Fantech 2SHE1021, 2SHE1871, 2SHE1221, 2SHE1661, 2SHE18B1 Operating Instructions & Parts Manual

...Page 1

perating Instructions & Parts Manual

O

2SHE07 thru 2SHE36

Please read and save these instructions.

bserving all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

o

Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by

Shutter-Mounted

Exhaust Fans

F

Description

Designed to ventilate stores, offices, factories, shops, farm buildings, etc. Efficient, easy-toinstall exhaust fan with automatic shutters. 7” to 36” diameter deep pitched propeller. Steel

intake guard complies with United States OSHA Federal 1/2” max. opening requirement. Wire

guard has charcoal gray metallic polyester finish to resist corrosion.

designed for wall mounting only.

Optional Accessories: Speed controllers, 3 amp model

NOTE: These units are

5ACC03SC, 5 amp model 5ACC05SC, 6 amp model 5ACC06AC, and 10 amp model 5ACC10SC.

A Sq.

39/16”

1/4 x 1/2” Slots

Figure 1 - Dimensions

Air Flow

B

3”

53/4”

C Sq.

Dimensions

Model Dia. A Sq. B C Sq.

2SHE0721* 07” 11

2SHE1021* 10 13

2SHE1221* 12 15

2SHE1661* 16 19

2SHE1871* 18 21

2SHE18B1 18 21

2SHE20B1W* 20 23

2SHE20B1X 20 23

2SHE20B1Y 20 23

2SHE20C1 20 23

2SHE24B1W* 24 27

2SHE24B1X 24 27

2SHE24C1G 24 27

2SHE24C1H‡ 24 27

2SHE30C1 30 33

2SHE36D1 36 39

(*) Speed controllable. (‡) Two speed.

Propeller

1

/8”

1

/8 59/16 10

1

/8 6

1

/8 61/2 16

1

/8 83/4 18

1

/8 12 1/2 18

1

/8 12 1/8 20

1

/8 12 1/8 20

1

/8 11 9/16 20

1

/8 12 1/8 20

1

/8 11 13/16 24

1

/8 12 5/16 24

1

/8 12 5/16 24

1

/8 13 5/8 24

1

/8 13 1/8 30

1

/8 13 1/8 36

15

4

/16”

08”

12

Unpacking

1. When receiving the unit, inspect carefully

for any damage that may have occurred

during transit.

2. Before installing, rotate the propeller to

be sure there are no obstructions which

would interfere with proper operation.

Adjust as required.

General Safety Infor

disconnecting power when installing or servicing the fan.

If the power disconnect is out-of-sight, lock it in the

open position and tag to prevent application of power.

Failure to do so may result in fatal electrical shock.

réparation du ventilateur, ne pas compter sur un

sélecteur comme seul moyen de coupure de

l’alimentation électrique. Si l’interrupteur d’alimentation

est hors de vue, le verrouiller en position d’arrêt et

apposer une plaquette interdisant son utilisation. À

défaut, un choc électrique pourrait être fatal.

1. Follow all local electrical and safety codes in

the United States and Canada, as well as

the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA)

in the United States, and the Canadian

Electric Code (CEC) in Canada.

cause injury.

2. Motor must be securely and adequately

grounded. This can be accomplished by

wiring with a grounded, metal-clad raceway

system, by using a separate

antech, Inc. and Systemair Mfg. certify

that the ventilators shown herein are

licensed to bear the AMCA Seal. The

r

atings shown are based on tests and

procedures performed in accordance with

A

MCA Publication 211 and AMCA

Publication 311 and comply with the

requirements of the AMCA Certified

R

atings Program.

mation

Do not depend on

any switch as sole means of

Do not touch motor.

May be hot enough to

Lors de

l’installation ou d’une

12118101

Page 2

Operating Instructions and Parts Manual

2SHE07 thru 2SHE36

G

eneral Safety Information

(Continued)

ground wire connected to the bare metal of

he motor frame, or other suitable means.

t

Motor will restart

without warning after

protector trips.

3. Always disconnect power source and lock it

in the open position before working on or

near a motor or its connected load.

In United States

to reduce the risk of injury

to persons, OSHA complying guards are required

when fan is installed within 8 feet of floor, ground, or

working level.

In Canada to reduce

persons, CSA complying guards are required when fan

is installed below 2.5 meters (8.2 feet) above floor or

grade level.

the risk of injury to

Do not use in

explosive atmospheres.

4. Be careful when touching the exterior of an

operating motor; it may be hot enough to be

painful or cause injury. With modern motors

this condition is normal if operated at rated

load and voltage; modern motors are built to

operate at higher temperatures.

5. Protect the power cable from coming in

contact with sharp objects.

6. Do not kink power cable and never allow the

cable to come in contact with oil, grease,

hot surfaces, or chemicals.

7. Make certain that the power source

conforms to the requirements of your

equipment.

Installation

1.Frame in the wall opening with 2 x 4”

lumber, to form a square. The opening

should be 1/2” larger than the shutter frame

(See Figure 1, dimension C).

2. Insert the fan (shutter end first) through the

opening. Attach the flange to the frame

using nails or screws (Not furnished).

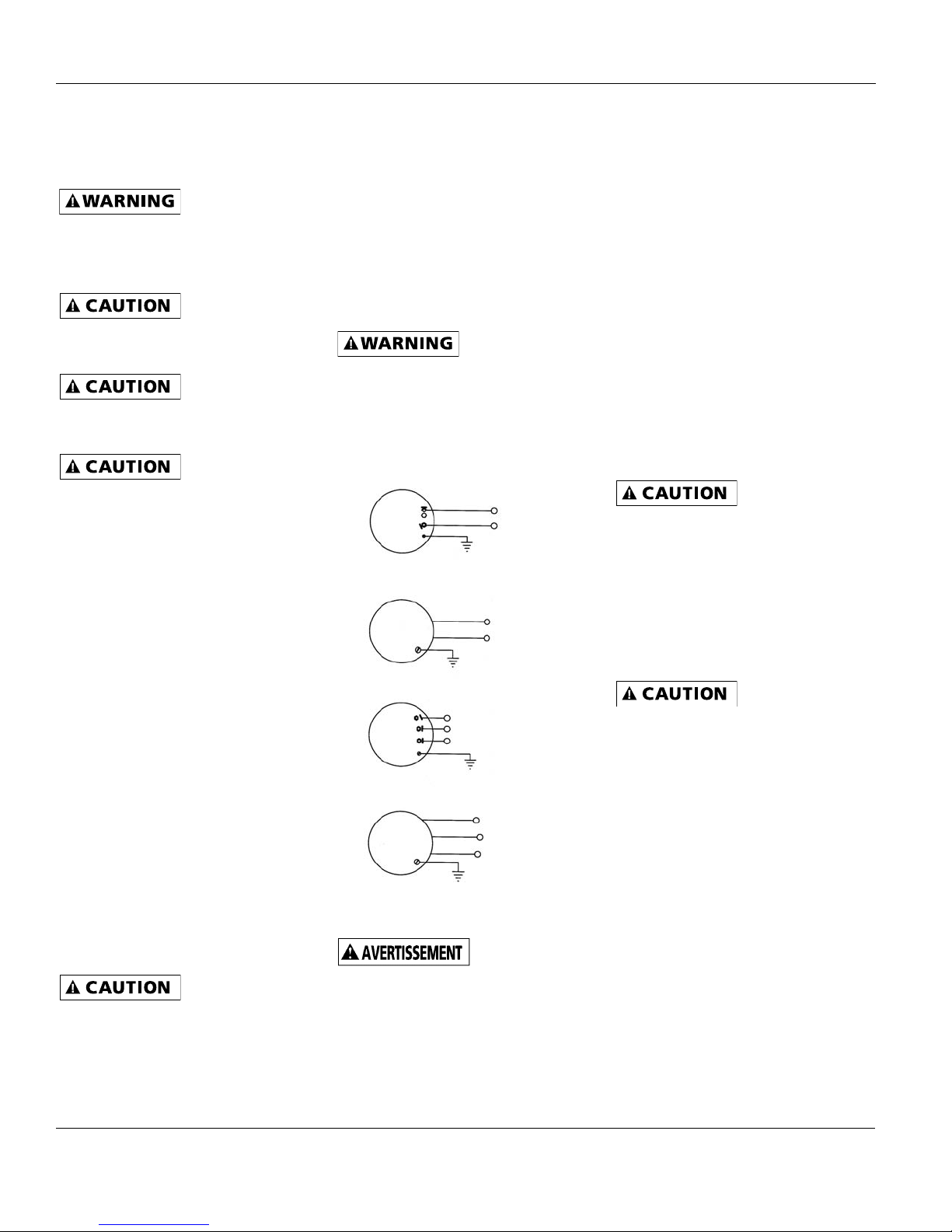

3. Connect power supply to the motor using an

approved wiring method. See preferred

wiring diagram in Figure 2.

The fan motor must

be securely and adequately

grounded to a suitable electrical ground such as a

grounded water pipe or ground wire system!

4. Before activating the fan, double-check to

ensure that there are no obstructions

(framing, stud, shutter, etc.) which would

interfere with proper fan operation.

O

peration

1. Keep the area free of objects that could

mpede air flow on either the intake side or

i

exhaust side of fan.

. For proper exhausting, a window, door, or

2

louver should be opened on the opposite side

of the area to be ventilated.

3.Turn the fan ON, the shutter will open

automatically. When the unit is turned OFF,

he shutter will close.

t

Maintenance

Do not depend on

any switch as sole means of

disconnecting power when installing or servicing the fan.

If the power disconnect is out-of-sight, lock it in the

open position and tag to prevent application of power.

Failure to do so may result in fatal electrical shock.

Single Speed

Line 1

Line 2

Single Speed

White

Black

Two Speed

H

C

L

Two Speed

White

Black

Red

Figure 2 - Wiring Diagram: 115 Volt Connection

ventilateur, ne pas compter sur un sélecteur comme

seul moyen de coupure de l’alimentation électrique.

Si l’interrupteur d’alimentation est hors de vue, le

verrouiller en position d’arrêt et apposer une

plaquette interdisant son utilisation. À défaut, un

choc électrique pourrait être fatal.

Line 1

Line 2

High

Common Line 1

Low

Common Line1

High

Low

l’installation ou

d’une réparation du

Minor and Routine

1.Disconnect and lock out power source

before servicing.

. Lubricate the motor sleeve bearings every six

2

months using S.A.E. 20 non-detergent oil.

Refer to Figure 2 for location of oil ports.

. Ball bearing motors are permanently

3

lubricated at the factory. No further

lubrication is necessary.

. Periodically clean the propellers, guard,

4

motor, and shutter of any accumulated dirt.

Parts Replacement

1. Refer to Figure 3 for parts placement.

2. Disconnect power before servicing.

3. Remove the four screws holding the guard

to the venturi panel. Remove the

guard/motor/propeller assembly.

4.Loosen the setscrew on blade hub and

remove the propeller.

Do not repair

damaged propellers. They

should be replaced with a properly balanced

replacement.

Maintenance

6. Loosen the nuts holding motor on guard and

remove motor. On split phase models, it is

also necessary to loosen and remove bolt and

nut holding wire brace to motor yoke tabs.

6. Reassemble the unit in reverse order of

disassembly.

Propeller is

installed hub first on motor

shaft, flush with end, and setscrew located over the

flat area.

2

Page 3

perating Instructions and Parts Manual

O

2SHE07 thru 2SHE36

2

6

Figure 3 — Replacement Parts Illustration

10, 13

1

12

11, 14

7

4

9

5

3

8

Replacement Parts List

Ref. 2SHE1661, 2SHE1871 2SHE18B1, 2SHE20 thru 2SHE24 2SHE30C1, 2SHE36D1

No. Description Qty. Qty. Qty.

1 Propeller 1 1 1

Shutter

2

3 Guard 1 1 1

4 Motor 1 1 1

5 Yoke brace — 1 1

6 Grommet — 4 —

7 10 x 3/4” Flat washer* — 4 4

3/8-24 x 1” HHCS screw*

8

3/8-24 Spinlock nut* — 1 1

9

10 #10-32 Spinlock nut* — 4 4

11

12 3/8 x 13/16” Flat washer*

13 #8-32 Spinlock nut* 4 — —

14 #10-32 x 1.0 HWH screw — — 8

(*) Standard hardware items, available locally.

#10-16 x 5/8” S.M. screw*

2SHE0721 thru 2SHE1221,

1

—

4

—

1

1

4

1

1

1

—

—

3

Page 4

Operating Instructions and Parts Manual

T

roubleshooting Chart

Symptom Possible Cause(s) Corrective Action

2SHE07 thru 2SHE36

Excessive noise 1. Dry motor bearings 1. Relubricate motor bearings

2. Loose propeller 2. Tighten setscrews in hub

3. Crooked or damaged propeller 3. Replace propeller

Fan inoperative 1. Blown fuse or open circuit breaker 1. Replace fuse or reset circuit breaker

2. Defective motor 2. Repair or replace motor

. Speed control set too low 3. Increase speed with controller

3

Insufficient air flow 1. Blocked intake or exhaust opening 1. Clear opening of obstruction or

increase size of opening

2. Low voltage 2. Determine cause and correct

3. Speed control set too low 3. Increase speed with controller

LIMITED WARRANTY: Fantech, Inc. warrants to the original purchaser that our products will be free from defects in material and workmanship for a period of one (1) year

from the date of shipment.

BY OPERATION OF LAW OR OTHERWISE, INCLUDING WITHOUT LIMITATION, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHETHER OR NOT THE PURPOSE OR

USE HAS BEEN DISCLOSED TO US IN SPECIFICATIONS, DRAWINGS OR OTHERWISE, AND WHETHER OR NOT OUR PRODUCTS ARE SPECIFICALLY DESIGNED AND/OR MANUFACTURED

BY US FOR PURCHASER'S USE OR PURPOSE.

This warranty does not cover any losses or damages due to misuse, accident, abuse, neglect, normal wear and tear, negligence (other than ours), unauthorized alteration,

use beyond rated capacity, or improper installation, maintenance or application. This warranty shall be null and void to the extent that purchaser supplied incorrect

information to us about the necessary product specifications or the environment in which the products were to be used, and our selection or design of the products for the

purchaser was based in part on such information.

If within thirty (30) days after purchaser's discovery of any warranty defects within the warranty period, purchaser notifies us thereof in writing, we shall, at our option,

repair, correct or replace F.O.B. point of manufacture, or refund the purchase price for, the products that we have found to be defective. Failure by purchaser to give such

written notice within the 30-day time period shall be deemed an absolute and unconditional waiver of purchaser's claim for such defects. Products repaired or replaced shall

be covered by this warranty for the remainder of the original warranty period or ninety (90) days from the date of shipment, whichever is longer.

Warranty claims should be sent to Fantech, Inc., Attn: Quality Department, 10048 Industrial Blvd., Lenexa, KS 66215. Included in the claim should be Order Number,

Model Numbers, Serial Numbers and a detailed description of the issues.

Purchaser assumes all other responsibility for any loss, damage or injury to persons or property arising out of the use of our products, either alone or in combination with

other products or components.

LIMITATION OF REMEDY AND LIABILITY: THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF ANY WARRANTY HEREUNDER SHALL BE LIMITED TO REPAIR, CORRECTION OR

REPLACEMENT, OR REFUND OF THE PURCHASE PRICE UNDER THE PRECEDING PARAGRAPH ENTITLED "LIMITED WARRANTY".

EMERSON VENTILATION PRODUCTS SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE AND IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR

CAUSE OF ACTION, SHALL OUR LIABILITY TO PURCHASER AND/OR ITS CUSTOMERS EXCEED THE PRICE PAID BY PURCHASER FOR THE SPECIFIC PRODUCT PROVIDED BY US THAT

GAVE RISE TO THE CLAIM OR CAUSE OF ACTION. PURCHASER AGREES THAT IN NO EVENT SHALL OUR LIABILITY TO PURCHASER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE

INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. The term "consequential damages" shall include, but not be limited to, loss of anticipated profits, business

interruption, loss of use or revenue, cost of capital, or loss or damage to property or equipment.

It is expressly understood that any technical advice furnished by us with respect to the use of our products is given without charge, and we assume no obligation or liability

for the advice given, or results obtained, all such advice being given and accepted.

THIS IS OUR SOLE AND EXCLUSIVE PRODUCT WARRANTY AND IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ARISING

For Customer/Technical Support call (800) 565-3548

United States

1712 Northgate Blvd.,

Sarasota, FL. 34234

Phone: 800.747.1762;

941.309.6000

Fax: 800.487.9915; 941.309.6099

www.fantech.net; info@fantech.net

Canada

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548;

506.743.9500

Fax: 877.747.8116; 506.743.9600

www.fantech.ca; info@fantech.ca

Fantech, reserves the right to modify, at any time and without notice, any or

all of its products’ features, designs, components and specifications to

maintain their technological leadership position.

Item #: 481810

Rev Date: 111408

Loading...

Loading...