Page 1

DTC400/DTC300/DTC300M Card Printer

Service Manual (Rev. 1.3)

Part Number: L000533

Page 2

RESTRICTED USE ONLY Fargo Electronics, Inc.

ii

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3), property of Fargo

Electronics, Incorporated

Copyright 2003, 2004, 2005, 2006 by Fargo Electronics, Incorporated. All rights reserved.

Printed in the United States of America. Exclusive permission is granted to authorized

resellers of Fargo products to reproduce and distribute this copyrighted document to

authorized Fargo customers, who have signed a “no disclosure agreement” regarding the

restricted, proprietary use of said document.

The revision number for this document will be updated to reflect changes, corrections,

updates and enhancements to this document.

Revision Control

Number

Revision 1.3 1 March 2005 DTC400/DTC300/DTC300M Card Printer Service

Revision 1.2 1 October 2004 Same document title

Revision 1.1 1 September 2004 Same document title

Revision 1.0 1 July 2004 Same document title

Date Document Title

Manual (Rev. 1.3)

These reference documents were thoroughly reviewed to provide Fargo with professional

and international standards, requirements, guidelines and models for our technical, training

and user documentation. At all times, the Copyright Protection Notice for each document was

adhered to within our Fargo documentation process. This reference to other documents does

not imply that Fargo is an ISO-certified company at this time.

ANSI/ISO/ASQ Q9001-2000 American National Standard

, (sub-title) Quality Management

Systems - Requirements (published by the American Society of Quality, Quality Press, P.O.

Box 3005, Milwaukee, Wisconsin 53201-3005)

The ASQ ISO 9000:2000 Handbook

(editors, Charles A. Cianfrani, Joseph J. Tsiakals and

John E. West; Second Edition; published by the American Society of Quality, Quality Press,

600 N. Plankinton Avenue, Milwaukee, Wisconsin 53203)

Juran's Quality Handbook

(editors, Joseph M. Juran and A. Blanton Godfrey; Fifth Edition,

McGraw-Hill)

Any questions regarding changes, corrections, updates or enhancements to this document

should be forwarded to:

Fargo Electronics, Incorporated

Support Services

6533 Flying Cloud Drive

Eden Prairie, MN 55344 (USA)

(952) 941-9470

(800) 459-5636

FAX: (952) 941-7836

www.fargo.com

E-mail: sales@fargo.com

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 3

RESTRICTED USE ONLY Fargo Electronics, Inc.

iii

Table of Contents

Section 1: Introduction _____________________________________________________ 1-1

How to use the manual _______________________________________________________________ 1-1

Safety Messages (review carefully)______________________________________________________ 1-2

DTC400/DTC300/DTC300M Card Printer Overview _______________________________________ 1-3

Reviewing the DTC400/DTC300/DTC300M Block Diagram _______________________________ 1-3

Reviewing the DTC400/DTC300/DTC300M Sequence of Operations ________________________ 1-4

Reviewing the DTC400/DTC300/DTC300M Boot up Sequence_____________________________ 1-7

Section 2: Specifications ____________________________________________________ 2-1

Table of Contents ___________________________________________________________________ 2-1

Regulatory Compliances ______________________________________________________________ 2-2

Agency Listings_____________________________________________________________________ 2-3

Technical Specifications ______________________________________________________________ 2-3

Visual Security Solutions (Specifications) ________________________________________________ 2-6

VeriMarkTM Cards - 2-D holographic foil application ____________________________________ 2-6

Custom HoloMarkTM Cards ________________________________________________________ 2-6

Visual Security - Card Stock Part Numbers _____________________________________________ 2-6

Visual Security - Fargo Certified Overlaminates (Special Order in 50 quantity minimum)_________ 2-6

Visual Security Card Stock - Tolerances _______________________________________________ 2-6

VeriMarkTM - Application Specifications______________________________________________ 2-7

HoloMarkTM and Custom HoloMarkTM - Application Specifications _______________________ 2-7

Functional Specifications _____________________________________________________________ 2-8

Printer Components: Front Cover to USB Port __________________________________________ 2-9

Printer Components: Print Ribbons __________________________________________________ 2-10

Printer Components: Resin-Only Print Ribbons ________________________________________ 2-11

Printer Components: Dye-Sublimation Print Ribbons____________________________________ 2-12

Printer Components: Dye-Sublimation/Resin Print Ribbons_______________________________ 2-13

Printer Components: Blank Cards ___________________________________________________ 2-14

Printer Module: Flipper Table Module Assembly (D900200)______________________________ 2-15

Section 3: Secure Print Security Suite _________________________________________ 3-1

Overview__________________________________________________________________________ 3-1

Print Notification Application _______________________________________________________ 3-1

Security Imaging Application________________________________________________________ 3-1

Print Diagnostics Application________________________________________________________ 3-1

Supplies e-Ordering Application _____________________________________________________ 3-1

Password Control Application _______________________________________________________ 3-1

Print Security Suite – Main Window __________________________________________________ 3-2

SecureMark Media ________________________________________________________________ 3-2

Section 4: Setup and Installation Procedures ___________________________________ 4-1

Table of Contents ___________________________________________________________________ 4-1

Printer Setup and Installation __________________________________________________________ 4-3

Choosing A Good Location _________________________________________________________ 4-3

About Moisture Condensation _______________________________________________________ 4-3

Printer Setup and Installation ___________________________________ Error! Bookmark not defined.

Choosing A Good Location __________________________________ Error! Bookmark not defined.

About Moisture Condensation ________________________________ Error! Bookmark not defined.

Unpacking and Inspection __________________________________________________________ 4-4

Reviewing the Printer (front view)____________________________________________________ 4-4

Reviewing the Printer (front view; Cartridge being installed) _______________________________ 4-5

Reviewing the LCD (top-front part of Printer)___________________________________________ 4-5

Connecting the Printer power________________________________________________________ 4-6

Installing the Print Ribbon Cartridge __________________________________________________ 4-7

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 4

RESTRICTED USE ONLY Fargo Electronics, Inc.

iv

Installing Blank Cards into the Card Hopper ___________________________________________ 4-10

Lowering the Card Output Hopper ___________________________________________________ 4-13

Flipper Table Module Installation______________________________________________________ 4-14

Installing the Flipper Table Module Assembly (D900200) ________________________________ 4-14

DTC400 Card Printer/Encoder Card Flipper Module Upgrade Kit_____________________________ 4-17

Introduction ____________________________________________________________________ 4-17

Installing the Card Flipper Module Upgrade Kit ________________________________________ 4-18

Printer Driver Installation ____________________________________________________________ 4-26

Installing the Printer Driver ________________________________________________________ 4-26

Printing a Test Print Image_________________________________________________________ 4-39

Printer Transport ___________________________________________________________________ 4-41

Moving the Printer to another location ________________________________________________ 4-41

Section 5: General Troubleshooting __________________________________________5-1

Table of Contents ___________________________________________________________________ 5-1

Safety Messages (review carefully)______________________________________________________ 5-3

Communications Errors_______________________________________________________________ 5-4

Resolving the Communication Errors__________________________________________________ 5-4

Print Process Errors__________________________________________________________________ 5-6

Resolving a Card Not Fed Error (Cards will not feed off the Hopper)_________________________ 5-6

Resolving a Card Not Fed Error (Two (2) or more card feed at the same time)__________________ 5-9

Resolving a Ribbon RFID Error (Ribbon RFID Antenna is Corrupted) ______________________ 5-11

Resolving a Ribbon RFID Error (Ribbon RFID Sensor is Corrupted) ________________________ 5-13

Resolving the Mag Verify Error_____________________________________________________ 5-14

Resolving the No Mag Installed Error ________________________________________________ 5-17

Resolving a Ribbon Sensor Error (Ribbon Miscue) ______________________________________ 5-19

Resolving a Ribbon Break Jam Error _________________________________________________ 5-21

Resolving a Ribbon Out Error ______________________________________________________ 5-23

Resolving a No Ribbon Installed Error________________________________________________ 5-24

Resolving a Invalid Ribbon Error____________________________________________________ 5-26

Resolving a Wrong Ribbon Error____________________________________________________ 5-28

Resolving a Card Jam Error ________________________________________________________ 5-30

Resolving a Headlift Motor or Sensor Error____________________________________________ 5-32

Resolving the Cover Open Error Message _____________________________________________ 5-33

Resolving the Blank Output issues___________________________________________________ 5-35

Flipper Table Module Assembly Problems_______________________________________________ 5-38

Resolving the No Flipper Table Module problem _______________________________________ 5-38

Resolving the Flipper Jam Error_____________________________________________________ 5-39

Diagnosing Image Problems __________________________________________________________ 5-41

Resolving the Pixel Failure problems_________________________________________________ 5-41

Resolving the Card Surface Debris problems___________________________________________ 5-42

Resolving the Incorrect Image Darkness problems ______________________________________ 5-43

Resolving Ribbon Wrinkle problems _________________________________________________ 5-45

Resolving the Excessive Resin Printing problems _______________________________________ 5-47

Resolving the Incomplete Resin Printing problems ______________________________________ 5-49

Resolving the Image Placement problems _____________________________________________ 5-50

Resolving the Poor Image Quality problems ___________________________________________ 5-53

Running the Self Test _______________________________________________________________ 5-54

Running the Standard Self Test Print _________________________________________________ 5-55

Running the Magnetic Self Test (HiCo Only) __________________________________________ 5-56

Section 6: Printer Adjustments_______________________________________________6-1

Table of Contents ___________________________________________________________________ 6-1

Safety Messages (review carefully)______________________________________________________ 6-4

Safety Messages (review carefully)______________________________________________________ 6-5

DTC400/DTC300 Print Driver Options __________________________________________________ 6-6

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 5

RESTRICTED USE ONLY Fargo Electronics, Inc.

v

Reviewing DTC400, DTC300 and DTC300M Printer Drivers ______________________________ 6-6

Reviewing DTC400 Printer Drivers ___________________________________________________ 6-6

Reviewing DTC300 Printer Driver____________________________________________________ 6-7

Reviewing DTC300M Printer Drivers _________________________________________________ 6-8

Using the Card tab (DTC400/DTC300/DTC300M) _________________________________________ 6-9

Adjusting the Card Size Option ______________________________________________________ 6-9

Adjusting the Orientation Option ____________________________________________________ 6-10

Selecting the number of copies______________________________________________________ 6-11

Using the Diagnostics button under the Card tab ________________________________________ 6-12

Using the Clean Printer Option______________________________________________________ 6-13

Using the Test Print button_________________________________________________________ 6-15

Using the About button____________________________________________________________ 6-16

Using the Device Options tab (DTC400/DTC300) _________________________________________ 6-17

Reviewing the Device Options tab (DTC400) __________________________________________ 6-17

Reviewing the Device Options tab (DTC300) __________________________________________ 6-18

Adjusting the Ribbon Type option ___________________________________________________ 6-19

Selecting the Auto Ribbon Select option ______________________________________________ 6-20

Adjusting the Color Matching option _________________________________________________ 6-21

Adjusting for the Resin Dither ______________________________________________________ 6-22

Using the Print Both Sides option____________________________________________________ 6-23

Using the Split 1 Set of Ribbon Panels option __________________________________________ 6-24

Using the Print Back Side First option ________________________________________________ 6-25

Using the Print Back Side Only option________________________________________________ 6-26

Using the Rotate Front 180 Degrees or Rotate Back 180 Degrees options ____________________ 6-27

Using the Disable Printing option____________________________________________________ 6-28

Using the Device Options tab (DTC300M)_______________________________________________ 6-29

Reviewing the Device Options tab (DTC300M) ________________________________________ 6-29

Adjusting the Ribbon Type option (DTC300M) ________________________________________ 6-30

Selecting the Auto Ribbon Select option (DTC300M)____________________________________ 6-31

Adjusting for the Resin Dither (DTC300M)____________________________________________ 6-32

Using the Resin Heat, Front (K) option (DTC300M)_____________________________________ 6-33

Using the Resin Heat, Back (K) option (DTC300M) _____________________________________ 6-34

Using the Overlay Heat (O) option (DTC300M) ________________________________________ 6-35

Using the Print Both Sides option (DTC300M) _________________________________________ 6-36

Using the Print Back Side First option ________________________________________________ 6-37

Using the Print Back Side Only option________________________________________________ 6-38

Using the Rotate Front 180 Degrees or Rotate Back 180 Degrees options ____________________ 6-39

Using the Disable Printing option____________________________________________________ 6-40

Using the Image Color tab (DTC400/DTC300) ___________________________________________ 6-41

Using the Resin Heat (K) option (Front and Back) ______________________________________ 6-42

Using the Overlay Heat (O) option___________________________________________________ 6-43

Using the Color Matching option and Default button_____________________________________ 6-44

Using the Calibrate tab (DTC400/DTC300/DTC300M)_____________________________________ 6-45

Using the Image Position Controls___________________________________________________ 6-46

Using the Sensors button __________________________________________________________ 6-48

Using the Settings button __________________________________________________________ 6-49

Using the Magnetic Encoding tab (DTC400/DTC300/DTC300M) ____________________________ 6-50

Using the Magnetic Track Selection radio buttons_______________________________________ 6-51

Using the Magnetic Track Options radio buttons________________________________________ 6-53

Using the Bit Density radio buttons __________________________________________________ 6-54

Using the Character Size radio buttons________________________________________________ 6-55

Reviewing the Enable MLE Support checkbox _________________________________________ 6-56

Using the ASCII Offset radio buttons_________________________________________________ 6-57

Using the LRC Generation radio buttons ______________________________________________ 6-58

Using the Character Parity radio buttons ______________________________________________ 6-58

Using the Shift Data Left checkbox __________________________________________________ 6-59

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 6

RESTRICTED USE ONLY Fargo Electronics, Inc.

vi

Reviewing the ISO Track Locations__________________________________________________ 6-60

Sending the Track Information______________________________________________________ 6-61

Entering the Track Information _____________________________________________________ 6-61

Reviewing Tracks 1, 2 and 3 (in table format) __________________________________________ 6-62

Reviewing the Track Data Note _____________________________________________________ 6-62

Reviewing the ASCII Code and Character Table ________________________________________ 6-63

Using the Overlay / Print Area tab (DTC400/DTC300/DTC300M) ____________________________ 6-64

Enabling the Frontside and Backside options___________________________________________ 6-65

Enabling the Frontside option (Overlay / Print Area)_____________________________________ 6-66

Enabling the Backside option (Overlay / Print Area)_____________________________________ 6-67

Using the Overlay / Print Area dropdown menu ________________________________________ 6-68

Using the Overlay / Print Area______________________________________________________ 6-70

Using the Defined Area Option _____________________________________________________ 6-72

Using Security Options (Visual Security Solutions) (Frontside option only)___________________ 6-77

Selecting Orientation - Landscape under Card tab_______________________________________ 6-78

Selecting the Visual Security Solutions dropdown menu (A to D) __________________________ 6-79

Selecting Orientation - Portrait under Card tab _________________________________________ 6-80

Selecting the Visual Security Solutions dropdown menu (E to H)___________________________ 6-81

Selecting the VeriMark radio button (Frontside option only)_______________________________ 6-82

Selecting the HoloMark radio button (Frontside option only) ______________________________ 6-83

Reviewing the Custom VeriMark Card (Custom Graphic in a 2D foil) _______________________ 6-84

Reviewing the Custom HoloMark Card (Custom Graphic in a 2D foil) ______________________ 6-85

Using the K Panel Resin tab (DTC400/DTC300) __________________________________________ 6-86

Enabling the Frontside and Backside options___________________________________________ 6-87

Enabling the Frontside option (K Panel Resin) _________________________________________ 6-88

Enabling the Backside option (K Panel Resin)__________________________________________ 6-89

Selecting from the Print All Black With K Panel options (Front and Back options) _____________ 6-90

Selecting the Full Card option (Front and Back options) __________________________________ 6-91

Selecting the Defined Area(s) option (Front and Back options)_____________________________ 6-92

Selecting the Undefined Area(s) option (Front and Back options)___________________________ 6-93

Selecting the Defined Area(s) function (Front and Back options) ___________________________ 6-94

Selecting the Print YMC under K and Print K Only options ______________________________ 6-101

Using the Printer Supplies tab (DTC400/DTC300/DTC300M) ______________________________ 6-102

Reviewing the Ribbon Information _________________________________________________ 6-103

Reviewing the Ribbon Level Indicator_______________________________________________ 6-104

Using the Printer Calibration Utility (DTC400/DTC300/DTC300M) _________________________ 6-105

Using the Image Darkness Option __________________________________________________ 6-106

Using the Print Top of Form Option_________________________________________________ 6-107

Using the Print End of Form Option_________________________________________________ 6-108

Using the Print Left of Form Option ________________________________________________ 6-109

Using the Magnetic Encoder Voltage Offset Option ____________________________________ 6-110

Adjusting the Hi-Co Voltage Offset _________________________________________________ 6-111

Adjusting the Lo-Co Voltage Offset_________________________________________________ 6-112

Using the Mag Top of Form Option_________________________________________________ 6-113

Using the Ribbon Tension Option __________________________________________________ 6-115

Using the LCD Contrast Option ____________________________________________________ 6-115

Using the Flipper Home Offset Option_______________________________________________ 6-116

Using the Flipper Center Offset Option ______________________________________________ 6-116

Using the Flipper Smart Angle Offset Option _________________________________________ 6-117

Section 7: Cleaning________________________________________________________ 7-1

Table of Contents ___________________________________________________________________ 7-1

Safety Messages (review carefully)______________________________________________________ 7-2

DTC400/DTC300/DTC300M Card Printer/Encoders Cleaning Kit (Part Number 085976)___________ 7-3

Supplies (included with the Cleaning Kit) ______________________________________________ 7-3

Cleaning the Printhead _______________________________________________________________ 7-4

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 7

RESTRICTED USE ONLY Fargo Electronics, Inc.

vii

Cleaning the Platen and the Card Feed Rollers _____________________________________________ 7-5

Cleaning the Printer’s Interior __________________________________________________________ 7-8

Cleaning the Printer’s Exterior _________________________________________________________ 7-8

Section 8: Parts Replacement ________________________________________________ 8-1

Table of Contents ___________________________________________________________________ 8-1

Safety Messages (review carefully)______________________________________________________ 8-4

Reviewing DTC400/DTC300/DTC300M Parts Replacement Table __________________________ 8-5

Reviewing the Main Print Board Connections __________________________________________ 8-22

Reviewing the Power/USB Board Connections _________________________________________ 8-22

Cover, Door and Tray Removal _______________________________________________________ 8-23

Replacing the Rear Cover (D900066) ________________________________________________ 8-23

Replacing the Left End Cap (D900064) _______________________________________________ 8-25

Replacing the Right End Cap (D900065-01 and –02) ____________________________________ 8-28

Replacing the Input Door Assembly (D900148) ________________________________________ 8-30

Replacing the Output Door Assembly (D900092) _______________________________________ 8-31

Replacing the Input Tray (D900097) _________________________________________________ 8-33

Replacing the Printhead Access Cover (D900029) ______________________________________ 8-35

Replacing the Magnetic Module Door (D900107) _______________________________________ 8-37

Replacing the Top Cover Assembly (includes Print Circuit Board)__________________________ 8-39

Replacing the Front Cover (D900072-03 DTC300M, D900072-02 DTC300, D900072-01 DTC400)8-42

Plate Removal _____________________________________________________________________ 8-44

Replacing the Baseplate (D900000)__________________________________________________ 8-44

Replacing the Clean Roller Plate (D900102) ___________________________________________ 8-50

Replacing the Ribbon Motor Supply Assembly (D900121), O-Ring Drive Belt (140212), Encoder

(A000126) Sensor and Motor (D840980)______________________________________________ 8-53

Board, Interface and Printhead Replacements_____________________________________________ 8-57

Replacing the Power/Communication Board (A000368) __________________________________ 8-57

Replacing the Printhead Assembly (D900023)__________________________________________ 8-59

Motor and Magnetic Head Replacements ________________________________________________ 8-62

Replacing the Headlift Motor Assembly (D900085) _____________________________________ 8-63

Replacing the Input Feed Motor Assembly (D900084) ___________________________________ 8-67

Replacing the Stepper Motor Assembly (D900087)______________________________________ 8-70

Replacing the Ribbon Take-up Motor (D900086) _______________________________________ 8-72

Replacing the Magnetic Head Assembly (D900050) _____________________________________ 8-75

Sensor Replacement ________________________________________________________________ 8-77

Replacing the Ribbon LED Sensor Assembly (A000374 and D900138)______________________ 8-77

Replacing the RFID Sensor Assembly (A000365), Ribbon Encoder Wheel (810492), Encoder Pulley

(D900106) and Ribbon Supply Hub (D900090)_________________________________________ 8-79

Replacing the Headlift Sensor Assembly (D900113)_____________________________________ 8-83

Roller, Cable and Fan Replacement ____________________________________________________ 8-85

Replacing the Platen Roller (D900041) _______________________________________________ 8-85

Replacing the Platen Roller (D900041) (continued)______________________________________ 8-87

Replacing the Card Cleaning or Feed Roller (D900040) (left of Platen) and the Card Drive Gear

(810266) _______________________________________________________________________ 8-88

Replacing the Input Pusher (D900104) _______________________________________________ 8-91

Replacing the Card Feed or Exit Roller (D900042) and the Card Drive Gear (810266) __________ 8-93

Replacing the Pinch Roller (D900098)________________________________________________ 8-96

Replacing the Cleaning Roller Lever (D900051) ________________________________________ 8-99

Replacing the Printhead Cable Assembly (D900035) ___________________________________ 8-102

Replacing the Fan Assembly (D900033) _____________________________________________ 8-104

Pulley Removal ___________________________________________________________________ 8-106

Replacing the Stepper Motor Idler Pulley (D840888) and the Platen Roller Drive Gear (D900047) 8-106

Replacing the Stepper Motor Idler Pulley Shaft Assembly (D900089) and the Stepper Motor Drive Belt

(F000094)_____________________________________________________________________ 8-108

Flipper Table Replacement __________________________________________________________ 8-110

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 8

RESTRICTED USE ONLY Fargo Electronics, Inc.

viii

Replacing the Flipper Table Module Assembly (D900200)_______________________________ 8-110

Section 9: Packing the Card Printer___________________________________________ 9-1

Section 10: Board Level Diagnostics _________________________________________ 10-1

Safety Messages (review carefully)_____________________________________________________ 10-1

Sensor and Motor __________________________________________________________________ 10-2

Reviewing the Sensor Location and Voltages __________________________________________ 10-2

Reviewing the Motor Voltages (when active) __________________________________________ 10-2

Section 11: Diagnostic Tool Utility___________________________________________11-1

Table of Contents __________________________________________________________________ 11-1

Using the Diagnostic Tool Utility ______________________________________________________ 11-2

Selecting from the Printer Selection menu_____________________________________________ 11-2

Reviewing customized Diagnostic Utility tabs for your Printer_____________________________ 11-3

Using the Diagnostic Utility tabs ______________________________________________________ 11-4

Selecting the Print Spooler tab in the Diagnostics Utility _________________________________ 11-4

Selecting the Firmware Updates tab in the Diagnostics Utility _____________________________ 11-9

Downloading Firmware Updates ___________________________________________________ 11-10

Selecting the Firmware File _______________________________________________________ 11-10

Placing the Printer in the Upgrade Mode _____________________________________________ 11-11

Sending the Firmware File ________________________________________________________ 11-12

Selecting the Mechanics tab in the Diagnostics Utility __________________________________ 11-13

Selecting the Self Tests tab in the Diagnostics Utility ___________________________________ 11-24

Selecting the Card Samples tab in the Diagnostics Utility ________________________________ 11-25

Selecting the Magnetic Encoding tab in the Diagnostics Utility ___________________________ 11-26

Selecting the Help button in the Diagnostics Utility ____________________________________ 11-27

Selecting the About button in the Diagnostics Utility ___________________________________ 11-28

Selecting the Exit button in the Diagnostics Utility _____________________________________ 11-29

Section 12: Firmware Upgrades_____________________________________________12-1

Introduction_______________________________________________________________________ 12-1

Requirements______________________________________________________________________ 12-1

Table of Contents __________________________________________________________________ 12-1

Safety Messages (review carefully)_____________________________________________________ 12-2

Downloading Firmware______________________________________________________________ 12-3

Downloading Firmware (continued)_________________________________________________ 12-14

Placing the Printer in the Firmware Upgrade Mode _______________________________________ 12-17

Sending the Firmware File __________________________________________________________ 12-19

Section 13: Fargo Technical Support ________________________________________13-1

Contacting Fargo Technical Support____________________________________________________ 13-1

Reading the Serial Numbers on a Fargo Printer ___________________________________________ 13-2

Finding out when a Fargo Card Printer was manufactured ________________________________ 13-2

Reviewing Example No. 1: Serial Number 80453289____________________________________ 13-2

Reviewing Example No. 2: Serial Number A1280224 ___________________________________ 13-2

Section 14: Reviewing the Spare Parts List ____________________________________ 14-1

Reviewing the DTC400/DTC300/DTC300M Spare Parts List _____________________________ 14-1

Section 15: Glossary of Terms ______________________________________________15-1

Section 16: Index_________________________________________________________16-1

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 9

Section 1: Introduction

How to use the manual

The DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3) is, in fact, the

troubleshooting and service manual for the entire card Printer. The manual is designed to

provide Installers and Technicians with quick, efficient lookup of related procedures,

components and terms. The manual can be used effectively either in soft or hard copy,

depending on the preference of the Installer or Technician.

Manual Description

Sequence of Operations,

Glossary of Terms and

Technical/Functional

Specifications (hyper-linked)

Table of Contents (hyperlinked)

Troubleshooting,

Replacement, Removal,

Diagnostic and Navigation

Procedures (in hyper-linked

Sections)

Cross-Referencing (hyperlinked)

Comprehensive Index

(hyper-linked)

You can go directly to the Sequence of Operations,

Glossary of Terms, Technical Specifications and

Functional Specifications to learn how to use the

processes, procedures, functions and windows for the

card Printer within concise, correlative tables.

You can use the automated Table of Contents to quickly

locate, for example, an error message, a procedure, the

index or an appendix.

You can go directly to Specifications, General

Troubleshooting, Printer Adjustments, Parts Replacement,

Printer Packing, Board Level Diagnostics, LCD On-Line

Menu Navigation and Firmware Updates to find

troubleshooting, removal and replacement procedures.

The section titles are always labeled according to their

function for consistent usage.

You can use the cross-referencing links to quickly locate,

for example, an error message or a procedure.

You can use the COMPREHENSIVE INDEX to quickly

locate information on the card Printer, relating to a

specification, a procedural step, a window or screen, a

component, a term, a qualifier or a related feature to this

Printer.

Page 10

RESTRICTED USE ONLY Fargo Electronics, Inc.

1-2

Safety Messages (review carefully)

Symbol Critical Instructions for Safety purposes

Danger: Failure to follow these installation guidelines can result in death or

serious injury.

Information that raises potential safety issues is indicated by a warning

symbol (as shown to the left).

• To prevent personal injury, refer to the following safety messages

before performing an operation preceded by this symbol.

• To prevent personal injury, always remove the power cord prior to

performing repair procedures, unless otherwise specified.

• To prevent personal injury, make sure only qualified personnel

perform these procedures.

Caution: This device is electrostatically sensitive. It may be damaged if

exposed to static electricity discharges.

Information that raises potential electrostatic safety issues is indicated

by a warning symbol (as shown to the left).

• To prevent equipment or media damage, refer to the following

safety messages before performing an operation preceded by this

symbol.

• To prevent equipment or media damage, observe all established

Electrostatic Discharge (ESD) procedures while handling cables in

or near the Circuit Board and Printhead Assemblies.

• To prevent equipment or media damage, always wear an

appropriate personal grounding device (e.g., a high quality wrist

strap grounded to avoid potential damage).

• To prevent equipment or media damage, always remove the

Ribbon and Cards from the Printer before making any repairs,

unless otherwise specified.

• To prevent equipment or media damage, take jewelry off of

fingers and hands, as well as thoroughly clean hands to remove oil

and debris before working on the Printer.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 11

RESTRICTED USE ONLY Fargo Electronics, Inc.

1-3

DTC400/DTC300/DTC300M Card Printer Overview

Reviewing the DTC400/DTC300/DTC300M Block Diagram

Motors Sensors Parts

1 Card Feed 6 Card Feed 13 Card Input Roller

2 Print Stepper 7 Ribbon Sensor 14 Cleaning Roller

3 Ribbon Drive 8 Ribbon Encoder 15 Card Feed Roller

4 Print Headlift 9 Headlift Sensor 16 Printhead Cooling

Fan

5 Ribbon Rewind

Motor

10 Printhead Thermistor 17 Card Input Hopper

11 Ribbon LED SNR 18 Magnetic Encoding

Head Module

12 RFID Antenna 19 Platen Roller

20 Pinch Roller

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 12

RESTRICTED USE ONLY Fargo Electronics, Inc.

1-4

Reviewing the DTC400/DTC300/DTC300M Sequence of Operations

The following sequence describes a full color print job with magnetic encoding.

Step

Process

1 The File information is received from the PC

2 Printer checks the installed Ribbon type stored in memory against the Ribbon

type command that was sent from the Printer.

a. If Ribbon type does not match, the media light will begin flashing.

3 The Card Input Motor and Print Stepper Motor engage.

4 The Card Feed Sensor detects leading edge of card and disengages the card

input Motor.

Continued on the next page

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 13

RESTRICTED USE ONLY Fargo Electronics, Inc.

1-5

Reviewing the DTC400/DTC300/DTC300M Sequence of Operations (continued)

Step Process

Step Process

5 The Print Ribbon Drive engages.

6 The Print Ribbon Sensor looks for the color transition from Yellow to Magenta.

Print Ribbon Encoder detects number of revolutions required to use an entire color

panel.

7 The Print Stepper Motor engages.

8 The Card Feed Sensor detects trailing edge of card.

9 The Print Stepper Motor queues card to the middle of the platen Roller. All Stop

10 The Print Headlift Motor engages.

11 The Print Headlift Sensor detects closed state.

12 The Print Headlift Motor disengages.

13 The Print Stepper Motor engages.

14 The Print Cover Sensor checks for a closed state.

15 The Ribbon Drive Motor engages.

16 The Image data is burned by the Printhead until image data is depleted. All Stop.

17 The Thermistor engages Printhead Cooling Fan to maintain proper operating

temperature.

18 The Headlift Motor engages.

19 The Print Headlift Sensor detects an open state.

20 The Print Headlift Motor disengages.

21 The Print Stepper Motor engages.

22 The Print Ribbon Drive engages.

Continued on the next page

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 14

RESTRICTED USE ONLY Fargo Electronics, Inc.

1-6

Reviewing the DTC400/DTC300/DTC300M Sequence of Operations (continued)

Step Process

23 The Card Feed Stepper Motor engages to queue card for magnetic encoding.

24 The Encoding data is written to the card.

25 The Magnetic Encoder verifies while the Stepper reverses the card.

26 After Ribbon advances a few encoder clicks, assume Ribbon free of card. All Stop.

27 Repeat steps 9 through 23 for the appropriate number of color/overlay panels.

28 The Card is ejected from the singled-sided Printer.

OR

The Card Feed Stepper engages to queue the card for the Flipper Table for the

dual-sided Printer.

29 All Stop.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 15

RESTRICTED USE ONLY Fargo Electronics, Inc.

1-7

Reviewing the DTC400/DTC300/DTC300M Boot up Sequence

Step Process

1 On Power up, the Printer checks the current state of the Card Feed Sensor and

the Headlift Sensor.

2 If the Headlift Sensor is found to be open, the Headlift Motor will turn until a

closed state is seen.

3 If the Card Feed Sensor is found to be blocked, the Card Feed Stepper will

engage to eject the card.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 16

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-1

Section 2: Specifications

The purpose of this section is to provide the User with specific information on the

Regulatory Compliances, Agency Listings, Technical Specifications and Functional

Specifications for the DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3).

Table of Contents

Section 2: Specifications __________________________________________________ 2-1

Table of Contents _________________________________________________________________ 2-1

Regulatory Compliances ____________________________________________________________ 2-2

Agency Listings___________________________________________________________________ 2-3

Technical Specifications ____________________________________________________________ 2-3

Technical Specifications (continued)______________________________________________ 2-4

Technical Specifications (continued)______________________________________________ 2-5

Visual Security Solutions (Specifications) ______________________________________________ 2-6

VeriMarkTM Cards - 2-D holographic foil application __________________________________ 2-6

Custom HoloMarkTM Cards ______________________________________________________ 2-6

Visual Security - Card Stock Part Numbers ___________________________________________ 2-6

Visual Security - Fargo Certified Overlaminates (Special Order in 50 quantity minimum)_______ 2-6

Visual Security Card Stock - Tolerances _____________________________________________ 2-6

VeriMarkTM - Application Specifications____________________________________________ 2-7

HoloMarkTM and Custom HoloMarkTM - Application Specifications _____________________ 2-7

Functional Specifications ___________________________________________________________ 2-8

Printer Components: Front Cover to USB Port ________________________________________ 2-9

Printer Components: Print Ribbons________________________________________________ 2-10

Printer Components: Resin-Only Print Ribbons ______________________________________ 2-11

Printer Components: Dye-Sublimation Print Ribbons__________________________________ 2-12

Printer Components: Dye-Sublimation/Resin Print Ribbons_____________________________ 2-13

Printer Components: Blank Cards _________________________________________________ 2-14

Printer Module: Flipper Table Module Assembly (D900200)____________________________ 2-15

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 17

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-2

Regulatory Compliances

Term Description

CSA The Printer manufacturer has been authorized by UL to represent

the Card Printer as CSA Certified under CSA Standard 22.2.

File Number: E145118

FCC The Card Printer complies with the requirements in Part 15 of the

FCC rules for a Class B digital device. (Note: These

requirements are designed to provide reasonable protection

against harmful interference in a residential installation.)

If equipment operation in a residential area causes unacceptable

interference to radio and TV reception, the operator is required to

take whatever steps are necessary to correct the interference.

ITS-EMC The Card Printer has been tested and complies with EN55022

Class B: 1995 and EN61000-3-2, EN61000-3-3 and

EN55024:1998 standards for EMI emissions.

(Note: Based on the above testing, the Printer manufacturer

certifies that the Card Printer complies with all current EMC

directives of the European Community and has placed the CE

mark on the Card Printer.)

UL-GS The Card Printer has been tested and complies with EN 60950-

1:2001 and bears the UL-GS mark.

License Number: 1176

UL The Card Printer is listed under UL IEC 60950-1 (2001)

INFORMATION TECHNOLOGY EQUIPMENT.

File Number: E145118, Volume 1, Section 22

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 18

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-3

Agency Listings

Term Description

EMC Standards CE, FCC, CRC c1374, BSMI, ITS (EN 55022 Class B:1998, FCC

Class B, EN 55024: 1998).

Safety

Standards

UL IEC 60950-1 (2001), CSA 22.2 No. 60950 and UL-GS (EN 609501:2001).

Technical Specifications

Type Description

Accepted

Standard

Card Sizes

Accepted

Card

Thickness

Accepted

Card Types

Agency

Listings

CR-80 (3.375"L x 2.125"W / 85.6mmL x 54mmW)

20 mil and 30 mil (.030" / .76mm)

PVC or polyester cards with polished PVC finish; monochrome resin

required for straight polyester

Safety: UL 1950, CSA C2.2 and TüV-GS (IEC-950) Emissions: FCC

Class A, CRC c1374, Class A and TüV-EMC (IEC-801 -2, -3, -4; CISPR

22, Class B), CE, BSMI

Barcodes Code 39, Code 128 B & C with and without check digit (available with

embedded font and barcode option)

• 2 of 5

• UPC-A

• EAN 13

• PDF-417 2D barcode and other symbologies (available via Windows

Driver)

Continued on the next page

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 19

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-4

Technical Specifications (continued)

Type Description

Card Input

100 cards (30 mil)

Hopper

Capacity

Colors

DTC400/DTC300: Up to 16.7 million (DTC300M): Monochrome

Dimensions See the Size and Weight information in this same table.

Humidity 20% to 80% non-condensing

Interface

• LEDs

• LCD display

• Softkey buttons (key ON/OFF button operation)

• Two-way/bi-directional communications

o PC-based error/status messages

Memory 2MB RAM

Operating

65° to 80° F / 18° to 27° C

Temperature

Print Area CR-80 edge-to-edge

Printer

Windows 98SE, Me/2000/XP

Drivers

Print Method

• Dye-Sublimation/Resin Thermal Transfer

• Resin Thermal Transfer

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Continued on the next page

Page 20

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-5

Technical Specifications (continued)

Type Description

Print Speed Print Speeds**

• 7 seconds per card / 514 cards per hour (K)* (DTC300M)

• 12 seconds per card / 300 cards per hour (KO)*

• 27 seconds per card / 133 cards per hour (YMCKO)*

• 35 seconds per card / 102 cards per hour (YMCKOK)*

• 35 seconds per card / 102 cards per hour (YMCFKO)*

*Indicates the Ribbon type and the number of Ribbon panels printed

where Y=Yellow, M=Magenta, C=Cyan, K=Resin Black, O=Overlay,

F=Flourescent

**Print speed indicates an approximate batch print speed and is

measured from the time a card feeds into the printer to the time it ejects

from the printer.

Print speeds do not include encoding time or the time needed for the PC

to process the image. Process time is dependent on the size of the file,

the CPU, amount of RAM and the amount of available resources at the

time of the print.

Resolution 300 dpi (11.8 dots/mm)

Supply

100-240 VAC, .6-1.3 A

Voltage

Supply

50 Hz/60 Hz

Frequency

System

Requirements

IBM-PC or compatible; Windows 98SE, Me, 2000 and XP; Pentium™

class 233 MHz computer with 64 MB of RAM or higher, 200 MB free hard

disk space or higher, USB 1.1

Weight and

Size

• Single-sided (weight): 8 lbs. / 3.65 kg

• Single-sided (size): 7.90"H x 13.62"W x 8.14"D / 200mmH x

346mmW x 207mmD

• Dual-sided (weight): 12 lbs. / 5.45 kg

• Dual-sided (size): 7.9"H x 18.28"W x 8.14"D / 200mmH x 465mmW

x 207mmD

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 21

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-6

Visual Security Solutions (Specifications)

VeriMarkTM Cards - 2-D holographic foil application

VeriMarkTM Cards are a low cost, customized 2-D holographic foil application, that is made

in two steps.

• The first step is to emboss a base foil 1.9 cm (L) x 1.3 cm (H) onto the surface of a

blank white card.

• The second step is debossing a custom made dye into the surface of the base foil -

leaving a customized image, logo or text provided by the customer.

• Two separate color foils are used to contrast the impression.

End Users will be able to choose between 8 different card placements (4 - landscape) and

(4-portrait) where the VeriMarkTM can be located. When its time to print through the Driver,

the End User will select the location on their organizations card design around which no

printing and overlay will be placed.

Custom HoloMarkTM Cards

A Custom HoloMark TM Card is a three-dimensional holographic image transferred to

metal foil and embossed to blank cards. The image is customer specific and the program

mirrors our holographic laminates program with a couple exceptions.

Visual Security - Card Stock Part Numbers

All Visual Security Cards will be offered on the following Fargo Card Stocks only:

• P/NNo. 81754 Ultra Card

• P/NNo. 81762 Ultra Card III with hi-coercivity magnetic stripe

• P/NNo. 81763 Ultra Card III

Visual Security - Fargo Certified Overlaminates (Special Order in

50 quantity minimum)

• Part No. 82255: PolyGuard 1.0 mil for HoloMarkTM and VeriMarkTM Cards, Clear

• Part No. 82256: PolyGuard 1.0 mil for HoloMarkTM and VeriMarkTM Cards, High

Resolution Globe design hologram with "Secure" micro-text

Visual Security Card Stock - Tolerances

• Tolerance of base foil placement will equal +/- .010" from the nearest edges of the card

• Tolerance of layered foil will equal +/- .010"

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 22

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-7

VeriMarkTM - Application Specifications

VeriMarkTM foils will cover a dimensional area of 1.9 cm length x 1.3 cm height. The

exclusive areas are as follows:

• VeriMarkTM Card customers will be able to choose 1 of 8 pre-defined placements

(corners) via Printer Driver (4 positions) Landscape and (4 Positions) Portrait mode.

• VeriMarkTM foil placement will not interfere with card punch slots .

• Foil color base is silver; debossed impression is gold foil.

• VeriMarkTM foil placement will be located 0.4 cm from the edges of the card except for

the top two locations on portrait orientation cards (positions E & F). The foil will be

located 0.9 cm from the top of the card and 0.4 cm from the sides of the card.

HoloMarkTM and Custom HoloMarkTM - Application Specifications

HoloMarkTM and Custom HoloMarkTM foils will cover a dimensional area of 1.5 cm x 1.5

cm. The exclusive areas are as follows:

• HoloMarkTM and Custom HoloMarkTM card end-users will be able to choose 1 of 8

pre-defined placements (corners) via Printer Driver (4 positions) Landscape and (4

positions) Portrait mode.

• HoloMarkTM foil placement will not interfere with card punch slots.

• Foil Color options will be silver or gold.

• Outside edge placement of Foil impression options on card will be 0.4 cm from edge of

card.

• HoloMarkTM foil placement options will be at all four corners of card located 0.4 cm

from edge of card.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 23

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-8

Functional Specifications

This Card Printer utilizes two different, yet closely related printing technologies to achieve

its remarkable direct-to-card print quality for dye-sublimation and resin thermal transfer.

The Card Printer will print from any IBM-PC® or compatible running Windows® 98SE, Me,

Windows 2000 or Windows XP.

The following describes how each of these technologies works:

Function Description

DyeSublimation

Resin

Thermal

Transfer

Dye-Sublimation is the print method the DTC400/DTC300/DTC300M uses

to produce smooth, continuous-tone images that look truly photographic.

(Note: This process uses a dye-based Ribbon roll that is partitioned by a

number of consecutive color panels.)

The panels are grouped in a repeating series of these three process colors

along the entire length of the Print Ribbon: yellow, magenta and cyan or

YMC.

The Printer always prints the yellow panel first, followed by the magenta

panel and the cyan panel. (Note: As the Print Ribbon passes beneath the

Printhead, hundreds of thermal elements within the Printhead heat the

dyes on the Ribbon. When these dyes are heated, they diffuse into the

surface of the card. A separate pass is made for each of the three color

panels on the Ribbon.)

By combining the colors of each panel and by varying the heat used to

transfer these colors, it is possible to print up to 16.7 million different

shades of color. (Note: This blends one color smoothly into the next,

producing photo-quality images with absolutely no dot pattern.)

Resin Thermal Transfer is the print method the Printer uses to print sharp

black text and crisp bar codes, which can be read by both infrared and

visible-light bar code scanners.

• Used to print ultra-fast, one-color ID cards on the

DTC400/DTC300/DTC300M. (Note: Like dye-sublimation, this process

uses the same thermal Printhead to transfer color to a card from a

resin-only Print Ribbon or the resin black (K) panel of a full color Print

Ribbon.)

• Solid dots of resin-based ink are transferred and fused to the surface of

the card. (Note: This produces durable, saturated printing.)

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 24

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-9

Printer Components: Front Cover to USB Port

Components Description

Front Cover Opens to allow access to the Ribbon Cartridge. (Note: This cover must

be closed in order for the Printer to begin printing.)

Printhead

The component of the Printer that actually does the printing. (Note: This

component is fragile and must not be bumped or touched with anything

other than a cleaning swab.)

Cancel button The Cancel button turns the Printer ON and OFF. (Note: It also

serves to cancel the current print job and reset the Printer for the next

print job.)

If a card is left within the Printer after a print job is canceled, it will

automatically be ejected when the Printer is turned back ON.

Pause button The Pause button is used to pause the Printer during normal operation

and also to resume operation after an error condition is cleared. (Note:

In general, as the icon above this button indicates, errors are related to

either the Ribbon or the cards. If an error occurs, the Pause LED will

flash.)

Card

Cleaning

Automatically cleans cards for higher print quality. (Note: Clean the

Card Cleaning Roller as needed.)

Roller

Card Input

Load blank cards into this Hopper.

Hopper

Power Port Connect to the included power cord.

USB Port Connect to a Windows PC with a USB cable.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 25

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-10

Printer Components: Print Ribbons

The Card Printer utilizes both dye-sublimation and/or resin thermal transfer methods to

print images directly onto blank cards. Since the dye-sublimation and the resin thermal

transfer print methods each provide their own unique benefits, Print Ribbons are available

in resin-only, dye-sublimation-only and combination dye-sublimation/resin versions.

To make it easier to remember which Print Ribbons are which, a letter code has been

developed to indicate the type of Ribbon panels found on each Ribbon. This letter code is

as follows:

= Dye-Sublimation Yellow Panel

= Dye-Sublimation Magenta Panel

= Dye-Sublimation Cyan Panel

= Resin Black Panel

= Clear Protective Overlay Panel

= Ultra Violet Flourenscing Panel

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 26

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-11

Printer Components: Resin-Only Print Ribbons

Resin-only Print Ribbons consist of a continuous roll of a single resin color. No protective

overlay panel (O) is provided since resin images do not require the protection of such an

overlay. The following resin-only Ribbon types are available for use with both

DTC400/DTC300/DTC300M:

Type Description

Standard Resin Black

(K) (provides 1,000

prints)

Premium Resin Black

(K) (provides 1,000

prints)

Colored Resin

(provides 1,000 prints)

Metallic Resin

(provides 500 prints)

This Ribbon provides high resin durability ideal for most

general-purpose monochrome ID card applications. Resin black

bar codes are readable by both infrared and visible-light bar

codes scanners.

This Ribbon provides maximum resin durability ideal for

applications such as access control where cards are repeatedly

swiped through a Magnetic Stripe reader. Resin black bar codes

are readable by both infrared and visible-light bar codes

scanners.

(Note: Using a Premium Resin Black Ribbon will provide better

photo realistic output.)

Several colored resin Ribbons are available in a variety of colors

for customizing or color-coding resin-only ID cards.

Metallic resin Ribbons are available for printing resin images

with a unique metallic sheen.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 27

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-12

Printer Components: Dye-Sublimation Print Ribbons

Note that the Printer requires both specialized and authorized Print Ribbons in order to

print and function properly.

Step Procedure

1 Do not run the cards with a contaminated, dull or uneven surface through the

Printer.

Caution: Printing onto such cards will ultimately lead to poor print

quality and will greatly reduce the life of the Printhead.

2 Always store the card stock in its original packaging or in a clean, dust-free

container.

3

Do not print onto cards that have been dropped or soiled. (Note: Printhead

damage caused by contaminated or poor quality cards will automatically void the

Printhead's factory warranty.)

4 If printing onto cards with a pre-punched slot, do not print over the area of the

card with the punched slot. (Note: To avoid this area when printing, use the

options in the Overlay / Print Area tab to omit printing in this area or punch the

slot after the card has printed.)

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 28

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-13

Printer Components: Dye-Sublimation/Resin Print Ribbons

Type Description

DyeSublimation/

resin Print

Ribbon

The Dye-Sublimation/resin Print Ribbon combines the yellow (Y),

magenta (M) and cyan (C) dye-sublimation panels with a resin black (K)

panel.

By combining both types of Ribbon panels, this Ribbon can be used to

print full-color, photo-quality images with the dye-sublimation panels

along with sharp, black text and bar codes with the resin black panel.

A clear overlay panel (O) is also included on most Ribbons to protect the

dye-sublimation images. Dye-Sublimation images must have an overlay

panel applied to them or they will quickly begin to wear or fade.

Full-Color

(YMCKO)

(provides 250

prints)

This Ribbon is used to print full-color photo ID cards along with resin

black text and bar codes. Both infrared and visible-light bar code

scanners can read bar codes printed with resin black.

• An overlay panel (O) is included to protect the full-color dye-

sublimation printing.

YMCKOK The designation of colored Ribbon by the Panels of color in the order in

which they are printed: Yellow (Y), Magenta (M), Cyan (C), Black (K),

Overlay (O), Black (K) (used for backside, black only printing).

YMCFKO The designation of colored Ribbon by the Panels of color in the order in

which they are printed: Yellow (Y), Magenta (M), Cyan (C), Flourescent

(F), Black (K), Overlay (O), (used for backside, black only printing).

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 29

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-14

Printer Components: Blank Cards

Type Description

Card Size The Card Printer accepts standard CR-80 sized and 20 mil. cards (3.370"L x

2.125"W / 85.6mmL x 54mmW) with a thickness of 30 mil (.030"/.762mm).

Card

Design

Card

Surface

UltraCard

Stock

The Printer will print onto any card with a clean, level and polished PVC

surface.

Although the Printer is equipped with card cleaning Rollers, it is very

important to always print onto cards specifically designed for direct-to-card

dye-sublimation printing.

Suitable cards must have a polished PVC surface free of fingerprints, dust or

any other types of embedded contaminants. In addition, cards must have a

completely smooth, level surface in order for the Printer to achieve consistent

color coverage.

Certain types of Proximity cards have an uneven surface that will inhibit

consistent color transfer.

• Certain types of smart card chips are raised slightly above the cards

surface which also results in poor color transfer.

Due to the importance of using high-quality blank cards, a factory-approved

card stock called UltraCard™ is available and recommended for best results.

• UltraCard stock has a glossy PVC laminate on top and bottom and is

optically inspected to provide the cleanest, most scratch and debris-

reduced cards possible.

• Two types of these cards are available: UltraCard and UltraCard III.

UltraCard stock has a PVC core and offers medium card durability.

UltraCard III stock has a 40% polyester core and offers high durability.

• Both types of UltraCards produce printed images with a glossy, photo-

quality finish.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 30

RESTRICTED USE ONLY Fargo Electronics, Inc.

2-15

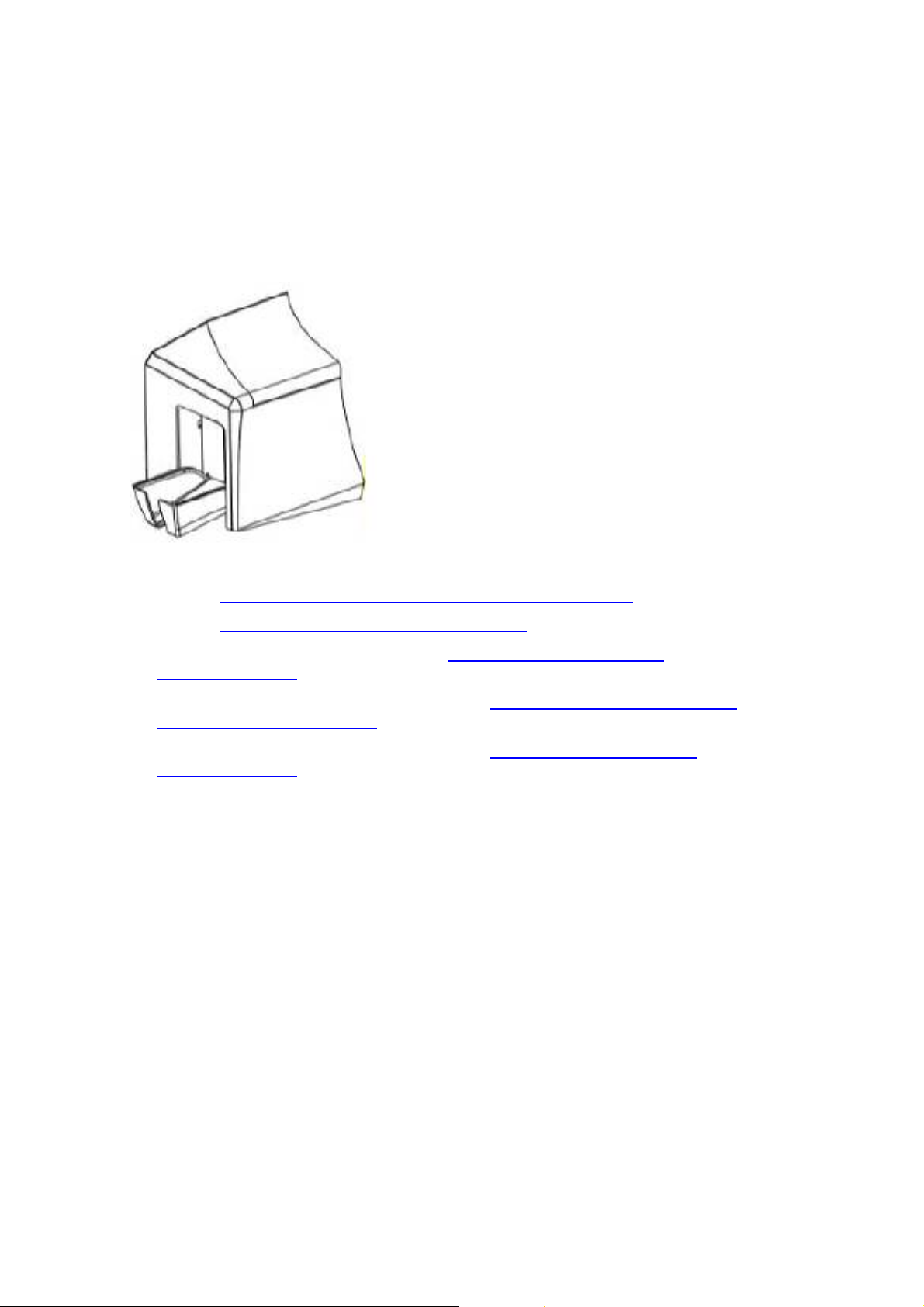

Printer Module: Flipper Table Module Assembly (D900200)

The Flipper Table Module Assembly (D900200) is an automated Flipping Module that

allows the Printer to print on the frontside and backside of each card.

Display: Flipper Table Module Assembly

Here are references within this document.

• See the Installing the Flipper Table Module Assembly (D900200)

• See the Flipper Table Module Assembly Problems

procedures.

procedure.

• See the Print Both Sides option in the Using the Device Options tab

(DTC400/DTC300) section.

• See the Front and Back radio buttons in the Using the Overlay / Print Area tab

(DTC400/DTC300/DTC300M) section.

• See the Front and Back radio buttons in the Using the K Panel Resin tab

(DTC400/DTC300) section.

• See the DTC400/DTC300/DTC300M Card Printer Service Manual for the replacement

procedures for this Printer.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 31

RESTRICTED USE ONLY Fargo Electronics, Inc.

3-1

Section 3: Secure Print Security Suite

Overview

SecureMark is a multi-faceted security solution that has been designed for Fargo

Electronics, our Import Suppliers, their Integrators and our Printer customers. The

SecureMark Media is the core component of the SecureMark program. Using RFID

technology, SecureMark Media raises the level of customer security and convenience.

SecureMark Media is used together with the Printer Security CD to convert a generic Fargo

Printer to a SecureMark Printer. After this conversion, the Printer will only accept Integrator

specific SecureMark media (Ribbon).

In order to enter the Fargo Secure Print Security Suite, an administrator must enter a

password and select a Printer. The Fargo Secure Print Security Suite consists of the

products listed below.

Refer to the Fargo Secure Print Security Suite User Guide for more detailed procedures.

Print Notification Application

The Print Notification Application gives the User the ability to send an e-mail to an

administrator when the Printer used during unauthorized hours.

Security Imaging Application

A Ribbon with a fluorescing panel is used to print an encrypted secure code, User-defined

text or a User-defined security graphic. The secure code can be used to produce the

Printer serial number, printing time and issue for a given card.

Print Diagnostics Application

An automated report captures Printer status and settings that can be sent to the Integrator

(or Fargo) technical support. This report can be easily e-mailed or faxed in order to

expedite faster service.

Supplies e-Ordering Application

This is an on-line Media ordering system that enables customers to order their unique

SecureMark media directly from their Integrators. When they press the order button, the

destination is their exact Ribbon on their Integrators web site.

Password Control Application

A password stored in the Printer protects a Printer from unauthorized use. Password

protection can be based on elapsed time to disable the Printer, entering a password for

each print or entering a password each day.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 32

RESTRICTED USE ONLY Fargo Electronics, Inc.

3-2

Print Security Suite – Main Window

Here are the icons for the five (5) applications within the Print Security Suite. See the

Functional Specification section and the Software Instructions section in this same

document for more detailed information on these five (5) applications. Caution: Be sure

and save your work in the Printer Security Suite. By selecting Save All on the File

dropdown menu, you can save your work on all active applications.

SecureMark Media

SecureMark Media is used together with the Print Security Suite to convert a generic Fargo

Printer to a SecureMark Printer. After this conversion, the Printer will only accept

Integrator-specific SecureMark media (Ribbon). The following is the basic process for

converting to SecureMark media.

a. The User installs the Print Security Suite.

b. The CD Installation process prompts the User to launch the Print Security Suite.

c. The Print Security Suite detects the SecureMark Media installed in the Printer and

prompts the User to convert the Printer to be SecureMark enabled.

d. The SecureMark conversion is completed and only Integrator specific SecureMark

media will work in this Printer.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 33

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-1

Section 4: Setup and Installation

Procedures

The following guide will walk you through the installation of the DTC400/DTC300/DTC300M

Card Printer Driver.

• Time Requirement (software): This software installation process will require

approximately 2 to 5 minutes (depending on the speed of your PC).

• Time Requirement (Printer): The time required to set up a standard

DTC400/DTC300/DTC300M Printer would be approximately 5 to 10 minutes.

The System Requirements are as follows:

IBM-PC or compatible, Windows® 98SE, Me/2000/XP, Pentium® class 233MHz computer

with 64MB of RAM or higher, 200MB free hard disk space or higher, USB 1.1

Table of Contents

Section 4: Setup and Installation Procedures ___________________________________ 4-1

Table of Contents ___________________________________________________________________ 4-1

Printer Setup and Installation __________________________________________________________ 4-3

Choosing A Good Location _________________________________________________________ 4-3

About Moisture Condensation _______________________________________________________ 4-3

Printer Setup and Installation ___________________________________ Error! Bookmark not defined.

Choosing A Good Location __________________________________ Error! Bookmark not defined.

About Moisture Condensation ________________________________ Error! Bookmark not defined.

Unpacking and Inspection __________________________________________________________ 4-4

Reviewing the Printer (front view)____________________________________________________ 4-4

Reviewing the Printer (front view; Cartridge being installed) _______________________________ 4-5

Reviewing the LCD (top-front part of Printer)___________________________________________ 4-5

Connecting the Printer power________________________________________________________ 4-6

Installing the Print Ribbon Cartridge __________________________________________________ 4-7

Installing the Print Ribbon Cartridge (continued) ______________________________________ 4-8

Installing the Print Ribbon Cartridge (continued) ______________________________________ 4-9

Installing Blank Cards into the Card Hopper ___________________________________________ 4-10

Installing Blank Cards into the Card Hopper (continued) _______________________________ 4-11

Installing Blank Cards into the Card Hopper (continued) _______________________________ 4-12

Lowering the Card Output Hopper ___________________________________________________ 4-13

Flipper Table Module Installation______________________________________________________ 4-14

Installing the Flipper Table Module Assembly (D900200) ________________________________ 4-14

Installing the Flipper Table Module Assembly (D900200) (continued) ____________________ 4-15

Installing the Flipper Table Module Assembly (D900200) (continued) ____________________ 4-16

DTC400 Card Printer/Encoder Card Flipper Module Upgrade Kit_____________________________ 4-17

Introduction ____________________________________________________________________ 4-17

Installing the Card Flipper Module Upgrade Kit ________________________________________ 4-18

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-19

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-20

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-21

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-22

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-23

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-24

Installing the Card Flipper Module Upgrade Kit (continued) ____________________________ 4-25

Printer Driver Installation ____________________________________________________________ 4-26

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 34

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-2

Installing the Printer Driver ________________________________________________________ 4-26

Installing the Printer Driver (continued) ____________________________________________ 4-27

Installing the Printer Driver (continued) ____________________________________________ 4-28

Installing the Printer Driver (continued) ____________________________________________ 4-29

Installing the Printer Driver (continued) ____________________________________________ 4-30

Installing the Printer Driver (continued) ____________________________________________ 4-31

Installing the Printer Driver (continued) ____________________________________________ 4-32

Installing the Printer Driver (continued) ____________________________________________ 4-33

Installing the Printer Driver (continued) ____________________________________________ 4-34

Installing the Printer Driver (continued) ____________________________________________ 4-35

Installing the Printer Driver (continued) ____________________________________________ 4-36

Installing the Printer Driver (continued) ____________________________________________ 4-37

Installing the Printer Driver (continued) ____________________________________________ 4-38

Printing a Test Print Image_________________________________________________________ 4-39

Printing a Test Print Image (continued)_____________________________________________ 4-40

Printer Transport ___________________________________________________________________ 4-41

Moving the Printer to another location ________________________________________________ 4-41

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 35

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-3

Printer Setup and Installation

Choosing A Good Location

Follow these guidelines:

• Place the unit in a location with adequate air circulation to prevent internal heat build up.

• Use the Printer's dimensions as a guideline for the minimum clearances to the unit.

(Note: Allow for adequate clearance in front of the unit to accommodate the unit with its

Covers open.)

• Do not install unit (a) near heat sources such as radiators or air ducts or (b) in a place

subject to direct sunlight, excessive dust, mechanical vibration or shock.

About Moisture Condensation

If the unit is brought directly from a cold to a warm location or is placed in a very damp room,

moisture may condense inside the unit. Should this occur, print quality may not be optimum.

Leave the unit turned OFF in a warm, dry room for several hours before using. This will allow

the moisture to evaporate.

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 36

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-4

Unpacking and Inspection

While unpacking your Printer, inspect the carton to ensure that no damage has occurred

during shipping. Make sure that all supplied accessories are included with your unit.

Check that the following items are included:

• Power Supply

• US Power Cable

• Europe Power Cable

• Software Installation CD/User Guide

• User Guide

• Warranty Statement, Registration Card and Compliancy Document

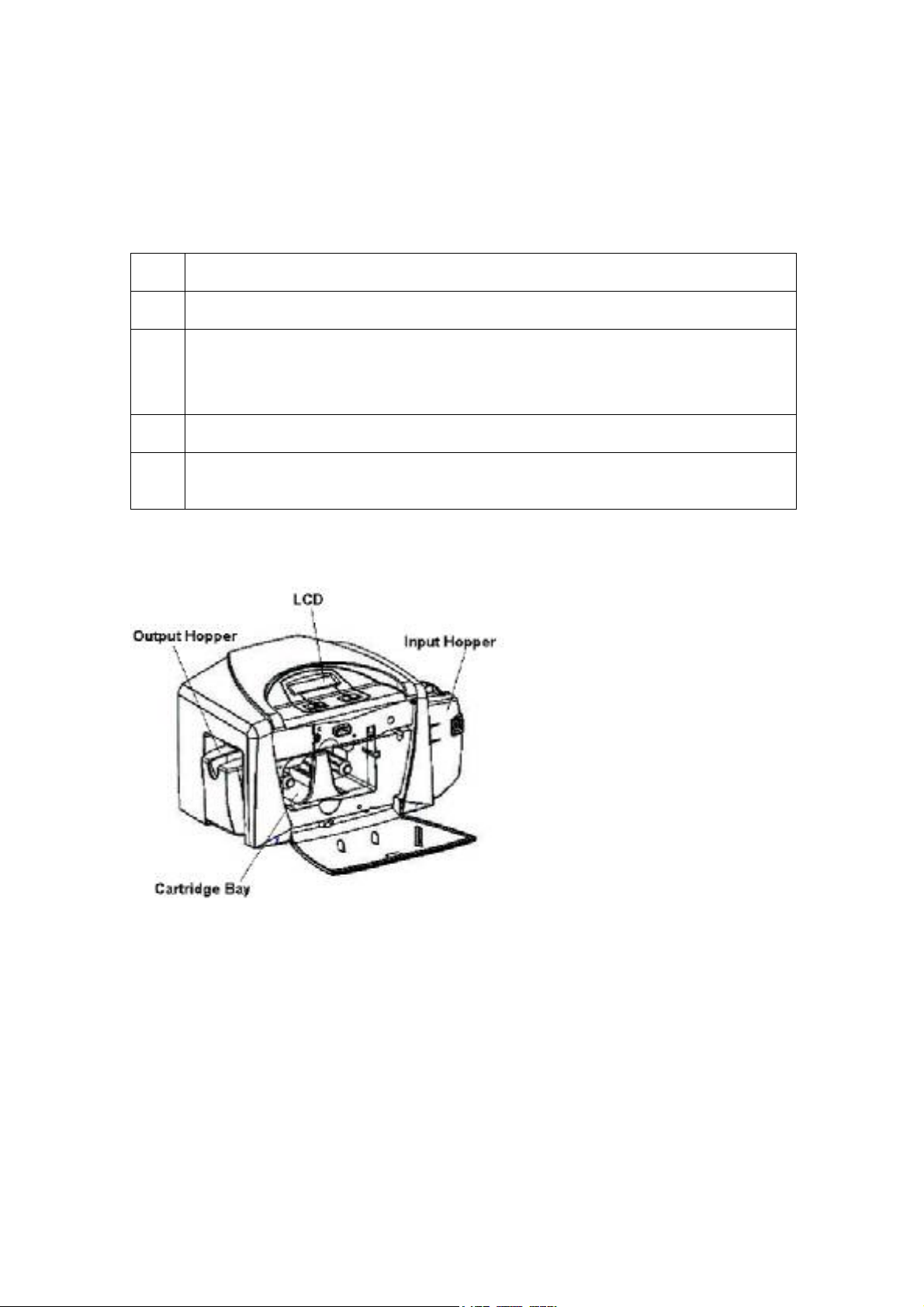

Reviewing the Printer (front view)

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 37

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-5

Reviewing the Printer (front view; Cartridge being installed)

Reviewing the LCD (top-front part of Printer)

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 38

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-6

Connecting the Printer power

Follow this procedure. (Note: Do not connect the Printer’s USB cable until prompted during

the Printer Driver installation.)

Step Procedure

1 Plug the AC adapter power cable into the back of the Printer. See Display A.

2 Plug the wall power cable into the AC power adapter.

3 Plug the wall power cable into a standard 110VAC power outlet.

Display A – Shows back of Printer with AC power cable (below).

DTC400/DTC300/DTC300M Card Printer Service Manual (Rev. 1.3)

Page 39

RESTRICTED USE ONLY Fargo Electronics, Inc.

4-7

Installing the Print Ribbon Cartridge