Page 1

Linear and angular

encoders

standard series

Page 2

Technology

An encoder measures the actual machine

position without the effect of any

mechanical inaccuracies. Machine errors

induced due to mechanical inaccuracies are

eliminated as the encoder is attached to the

machine guide ways and hence provides the

actual machine position to the controller.

Some of the potential sources of such errors

in a machine tool such as lead screw pitch,

certain amount of backlash and thermal

behavior can be minimized using these

encoders.

Measuring methods

Fagor uses two measuring methods in their incremental

encoders:

• Graduated glass: Linear encoders with a measuring

length of up to 3

light from the LED goes through an engraved glass and a

reticule before reaching the receiving photo diodes. The

period of the generated electrical signals is the same as the

graduation pitch.

• Graduated steel: Linear encoders with a measuring length

over 3

040 mm use auto imaging principle which uses

diffuse light reflected from the graduated steel tape. This

optical reading system consists of a LED as a light source,

a mesh that creates the image and a monolithic photo

detector element in the image plane, which is specially

designed and patented by Fagor.

040 mm use optical transmission. The

Types of incremental encoders

• Linear encoder: Suitable for applications on milling,

turning, boring mills, grinding machines for feedrates of up

to 120 m/min and vibration levels up to 10 g.

• Rotary encoder: Used as measurement device for rotary

axis, angular speed and also for linear movements for

mechanisms like lead screws etc. They are widely used

in machine tools, wood working equipment, robots and

material handlers etc.

Enclosed design

The graduated scale in a linear encoder is protected by the

enclosed aluminum profile. The highly durable sealing lips

protect the encoder from industrial contaminants and liquid

splashes as the reader head moves along the profile. The

reader head movement in complete synchronization captures

and transmits the position and movement of the machine.

The reader head moves along the graduated scale on linear

bearings minimizing the friction. For enhanced protection

against contamination both ends of the encoder and also the

reader head can be connected to pressurized air.

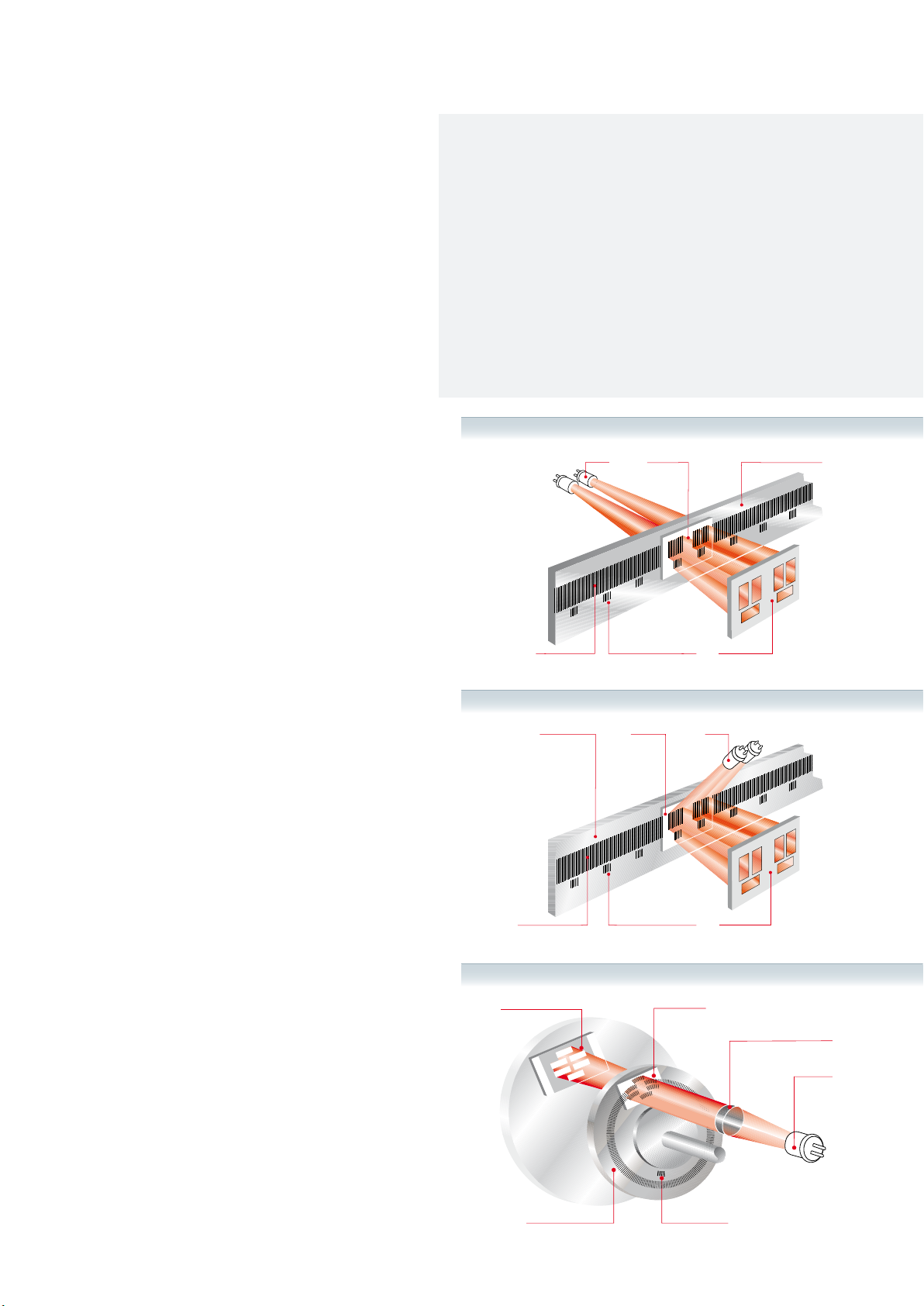

Graduated glass linear encoder

LED’s Graduated glassGrid

Etching Receiving photo-diodes

Reference marks

Graduated steel linear encoder

Graduated steel Grid LED’s

2

Etching

Reference marks

Graduated glass rotary encoder

Receiving photo-diodes

Graduated glass disk

Receiving photo-diodes

Grid

Flat convex lens

LED

Reference marks

Page 3

Graduated glass

Cursor

Sealing lips

Reader head

Air intake at both ends

Incremental

Distance-coded

Air intake on the reader head

Linear encoder

Series

F 50.1 50.2 50.3 100

C, M 10.02 10.04 10.06 20

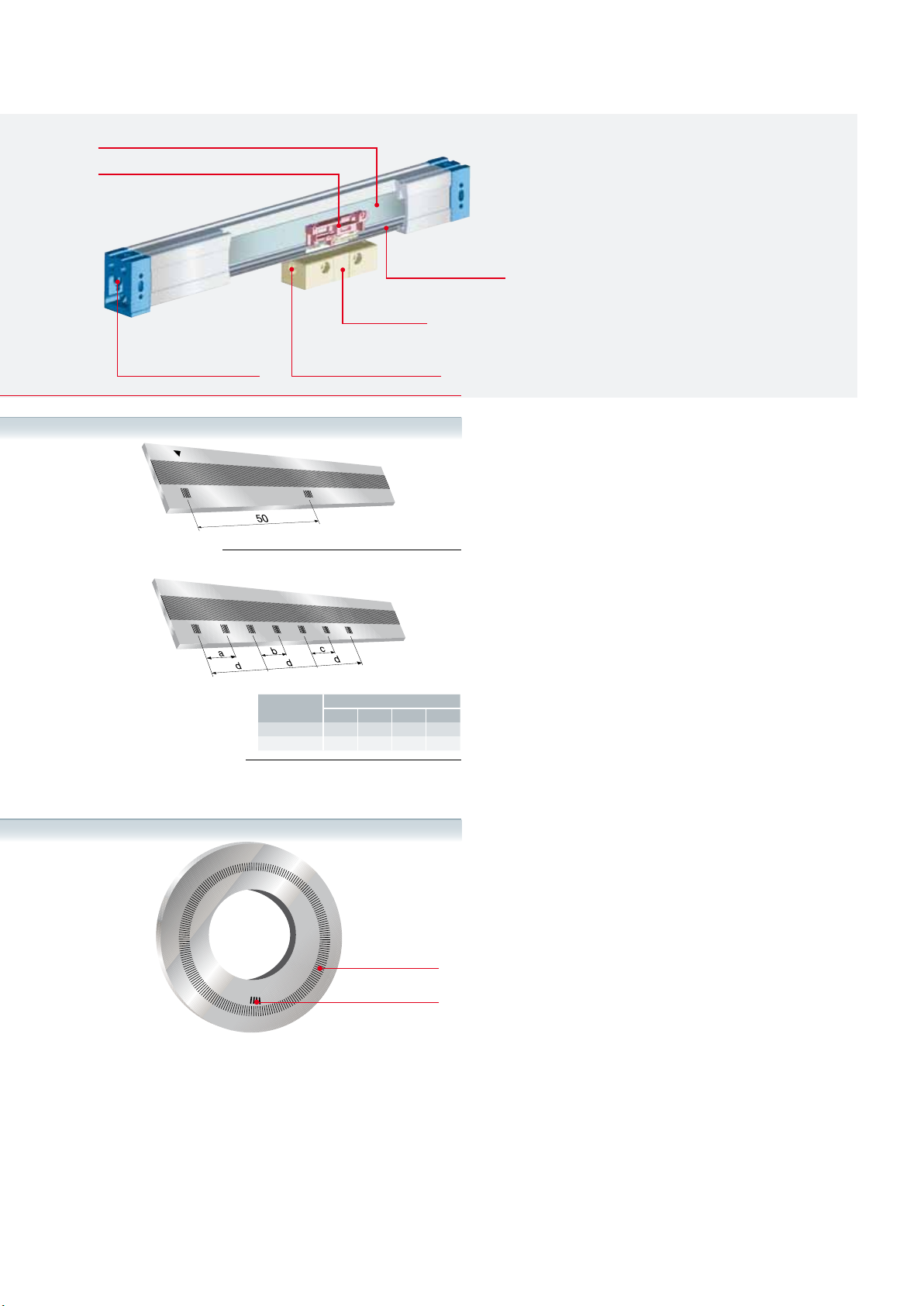

Distances

a b c d

Reference signals (I0)

The reference signal is a specially etched mark along the

graduated glass, which when scanned generates a pulse

signal. They are used to set/recover the machine zero

position and avoid possible errors after powering up the DRO

or CNC system.

Fagor provides two different types of reference marks

• Incremental: The reference signal is synchronized with the

feedback pulses to ensure perfect measuring repeatability.

Linear: One every 50 mm of travel.

Rotary: One signal per turn.

• Distance-coded: Each distance coded reference signal

is separated from the next signal a different distance

according to predefined mathematical function. The actual

position value after power up is restored by moving through

two consecutive reference signals. This is very useful for

long travel axes as the movement needed to recover actual

position is minimum.

I

:

0

incremental

Rotary encoder

I

0

Pitch

Zero position

3

Page 4

E N C O D E R S

Electrical output signals

D i f fe re nt ia l T TL

These are complementary signals in compliance with the

EIA standard RS-422. This characteristic together with a

line termination of 120 Ω, twisted pair, and an overall shield

provide greater immunity to electromagnetic noise caused by

the surrounding environment.

Characteristics

I

Signals A, /A, B, /B,

Signal level VH ≥ 2.5V IH= 20 mA

VL ≤ 0.5V IL= 20 mA

With 1 m cable

90º reference signal (

I

) Synchronized with A and B

0

Switching time t+/t-< 30ns

With 1 m cable

T period according to model

Max. cable length 50 meters

Load impedance Z

o= 120 Ω between differential

0

, / I

0

N o di ff er en t i a l TT L

Characteristics

Signals A, B, /

Signal level A, B, I

90º reference signal (

0

I

) Synchronized with A and B

0

Switching time t+/t-< 30ns

T period according to model

Max. cable length 20 meters

Voltage drop across cable

The voltage requirements for a TTL encoder are 5V ±5%.

A simple formula described below, may be used to calculate

the maximum cable length depending on the cross section

diameter of the supply cable:

L

max = (VCC-4,5)* 500 / (ZCABLE/Km* IMAX)

Example

V

cc = 5V, IMAX = 0.2 Amp (with 120 Ω load)

2

Z (1 mm

Z (0.5 mm

Z (0.25 mm

Z (0.14 mm

) = 16.6 Ω/Km (Lmax= 75 m)

2

) = 32 Ω/Km (Lmax= 39 m)

2

) = 66 Ω/Km (Lmax= 19 m)

2

) = 132 Ω/Km (Lmax= 9 m)

I

0

VH ≥ 3.5 V IH = 4 mA

VL ≤ 0.4 V IL = 4 mA

with 1 m cable

with 1 m cable

Cable length

4

meters

Page 5

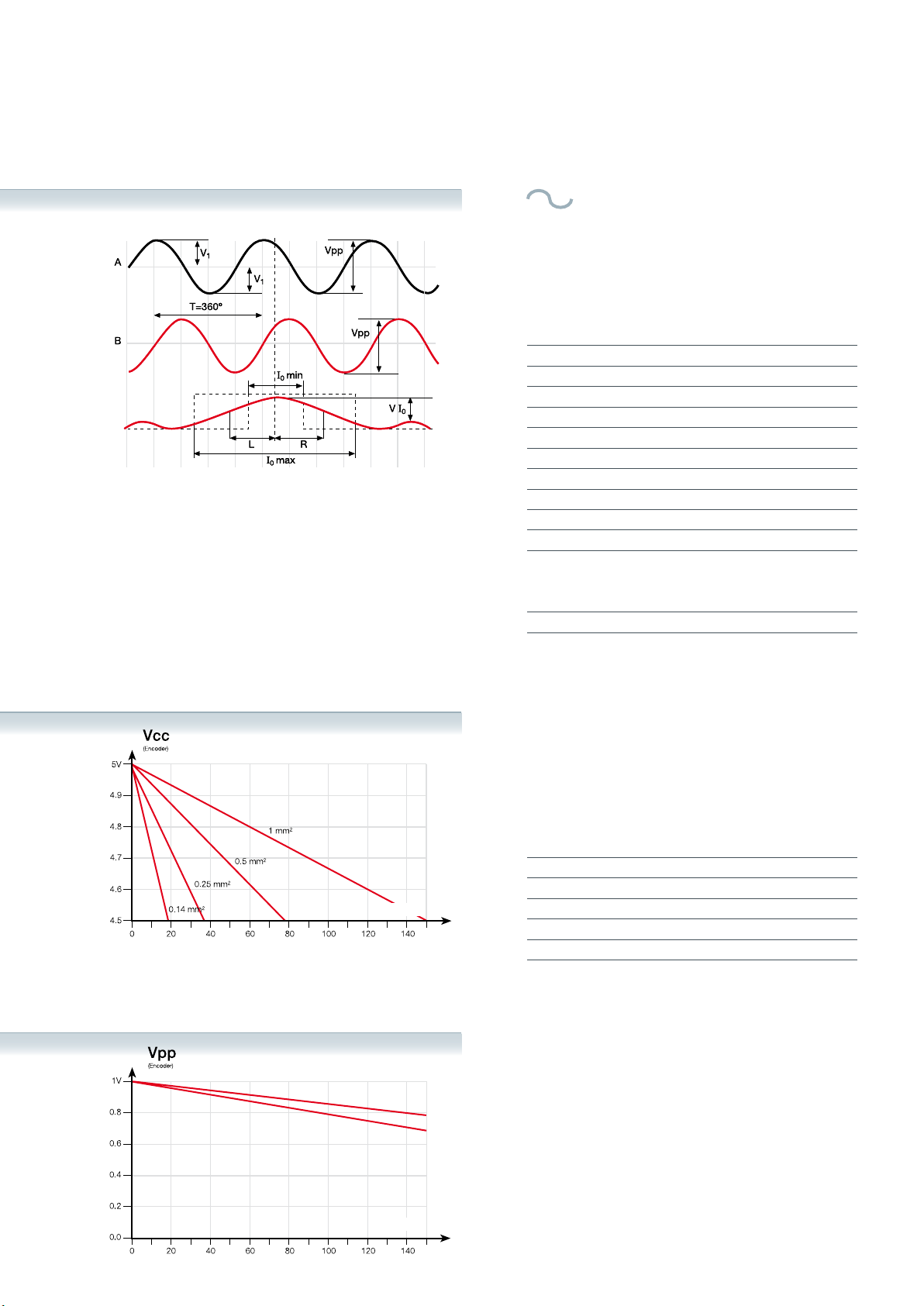

D i f fe re nt ia l 1 V pp

They are complementary sinusoidal signals whose differential

value is 1 Vpp centered on V

with a line termination of 120 Ω, twisted pair, and an overall

shield provide greater immunity against electromagnetic noise

caused by their surrounding environment.

Characteristics

Signals A, /A, B, /B,

VApp 1 V +20%, -40%

V

Bpp 1 V +20%, -40%

DC offset 2.5 V ±

Signal period according to model

Max. cable length 150 meters

A, B centered: |V

A&B relationship V

1-V2| / 2 Vpp ≤

App / VBpp 0.8

A&B phase shift: 90°

I

amplitude: VI0 0.2 ÷ 0.8 V

0

I

width: L + R I0_min: 180°

0

I

synchronism: L, R 180º ± 90º

0

cc/2. This characteristic together

I

0, / I0

0.5 V

0.065

÷

1.25

±

10°

I

_typ: 360°

0

I

_max: 540°

0

Cable length

meters

0.14 mm

0.09 mm

Voltage drop across cable

The voltage requirements for a 1 Vpp encoder are 5V ±10%.

A simple formula may be used to calculate the maximum

cable length depending on the cross section diameter of the

supply cables.

L

max = (VCC-4,5)* 500 / (ZCABLE/Km* IMAX)

Example

V

cc = 5V, IMAX= 0.1 Amp

2

Z (1 mm

Z (0.5 mm

Z (0.25 mm

Z (0.14 mm

) = 16.6 Ω/Km (Lmax= 150 m)

2

) = 32 Ω/Km (Lmax= 78 m)

2

) = 66 Ω/Km (Lmax= 37 m)

2

) = 132 Ω/ Km (Lmax= 18 m)

1 Vpp signal damping due to the cable

section

2

2

Besides attenuation due to signal frequency, there is another

signal attenuation caused by the section of the cable

connected to the encoder.

Cable length

meters

5

Page 6

I N C R E M E N T A L

F series

L I N E A R

Gene ral s pecif icati on

Measurement By means of stainless steel linear encoder

Steel tape accuracy ± 5 µm

Maximum speed 120 m/min.

Maximum vibration 10 g

Moving thrust < 5 N

Operating

temperature

Storage temperature -20 ºC...70 ºC

Weight 1.50 kg + 4 kg/m

Relative humidity 20...80%

Protection

Reader head With detachable cable connector

with 100 μm etching pitch

0 ºC...50 ºC

IP 53 (standard)

IP 64 (DIN 40050) using pressurized air in

linear encoders at 0.8 ± 0.2 bar

Especially designed for machines with longer travels and

they are available up to 30 m in length. In the incremental

model the reference marks are 50 mm apart and distance

coded model is also available. Both models come with a

detachable cable connectors in the reader head. The steel

tape graduation pitch is 100 μm. For measuring lengths over

4040 mm the encoder is supplied in multiple sections and is

assembled together at the time of installation.

Measuring lengths in millimeters

• Measuring lengths from 440 mm to 30 m in 200 mm

increments. Contact Fagor Automation for custom length

scales over 30 m.

Spec ific chara cteri stics

FT

FOT

Resolution 5 µm 1 µm Up to 0.1 µm

Reference marks (

Output signals

T period of output

signals

Limit frequency 100 kHz 500 kHz 20 kHz

Maximum cable length 20 m 50 m 150 m

Supply voltage 5 V ±5% ,100 mA (without load)

I

)

0

FOT, FOX, FOP: Distance-coded

TTL

20 µm 4 µm 100 µm

6

FX

FOX

FT, FX, FP: every 50 mm

TTL differential

5 V ± 10%, < 100 mA

(without load)

FP

FOP

I

0

1 Vpp

Page 7

Sing le F model

Dimensions in mm

Non-distance

coded

Distance-coded

Modu lar F mode l

Measuring length

Machine way

Non-distance

coded

Distance-coded

Orde r ide ntifi catio n

Example for an incremental encoder : FX - 36

F X 36

Type of profile:

F: for long distances

Type of reference mark

• Blank space: Incremental, one mark

every 50 mm

• O: Distance-coded marks

I

:

0

Type of signal:

• T: 5 μm resolution TTL

• X: 1 μm resolution differential TTL

• P: 1 Vpp sinusoidal

Measuring length

Machine way

Number of

intermediate modules

Ordering length code:

In the example (36) = 3640 mm

7

Page 8

I N C R E M E N T A L

C series

L I N E A R

Gene ral s pecif icati on

Measurement By means of graduated glass scale,

Maximum speed 60 m/min.

Maximum vibration 3 g

Moving thrust < 5 N

Operating

temperature

Storage temperature -20 ºC...70 ºC

Weight 1.2 kg + 2.5 kg/m

Relative humidity 20...80%

Protection

Reader head With detachable cable connector

with 20 μm etching pitch

0 ºC...50 ºC

IP 53 (standard)

IP 64 (DIN 40050) using pressurized air in

linear encoders at 0.8 ± 0.2 bar

Designed for applications on standard machines with travels

up to 3040 mm. With reference marks every 50 mm or

distance-coded and detachable cable connector built into the

reader head.

Measuring lengths in millimeters

220 • 270 • 320 • 370 • 420 • 470 • 520 • 620 • 720 • 770

820 • 920 • 1020 • 1140 • 1240 • 1340 • 1440 • 1540

1640 • 1740 • 1840 • 1940 • 2040 • 2240 • 2440 • 2640

2840 • 3040

Spec ific chara cteri stics

CT

COT

Accuracy ± 10 μm ± 5 μm

Resolution 5 μm 1 μm Up to 0.1 µm

I

Reference marks (

Output signals

T period of output

signals

Limit frequency 50 kHz 250 kHz 50 kHz

Maximum cable length 20 m 50 m 150 m

Supply voltage 5 V ± 5%,100 mA (without load)

)

0

COT, COX, COP: Distance-coded

TTL

20 µm 4 µm 20 µm

8

CX

COX

CT, CX, CP: every 50 mm

TTL differential

5 V ± 10%, < 100 mA

(without load)

CP

COP

I

0

1 Vpp

Page 9

C mo del

Dimensions in mm

I

every 50 mm

0

Air intake at both ends (M5)

Machine way

Distance-coded

Measuring length

Measu ring lengt hs (C M)

For CM ending in 20 A= 10

For CM ending in 40 A= 20

For CM ending in 70 A= 35

Orde r ide ntifi catio n

Example for an incremental encoder : COP - 425

C O P 42 5

Type of profile:

C for wide

spaces

I

Type of reference mark

• Blank space: Incremental, one

mark every 50 mm

• O: Distance-coded marks

:

0

Type of signal:

• T: 5 μm Resolution TTL

• X: 1 μm Resolution differential TTL

• P: 1 Vpp sinusoidal

Measuring length

in cm:

In the example

(42) = 42 cm = 420 mm

Accuracy of the linear

encoder:

• 5: ± 5 μm

• Blank space: ± 10 μm

9

Page 10

I N C R E M E N T A L

M series

L I N E A R

Gene ral s pecif icati on

Measurement By means of graduated glass scale,

Maximum speed 60 m/min

Maximum vibration 3 g

Moving thrust < 5 N

Operating

temperature

Storage temperature -20 ºC...70 ºC

Weight 0.58 kg + 0.6 kg/m

Relative humidity 20...80%

Protection

Reader head

with 20 μm etching pitch

0 ºC...50 ºC

IP 53 (standard)

IP 64 (DIN 40050) using pressurized air in

linear encoders at 0.8 ± 0.2 bar

With detachable cable connector

(except MKT and MKX)

Spec ific chara cteri stics

MT

MOT

MTD M KT

Designed for applications on standard machines with travels

up to 1540 mm. With reference marks every 50 mm or

distance-coded and detachable cable connector built into

the reader head (except the MK series where the reader head

comes standard with a 3-meter attached cable).

Measuring lengths in millimeters

40 (*) • 70 • 120 • 140 • 170 • 220 • 270 • 320 • 370

420 • 470 • 520 • 620 • 720 • 770 • 820 • 920 • 1020

1140 • 1240 • 1340 • 1440 • 1540

(*) On MT and MX models.

MX

MOX

MKX

MP

MOP

Accuracy ± 10 μm ± 5 μm ± 10 μm ± 5 μm

Resolution 5 μm 1 μm Up to 0.1 µm

I

MKT and MKX:

I

Reference marks (

Output signals

T period of output signals 20 µm 4 µm 20 µm

Limit frequency 50 kHz 250 kHz 50 kHz

Maximum cable length 20 m 50 m 20 m 50 m 150 m

Supply voltage 5 V ±5% ,100 mA (without load)

)

0

TTL TTL differential 1 Vpp

MT, MTD, MX and MP:

MOT, MOX and MOP: Distance-coded

every 50 mm

0

I

every 50 mm

0

I

0

5 V ± 10%, < 100 mA

(without load)

10

Page 11

M mo del

Dimensions in mm

I

every 50 mm

0

Distance-coded

MK m odel

I

every 50 mm

0

Air intake at both ends (M5)

Centered point for Ø3 dowel pin

Machine way

Measuring length

Air intake at both

ends (M5)

Centered point for Ø

dowel pin

Machine way

Measuring length

3

Measu ring

lengt hs (C M)

For CM ending in 20 A= 10

For CM ending in 40 A= 20

For CM ending in 70 A= 35

Orde r ide ntifi catio n

Example for an incremental encoder : MOP - 425

M O P 42 5

Type of profile:

M: for limited

spaces

I

Type of reference mark

• Blank space: Incremental, one

mark every 50 mm

• O: Absolute distance-coded

marks

:

0

Type of signal:

• T: 5 μm resolution TTL

• TD: 5 μm resolution differential TTL

• X: 1 μm resolution differential TTL

• P: 1 Vpp sinusoidal

Measuring lengths

in cm:

In the example

(42) = 42 cm = 420 mm

Accuracy of the linear

encoder:

• 5: ± 5 μm

• Blank space: ± 10 μm

11

Page 12

I N C R E M E N T A L

MM series

L I N E A R

Gene ral s pecif icati on

Measurement By means of graduated glass scale,

Maximum speed 60 m/min.

Maximum vibration 3 g

Moving thrust < 5 N

Operating

temperature

Storage temperature -20 ºC...70 ºC

Weight 0.58 kg + 0.5 kg/m

Relative humidity 20...80%

Protection IP 53 (standard)

Reader head

with 20 μm etching pitch

0 ºC...50 ºC

IP64 (DIN 40050) using pressurized air in

linear encoders at 0.8 ± 0.2 bar

With detachable cable connector

(except MMKT and MMKX)

Designed for applications on standard machines with travels

up to 520 mm. With reference marks every 50 mm and

detachable cable connector built into the reader head (except

the MMK series where the reader head comes standard with

a 3-meter attached cable). With very small profile, 5 mm less

than the M series they are ideal for tight spaces.

Measuring lengths in millimeters

40 (*) • 70 (*) • 120 • 140 • 170 • 220 • 270 • 320 • 370

420 • 470 • 520

(*) On MMT and MMX models.

Spec ific chara cteri stics

MMT M MK T MM X M MK X M MP

Accuracy ± 10 μm ± 5 μm ± 10 μm ± 5 μm

Resolution 5 μm 1 μm 0.1 μm

I

Reference marks

Output signals

T period of output signals 20 µm 4 µm 20 µm

Limit frequency 50 kHz 250 kHz 50 kHz

Maximum cable length 20 m 50 m 150 m

Supply voltage 5 V ± 5%,100 mA (without load)

I

0

TTL TTL differential 1 Vpp

12

every 50 mm

0

5 V ± 10%, < 100 mA

(without load)

Page 13

MM m odel

Dimensions in mm

Machine way

Measuring length

MMK model

Machine way

Measuring length

Orde r ide ntifi catio n

Example for an incremental encoder : MMT-27

MM T 2 7

Type of profile:

MM: for very limited space

Type of signal:

• T: 5 μm resolution TTL

• X: 1 μm resolution differential TTL

• P: 1 Vpp sinusoidal

Measuring lengths in cm:

In the example

(27) = 27 cm = 270 mm

13

Page 14

I N C R E M E N T A L

MTD-P-2R series

L I N E A R

Gene ral s pecif icati on

Measurement By means of graduated glass scale,

Maximum speed 60 m/min.

Maximum vibration 3 g

Moving thrust < 5 N

Operating

temperature

Storage temperature -20 ºC...70 ºC

Weight 0.58 kg + 2.43 kg/m

Relative humidity 20...80%

Protection IP 53 (standard)

Reader head With detachable cable connector

with 20 μm etching pitch

0 ºC...50 ºC

IP64 (DIN 40050) using pressurized air in

linear encoders at 0.8 ± 0.2 bar

Designed for applications on press brakes with strokes up

to 1540 mm. The linear encoder comes with a universal joint

for reader head movement and an aluminum support that is

mounted directly on the machine.

Measuring lengths in millimeters

40 • 70 • 120 • 140 • 170 • 220 • 270 • 320 • 370 • 420

470 • 520 • 620 • 720 • 770 • 820 • 920 • 1020 • 1140

1240 • 1340 • 1440 • 1540

Spec ific chara cteri stics

MTD -P -2 R

Accuracy ± 10 μm

Resolution 5 μm

I

at the ends

Reference marks (

Output signals

T period of output signals 20 µm

Limit frequency 50 kHz

Maximum cable length 50 m

Supply voltage 5 V ±5% ,100 mA (without load)

I

)

0

14

Two

0

TTL differential

Page 15

MTD- P-2R model

Dimensions in mm

Machine way

Measuring length

Measu ring lengt hs (C M)

For CM ending in 20 A= 10

For CM ending in 70 A= 35

Orde r ide ntifi catio n

Example for an incremental encoder: MTD-77 P-2R

M TD 77 P2R

Type of profile:

M: for limited space

Type of signal:

TD: 5 µm resolution differential

TTL

Measuring lengths in cm:

In the example

(77) = 77 cm = 770 mm

Reference mark

I

at both ends

Two

0

I

:

0

15

Page 16

I N C R E M E N T A L

H, S series

R O T A R Y

Gene ral s pecif icati on

S SP H / H A HP

Measurement With graduated disk

Accuracy ± 1/10 of the pitch

Maximum speed 12000 rpm

Vibration 100 m/s

Shock 300 m/s

Inertia 16 gr/cm

Turning torque

Type of shaft Solid shaft Hollow shaft

Maximum load on the shaft

Axial: 10 N

Radial: 20 N

Weight 0.3 kg

Ambient characteristics:

Running temperature 0 °C…+70 °C

Storage temperature -30 °C…+80 °C

Relative humidity 98% non-condensing

Protection IP 64 (DIN 40050). On S and SP models: Optional IP 66

Light source IRED (InfraRed Emitting Diode)

Maximum frequency 200 kHz

Reference signal

Supply voltage

I

0

5% (TTL)

±

One reference signal per encoder turn

5 V

± 10% (1 Vpp)

Consumption 70 mA typical, 100 mA max. (without load)

TTL

Output signals

differential

Maximum cable length 50 m 150 m 50 m 150 m

2

(10 ÷ 2000 Hz)

2

(11 m/s)

2

0.003 Nm (30 gr/cm)

max. at 20 °C

5 V

5 V

± 5% (TTL)

1 Vpp

TTL

differential

–

5 V

± 10% (1 Vpp)

1 Vpp

Number of pulses/turn

S S P H HA HP

50 – 50 – –

100 – 100 – –

200 – 200 – –

250 – 250 – –

400 – 400 – –

500 – 500 – –

600 – 600 – –

635 – 635 – –

1

000 1 000 1 000 – 1 000

1

024 1 024 1 024 1 024 1 024

1

250 1 250 1 250 1 800 1 250

1

270 1 270 1 270 2 000 1 270

1

500 1 500 1 500 2 048 1 500

2

000 2 000 2 000 2 500 2 000

2

500 2 500 2 500 3 000 2 500

3

000 3 000 3 000 3 600 3 000

– 3

600 – 4 000 –

– 4

320 – 4 096 –

5

000 5 000 – 5 000 –

– – – 10

000 –

16

Page 17

S, S P mod el

H, H P mod el

Dimensions in mm

Roller bearings

L: Min. 9 mm, max. 16 mm

HA m odel

ØD g 7

mm

3

4

6

6.35

7

8

9.53

10

Shaft

Orde r ide ntifi catio n - m odels H, H P, S and SP

Example for a Rotary Encoder: SP-1024-C5-R-12-IP 66

S P 10 24 C5 R 12 IP 66

Model:

• S: Solid shaft

• H: Hollow shaft

Type of signal:

• Blank space:

square signal

(TTL or HTL)

• P: 1 Vpp

sinusoidal signal

Number of

pulses/turn:

(See table

page 16)

Type of connector:

• Blank space: 1 m cable

without connector

• C: Flange socket

CONNEI 12

• C5: 1 m cable with

CONNEI 12 connector

Cable exit:

• R: Radial

• A: Axial

space: Axial

Blank

Voltage:

• Blank space:

Standard 5 V supply

• 12: Optional 12 V

supply (only for

HTL signal)

Protection:

• Blank space:

Standard

protection (IP 64)

• IP 66: Protection

IP 66

Orde r ide ntifi catio n - H A mod el

Example for a Rotary Encoder: HA - 22132 - 2500

HA 2 2 1 3 2 2 500

In all

cases

Type of clamp:

• 1: Rear clamp

• 2: Front clamp

Size of the

hollow shaft

(ØA):

• 1: 10 mm

• 2: 12 mm

Output signals:

I

• 1: A, B,

inverted

plus their

0

Type of connection:

• 1: Radial cable (2 m)

• 2: CONNEI 12 radial

connector built into it

• 3: Radial cable (1 m) with

CONNEI 12 connector

Supply voltage:

• 1: Push-Pull

(11-30 V)

• 2: RS-422 (5 V)

Number of pulses/

turn:

(See table page 16)

17

Page 18

accessories

Connection cables

Connection to FAGOR

EC…T-D

Lengths: 1, 3, 6, 9 and 12 meters

SUB D 15 HD connector (male Pin )

Pin Signal Color

1 A Green

3 B Brown

5

9 +5 V Yellow

11 0 V White

15 Ground Shield

Housing Ground Shield

I

0

Grey

EC…P-D

Lengths: 1, 3, 6, 9 and 12 meters

SUB D 15 HD connector (male Pin )

Pin Signal Color

1 A Green

2 /A Yellow

3 B Blue

4 /B Red

5

6

9 +5 V Brown

11 0 V White

15 Ground Shield

Housing Ground Shield

I

0

I

0

Grey

Pink

Coupling for rotary encoders

For solid shaft encoders

40

Ø 6

Ø 20

Ø 25

AF model AC model A L model

Spec ific chara cteri stics

Maximum radial misalignment permitted

Maximum angular misalignment permitted

Maximum axial misalignment permitted

25,4

Ø 6

AF AC A L

2 mm 1 mm 0.2 mm

8º 5º 4º

± 1.5 mm

Ø 19,2

Ø 6

–

19,6

± 0.2 mm

AH coupli ng s

Couplings for hollow shaft encoders

The hollow shaft encoders are

accompanied by a standard

6 mm cap diameter (Ø

6).

Can also be supplied in the following

diameters:

Ø 3, Ø

4, Ø 6, Ø 7, Ø 8 and Ø 10 mm, 1/4”

and 3/8”.

AD washer

Washer for mounting rotary encoder

models H, HP, S, SP.

Maximum torque that may be transmitted

Torsion rigidity

Maximum rotating speed

18

2 Nm 1.7 Nm 0.9 Nm

1.7 Nm/rad. 50 Nm/rad. 150 Nm/rad.

000 rpm

12

Page 19

Fagor Automation shall not be held responsible for any printing or transcribing errors in the catalog and reserves the right to make any changes to the characteristics of its products

without prior notice. You must always compare the data with that appearing in the manual that comes with the product.

19

Page 20

ER-073/1994

Fagor Automation holds the ISO 9001

Quality System Certificate and the

Certificate for all products manufactured.

subs i d i a r y d i s trib u t o r

america

BOGOTÁ

BUENOS AIRES

CHICAGO

DALLAS

EL SALVADOR D.F.

LIMA

LOS ANGELES

MEXICO D.F.

MONTERREY N.L.

MONTEVIDEO

MONTREAL

NEW JERSEY

SANTIAGO

SAO PAULO

TAMPA

TORONTO

USURBIL

ESKORIATZA

BEIJING

europe

HeadquartersPlants

MONDRAGÓN

africa

JOHANNESBURG

BARCELONA

BJERRING BRO

BUCHAREST

BUDAPEST

CLERMONT FERRAND

GOMEL

GÖPPINGEN

GÖTEBORG

ISTANBUL

IZEGEM

KAPELLEN

KOTLIN

LANGENTHAL

LOG PRI BREZOVICI

MILANO

MOSKVA

NEUCHATEL

NORTHAMPTON

PORTO

PRAHA

ROOSENDAAL

THESSALONIKI

TOIJALA

UTRECHT

WIEN

asia

BANGALORE

BANGKOK

CHENGDU

DELHI

GUANGZHOU

HO CHI MINH CITY

HONG KONG

JAKARTA

KUALA LUMPUR

MANILA

NANJING

PUNE

RAJKOT

SHANGHAI

SEOUL

SINGAPORE

TAICHUNG

TEL-AVIV

TOKYO

EPS - CAP STD. EN 0513

oceania

AUCKLAND

DUNEDIN

MELBOURNE

SYDNEY

worldwide automation

Loading...

Loading...