Page 1

Operating Instructions

970922-510343-(02)

Color ID Card Printer II

© Copyright 1997 All rights reserved.

Page 2

Notices

The information in this document is subject to change

without notice.

NO WARRANTY OF ANY KIND IS MADE WITH

REGARD TO THIS MATERIAL, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

No liability is assumed for errors contained herein or for

incidental damages in connection with the furnishing,

performance, or use of this material.

This document contains proprietary information which

is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced,

or translated into another language without prior

written consent.

Patent Pending

Trademark Acknowledgements

IBM is a registered trademark of International Business

Machines Corporation. Windows is a trademark of

Microsoft Corporation. All other trademarks are the

property of their respective owners.

Printing History

Edition 1.2, #970922

© Copyright 1997 All rights reserved.

iii

Page 3

For Users in the United States:

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio

or television reception, which can be determined by

turning the equipment off and on, the user is

encouraged to try to correct the interference by one or

more of the following measures:

■

Re-orient or relocate the receiving antenna.

■

Increase the separation between the equipment

and receiver.

■

Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

■

Consult the dealer or an experienced radio/TV

technician for help.

Use of a shielded cable is required to comply with the

Class A limits of Part 15 of the FCC Rules.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate and/or obtain warranty service for

this equipment.

For Users in Canada:

This digital apparatus does not exceed the Class A

limits for radio noise for digital apparatus set out on the

Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique nÕemet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la class A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

iv

Page 4

Table of

Contents

Section 1: Introduction

A. How Your Color ID Card Printer

Works .............................................................1

B. Special Features ...........................................1

Section 2: Safety Precautions...........................3

Section 3: Getting Started

A. Choosing a Good Location ......................12

B. About Moisture Condensation ................12

C. Unpacking and Inspection .......................12

D. Identifying the Parts .................................13

Section 4: Ribbons and Cards

A. About Ribbons ...........................................15

B. Loading Ribbon into the Printer ..............17

C. About Cards................................................18

D. Loading Cards into the Printer ................20

Section 5: Card Laminating

A. About the PrinterÕs Laminator.................21

B. About Overlaminates ................................22

C. Loading the Overlaminate into

the Printer....................................................23

Section 6: Hooking Up the Printer

A. Applying Power ........................................25

B. Running the Self Test ................................25

C. Connecting the Color ID Card

Printer to Your Computer .........................26

Section 7: Installing and Using the Color ID

Card Printer Driver

A. Installing the Windows

Printer Driver .............................................28

B. Installing the 32-Bit Print Spooler for

Windows 95 ................................................30

C. Setting Up the Windows

Printer Driver .............................................32

D. Printing a Card ..........................................40

Section 8: Maintenance

A. Supplies Required .....................................41

B. Standard Printhead Cleaning...................42

C. Expanded Printhead Cleaning ................42

D. Cleaning the PrinterÕs Case .....................43

E. Cleaning the Inside of the Printer ...........43

F. Clearing a Card Jam ..................................43

G. Clearing a Ribbon Jam ..............................44

H. Cleaning the Card Feed Rollers ..............44

I. Cleaning the Drive Roller .........................45

J. Maintaining the Cleaning Rollers............46

v

Page 5

Section 9: Mechanical Adjustments

A. Adjusting the Card Input Guides............47

B. Adjusting the Internal Card Guide..........47

C. Adjusting the Card Separator Flap..........49

D. Adjusting the Laminator...........................51

Section 10: Troubleshooting .........................53

Section 11: Technical Specifications...........58

Appendix A: Magnetic Stripe Encoding

Module

A. Introduction ................................................59

B. Track Locations...........................................60

C. Sending Track Information .......................60

Appendix B: Interfacing Information

A. Introduction ................................................62

B. Centronics-type Parallel Interface ...........62

Index .................................................................63

vi

Page 6

1

The Color ID Card Printer utilizes dye-sublimation

printing technology to achieve its direct-to-card

photo-quality output. Dye-sublimation is a process

which uses a dye-based ribbon roll that is

partitioned by a number of consecutive color

panels. The panels are grouped in a repeating

series of four separate colors, Yellow, Magenta,

Cyan, and Black (YMCK), along the entire length

of the ribbon. The ID Card Printer always prints

the yellow panel first, followed by the magenta

panel, the cyan panel, and finally the black panel.

If applicable, the fifth clear overlay panel will

always follow the black panel.

As the ribbon and card pass simultaneously

beneath the printhead, the hundreds of thermal

elements within the printhead heat the dyes on the

ribbon. When these dyes are heated, they vaporize

and diffuse into the surface of the card. By varying

the heat intensity of each thermal element within

the printhead, it is possible for each transferred dot

of color to vary in hue, thus blending one color into

the next. The result? Continuous-tone, photorealistic color images.

The Color ID Card Printer will print from any IBMPC

¨

or compatible running Windowsª 3.1x or

Windows 95. This means that you can use the

printer with virtually any software package

running under Windows without any special setup or configuration beyond the initial installation

of the specific software driver and interface cable.

Data is sent to the Color ID Card Printer in a bitmapped, rasterized format so your computer,

along with the printer driver software, will do

almost all of the complex Raster Image Processing

(ÒRIPÓ) work; therefore, the faster your computer,

the faster the image will be RIPÕd and sent to the

printer.

A. How Your

Color ID Card

Printer Works

1

Introduction

Congratulations

on your purchase

of the Color ID

Card Printer. This

printer has been

designed to

provide you with

stunning, photoquality color

output on a

variety of

different card

sizes and

thicknesses. It

offers many

features which

easily allow you

to create full-color

photo ID cards

complete with

high resolution

graphics, text, bar

codes, and even a

clear or

holographic

overlaminate.

B. Special

Features

Your Color ID Card Printer has many distinct

advantages over other color ID card printers. Its

100 card capacity card hopper allows for automatic

card feeding which reduces the time and personnel

required to create a photo ID card. In addition, the

Color ID Card Printer offers:

■

Automatic, dual-sided printing in color or

monochrome

Page 7

■

Simultaneous dye-sublimation/resin thermal

transfer printing capability for printing

continuous-tone photos and crisp, readable bar

codes

■

Thermal transfer film or polyester chip

overlaminate capabilities

■

Optional magnetic stripe or smart card encoding

capabilities

■

A fast print speed of just 30 seconds/full color

card

■

Fast, 32-bit print spooler for Windows 95

■

Dual-sided card cleaning system

■

Upgradable memory (2MB maximum)

■

Optional color matching software

■

Optional Ethernet network support

And best of all, operation of the printer is simple

and straight forward. Please refer to the remainder

of this manual for instructions on setting up and

printing with your new Color ID Card Printer.

2

Page 8

2

Safety

Precautions

Before operating the

unit, please read the

following safety

precautions carefully.

3

Warnings

CAUTION!

TO PREVENT FIRE OR SHOCK HAZARD,

DO NOT EXPOSE THE UNIT TO RAIN OR

MOISTURE. TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE

FRONT, TOP OR BACK PANELS. NO USERSERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE

PERSONNEL.

■

Operate the unit only on 110-120 VAC, 50/60 Hz.

For printers that have been shipped outside of

the United States and Canada, operate the unit

only on 220-240 VAC, 50/60 Hz. If you have any

doubt as to whether you have a unit with the

correct voltage rating for your countryÕs power

supply, DO NOT ATTEMPT TO USE THE

UNIT. Contact your dealer or the factory.

■

Stop operation immediately if any liquid or solid

object should fall into the cabinet. Unplug the

unit and have it checked by qualified service

personnel.

■

Do not disassemble the cabinet. Refer servicing

only to qualified personnel.

■

Service personnel: parts of this device may be

damaged if exposed to static electrical discharges

generated by various means, such as walking on

a carpeted floor. To avoid potential damage,

always wear an appropriate personal grounding

device, such as a wrist strap (w/ integral resistor)

connected to an ESD ground. Or, at a minimum,

make positive contact with the bare metal chassis

of the printer with your hand prior to touching

any internal electrical components.

Page 9

1

Sicherheitsmaßnahmen

4

Machen Sie sich vor

Inbetriebnahme des

Geräts mit den

Sicherheitsmaßnahmen

gründlich vertraut.

Sicherheitshinweise

VORSICHT!

ZUR VERHÜTUNG VON FEUERGEFAHR

ODER ELEKTRISCHEN SCHLÄGEN DAS

GERÄT VOR REGEN ODER FEUCHTIGKEIT

SCHÜTZEN. UM DIE GEFAHR VON

STROMSCHLÄGEN ZU VERHINDERN,

OBERE, SEITLICHE UND HINTERE

ABDECKUNG NICHT ABNEHMEN. DAS

GERÄT ENTHÄLT KEINE TEILE, DIE VOM

BENUTZER GEWARTET WERDEN KÖNNEN.

WARTUNGSARBEITEN DÜRFEN NUR VON

QUALIFIZIERTEM FACHPERSONAL

DURCHGEFÜHRT WERDEN.

■

Das GerŠt nur mit 120 V 50/60 Hz Wechselstrom

betreiben. Drucker, die au§erhalb der USA und

Kanada verwendet werden, nur mit 220/240 V

50/60 Hz Wechselstrom betreiben. Wenn Sie

nicht sicher sind, ob Ihr GerŠt mit der Spannung

des šrtlichen Stromnetzes arbeitet, DAS GERÄT

NICHT IN BETRIEB NEHMEN. Wenden Sie

sich an Ihren HŠndler oder den Hersteller des

GerŠts.

■

Den Betrieb sofort unterbrechen, wenn ein

Gegenstand in das GehŠuse gefallen oder

FlŸssigkeit eingedrungen ist. Den Netzstecker

ziehen und das GerŠt von qualifiziertem

Wartungspersonal ŸberprŸfen lassen.

■

Keine GehŠuseteile abnehmen. Wartungsarbeiten

nur von qualifiziertem Fachpersonal

durchfŸhren lassen.

Page 10

5

1

Consignes

de sécurité

Avant d’utiliser

l’appareil, prière de

lire attentivement les

consignes de sécurité

suivantes.

Avertissements

ATTENTION!

POUR EVITER TOUT RISQUE D’INCENDIE

OU D’ELECTROCUTION, NE PAS EXPOSER

L’APPAREIL A LA PLUIE OU A L’HUMIDITE.

POUR EVITER TOUTE DECHARGE

ELECTRIQUE, NE PAS RETIRER LES

PANNEAUX AVANT, SUPERIEUR OU

ARRIERE. NE PAS TENTER DE REPARER

SOI-MEME LES PIECES A L’INTERIEUR DE

L’APPAREIL. CONFIER L’ENTRETIEN DE

L’APPAREIL A UN PERSONNEL QUALIFIE.

■

Faire fonctionner lÕappareil uniquement sur

courant alternatif de 110/120 V, 50 ou 60 Hz. Les

imprimantes expŽdiŽes en-dehors des Etats-Unis

et du Canada fonctionnent uniquement sur

courant alternatif de 220/240 V, 50 or 60 Hz. En

cas de doute sur la compatibilitŽ entre la tension

nominale de lÕappareil et le courant du pays

dÕutilisation, NE PAS TENTER D’UTILISER

L’APPAREIL. Contacter le revendeur ou lÕusine.

■

Arr•ter immŽdiatement le fonctionnement si un

liquide ou un solide venait ˆ sÕinfiltrer ˆ

lÕintŽrieur de lÕarmoire. DŽbrancher lÕappareil et

le faire vŽrifier par un personnel qualifiŽ.

■

Ne pas dŽmonter lÕappareil. Confier lÕentretien

de lÕappareil ˆ un personnel qualifiŽ.

Page 11

1

Precauciones

de seguridad

Antes de operar la

unidad, haga el favor

de leer detenidamente

las siguientes

precauciones de

seguridad.

6

Advertencias

¡PRECAUCION!

PARA EVITAR PELIGROS DE INCENDIO O

CHOQUE ELECTRICO, NO EXPONGA LA

UNIDAD A LA LLUVIA NI A LA HUMEDAD.

PARA REDUCIR EL RIESGO DE CHOQUE

ELECTRICO, NO QUITE LOS PANELES

FRONTALES, SUPERIORES, LATERALES NI

DE FONDO. EL INTERIOR NO TIENE PIEZAS

REPARABLES POR EL USUARIO. PARA

SERVICIO DE REPARACION Y

MANTENIMIENTO SOLICITE LA ATENCION

DE UN TECNICO DE SERVICIO

AUTORIZADO.

■

Opere la unidad s—lo a 110-120 VAC, 50/60 Hz.

Para las impresoras enviadas fuera de los Estados

Unidos y Canad‡, opere la unidad s—lo a 220-240

VAC, 50/60 Hz. Si no est‡ seguro que la unidad

que tiene es compatible al voltaje de la corriente

elŽctrica de su pa’s, NO INTENTE USAR LA

UNIDAD. Llame al representante de ventas o a

la f‡brica.

■

Detenga la operaci—n inmediatamente si algœn

l’quido u objeto s—lido cayera en el armario.

Desenchufe la unidad y h‡gala revisar por un

tŽcnico de servicio autorizado.

■

No desarme el armario. Para servicio de

mantenimiento, solicite la atenci—n de un tŽcnico

autorizado.

Page 12

Prima di dare inizio al

funzionamento

dell’unità, siete

pregati di leggere

attentamente le

seguenti precauzioni

di sicurezza.

1

Precauzioni

per la

Sicurezza

7

Avvertenze

ATTENZIONE!

ONDE EVITARE IL PERICOLO DI INCENDIO

O SCOSSA ELETTRICA, NON ESPORRE

L’UNITÀ ALLA PIOGGIA OD UMIDITÀ.

EVITARE DI RIMUOVERE I PANNELLI

ANTERIORE, SUPERIORE, O POSTERIORE

PER RIDURRE IL RISCHIO DI SCOSSA

ELETTRICA. LA MANUTENZIONE DELLE

PARTI INTERNE DELL’UNITÀ NON É DI

COMPETENZA DELL’UTENTE. AI FINI

DELLA RIPARAZIONE RIVOLGERSI AL

PERSONALE DI COMPETENZA.

■

Negli Stati Uniti e Canada lÕunitˆ funziona solo

con alimentazione a 110-120 VAC, 50/60 Hz. Le

stampanti destinate ad altri paesi funzionano

solo con alimentazione a 220/240 VAC, 50/60 Hz.

Qualora non abbiate la certezza che il

trasformatore e la spina di cui disponete siano

quelli adeguati allÕalimentazione erogata nel

vostro paese, NON USARE L’UNITÀ. Rivolgersi

piuttosto al rivenditore o la fabbrica del luogo.

■

Arrestare immediatamento il funzionamento

dellÕunitˆ qualora si verifichi un versamento di

liquido o la caduta di un oggetto solido al suo

interno. Staccare la spina e rivolgersi al personale

di assistenza qualificato.

■

Non smontare la struttura dellÕalloggiamento. Le

riparazioni vanno effettuate solo dal personale di

competenza.

Page 13

1

Precauções

de

Segurança

Antes de operar esta

unidade, leia

cuidadosamente as

seguintes precauções

de segurança.

Advertências

CUIDADO!

PARA EVITAR PERIGO DE CHOQUES

ELÉTRICOS OU INCÊNDIO, NÃO EXPONHA

A UNIDADE À CHUVA OU UMIDADE. PARA

REDUZIR O RISCO DE CHOQUES

ELÉTRICOS, NÃO REMOVA OS PAINÉIS

DIANTEIRO, SUPERIOR OU TRASEIRO.

NENHUMA PEÇA NO INTERIOR DESTA

UNIDADE PODE SER CONSERTADA PELO

USUÁRIO. PEÇA ASSISTÊNCIA AO PESSOAL

DE MANUTENÇÃO QUALIFICADO.

■

Opere esta unidade somente em 110-120 VAC,

50/60 Hz. As impressoras enviadas para fora dos

Estados Unidos ou Canad‡ devem ser operadas

somente em 220-240 VAC, 50/60 Hz. Se voc• n‹o

souber se a sua unidade tem a voltagem correta

para o sistema elŽtrico do seu pais, NÃO TENTE

USAR ESTA UNIDADE. Entre em contato com

seu revendedor ou com a f‡brica.

■

Pare imediatamente a opera•‹o se qualquer

l’quido ou objeto s—lido cair no gabinete.

Desligue a unidade da tomada e leve-a ao pessoal

de manuten•‹o qualificado.

■

N‹o desmonte o gabinete. Pe•a assist•ncia

somente ao pessoal qualificado.

8

Page 14

9

Chinese or Japanese to be

keylined here

Page 15

10

Chinese or Japanese to be

keylined here

Page 16

11

Arabic to be keylined here

Page 17

3

Getting

Started

12

A. Choosing a

Good Location

Place the unit in a location with adequate air

circulation to prevent internal heat build up.

1. Use the dimensions specified in Section 11 as a

guideline for the minimum clearances to the unit.

NOTE

Allow for adequate clearance above the unit to

accommodate the height of the unit with its covers open.

2. Do not install unit (a) near heat sources such as

radiators or air ducts, or (b) in a place subject to

direct sun-light, excessive dust, mechanical

vibration or shock.

B. About

Moisture

Condensation

If the unit is brought directly from a cold to a

warm location, or is placed in a very damp room,

moisture may condense inside the unit. Should this

occur, print quality may not be optimum. Leave

the unit turned OFF in a warm, dry room for

several hours before using. This will allow the

moisture to evaporate.

C. Unpacking and

Inspection

While unpacking your printer, inspect the carton to

ensure that no damage has occurred during

shipping. Make sure that all supplied accessories

are included with your unit. The following items

should be included with your Color ID Card

Printer:

■

Printer

■

Power Cord

■

Cleaning Roller

■

Printer Driver Diskette (3.5Ó)

■

32-bit Print Spooler Software; for use in

Windows 95 only

■

Warranty Statement and Registration Card

■

This manual and other printed information

Save the carton and packing materials. They will

come in handy when transporting the unit or

shipping it for service.

Page 18

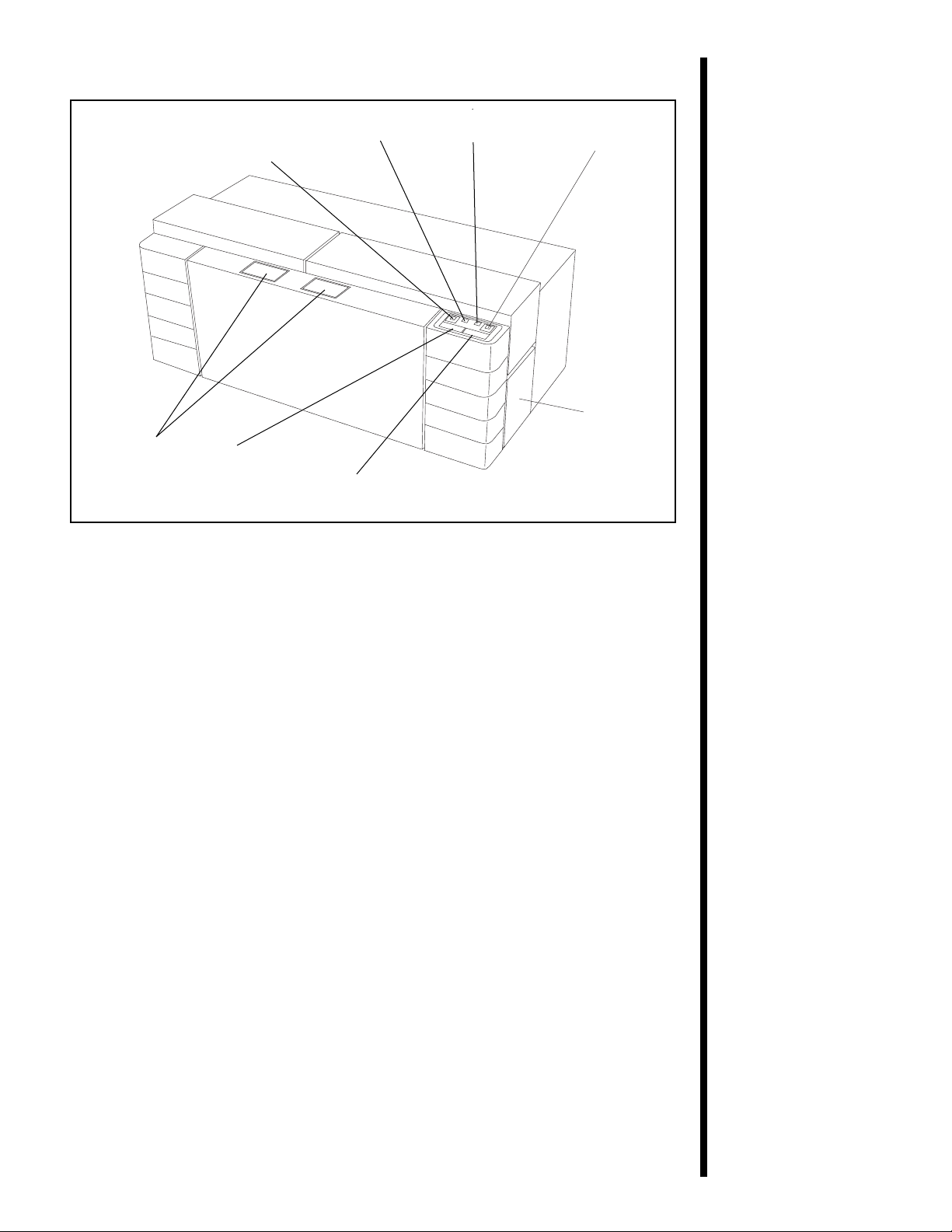

13

Cover

Release

Buttons

on/cancel

Card

Hopper

Door

clean/ribbon

on-line

Button

on/cancel

Button

laminator

LED

on-line

LED

D. Identifying

the Parts

1. This illustration shows all of the control

buttons and the LED indicator lights found on the

front of the Color ID Card Printer. The laminator

light indicates the current status of the printerÕs

built-in laminator. When the light is flashing, the

laminator is either heating up or cooling down.

When the light is solid, the laminator has reached

and is maintaining its target temperature.

The on/cancel button signifies that the printer

power is ON and also serves to cancel the current

print job and reset the printer for the next print job.

This button also ejects any cards left within the

printer after a print job is canceled.

The on-line button takes the printer on and offline. The printer must have the on-line light

illuminated in order to print. When flashing, the

on-line light also serves to indicate a print error

condition. Such conditions are discussed in

Section 10 of this manual.

The clean/ribbon light illuminates when your

ribbon supply is getting low. The light will

illuminate when approximately 10-20 prints are left

on the ribbon. The clean/ribbon light also serves as

a reminder that the printer should be cleaned

during every ribbon change (about every 250

prints) according to the steps in this manualÕs

Maintenance Section.

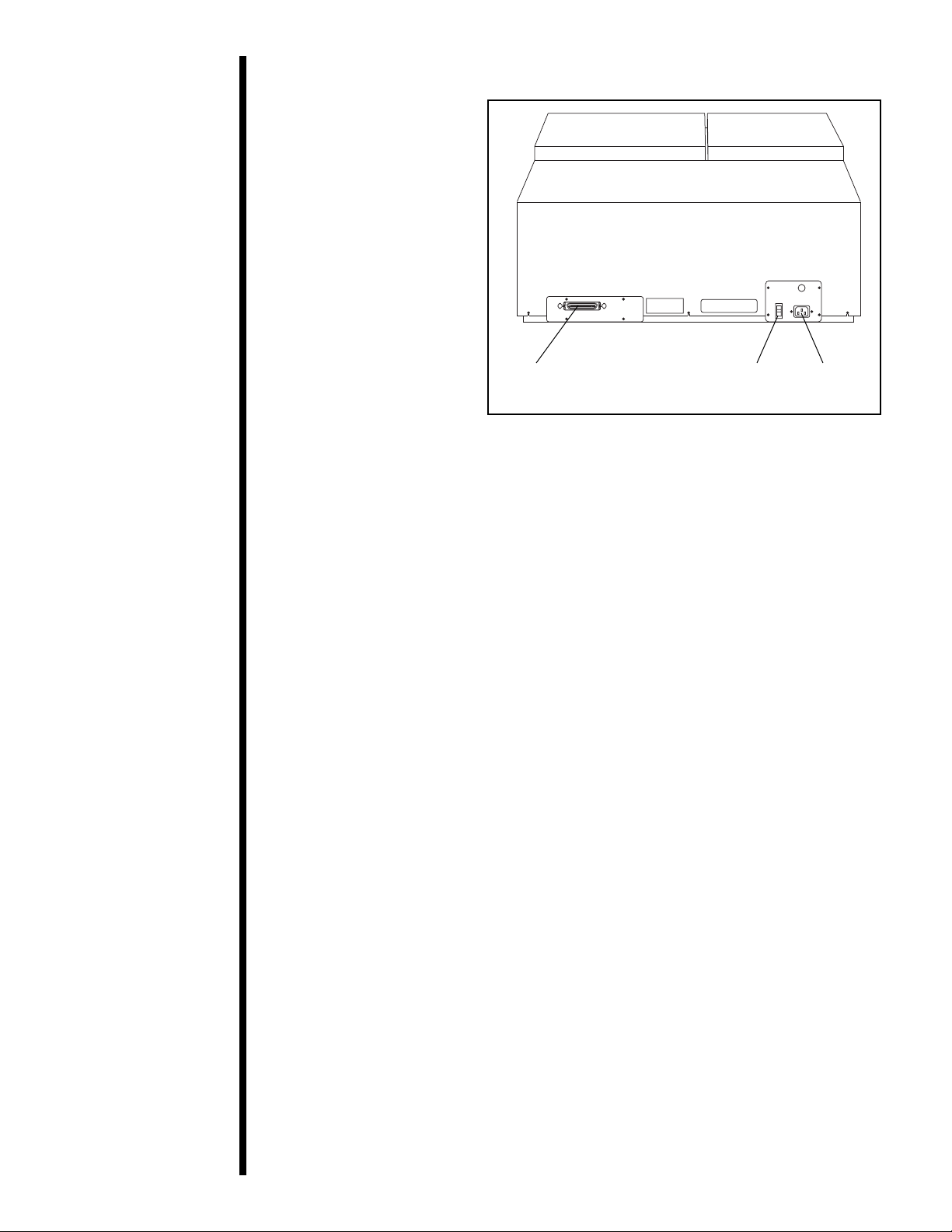

Page 19

14

2. This illustration

shows the input ports

found on the rear panel

of the printer. For

complete instructions

about each of these

features, see later

sections of this manual.

Power

Input

Port

Parallel

Interface

Power

Switch

Page 20

15

4

Ribbons and

Cards

The Color ID Card Printer has the following ribbon

types available for printing:

■

Standard Resin Black (K) ribbon with no clear

overlay panel (produces 1,000 prints)

■

A variety of Colored Resin ribbons with no clear

overlay panel (produce 1,000 prints)

■

Premium Resin Black (K) ribbon with no clear

overlay panel (produces 1,000 prints)

■

A gold Metallic Resin ribbon with no clear overlay

panel (produces 1,000 prints)

■

Dye-Sublimation Black (BO) ribbon with a clear

overlay panel (produces 500 prints)

■

Full-Color (YMCBO) ribbon with a dyesublimation black panel and a clear overlay panel

(produces 250 prints)

■

Full-Color (YMCKO) ribbon with a resin black

panel and a clear overlay panel (produces 250

prints)

■

Full-Color (YMCKOK) ribbon with 2 resin black

panels and a clear overlay panel (produces 250

prints)

■

Full-Color (YMCKK) ribbon with 2 resin black

panels and NO clear overlay panel (produces 250

prints)

The ribbons which have a clear overlay panel (O)

will print an ID card and place a clear, protective

overlay over the cardÕs printable area. Be sure that

the Overlay option within the printer driver setup

window is selected when printing with these ribbons

unless you intend to utilize the printer's built-in

laminator. When applying the PolyGuard

overlaminate, do not apply the ribbonÕs clear overlay

panel since it will interfere with the transfer of the

overlaminate material. When applying the film

overlaminate, the ribbonÕs clear overlay should be

applied on top of the overlaminate. See Section 5-B

for further overlaminate information. See Section

7-B for instructions on enabling or disabling the

printerÕs Overlay option.

All color or monochrome dye-sublimation cards must have

either a printed overlay or a chip or film overlaminate

applied to them. If neither of these types of protective

coatings are applied, your card's dye-sublimation image

will quickly begin to wear or fade. Cards printed solely

with monochrome resin text, bar codes, or images do not

require any type of protective overlay or overlaminate.

A. About

Ribbons

NOTE

Page 21

16

The ribbons which utilize a resin black (K), are

intended for printing bar codes onto cards which

can be read by both infra-red and visible light bar

code scanners. Bar codes printed with a dyesublimation black (B) can only be read by a visible

light bar code scanner.

The black monochrome-only resin ribbons (K) are

available in both a premium and standard quality.

The premium resin black ribbon provides

maximum durability and is ideal for applications

such as access control where cards are repeatedly

swiped through a magnetic stripe reader. The

standard resin black ribbon provides high

durability ideal for most general purpose ID card

applications.

In addition to a standard black resin ribbon, several

other standard resin ribbons are also available in a

variety of spot colors including blue, green, red,

and metallic gold. All monochrome resin ribbons

provide 1,000 prints. Bar codes printed with the

blue and green ribbons can be read by both infrared and visible light bar code scanners. Bar codes

printed with the metallic gold ribbon can only be

read by an infra-red bar code scanner. Bar codes

printed with the red ribbon are NOT readable.

The Full-Color YMCKK ribbon is intended to be

used for dual-sided printing. By supplying two

resin black panels, this ribbon lets you print fullcolor on one side and monochrome resin black on

the other, without wasting an entirely new set of

ribbon panels for the monochrome side. Since no

overlay panel is included, this ribbon must be used

in conjunction with the printerÕs overlaminate

function. If you do not wish to use the

overlaminate function, another Full-Color

YMCKOK ribbon is available which also includes a

clear overlay panel. When printing with either of

these ribbons, no overlaminate is necessary for the

monochrome resin black side.

Watches, rings, bracelets, and other jewelry can damage

the printhead if accidentally bumped against it. For best

results, remove such items before installing or removing

ribbons.

IMPORTANT!

Page 22

17

2. The supply end of

the ribbon is the side

with the fresh, unused

ribbon on it. The

ribbon take-up is the

other end.

3. Open the top-right

cover of the printer by

pressing its Cover

Release Button. Allow

the cover to swing up

and open.

4. With the cover

open, place the supply

end of the ribbon in

between the two black

Ribbon Drive Hubs

located on the far righthand side of the

printerÕs interior. Make

certain that the ribbon

is fed from underneath

the ribbon roll. (Hint:

The Ribbon Drive Hub

nearest you, as you are

looking into the printer

from the front, is spring

loaded. Use the end of the

ribbon supply core to

push in this Ribbon

Drive Hub when

inserting the ribbon.)

Supply

Take-up

Follow these steps to load ribbon into the Printer:

1. Remove the ribbon from its packaging. Do not

touch the colored portion of the ribbon. Oil or dirt

from your hands can impair print quality.

B. Loading

Ribbon into the

Printer

Take-up Ribbon

Drive Hubs

Supply Ribbon

Drive Hubs

Ribbon

Sensor

Page 23

18

6. Close the cover. When you start to print, the

Ribbon Drive Hubs will automatically engage the

notches on both cores of the ribbon roll.

Do not reverse the ribbon. Damage may occur to the

thermal printhead!

5. Place the take-up

end of the ribbon roll

in between the two

black Ribbon Drive

Hubs located about six

inches (152mm) to the

left of the ribbon

supply Ribbon Drive

Hubs. Load the ribbon

take-up end of the

ribbon just as you

loaded the ribbon

supply end in step 4.

When loaded properly,

the ribbon should feed

underneath both ends

of the ribbon roll.

C. About Cards

The Color ID Card Printer accepts a variety of

different card sizes and thicknesses and will print

to any card with a clean, level, polished PVC

surface (see Section 11 for accepted card size

specifications). The printer can also print onto

smart cards, but one must be careful not to print or

place a clear overlay over the area containing the

actual IC chip. Printing over this area could

damage both the IC chip and the printerÕs

printhead. To avoid printing over this area, select

the Smart Card option from the printer driver

setup (see Section 7-B for printer driver

information).

Although the Color ID Card Printer is equipped

with a card cleaning roller, it is very important to

always print onto cards specifically designed for

direct-to-card dye-sublimation printing. Such cards

must have a polished PVC surface free of

fingerprints, dust, and any other types of

embedded contaminants. In addition, these cards

must have a completely smooth and level surface

in order for the printer to achieve consistent color

coverage (many brands of Proximity cards have an

uneven surface which can inhibit consistent color

transfer). For information on cards suitable for

direct-to-card dye-sublimation printing, contact

your authorized Color ID Card Printer dealer or

the printer manufacturer.

IMPORTANT!

Supply Roll

Cleaning Roller Assembly

Take-up Roll

Page 24

19

Never run cards with a contaminated, dull, or

uneven surface through the printer. Printing onto

such cards will ultimately lead to poor print

quality and will greatly reduce the life of your

printhead. In addition, always store your card

stock in its original packaging or in a clean, dustfree environment. Do not print onto cards which

have been dropped or soiled. Printheads damaged

by contaminated or poor quality cards will

automatically void the printhead’s factory

warranty.

1. Some card stocks, particularly 10 mil card stocks, are

surfaced with a thin coating of a talcum based lubricant.

This lubricant is intended to keep the cards from

sticking to one another, however, the dusty nature of the

lubricant will greatly inhibit print quality and may even

damage the printer. Do not print onto these types of

cards.

2. Avoid using card stock which has a signature pad on

the back side of the card. A signature pad will often

leave a residue on the top of the card stacked beneath it.

This residue will discolor the card’s surface when

printed. If a card signature is required, use cards with a

matte finish on the reverse side and a polished PVC

finish on top. Signatures can be applied to the matte

finished side with a permanent ink pen after printing.

3. If printing onto cards with a pre-punched slot, do not

print over the area of the card with the punched slot.

Printing over this uneven area could damage the

printhead. To avoid this area when printing in portrait

orientation, select the Punch card size option from

within your printer driver setup (see Section 7-B for

printer driver information). When selected, this option

allows your printer to print up to but not over the

punched area of the card. This option does not apply to

pre-punched cards intended to be printed and worn in

landscape orientation. If you need to print over the

entire area of the card, punch the slot after the card has

printed.

NOTES

Page 25

20

The Color ID Card Printer will hold a maximum of

100 cards (based on a standard CR-80 card size) in

its Card Hopper. The Printer automatically feeds

each card and adjusts to each cardÕs particular size

and thickness. Significantly larger or thicker cards,

however, may require slight printer adjustments

for consistent printing. See Section 9 for details on

such adjustments. To load the cards into the

printer, refer to the following steps:

1. Remove a stack of 100 or fewer cards from the

card packaging. Do not touch the area of the card

where you intend to print. Oil or dirt from your

hands can impair print quality.

2. Open the Card Hopper Door located on the

right-hand side of the printerÕs exterior by

grasping the top of the door and pulling down.

Allow the door to swing completely open.

3. Insert the stack of cards into the printer by

depressing the spring loaded Card Input Tray and

placing the cards between the Card Input Guides

(see Section 9 for further Card Input Guide

information). Always load cards with the top or

primary print side facing up. If inserting cards

with a magnetic stripe, be sure that the magnetic

stripe is positioned downward and that the stripe

is oriented toward the rear of the printer. If

inserting smart cards or cards with a pre-punched

slot, be sure the smart card chip is positioned

upward and that the chip or slotted end of the card

is inserted first.

D. Loading Cards

into the Printer

NOTE

4. Once the cards

have been inserted,

remove the top card

and throw it away if

you suspect it has been

contaminated with oil

from your fingertips.

Close the Card Hopper

Door. The cards will

automatically feed off

the top of the stack.

The printer’s 100 card capacity is figured using a

standard CR-80 3.375”L x 2.125”W x .030” (85.6mmL

x 54.0mmW) card size. Please be aware of this when

inserting cards of varying thicknesses.

Card Input Guides

Card Input Tray

Card Input Hopper Door

Page 26

21

5

Card

Laminating

CAUTION!

!

A. About the

Printer’s

Laminator

In addition to printing and applying the standard

clear overlay included on the Color ID Card

PrinterÕs various ribbons, the printer also provides

a built-in lamination system for applying a more

secure, tamper-resistant overlaminate. This built-in

laminator is controlled by both the printer itself and

the printerÕs software driver.

Upon initial power up of the printer, you will

notice that the Laminator LED indicator light on

the front of the printer will flash. This indicates that

the laminator is heating up to its preset, or default

laminating temperature of approximately 300¡ F

(150¡ C). This heating process will generally take

about 5 minutes before the laminator is heated to

the default temperature. Once the laminator

reaches its default temperature, the Laminator LED

light will stop flashing and will remain solid. The

Laminator LED light will flash only when the

laminator is heating up or cooling down to the

prescribed temperature.

If you wish to change the temperature of the

laminator, you can adjust its temperature through

the Lamination controls within the printer driver

setup window (see Section 7-B). Once adjusted, the

new temperature settings will be sent down with

the next print job along with the rest of the printer

driver information. Before printing begins, the

Laminator light will flash and the laminator will

automatically adjust itself to the new temperature

setting. This new temperature setting will remain

programmed within the printer until it is once

again changed within the printer driver or until the

printer is turned OFF. Whenever the printer is

turned OFF, the laminator will automatically reset

itself and return to its default temperature the next

time the printer is powered ON. Pressing the

on/cancel button serves this same purpose in that it

will also reset the laminator to its default

temperature. The temperature setting within the

printer driver, however, will stay the same until

you change it.

THE PRINTER’S LAMINATION ROLLER CAN

REACH TEMPERATURES EXCEEDING 350° F

(175° C). USE EXTREME CAUTION WHEN

OPERATING THE LAMINATOR. NEVER TOUCH

THE LAMINATION ROLLER UNLESS THE

PRINTER POWER HAS BEEN TURNED OFF FOR

AT LEAST 20-30 MINUTES!

Page 27

22

B. About

Overlaminates

The Color ID Card PrinterÕs internal lamination

system allows you to choose between either a

thermal transfer film overlaminate or a polyester

chip overlaminate called PolyGuardª. These two

unique overlaminates are available in two specific

designs. The film overlaminate is available as

simply a clear material or with a generic,

preprinted holographic-type design and is

approximately 2 microns thick.

PolyGuard, which is approximately 1 mil (.001Ó)

thick, is available in these same designs but

provides for greater durability than the thermal

film overlaminate. PolyGuard should always be

used if you need ID cards with the highest degree

of durability and security.

If you require custom thermal transfer film or

PolyGuard overlaminate designs, please contact

your reseller or the printer manufacturer for more

information.

If using the thermal transfer film overlaminate, you must

use it in conjunction with a ribbon which provides a clear

overlay panel. When used with this type of ribbon, the

printer will apply the clear overlay panel of the ribbon

over the film lamination layer of a printed card. This

process is required for maximizing card durability when

laminating with the thermal transfer film material. The

ribbon types which do not provide an overlay panel or

support overlay printing are Monochrome Resin and 5

Color Resin black. Avoid using these types of ribbons

in conjunction with the thermal transfer film material.

These ribbon types are ideal, however, when laminating

with PolyGuard.

IMPORTANT!

Page 28

23

CAUTION!

!

C. Loading the

Overlaminate

into the Printer

The loading process for both the thermal transfer

film and the PolyGuard overlaminate material is

the same. Refer to the following steps to load either

type of overlaminate into the Printer.

DO NOT TOUCH THE METAL LAMINATION

SHIELD OR THE LAMINATION ROLLER WHEN

LOADING OVERLAMINATE. YOU WILL BURN

YOURSELF!

1. Remove the

overlaminate from its

packaging.

2. The supply end of

the overlaminate roll is

the side containing the

fresh, unused portion

of the overlaminate.

The take-up end is the

other side.

3. Open the top-left

cover of the printer by

pressing its Cover

Release Button. Allow

the cover to swing up

and open.

4. With the cover

open, place the supply

end of the

overlaminate roll in

between the two black

Lamination Drive

Hubs located just to the

left of the printerÕs

card flipping

mechanism. Make

certain that the

overlaminate material

is fed from underneath

the roll. (Hint: The

Lamination Drive Hub

nearest you, as you are

looking into the printer

from the front, is spring

loaded. Use the end of the

roll’s supply core to push

in this hub when

inserting the

overlaminate roll.)

Supply

Take-up

Card Flipping

Mechanism

Take-up

Lamination

Drive Hubs

Supply

Lamination

Drive Hubs

Page 29

24

6. Close the cover. When you start to print, the

Lamination Drive Hubs will automatically engage

the notches on both cores of the overlaminate roll.

IMPORTANT!

5.

Place the take-up

end of the roll in

between the two black

Lamination Drive

Hubs located on the

far left-hand side of

the printerÕs interior.

Load the take-up end

of the roll just as you

loaded the supply end

in step 4. When loaded

properly, the

overlaminate material

should feed

underneath both ends

of the overlaminate

roll.

Supply Roll

Take-up Roll

Do not reverse the overlaminate roll. Damage may occur

to the lamination roller!

Page 30

25

6

Hooking Up

the Printer

ON

OFF

AC POWER

PARALLEL

SW1

O

I

B. Running the

Self Test

A self test should now be performed to check for

proper operation of the printer. The standard self

test function requires only that a full-color ribbon

and at least one card is installed. The standard self

test function prints onto both sides of a card but

does not utilize any of the printerÕs overlay

capabilities. If printing with a full-color ribbon

with a resin black panel, most rectangles on the

back side of the self test card will appear as solid

black. A sample of the self test pattern is shown on

the following page.

1. If power is ON, turn it OFF now by pressing

the on/cancel button. The LED indicator lights

should no longer be illuminated. Verify that a fullcolor ribbon is installed and that cards are properly

loaded.

2. Press and hold the on-line button.

3. While holding the on-line button down, turn

the printer power back ON by quickly pressing

and releasing the on/cancel button.

4. Release the on-line button. The gray scale self

test will begin printing approximately 5 seconds

after the on-line button has been released.

A. Applying

Power

1.

Locate the power

cord supplied with

your printer.

2. With the printerÕs

power switch turned

OFF, place one end of

the power cord into the

power port on the rear

panel of the printer.

3. Place the other end

of the power cord into

an available wall

outlet.

4. Once the power

cord is connected, turn

the power switch

located on the rear

panel of the printer to

its ON position.

Page 31

The Color ID Card Printer is designed to be used

with nearly any IBM-PC or compatible running

Windows 3.1x or Windows 95. A minimum of a

486 DX class computer with 4MB RAM or higher is

required. For best performance, a Pentiumª class

computer with 8 MB RAM or higher is

recommended.

The printer is equipped with an ECP-compatible,

high-speed Centronics parallel port. This port is

the means through which the printer receives data

from your computer. To connect the printer to

your computer, obtain a shielded, bi-directional

parallel cable and refer to the following steps:

1. Connect the

Centronics-type

parallel side to the

printer. Snap the

fastening clips into

place.

Self Test Example: (Actual size)

26

v1.x.x

C. Connecting

the Color ID

Card Printer to

Your Computer

Page 32

27

2. Connect the other

side to the back of your

PC at the PARALLEL

connector.

3. The printer must have its on-line light

illuminated to receive data. If the light is not ON,

press the on-line button.

4. If the on-line light is flashing, check for a card

mis-feed or jam and correct according to Section 8.

Press the on-line button to resume operation.

Page 33

28

A. Installing the

Windows Printer

Driver

The Color ID Card Printer can be used with

virtually any Microsoft Windows 3.1x or Windows

95 software application program. Before printing,

you must tell the application that youÕre using the

Color ID Card Printer. This is accomplished the

first time you use the printer by installing in

Windows what is called a Òprinter driver.Ó The

printer driver is simply a diskette with software on

it that gives the printer the proper commands it

needs in order to print. After youÕve installed the

driver, put the driver diskette away in a safe place

for possible future use.

NOTE

This section of the Operator’s Manual assumes that you

are already familiar with Windows and know how it

operates. If you are not yet familiar with Windows,

consult the appropriate Microsoft documentation to

become familiar with the basics of Windows before

proceeding.

Windows 95

To install the printer driver into Windows 95, refer

to the following:

1. Insert the printer driver diskette into your

computerÕs disk drive.

2. Click the Start button, point to Settings, and

select Printers.

3. Double-click on the Add Printer icon.

7

Installing

and Using

the Color ID

Card Printer

Driver

Page 34

4. Follow the on-screen instructions to complete

installation. When prompted, do not have

Windows print a test print, since you most likely

performed a printer self test in Section 6. Once

installed, the ÒColor ID Card IIÓ printer icon will

appear in the Printers folder.

Before installing updated printer driver versions,

always delete the existing printer driver version from

your system. To do this, simply select the printer driver

from within the Printers folder, and press the Delete

key.

Windows 3.1x

To install the printer driver into Windows 3.1x,

refer to the following:

1. After starting Windows, go to the Main

program group and select Control Panel.

2. From the Control Panel, select Printers.

3. Select Use Print Manager from the bottom left

of the Printers window.

4. Select the Add>> button.

5. Highlight the Install Unlisted or Updated

Printer option from List of Printers.

6. Select the Install button.

7. Insert the supplied Printer Driver diskette into

your computerÕs disk drive. If you insert the

diskette in a drive other than the A: drive

displayed in the Install Driver dialog box, you

must change the drive designation. Select the OK

button.

8. ÒColor ID Card IIÓ should now be listed in the

Add Unlisted or Updated Printer dialog box.

Select the OK button. Your PCÕs disk drive will

now load the printer driver. Depending upon

your computer, loading will take about 10 to 20

seconds.

9. Select the Set As Default Printer button in the

Printers window. The Color ID Card Printer has

now been selected as your default (main) printer.

If you wish to use another printer later, you must

de-select the Color ID Card Printer and switch

back to the other printerÕs driver.

29

NOTE

Page 35

30

10.Finally, select the Connect button. Check that

the box called Fast Printing Direct to Port is

selected. Although this option is not necessary, it

helps optimize printer driver speed and

performance. Select OK to exit the Connect

window. Select Close to exit the Printers window.

Your Color ID Card Printer ships with a print

utility program called the 32-Bit Print Spooler. This

print spooler is for use only with Windows 95.

Once installed, the print spooler is able to process

your print jobs and send them to the printer at

consistently faster speeds than if sending print jobs

through the Windows 95 print spooler. This is

especially true if printing with an ECP compatible

parallel port or if printing off a network. The 32-Bit

Print Spooler is ideal for printing a large number of

consecutive ID cards, for printing larger file

formats (1 MB of more), or if printing on a

somewhat slower computer.

The 32-Bit Print Spooler installs just like any other

standard Windows application program. To install

the 32-Bit Print Spooler, refer to the following:

1. Insert the 32-Bit Print Spooler diskette into your

computerÕs disk drive.

2. Click the Start button, point to Settings, and

select Control Panel.

3. Double-click on the Add/Remove Programs

icon.

B. Installing the

32-Bit Print

Spooler for

Windows 95

Page 36

31

4. Follow the on-screen instructions to complete

installation. When installed, the 32-Bit Print

Spooler will appear in the Programs group of the

Start menu.

NOTE

Before installing updated 32-Bit Print Spooler versions,

always uninstall the existing print spooler version from

your system. To do this, simply select 32-Bit Print

Spooler from the list of programs in the Add/Remove

Programs Properties window and click on the

Add/Remove button.

To print with the 32-Bit Print Spooler, you must

select the Fast 32-bit Spooler option from within

the printer driver setup window as described in

section C. When this option is selected, the print

spooler will automatically open and close with the

start and finish of each print job.

NOTE

You can also manually open the 32-Bit Print Spooler

simply by selecting its icon from the Programs group of

the Start menu.

When the 32-Bit Print Spooler is running, its icon

will appear in the Windows 95 Task Bar. During a

print job, it is sometimes helpful to click on this

icon to bring the 32-Bit Print Spooler status

window to the foreground of your application.

This window provides a number of details about

the print jobs being sent to the Color ID Card

Printer.

The Current Job tab tells you the name and size of

the file printing, the progress of the overall print

job, as well as the total number of copies left to

print. It also provides buttons which allow you to

pause or cancel the print job at any time during the

printing process.

The Settings tab tells you the port and printer to

which you are printing and also allows you to

configure the timeout setting. In most instances,

the settings under this tab rarely need to be

changed.

Page 37

32

The Job Queue tab appears only when a print job is

being sent to the printer. This tab tells you the

name and status of each job in the queue and shows

you the order in which the jobs will print if you

have sent multiple jobs to the printer. A control

button is also provided which allows you to delete

every job listed in the queue. To delete the job

currently being printed, simply select the Cancel

Print button under the Current Job tab.

C. Setting Up

the Windows

Printer Driver

Once the printer driver has been successfully

installed, you will need to set the driver up for the

particular card size and type of ribbon you have

installed in the printer. There are also several

additional options that can be selected. Use the

following steps to select the appropriate printer

driver settings:

1. If using Windows 3.1x, go back to the Control

Panel and the Printers group using steps 1 and 2 on

pages 27 and 28. If using Windows 95, Click the

Start button, point to Settings, and select Printers.

Then, click on the Color ID Card II icon with the

right mouse button and select Properties. The

Properties window will appear.

2. In Windows 3.1x, select the Setup button. In

Windows 95, click on the Details tab of the

Properties window and select the Setup button.

NOTE

Some applications allow you to change these same

printer driver options from their “Print” and/or “Printer

Setup” screens. This means that you don’t have to go

back to the main printer setup window each time you

want to change a setting or option in the printer driver.

These applications will usually give you the same choices

and options, but in a slightly altered format.

3. The Color ID Card II

Printer screen appears.

Change the options as

follows:

Page 38

33

Card Size

Click on the Card Size down arrow. A list of card

size selections will appear. The Std CR-80 and

Oversize selections allow you to print and overlay

the entire printable area of a standard or oversized

card. Keep in mind that all card sizes have a slight

non-printable margin around the entire edge of the

card. The Smart Card, Magstripe, and Punch

Offset selections allow you to print and overlay

only within the given card areas. The Smart Chip

selection allows you to print and overlay anywhere

on a card except over the immediate location of a

standard smart card chip. These selections prevent

you from printing over or damaging the area of the

card containing the magnetic stripe, IC chip, or

punched slot.

The Dual Side: CR-80/Magstripe selection should

be selected only when printing onto both sides of a

standard CR-80 card which has a magnetic stripe

on the back. This option allows you to print and

overlay the entire front of a card while applying an

overlay only onto the area opposite the magnetic

stripe on the back of a card. This prevents the

magnetic stripe from being damaged. Although

this options prevents the overlay from being

applied to the magnetic stripe area of a card, it is

still possible to print text or images over the

magnetic stripe. Therefore, when designing the

back of your card format, you must be careful not

to place any printable objects over the magnetic

stripe area of the card. Note that the Duplex

Printing option must be selected to print onto both

sides of a card.

The JIS II Magstripe Side option should be

selected only when printing onto cards with a

Japanese standard JIS II magnetic stripe. Select the

card size option thatÕs appropriate for the type of

card you are using (see Section 4-C for important

card stock information).

Ribbon Type

Click on the Ribbon Type down arrow. A list of

ribbon selections will appear. Select the ribbon type

option thatÕs appropriate for the type of ribbon you

are using (see Section 4-A for further ribbon

information).

Color Matching

Click on the Color Matching down arrow and

select the appropriate color matching option. Select

None if you are more interested in print speed

rather than print color, if you have already color

corrected your image for printing, or if you are

using some other third party color matching

software.

Page 39

34

Select Algebraic if you would like the printer

driver to make very simple, yet fast, color balance

adjustments. This option gives you more natural

looking images without actually utilizing any

specific color matching software and without

slowing down the processing speed of the printer

driver. When selected, this color matching method

can be customized by selecting the Controls button.

The FargoColor

™

option is only available when the

printerÕs optional color matching software upgrade

has been installed. Select this option to enable color

matching profiles written specifically for your

printer. The FargoColor option automatically

adjusts the color of your image according to

preconfigured printer profiles and default system

profiles. This results in a very precise color match

compliant with ICC standards. Please note that

since the FargoColor option is intended to match

photographic color hues as closely as possible, you

may notice that some colors may appear slightly

muted when printing simple spot colors.

Dither Mode

This option only effects objects printed with a

monochrome resin ribbon type or those objects

printed with the monochrome resin panel of a fullcolor ribbon. Click on the Dither Mode down

arrow and select the appropriate dither method

according to the type of image you are printing.

Overlay

This option is only applicable if you are using a

ribbon with a clear overlay panel. If using such a

ribbon, select this option to enable the printer to

place a clear overlay over the entire printable area

of the given card size. Do not select this option,

however, if you are not using a ribbon with a clear

overlay panel or if you intend to apply a separate

overlaminate to the card. Remember that all dyesublimation prints must have either the ribbonÕs

overlay or a separate overlaminate applied to them

to prevent premature wear or fading.

K Panel Graphics

In most application programs, when printing with

a Full-Color YMCKO ribbon, the Color ID Card

Printer driver prints all bitmapped images with the

ribbonÕs yellow, magenta, and cyan color panels

(YMC). Any black contained in these bitmapped

images is printed by combining equal amounts of

yellow, magenta, and cyan. This type of black is

called a ÒcompositeÓ black. The resin black (K)

panel of the ribbon is only used when printing

TrueType black text and TrueType bar codes.

Page 40

35

The printer driver distinguishes between text and

image objects in order for TrueType black text and

bar codes to always be printed with a true resin

black. Resin black is essential when printing bar

codes, since only resin black bar codes can be read

by both infra-red and visible light bar code

scanners. Composite or dye-sublimation black bar

codes can only be read by visible light bar code

scanners.

In some cases, however, this print method may not

be acceptable. If, for example, you are printing bar

codes which are not TrueType bar codes but rather

bitmapped bar codes, such bar codes will be

printed as a composite black (i.e., with the YMC

panels only). In addition, when printing from

certain application programs, the printer driver is

also forced to print all objects, even black text or

bar codes, with the yellow, magenta, and cyan

color panels. This happens because some

application programs interpret both text and image

objects as bitmapped images.

If your particular application program does not

differentiate between TrueType text and image

objects or if you are printing bitmapped bar codes,

select the K Panel Graphics print option. This

option forces the printer driver to print all of the

black within text, bar codes, or bitmapped images

with all four of the ribbon’s YMCK panels.

K Panel Only

This option is only active when the K Panel

Graphics option is selected. When the K Panel

Only option is selected, all of the black within text,

bar codes, or bitmapped images will be printed

only with the ribbonÕs resin black (K) panel (i.e.,

without the YMC composite black underneath).

Selecting this option increases the precision of

printed bitmapped bar codes, thereby assuring

greater accuracy when read by a bar code scanner.

Split Ribbon

Print

Select this option to automatically print full-color

on the front of a card and monochrome on the back

of a card using a standard Full-Color YMCKO

ribbon. This option allows the printer to print the

front of a card with the ribbonÕs yellow, magenta,

and cyan (YMC) panels and the back of a card with

the ribbonÕs black (K) panel. The ribbonÕs clear

overlay is applied last to the cardÕs front side.

Selecting this option provides the most economical

means of printing a dual-sided card with overlay,

since you avoid wasting an entirely new set of

ribbon panels just to print the monochrome back

side. Note that the Duplex Printing option is

automatically enabled when this option is selected.

Page 41

36

Back Side Only

Select this option to print the back side of a card

only. This option allows you to conveniently print

the back side of preprinted cards which also must

have their magnetic stripe or smart card chip

encoded. Be sure to load cards in the usual fashion

as described in Section 4-D. Note that when this

option is selected, the Duplex Printing option is

automatically disabled.

Rotate 180º

This option allows you to rotate your image 180¼

when printed. Select this option if you wish to

change the position of your image in relation to the

set location of a cardÕs magnetic stripe.

Mag Encode

Only

Select this option if you wish to send only the

magnetic track data of a card format to the printer.

This unique feature enables the Color ID Card

Printer to function solely as a magnetic stripe

encoder so you can easily encode or re-encode

preprinted cards without wasting additional time,

effort, or printing supplies.

Write Direct

to Port

Selecting this option provides the fastest print

processing when printing through a standard

parallel port which is not ECP compatible or when

printing exclusively from Windows 3.1x. When

selected, this option allows the printer driver to

bypass the Windows 3.1x Print Manager or the

print spooler of Windows 95 and to send all print

data directly to the Color ID Card Printer. This

option devotes all of your system resources to the

current print job, thereby increasing overall print

speed. When the print job is finished, your system

resources will again be released and devoted to the

normal function of your on-screen applications.

Depending upon the processing speed and brand

of your computer, you may or may not need to

select this option when printing with the Color ID

Card Printer. For most computers with a non-ECP

compatible parallel port, selecting this option will

enhance the speed of the rasterizing and printing

process. In this case, the Write Direct to Port option

should be selected. For some computers, however,

this option may either not be supported by the

particular brand of PC or simply may not be

necessary due to the PCÕs fast processing speed. In

this case, the Write Direct to Port option should

not be selected.

NOTE

This option will not function properly if using any type

of external printer buffer. When using a printer buffer,

all print jobs should be sent through the system print

Page 42

spooler or through the Color ID Card Printer’s 32-Bit

Print Spooler for Windows 95.

Fast 32-bit

Spooler

Select this option for consistently faster print

processing. This option is only selectable if

operating under Windows 95 and if the included

32-Bit Print Spooler software has been installed.

When selected, this option allows the printer

driver to send all print jobs to the Color ID Card

PrinterÕs 32-Bit Print Spooler rather than to the

Windows 95 print spooler. See section B for

complete details on the 32-Bit Print Spooler. This

option and the 32-Bit Print Spooler software will

not function in Windows 3.1x.

Duplex Printing

Select this option to automatically print on both the

front and back side of a card. This option can be

selected in conjunction with any application

program which supports a multiple page

document. In other words, your program must be

able to send down two or more separate pages to

be printed within the same document.

For example, if you would like to print a full color

ID format on the front of your card and

monochrome text or bar codes on the back, you

would simply create the full color front side of the

card on page 1 of your document and the

monochrome back side on page 2. The printer

driver will always place all odd numbered pages

on the front side of the card and all even numbered

pages on the back side.

Orientation

Select either Portrait or Landscape. Selecting

Portrait causes the card to print in a vertical

orientation. Selecting Landscape causes the card to

print in a horizontal orientation. An icon

illustrating a printed card helps represent the

difference between the two.

37

Page 43

38

Controls

Select this button to display options for controlling

a printed cardÕs Brightness, Contrast, or Gamma, as

well as for controlling the cardÕs individual color

balance for Yellow, Magenta, and Cyan. Select the

Default button to return all control options to the

original settings. When the Algebraic color

matching option is selected, all control options will

display and can be adjusted. When the None or

FargoColor color matching options are selected,

only the Brightness (Heat) option will display.

Magnetics

When magnetically encoding a card with the Color

ID Card Printer, the ISO standards for magnetic

encoding will automatically be used. These

standard settings will suffice for most encoding

applications and rarely need to be modified. If

modification is necessary, however, please see

Appendix A for more information on the printerÕs

magnetic encoding process.

Page 44

Lamination

Select this button to display options for controlling

the printerÕs lamination process. When the No

Lamination option is selected, the printerÕs built-in

laminator will not be used. When using the

laminator, select from these options to choose the

card side(s) you would like to laminate or to select

the Lamination Type according to the overlaminate

material you currently have installed. In addition,

you can also select the Lamination Dwell Time or

through-put speed of a card in seconds/inch as

well as the Lamination Temperature. The default

settings for the Lamination Dwell Time and

Lamination Temperature should be accurate for

most card stocks and overlaminate types. See

Section 5 for more information on the printerÕs

lamination process.

IMPORTANT!

If you select the Film Lamination w/ Overlay option,

you must be using a ribbon which provides a clear

overlay panel. When used with this type of ribbon, the

printer will apply the clear overlay panel of the ribbon

over the film lamination layer of a printed card. This

process is required for maximizing card durability when

laminating with the thermal transfer film material. The

ribbon types which do not provide an overlay panel or

support overlay printing are Monochrome Resin and 5

Color, Resin Black. Avoid using these types of ribbons

in conjunction with the thermal transfer film material.

Selecting the printer driver’s standard Overlay option

forces the printer to automatically place the ribbon’s

clear overlay panel onto whichever side or sides of the

card you are printing. The Film Lamination w/

Overlay option overrides the standard Overlay option

for the card’s laminated side only, forcing the printer to

place the ribbon’s clear overlay on top of the film

overlaminate rather than beneath it.

39

Page 45

For example, if you are printing onto both sides of a card

and you have both the Overlay and the Film

Lamination w/ Overlay options selected, the ribbon’s

clear overlay panel will be placed on top of the film

laminated side as well as over the printed reverse side.

As a rule, do not select the standard

Overlay option in

conjunction with the Film Lamination w/ Overlay

option if you do not wish to place the ribbon’s clear

overlay onto the printed, non-laminated back side of a

card.

4. After your selections have been made, close out

of the printer setup window. You are now ready to

go to an application program and print. All printer

driver options selected will stay the same until you

change them.

D. Printing a Card

Now that youÕve set up the printer, loaded media,

and installed the printer driver, youÕre ready to

print an ID card. Follow these steps to print your

first card:

1. Go to the Windows application program in

which you will be creating your cards and open or

create a card format.

2. Once you are ready to print, select Print Setup

(or the equivalent) from the programÕs File menu to

verify that the printer driver settings are correct for

your card design. Remember to select the proper

card size and ribbon type and, if applicable, to

verify that the proper magnetic and/or lamination

settings are selected. After youÕve properly

configured the driver, select the Print button from

the applicationÕs Print screen.

3. The Color ID Card PrinterÕs RIP (raster image

processing) begins. The image processing time will

vary depending upon the complexity of the image

and the processing speed of your computer.

4. After the image is processed and sent to the

printer, the printer will draw in a card and print

the first color (yellow), followed by the remaining

colors (magenta, cyan, and black). If using a ribbon

with a clear overlay, the clear overlay panel will

print immediately after the last color panel. If

printing onto the back side of a card, encoding, or

applying an overlaminate, the printer will finish

these functions last and then eject the card.

5. If everything looks good, youÕve successfully

completed set-up, initial testing, and printing with

your Color ID Card Printer.

40

Page 46

41

8

Maintenance

Your Color ID

Card Printer is

built to require a

minimum of

maintenance.

Nevertheless,

there are a few

procedures you

can perform on a

regular basis or

as needed to

ensure the best

possible

performance. Use

the illustration at

the top of this

page to locate the

items discussed

within this

section.

A. Supplies

Required

For the maintenance procedures outlined in this

section, you will need the following items:

■

Isopropyl alcohol

■

Acetone

■

Standard clear adhesive tape or masking tape

■

Soft, lint-free cloth

Or, to make these maintenance procedures more

convenient, a Printer Cleaning Kit is available from

your reseller or from the printer manufacturer. This

optional kit includes the following:

■

Printhead Cleaning Pens pre-moistened with

99.99% isopropyl alcohol for cleaning your

printerÕs printhead.

■

Cleaning Cards with an adhesive backing for

automatically cleaning your printerÕs gray card

feed rollers and cleaning rollers.

■

Cleaning Pads pre-moistened with 99.99%

isopropyl alcohol for cleaning your printerÕs

drive roller and general inside area.

IMPORTANT! 1. Never use a sharp tool or abrasive object of any kind

to clean the printhead. You will damage the printhead!

2. Watches, rings, bracelets, and other jewelry can

damage the printhead if accidentally bumped against it.

For best results, remove such items before touching any

internal components of printer.

3. Internal components of the printer, such as the

printhead, may be damaged if exposed to static electrical

discharges generated by various means, such as walking

on a carpeted floor. To avoid potential damage, always

wear an appropriate personal grounding device, such as

Drive

Rollers

Cleaning

Roller

Assembly

Printhead Printhead Assembly

Supply Ribbon

Drive Hubs

Page 47

42

a wrist strap (with integral resistor) connected to an

ESD ground. Or, at a minimum, make positive contact

with the bare metal chassis of the printer with your hand

prior to touching any internal electrical components.

B. Standard

Printhead

Cleaning

This procedure should be performed if you notice a

streak on the card where color was not transferred.

This procedure should also be performed during

every ribbon change or after every 250 prints in

order to maintain consistent print quality. The

printhead is located near the center of the opened

top cover assembly.

1. Open the printerÕs top-right cover by pressing

its Cover Release Button.

2. If you observe dust and/or other particles

laying on the top surface of the ribbon, manually

roll it up into the take-up roll. Occasionally, dust

may settle on the top surface of the ribbon and

cause print quality problems.

3. Use a Printhead Cleaning Pen from the Printer

Cleaning Kit or a soft, lint-free cloth slightly

moistened with isopropyl alcohol to wipe dust and

other accumulated particles off the surface of the

printhead. If using a cloth, be extremely careful not

to use too much alcohol. It must not be allowed to

drip into the printer!

4. Once the printhead is completely dry, shut the

cover. If a streak persists, perform the steps in

section C.

C. Expanded

Printhead

Cleaning

Perform if you have a streak on the printed output

that canÕt be solved by the Standard Printhead

Cleaning procedure. To maintain your printerÕs

high quality of printing, this procedure should also

be performed approximately every 2,500 prints as

part of the printerÕs general maintenance program.

1. Open the printerÕs top-right cover by pressing

its Cover Release Button.

2. Use a soft, lint-free cloth slightly moistened

with acetone to wipe off the surface of the

printhead. Be extremely careful not to use too much

acetone. It must not be allowed to drip into the

printer!

CAUTION!

ACETONE IS A VERY POWERFUL SOLVENT. DO

NOT APPLY ACETONE TO ANY OTHER AREA OF

THE PRINTER, SINCE IT WILL DESTROY THE

FINISH OF PAINT, RUBBER, AND PLASTIC.

Page 48

43

3. Allow the printhead to thoroughly dry before

closing the cover.

4. Shut the cover. If a streak persists, contact your

dealer or the technical support number listed on

the insert in this manual for further assistance.

D. Cleaning the

Printer’s Case

Your Color ID Card Printer has a durable casing

that should retain its luster and appearance for

many years. Clean it only with a soft cloth slightly

dampened with water or a mild soap. Do not use

excess water or cleaning solvents of any kind.

Never spray the cabinet with a cleaner. Rather,

spray the cloth first, then wipe down the printer.

E. Cleaning the

Inside of the

Printer

As you use your printer, dust and other foreign