Page 1

4 NOV 2016 - V 1.0

INSTALLATION MANUAL

SIENA SERIES

Page 2

CONGRATULATIONS

Congratulations and thank you for choosing

a Falmec rangehood.

To avoid the risks that are always present

when you use an electrical appliance it is

important that the rangehood is installed

correctly and that you read the safety

instructions carefully to avoid misuse

and hazards.

We recommend that you keep this

instruction booklet for future reference

and pass it on to any future owners.

Important Information

AFTER UNPACKING THE RANGEHOOD PLEASE REVIEW YOUR NEW ITEM TO ENSURE

THAT IT HASN’T BEEN DAMAGED IN TRANSIT OR IS MISSING ANY COMPONENTS.

FAILURE TO REPORT ANY ISSUE WITHIN 72 HOURS OF RECEIPT OF YOUR ITEM MAY

RESULT IN ADDITIONAL CHARGES.

Environmental Tip

Information on disposal for users

Most of the packing materials are recyclable. Please

dispose of those materials through your local

recycling depot or by placing them in a appropriate

collection bin.

If you wish to discard this product, please contact

your local authorities and ask for the correct method

of disposal.

TO AVOID THE RISK OF INJURY

OR DAMAGE TO THE PRODUCT IT

IS ESSENTIAL TO READ THESE

INSTRUCTIONS PRIOR TO

INSTALLATION AND USE

Page 3

PRODUCT DESCRIPTION & CARTON CONTENTS

CARTON 1 - HOOD UNIT

INTEGRATED HOOD - ON BOARD HOOD

Models include:

SIENA F3SN60S1, F3SN90S1 and F3SND90S1

Included in the carton:

1. Main hood housing including control module and lighting

2. Baffle filters

3. Grease trap

4. Fixing screws

5. Operating & installation guide

Page 4

SAFETY INSTRUCTIONS

AND WARNINGS

Installation operations are to be carried out by skilled and qualified

installers in accordance with the instructions in this booklet and in

compliance with the regulations in force.

DO NOT use the hood if the power supply cable or other components are damaged:

disconnect the hood from the electrical power supply and contact the Dealer or an authorised

Servicing Dealer for repairs.

Do not modify the electrical, mechanical or functional structure of the equipment.

Do not personally try to carry out repairs or replacements. Interventions carried out

by incompetent and unauthorised persons can cause serious damage to the unit or

physical and personal harm, not covered by the Manufacturer’s warranty.

WARNINGS FOR THE INSTALLER

TECHNICAL SAFETY

Before installing the hood, check the integrity and function of each part.

Should anomalies be noted, do not proceed with installation and contact

the Dealer.

Do NOT install the hood if an aesthetic (or cosmetic) defect has been detected. Put it

back into its original package and contact the dealer.

No claim can be made for aesthetic (or cosmetic) defects once it has been installed.

During installation, always use personal protective equipment (e.g.: Safety shoes) and adopt

prudent and proper conduct.

The installation kit (screws and plugs) supplied with the hood is only to be used on masonry

walls: in case of installation on walls of a dierent material, assess other installation options

keeping in mind the type of wall surface and the weight of the hood (indicated on page 2).

Keep in mind that installations with dierent types of fastening systems from those supplied, or

which are not compliant, can cause electrical and mechanical seal danger.

Do not install the hood outdoors and do not expose it to atmospheric elements

(rain, wind, etc.).

ELECTRICAL SAFETY

The electrical system to which the hood is to be connected must be in

accordance with local standards and supplied with earthed connection in

compliance with safety regulations in the country of use. It must also

comply with European standards regarding radio antistatic properties.

Before installing the hood, check that the electrical mains power supply corresponds with

what is reported on the identification plate located inside the hood.

The socket used to connect the installed equipment to the electrical power supply must be

within reach: otherwise, install a mains switch to disconnect the hood when required.

Any changes to the electrical system must be carried out by a qualified electrician.

The maximum length of the flue fastening screws (supplied by the manufacturer) must

be 13 mm. Use of non-compliant screws with these instructions can lead to danger of an

electrical nature.

Do not try to solve the problem yourself in the event of equipment malfunction, but contact the

Dealer or an authorised Servicing Department for repairs.

If the equipment is sold or transferred to another person, make sure that the booklet

is also supplied so that the new user can be made aware of the hood’s operation and

relative warnings.

After the stainless steel hood has been installed, it will need to be cleaned to remove any

residues remaining from the protection adhesive as well as any grease and oil stains which,

if not removed, can cause irreversible damage to the hood surface. To properly clean the

unit, the manufacturer recommends using the supplied moist wipes, which are also available

sold separately.

Insist on original spare parts.

INTENDED USE

The equipment is solely intended to be used to extract fumes generated from cooking

food in non-professional domestic kitchens: any other use is improper. Improper use

can cause damage to persons, things, pets and exempts the Manufacturer from

any liability.

The equipment can be used by children over the age of 8 and by persons with reduced

physical, sensory and mental abilities, or with no experience or knowledge, as long as they

do so under supervision or after having received relative instructions regarding safe use of the

equipment and understanding of the dangers connected to it.

Children are not to play with the equipment. Cleaning and maintenance by the user must not

be carried out by children without supervision.

USE AND CLEANING WARNINGS

Before cleaning or carrying out maintenance operations, disconnect the

equipment by removing the plug or switching o the main switch.

Do not use the hood with wet hands or bare feet.

Always check that all electrical parts (lights, extractor fan) are o when the equipment is not

being used.

The maximum overall weight of any objects placed or hung (if applicable) on the hood must

not exceed 1.5 Kg.

Always supervise the cooking process during the use of deep-fryers: Overheated oil can

catch fire.

Do not leave open, unattended flames under the hood.

Do not prepare food over an open flame under the hood.

Never use the hood without the metal anti-grease filters: in this case, grease and dirt will

deposit in the equipment and compromise its operation.

Accessible parts of the hood can be hot when used at the same time as the cooking

appliances.

Do not carry out any cleaning operations when parts of the hood are still hot.

There can be a risk of fire if cleaning is not carried out according to the instructions and

products indicated in this booklet.

Disconnect the main switch when the equipment is not used for long periods of time.

If other appliances that use gas or other fuels are being used at the same

time (boiler, stove, fireplaces, etc.), make sure the room where the fumes

are discharged is well-ventilated, in compliance with the local regulations.

INSTALLATION

only intended for qualified personnel

When installing the hood, disconnect the equipment by removing the plug

or switching o the main switch.

FUMES DISCHARGE SAFETY

Do no connect the equipment to discharge pipes of fumes produced from

combustion (for example boilers, fireplaces, etc.).

Before installing the hood, ensure that all standards in force regarding discharge of air out of

the room have been complied with.

USER WARNINGS

These warnings have been drawn up for your personal safety and those of

others. You are therefore kindly asked to read the booklet carefully in its

entirety before using the or cleaning the equipment.

The Manufacturer declines all responsibility for any damage caused directly, or

indirectly, to persons, things and pets as a consequence of failing to comply with the

safety warnings indicated in this booklet.

It is imperative that this instructions booklet is kept together with the equipment for

any future consultation.

Before installing the hood, carefully read the chapter “SAFETY

INSTRUCTIONS AND WARNINGS”.

TECHNICAL FEATURES

The technical specifications are exhibited on the labels located inside the hood.

POSITIONING

The minimum distance between the highest part of the cooking equipment and the

lowest part of the hood is indicated in the installation instructions.

Generally, when the hood is placed over gas cookers, the distance must be at least 65 cm

(25.6’’). However, according to an interpretation of standard EN60335-2-31 dated 11-07-2002

of TC61 (sub-clause 7.12.1 meeting 15 agenda item 10.11), the minimum distance between the

cooker and lower part of the hood can be reduced to the quota reported in the installation

instructions.

Should the instructions for the gas cooker specify a greater distance, this must be taken into

consideration.

Do not install the hood outdoors and do not expose it to outdoor environment (rain, wind, etc.).

Page 5

OPERATION

24h

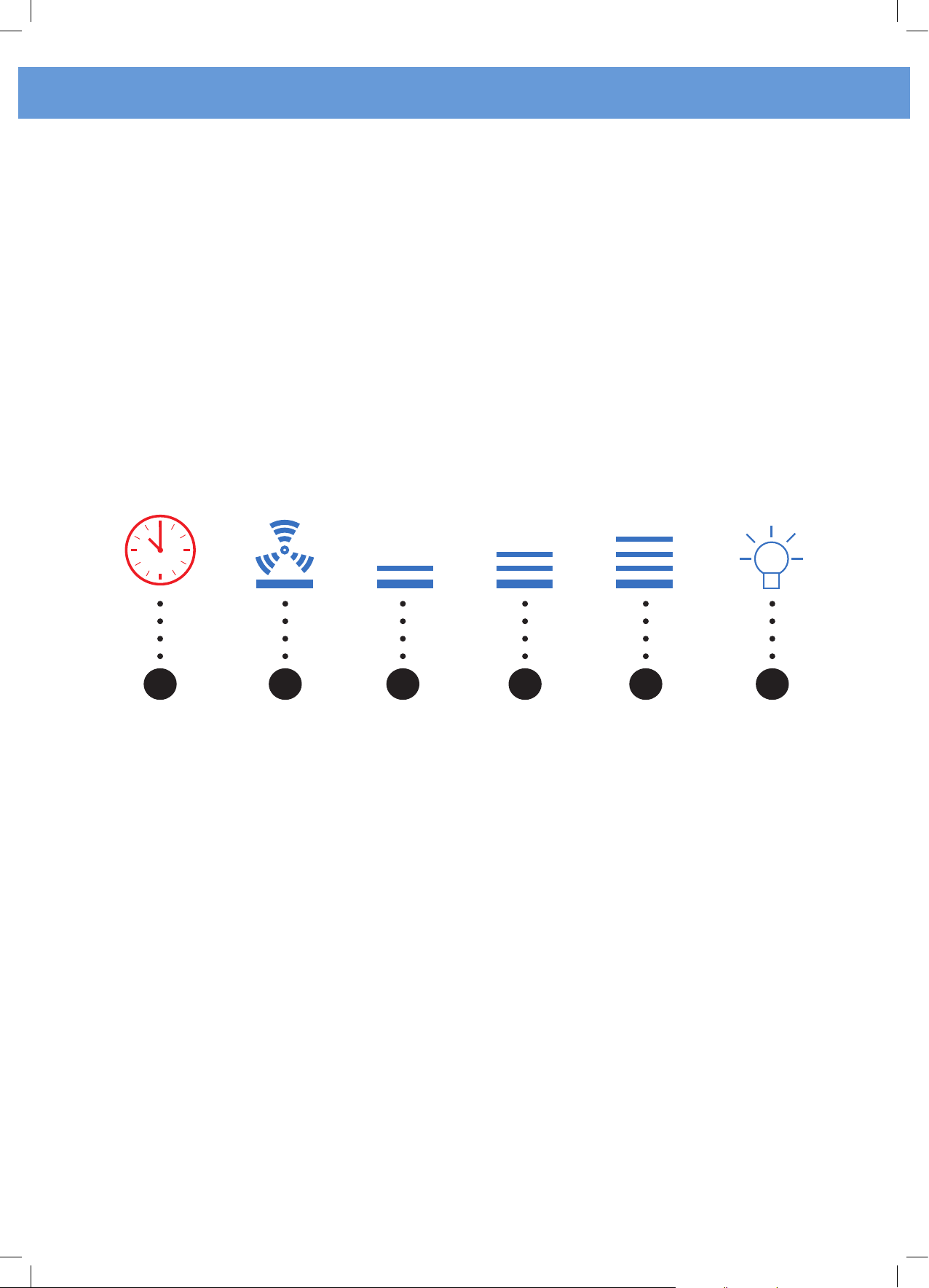

OPERATING YOUR CONTROL PANEL WITH THE 6 BUTTON TOUCH CONTROL

Turning the extraction function ON or OFF:

• In standby mode, press button 2 to turn on operating mode, then press buttons 3 through to 5 to change

the speed.

• The hood has three speed options and a boost speed plus the 24 recirculating mode.

• To turn hood off, press button 2 repeatedly until hood returns to standby mode.

Turning the light function ON or OFF:

Press button 6 to turn on or turn off the light in either standby mode or when the hood is in use. Light will remain on indefinitely

until switched off using button 6 again, otherwise will switch off when time elapses in timer mode (when in use).

Turning the timer function ON or OFF:

In operating mode, press button 1 to engage the timer function.

The default time set is 15 minutes and cannot be increased or decreased.

1 2 3 4 5 6

BUTTON 1:

TIMER (Red LED flashing)

Auto switch-off after 15 min.

The function deactivates (red LED off ) if:

- The motor turns off (key ).

- The speed is changed (keys +/-).

FILTER ALARM (red LED steady on)

Anti-grease filter maintenance after approximately

30 hours of operation. Press and hold the button for

3 seconds to reset.

BUTTON 2: Motor ON/OFF

Motor on/off and Speed1

If pressed for more than 3 seconds, it activates the 24h

cycle (1h ON -> 3h OFF -> 1h ON)

BUTTON 3: Speed 2 activation

BUTTON 4: Speed 3 activation

BUTTON 5: Speed 4 activation for 10 minutes only

BUTTON 6: Light on/off

Rangehood activates for 1 hour on speed 1 and then turns off

for 3 hours. This cycle repeats for the next 24 hours.

Page 6

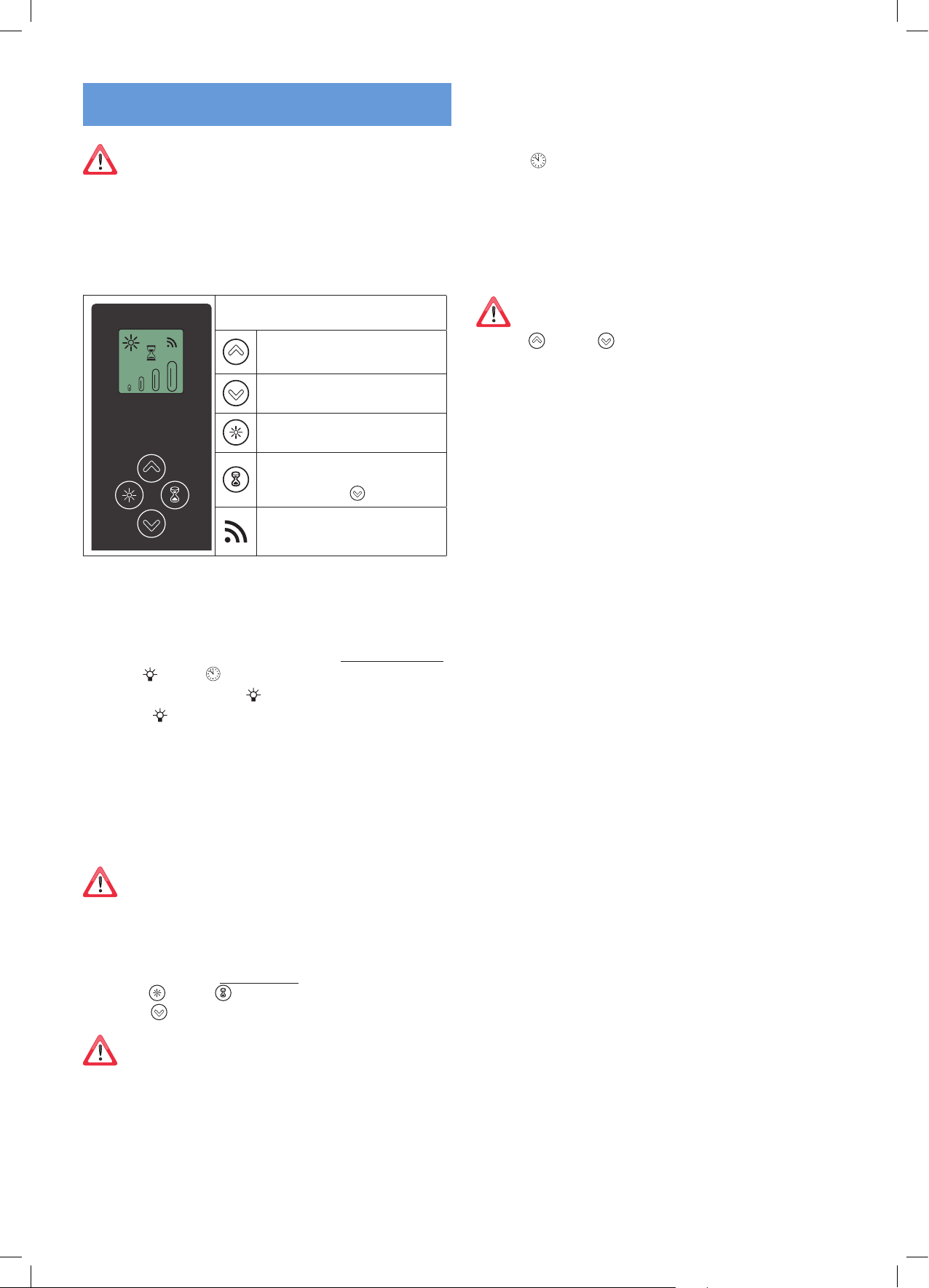

USING THE RADIO CONTROL

WARNINGS!:

The radio control is optional.

Follow the entire procedure described below if purchased.

Place the hood away from sources of electromagnetic waves (e.g. microwave ovens),

which could interfere with the radio control and with the hood electronics.

The maximum operating distance is 5 metres, that may vary according to the presence of electromagnetic interferences.

Radio control operated at 433.92MHz.

The radio control consists of two parts:

- the receiver built into the hood;

- the transmitter shown here in the figure.

PAIRING THE RADIO CONTROL WITH THE HOOD

USING THE ELECTRONIC PUSHBUTTON PANEL

press TIMER

the red LED lights up.

press any key on the radio control within 10 seconds.

RESTORING DEFAULT CODE

the procedure is to be carried out if the hood is disposed of, sold or transferred.

on the hood pushbutton panel for 2 seconds:

DESCRIPTION OF TRANSMITTING COMMANDS

UP

Motor switch-on and speed increase from 1

to 4. Speed 4 is only active for 10 minutes.

DOWN

Speed decrease and motor switch-o

Light ONOFF

TIMER ON: The motor automatically

switches o after 15 min.

The function is automatically disabled if the

motor is switched o (

Command transmission active

ACTIVATION PROCEDURE

Before using the radio control, follow the procedure below on the hood pushbutton panel:

• Press LIGHT

• Release the two keys and press LIGHT again until all LEDs are lit up.

• Release LIGHT : now the receiver is active.

This procedure is also used to deactivate the receiver.

and TIMER simultaneously until all LEDs start flashing.

key)

Disconnect the power to the hood before starting the procedure.

• Press UP

onds: reset is confirmed by three brief flashes of the display.

• Reconnect the hood to the electrical power supply.

• Proceed with associating the hood and the radio control, as described in point 2.

and DOWN simultaneously on the radio control for more than 5 sec-

RADIO CONTROL CODE CHANGE

With only one radio control, go directly to point 2.

With several radio controls in the same room, a new code can be created by following the

procedure below.

Disconnect the power to the hood before starting the procedure.

CREATE A NEW CODE

The procedure is to be carried out on the radio control.

• Press LIGHT

• Press DOWN

play. The new code cancels and replaces the previous default code.

Reconnect the hood to the electrical power supply, making sure that the

lights and motor are o.

and TIMER simultaneously until the display starts flashing.

on the radio control: saving is confirmed by three brief flashes of the dis-

Page 7

MAINTENANCE

Before cleaning or carrying out maintenance operations, disconnect the

equipment by removing the plug or switching o the main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease filters: frequent cleaning of the filters

and their supports ensures that no flammable grease is accumulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every 15 days to

prevent oily substances and grease from sticking to them. To clean the brushed stainless steel

hood, the Manufacturer recommends using "Magic Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a damp cloth,

slightly moistened with mild, liquid detergent or denatured alcohol.

Finish o cleaning by rinsing well and drying with soft cloths.

or abrasive cloths.

Do not use too much water next to the push button control panel and

lighting devices in order to prevent humidity from reaching electronic

parts.

DISPOSAL AFTER END OF LIFE

The crossed-out trash or refuse bin symbol on the appliance means that the

product is WEEE, i.e. “Waste electrical and electronic equipment’’, accordingly it

must not be disposed of with regular unsorted waste (i.e. with ‘’mixed house-

hold waste’’), but it must be disposed of separately so that it can undergo specific

processing for its re-use, or a specific treatment, to remove and safely dispose of any substances that may be harmful to the environment and remove the raw materials that can be

recycled. Proper disposal of these products contributes to saving valuable resources and

avoid potential negative eects on personal health and the environment, which may be

caused by inappropriate disposal of waste.

You are kindly asked to contact your local authorities for further information regarding the designated waste collection points nearest to you. Penalties for improper disposal of such waste

can be applied in compliance with national regulations.

INFORMATION ON DISPOSAL IN EUROPEAN UNION COUNTRIES

The EU WEEE Directive was implemented dierently in each country, accordingly, if you wish

to dispose of this appliance we suggest contacting your local authorities or dealer to find out

what the correct method of disposal is.

INFORMATION ON DISPOSAL IN NONEUROPEAN UNION COUNTRIES

The crossed-out trash or refuse bin symbol is only valid in the European Union: if you wish to

dispose of this appliance in other countries, we suggest contacting your local authorities or

dealer to find out what the correct method of disposal is.

The glass panels can only be cleaned with specific, non-corrosive or non-abrasive detergents

using a soft cloth.

The Manufacturer declines all responsibility for failure to comply with these instructions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside the hood,

with liquids or solvents.

For the internal metal parts, see the previous paragraph.

LIGHTING

The range hood is equipped with high eciency, low consumption LED spotlights with extremely long duration under normal use conditions.

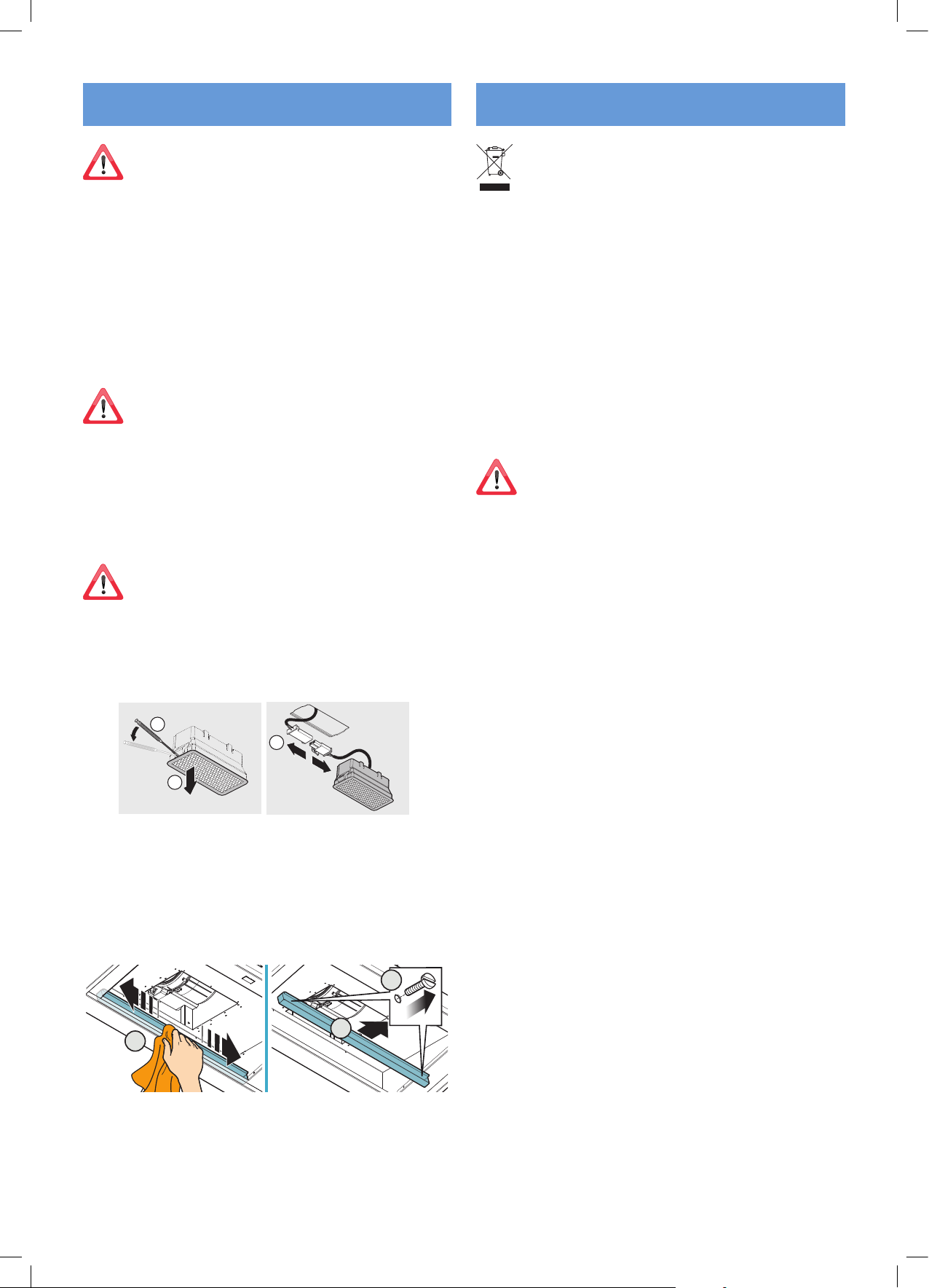

Should the LED spotlight need to be replaced, proceed as shown in the figure.

1

3

2

12V

GREASE DRIP TRAY

WARNING!

The Manufacturer reserves the right to make changes to the equipment at any time and without prior notice. Printing, translation and reproduction, even partial, of this manual are bound

by the Manufacturer’s authorisation.

Technic al information, graphic representations and specifications in this manual are for information purposes and cannot be divulged.

This manual is written in Italian. The Manufacturer is not responsible for any transcription or

translation errors.

It is advisable to clean the tray every 15 days.

Do not use corrosive, acid or alkaline detergents.

For more thorough cleaning, remove the oil collection tray (see figure) and wash it with hot water and washing up liquid. Rinse it well and wait for it to be completely dry before reassembling

it. They are dishwasher safe.

2

3

1

Page 8

FUMES DISCHARGE (SIENA F3SN60S1, F3SN90S1 and F3SND90S1 ONLY)

In this version the fumes and vapours are discharged outside through the exhaust pipe.

To this end, the hood outlet fitting must be connected via a pipe, to an external output.

The outlet pipe must have:

• A diameter not less than that of the hood fitting.

• A slight slope downwards (drop) in the horizontal sections to prevent condensation from flowing back into the motor.

• The minimum required number of bends.

• The minimum required length to avoid vibrations and reduce the suction performance of the hood.

Page 9

HOOD INSTALLATION GUIDE - INTEGRATED HOODS - ON BOARD MOTOR

INTEGRATED HOOD

Models include SIENA F3SN60S1, F3SN90S1 and F3SND90S1

WARNING

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING, PR KITCHEN & WASHROOM

SYSTEMS PTY LTD RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE.

FOR BUILDING PURPOSES THE UNIT SHOULD BE PROVIDED TO THE CABINET MAKER /

BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

CONFIGURING HOOD FOR BACK DUCTED INSTALLATION

Note: Hood is delivered in with motor positioned for ducting through top of unit. To change to back ducted postion, perform

the following steps

STEP 1 (F3SN60S1 & F3SN90S1 MODELS ONLY):

Remove the screws from within the main body of the rangehood along the back above the grease trap, on the left and right side . Once

the screws are removed, the main body of the rangehood will separate away from stainless steel fascia. Following this, remove the panel

containing the led lights and controller and set aside.

STEP 2:

Remove external face plate covering back ducted hole by unscrewing at the two fixing points. Inside the hood locate the four fixing screws

holding the motor and fixing plate to the top of the rangehood chasis.

Remove the screws, unplug motor and then proceed to lift it up out of the chassis and rotate 180° horizontally and 90° vertically in a anticlockwise direction. Lower the motor back into the chassis and push flange through exposed hole in back of the chassis.

NOTE: Motor on the deep model does not need to be lifted out in order to be rotated and can be done so inside of chassis.

STEP 3:

Re-secure the motor and fixing plate to the back of the chassis with the 4 screws removed in step 2. Finally re-secure the lighting and control

panel along with external surround removed in step 1

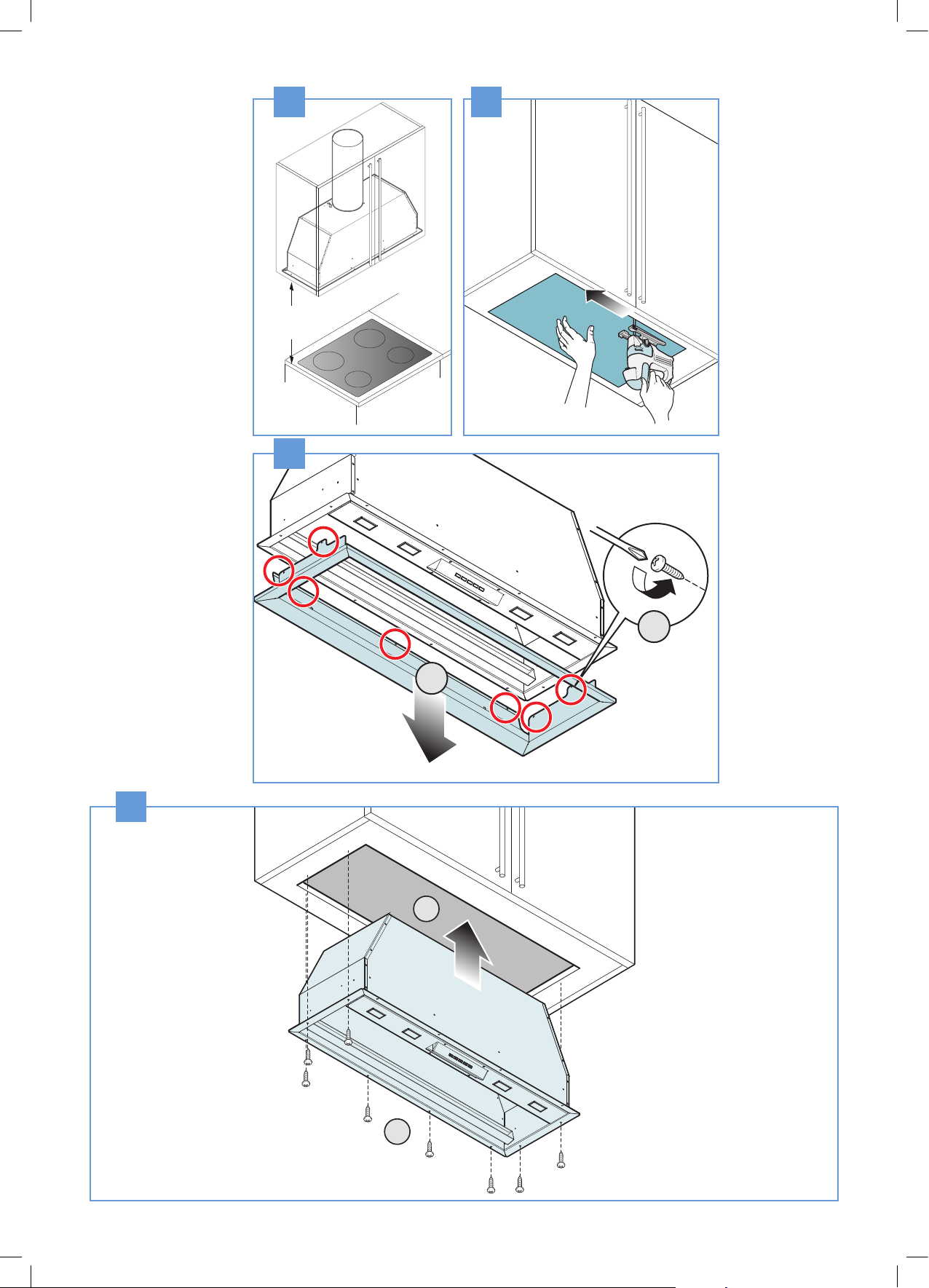

HOOD INSTALLATION

STEP 1:

To install into your overhead cupboard, several holes may need to be cut into shelves to enable the ducting to exit the cavity. Ensure the hood

is mounted as close to the centre of the cooking surface as possible.

NOTE:

The height of the underside of the hood body must be a minimum of 600 mm above an electric cooktop & 650 mm above a gas cooktop and

a maximum height of 1200 mm. If the instructions of the hob specify a greater distance than the minimum detailed, this shall be the minimum

height for installation. Building codes that stipulate a minimum dimension may vary from state to state, please check with your local council

prior to installation.

STEP 2:

If a shelf is fitted within the cupboard cut out a central 155mm hole in the shelf for ducting, matching the holes position to that of the outlet on

top of the hood. Additional holes might need to be cut to feed the duct out to the roof cavity.

STEP 3:

Remove the screws from within the main body of the rangehood along the back above the grease trap, on the left and right side . Once the

screws are removed, the main body of the rangehood will separate away from stainless steel fascia.

Page 10

HOOD INSTALLATION GUIDE - INTEGRATED HOODS - ON BOARD MOTOR

STEP 4:

The returns on the main body are now exposed. These are used to fix the main body on to the cabinetry. Place the hood in the cabinet in the

level position ensuring that the controls and display will be visible when standing in front of the unit. Using the pre-drilled mounting holes,

screw the hood into position.

STEP 5:

Once the main body is secure into the cabinetry the stainless steel fascia can then be slid inside the main body. The fascia will cover the

screws that have fixed the main body into the cabinetry. Place the screws back into place which were removed in step 3.

STEP 6:

Connect the hood outlet (in the top or back ducted position) to 150 mm ducting leading to an external output.

STEP 7:

Attach the male plug of the rangehood unit to the main power supply.

Note to electricians: Standard 10 amp general power outlet (GPO) required. Position GPO as close to the hood unit

as possible.

GREASE TRAP AND BAFFLE FILTERS:

The integrated range of hoods utilize a removable grease trap that is used to catch excess amounts of grease and condensate from the

baffle filters. This trap can be removed for cleaning. The trap consists of a concave channel with fixing points in the channel of the trap. The

baffle filters will then sit within the channel, with the filter vanes running downward.

Page 11

1 2

600650

mm

3

1

2

4

3

4

Page 12

5

6

2

1

2

7 8

2

1

3

Page 13

SIENA 60 / 90

87

379 / 688

505 / 815

560 / 870

512 / 822

247

331

341

238

280

150

280

250

CUTOUT DIMENSIONS

Page 14

SIENA 90 DEEP

326

562

236

353

228

804

870

87

150

10 321

380

814

CUTOUT DIMENSIONS

330

Page 15

PROFESSIONAL WARRANTY

All FALMEC range hoods and remote motors come with a 5 year parts and labour warranty. PRKS will correct, free of charge, any defects in

material or workmanship for the period of 5 years, subject to the terms of our warranty stated below.

In addition to this warranty stated above, all remote motors from both the Designer and Professional series are covered for an additional 5

years motor replacement warranty.

This warranty will be void if any model is used for commercial purposes. Some examples of commercial purposes include, but are not limited

to restaurants, cafés, schools, clubs.

All Designer and Professional (with the exception of BBQ models) rangehoods are designed and warranted “strictly for indoor use

(household kitchen) only.

Please note: The benefits provided by this warranty are in addition to all other rights and remedies in respect to the product which the

consumer has under the Australian competition and Consumer Act 2010.

1. This warranty only applies for products installed by a qualified person and when provided with a certificate of compliance in accordance

with State/Territory laws.

2. This product must be used in accordance with the manufacturer’s instructions. This warranty does not apply should the defect in or

failure of the product be attributable to misuse, abuse, accident or non-observation of the manufactures instructions on the part of the

user. FALMEC appliances does not accept liability for any direct or consequential loss, damage or other expense caused by or arising

out of any failure to install or use the product in accordance with the manufacturer’s instructions.

3. The warranty does not cover failures due to normal wear and tear with reasonable use or consumable components such as globes,

filters, etc.

4. Turbulence or motor noise is not considered a warrantable item and is considered part of the normal operation of the rangehood. The

level of noise experienced will depend on several contributing factors such as power level, duct length and position of remote motor

placement.

5. PRKS, at its own discretion may replace or repair any defective component(s) to affect a repair due to any faulty workmanship and

material. The warranty does not cover breakage of outer glass panels attributed to external damage.

6. The warranty provided is a “Repair Warranty” and in an extreme event if a repair cannot take place, a replacement will be provided of an

equivalent current model where the balance of the warranty period from the original date of purchase will take effect.

7. This warranty is immediately void if the serial or model number label is removed, defaced, serviced or repaired by a unauthorised/

unqualified personal or used for industrial/commercial purposes.

8. Warranty will be only provided when a proof of the original purchase is presented to an authorised dealer or reseller before or at the time

of service.

9. This warranty does not cover any corrosion or defect as a result of the product being installed in an environment in which the appliance

is not protected from the weather.

10. It is the responsibility of the customer to ensure the appliance is easily accessible for a service technician to carry out required repairs.

Any obstruction prohibiting access to the product by building materials of any kind will be required to be removed and reinstalled by the

customer.

11. This warranty covers the first 50 km travelled by a repair technician to the appliance location and return. Any travel in excess of 50 km

each way is not covered by the warranty.

PRKS has a service network in all metropolitan areas and most regional areas. Where the warranty claim has been made outside a radius of

50 km from any store where the product can be purchased, the customer is responsible for the cost of delivery to the nearest service agent

or the travel cost for a technician to travel to a location outside the 50 km radius

YOUR STATUTORY RIGHTS

FALMEC products fully assures all customers that our goods come with guarantees that cannot be excluded under the Australian Consumer

Law. You are entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a

major failure. You are also entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable

loss or damage.

The benefits under FALMEC’s warranty are in addition to other rights you have at law in relation to the appliances or services to which the

warranty relates.

Page 16

PROFESSIONAL WARRANTY

OUTDOOR USE OF PROFESSIONAL RANGEHOODS

Outdoor BBQ models from the Falmec Professional series are warranted for use above barbecues and in alfresco areas with one open wall

and a solid roof such as that they are not exposed to the elements.

Professional BBQ models MUST only have the specified 2010 m3/h motor installed in conjunction with the hood.

In the scenario where the hood is located near the ocean or exposed to salty air, regular care and cleaning of the hood is recommended to

prevent any corrosion. Corrosion is not considered as a defect unless reported prior to the initial install.

This warranty will be void if the outdoor models from the Falmec Professional series are used for commercial purposes. Some examples of

commercial purposes but not limited to, include restaurants, cafés, schools, clubs.

REMOTE MOTORS

In addition to the standard 5 years parts and labour warranty stated above, all remote motors from both the Designer and Professional Series’

are covered for an additional 5 year parts only warranty, therefore giving a total coverage of 10 years. This warranty covers replacement of

any parts subject to manufacture defect but does not cover any labour associated with the install of said parts. This warranty is conditional

by the following items:

• If installed in coastal applications the external housing must have a anti-corrosive coating applied. The internal fan may also require

additional cleaning/washdown as a result of exposure to salt in the air.

• Fan must be installed in a position that it will not be subjected to excessive duct temperatures (40° covers all models)

• Filters must be in place within the rangehood and regularly maintained/cleaned/replaced as needed.

SUPPORT

At PRKS we place great importance on customer satisfaction and that is why we have established a dedicated and experienced customer

support team that you can rely on.

Should you ever need to make a warranty related enquiry about your FALMEC product simply call 03 9700 9100 (Australia)

or 09 964 0400 (New Zealand) to speak with our friendly customer service consultants. We suggest you have the following

information close at hand to make the process as easy as possible:

1. Model number of your appliance

2. Serial number of your appliance

3. A copy of your original purchase receipt

4. Address details of where the appliance is installed

Loading...

Loading...