Fairchild FAN9611, FAN9612 service manual

www.fairchildsemi.com

FEB388_003

FAN9611/FAN9612 400W Interleaved

Dual BCM PFC Controller

Evaluation Board User Guide

Featured Fairchild Product: FAN9611, FAN9612

Please contact a local Fairchild Sales representative

for an evaluation board.

© 2010 Fairchild Semiconductor Corporation 1 FEB388_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

Table of Contents

1. Overview of the Evaluation Board ........................................................................................... 3

2. Key Features ............................................................................................................................. 4

3. Specifications ............................................................................................................................ 5

4. Test Procedure .......................................................................................................................... 6

5. Schematic .................................................................................................................................. 7

6. Boost Inductor Specification .................................................................................................... 8

7. Line Filter Inductor Specifications ........................................................................................... 9

8. PCB Layout ............................................................................................................................. 10

9. Bill of Materials (BOM) ......................................................................................................... 14

10.Test Results ............................................................................................................................. 16

10.1. Startup ......................................................................................................................... 16

10.2. Normal Operation ....................................................................................................... 18

10.3. Line Transient ............................................................................................................. 20

10.4. Load Transient ............................................................................................................ 21

10.5. Brownout Protection ................................................................................................... 22

10.6. Phase Management ..................................................................................................... 24

10.7. Efficiency .................................................................................................................... 27

10.8. Harmonic Distortion and Power Factor ...................................................................... 28

11.References ............................................................................................................................... 30

12.Ordering Information .............................................................................................................. 30

13.Revision History ..................................................................................................................... 30

© 2010 Fairchild Semiconductor Corporation 2 FEB279_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

The following user guide supports the FAN9611/12 400W evaluation board for

interleaved boundary-conduction-mode power-factor-corrected supply. It should be used

in conjunction with the FAN9611/12 datasheet as well as the Fairchild application note

AN-6086 Design Considerations for Interleaved Boundary-Conduction Mode PFC Using

FAN9611 / FAN9612. Although marked FAN9612, the evaluation board can be

interchangeably used to evaluate either the FAN9611 (10V turn-on threshold) or

FAN9612 controller (12.5V turn-on threshold). Please visit Fairchild’s website at

www.fairchildsemi.com

for additional information.

1. Overview of the Evaluation Board

The FAN9611/12 interleaved dual Boundary-Conduction-Mode (BCM) Power-FactorCorrection (PFC) controllers operate two parallel-connected boost power trains 180º out

of phase. Interleaving extends the maximum practical power level of the control

technique from about 300W to greater than 800W. Unlike the continuous conduction

mode (CCM) technique often used at higher power levels, BCM offers inherent zerocurrent switching of the boost diodes (no reverse-recovery losses), which permits the use

of less expensive diodes without sacrificing efficiency. Furthermore, the input and output

filters can be smaller due to ripple current cancellation between the power trains and

doubling of effective switching frequency.

The advanced line feedforward with peak detection circuit minimizes the output voltage

variation during line transients. To guarantee stable operation with less switching loss at

light load, the maximum switching frequency is clamped at 525kHz. Synchronization is

maintained under all operating conditions.

Protection functions include output over-voltage, over-current, open-feedback, undervoltage lockout, brownout, and redundant latching over-voltage protection. The

FAN9611/12 is available in a lead-free 16-lead SOIC package.

This FAN9611/12 evaluation board is a four-layer board designed for 400W (400V/1A)

rated power. Thanks to the phase management, the efficiency is maintained above 96% at

low-line and high-line, even down to 10% of the rated output power. Efficiency is 96.4%

at line voltage 115V

and 98.2% at 230V

AC

under full-load conditions.

AC

© 2010 Fairchild Semiconductor Corporation 3 FEB279_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

2. Key Features

Low Total Harmonic Distortion, High Power Factor

180° Out-of-Phase Synchronization

Automatic Phase Disable at Light Load

1.8A Sink, 1.0A Source, High-Current Gate Drivers

Transconductance (g

Voltage-Mode Control with (V

Closed-Loop Soft-Start with Programmable Soft-Start Time for Reduced Overshoot

Minimum Restart Timer Frequency to Avoid Audible Noise

Maximum Switching Frequency Clamp

Brownout Protection with Soft Recovery

Non-Latching OVP on FB Pin and Second-Level Latching Protection on OVP Pin

Open-Feedback Protection

Over-Current and Power-Limit Protection for Each Phase

Low Startup Current: 80µA Typical

Works with DC, 50Hz to 400Hz AC Inputs

) Error Amplifier for Reduced Overshoot

M

)2 Feed-forward

IN

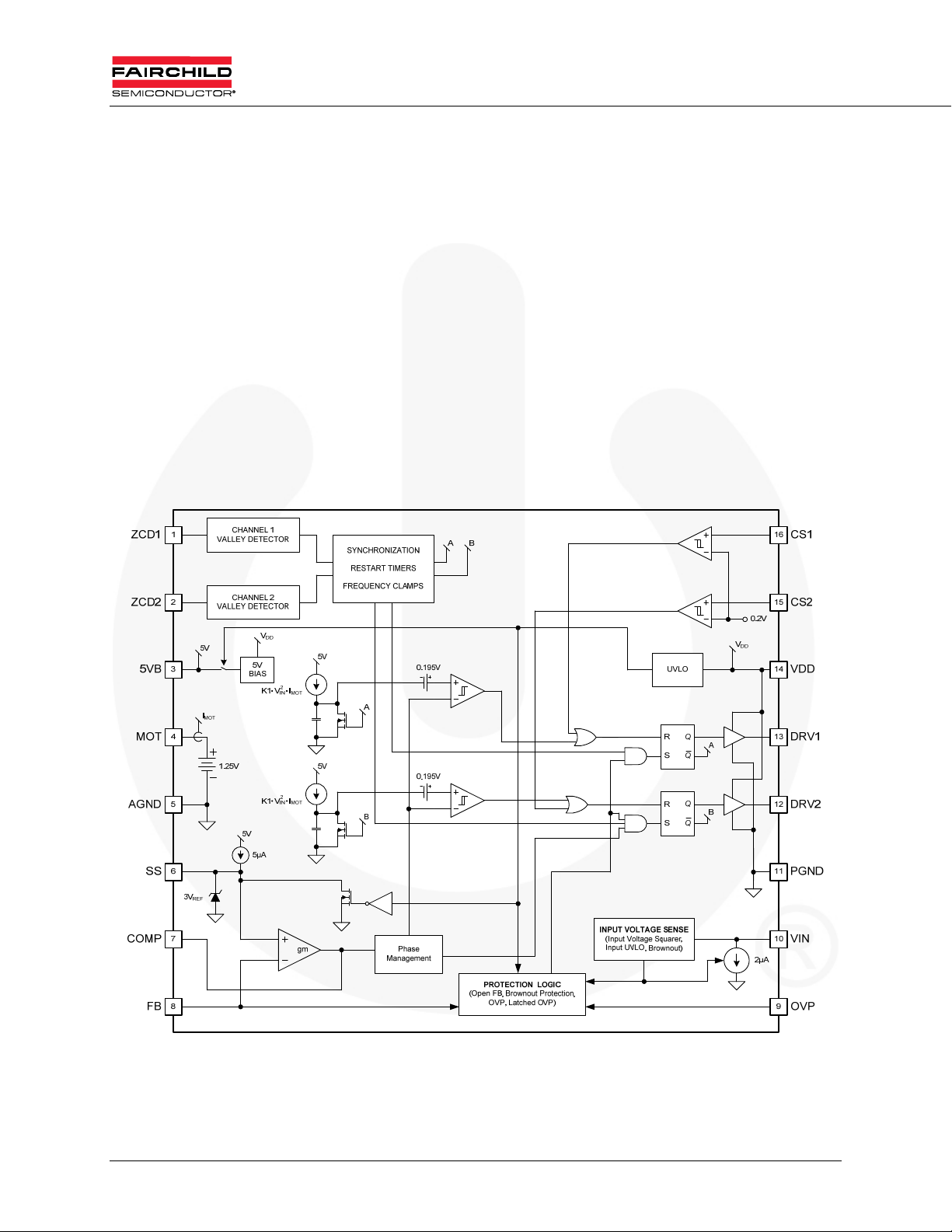

Figure 1. Block Diagram

© 2010 Fairchild Semiconductor Corporation 4 FEB279_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

3. Specifications

This board has been designed and optimized for the following conditions:

Input Voltage Range Rated Output Power

VIN Nominal : 85~264VAC

V

Supply : 13VDC~18VDC

DD

Note:

1. Minimum output voltage during the 20ms hold-up time is 330VDC.

400W 400V-1A

Output Voltage

(Rated Current)

V

V

f

Efficiency > 96% down to 20% load (115V

Efficiency > 97% down to 20% load (230V

= 85~264VAC

LINE

= 400V

OUT

> 50kHz

SW

AC

AC

)

)

PF > 0.99 at full load

The trip points for the built-in protections are set as below in the evaluation board.

The non-latching output OVP trip point is set at 108% of the nominal output voltage.

The latching output OVP trip point is set at 117% of the nominal output voltage.

The line UVLO (brownout protection) trip point is set at 68V

(10VAC hysteresis).

AC

The pulse-by-pulse current limit for each MOSFET is set at 9.1A.

The maximum power limit is set at ~120% of the rated output power. The phase

management function permits phase shedding/adding ~15% of the nominal output power

for high line (230V

). This level can be programmed by modifying MOT resistor (R6).

AC

© 2010 Fairchild Semiconductor Corporation 5 FEB279_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

4. Test Procedure

Before testing the board; DC voltage supply for VDD, AC voltage supply for line input,

and DC electric load for output should be connected to the board properly.

1. Supply V

specification for V

for the control chip first. It should be higher than 13V (refer to the

DD

turn-on threshold voltage in Table 1).

DD

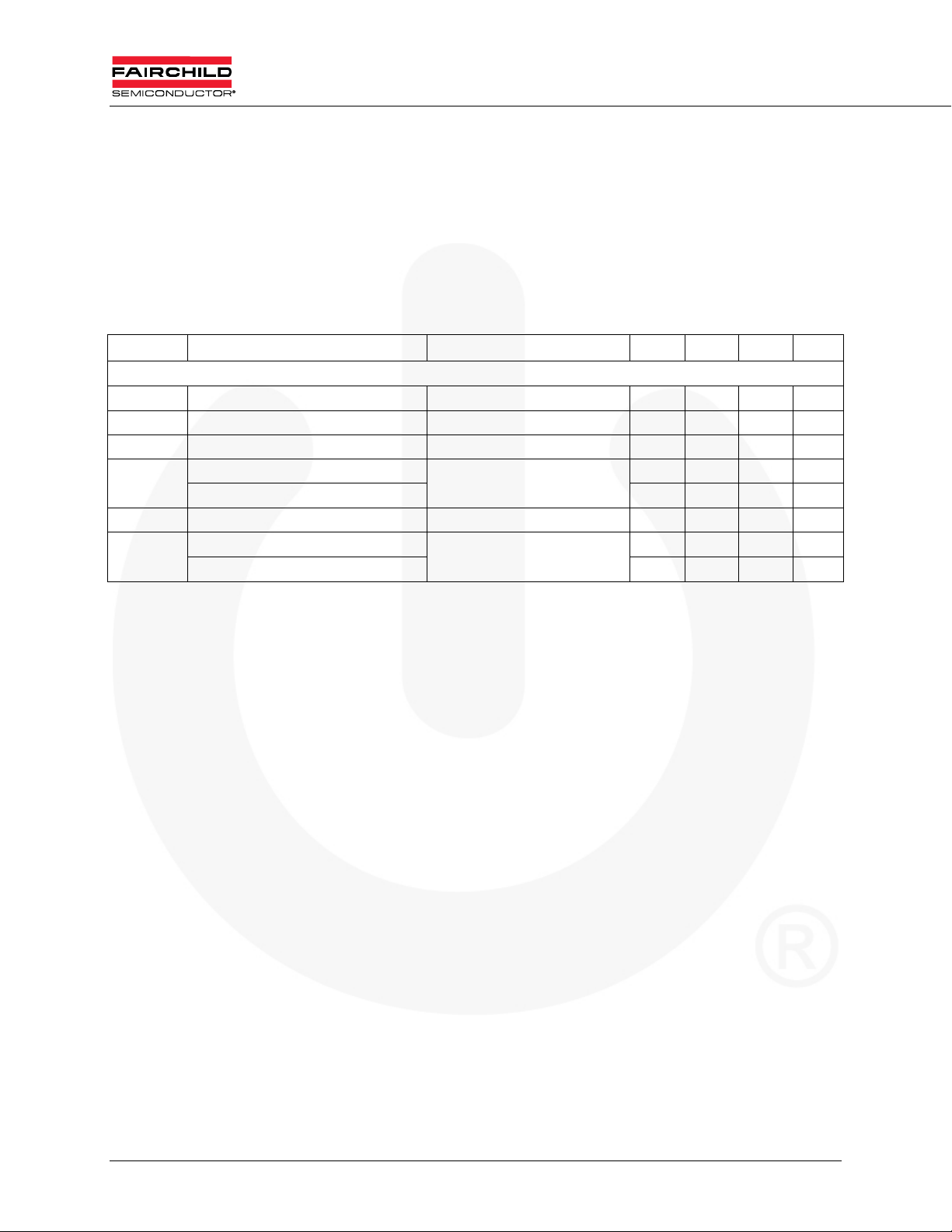

Table 1. Specification Excerpt from FAN9611/12 Datasheet

Symbol Parameter Conditions Min. Typ. Max. Unit

Supply

I

Startup Supply Current VDD = VON – 0.2V 80 110 µA

STARTUP

IDD Operating Current Output Not Switching 3.7 5.2 mA

I

Dynamic Operating Current fSW = 50kHz; C

DD_DYM

VON

V

OFF

V

HYS

UVLO Start Threshold, FAN9611

UVLO Start Threshold, FAN9612 12.0 12.5 13.0 V

UVLO Stop Threshold Voltage VDD Decreasing 7.0 7.5 8.0 V

UVLO Hysteresis, FAN9611

UVLO Hysteresis, FAN9612 5.0

VDD Increasing

V

– V

OFF

ON

= 2nF 4 6 mA

LOAD

9.5 10.0 10.5 V

2.5

V

V

2. Connect the AC voltage (85~265VAC) to start the FAN9611/12 evaluation board.

Since FAN9611/12 has brownout protection, any input voltages lower than operation

range triggers the protection.

3. Change load current (0~1A) and check the operation.

© 2010 Fairchild Semiconductor Corporation 6 FEB279_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

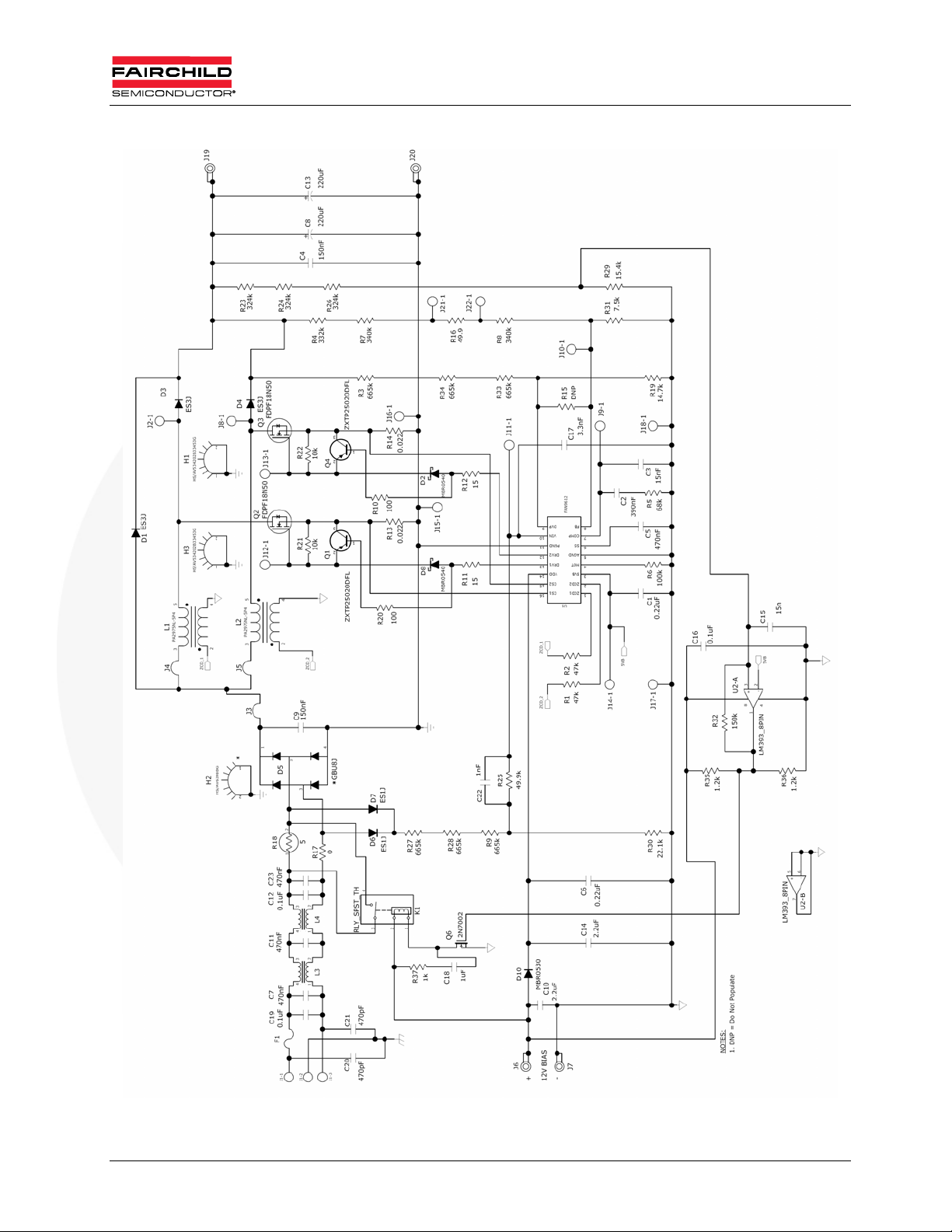

5. Schematic

Figure 2. FAN9611/12 400W Evaluation Board Schematic

© 2010 Fairchild Semiconductor Corporation 7 FEB388_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

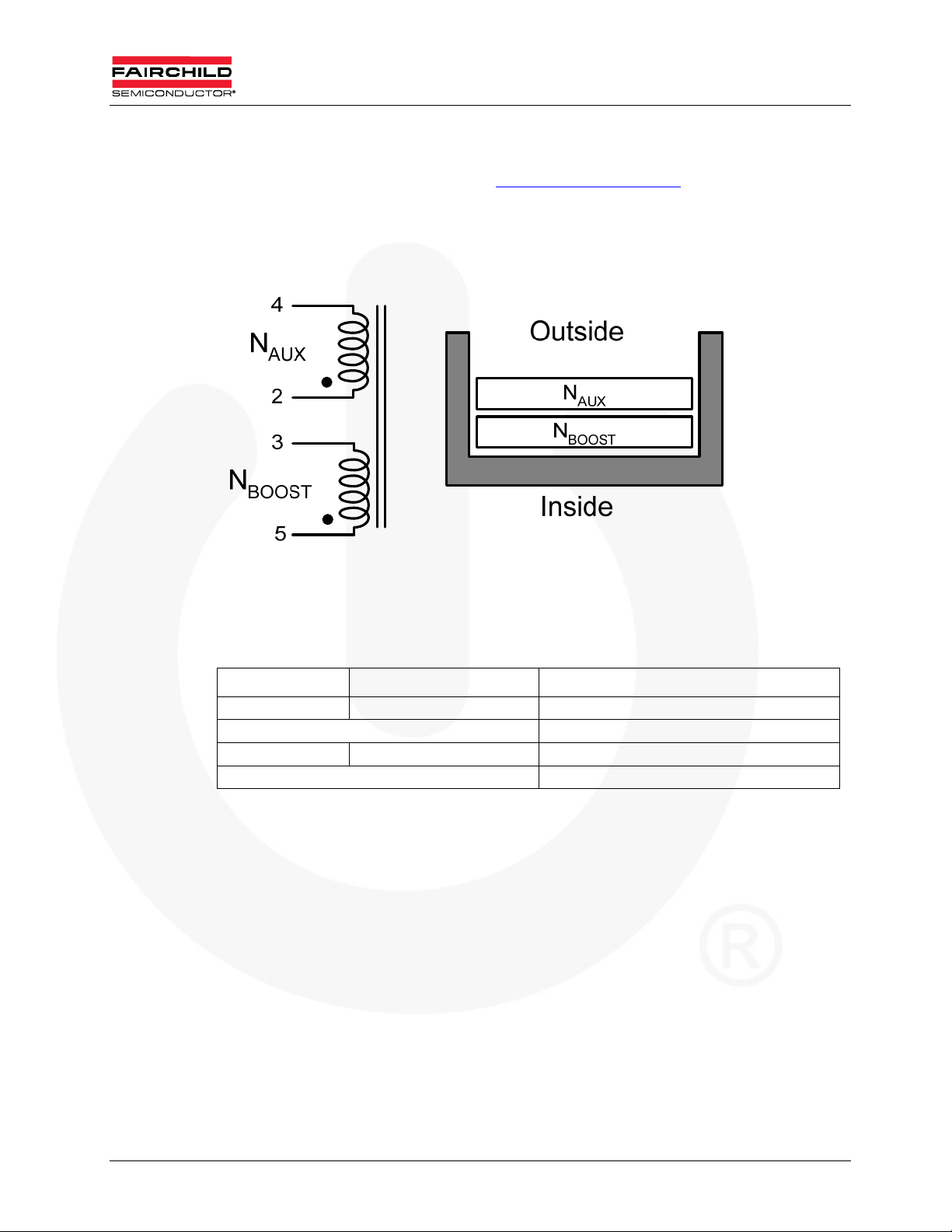

6. Boost Inductor Specification

PA2975NL-5P4 from Pulse Electronics (www.pulseelectronics.com)

Core: PQ3230 (Ae=161mm2)

Bobbin: PQ3230

Inductance : 200H

Figure 3. Boost Inductor used in this FAN9611/12 Evaluation Board

Table 2. Inductor Turns Specifications

Pin Turns

N1 5 3 30

Insulation Tape

N2 2 4 3

Insulation Tape

© 2010 Fairchild Semiconductor Corporation 8 FEB388_FAN9611/12 • Rev. 0.0.3

www.fairchildsemi.com

7. Line Filter Inductor Specifications

Electrical Specifications (1kHz, 1V)

- Inductance: 9.0mH (min.) for each winding

- DC resistance: 0.05Ω (max.) for each winding

- Number of turns: 0.9mm×2/30.5 turns for each winding

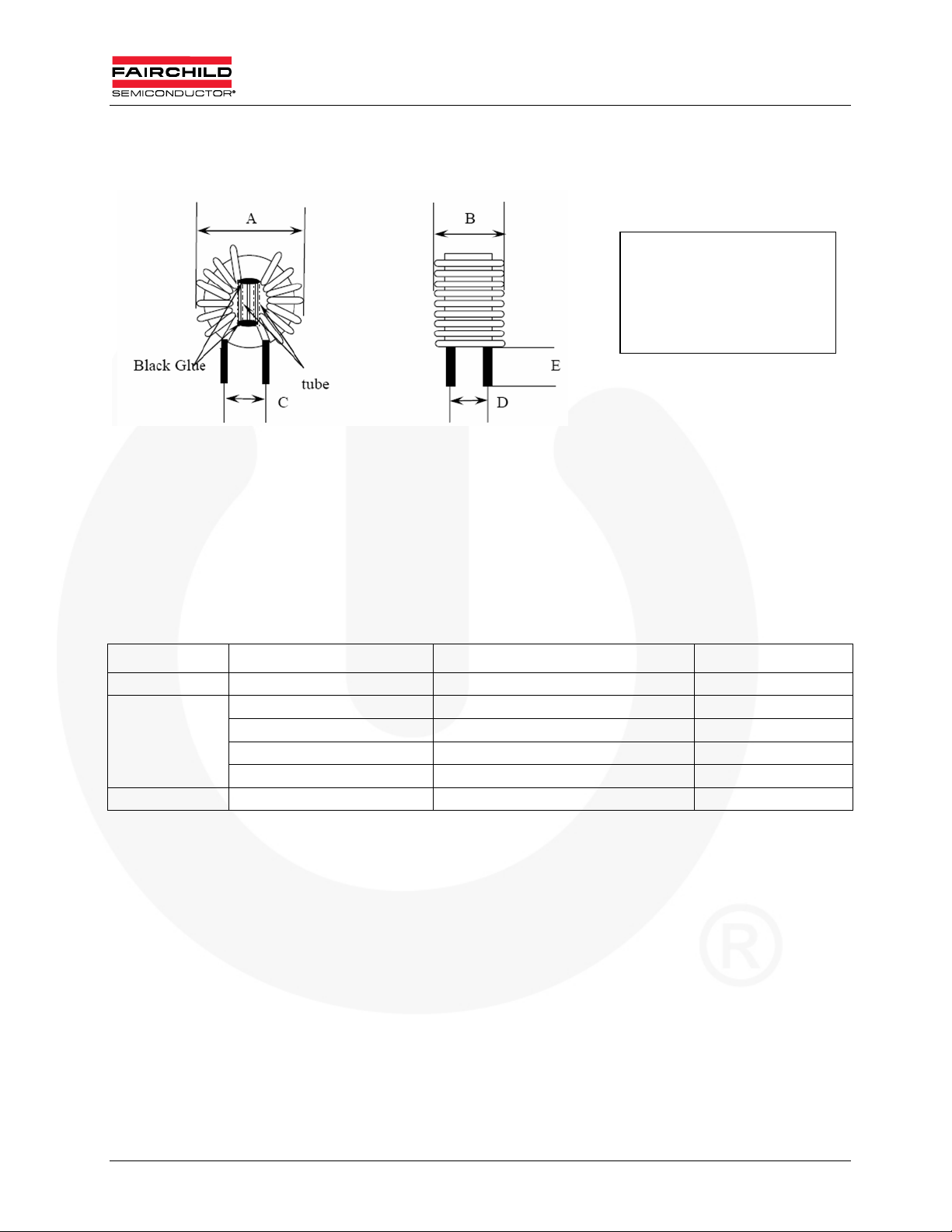

Figure 4. Line Filter Inductor Specification

A : 30mm (max)

B: 15 mm (max)

C: 11 mm

D: 13 mm

E: 15±1 mm

Table 3. Materials List

Component Material Manufacturer UL File Number

Core T22x14x08 Core T22x14x08, TOMITA

THFN-216 Ta Ya Electric Wire Co,. Ltd. E197768

Wire

Solder 96.5%, Sn, 3%, Ag, 0.5% Cu Xin Yuan Co., Ltd.

UEWN/U PACIFIC Wire and cable Co., Ltd. E201757

UEWE Tai-1 Electric Wire & Cable Co., Ltd. E85640

UWY Jang Shing Wire Co., Ltd. E174837

© 2010 Fairchild Semiconductor Corporation 9 FEB388_FAN9611/12 • Rev. 0.0.3

Loading...

Loading...