Page 1

Installation and Operation Manual

HERO HS300

Whole House Filtration Unit

PARTS IN THE BOX

Whole House HS300, 1 pc

Power cord, 5 ft, 1 pc

Plenum seal, 7.5 ft, 1 pc

Screws, 8 x 32 x 1/2”, 16 pcs

Template, 1 pc

Item #: 463882

Rev Date: 2020-09-22

REPLACEMENT FILTERS

#463046 - Replacement Pre-Filter with Carbon, 1 pc

#463048 - Replacement HEPA Filter, 1 pc

Your Fantech HEPA Filtration system should be installed in conformance with the appropriate local, provincial or state

requirements or in the absence of such requirements with the current edition of the National Building Code, and / or

ASHRAE’s “ Good Engineering Practices”.

United States

Lenexa, KS, 66215

Tel.: 800.747.1762

Fantech reserves the right to modify, at any time and without notice, any or all of its products’ features, designs,

components and specifications to maintain their technological leadership position.

Please visit our website www.fantech.net for more detailed technical information.

Canada

Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548

Page 2

2

Note Warning/

Important

note

Information Technical

information

Practical tip

PLEASE READ THIS MANUAL BEFORE INSTALLING UNIT

Prior to installing, serious consideration must be taken to insure this ltration system will operate

properly if integrated to any other type of mechanical system, i.e. a forced air system, or an air

handling unit. To insure proper operation & compatibilities of both system, it is required that you

follow the instructions in this manual.

LIMITATIONS: The product is for residential

applications only. Must be installed in accordance with all national and local regulations,

building and safety codes.

This product is designed and manufactured

to provide reliable performance. Sometime

even most reliable products will experience

occasional failures, and this possibility should

be recognized by the user.

If these products are used in a life support

ventilation system where failure could result

in loss or injury, the user should provide

adequate back-up ventilation, supplementary

natural ventilation or failure alarm system, or

acknowledge willingness to accept the risk of

such loss or injury.

Your Fantech HEPA Filtration system should be

installed in conformance with the appropriate

local, provincial or state requirements or in the

absence of such requirements with the current

edition of the National Building Code, and/or

ASHRAE’s “Good Engineering Practices”.

CAUTION:

TURN OFF ALL INTEGRAL DISCONNECTS

BEFORE SERVICING

fantech

Page 3

Table of Content

INTRODUCTION..............................................................................4

SPECIFICATIONS.............................................................................4

INSTALLATION ..............................................................................5

GENERAL OPERATION INFORMATION ..............................................................7

MAINTENANCE .............................................................................8

3

REPLACEMENT FILTER ........................................................................8

MAINTENANCE SCHEDULE .....................................................................9

PARTS LIST ...............................................................................20

fantech

Page 4

4

17"

(431mm)

(307mm)

(305mm)

(431mm)

13"

(328mm)

22"

(557mm)

8"

(201 mm)

Power connection

Introduction

HEPA AIR FILTRATION SYSTEMS

You have purchased a very effective air cleaning and treatment system

incorporating HEPA (High Efciency Particulate Arrestance) lter

technology. This is the type of air cleaning equipment that respiratory

specialists recommend most.

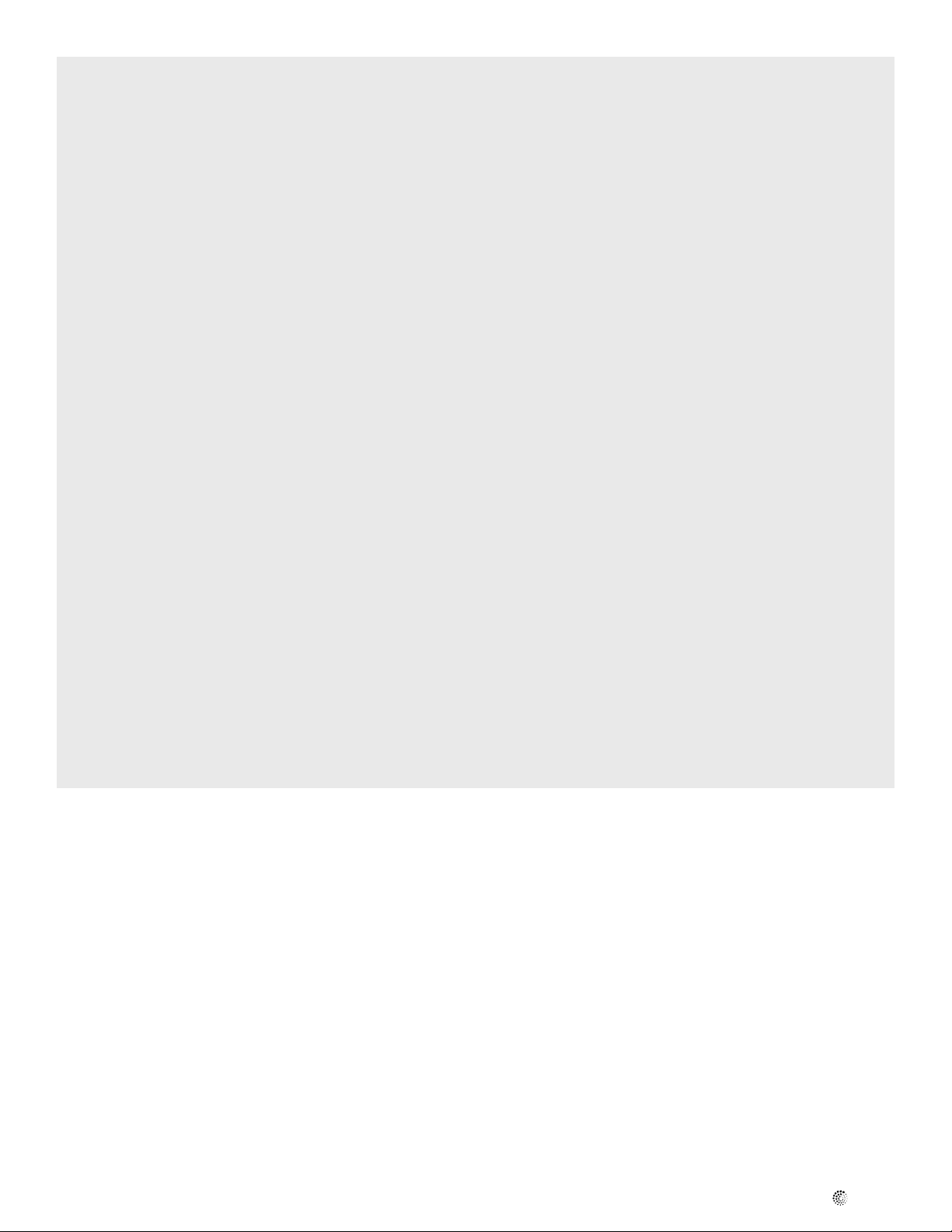

Specification

To optimize the performance of your HEPA Filtration System, it should

be installed by a professional contractor who is familiar with your indoor

air quality situation and the operation of other heating, ventilation and air

conditioning equipment that you may have.

Filtration Stage 1 & 2 Pre-Filter with Carbon (#463046)

Filtration Stage 3 HEPA Filter (# 463048)

Weight 28 lbs (12.7 kg)

Plenum Mount Port Opening 16" x 3.5" (406 mm x 89 mm)

Collar Mount Port Opening 8" (203 mm) Round*

Installtion Type Plenum, Wall* or Floor* Mounted

Installation

RETURN AIR PLENUM INSTALLATION

Front View Side View - Clearance Back View

Electrical Supply 120VAC @ 60 Hz

Power Consumption 134W

Certication cCSAus

Airow (low/high speed) 220/300 cfm

22"

(557mm)

12"

12"

RETURN AIR PLENUM INSTALLATION AND STAND ALONE INSTALLATIONS

Front View Side View - Clearance Side View

12"

(305mm)

fantech

17"

12"

(307mm)

17"

(431 mm)

Page 5

Planning Installation

5

For integrated system installation

• Verify clearance on the ductwork to mount the unit using the Forced

Air heating/cooling system

• Minimum clearance requirements for maintenance and service

• Electrical power requirements

• Interaction between the HEPA lter unit and other mechanical

devices.

The Whole House HEPA unit is a versatile appliance with multiple

installations conguration. It is recommended to take your time in

planning the installation.

Several Installations are illustrated herein’ for Whole House ltration

applications:

• Return to return integrated with the forced air heating/cooling

system.

• Central draw points using dedicated duct system

Types of Intsallation

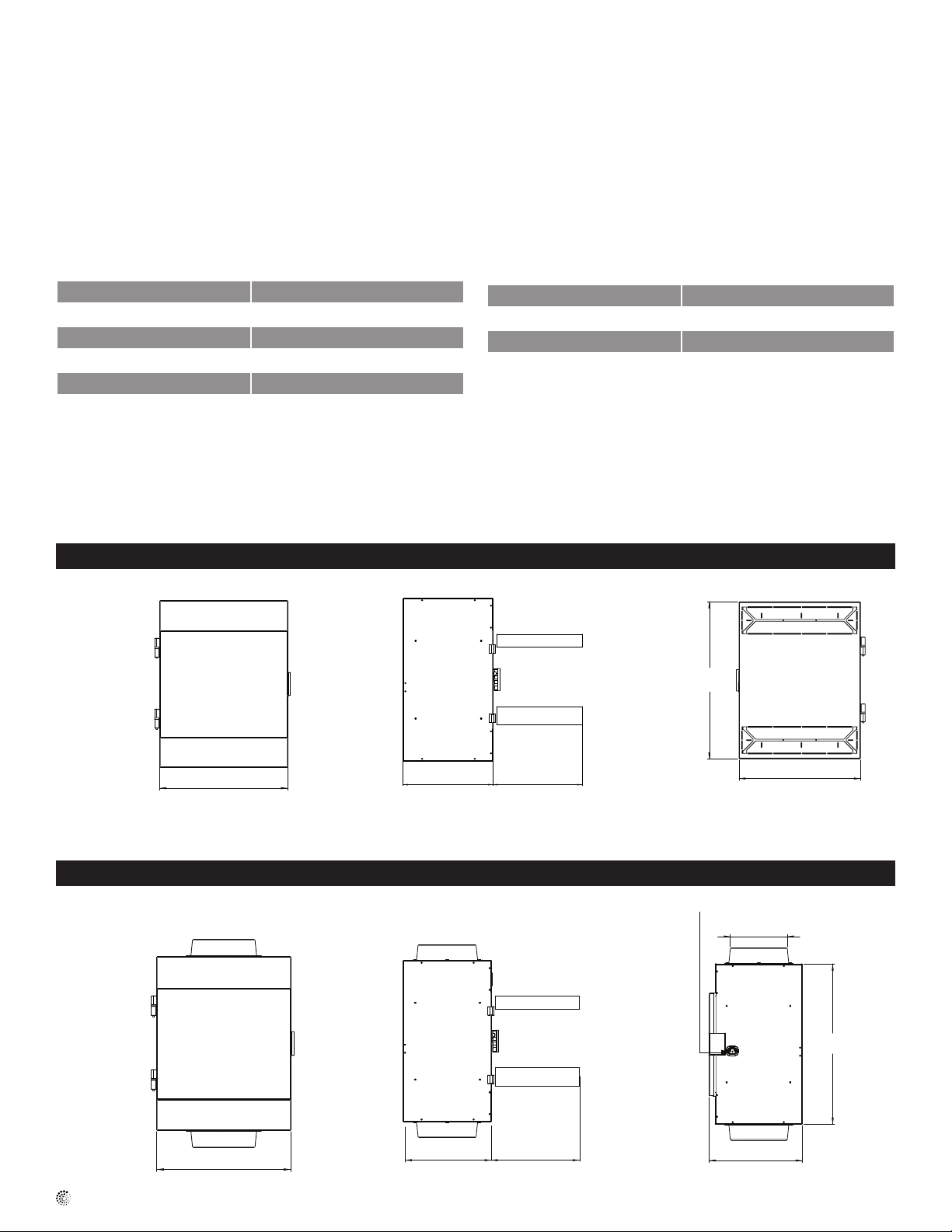

I. RETURN TO RETURN INTEGRATED SYSTEM

DUCTING FLAIR SYSTEM

Installation

The Whole House HEPA Filtration system is

designed to install directly onto the return

air plenum of the forced air heating/cooling

system. Choosing this type of installation

eliminates the need to externally duct the

HEPA lter unit to the plenum system. If

you choose this type of installation, it is

recommended that you run the fan on your

forced air system continuously to maximize its

cleaning ability.

COLLAR MOUNT SYSTEM

Installation

Whole House HEPA Filtration system can

be converted to use 8 inch round collars for

application requiring ducting. The kit includes

two, 8 inch round collars, two mounting

brackets for wall or oor mounting, installation

guide and fasteners.

Tips to installer

The Whole House HEPA Filtration

system does not replace the lter

from the forced air heating/cooling

system. Regular maintenance of

this lter is necessary to permit

the good operation of the forced air

heating/cooling system.

DUCTING FLAIR SYSTEM

(Hepa Mounted on Duct)

Return

Air Plenum

Forced Air Heating

/Cooling System

To living

space

OPTIONAL COLLAR SYSTEM

(Hepa Mounted on Wall)

Return

Air Plenum

Forced Air Heating

/Cooling System

To living

space

INSTALLATION SHOULD BE PERFORMED BY A CERTIFIED PROFESSIONAL.

Consult your HVAC product manufacturer if the usage of this product will affect the performance of your forced air heating / cooling system.

II. STAND ALONE SYSTEM

ATTIC INSTALLATION

Ideal for homes without a forced air heating

/ cooling system. Allows for air ltration and

circulation throughout the home.

HEPA system must be operated continuously whenever a part or all the

system is located in an unconditioned space to avoid condensation in the

ductwork below freezing (0°C, 32°F).

BASEMENT INSTALLATION

Ducting will usually consist of one return

with grille from one side of the home, and

one supply with grille at the opposite end of

the home.

MODE

RANGE

C

°

INTERN

OFF

0

2

-

CONT

NORMAL

/

RECIRC

REDUCED

MAINTENANCE

R

É

T

E

É

/

R

E

V

M

CYCLES / HOUR

I

M

U

S

H

20 / 40

/

30/30

E

R

U

T

A

R

E

P

T

M

E

fantech

Page 6

6

Installation Step by Step

TOOLS REQUIRED

• Phillips #2 or Robertson #1 screwdriver

• 3/32” drill bit

• Tin snips or metal shear

• Power Drill

LOCATION

Return side connections is to be installed after the

last branch on the return air plenum and minimum

2 linear ft distance from furnace.

A 5-ft power cord is supplied with the unit. If not

available a 120VAC outlet needs to be supplied.

Note to installer

Refer to the general operation

information section for details on how

to remove the unit’s door and lters.

Tips to installer

Please consult local authorities to nd

out whether the installation of electrical

products requires the services of

a certied technician or electrician.

Removing the lters from the unit will

facilitate your job.

DUCTING FLAIRS

MOUNTING SYSTEM

The Whole-House HEPA Plenum Systems are designed for single person installation.

Once the holes are made in the main return duct

and the unit is aligned, the installer just has to

unfold the «Ducting Flairs» and screw the unit in

place.

STEP BY STEP INSTALLATION

Steps involved in the preparation of the plenum mount system are as followed:

Step 1

Preparing return air plenum

Find a location that satises both service and maintenance requirements and proceed to cut holes as

illustrated below.

THIS LINE MUST BE LEVEL / CETTE LIGNE DOIT ÊTRE AU NIVEAU

Drill Hole (3/32")

Drill Hole (3/32")

Percer un trou

Drill Hole (

3/32")

Percer un trou

3.5"

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

Percer un trou

3.5"

Drill Hole (3/32")

Percer un trou

Tape template to return air plenum. Cut opening with metal shears, predrill for the securing screws

and remove template.

Step 2

Remove the door and lters and proceed to cut the insulation as illustrated below.

Cut the insulation along the inside edge of both inlet and outlet ports to remove the insulation from the port openings.

Cut the four metal tabs to release the mounting airs for the inlet and outlet ports.

Drill Hole (3/32")

Percer un trou

Percer un trou

Drill Hole (3/32")

Percer un trou

16"

Drill Hole (3/32")

Drill Hole (3/32")

Percer un trou

Percer un trou

ATTENTION

Cut

CUT THE EDGES SHOWN ONLY

COUPER LES SURFACES INDIQUÉS SEULEMENT

Drill Hole (3/32")

Percer un trou

16"

Drill Hole (3/32")

Percer un trou

Item # 461481

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

un trou

Percer

Drill Hole (3/32")

Percer un trou

Preparing ducting airs

One cut permits the clean removal of the insulation piece.

The unit should look like this

when the foam piece is remvouved.

Tips to installer

It is recommended that the ltration unit

have a devoted receptacle with 120V.

It is not recommended to connect unit

with an extension cord. If no receptacle

is available please call an electrical contractor to have one installed.

fantech

Apply plenum seal tape all around both openings on the back of the unit. Bend tabs outward approximately 90 degrees.

Step 3

Mount Hepa

Align unit into place. Unfold the ducting airs completly to sandwich the return air plenum between the

ducting air and the ltration unit. Install unit as usual using all supplied fastening hardware.

Page 7

Installation Step by Step (cont.)

7

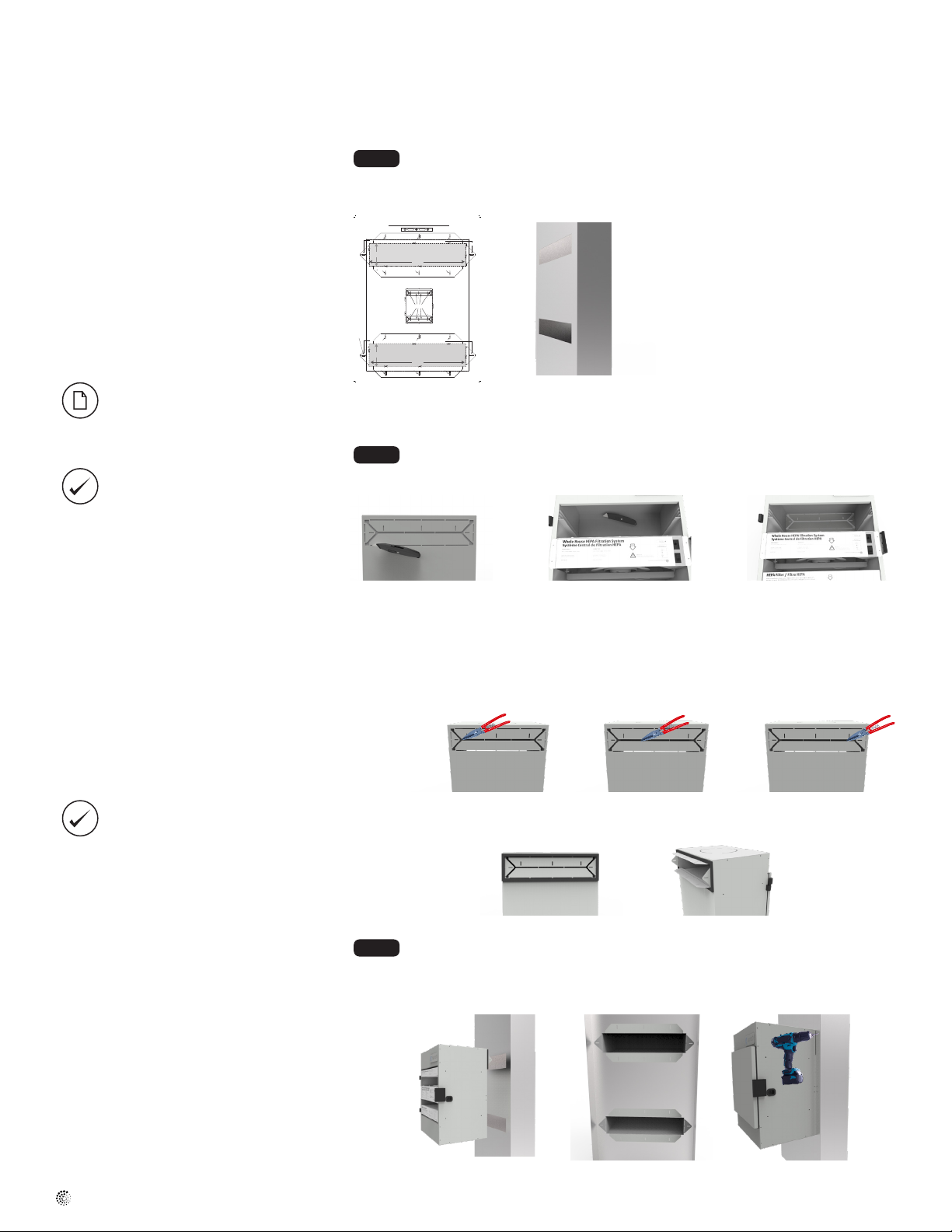

MAKE SURE TO INSTALL FILTER ACCORDING TO AIR

FLOW DIRECTION FOR MAXIMUM PERFORMANCE

Check for this symbol on each lters and it is located

on the unit’s motor plate.

STEP BY STEP INSTALLATION

Steps involved in the preparation of the plenum mount system are as followed:

Step 4

Finishing

Stage 1: Pre-Filter

Stage 2: Carbon Filter

Stage 3: HEPA Filter

Remove protective plastic covers

from all lters and replace them

in their proper location

(Stage 1, 2 and 3).

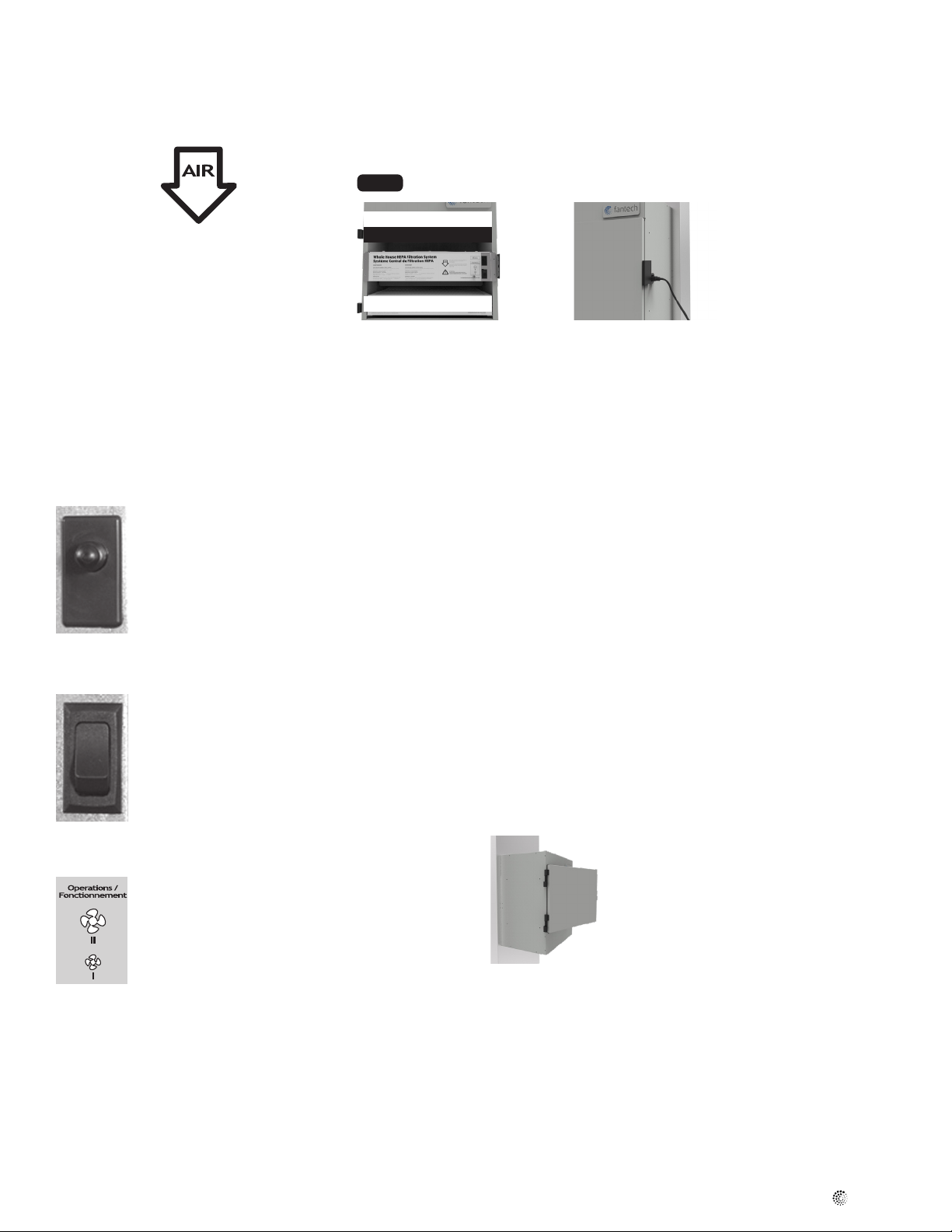

General Operating Information

DOOR SWITCH

MODE SELECTOR

• II (300 CFM)

• I (220 CFM)

OPERATIONS

Maximum Filtration

(300 cfm)

Normal Filtration

(220 cfm)

FUNCTION

The Whole House HEPA system is comprised of

a ventilator, speed selection switch,

3 stages of ltration and the cabinet enclosure

system. The ventilator pulls air through the

pre-lter and then threw the impregnated carbon

pad for odor control and nally the last stage

of ltration is the HEPA lter which removes

99.97% of particles 0.3µm in size.

OPERATION MODE OPTIONS

The unit features two speeds of operation for

your convenience. The speed selection switch

is located on the front of the motor assembly.

At lowest speed the unit will provide 220 CFM

of clean air while at highest speed, the unit will

provide 300 CFM of clean air. It is recommended

that the unit be operated on highest speed

at all times to maximize the benets of the

HEPA ltration system. If for some reason the

ltration needs are not

as important then one

might operate the unit at

low speed.

An access door is

provided at the front

of the unit to permit

access to the lters and

speed selection switch. Opening the latch on the

right side of the unit will permit the door to swing

open. A safety door interlock switch cuts the

power to the motors for your safety. If needed

the door can be removed from the cabinet hinges

by holding the top part of the door with one hand

and gently taping on the bottom edge of the door

with the other hand to release the door from its

hinges.

Replace door and insert power

cord into the receptacle of the

lter units and the other end into

wall outlet.

RECOMMENDED OPERATION

The return plenum mount model operates

in conjunction with your forced air heating/

cooling system. A forced air distribution system

continuously circulates the same air inside your

home. The whole house HEPA ltration system

operates on the principal of bypass ltration,

which means that a portion of the air being

returned into the furnace is ltered on each

pass. Over time all the air in the home gets

cleaned. It is recommended that the furnace

blower be in operation whenever the ltration

system is in operation.

For stand-alone attic installation, the HEPA

ltration system must be operated continuously

whenever a part of all the system is located in an

unconditionned space to avoid condensation in

the ductwork below freezing (32°F ,0°C)

Maintenance of the unit should be performed at

regular interval to keep the benets of the HEPA

ltration unit.

fantech

Page 8

8

General Maintenance Information

WHEN SHOULD I SERVICE

MY UNIT?

SERVICE AND ACCESSORIES

Detailed maintenance information is located on the

front decal on motor plate.

PRE-FILTER WITH CARBON (463046)

Replace lters every 3 to 6 months or as needed.

HEPA FILTER (463048)

Replace lter every 2 to 5 years or as needed.

Check regularly to maintain maximum performance

from your

HVAC system.

For replacement lters, contact your local HVAC

contractor.

INSIDE THE UNIT

Once a year or as needed, clean the interior of the

unit (Wall and Motor Plate) with a mild and nonabrasive soap. It is recommended to use products

that are environmentally friendly.

Tips to homeowner/installer

ALWAYS UNPLUG UNIT

BEFORE SERVICING

CHANGING FILTERS

After opening the unit’s

door, grasp both edges of

lter and pull with equal

force to slide out the

lter.

CLEANING

Once a year or as needed,

clean the interior of the

unit (Wall and motor

plates) using mild nonabrasive soap and water.

It is recommended to

use products that are

environmentally friendly.

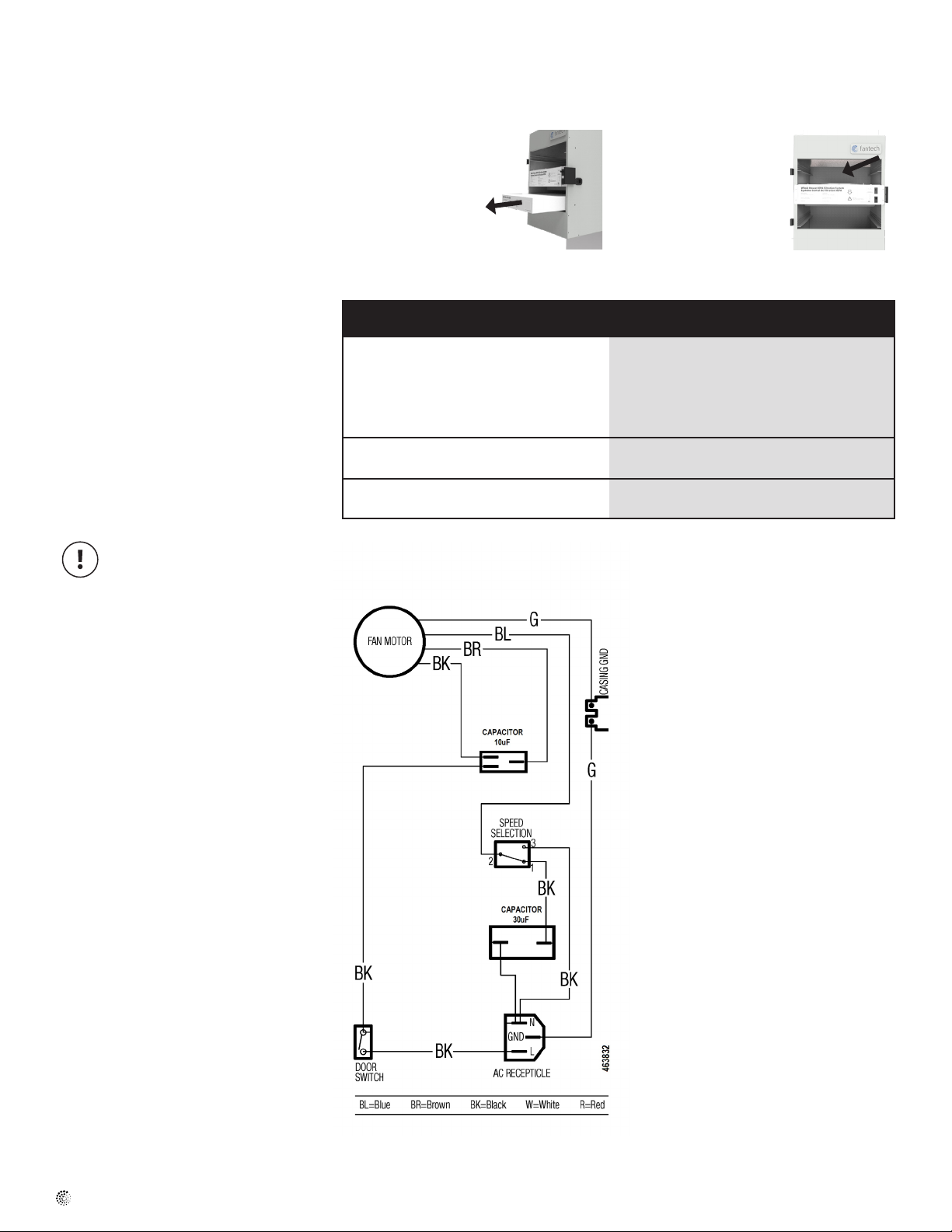

TROUBLESHOOTING

TROUBLESHOOTING SUGGESTIONS

Unit does not operate • Is power cord fully inserted in the unit’s

connector?

• Is outlet powered?

• Is door interlock switch operating?

Unit operates only on one speed. Possible loose wire inside electrical box, contact

you local contractor.

Unit vibrates Check for excessive dust build up or missing

balancing weight on the impeller wheel.

ELECTRICAL WIRING DIAGRAM

fantech

Page 9

Maintenance

9

Warranty

Schedule

Date Type of Service performed Service Technician

• The maintenance free motors are

permanently lubricated and are

guaranteed for 7 years. They are

factory balanced to prevent

vibrations and promote silent

operation.

• All other components have a 5 year

limited warranty. (filters not included)

• The limited warranty covers normal

use. It does not apply to any defects,

malfunctions or failures as a result

of improper installation, abuse,

mishandling or misapplication,

fortuitous occurrence or any other

circumstances outside

manufacturer's control.

• The warranty is in effect for 5 years

on parts and 7 years on the motor

after the date of purchase, including

parts replaced during this time

period. If there is no proof of

purchase available, the date

associated with the serial number

will be used for the beginning of the

warranty period. Parts are a 1 year

warranty when replaced after the

initial warranty has expired.

• This warranty is the exclusive and only

warranty in effect and all other

warranties either expressed or

implied are invalid.

• Warranty from the manufacturer is

for parts only and does not include

labor or shipping to service or repair

them.

fantech

Page 10

10

fantech

Page 11

HERO HS300

Système de filtration d'air

PIÈCES DANS LA BOÎTE

Système de filtration d'air HS300, 1 pc

Cordon d'alimentation, 5 pi, 1 pc

Joint de plénum, 7,5 pi, 1 pc

Vis, 8 x 32 x 1/2”, 16 pcs

Gabarit, 1 pc

No. d'article: 463882

Date de rév.: 2020-09-22

Manuel d'installation

FILTRES DE REMPLACEMENT

#463046 - Filtre de remplacement, Préltre avec carbone 1 pièce

#463048 - Filtre de remplacement HEPA, 1 pièce

Votre système de filtration HEPA de Fantech doit être installé conformément aux exigences de la municipalité, de la province

ou de l’État où vous habitez ou, à défaut de telles exigences, conformément à l’édition actuelle du Code national du bâtiment

du Canada ou aux « méthodes d’ingénierie appropriées » de l’ASHRAE.

United States

Lenexa, KS, 66215

Tel.: 800.747.1762

Fantech reserves the right to modify, at any time and without notice, any or all of its products’ features, designs,

components and specifications to maintain their technological leadership position.

Please visit our website www.fantech.net for more detailed technical information.

Canada

Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548

Page 12

12

Note Warning/

Important

Information Technical

information

Practical tip

note

VEUILLEZ LIRE LE PRÉSENT MANUEL AVANT D’INSTALLER L’APPAREIL

Avant de procéder à l’installation, examinez avec soin la façon dont le système fonctionnera s’il

est relié à tout autre appareil mécanique, notamment une fournaise à air pulsé ou un appareil de

traitement d’air dont la pression statique est plus élevée.

LIMITATIONS: Le produit est destiné

uniquement aux applications résidentielles.

Doit être installé conformément à toutes les

réglementations nationales et locales, ainsi

qu'aux codes du bâtiment et de sécurité.

MISE EN GARDE:

ÉTEIGNEZ TOUS LES DÉCONNEXIONS INTÉGRALES AVANT L'ENTRETIEN

Les produits sont conçus et fabriqués pour

fournir une performance able, mais ils ne sont

pas garantis à 100% sans défaut. Même les

produis ont des pannes occasionnelles et cette

possibilité devrait être reconnue par l'utilisateur.

Si ces produits sont utilisés dans un système

de ventilation qui maintien des fonctions vitales

où une défaillance pourrait entraîner des pertes

ou des blessures, l'utilisateur doit fournir une

ventilation de secours adéquate, une ventilation

supplémentaire naturelle, un système d'alarme

de défaillance ou d'accepter les risques de

pertes ou de blessures.

Votre système de ltration HEPA de Fantech

doit être installé conformément aux exigences

de la municipalité, de la province ou de l’État où

vous habitez ou, à défaut de telles exigences,

conformément à l’édition actuelle du Code national

du bâtiment du Canada ou aux « méthodes

d’ingénierie appropriées » de l’ASHRAE.

fantech

Page 13

Table des matières

INTRODUCTION.............................................................................14

13

DIMENSIONS ..............................................................................14

SPÉCIFICATIONS............................................................................14

INSTALLATION .............................................................................15

INFORMATION GÉNÉRAL ......................................................................17

ENTRETIENT ..............................................................................18

FILTRES DE REMPLACEMENT ..................................................................18

CALENDRIER D'ENTRETIEN ....................................................................19

LISTE DES COMPOSANTES ....................................................................20

fantech

Page 14

14

17"

(431mm)

(431mm)

13"

(328mm)

22"

(557mm)

8"

(201 mm)

Power connection

Introduction

SYSTÈME DE FILTRATION D'AIR HEPA

Vous êtes l’heureux propriétaire d’un système d’épuration et de

Craitement de l’air très efcace mis au point selon la technologie

de ltration HEPA (ltre à particules à haute efcacité). Il s’agit

du type d’appareil d’épuration de l’air le plus recommandé par les

inhalothérapeutes.

Spécification

An d’optimiser les performances de votre système de ltration HEPA,

celui-ci doit être installé par un entrepreneur professionnel bien au fait du

niveau de qualité de l’air ambiant de votre maison et connaissant

bien le fonctionnement du matériel de chauffage, de ventilation ou de

climatisation que vous possédez.

Filtration Stage 1 & 2 Préltre avec carbone (no. 463046)

Filtration Stage 3 Filtre HEPA (no. 463048)

Poids 28 lbs (12.7 kg)

Retour/Retour

16" x 3.5" (406 mm x 89 mm)

Ouverture des orices

Conduits indépendant

8" (203 mm) Rond*

Ouverture des orices

Installation

INSTALLATION SUR CONDUIT DU RETOUR DE VOTRE SYSTÈME

Vue Avant Vue Côté - Dégagement Vue Arrière

Types d'installation Retour/Retour ou indépendant

Voltage 120VAC @ 60 Hz

Ampérage 134W

Certication cCSAus

Débit d'air 220/300 cfm

22"

(557mm)

INSTALLATION SUR CONDUIT DU RETOUR

Vue Avant Vue Côté - Dégagement Vue Côté

17"

fantech

12"

(307mm)

12"

(307mm)

12"

(305mm)

12"

(305mm)

17"

(431 mm)

Page 15

living

Planification de l'installation

15

Pour l’installation d`un système intégré

• Vériez le dégagement des conduits du système pour monter

l’appareil en utilisant le système central à air forcé.

• Conditions de dégagement minimum pour l’entretien et le service de

l’appareil.

• Prise de courant électrique distincte.

• Intéraction entre le Système de Filtration HEPA et autres dispositifs

mécaniques.

Le Système de Filtration HEPA est un appareil avec conguration

multiple d’installations. Il est recommandé de prendre votre temps pour

planier l’installation.

Plusieurs types d’installations sont illustrés ci-dessous pour le Système

de Filtration HEPA:

• Sur le conduit du retour d’air, intégré avec le système central à air

forcé.

• Points centraux d’aspiration en utilisant un système avec réseau de

conduit.

• Consultez le fabricant pour d’autres applications spéciales./

Types d'intsallation

I. RETOUR AU SYSTÈME INTÉGRÉ DE RETOUR

SYSTÈME «DUCTING FLAIR »

Installation

Le Système de Filtration HEPA est conçu

pour une installation sur le conduit de retour

d’air du système central à air forcé. Ce

type d’installation élimine la nécessité d’un

réseau de conduit indépendant au système

central à air forcé. Si vous choisissez ce

type d’installation, il est recommandé que le

ventilateur du système central soit en fonction

continue pour maximiser la ltration.

SYSTÈME PAR CONDUITS

Installation

Le Système de Filtration HEPA peut

être converti pour utiliser des conduits

indépendants avec collets de 8 – pouce, pour

une application qui exige une installation de

conduits. Le kit inclus deux collets de 8 –

pouce, deux supports de montage mural ou de

plancher, le guide d’installation et les écrous

de xation.

CONSEIL POUR L’INSTALLATEUR

Le Système de Filtration HEPA ne

remplace pas le ltre du système

central à air forcé, l’entretien

régulier du ltre est nécessaire

pour permettre la bonne opération

du système

SYSTÈME «DUCTING FLAIR »

(RETOUR/RETOUR)

Return

Air Plenum

Forced Air Heating

/Cooling System

To living

space

SYSTÈME PAR CONDUITS

(AUTONOME)

Return

Air Plenum

Forced Air Heating

/Cooling System

To

space

L’INSTALLATION DEVRAIT ÊTRE EFFECTUÉE PAR UN PROFESSIONNEL CERTIFIÉ.

Assurez-vous de vérier auprès de vos codes de construction locaux et de votre fabricant du système central à air forcé.

II. SYSTÈME INDÉPENDANT

INSTALLATION DE GRENIER

Idéal pour des maisons sans système

central à air forcé. Assure la ltration et

de la circulation d’air dans toute la maison.

Le Système de Filtration HEPA doit être en fonction sans interruption

lorsque qu’une partie ou tout le système est installé dans un endroit

non-chauffée pour éviter la condensation dans les conduits lorsque les

conditions sont au-dessous de zéro (32°F, 0°C)

INSTALLATION AU SOUS-SOL

Le réseau de conduits se compose

habituellement d’une grille de retour

d’un côté de la maison, et d’une grille

d’approvisionnement à l’extrémité opposée

de la maison.

MODE

RANGE

C

°

INTERN

OFF

0

2

-

CONT

NORMAL

/

RECIRC

REDUCED

MAINTENANCE

R

É

T

E

É

/

R

E

V

M

CYCLES / HOUR

I

M

U

S

H

20 / 40

/

30/30

E

R

U

T

A

R

E

P

T

M

E

fantech

Page 16

16

Installation étape par étape

OUTILS REQUIS

• Un tournevis #2 « Philips »

ou « Robertson #1 »

• Mèche de 3/32 po

• Ciseau à métal

• Perceuse

EMPLACEMENT

Les connexions du côté retour doivent être

installées après dernier branchement sur le

plénum de reprise d'air et minimum Distance de 2

pieds linéaires de la fournaise.

Un cordon d'alimentation de 1,50 mètre est fourni

avec l'unité. Si non disponible, une prise 120VAC

doit être fournie.

Note à l'installateur

Référez-vous au guide d’opération pour

les détails sur la façon d’enlever la porte

et les ltres de l’appareil.

Conseil pour l'installateur

Intégrer le Système de Filtration HEPA

avec le système central à air forcé est

possible à l’aide d’un relais auxiliaire

optionel. Veuillez consulter les autorités

locales pour l’information sur l’installation

des produits électriques s’ils exigent

les services d’un technicien ou d’un

électricien certié.

INSTALLATION ÉTAPE PAR ÉTAPE

Les étapes impliquées pour le raccordement de l`appareil au conduit de retour d’air du système

central à air forcé sont comme suit:

Étape 1

Préparation du conduit de retour d’air

Déterminer un endroit qui satisfait les besoins de service et l’entretien de l`appareil et procédez à

couper les ouvertures comme illustré ci-dessous.

THIS LINE MUST BE LEVEL / CETTE LIGNE DOIT ÊTRE AU NIVEAU

Drill Hole (3/32")

Drill Hole (3/32")

Percer un trou

3/32")

Drill Hole (

Percer un trou

3.5"

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

Percer un trou

3.5"

Drill Hole (3/32")

Percer un trou

Tape A l’aide d’un ruban adhésif attache le modèle sur le conduit du retour d’air.

Coupez l’ouverture avec des ciseaux à métal et procédez à perforer les trous pour les écrous de xation.

Étape 2

Enlevez la porte et les ltres et couper l’isolation comme illustré ci-dessous.

Coupez l’isolation le long des 2

bordures intérieures des orices

de la sortie et de l’entrée d’air, ensuite enlevez l’isolation des ouvertures.

Coupez les quatre volets en métal pour libérer les orices « Ducting Flair » de leur support pour les

orices de la sortie et de l’entré d’air.

Drill Hole (3/32")

Percer un trou

Percer un trou

Drill Hole (3/32")

Percer un trou

16"

Drill Hole (3/32")

Drill Hole (3/32")

Percer un trou

Percer un trou

ATTENTION

Cut

CUT THE EDGES SHOWN ONLY

COUPER LES SURFACES INDIQUÉS SEULEMENT

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

Percer un trou

Item # 461481

Drill Hole (3/32")

Percer un trou

Drill Hole (3/32")

un trou

Percer

16"

Drill Hole (3/32")

Percer un trou

Préparation des orices « Ducting Flairs »

Une seule coupe permet un déplacement facile du morceau

d’isolation

L’appareil devrait ressembler

à ceci quand les morceaux

d’isolant sont déplacés.

SYSTÈME «DUCTING FLAIR »

Le Système de Filtration HEPA est conçu pour installation sur le conduit de retour d’air du système

central à air forcé. Ce type d’installation élimine

la nécessité d’un réseau de conduit indépendante

au système centrale à air forcé. Si vous choisissez ce type d’installation, il est recommandé que

le ventilateur du système central soit en fonction

continue pour maximiser la ltration.

Note à l'installateur

Il est recommandé que le Système de

Filtration HEPA aie une prise de courant exclusive de120 volts. Il n’est pas

recommandé de relier l’appareil à un

cordon prolongateur. Si aucun prise

n`est disponible veuillez consulter les

autorités locales pour l’information sur

l’installation des produits électriques

s’ils exigent les services d’un technicien

ou d’un électricien certié

fantech

Appliquez la bande scellement tout autour des deux ouvertures sur le dos de l’appareil.

Poussez les volets de métal vers l’extérieur approximativement à 90 degrés.

Étape 3

Installation de l’appareil

Insérez l’appareil en place. Repliez les orices « Ducting Flairs » complètement pour serrer l’appareil au conduit

de retour d’air. Installez l’unité comme d’ habitude à l’aide des vis fournis

.

Page 17

Installation étape par étape (suite)

17

VEILLEZ INSTALLER LES FILTRES SELON

LA DIRECTION DU DÉBIT D’AIR POUR UNE

PERFORMANCE MAXIMUM

Examinez le symbole de chaqu`un des ltres

pour s`assurer de la bonne direction de l`air. Il

est aussi inscrit sur le coffret du moteur de

l`appareil.

INSTALLATION ÉTAPE PAR ÉTAPE (suite)

Les étapes impliquées pour le raccordement de l`appareil au conduit de retour d’air du système central à

air forcé sont comme suit:

Étape 4

La nition

Stage 1: Pré-ltre

Stage 2: Filtre Charbon

Stage 3: Filtre HEPA

Enlevez les couvertures protectrice en plastique des ltres et

installez les à l’endroit approprié.

(Stage 1, 2 et 3)

Replacez la porte et insérez le

cordon de raccordement dans le

receptacle de l`appareil et l`autre

extrémité dans la prise murale.

INFORMATION GÉNÉRAL POUR LE FONCTIONNEMENT DE L’APPAREIL

COMMUTATEUR

SÉLECTEUR DE MODE

• II (300 PCM)

• I (220 PCM)

OPÉRATIONS

Filtration maximum

(300 PCM)

Filtration normal

(220 PCM)

FUNCTION

Le Système de Filtration HEPA est composé d’un

ventilateur, d’un commutateur de choix vitesse,

3 niveau de ltration. Le ventilateur tire l’air à

travers le pré-ltre et du ltre imbibé de charbon

qui capte les grosses particules et qui élimine

les odeurs et nalement la dernière phase de

ltration est le ltre HEPA qui enlève 99,97% de

particules 0.3µm de taille.

MODE DE FONCTION

L’unité comporte deux vitesses d’opération pour

votre convenance. Le commutateur de choix de

vitesse est situé sur le coffret avant du moteur.

À la plus basse vitesse l’appareil fournira un

débit d’air de 220 PCM, tandis qu’à la vitesse

maximum un débit d’air sera de 300 PCM .

Il est recommander que l’unité soit actionnée

sur la vitesse la plus élevée à tout moment

pour maximiser les avantages du Système

de Filtration HEPA. Si pour quelque raison

les besoins de ltration ne sont pas requis,

on pourrait alors actionner l’unité à la vitesse

réduite.

Une porte d’accès à

l’avant de l’appareil

permet l’accès facile

aux ltres et au

commutateur de

choix de vitesse. Un

commutateur « ON/

OFF» situé sur le coffret avant du moteur coupe

la puissance du moteur lorsque la porte d’accès

est ouverte pour votre sécurité. Si nécessaire la

porte peut être enlevée de l’appareil en tenant la

partie supérieure de la porte avec une main et

en tapent doucement sur le rebord inférieur de

la porte avec l’autre main pour libérer la porte de

ses charnières.

OPÉRATION RECOMMANDÉE

Le Système de Filtration HEPA intégré avec le

système central doit fonctionné en conjonction

avec votre système central à air forcé. Un

système central à air forcé de distribution circule

sans interruption le même air à l’intérieur de

votre maison. Le Système de Filtration HEPA

opère principalement avec une ltration par

déviation, qui signie qu’une partie de l`air étant

retourné dans le système central est ltrée sur

chaque passage. Avec une période de temps l’air

dans la maison devient plus sain et ltré. Il est

recommandé que le ventilateur de votre système

central soit en fonction, lorsque que le Système

de Filtration HEPA est en opération.

Pour l’installation indépendante de grenier,

le Système de Filtration HEPA doit être en

opération sans interruption lorsqu’une partie

ou tout le système est placé dans un endroit

non-chauffée pour éviter la condensation dans

le réseau de conduit, lorsque les conditions sont

au-dessous du point de congélation (32°F, 0°C).

L’entretien de l’appareil devrait être exécuté

à des intervalles réguliers pour assurer les

avantages de l’appareil du Système de Filtration

HEPA.

fantech

Page 18

18

Information générale d'entretien

QUAND DEVRAIT ON FAIRE

L’ENTRETIENT DE L’APPAREIL?

SERVICE ET ACCESSOIRES

L’information d’entretien est située sur la plaque

avant du coffret de moteur.

LE PRÉFILTRE AVEC CHARBON (463046)

Remplacez les ltres tous les 3 à 6 mois ou lorsque

nécessaire.

LE FILTRE HEPA (463048)

Remplacez tous les 2 à 5 ans ou lorsque

nécessaire.

À L’INTÉRIEUR DE L’UNITÉ

Une fois par an ou lorsque nécessaire, nettoyez

l’intérieur de l’unité avec du savon doux et nonabrasif. Il est recommandé d’utiliser des produits

non nuisibles à l’environnement.

Note au propriétaire/ installateur

DÉBRANCHEZ TOUJOURS L’UNITÉ

AVANT L’ENTRETIEN

REMPLACER LES FILTRES

Après avoir ouvert la

porte d’accès, saisit les

deux bords du ltre

et retirer avec force égale

du cabinet.

NETTOYAGE

En nettoyant une fois par

an ou comme nécessaire,

nettoyez l’intérieur de

l’unité employant le savon

non-abrasif doux. Il est

recommandé d’employer

les produits non nuisibles à

l’environnement.

DÉPANNAGE

DÉPANNAGE SUGGESTIONS

L'appareil ne fonctionne pas Le cordon est-il entièrement inséré dans

l’appareil? La sortie est-elle actionné? Le

commutateur de couplage de porte fonctionnet-il?

L’appareil fonctionne seulement sur une

vitesse

L’appareil vibre. Vérie l’excessif de poussière ou le contrepoids

Un l lâche possible à l’intérieur de la boîte

électrique, entrent en contact avec votre entrepreneur local.

manquand sur la roue du moteur.

DIAGRAMME DE CÂBLAGE

ÉLECTRIQUE

fantech

Page 19

Maintenance

19

Garantie

Calendrier

Date Entretien effectué Technicien

• Les moteurs sans entretien sont

graissés à vie et garantis pendant 7

ans. Ils sont en outre équilibrés en

usine pour prévenir les vibrations et

favoriser un fonctionnement

silencieux.

• Tous les autres composants

bénéficient d’une garantie limitée de

5 ans (filtres non compris).

• La garantie limitée est liée à une

utilisation normale. Elle ne couvre

pas les défauts, défauts de

fonctionnement ou défaillances

causés par une mauvaise installation,

un mauvais traitement, une

mauvaise manipulation, un usage

incorrect, un cas fortuit ou toute

autre circonstance indépendante de

la volonté du fabricant.

• Les pièces, y compris les pièces de

rechange posées ultérieurement,

sont garanties pendant 5 ans à

partir de la date d’achat de l’appareil.

Le moteur est garanti pendant 7 ans

à partir de la date d’achat. S’il

n’existe aucune preuve d’achat, la

date associée au numéro de série

devient la date de début de la

période de garantie. Une pièce de

rechange posée après l’expiration de

la garantie de la pièce d’origine est

garantie pendant 1 an.

• La présente garantie est la seule et

unique en vigueur; toutes les autres

garanties, expresses ou implicites,

sont invalides.

• La garantie du fabricant ne couvre

que les pièces; elle ne couvre ni le

coût de la main-d’oeuvre ni les frais

occasionnés par l’expédition des

pièces aux fins d’entretien ou de

réparation.

fantech

Page 20

20

Parts list • Liste des composantes

8

10

BOM # Description

1 Motor Assembly 463137

2 HEPA Filter 463048

3 Pre-filter with Carbon 463046

4 Capacitor, 10μF 410040

5 Capacitor, 30μF 412303

6 Door Switch 463114

7 Rocker Switch 463138

8 8” Collar Mount Kit 463085

9 Power Cord 463104

10 Door Hinge & Latch kit 463090

Wiring Diagram 463832

HERO HS300

(463870)

8

4

5

10

9

6

7

3

1

2

fantech

Page 21

Notes

21

fantech

Page 22

22

Notes

fantech

Page 23

Notes

23

fantech

Page 24

Fantech reserves the right to make technical changes.

For updated documentation please refer to www.fantech.net

Fantech®

Fantech se réserve le droit de faire des changements techniques. Pour de la documentation à jour, s'il vous plaît se

référer au www.fantech.net

Loading...

Loading...