Page 1

AD-21BDD

Instruction Manual

FAGOR GLASSWASHER WITH DRAIN PUMP AND

DETERGENT DISPENSER

Fagor Australasia Pty Ltd

7 Boola Place

Dee Why

NSW 2099

Phone: 02 9984 7533

Fax: 02 9984 7544

Email: info@fagor.com.au

Page 2

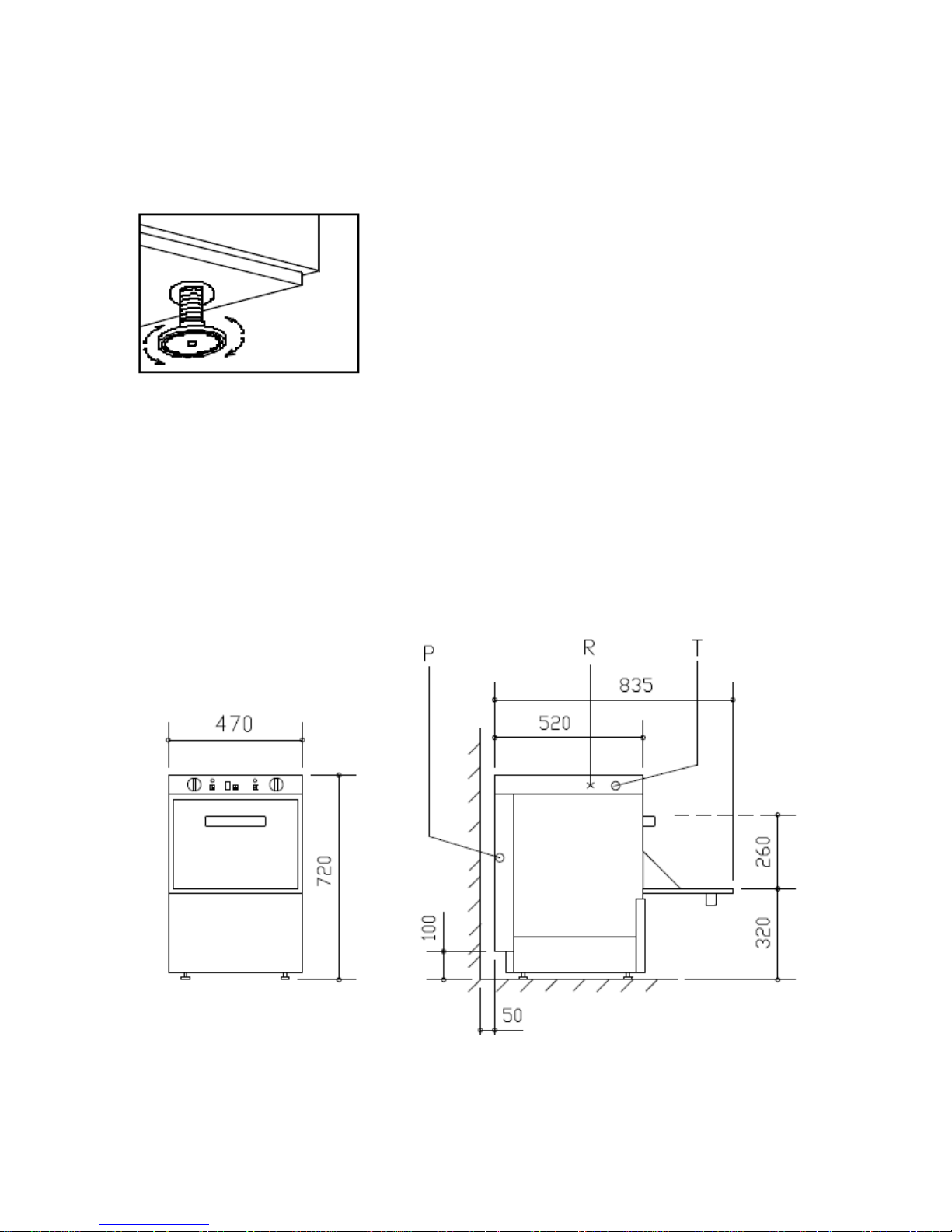

1. POSITIONING

1.1 For the machine to work properly, you must ensure that it is level. Four

threaded bolts (legs) are supplied with your machine. These should be fitted to the

underside of the machine and adjusted to level the machine, as shown in Figure 1.

Figure 1

2. INSTALLATION

2.1 Connect the mains to the water supply, as shown in Figures 2 and 3. The

machine should be connected to a hot water supply of above 50°C but no more

than 60°C to allow the machine to operate efficiently. Inlet operating pressure is

400 kPa and maximum inlet supply temperature is 60°C.

2.2 If the pressure is more than 70 PSI, a pressure limiting valve should be fitted.

Figure 2

Page 3

A= Water inlet

D= Drain hose 25mm in diameter and must be installed in accordance with AS/NZS3500.2 (drainage) by means of

coupled connection to a DN40 or larger pipe.

E= Electric s. Cable

NOTE: must be installed in accordance with AS/NZS3500.1 (water

service supply) including installation of the supplied backflow

prevention device

Figure 3

S = Stopcock / F = Filter / H= Fagor supplied hose and backflow prevention device / E = Electrovalve /

B = Electropump / C= Drain collector / D= Drain hose

2.3 Dynamic pressure during rinse is 2÷4 Kg/cm2. If the pressure is less than 2

kg/cm2 (28 PSI), an electrical pressure pump should be installed, as shown in

Figure 4.

Page 4

Figure 4

S = Stopcock / F = Filter / H= Fagor supplied hose and backflow prevention device / E = Electrovalve / B

= Electropump / C= Drain collector / D= Drain hose

2.4 When the water hardness level is above 10º F, a water softener should be

installed.

2.5 A stopcock should be fitted below the machine’s water intake.

2.6 Fix the drain hose as shown in Figure 5 and fit a siphon pipe to prevent bad

smells. Please note the maximum height of the drain hose indicated on Figure 2.

Do not extend the length of the drain hose supplied with your machine.

Figure 5

A=Overflow / C=Drain collector / D=Drain hose / F =Filter

2.7 Connect the electrical connections, referring to Figures 2, 6 and 7.

2.8 For access to the connection strip (R), remove the cover (T) and the rear panel

(P).

Page 5

2.9 Fix the sheathed cable to (E), leaving enough cable to remove the electrical

panel from the front.

2.10 Connect the strip as shown in Figure 6.

2.11 Fit a general switch (I) independent of the appliance with a distance between

contact equal to or more than 3mm.

2.12 The machine must be earthed.

Figure 6

Figure 7

Figure 8: Technical Specifications of AD-21BDD

Model

Water

inlet

pressure

Supply

Voltage

Tank

Heating

Element

Boiler

Heating

Element

Max.

power

used

Basket

size

Cycle

duration

Tank

capacity

Rinse

water

consumed

Net

Weight

AD21B

DD

(200÷400

kPa)

(2÷4

Kg/cm2)

(28÷ 56

psi)

230-V-

1N

15 A 1

Phase

2 KW 2.8 KW

3.13

KW

400x400

mm

90”,

120”,

180”

15 litres

2,5

litres/rinse

39 KG

(220-240V-1N~)

am/ve=yellow-green

a= blue

m= brown

r= red

n= black

Page 6

3. USING YOUR AD-21 BDD GLASSWASHER WITH DRAIN PUMP AND

DETERGENT DISPENSER

3.1 Put the clear hose (located at the back of the machine), into a bottle of liquid,

non-foaming detergent. Make sure that the filter on the end of the pipe is fully

submerged and the pipe is not kinked.

3.2 Put the blue hose (located at the back of the machine), into a bottle of rinse aid.

Make sure that the filter on the ends of the pipe is fully submerged and the pipe is not

kinked.

3.3 Prepare crockery for washing by removing large bits of food before loading the

crockery into the baskets. Glassware should be washed first. Plates should not be

stacked on top of each other (see Figure 9). Cups and glasses should be washed

upside down. Cutlery should be washed in the yellow cutlery baskets with handles at

the bottom; each yellow basket should contain a mixture of spoons, forks and knives

for optimum washing conditions. The cutlery holders should be put into one of the

baskets.

Figure 9

3.4 Load the machine with a basket of dirty dishes/cutlery. Close the door and

press the switch button (1 on Figure 10) to turn machine on. Pilot light (2) will come

on and the boiler and wash tank will begin to fill up with water and heat up.

Figure 10

AD-21BDD

3.5 Wait for water to heat up to required temperature. The thermometer (9)

indicates the rinse temperature and the thermometer (10)indicates the wash

temperature. The machine is ready when the thermometer (9) indicates 85-90°C and

the thermometer (10) indicates 55-60°C. The glassw asher is fitted with a thermostop

to ensure a minimum rinse temperature of 85°C. The temperature of the incoming

water should be 50°C or more. Colder water may affect the machine’s performance.

Page 7

3.6 Press P1, P2 or P3 button to select the require length of the wash (90”, 120’’ or

180” respectively). The appropriate LED (4,6 & 8 on Figure 10) will light up.

3.7 When the cycle has finished, the LED will go off. The door can be opened and

the basket removed. Another basket of crockery can be inserted and button P1, P2 or

P3 pressed for another wash cycle to start. Never place a basket of washed dishes on

top of the machine; water could drip from the basket and damage the machine’s

electrical components.

3.8 The glasswasher drains automatically in each cycle. At the end of each day or

service, or as required, the glasswasher should be completely drained. See details

below:

Make sure the machine is

turned on.

1- Remove the upstand

(drain plug) by pulling it up

from inside the filter (See

photo and ‘A’ in Fig. 5).

2- Leave the door open and

press the button P1

for 5 seconds until the

green light flashes.

3- You will hear the pump

start to work and see the

drain out. When the pump

stops making a noise and

the water is drained out,

remove the suction filter (

‘F’ on Fig. 5) by turning it

anti-clockwise and pulling

out. Use soapy water to

clean the filter, ensuring

that all particles are

removed.

4- Replace suction filter and drainplug in machine. The machine is now ready to be

re-used or turned off, as appropriate.

Page 8

4.- MAINTENANCE

4.1 Check the detergent and rinse liquid containers on a daily basis to ensure

levels are sufficient and the filters on the ends of the pipes are fully submerged.

Check pipes leading from the containers for kinks.

4.2 Everyday, clean the suction filter (F on figure 5). To do this, remove the antioverflow device (drain plug) in the middle of the suction filter, turn (F) anticlockwise

and lift it up. Use soapy water for cleaning, not abrasive detergents. Never use jets of

water to clean the outside of the machine.

4.3 Check that all parts are securely fixed, in particular that the screws on the wash

and rinse arms have not worked loose.

4.4 If the machine is not going to be used for a long time, cover its surfaces with a

coating of petroleum jelly.

5 ELECTRICAL AND MECHANICAL PROBLEMS – (TROUBLESHOOTING)

The following should be checked before calling for technical service

5.1 If the machine has no power, check if it is plugged in to the power supply and

that the voltage coincides with that required by the machine.

5.2 If the machine has no power, check if the power cord is damaged, in which case

it should be replaced by the manufacturer or by its aftermarket service or by other

qualified personnel in order to prevent hazards.

5.3 If the water connection or the start up take too long check the water supply is

working at the required temperature and that the drain plug has been inserted.

5.4 If the machine is not rinsing or washing properly, check that the arms rotate

properly and the nozzles are not blocked. To remove the rise arm, unscrew the thumb

screw in the central support (using a coin). Wash the rinse arm in soapy water and

reposition. Tighten the screw.

5.5 If the machine is not washing or rinsing properly, check the levels of rinse aid

and detergent and check that the supply pipes are not kinked and do not have an air

bubble blocking them.

5.6 After sales service:

Fagor Australasia Pty. Ltd., 7 Boola Place, Dee Why, NSW.

Tel. 02 9984 7533

Email: info@fagor.com.au

Page 9

6. INFORMATION FOR TECHNICIANS

6.1 CONFIGURATION OF THE DIPS

FAGOR

ELECTRIC

ADVANCE

MODEL

DIP1 DIP2 DIP3 DIP4

CYCLE TIMES

(seconds)

AD 21 BDD OFF OFF OFF OFF

P1= 90 / P2=120 /

P3=180

DIP1= OFF, when the door is closed, the glasswasher continues washing only if the

cycle has not finished.

DIP2 = OFF

DIP1 + DIP3 , with the different possible combinations, we programme the cycle times.

DIP4 = OFF

6.2 ERROR DIAGNOSIS.

Faults are diagnosed with impulse trains from the ON/OFF LED. The trains are formed

by “x” impulses lasting 0.5 seconds. (ON) and a wait of 2 seconds, as shown in the

following figure:

1. ERROR: OPEN DOOR

This is indicated by a one-impulse train. That is, the ON/OFF LED lights up for 0.5

seconds and then remains unlit for 2 seconds before lighting up again. This continues

as long as the door is open and the selected cycle is unfinished.

2. TANK FILL ERROR.

This is indicated by a two-impulse train. That is, the ON/OFF LED lights up twice for

0.5 seconds each time and then remains unlit for 2 seconds, then lighting up again

twice. This continues while the water in the tank does not reach the correct level in

the specified time.

Page 10

3. TANK DRAINAGE ERROR.

This is indicated by a three-impulse train. That is, the ON/OFF LED lights up three

times for 0.5 seconds each time and then remains unlit for 2 seconds, then lighting up

again three times. This continues while the drainage pump does not drain the water in

the tank to the correct level in the specified time.

4. BOILER HEATING ERROR.

This is indicated by a four-impulse train. That is, the ON/OFF LED lights up four times

for 0.5 seconds each time and then remains unlit for 2 seconds, then lighting up again

four times. This continues while the water in the boiler does not reach the correct

temperature in the specified time.

5. TANK HEATING ERROR.

This is indicated by a five-impulse train. That is, the ON/OFF LED lights up five times

for 0.5 seconds each time and then remains unlit for 2 seconds, then lighting up again

five times. This continues while the water in the tank does not reach the correct

temperature in the specified time.

7. THE FINAL HOLDER OF THE CONTAINER IS RESPONSIBLE FOR ITS

MANAGEMENT.

The use of the WEEE symbol indicates that this product may not be

treated as household waste.

By ensuring this product is disposed of correctly, you will help

protect the environment.

For more detailed information about the recycling of this product,

please contact your local authority, your household waste disposal

service provider or the shop where you purchased the product.

Loading...

Loading...