Page 1

Installation and Operational Manual

fantech

1WHC • 1WMS Series

Wall Mount Cabinet Exhaust and Supply Fans

Item #: 481844

Rev Date: 080813

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Fantech, Inc. and Systemair

Mfg. certify that the ventilators shown herein are licensed

to bear the AMCA Seal. The

ratings shown are based

on tests and procedures

performed in accordance with

AMCA Publication 211 and

AMCA Publication 311 and

comply with the requirements

of the AMCA Certied Ratings

Program.

Page 2

2

Note Warning /

Information Technical

Important

note

Do not depend on any switch as the sole means of disconnecting power

when installing or servicing the fan. If the power disconnect is out-ofsight, lock it in the open position and tag to prevent application of power.

Failure to do so may result in fatal electrical shock.

1. Follow all local electrical and safety codes in the United States and

Canada, as well as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA) in the United States, and

the Canadian Electric Code (CEC) in Canada.

2. Make certain that the power source conforms to the requirements of

your equipment.

3. Motor must be properly grounded by wiring with a grounded metal

raceway system, using a separate ground wire connected to the bare

metal of the motor frame or other suitable means.

Motor will restart without warning after protector trips.

Practical tip

information

4. Protect the power cable from coming into contact with sharp objects.

5. Do not kink the power cable and never allow the cable to come in

contact with oil, grease, hot surfaces, or chemicals.

Do not use in explosive atmospheres.

In America to reduce the risk of injury to persons, OSHA complying guards

are required when fan is installed within 8 feet of floor, ground, or

working level.

In Canada to reduce the risk of injury to persons, CSA complying guards

are required when fan is installed below 2.5 meters (8.2 feet) above floor

or grade level.

7. Always disconnect power source before working on or near a motor

or its connected load. If the power disconnect point is out-of-sight,

lock it in the open position and tag to prevent unexpected application

of power.

Description

Wall cabinet exhaust and supply fans are high volume, belt-drive fans used for ventilation in commercial, industrial, and agricultural applications with

static pressures up to 0.25 wg.

Fans are completely assembled, ready for installation. Units feature a galvanized venturi and housing, high efficiency propeller, rubber isolated, pressfit pillow block ball bearings , and totally enclosed, air over, ball bearing motors. All fans are UL Listed, Subject 705, and CSA approved . Guards

comply with United States OSHA Federal 1/2” opening requirement. Fan drives feature a variable pitch motor pulley to reduce fan speed by approximately 20% to provide proper air volume for specific applications.

1WMC54KY is UL Listed Only and features a polyester powder coated venturi and cast iron pillow block bearings. Models 1WMC36G7

and 1WMC48H7 are not UL listed or CSA certified.

Unpacking and inspection

1. When receiving fan, inspect carefully for any damage that may have occurred during transit. Check for loose, missing, or damaged parts.

2. Before installing, rotate the propeller to be sure there are no obstructions which would interfere with proper operation. Adjust as required.

Do not insert fingers or foreign objects into fan.

fantech

Page 3

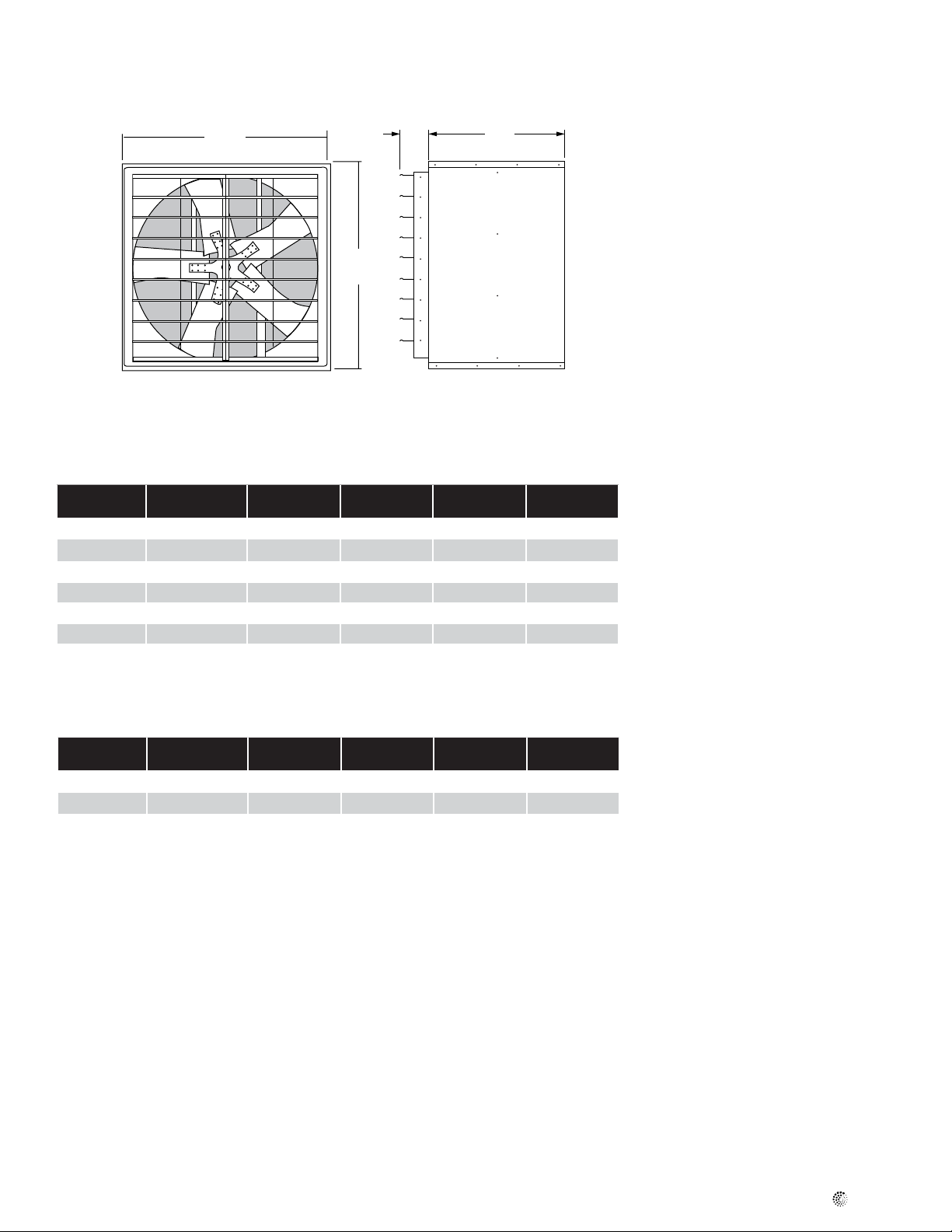

Dimensions

3

D

A

D

C

B

Figure 1: Dimensions

Table 1: Dimensional data Exhaust Fans

Model Fan size A B C Shipping Weight

1WMC24 24 28

1WMC30 30 34

1WMC36 36 40

1WMC42 42 46

1WMC48 48 54

1WMC54 54 60

/

4

1

/

4

1

/

4

1

/

4

1

/

4

1

/

4

28 1/

34

40 1/

46 1/

54 1/

60 1/

4

1

/

4

4

4

4

4

24 1/

25 1/

26 1/

28 1/

28 1/

47 3/

4

4

4

4

4

4

1

Dimensional information is in inches.

(Lbs)

123

176

196

242

288

635

Table 2: Supply Fans

Model Fan size A B C Shipping Weight

(Lbs)

1WMS24 24 28

1WMS36 36 40

1WMS48 48 54

1

/

4

1

/

4

1

/

4

28

40 1/

54 1/

1

/

4

4

4

30 143

32 1/

33 3/

4

4

208

311

Dimensional information is in inches.

fantech

Page 4

4

Installation

Drive Assembly

1. Place the motor base so that the anges are facing UP.

On motors with side conduit boxes. Interference may occur

with the side plates. In such instances, turn the base over

(anges down).

2. Secure the motor base to the frame tubes using the bolts provided.

Do not tighten the nuts at this time.

3. Mount the pulleys (motor and fan) on their respective shafts. A key is

included in the hardware package for the fan pulley. In all instances, the

larger diameter pulley mounts on the fan shaft. For some horsepower/

drive combinations, a bushed pulley is provided. The motor pulley

should be as close to the motor face as possible.

4. Slip the belt(s) into the fan pulley grooves.

5. Place the motor on the motor base so that the belt(s), hanging freely

Installation

1. Fans should be installed in a framed rigid

wall opening located where there will be no

obstruction to the ow of air into or out of

the fan.

NOT recommended for portable or

mobile installations or suspension

mounting with wire or chain.

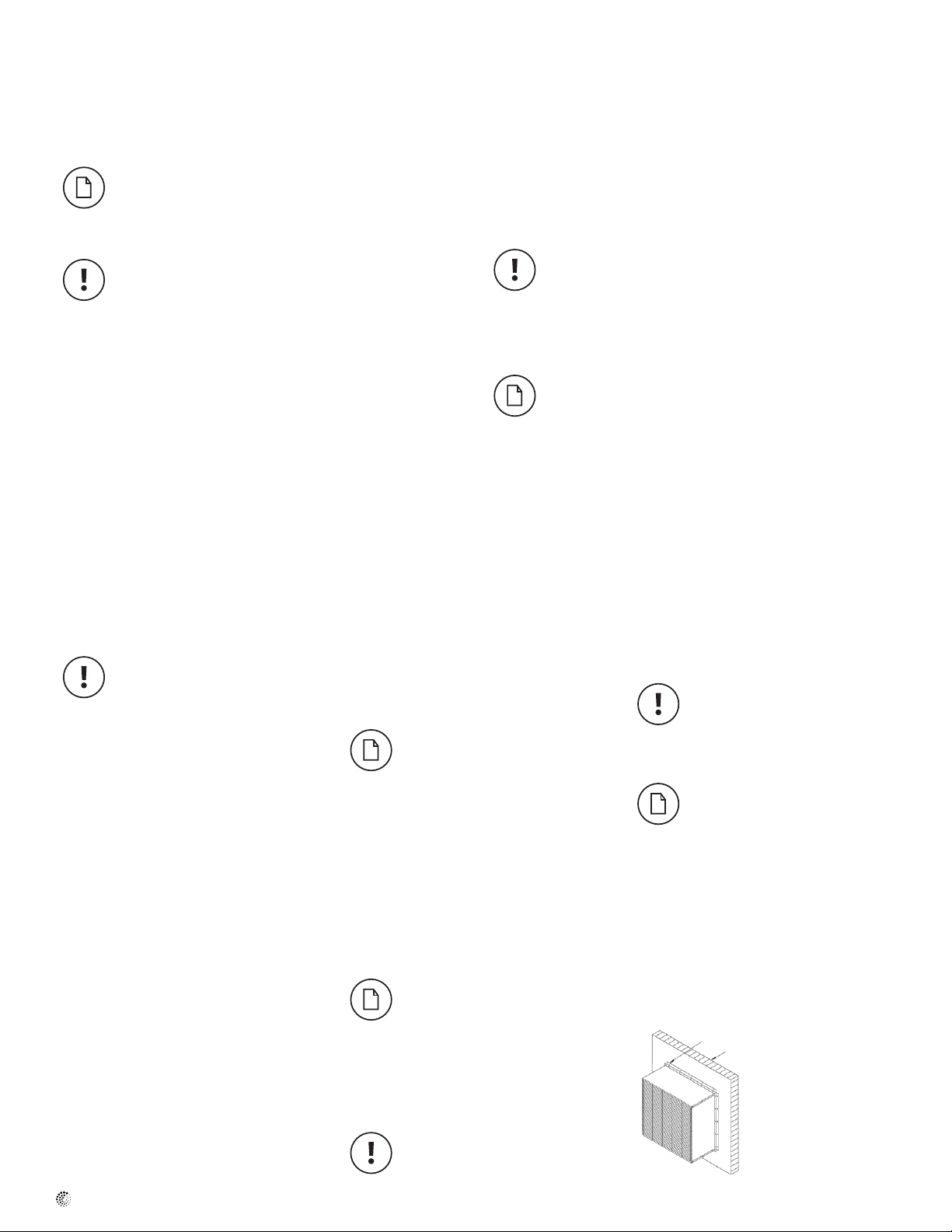

2. Once a location has been determined; an

opening should be made in the wall and

framed to provide 1/4 to 1/2” total clearance

around the fan housing, (Refer to “Dimension” table).

3. Framing must be able to support the weight

of the fan assembly, (Refer to “Dimension”

table for weight). Reinforce wall, depending

on the construction of the wall.

4. Position fan assembly in the framed opening. It is recommended that, for maximum

weather protection, the fan housing extend

beyond the exterior of the building as little as

possible. Supply fans require a weather hood

to reduce the risk of moisture entering the

building.

5. Attach (4) mounting angles to the fan housing and wall framing, (Refer to Figure 2).

a. Use pre-punched holes in mounting angles

as a template for drilling holes in fan

housing.

b. Bolt angles to housing using bolts, (5/16”

recommended, not supplied with unit). Every hole must be used. Do not skip holes.

c. Mounting angles must be securely

fastened to wall framing using hardware,

(not furnished) appropriate for the wall

construction.

Fan housing must be square in the

wall opening. The housing should be

level or tilted a maximum of 5° down

to the exhaust side.

6. Any gap between the fan housing and the

wall opening should be sealed from the

outside of the building.

7. Make certain that power source conforms to

the requirements of the fan.

8. Access the fan motor by removing the intake

guard.

The guard may be pivoted up, (or

down) by removing all but the (2)

top, (or bottom) corner fasteners.

Corner fasteners can act as hinges

to pivot guard and secure it out of

way. DO NOT overtighten fasteners

to avoid stripping the threads.

All electrical connections should be

made by a qualied electrician.

from the fan pulley, slip into the motor pulley grooves.

6. Position the motor on the base with the end of the motor shaft approximately even with the outer edge of the frame tubing. Align the

motor holes with the base holes and, using the bolts provided in the

hardware package, securely mount the motor. As the motor is drawn

down into position, tension will also be applied to the belt(s).

When assembling the motor and drive, the pulleys must be

aligned to keep the belt(s) straight. This is accomplished by

ensuring that the motor and fan pulley grooves are directly in

line with one another.

7. Adjust the motor base height as required to assure proper belt tension.

Proper tension is approximately 1/4” to 1/2” movement of the

belt when pressed at midspan under normal thumb pressure.

Do not overtighten the belt(s). However, new belts should be

tighter than used belts. On multiple belt installations, belts

should be matched and replaced only in sets.

9. Connect power to the motor using an

approved wiring method (motor terminal

connection data is provided on the motor

nameplate and on the motor terminal box

cover plate). Use adequate size wire for all

branch and feeder runs.

The fan motor must be securely and

adequately grounded to a suitable

electrical ground such as a

grounded water pipe or ground wire

system!

Motor cable should be routed

through fan housing using any one of

the knock-out positions provided.

Use grommet provided to protect

the motor cable from the knock-out

hole edges.

10. Before activating fan, inspect to be sure

that there are no obstructions or debris that

would interfere with propeller or the shutter.

11. Reposition intake guard in place and reinstall all fasteners.

12. Unit is ready for operation.

Mounting Angles

Wall

Figure 2 Mounting Angles

fantech

Page 5

Operation

1. Apply power to start and stop the fan. Be sure that the rotation of the propeller is correct as shown on the directional arrow on the unit.

2. Adjust for proper air volume.

a. Motor pulley is set from the factory for maximum fan speed/air volume.

b. Motor pulley can be adjusted by loosening set screw and unscrewing pulley by 1/2 turn (to keep set screw on at surface).

c. Adjust motor pulley until proper air volume is being exhausted.

If motor pulley has been adjusted, belt must be re-aligned by repositioning the propeller pulley on the fan shaft.

3. Upon initial operation, amps and, if possible, motor RPM should be checked against nameplate values to determine that fan is not being overloaded.

4. V-belt tension should be adjusted after rst 24 hours for proper operation. Belt(s) should deect 1/4” to 1/2” when depressed by thumb midpoint

between pulleys.

Maintenance

5

Do not depend on any switch as the sole means of disconnecting power when installing or servicing the fan. If the power disconnect is

out-of-sight, lock it in the open position and tag to prevent application of power. Failure to do so may result in fatal electrical shock.

1. Periodically check belt tension and adjust as necessary. Refer to “Operation” section.

2. When checking for belt tension, it is advisable to clean the intake guard, propeller, and exhaust shutter blades. This will remove any accumulated dirt

which could reduce air volume or cause propeller unbalance resulting in excessive vibration.

3. Fan pillow block bearings are prelubricated at the factory and require no further lubrication.

fantech

Page 6

6

Repair Parts List for Exhaust Fans

14

4

1

12

11

11

2

13

11

7

16

Figure 3: Repair parts illustration

Ref no. Description Part number for models:

WHV 24

1 Propeller 1

2 Motor 1

3 Intake guard 1

4 Exhaust shutter 1

5 Fan pulley 1

6 V-belt 1

7 Motor pulley 1

8 † Shaft/bearing assembly 1

9 1” Bearing, 6205 double dealed 2

10 Rubber bearing isolator 2

11 5/16-24 x .75 HHC screw* 16

12 5/16 x .688 x .065 F;at washer* 16

13 5/16-24 Spinlock nut* 16

14 10-32 x 1.0 HWH screw* 20-26

15 Guard retaining clip 12-14

16 Mounting angle 4

* Standard hardware item, available locally

† Replace entire shaft/bearing assembly (Item #8) unless facilities are available for pressing bearings onto shaft.

38, or 9, 10

15

5

14

6

fantech

Page 7

Troubleshooting

Symptom Possible causes Corrective Action

Excessive noise and/or

vibration

Fan inoperative 1. Blown fuse or open circuit breaker

Too much airow 1. Insufcient static pressure (SP)

1. Defective bearing or foreign material

inside bearing

2. Pulley not tight on shaft

3. Loose propeller

4. Loose belt(s)

5. Belt(s) are worn, oily or dirty

6. Misaligned pulley(s)

7. Crooked or damaged propeller

8. Motor or motor base not securely

anchored

9. Bent fan shaft

2. Broken belt

3. Loose pulley

4. Defective motor

5. Electricity turned off

2. Propeller running too fast

1. Replace entire shaft/bearing assembly

2. Check alignment and tighten setscrew

3. Tighten setscrews

4. Adjust tension

5. Clean or replace

6. Realign

7. Replace

8. Secure properly

9. Replace shaft/bearing assembly

1. Replace fuse or reset circuit breaker

2. Replace

3. Check alignment and tighten

4. Repair or replace

5. Contact local power company

1. Correct system pressure accordingly

2. Adjust variable pitch pulley to reduce propeller speed/air ow

7

Insufcient air ow 1. Shutter stuck shut

2. Fan speed too slow

3. Belt slippage

1. Repair

2. Check for proper pulley adjustment

3. Replace and/or adjust tension

fantech

Page 8

8

Warranty

Fantech, Inc. warrants to the original purchaser that our products will be

free from defects in material and workmanship for a period of one (1)

year from the date of shipment. THIS IS OUR SOLE AND EXCLUSlVE

PRODUCT WARRANTY AND IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, ARISING BY OPERATION OF LAW

OR OTHERWISE, INCLUDING WITHOUT LIMITATION, MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE WHETHER OR NOT THE

PURPOSE OR USE HAS BEEN DISCLOSED TO US IN SPECIFICATIONS,

DRAWINGS DR OTHERWISE, AND WHETHER OR NOT OUR PRODUCTS

ARE SPECIFICALLY DESIGNED AND/OR MANUFACTURED BY US FOR

PURCHASER’S USE OR PURPOSE.

This warranty does not cover any losses or damages due to misuse,

accident, abuse, neglect, normal wear and tear, negligence [other than

ours), unauthorized alteration, use beyond rated capacity, or improper

installation, maintenance or application. This warranty shall be null and

void to the extent that purchaser supplied incorrect information to us

about the necessary product specifications or the environment in which

the products were to be used, and our selection or design of the

products for the purchaser was based in part on such information.

Limitation of Warranty and Liability

THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF ANY WARRANTY

HEREUNDER SHALL BE LIMITED TO REPAIR, CORRECTION OR

REPLACEMENT, OR REFUND OF THE PURCHASE PRICE UNDER THE

PRECEDING PARAGRAPH ENTITLED “LIMITED WARRANTY”. FANTECH

VENTILATION PRODUCTS SHALL NOT BE LIABLE FOR DAMAGES

CAUSED BY DELAY IN PERFORMANCE AND IN NO EVENT,

REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION,

SHALL OUR LIABILITY TO PURCHASER AND/OR ITS CUSTOMERS

EXCEED THE PRICE PAID BY PURCHASER FOR THE SPECIFIC PRODUCT

PROVIDED BY US THAT GAUE RISE TO THE CLAIM OR CAUSE OF

If within thirty (30) days after purchaser’s discovery of any warranty

defects within the warranty period, purchaser notifies us thereof in

writing, we shall, at our option, repair, correct or replace F.O.B. point of

manufacture, or refund the purchase price for, the products that we have

found to be defective. Failure by purchaser to give such written notice

within the 30-day time period shall be deemed an absolute and

unconditional waiver of purchaser’s claim for such defects. Products

repaired or replaced shall be covered by this warranty for the remainder

of the original warranty period or ninety (90) days from the date of

shipment, whichever is longer.

Warranty claims should be sent to Fantech, Inc.,

Attn: Quality Department, 10048 Industrial Blvd., Lenexa, KS 66215.

Included in the claim should be Order Number, Model Numbers, Serial

Numbers and a detailed description of the issues.

Purchaser assumes all other responsibility for any loss, damage or injury

to persons or property arising out of the use of our products, either

alone or in combination with other products or components.

ACTION. PURCHASER AGREES THAT IN NO EVENT SHALL OUR

LIABILITY TO PURCHASER AND/OR ITS CUSTOMERS EXTEND TO

INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. The

term “consequential damages” shall include, but not be limited to,

loss of anticipated profits, business interruption, loss of use or revenue,

cost of capital, or loss or damage to property or equipment.

It is expressly understood that any technical advice furnished by us with

respect to the use of our products is given without charge, and we

assume no obligation or liability for the advice given, or results obtained,

all such advice being given and accepted.

Warning

Fantech products are designed and manufactured to provide reliable

performance, but they are not guaranteed to be 100% free from

defects. Even reliable products will experience occasional failures and

this possibility should be recognized by the user. If these products are

used in a life support ventilation system where failure could result in loss

or injury, the user should provide adequate backup ventilation,

supplementary natural ventilation, failure alarm system, or acknowledge

willingness to accept the risk of such loss or injury.

For Customer/Technical Support call (800) 565-3548

fantech

Page 9

Notes

9

fantech

Page 10

10

Notes

fantech

Page 11

Notes

11

fantech

Page 12

fantech

Fantech reserves the right to make technical changes.

For updated documentation please refer to www.fantech.net

Fantech®

Loading...

Loading...