Page 1

Page 2

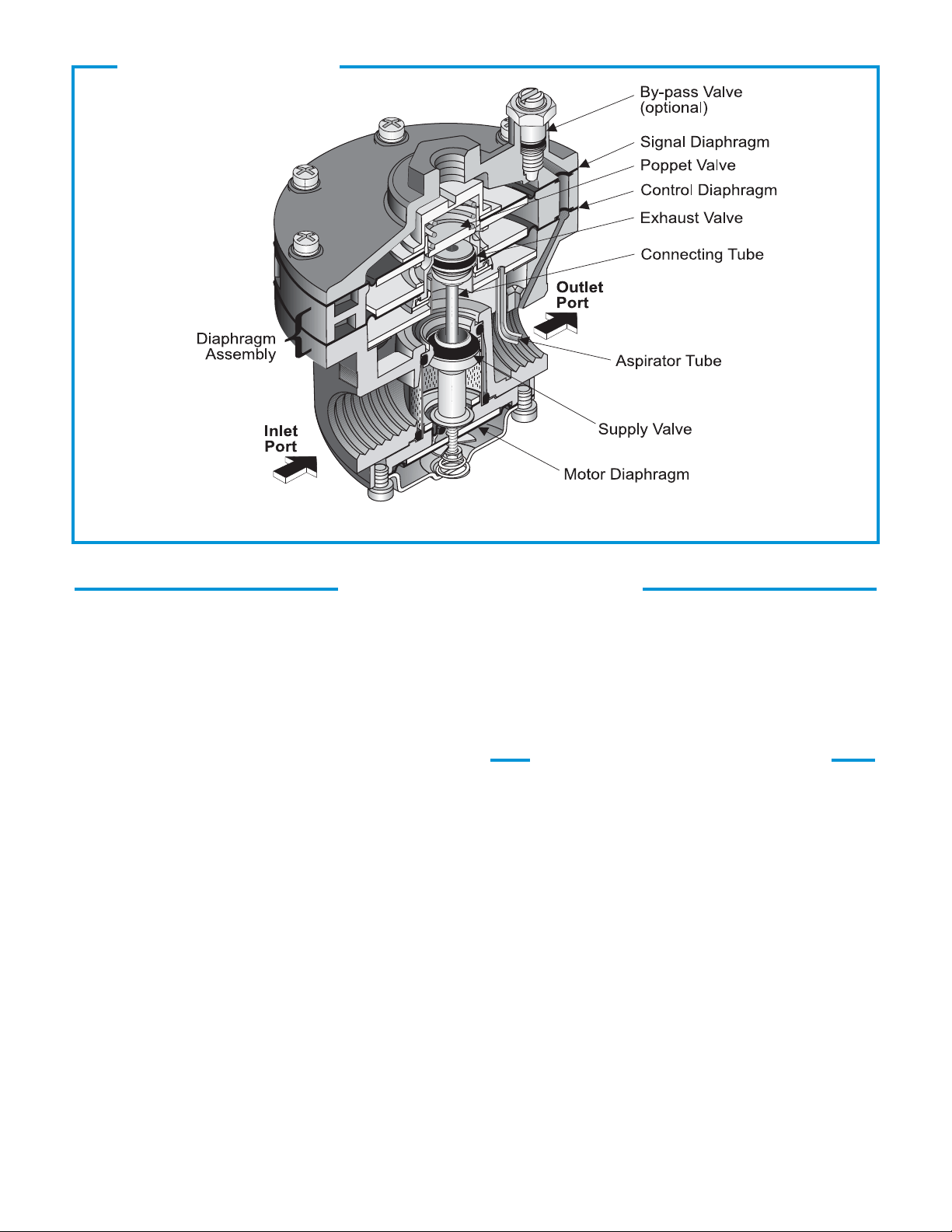

CROSS SECTION

Figure 1. Model 4500A Detail Drawing

GENERAL INFORMATION

The Model 4500A Pneumatic Volume Booster reproduces a pneumatic signal in a 1:1 ratio or in multiplying

or dividing ratios. It is ideal for systems requiring input

isolation or increased flow capacity.

The Model 4500A has the following features:

Five (5) signal to output ratios meet most control element

•

requirements.

Control sensitivity of 1" water column allows use in

•

precision applications.

Large Supply and Exhaust V alves provide high forward

•

and exhaust flows.

Soft Supply and Exhaust Valve seats minimize air con-

•

sumption.

A balanced Supply Valve minimizes the effect of supply

•

pressure variation.

An Aspirator Tube compensates downstream pressure

•

droop under flow conditions.

A separate Control Chamber isolates the diaphragm

•

from the main flow to eliminate hunting and buzzing.

Optional remote feedback port minimizes pressure drop

•

at final control element under flow conditions.

1 Model 4500A

The optional adjustable By-pass Valve lets you tune for

•

optimum dynamic response. (1:1 Ratio Only)

Unit construction lets you service the Model 4500A without

•

removing it from the line.

OPERATING PRINCIPLES

When signal pressure on the top of the Signal Diaphragm creates a downward force on the Diaphragm

Assembly , the Supply Valve opens. Output pressure

flows through the Outlet Port and the Aspirator Tube

to the Control Chamber to create an upward force on

the bottom of the Control Diaphragm. When the

setpoint is reached, the force of the signal pressure

that acts on the top of the Signal Diaphragm balances

with the force of the output pressure that acts on the

bottom of the Control Diaphragm to close the Supply

Valve.

When the output pressure increases above the signal pressure, the Diaphragm Assembly moves upward to close the Supply V alve and open the Exhaust

V alve. Because the Poppet V alve is closed, pressure

flows down the Connecting Tube to the bottom of the

Motor Diaphragm. This pressure keeps the Supply

Valve tightly closed while in the exhaust mode. The

Poppet Valve opens and excess output pressure

exhausts through the vent in the side of the unit until

it reaches the setpoint. For more information, see

Figure 1.

Page 3

3/8

9.5

5/16

8.1

By-pass Valve

1:1 Ratio Only

(optional)

1/4 NPT

Signal Port

43/64

20.4

31/64

12.2

By-pass

Valve Open

By-pass

Valve Closed

OUTLINE DIMENSIONS

Hex.

1

25.4

1 13/32

35.9

1/2 NPT Tapped

Exhaust Port

(optional)

5 5/64

128.8

3 19/64

83.8

3/8 NPT

Inlet Port

3 1/2

Face Dim.

88.9

(typical)

3 13/32

86.6

FUNCTIONAL SPECIFICA TIONS

Maximum

Output

Pressure

Maximum

Supply

Pressure

Ratio

[BAR]

(kPa)

[BAR]

(kPa)

1:1 1:2 1:3

psig

150

[10.0]

(1000)

psig

250

[17.0]

(1700)

(1000)

(1700)

Flow Capacity

100 psig, [7.0 BAR],

(700kPa) supply,

SCFM

150

20 psig, [1.5 BAR],

(150 kPa) set point.

(m3/HR)

(255)

Exhaust

Vents (8)

(keep clear)

1/8 NPT

Remote

Feedback

Port

(optional)

3/8 NPT

Outlet Port

(typical)

1/4 NPT

Gage Ports (2)

(typical)

2 19/64

58.5

1 9/16

39.6

Figure 2. Model 4500A Outline Dimensions

SPECIFICATIONS

PERFORMANCE SPECIFICATIONS

2:1

3:1

150

[10.0]

250

[17.0]

150

(255)

150

[10.0]

(1000)

250

[17.0]

(1700)

150

(255)

75

[5.0]

(500)

250

[17.0]

(1700)

150

(255)

50

[3.5]

(350)

250

[17.0]

(1700)

150

(76.5)

Sensitivity

Water Column

Ratio Accuracy

% of 100 psig, [7.0 BAR],

(700 kPa) output span.

% of output span with

100 psig, [7.0 BAR],

(700kPa) input span.

Supply

Pressure Effect

for change of 100 psig

[7.0 BAR], (700 kPa).

Ratio

(cm)

psig

[BAR]

(kPa)

4 1/2

114.3

1:1 1:2 1:3

1"

2"

(2.54)

(5.08)

3.0 3.0 3.0

0.10

0.20

[.007]

[.014]

(0.7)

(1.4)

3"

(7.62)

0.30

[.021]

(2.1)

5 53/64

148.2

2 53/64

71.8

2:1

2"

(5.08)

3.0 3.0

0.10

[.007]

(0.7)

3:1

2"

(5.08)

0.10

[.007]

(0.7)

Exhaust Capacity

Downstream Pressure

5 psig, [.35 BAR],

(35 kPa) above

20 psig, [1.5 BAR],

(150 kPa) set point.

SCFM

(m3/HR)

40

(65.2)

40

(65.2)

40

(65.2)

40

(65.2)

40

(18.7)

Ambient

Temperature

Materials

of Construction

Body & Housing . . . . . . . . . . . . . . . . . .

Trim . . . . . . . . . . . . . . . .

Diaphragm . . . . . . . . . . . . . . . .

-40

-0

F to 200

-0

F

(-400C to 93.30C)

Aluminum

Zinc Plated Steel, Brass

Nitrile on Dacron

Model 4500A 2

Page 4

TYPICALAPPLICATION

1

4

E

VRG CONTROLS USE MODEL 4514AE

x

x

x

4-20 mA

120 psig,

[8.0 BAR],

(800 kPa)

Supply

Pneumatic

Electrical

Controller

4-20 mA Feedback

Model

T8000

30 psig, [2.0 BAR], (200 kPa) or

50 psig, [3.5 BAR], (350 kPa)

Model

T6000

Tire

B

Model

4516A

Figure 3. Model 4500A Inflation and Test Pressure Application

TYPICAL APPLICATION

The Model 4500A controls inflation and test pressures of a tire testing machine. An electronic controller transmits a 4-20 mA signal to a TA6000-405

transducer. The transducer sends an output signal

to a Model 4516A Booster. The booster provides a

set pressure to set the tire on the bead. The booster

also reduces and maintains the pressure during

testing. The T8000 senses the tire pressure and

sends a 4-20mA signal to the Controller to close the

loop. For more information, see Figure 3.

INST ALLA TION

For installation instructions, see the Model 4500A Pneumatic Volume Booster IOM, IS-2004500A.

ORDERING INFORMATION

ORDERING INFORMATION

Catalog Number

Ratio

1:1

1:2

1:3

2:1

3:1

Pipe Size

3/8 NPT

1/2 NPT

3/4 NPT

Options

T apped Exhaust

By-pass V alve

Feedback

BSPT(T apered)

BSPP (Parallel)

1

For 1:1 Ratio Only.

2

BSPP Threads in Inlet & Outlet. Others BSPT.

1

2

45

(1)

(2)

(3)

(4)

(5)

A

(3)

(4)

(6)

(E)

(I)

(P)

(U)

(H)

CS-2004500A

Litho in USA

Rev. B 11/02

Loading...

Loading...