Fairchild FAN6747WALMY service manual

FAN6747WALMY

Highly Integrated Green-Mode PWM Controller

FAN6747WALMY — Highly Integrated Green-Mode PWM Controller

June 2012

Features

High-Voltage Startup

AC-Line Brownout Protection by HV Pin

Constant Output Power Limit by HV Pin

(Full AC-Line Range)

Built-in 8ms Soft-Start Function

Leading-Edge Blanking (LEB)

Short-Circuit Protection (SCP) with 15ms Debounce

Time as Output Short

Peak-Current Mode Operation with Cycle-by-Cycle

Current Limiting

Low Startup Current: 30µA

Low Operating Current: 1.7mA

Over-Temperature Protection (OTP) with External

Negative-Temperature-Coefficient (NTC) Thermistor

PWM Frequency Decreasing at Green-Mode

V

Over-Voltage Protection (OVP)

DD

Internal Latch Circuit for OVP, OTP, SCP, and OCP

Applications

General-purpose switched-mode power supplies

(SMPS) and flyback power converters, including:

Power Adapters

SMPS with Peak-Current Output, such as for

Printers, Scanners, and Motor Drivers

AC/DC NB Adapters

Open-Frame SMPS

Description

The highly integrated FAN6747WA PWM controller

provides several features to enhance the performance

of flyback converters. To minimize standby power

consumption, a proprietary Green-Mode function

provides off-time modulation to decrease the switching

frequency with load condition.

Under zero-load condition, the power supply enters

Burst Mode. Burst frequency can be low to reduce

power. Green Mode enables the power supply to meet

international power conservation requirements.

The FAN6747WA is specially designed for SMPS with

peak-current output. It incorporates a cycle-by-cycle

current limiting and Over-Current-Protection (OCP) that

can handle peak load with a debounce time. Once the

current is over the threshold level, it triggers the first

counter for 15ms and checks if V

is, the PWM latches off for SCP. If V

11.5V; it keeps counting for 860ms, then the PWM

latches off for OCP.

FAN6747WA also integrates a frequency-hopping

function that helps reduce EMI emission of a power

supply with minimum line filters. The built-in

synchronized slope compensation helps achieve stable

peak-current control. To keep constant output power

limit over the universal AC input range, the current limit

is adjusted according to AC line voltage detected by the

HV pin. The gate output is clamped at 14V to protect the

external MOSFET from over-voltage damage.

Other protection functions include AC-line brownout

protection with hysteresis and VDD Over-Voltage

Protection (OVP). For Over-Temperature Protection

(OTP), an external NTC thermistor can be applied to

sense the ambient temperature. When OCP, OVP,

SCP, or OTP is activated, an internal latch circuit

latches off the controller. The latch is reset when the

supply is removed.

V

DD

is below 11.5V. If it

DD

is higher than

DD

Ordering Information

Part Number

FAN6747WALMY -40 to +105°C

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN6747WALMY • Rev. 1.0.2

Operating

Temperature Range

Package

8-Lead, Small-Outline Integrated Circuit (SOIC),

JEDEC MS-012, .15-Inch Narrow Body

Packing

Method

Tape & Reel

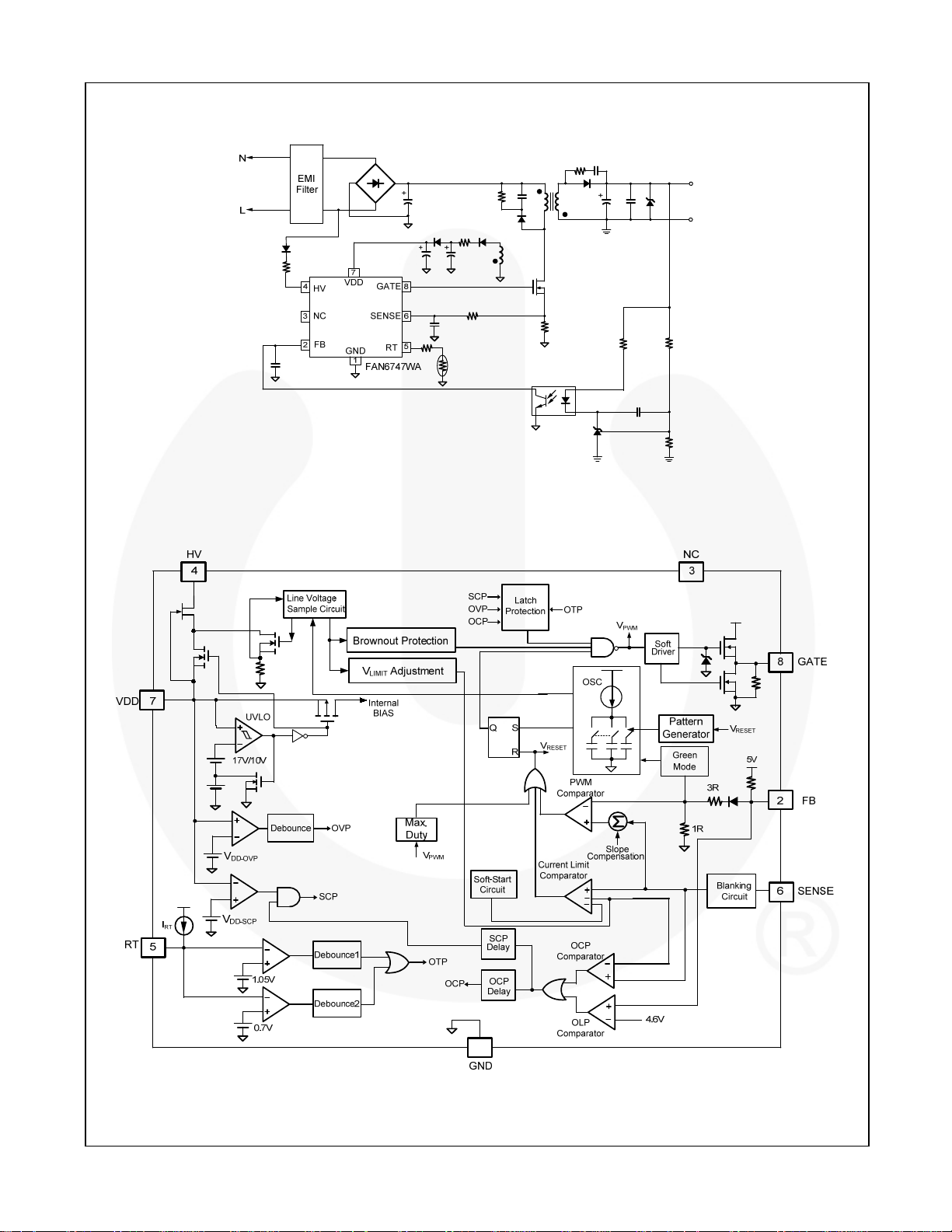

Application Diagram

FAN6747WALMY — Highly Integrated Green-Mode PWM Controller

Figure 1. Typical Application

Internal Block Diagram

Figure 2. Functional Block Diagram

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN6747WALMY • Rev. 1.0.2 2

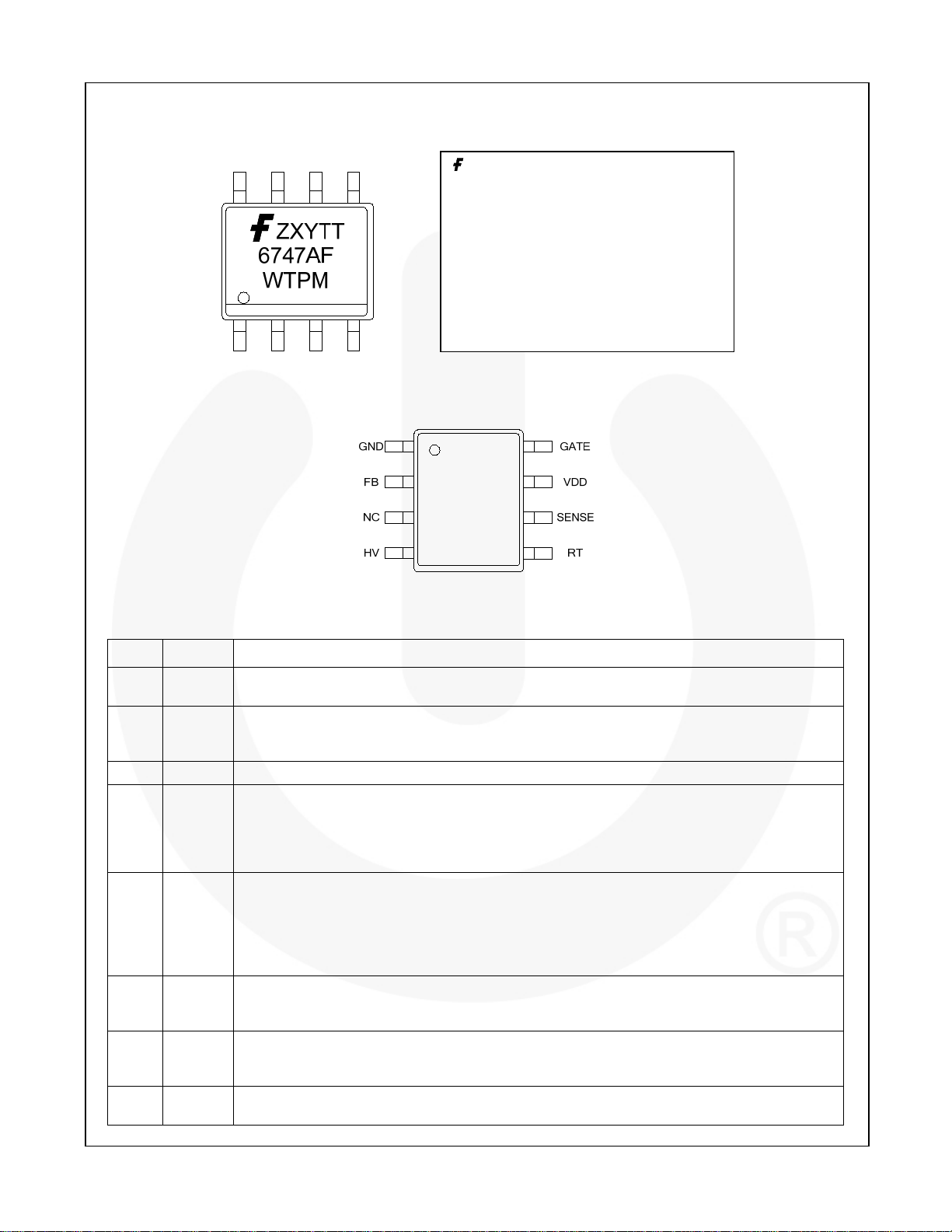

Marking Information

Pin Configuration

: Fairchild Logo

Z: Plant Code

X: Year Code

Y: Week Code

TT: Die Run Code

F: L = OCP Latch

T: Package Type (N =DIP, M = SOP)

Green Compound

P: Y =

M: Manufacturing Flow Code

Figure 3. Top Mark

FAN6747WALMY — Highly Integrated Green-Mode PWM Controller

Figure 4. Pin Assignments

Pin Definitions

Pin # Name Description

1 GND

2 FB

3 NC No Connection.

4 HV

5 RT

6 SENSE

7 VDD

8 GATE

Ground. This pin is used for the ground potential of all the pins. A 0.1µF decoupling capacitor

placed between VDD and GND is recommended.

Feedback. The output voltage feedback information from the external compensation circuit is fed

into this pin. The PWM duty cycle is determined from this pin and the current-sense signal from

Pin 6 (SENSE).

High-Voltage Startup. This pin is connected to the line input via diodes and resistors to meet

brownout and high/low line compensation. Once the voltage of the HV pin is lower than the

brownout voltage, PWM output is turned off. High/low line compensation dominates the OverCurrent Protection (OCP) level and cycle-by-cycle current limit to solve the unequal OCP level

and power-limit problem under universal input.

Over-Temperature Protection. For Over-Temperature Protection (OTP), an external NTC

thermistor is connected from this pin to GND. The impedance of the NTC decreases at high

temperatures. Once the voltage of the RT pin drops below the threshold voltage, the controller

latches off the PWM. If the RT pin is not connected to the NTC resistor for over-temperature

protection, it is recommended to place one 100K resistor to ground to prevent noise

interference. This pin is limited by an internal clamping circuit.

Current Sense. This pin is used to sense the MOSFET current for the Current-Mode PWM and

OCP. If the switching current is higher than the OCP threshold and lasts for 860ms, the controller

latches off the PWM.

Supply Voltage. IC operating current and MOSFET driving current are supplied using this pin.

This pin is connected to an external bulk capacitor of typically 10µF. The threshold voltages for

startup and turn-off are 17V and 10V, respectively. The operating current is lower than 2mA.

Gate Driver Output. The totem-pole output driver for the power MOSFET. It is internally

clamped below 14V.

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN6747WALMY • Rev. 1.0.2 3

FAN6747WALMY — Highly Integrated Green-Mode PWM Controller

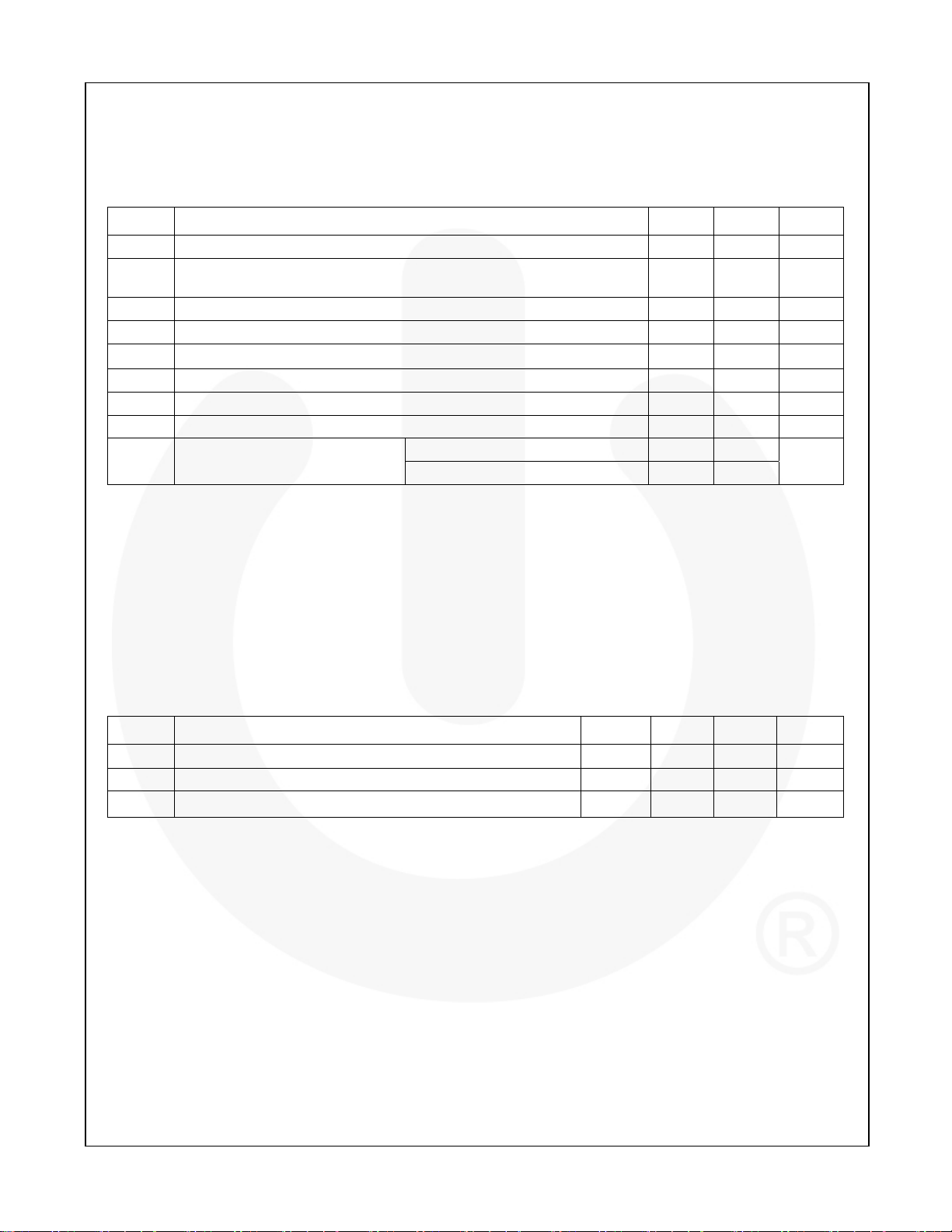

Absolute Maximum Ratings

Stresses exceeding the absolute maximum ratings may damage the device. The device may not function or be

operable above the recommended operating conditions and stressing the parts to these levels is not recommended.

In addition, extended exposure to stresses above the recommended operating conditions may affect device reliability.

The absolute maximum ratings are stress ratings only.

Symbol Parameter Min. Max. Unit

VDD DC Supply Voltage 30 V

VHV

ΘJA

T

ESD

Notes:

1. Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device.

2. All voltage values, except differential voltages, are given with respect to the network ground terminal.

3. ESD with HV pin: CDM=1250V and HBM=1000V.

4. ESD without HV pin: CDM and HBM sign actual level (no derating).

Suddenly Input Voltage to HV Pin within 1 Second

(Series connect with R

VL Input Voltage to FB, SENSE, and RT Pins -0.3 7.0 V

PD Power Dissipation (TA<50°C) 400 mW

Thermal Resistance (Junction-to-Ambient) 150 °C/W

TJ Operating Junction Temperature -40 +125 °C

Storage Temperature Range -55 +150 °C

STG

TL Lead Temperature (Soldering, 10 Seconds) +260 °C

Electrostatic Discharge Capability,

All Pins Except HV Pin

HV

)

Human Body Model, JESD22-A114 5

Charge Device Model, JESD22-C101 2

640 V

kV

Recommended Operating Conditions

The Recommended Operating Conditions table defines the conditions for actual device operation. Recommended

operating conditions are specified to ensure optimal performance to the datasheet specifications. Fairchild does not

recommend exceeding them or designing to Absolute Maximum Ratings.

Symbol Parameter Min. Typ. Max. Unit

TA Operating Ambient Temperature -40 +105 °C

VHV Input Voltage to HV Pin 500 V

RHV HV Startup Resistor 150 200 250 k

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN6747WALMY • Rev. 1.0.2 4

FAN6747WALMY — Highly Integrated Green-Mode PWM Controller

Electrical Characteristics

VDD=15V and TA=25°C, unless otherwise specified.

Symbol Parameter Condition Min. Typ. Max. Unit

VDD Section

VOP Continuously Operating Voltage 24 V

V

Turn-On Threshold Voltage 16 17 18 V

DD-ON

V

PWM Turn-Off Threshold Voltage 9 10 11 V

DD-OFF

Threshold Voltage on VDD for HV

V

DD-OLP

JFET Turn-On in Protection

Condition

V

DD-LH

Threshold Voltage on VDD Pin for

Latch-Off Release Voltage

Threshold Voltage on VDD Pin for

V

DD-AC

Disable AC Recovery to Avoid

Startup Failed

V

DD-SCP

ILH

I

DD-ST

I

DD-OLP

I

DD-OP1

I

DD-OP2

Threshold Voltage on VDD Pin for

Short-Circuit Protection (SCP)

Holding Current Under Latch-Off

Conduction

Startup Current V

Holding Current at PWM-Off

Phase

Operating Supply Current when

PWM Operating

Operating Supply Current when

PWM Stop

Threshold Voltage on VDD Pin for

V

V

DD-OVP

Over-Voltage Protection

DD

(Latch-Off)

t

D-OVP

VDD OVP Debounce Time VFB > V

After Trigger OCP/

SCP/ OVP/ OTP

5.5 6.5 7.5 V

3.5 4.0 4.5 V

V

V

> V

FB

FBO

DD-OFF

V

DD-OFF

+3 V

+1 V

DD-OFF

DD-OFF

+3.5 V

+1.5 V

DD-OFF

DD-OFF

+4 V

+2 V

VDD=5V 80 100 120 A

– 0.16V 30 A

DD-ON

V

+0.1V 180 240 300 A

DD-OLP

V

=20V, VFB=3V

DD

Gate Open

V

=20V, VFB=3V

DD

Gate Open

1.7 2.0 mA

1.2 1.5 mA

24 25 26 V

75 160 245 s

FB-N

Continued on the following page…

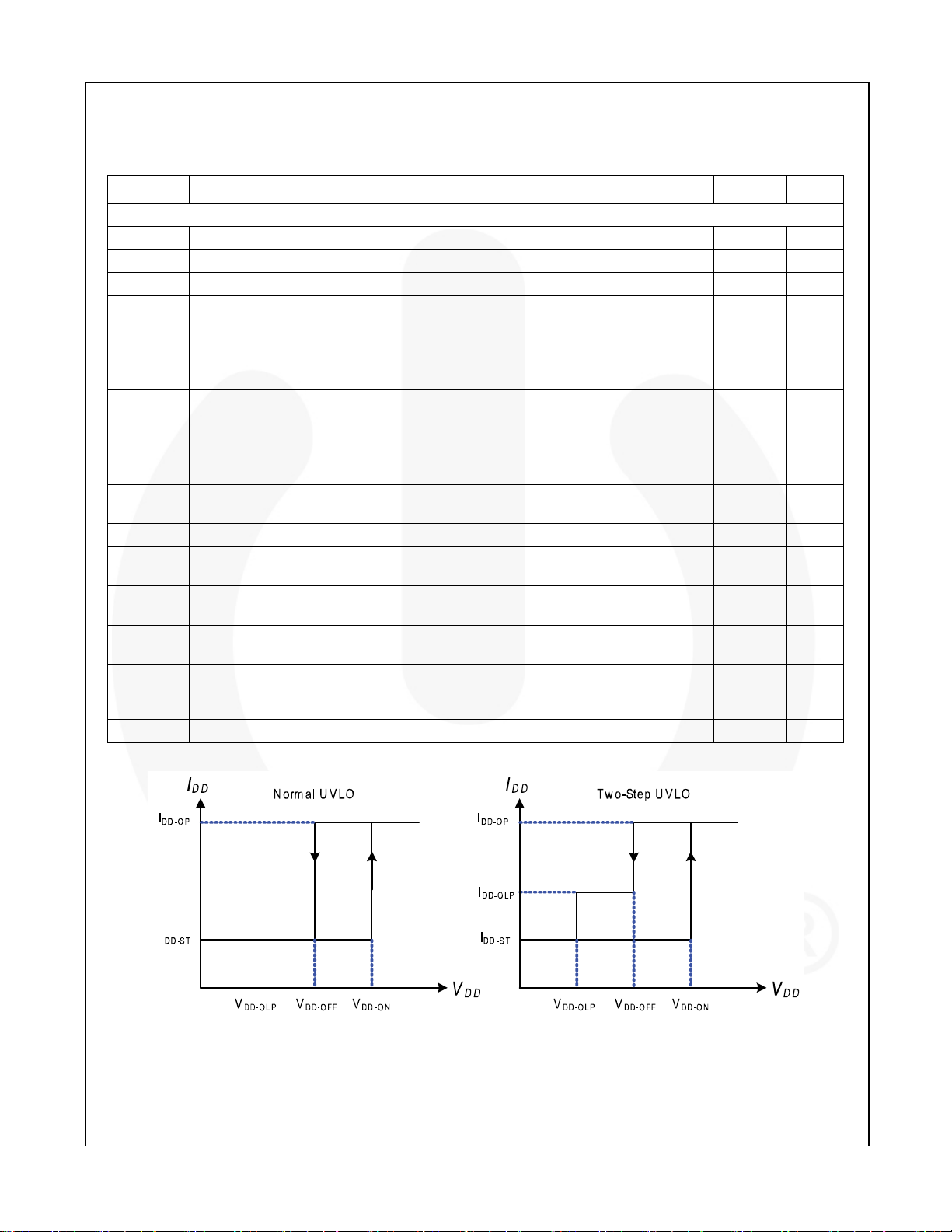

Figure 5. UVLO Specification

© 2011 Fairchild Semiconductor Corporation www.fairchildsemi.com

FAN6747WALMY • Rev. 1.0.2 5

Loading...

Loading...