Features at +2.7V

•80µA supply current per channel

• 1.2MHz gain bandwidth product

• Output voltage range: 0.01V to 2.69V

• Input voltage range: -0.25V to +1.5V

• 1.5V/µs slew rate

• LMV321 directly replaces other industry standard LMV321

amplifiers; available in SC70-5 and SOT23-5 packages

• LMV358 directly replaces other industry standard LMV358

amplifiers; available in MSOP-8 and SOIC-8 packages

• LMV324 directly replaces other industry standard LMV324

amplifiers; available in TSSOP-14 and SOIC-14 packages

• Fully specified at +2.7V and +5V supplies

• Operating temperature range: -40°C to +125°C

Applications

• Low cost general purpose applications

• Cellular phones

• Personal data assistants

• A/D buffer

• DSP interface

• Smart card readers

• Portable test instruments

• Keyless entry

• Infrared receivers for remote controls

•Telephone systems

• Audio applications

• Digital still cameras

• Hard disk drives

• MP3 players

Description

The LMV321 (single), LMV358 (dual), and LMV324 (quad)

are a low cost, voltage feedback amplifiers that consume only

80µA of supply current per amplifier. The LMV3XX family

is designed to operate from 2.7V (±1.35V) to 5.5V (±2.75V)

supplies. The common mode voltage range extends below the

negative rail and the output provides rail-to-rail performance.

The LMV3XX family is designed on a CMOS process and

provides 1.2MHz of bandwidth and 1.5V/µs of slew rate at a

low supply voltage of 2.7V. The combination of low power,

rail-to-rail performance, low voltage operation, and tiny package options make the LMV3XX family well suited for use in

personal electronics equipment such as cellular handsets,

pagers, PDAs, and other battery powered applications.

LMV321, LMV358, LMV324

General Purpose, Low Voltage, Rail-to-Rail Output Amplifiers

www.fairchildsemi.com

Rev. 1 November 2002

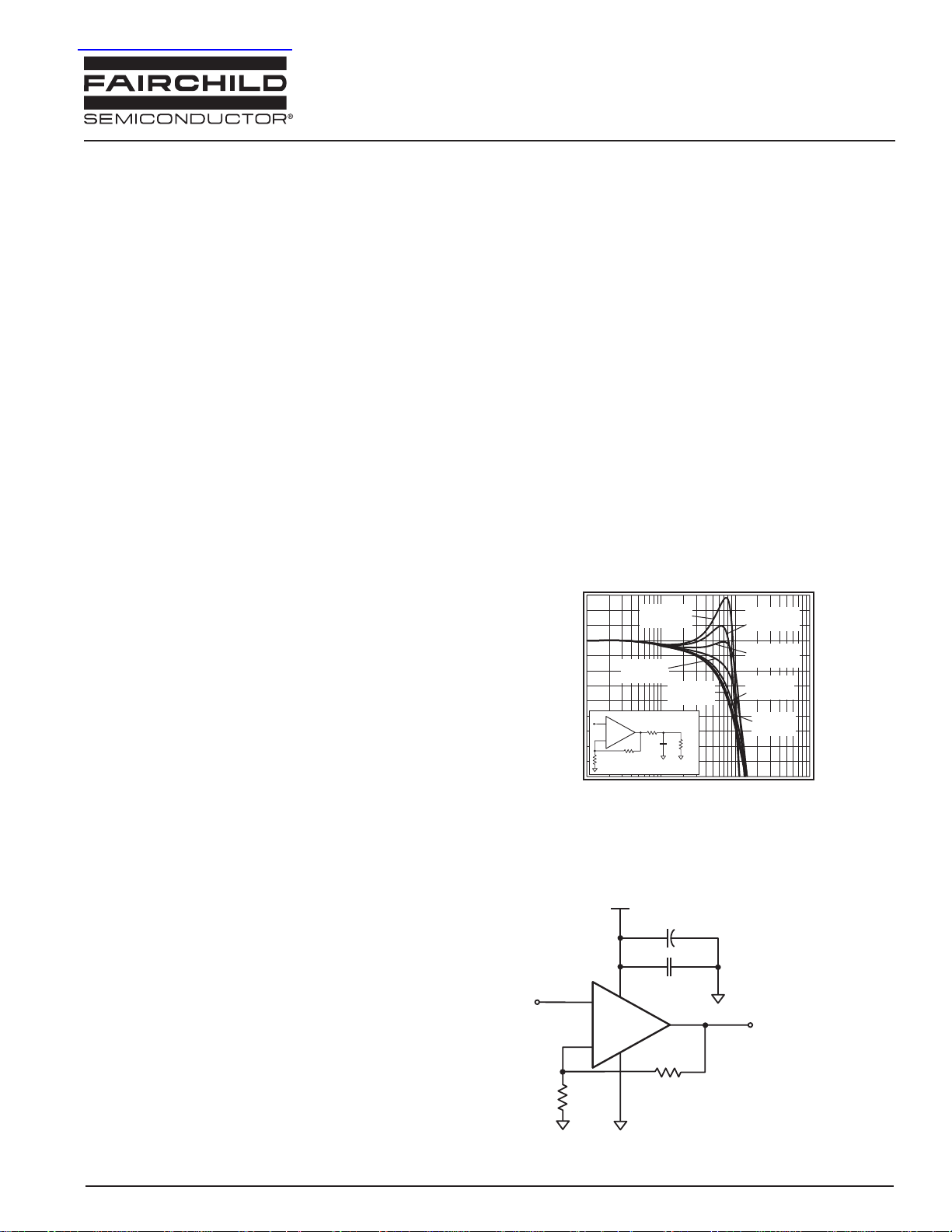

Typical Application

查询LMV321AP5NL供应商

Frequency Response vs. C

CL = 200pF

= 0

R

s

CL = 50pF

= 0

R

s

CL = 20pF

R

s

+

R

10kΩ

Frequency (MHz)

s

0.1

C

2kΩ

L

Magnitude (1dB/div)

10kΩ

0.01

= 0

L

CL = 200pF

R

CL = 100pF

R

CL = 10pF

R

1

= 225Ω

s

= 0

s

= 0

s

CL = 2pF

= 0

R

s

10

+In

R

g

+V

s

+

LMV3XX

-

6.8µF

+

0.01µF

R

f

Out

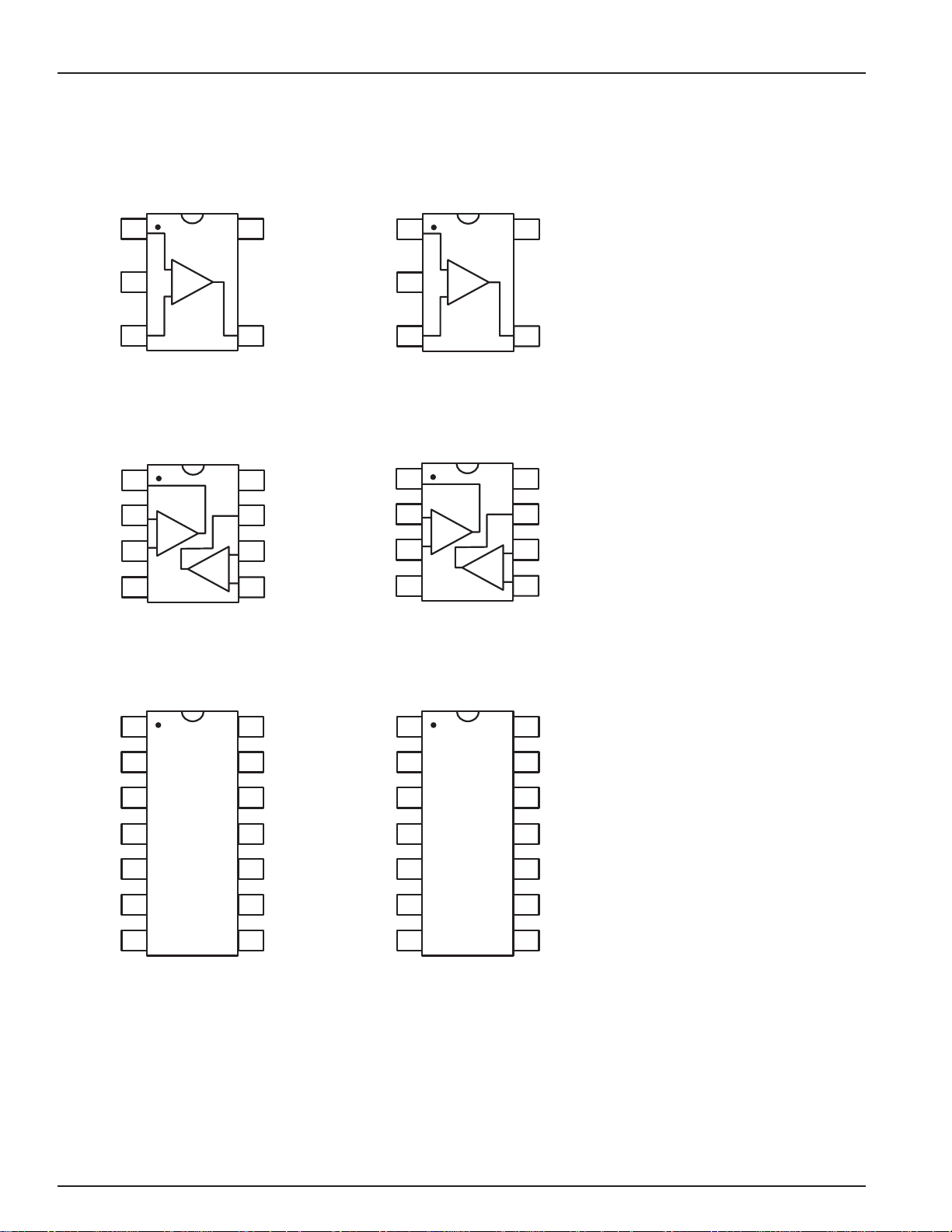

DATA SHEET LMV321/LMV358/LMV324

2 Rev. 1 November 2002

LMV321

SC70-5

LMV358

MSOP-8

SOIC-8

LMV324

TSSOP-14

SOT23-5

Pin Assignments

SOIC-14

+In

-V

s

-In

Out1

-In1

+In1

-V

s

1

2

3

1

2

3

4

+

–

-

+

+V

5

4

8

7

6

-

+

5

s

Out

+V

s

Out2

-In2

+In2

Out1

-In1

+In1

+In

-V

-In

-V

1

+

2

s

–

3

1

2

-

+

3

4

s

-

+

+V

5

4

8

7

6

5

s

Out

+V

s

Out2

-In2

+In2

Out1

-In1

+In1

+V

s

+In2

-In2

Out2

1

2

3

4

5

6

7

14

13

12

11

10

9

8

Out4

-In4

+In4

-V

s

+In3

-In3

Out3

Out1

-In1

+In1

+V

+In2

-In2

Out2

1

2

3

4

s

5

6

7

14

13

12

11

10

9

8

Out4

-In4

+In4

-V

s

+In3

-In3

Out3

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 3

Absolute Maximum Ratings

Parameter Min. Max. Unit

Supply Voltages 0+6V

Maximum Junction Temperature – +175 °C

Storage Temperature Range -65 +150 °C

Lead Temperature, 10 seconds – +260 °C

Input Voltage Range -

Vs-0.5 +Vs+0.5

V

Electrical Specifications

(Tc= 25°C, Vs= +2.7V, G = 2, RL= 10kΩ to Vs/2, Rf= 10kΩ, V

o (DC)

= Vcc/2; unless otherwise noted)

Parameter Conditions Min. Typ. Max. Unit

AC Performance

Gain Bandwidth Product CL= 50pF,RL=2kΩ to Vs/2 1.2 MHz

Phase Margin 52 deg

Gain Margin 17 dB

Slew Rate Vo= 1V

pp

1.5 V/µs

Input Voltage Noise >50kHz 36 nV/√Hz

Crosstalk: LMV358 100kHz 91 dB

LMV324 100kHz 80 dB

DC Performance

Input Offset Voltage

1

1.7 7 mV

Average Drift 8 µV/°C

Input Bias Current

2

<1 nA

Input Offset Current

2

<1 nA

Power Supply Rejection Ratio

1

DC 50 65 dB

Supply Current (Per Channel)

1

80 120 µA

Input Characteristics

Input Common Mode Voltage Range1LO 0 -0.25 V

HI 1.5 1.3 V

Common Mode Rejection Ratio

1

50 70 dB

Output Characteristics

Output Voltage Swing RL= 10kΩ to Vs/2; LO

1

0.1 0.01 V

RL= 10kΩ to Vs/2; HI

1

2.69 2.6 V

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

Notes:

1. Guaranteed by testing or statistical analysis at +25°C.

2. +IN and -IN are gates to CMOS transistors with typical input bias current of <1nA. CMOS leakage is too small to practically measure.

Recommended Operating Conditions

Parameter Min. Max. Unit

Operating Temperature Range -40 +125 °C

Power Supply Operating Range 2.5 5.5 V

DATA SHEET LMV321/LMV358/LMV324

4 Rev. 1 November 2002

Electrical Specifications

(Tc= 25°C, Vs= +5V, G = 2, RL= 10kΩ to Vs/2, Rf= 10kΩ, V

o (DC)

= Vcc/2; unless otherwise noted)

Parameter Conditions Min. Typ. Max. Unit

AC Performance

Gain Bandwidth Product CL= 50pF,RL=2kΩ to Vs/2 1.4 MHz

Phase Margin 73 deg

Gain Margin 12 dB

Slew Rate 1.5 V/µs

Input Voltage Noise >50kHz 33 nV/√Hz

Crosstalk: LMV358 100kHz 91 dB

LMV324 100kHz 80 dB

DC Performance

Input Offset Voltage

1

17mV

Average Drift 6 µV/°C

Input Bias Current

2

<1 nA

Input Offset Current

2

<1 nA

Power Supply Rejection Ratio

1

DC 50 65 dB

Open Loop Gain

1

50 70 dB

Supply Current (Per Channel)

1

100 150 µA

Input Characteristics

Input Common Mode Voltage Range1LO 0 -0.4 V

HI 3.8 3.6 V

Common Mode Rejection Ratio

1

50 75 dB

Output Characteristics

Output Voltage Swing RL= 2kΩ to Vs/2; LO/HI 0.036 to 4.95 V

RL= 10kΩ to Vs/2; LO

1

0.1 0.013 V

RL= 10kΩ to Vs/2; HI

1

4.98 4.9 V

Short Circuit Output Current

1

sourcing; Vo= 0V 5 +34 mA

sinking; Vo= 5V 10 -23 mA

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

Notes:

1. Guaranteed by testing or statistical analysis at +25°C.

2. +IN and -IN are gates to CMOS transistors with typical input bias current of <1nA. CMOS leakage is too small to practically measure.

Package Thermal Resistance

Package θ

JA

5 lead SC70 331.4°C/W

5 lead SOT23 256°C/W

8 lead SOIC 152°C/W

8 lead MSOP 206°C/W

14 lead TSSOP 100°C/W

14 lead SOIC 88°C/W

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 5

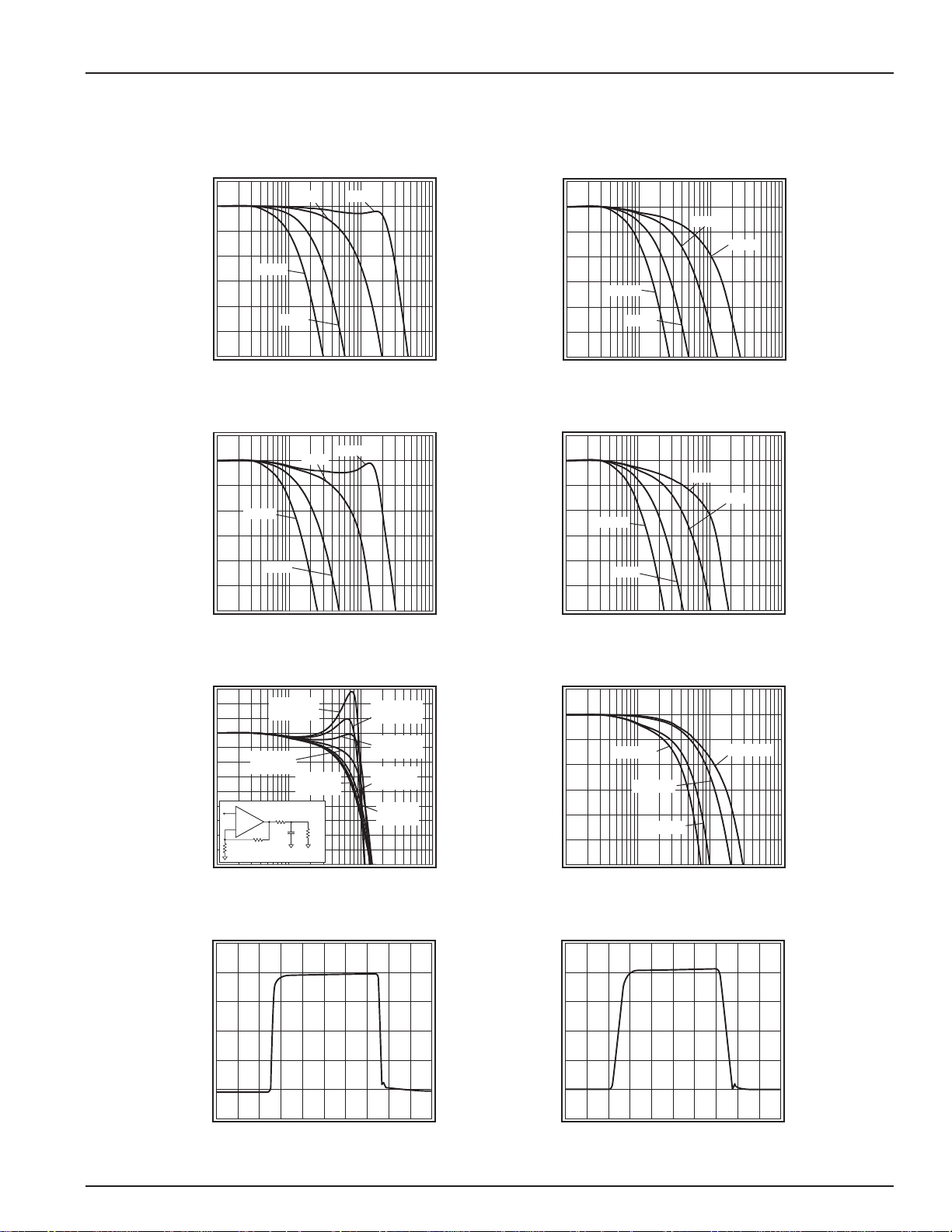

Typical Operating Characteristics

(Tc= 25°C, Vs= +5V, G = 2, RL= 10kΩ to Vs/2, Rf= 10kΩ, V

o (DC)

= Vcc/2; unless otherwise noted)

Non-Inverting Freq. Response Vs = +5V

G = 2

G = 10

G = 5

G = 1

Normalized Magnitude (1dB/div)

0.01

0.1

1

Frequency (MHz)

Non-Inverting Freq. Response Vs = +2.7V

G = 1

G = 2

G = 10

G = 5

Normalized Magnitude (1dB/div)

0.01

0.1

1

Frequency (MHz)

Inverting Frequency Response Vs = +5V

G = -2

G = -1

G = -10

G = -5

Normalized Magnitude (1dB/div)

10

0.01

0.1

1

10

Frequency (MHz)

Inverting Freq. Response Vs = +2.7V

G = -1

G = -2

G = -10

G = -5

Normalized Magnitude (1dB/div)

10

0.01

0.1

1

10

Frequency (MHz)

Frequency Response vs. C

CL = 200pF

= 0

R

s

CL = 50pF

= 0

R

s

CL = 20pF

= 0

R

s

+

R

Magnitude (1dB/div)

10kΩ

0.01

s

10kΩ

0.1

C

2kΩ

L

1

Frequency (MHz)

Small Signal Pulse Response

0.25

0.2

0.15

0.1

Output (V)

0.05

0

-0.05

02024681012141618

Time (µs)

L

CL = 200pF

= 225Ω

R

s

CL = 100pF

= 0

R

s

CL = 10pF

= 0

R

s

CL = 2pF

= 0

R

s

Frequency Response vs. R

RL = 1kΩ

RL = 10kΩ

Magnitude (1dB/div)

10

0.01

RL = 2kΩ

0.1

L

RL = 100kΩ

1

10

Frequency (MHz)

Large Signal Pulse Response

2.5

2

1.5

0.1

Output (V)

0.5

0

-0.5

02024681012141618

Time (µs)

DATA SHEET LMV321/LMV358/LMV324

6 Rev. 1 November 2002

Typical Operating Characteristics

(Tc= 25°C, Vs= +5V, G = 2, RL= 10kΩ to Vs/2, Rf= 10kΩ, V

o (DC)

= Vcc/2; unless otherwise noted)

Input Voltage Noise

100

80

70

60

50

nV/√Hz

40

30

20

1

10

100

Frequency (kHz)

Open Loop Gain & Phase vs. Frequency

0

-45

-90

-135

-180

-225

Open Loop Phase (deg)

-270

10

100

Phase

|Gain|

100k10k1k

Frequency (Hz)

RL = 2kΩ

CL = 50pF

1M

1000

100

Open Loop Gain (dB)

80

60

40

20

0

-20

10M

Total Harmonic Distortion

0.6

Vo = 1V

0.5

0.4

0.3

THD (%)

0.2

0.1

0

0.1

pp

1

Frequency (kHz)

10

100

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 7

Application Information

General Description

The LMV3XX family are single supply, general purpose,

voltage-feedback amplifiers that are pin-for-pin compatible

and drop in replacements with other industry standard

LMV321, LMV358, and LMV324 amplifiers. The LMV3XX

family is fabricated on a CMOS process, features a rail-to-rail

output, and is unity gain stable.

The typical non-inverting circuit schematic is shown in

Figure 1.

Figure 1: Typical Non-inverting configuration

Power Dissipation

The maximum internal power dissipation allowed is directly

related to the maximum junction temperature. If the maximum

junction temperature exceeds 150°C, some performance

degradation will occur. If the maximum junction temperature

exceeds 175°C for an extended time, device failure may occur.

Driving Capacitive Loads

The Frequency Response vs CLplot on page 4, illustrates the

response of the LMV3XX family. A small series resistance (Rs)

at the output of the amplifier, illustrated in Figure 2, will improve

stability and settling performance. R

s

values in the Frequency

Response vs CLplot were chosen to achieve maximum band-

width with less than 1dB of peaking. For maximum flatness,

use a larger Rs. As the plot indicates, the LMV3XX family

can easily drive a 200pF capacitive load without a series

resistance. For comparison, the plot also shows the LMV321

driving a 200pF load with a 225Ω series resistance.

Driving a capacitive load introduces phase-lag into the output

signal, which reduces phase margin in the amplifier. The

unity gain follower is the most sensitive configuration. In a

unity gain follower configuration, the LMV3XX family

requires a 450Ω series resistor to drive a 200pF load. The

response is illustrated in Figure 3.

Figure 2: Typical Topology for driving a

capacitive load

Figure 3: Frequency Response vs CLfor unity

gain configuration

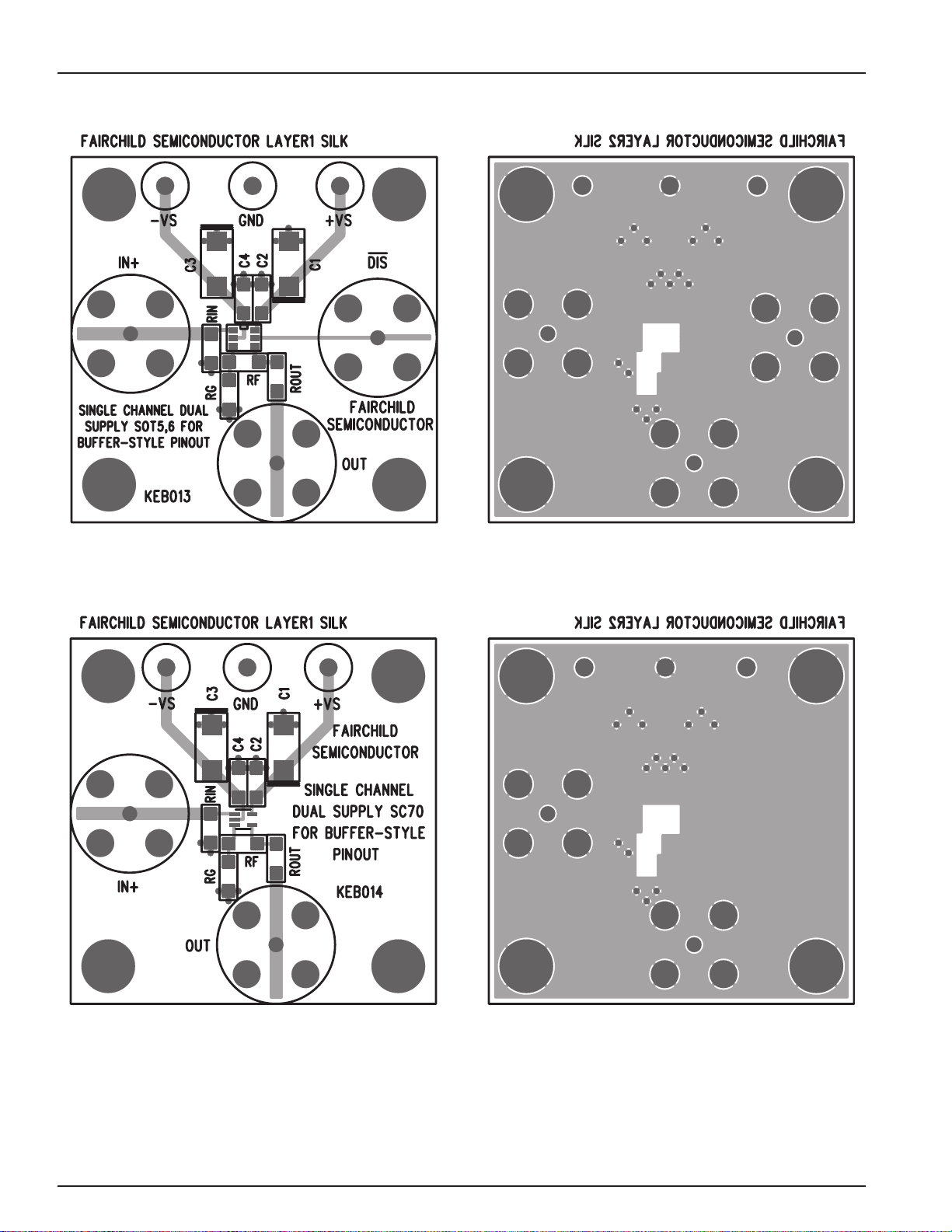

Layout Considerations

General layout and supply bypassing play major roles in high

frequency performance. Fairchild has evaluation boards to

use as a guide for high frequency layout and as aid in device

testing and characterization. Follow the steps below as a

basis for high frequency layout:

• Include 6.8µF and 0.01µF ceramic capacitors

• Place the 6.8µF capacitor within 0.75 inches of

the power pin

• Place the 0.01µF capacitor within 0.1 inches of

the power pin

• Remove the ground plane under and around the part,

especially near the input and output pins to reduce

parasitic capacitance

• Minimize all trace lengths to reduce series inductances

Refer to the evaluation board layouts shown in Figure 5 on

page 8 for more information.

+

LMV3XX

10kΩ

10kΩ

R

s

C

2kΩ

L

+V

s

6.8µF

+

+In

0.01µF

+

LMV3XX

Out

R

f

R

g

3

2

1

0

-1

-2

-3

-4

-5

Magnitude (dB)

-6

-7

-8

-9

0.01 0.1 1 10

CL = 50pF

Rs = 0

CL = 100pF

Rs = 400Ω

CL = 200pF

Rs = 450Ω

Frequency (MHz)

DATA SHEET LMV321/LMV358/LMV324

8 Rev. 1 November 2002

Evaluation Board Information

The following evaluation boards are available to aid in the

testing and layout of this device:

Evaluation board schematics and layouts are shown in Figures

4 and 5.

Eval Bd Description Products

KEB013 Single Channel, Dual Supply, LMV321AS5X

SOT23-5 for buffer-style pinout

KEB014 Single Channel, Dual Supply, LMV321AP5X

SC70-5 for buffer-style pinout

KEB006 Dual Channel, Dual Supply, LMV358AM8X

8 lead SOIC

KEB010 Dual Channel, Dual Supply, LMV358AMU8X

8 lead MSOP

KEB012 Quad Channel, Dual Supply, LMV324AMTC14X

14 lead TSSOP

KEB018 Quad Channel, Dual Supply, LMV324AM14X

14 lead SOIC

Evaluation Board Schematic Diagrams

Figure 4a: LMV321 KEB013 schematic Figure 4b: LMV321 KEB014 schematic

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 9

Evaluation Board Schematic Diagrams (Continued)

Figure 4c: LMV358 KEB006/KEB010 schematic

Figure 4d: LMV324 KEB012/KEB018 schematic

DATA SHEET LMV321/LMV358/LMV324

10 Rev. 1 November 2002

Figure 5a: KEB013 (top side) Figure 5b: KEB013 (bottom side)

Figure 5c: KEB014 (top side) Figure 5d: KEB014 (bottom side)

LMV321 Evaluation Board Layout

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 11

Figure 5g: KEB010 (top side) Figure 5h: KEB010 (bottom side)

LMV358 Evaluation Board Layout

Figure 5e: KEB006 (top side) Figure 5f: KEB006 (bottom side)

DATA SHEET LMV321/LMV358/LMV324

12 Rev. 1 November 2002

LMV324 Evaluation Board Layout

Figure 5i: KEB012 (top side) Figure 5j: KEB012 (bottom side)

Figure 5k: KEB018 (top side) Figure 5l: KEB018 (bottom side)

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 13

LMV321 Package Dimensions

b

e

e1

D

C

L

E

C

L

C

L

A

A2

A1

α

E1

C

2

DATUM ’A’

C

L

NOTE:

1. All dimensions are in millimeters.

2 Foot length measured reference to flat

foot surface parallel to DATUM ’A’ and lead surface.

3. Package outline exclusive of mold flash & metal burr.

4. Package outline inclusive of solder plating.

5. Comply to EIAJ SC74A.

6. Package ST 0003 REV A supercedes SOT-D-2005 REV C.

SYMBOL MIN MAX

A 0.90 1.45

A1 0.00 0.15

A2 0.90 1.30

b 0.25 0.50

C 0.09 0.20

D 2.80 3.10

E 2.60 3.00

E1 1.50 1.75

L 0.35 0.55

e 0.95 ref

e1 1.90 ref

α 010

SOT23-5

SC70

C

L

b

C

L

A

A2

e

HE

D

C

L

A1

C

L

Q1

NOTE:

1. All dimensions are in millimeters.

2. Dimensions are inclusive of plating.

3. Dimensions are exclusive of mold flashing and metal burr.

4. All speccifications comply to EIAJ SC70.

L

SYMBOL MIN MAX

e 0.65 BSC

D1.802.20

E

C

b0.150.30

E1.151.35

HE 1.80 2.40

Q1 0.10 0.40

A2 0.80 1.00

A1 0.00 0.10

A 0.80 1.10

c 0.10 0.18

L 1.10 0.30

DATA SHEET LMV321/LMV358/LMV324

14 Rev. 1 November 2002

LMV358 Package Dimensions

HE

C

L

ZD

C

L

e

D

Pin No. 1

B

A

A1

A2

7°

L

DETAIL-A

DETAIL-A

C

h x 45°

α

NOTE:

1. All dimensions are in millimeters.

2. Lead coplanarity should be 0 to 0.10mm (.004") max.

3. Package surface finishing:

(2.1) Top: matte (charmilles #18~30).

(2.2) All sides: matte (charmilles #18~30).

(2.3) Bottom: smooth or matte (charmilles #18~30).

4. All dimensions excluding mold flashes and end flash

from the package body shall not exceed o.152mm (.006)

per side(d).

SYMBOL MIN MAX

A1 0.10 0.25

B 0.36 0.46

C 0.19 0.25

D 4.80 4.98

E 3.81 3.99

e 1.27 BSC

H 5.80 6.20

h 0.25 0.50

L 0.41 1.27

A 1.52 1.72

0

ZD 0.53 ref

A2 1.37 1.57

8

SOIC-8

SOIC

eS

E/2 2X

E3

E4

12

ccc

ABC

– B –

2

37

2

64

D2

A2

A

A1

– A –

– C –

bbb

AB

C

M

b

D

43

aaa

A

E1

– H –

t1

t2

Gauge

Plane

0.25mm

R1

R

L

L1

03

02

01

Detail A

Scale 40:1

Section A - A

b

cc1

b1

E2

E1

E

Detail A

5

A

A

SYMBOL MIN MAX

A 1.10

A1 0.10 ±0.05

A2 0.86 ±0.08

D 3.00 ±0.10

D2 2.95 ±0.10

E 4.90 ±0.15

E1 3.00 ±0.10

E2 2.95 ±0.10

E3 0.51 ±0.13

E4 0.51 ±0.13

R 0.15 +0.15/-0.06

R1 0.15 +0.15/-0.06

t1 0.31 ±0.08

t2 0.41 ±0.08

b 0.33 +0.07/-0.08

b1 0.30 ±0.05

c 0.18 ±0.05

c1 0.15 +0.03/-0.02

01 3.0°±3.0°

02 12.0°±3.0°

03 12.0°±3.0°

L 0.55 ±0.15

L1 0.95 BSC –

aaa 0.10 –

bbb 0.08 –

ccc 0.25 –

e 0.65 BSC –

S 0.525 BSC –

MSOP-8

–

NOTE:

1All dimensions are in millimeters (angle in degrees), unless otherwise specified.

2 Datums – B – and – C – to be determined at datum plane – H – .

3 Dimensions "D" and "E1" are to be determined at datum – H – .

4 Dimensions "D2" and "E2" are for top package and dimensions "D" and "E1" are for bottom package.

5 Cross sections A – A to be determined at 0.13 to 0.25mm from the leadtip.

6 Dimension "D" and "D2" does not include mold flash, protrusion or gate burrs.

7 Dimension "E1" and "E2" does not include interlead flash or protrusion.

MSOP

LMV321/LMV358/LMV324 DATA SHEET

Rev. 1 November 2002 15

E/22X

ddd C B A

6

6

1.0

1.0

123

9

e /2

E1 E

e

N

8

– B –

7

2X

N/2 TIPS

1.0 DIA

– A –

7

– C –

aaa C

ccc

8 3

D

CBAbbb

M

b NX

A1

A2

A

c1

c

(b)

b1

5

SECTION AA

10

A

A

– H –

GAGE

PLANE

0.25

(0.20)

(02)

R1

R

01

(L1)

L

(03)

NOTES:

1 All dimensions are in millimeters (angle in degrees).

2 Dimensioning and tolerancing per ASME Y14.5–1994.

3 Dimensions "D" does not include mold flash, protusions or gate burrs. Mold flash protusions or gate burrs shall not exceed 0.15 per side .

4 Dimension "E1" does not include interlead flash or protusion. Interlead flash or protusion shall not exceed 0.25 per side.

5 Dimension "b" does not include dambar protusion. Allowable dambar protusion shall be 0.08mm total in excess of the "b" dimension at maximum

material condition. Dambar connot be located on the lower radius of the foot. Minimum space between protusion and adjacent lead is 0.07mm

for 0.5mm pitch packages.

6 Te rminal numbers are shown for reference only.

7 Datums – A – and – B – to be determined at datum plane – H – .

8 Dimensions "D" and "E1" to be determined at datum plane – H – .

9 This dimensions applies only to variations with an even number of leads per side. For variation with an odd number of leads per side, the "center"

lead must be coincident with the package centerline, Datum A.

10

Cross sections A – A to be determined at 0.10 to 0.25mm from the leadtip.

SYMBOL MIN NOM MAX

A – – 1.10

A1 0.05 – 0.15

A2 0.85 0.90 0.95

L 0.50 0.60 0.75

R 0.09 – –

R1 0.09 – –

b 0.19 – 0.30

b1 0.19 0.22 0.25

c 0.09 – 0.20

c1 0.09 – 0.16

01 0° – 8°

L1 1.0 REF

aaa 0.10

bbb 0.10

ccc 0.05

ddd 0.20

e 0.65 BSC

02 12° REF

03 12° REF

TSSOP-14

D 4.90 5.00 5.10

E1 4.30 4.40 4.50

E 6.4 BSC

e 0.65 BSC

N 14

TSSOP

LMV324 Package Dimensions

SOIC

D

e

C

L

ZD

7°

HE

DETAIL-A

h x 45°

α

L

DETAIL-A

C

C

L

B

A2

Pin No. 1

A1

A

SYMBOL MIN MAX

A1 .0040 .0098

B .014 .018

C .0075 .0098

D .337 .344

E .150 .157

e .050 BSC

H .2284 .2440

h .0099 .0196

L .016 .050

A .060 .068

0

ZD 0.20 ref

A2 .054 .062

NOTE:

1. All dimensions are in inches.

2. Lead coplanarity should be 0 to 0.10mm (.004") max.

3. Package surface finishing:

(2.1) Top: matte (charmilles #18~30).

(2.2) All sides: matte (charmilles #18~30).

(2.3) Bottom: smooth or matte (charmilles #18~30).

4. All dimensions excluding mold flashes and end flash

from the package body shall not exceed o.152mm (.006)

per side (d).

SOIC-14

8

www.fairchildsemi.com © 2002 Fairchild Semiconductor Corporation

Ordering Information

Model Part Number Package Container Pack Qty

LMV321 LMV321AP5X SC70-5 Reel 3000

LMV321 LMV321AS5X SOT23-5 Reel 3000

LMV358 LMV358AM8X SOIC-8 Reel 2500

LMV358 LMV358AMU8X MSOP-8 Reel 3000

LMV324 LMV324AMTC14X TSSOP Reel 2500

LMV324 LMV324AM14X SOIC Reel 2500

Temperature range for all parts: -40°C to +125°C.

DATA SHEET LMV321/LMV358/LMV324

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICES TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN.

FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY

LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE

PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for

surgical implant into the body, or (b) support or sustain life, and (c) whose failure to perform

when properly used in accordance with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury of the user.

2. A critical component in any component of a life support device or system whose failure

to perform can be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or effectiveness.

Loading...

Loading...