www.fairchildsemi.com

User Guide for

AN-8026: FAN9611 / FAN9612 400W

1-Layer Evaluation Board (FEB-301)

Featured Fairchild Product:

FAN9611 / FAN9612

Direct questions or comments

about this Evaluation Board to:

“Worldwide Direct Support”

Fairchild Semiconductor.com

© 2009 Fairchild Semiconductor Corporation AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

Table of Contents

1.Overview of the Evaluation Board ............................................................................................. 3

2.General Specification .................................................................................................................. 3

3.Test Procedures ........................................................................................................................... 4

4.Schematic .................................................................................................................................... 6

5.Specification Approval ............................................................................................................... 7

6.Boost Inductor Specification ...................................................................................................... 9

6.1. Electrical Specification ............................................................................................... 10

7.Bill of Materials ........................................................................................................................ 12

8.Test Results ............................................................................................................................... 16

8.1. Startup ......................................................................................................................... 16

8.2. Normal Operation ....................................................................................................... 17

8.3. Line and Load Transient ............................................................................................. 18

8.4. Brown in/out Protection ............................................................................................. 19

8.5. Phase Management ..................................................................................................... 20

8.6. Efficiency.................................................................................................................... 21

8.7. Harmonic Distortion and Power Factor ...................................................................... 22

9.References ................................................................................................................................. 24

© 2009 Fairchild Semiconductor Corporation 2 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

The following user guide supports the FAN9611 / FAN9612 400W evaluation board for

interleaved boundary-conduction mode power factor corrected supply. The user guide

should be used in conjunction with the FAN9611/FAN9611 / FAN9612 datasheet as well

as the Fairchild application note AN-6086 — Design Considerations for Interleaved

Boundary-Conduction Mode PFC Using FAN9611 / FAN9612. The user guide and the

evaluation board can also be used to evaluate FAN9611 controller which has the lower

turn-on threshold. Please visit Fairchild’s website at www.fairchildsemi.com

information.

1. Overview of the Evaluation Board

The FAN9611 / FAN9612 interleaved dual Boundary-Conduction-Mode (BCM) PowerFactor-Correction (PFC) controller operates two parallel-connected boost power trains

180º out of phase. Interleaving extends the maximum practical power level of the control

technique from about 300W to greater than 800W. Unlike the continuous conduction

mode (CCM) technique often used at higher power levels, BCM offers inherent zerocurrent switching of the boost diodes (no reverse-recovery losses), which permits the use

of less expensive diodes without sacrificing efficiency. Furthermore, the input and output

filters can be smaller due to ripple current cancellation between the power trains and

effectively doubling the switching frequency.

The advanced line feedforward with peak detection circuit minimizes the output voltage

variation during line transients. To guarantee stable operation with less switching loss at

light load, the maximum switching frequency is clamped at 600kHz. Synchronization is

maintained under all operating conditions.

for

Built-in protection functions include output over-voltage, over-current, open-feedback,

under-voltage lockout, brownout, and redundant latching over-voltage. The FAN9611 /

FAN9612 is available in a lead-free 16-lead SOIC package.

Fairchild offers and evaluation board to aide in design and test of applications using the

FAN9611 / FAN9612. The FAN9611 / FAN9612 evaluation board is a single-layer board

designed for 400W (400V/1A) rated power. Thanks to the phase management, the

efficiency is maintained above 95% at low-line and high-line, even down to 10% of the

rated output power. The efficiencies for full-load condition are 96.3% and 98.0% at line

voltages of 115V

and 230VAC, respectively.

AC

2. General Specification

Specification Min. Max. Units

Input

VIN AC Voltage 90 264 VAC

VIN AC Frequency 47 63 Hz

VDD Supply 13 16 VDC

Output

Output Voltage 400 V

Output Current 1 A

Total Output Power

Maximum Load Output Power 400 W

© 2009 Fairchild Semiconductor Corporation 3 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

3. Test Procedures

Before testing the board; DC voltage supply for VDD, AC voltage supply for line input,

and DC electric load for output should be connected to the board properly.

1. Supply V

specification for V

2. When V

the inrush current limit relay is turned on by 5V reference (pin #3), the relay turns on

when FAN9611 / FAN9612 comes out of UVLO by supplying V

3. Connect the AC voltage (90~264V

FAN9611 / FAN9612 has brownout protection and line OVP, any input voltages out

of operation range trigger protections.

4. Change load current (0~1A) and check the operation. The board is designed to go

into phase shedding for output power below around 55W. It goes back to twochannel interleaving operation for output power above around 110W.

Table 1. Test Equipment

Test Model

Test Date

Test Temperature

Test Equipment

Test Items

for the control chip first. It should be higher than 13V (refer to the

DD

turn-on threshold voltage).

DD

is supplied, a "click" sound from the relay is heard. This is normal. Since

DD

FEB301-001

Sept.7, 2009

Ambient

AC Source: Chroma 61603 AC POWER SOURCE

Electronic Load: Chroma 63108

Power Meter: WT210

Oscilloscope: Lecroy wavesurfer 24Xs

DC Source: ABM 9306D

Startup

Normal Operation

Normal Operation

Line and Load Transient

Brown in/out Protection

Phase Management

Efficiency

Harmonic Distortion and Power Factor

higher than 13V.

DD

) to start the FAN9611 / FAN9612. Since

AC

© 2009 Fairchild Semiconductor Corporation 4 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

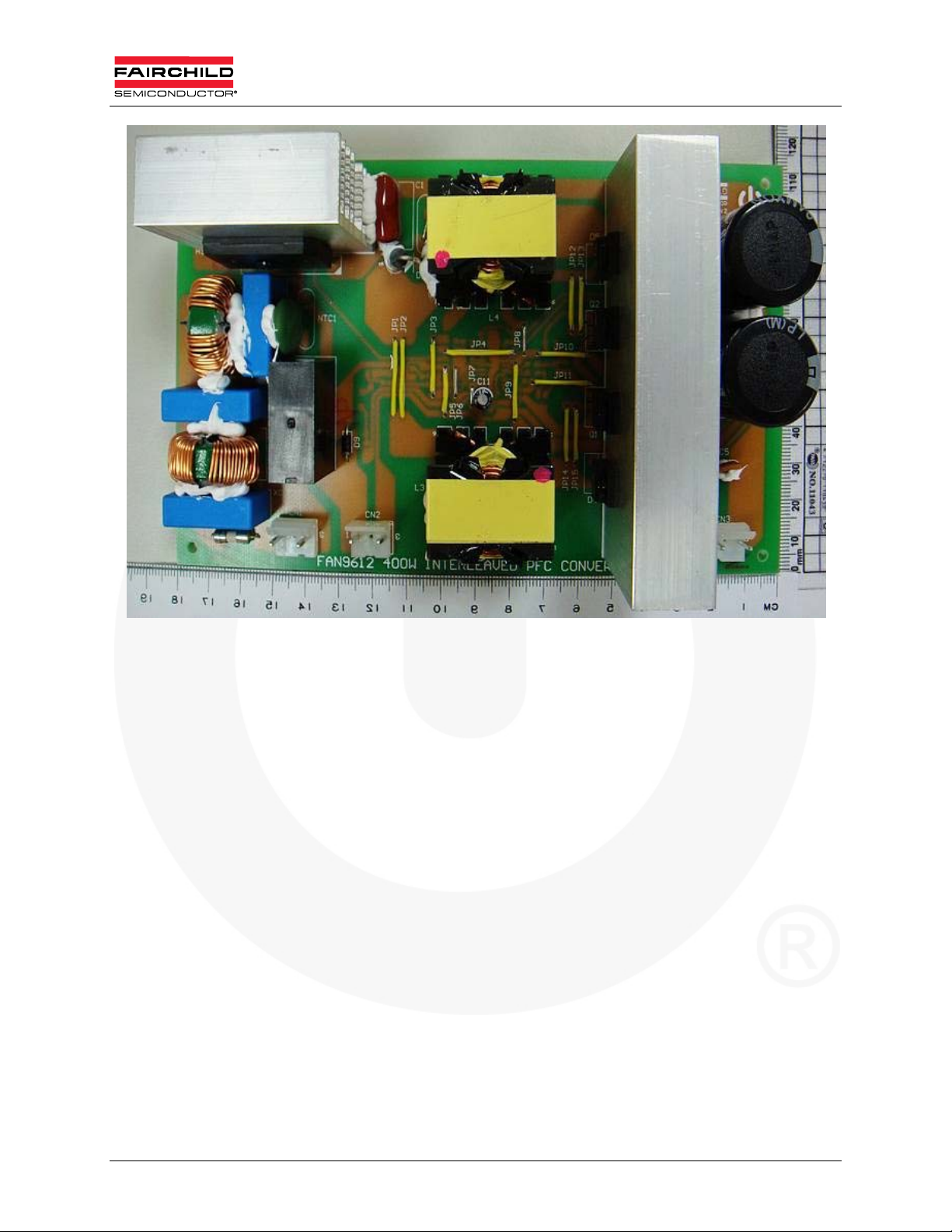

Figure 1. Photograph of Tested Board

© 2009 Fairchild Semiconductor Corporation 5 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

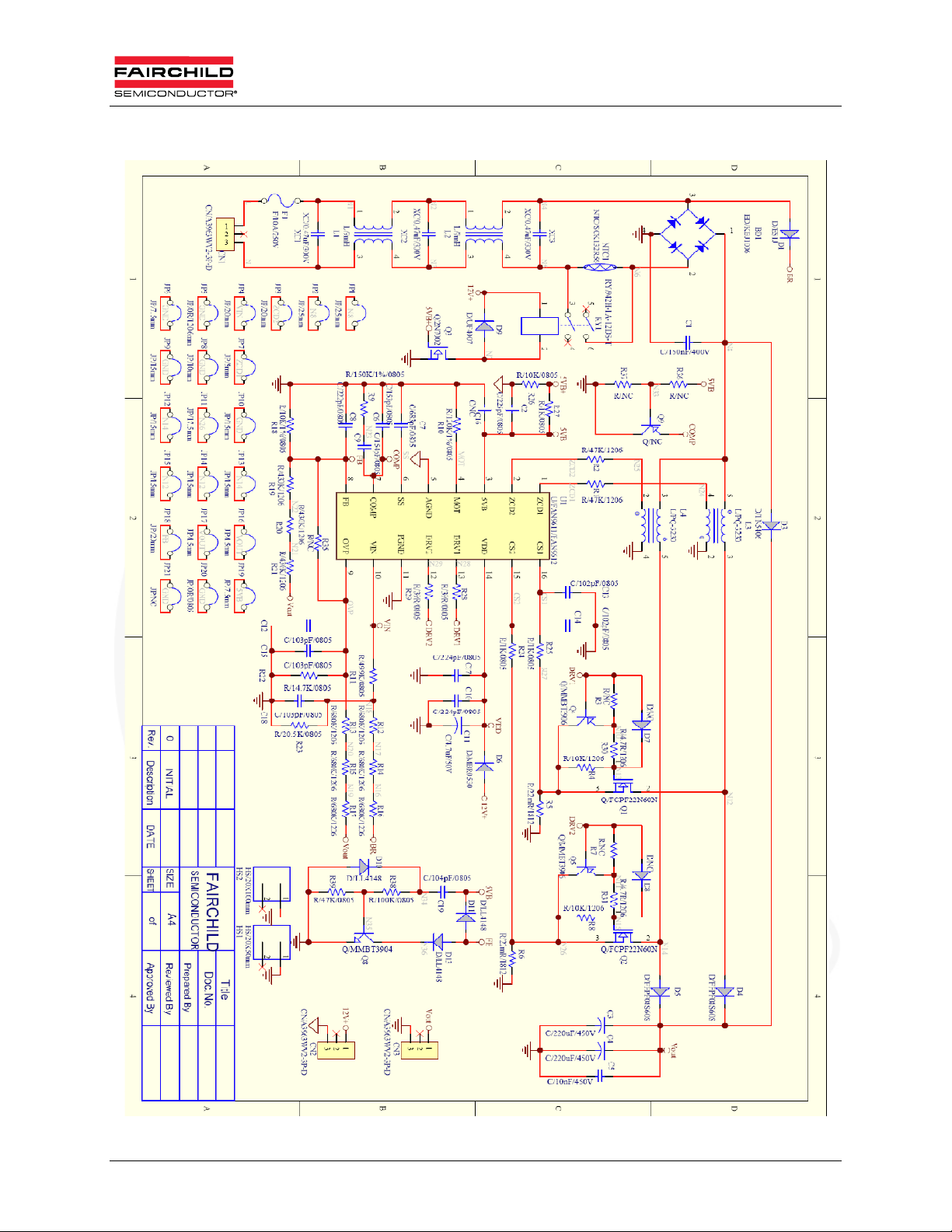

4. Schematic

Figure 2. FAN9611 / FAN9612 400W Evaluation Board Schematic

© 2009 Fairchild Semiconductor Corporation 6 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

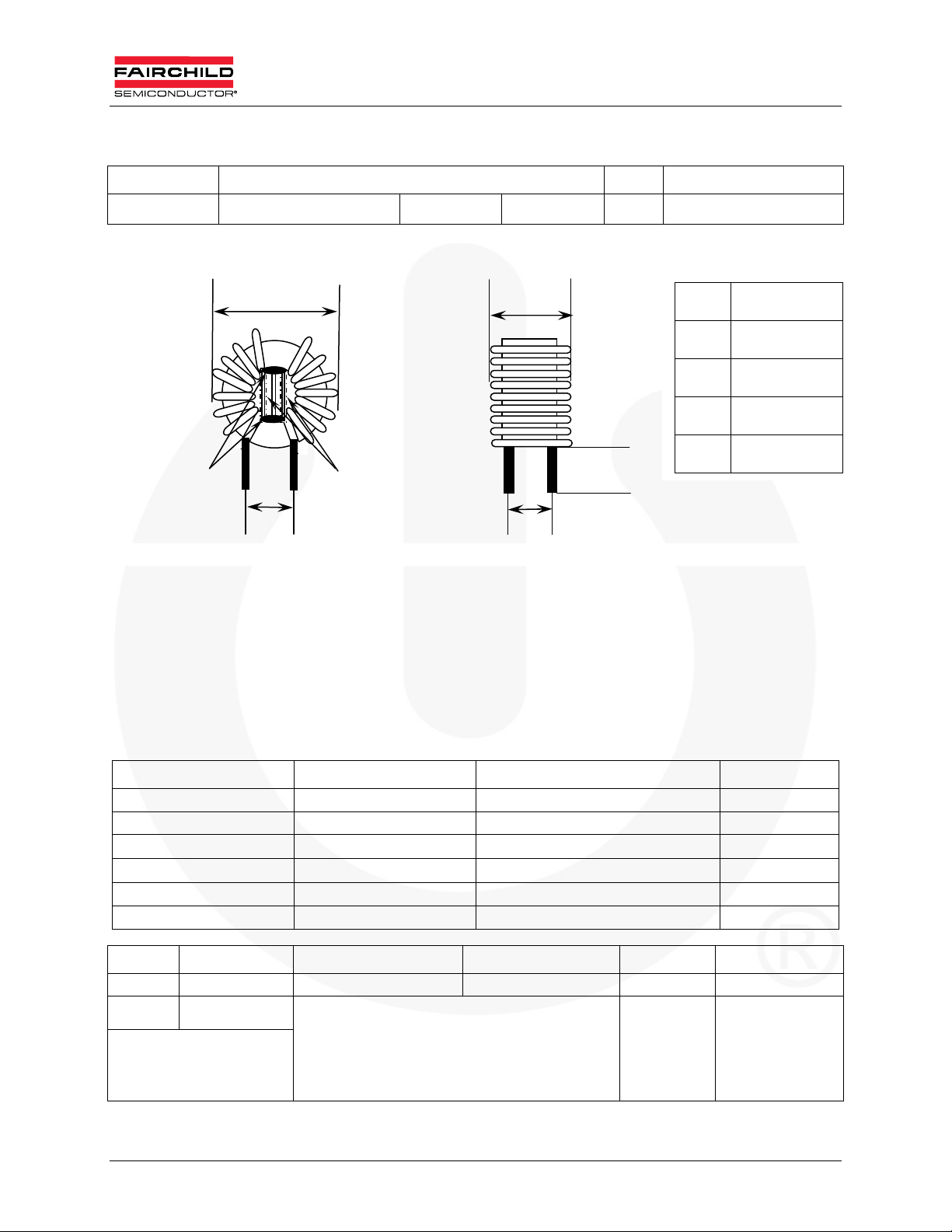

5. Specification Approval

Customer Fairchild Semiconductor P/N: TRN-0197

Date 08/04/2006 Version A Page 1/1

Dimension Unit: mm

A B

Black Glue E

tube

C D

Middle partition board thickness of 2mm

(Safety Regulation)

A 30 max

B 5 max

C 11 ref

D 13 ref

E

151

Electrical Specification: 1kHz 1V

Inductance:L1=L2:9.0mH minimum

DC Resistance: L1=L2:0.05 maximum

Turn and Wire: L1=L2:0.9 x 30.5TSx2

Materials List:

Component Material Manufacturer UL File #

1. CORE T22x14x08 TOMITA

2. WIRE THFN-216 Ta Ya Electric Wire Co., Ltd. E197768

UEWN/U

UEWE

UWY Jang Shing Wire Co., Ltd. E174837

3. Solder 96.5% Sn,3% Ag,0.5% Cu, Xin Yuan Co., Ltd.

Unit m/m Drawn Check Title

TEL (02)29450588 Ci wun Chen Guo long Huang IDENT#. TRN-0197

FAX (02)29447647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I0060

PACIFIC Wire Cable Co., Ltd.

Tai-l Electric Wire Cable Co., Ltd.

E201757

E85640

© 2009 Fairchild Semiconductor Corporation 7 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

www.fairchildsemi.com

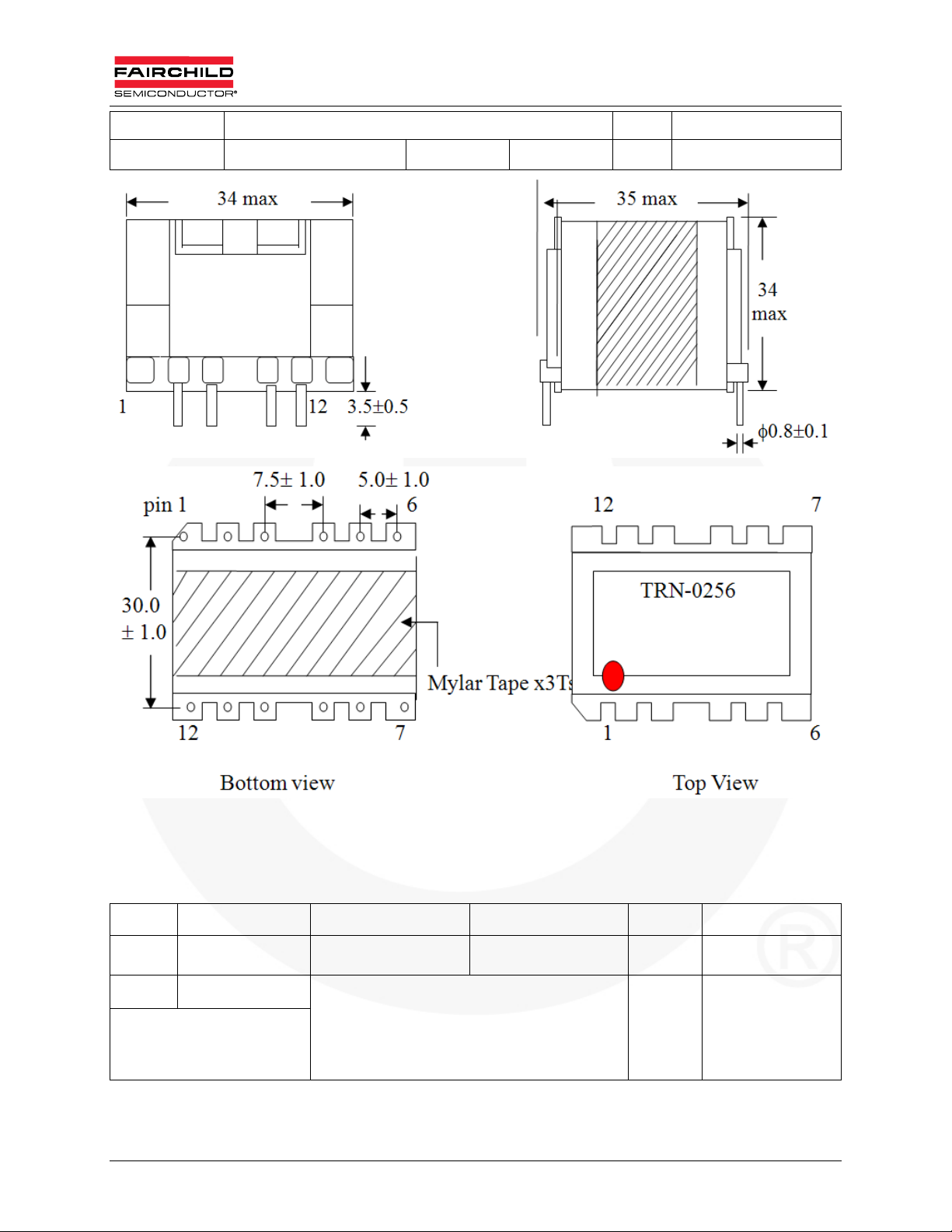

Customer Fairchild Semiconductor P/N: TRN-0256

Date 09/02/2009 Version A Page 1/4

Notes:

1. Pin 1,6,7,8,10,11,12 removed.

2. Add insulation tape *3 turns to fix core and bobbin.

3. The red symbol indicates first pin.

Unit m/m Drawn Check Title

TEL (02)2 945-0588 Ci wun Chen Guo long Huang IDENT# TRN-0256

FAX (02)2944-7647

No.26-1, Lane 128, Sec. 2,

Singnan Rd., Jhonghe City,

Taipei County 235, Taiwan

(R.O.C.)

© 2009 Fairchild Semiconductor Corporation 8 AN-8026 / FEB301_FAN9611 / FAN9612 • Rev. 0.0.4

SEN HUEI INDUSTRIAL CO.,LTD. D W G# I3205

Loading...

Loading...