.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

Continued on the next page

16

Page 31

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Access Card Slot to Parallel Interface Port

Component Description

Resin Thermal

Transfer

Access Card

Slot

Card Input

Hopper

Card Output

Hopper

Card

Lamination

Module

Resin Thermal Transfer is the print method the Printer uses to print

sharp black text and crisp bar codes that can be read by both infrared

and visible-light bar code scanners.

Like dye-sublimation, this process uses the same thermal Printhead to

transfer color to a card from a resin-only Print Ribbon or the resin black

(K) Panel of a full color Print Ribbon.

The difference, however, is that solid dots of resin-based ink are

transferred and fused to the surface of the card. (Note: This produces

very durable, saturated printing.)

If using the Printer's optional SmartGuard Security Feature, this is the

slot in which a SmartGuard Access Card is inserted.

Load blank cards into this hopper.

Stores printed cards.

Works in conjunction with the Printer to apply a variety of different

overlaminates to printed cards, providing increased card durability and

security. The Module has its own LED indicator light and control

buttons; so it can be operated separately from the Printer. (Note:

When printing a batch of cards, the Printer can be encoding and

printing one card while the Lamination Module laminates another card.)

See Section 3: Card Lamination Module

on page 136.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

Continued on the next page

17

Page 32

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Access Card Slot to Parallel Interface Port (continued)

Component Description

Card Output

Guide

If the Printer is equipped with an optional Card Output Stacker, adjust

the stacker's Card Output Guide to the proper card size prior to printing,

as shown below. (Note: This will ensure consistent card ejecting and

stacking.)

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

18

Page 33

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Access Card Slot to Parallel Interface Port (continued)

Component Description

Film Tension

Knobs

Allows you to manually tighten the HDP film after loading or whenever

the Transfer Station is opened, as shown below.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

19

Page 34

RESTRICTED USE ONLY Fargo Electronics, Inc.

Softkey Buttons

Printer Components: Access Card Slot to Parallel Interface Port (continued)

Component Description

Front Access

Door

LCD Display Displays the current status of the Printer.

LED Light Indicates the Printer ON, OFF, pause and error conditions.

Print Station Prints images onto the HDP film.

Printhead The component of the Print Station that actually does the printing. This

Softkey Buttons Current function is displayed above the button and will change

Opens to allow access to the inside of the Printer.

component is fragile and must not be bumped or touched with anything

other than a cleaning pen.

depending upon the Printer's mode of operation.

Continued on the next page

Scroll Buttons

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

20

Page 35

RESTRICTED USE ONLY Fargo Electronics, Inc.

Unlock Release Lever

Transfer Stations

Print Station

Printer Components: Access Card Slot to Parallel Interface Port (continued

Component Description

Scroll Buttons Used to scroll through menus and sub-menus and to adjust certain

menu options.

Transfer Station Transfers printed images and the HDP film to blank cards.

Transfer Station

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

to open Print and

21

Page 36

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Access Card Slot to Parallel Interface Port (continued)

Component Description

Card Thickness

Adjusts the Printer to feed varying card thicknesses.

Adjustment

Knob

Card Cleaning

Assembly

Automatically cleans cards for higher print quality. (Note: Clean this

assembly after every 250 cards or as needed.)

Power Switch Turns the Printer power ON and OFF.

Power Port Connect to the included power cord.

Parallel

Connect to a Windows PC with a parallel cable. See below.

Interface Port

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

22

Page 37

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: Access Card Slot to Parallel Interface Port (continued)

Component Description

Release Lever Locks and unlocks the Print and Transfer Stations so they can be

opened and closed. (Note: This lever must be in its locked position in

order for the Printer to begin printing.)

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

23

Page 38

RESTRICTED USE ONLY Fargo Electronics, Inc.

LCD Display

Softkey Buttons

Card Input Hopper

Front Access Door

Printer Components: Access Card Slot to Parallel Interface Port (continued)

Refer to the previous table.

Print Station

Card Output

Hopper

Film Tension

Knobs

Transfer Station

Printhead

Release Lever

LED Light

Scroll Buttons

Access

Card Slot

Card Thickness

Adjustment Knob

Card Cleaning

Assembly

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

24

Page 39

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: LCD and Softkey Control Pad

The Printer provides a four line, eighty (80) character LCD Displays that can communicate

helpful information about the Printer's operation.

• The top three lines of the LCD Display will always be used to communicate print status,

error messages and menu options.

• The bottom line of the LCD Display will always be used to communicate the current

function of the Printer's softkey buttons.

This section describes how the LCD Display and Softkey Control Pad work together.

Component Description

Softkey

Buttons

The Printer has three softkey buttons that appear below the LCD

Display. Their current function is indicated by the words appearing above

them. This function will change according to the Printer's current mode of

operation.

• Press the corresponding softkey button under the choice you want to

select. If no word appears above a particular button, this indicates it

has no function in that particular mode of operation. The Printer also

has another type of button on its control pad called scroll buttons.

These buttons are located just to the right of the LCD Display.

• Use these buttons to scroll through help text, to navigate through the

Printer's menus and to adjust certain Printer settings.

LCD Display The Printer's LCD Display will change according to the Printer's current

mode of operation.

System Check

Screens

When the Printer is first powered ON, the Printer's system check screens

will briefly appear to display and test the amount of installed Printer

memory, align the Print Ribbon and HDP film and lastly to display the

READY screen and current Firmware version.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

25

Page 40

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: LCD and Softkey Control Pad (continued)

Component Description

Ready/Printer

Open Screens

Once the Printer has finished its system check and with the Print and

Transfer Stations closed, the Printer will display READY to indicate that

the Printer is ready for operation. (Note: The Printer will stay in this

mode until it receives a print job or it is turned OFF.)

• If the Release Lever is unlocked, the Release Lever Unlocked screen

will appear to remind you this item is open.

• If the Print and Transfer Stations are opened, the Printer Open

screen will appear. Press either the Forward or Back buttons to

move the Printer's card path rollers in the indicated direction. Use the

scroll buttons to select between moving the Print-Side Card Rollers or

the Input-Side Card Rollers. This is helpful when cleaning the Printer

or if clearing jammed media. In any of these screens, the Printer will

always display the Menu option above the center softkey button.

Press this button to access the Printer's menu options. (Note: The

Menu option is available only in the Ready/Printer Open screens.)

• If the Printer is equipped with the Card Lamination Module and the

Lamination Station is opened, no LCD message will appear. Instead,

the Lamination Module's LED will flash. (Note: To move the

Lamination Module's rollers, push the Module's Cancel or Resume

buttons.)

• If both the Print Station and Lamination Station are open, the LCD's

FORWARD and BACK softkey buttons will move ALL rollers. In any

of these screens, the Printer will always display the MENU option

above the center softkey button. Press this button to access the

Printer's menu options. (Note: The MENU option is available only in

the READY/PRINTER OPEN screens.)

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

Continued on the next page

26

Page 41

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: LCD and Softkey Control Pad (continued)

Component Description

Print Status

Screen

During operation, the LCD will indicate the current Print Status by

showing you the area of the Printer that is active. It does this by

displaying the following icons on the second line:

• FDR Indicates the Feeder Station is feeding a blank card into the

Printer.

• ENC Indicates the Encode Station is encoding a card (appears only if

you are using a Printer with an optional built-in Encoding Module).

• PRT Indicates the Print Station is printing onto the HDP film.

• TFR Indicates the Transfer Station is transferring an image to a blank

card.

• LAM indicates the Lamination Station is applying an overlaminate to a

card (appears only if using a Printer equipped with the optional Card

Lamination Module. See Section 3: Card Lamination Module

on page

136.

Since the Printer is capable of performing several of these functions

simultaneously, one or all of these icons may appear at once, depending

on if you are printing just one card or a batch of cards.

The Print Status screen always displays Cancel in the lower left and

Pause in the lower right.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

27

Page 42

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: LCD and Softkey Control Pad (continued)

Component Description

The Cancel

button

The Pause

button

Use this button to cancel print jobs and reset the Printer for the next print

job.

• This Cancel function will cancel all print jobs in the Printer and will

completely reset the Printer. In this case, be sure to cancel the print

jobs from the PC before pressing YES.

• Canceling all print jobs (in the middle of a batch print) will force the

Printer to waste or delete any images that may already have printed

on the HDP film.

Caution: To avoid this, select the Print in Single Card Mode

option from the Printer Driver before sending the next print job. If a card

is left within the Printer after a print job is canceled, it will automatically

be ejected.

Use this button to pause the Printer at any time during operation. Note

the Printer will always finish its current task before pausing.

When the Printer is paused, the LED Light will flash and the Pause

softkey button will change to Resume.

Press Resume to continue Printer operation.

The LED Light This light works in conjunction with the Printer's LCD Display to help

communicate the Printer's current status. It is especially effective when

you are too far away from the Printer to read the LCD Display. The

following explains how to interpret both LED Lights on the exterior of the

Printer.

• Off: Indicates the Printer power is OFF.

• Solid GREEN: Indicates the Printer is powered ON and ready for

operation.

• Flashing GREEN: Indicates a Printer ERROR or ATTENTION

condition. Refer to the Printer's LCD Display for information.

Continued on the next page

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

28

Page 43

RESTRICTED USE ONLY Fargo Electronics, Inc.

Printer Components: LCD and Softkey Control Pad (continued)

Component Description

Error/Attention

Screens

The Printer is capable of communicating two similar yet different types of

message or prompt screens:

The first is called an ERROR screen. (Note: This screen appears if an

error occurs and will completely stop Printer operation. In this case, the

LCD will display ERROR on the first line and a brief description of the

error on the second line. If multiple errors occur at the same time, the first

line will display ERROR 1 of 2 or whatever the total number of errors may

be. To see the other error(s), use the scroll keys.)

• Press the Help button if you would like a more detailed explanation of

the error message. This will bring up the help screen explaining the

nature of the error and how to correct it. If necessary, use the scroll

buttons to scroll down the paragraph of help text.

• Press Quit when you are done reading. Once the error is corrected,

resume operation or reset the Printer according to how you were

instructed in the help screen.

The second type of prompt is called an Attention screen. (Note: This

screen will not stop Printer operation and serves to communicate helpful