Page 1

Part # 400-MW-002

WARNING!

ev. 002 / 8-18-10

R

The Communicator II

Model # MWCK04

Wireless Transmitter/Receiver Kit

Installation Instructions

TRANSMITTER INSTALLATION:

1- Remove lid from top of the MWCT04 Transmitter to reveal mounting holes.

Position the Transmitter near the bottom of the door and mark the mounting

hole locations.

2. Remove the Transmitter from door, drill holes and mount the Transmitter with

screws supplied. NOTE: DO

Only use holes in the 4 corners of the box. Any additional holes in the transmitter

box will cause water to enter and a loss of warranty.

3- Loosen wirefitting nut and feed the 2 or 4 wire sensingedge leads into theTransmitter housing trimming offexcess wire.

4- Attach the 4-lead wires to the large green two-part terminal block connector as White, White, Black, Black. If a 2-lead wire

connection is appropriate, connect them to the middle terminals, i.e. none,White, Black, none.Tighten the wire fitting nut

to assure water tight connection.

5- Adjust Dip Switches: 1= Address Selector 2= Address Selector 3= Address Selector 4= Address Selector

5= OFF for 4-wire edges, ON for 2-wire 10KΩ terminal edges 6= Edge Input ON=N/O OFF= N/C 7= Always OFF

8= OFF for Normal Operations, ON for Test Mode (transmitteralways “ON”)

NOTE:thefour DIP address switches must be setidentically on the transmitter and receiver.

NOT drill any holes in the transmitter box.

Edge Sensor

roper Mounting Location on Bottom Bar

P

6- Be sure that the battery strap is connected and insert 9 Volt battery into the lid of the unit, and replace the lid.

The Green LED light should light up briefly, indicating that the unit is functioning properly.

WARNING!

TO REDUCE RISK OF SEVERE INJURY OR DEATH; READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS

TO PREVENT ELECTROCUTION: DISCONNECT POWER AT FUSE BOX OR CIRCUIT BREAKER AND DOOR OPENER BEFORE WIRING PERMANENTLY.

IMPROPER WIRING COULD CAUSE ELECTROCUTION OR DAMAGE TO CIRCUITRY.FOLLOW ALL LOCAL BUILDING CODES AND NATIONAL ELECTRICAL CODES.

RECEIVER INSTALLATION:

1- Hold the MWCR04 Receiver in the mounting position near the operator: mark and drill mounting holes.

2- Attach a 24VAC (at least 100mA) source to the Red & Black wires. A 24 VDC source may also be used with Red to positive

(+) and Black to negative (-). When using 24 VAC, check to see if one

leg is connected to the operator case. If connected to the case, connect

that leg to the Black wire of the receiver.

3- Connect the Whitewires to the Safety Edge input forthe motor operator.

The output relays will bear a resistive load of 1A at 24VAC.

The state of the relay is shown with a Yellow LED. The LED is

illuminated when the channel is in a SAFE operating condition

and will go out under fault condition. Relay contacts can

be selected N/O or N/C by moving jumpers (shunts)

inside the enclosure.

4- Adjust Dip Switches: 1= Address Selector 2= Address Selector

3= Address Selector 4= Address Selector 5= OFF for Standard

operation (all faults and safety edge activity activate the operator’s

safety edge input)

5- Mount the Receiver near the operator using the 2 screws supplied.

Take care to make sure the rigid wire antenna completely extends past

any metal of the operator enclosure.

Typical Installation

Proper location

of a MWCR-04

Receiver with

Antenna

Proper location

of the MWCT-04

Transmitter on

the Bottom Bar

6- Attach Coax Rigid Wire antenna. (The unit will not work

MILLER EDGE, INC. • P.O. Box 159 • West Grove, PA 19390 • 610-869-4422 • Fax: 610-869-4423 • 1-800-220-3343 • www.milleredge.com

MILLER EDGE, INC. • 6809 South Harl Avenue • Suite A • Tempe, AZ 85283 • 480-755-3565 • Fax:480-755-3558 • 1-800-887-3343

unless the rigid antenna is properly attached.)

U.S.Patent # 7,123,144

Page 2

Part # 400-MW-002

ev. 002 / 8-18-10

R

NORMAL START-UP SEQUENCE

- On Power Up, the receiver performs a light-test for 1/2 second ”ON” and 1/2 second “OFF” and then begins normal operations.

1

When the battery is connected to the transmitter, it also lights it’s Green (Activity) LED for 1/2 second “ON” and 1/2 second “OFF”

and then begins normal operations.

2- Apply power to receiver; the Green (POWER ON) LED should come on with one Yellow (SAFETY EDGE, RELAY 1) LED, near

antenna end of the receiver.

3- Press (activate) the Safety Edge; the Green TransmitterLED shouldblink “ON” briefly, and the receiver’s Green (Signal Acquired) LED should

also blink “ON”. The Yellow (Safety Edge Active) LED should light and stay lighted for as long as the Safety Edge is activated,and go “OFF”

when the Safety Edge is released. If there are no faults sensed, the Red (Maintenance Required)LED will remain “OFF”.

4- When the Safety Edge is pressed, the receiver’s Yellow (Safety Edge, Relay1) LED will go “OFF” and the Yellow (Safety Edge Active) LED

will go “ON”.

5- If the Safety Edge is pressed for longer than 1/4 second while the door is closing, the door should stop and reverse.

6- If the Red (Maintenance Required) LED comes on during door operation at any time, a fault is indicated. Slow blinking indicates that

a weak battery is sensed in the transmitter. Fast blinking indicates that a wiring fault to the Safety Edge is sensed. Solid “ON” indicates

that the receiver has not heard from the transmitter in over 10 minutes.

TROUBLE SHOOTING HINTS

1- The receiver’s Green (Power-On)LED is not illuminated:

a) Checkwith a VOM to see if 24 voltsAC or DC is present at the receiver.

b) If using DC power, check to make sure Red is positive and Black is negative.

2- The Transmitter’s Green LED never comes on:

a) Check to make sure the batteryis connectedand check battery voltage(shouldbe 8.2 voltsor higher).

b) Remember: the transmitter only comes on briefly when the sensing edge is pressed or released, and once every 5 minutes if

there is no other activity.

3- The Transmitter’sGreenLED comes on, but not the receiver’sGreen (Signal Acquired)LED comeson - Check address DIP switches, they

must be set indentically.

If they are identical, symptom could be a result of low RF signal strength. Check antenna location: should be outside of any

metal enclosure(s), and pointing away from the operator case.

4- The receiver’s Red (Maintenance Required) LED is on:

a) Slowly Blinking; Verify battery voltage. It should be 8.2 volts or higher, if not replace with same type (Lithium 9 Volts).

b) Fast Blinking; Check the wires to the safety edge: One is not being sensed as connected.

c) Solid; Receiver has not heard from the transmitter within last 10 minutes. Press the sensing edge at least once to send a

message and clear the fault..

5- The receiver’s Yellow (Safety Edge, Relay 1) LED is not illuminated, Green (Signal Acquired) LED illuminates, Edge tested good,

door/gate always goes to fault location.

a) Check edge wire connections to make sure the colors are correct and that bare wire is contacted inside the terminal block.

b) Check for wire short circuit between the Black sensing edge wires and the White sensing edge wires.

TROUBLE SHOOTING GUIDE

ACTION TRANSMITTER RECEIVER

Door encounters an obstacle,

edge is compressed (Closed)

Door has Safety Edge fault

(Broken Wire)

Transmitterhas Low Battery

Green LED Blinks sends RF signal,

microprocessor is awake

Green LED Blinks when fault message is sent

Green LED Blinks when fault message is sent

Yellow LED (Relay #1) OFF

Yellow LED (S.E. Active) ON

Green LED (Signal Aquired) Blinks

Red LED (Maint. Req.) Blinks Quickly

Green LED (Signal Acquired) Blinks

Yellow LED (Relay #1) “OFF”

Red LED (Maint. Req.) Blinks Slowly

Yellow LED (S.E. Active) “OFF”

Yellow LED (Relay #1) “OFF”

Receiver has not heard from

the transmitter for more than

10 minutes

MILLER EDGE, INC. • P.O. Box 159 • West Grove, PA 19390 • 610-869-4422 • Fax: 610-869-4423 • 1-800-220-3343 • www.milleredge.com

MILLER EDGE, INC. • 6809 South Harl Avenue • Suite A • Tempe, AZ 85283 • 480-755-3565 • Fax:480-755-3558 • 1-800-887-3343

Doesn’t Matter

U.S.Patent # 7,123,144

Red LED (Maint. Req.) “ON”

Yellow LED (Relay#1) “OFF”

Page 3

The Communicator II

BATTERY

POWER

24V

N

O

N

C

NO NC

CH 1

CH 2

GRN YEL GRN RED

1 2 3 4 5

ANT

Model # MWCR-04 Receiver is designed to work only

with the Model # MWCT-04 Transmitter

RED: 24V AC/ + 24V DC

BLACK:POWER GND.

WHITE: RELAY OUTPUTS

POWERON

(GRN.)

R

ELAY

O

UTPUT

(YEL.)

F

UTURE

U

SE

(YEL.)

The Communicator II

FUTURE

USED

(GRN.)

S

ENSING

EDGE

ACTIVE

(YEL.)

S

IGNAL

AQUIRED

(GRN.)

M

AINT.

REQUIRED

(RED)

Model # MWCR-04

228-26

1-800-220-3343

M

Miller Edge

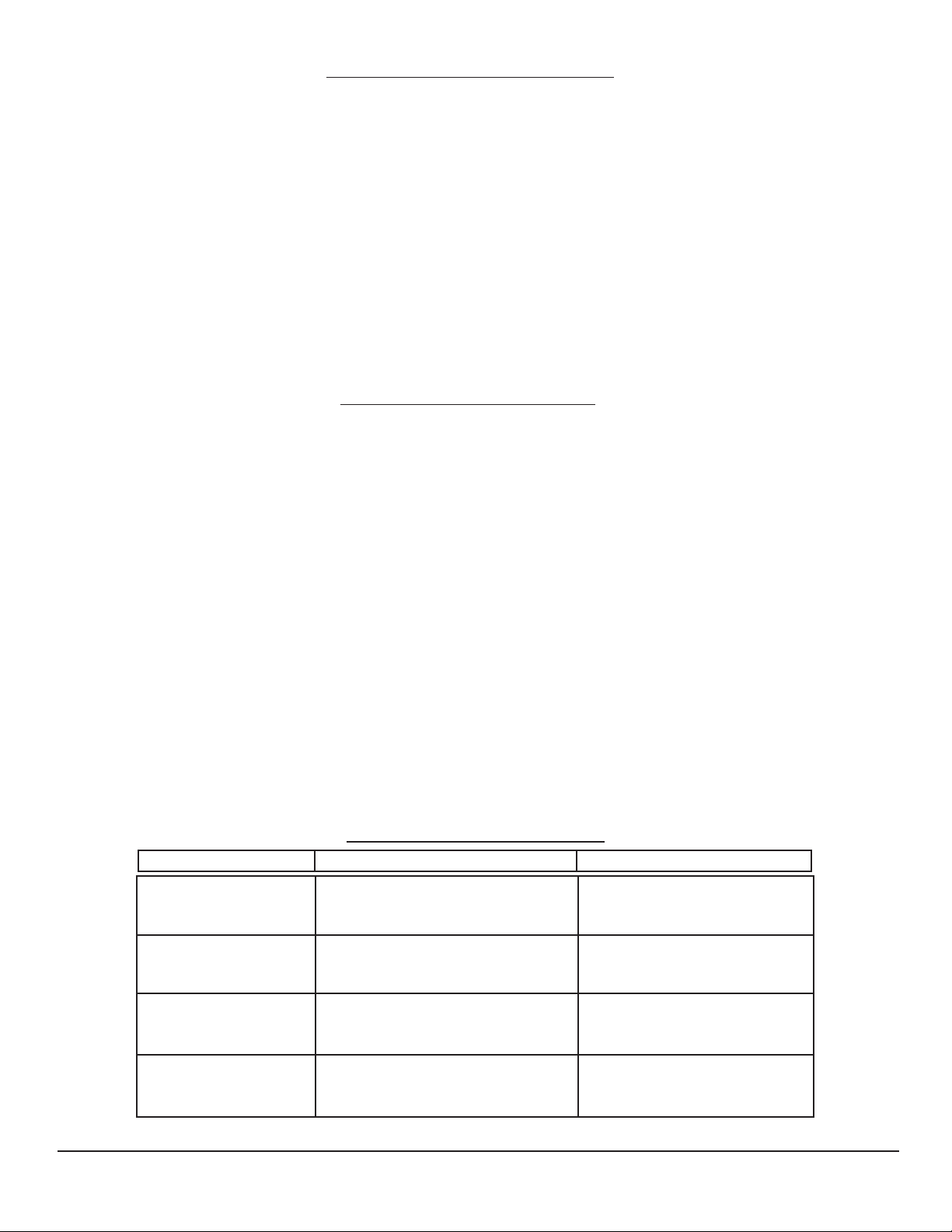

Wireless Transmitter Wiring Diagram

1 RECEIVER W/ 1 TRANSMITTER

SENSING EDGE INPUT

White, White, Black, Black)

(

2

-wire

(none, White, Black, none)

8 POS. DIP

SWITCH SETTINGS

4-wire

TRANSMITTER SWITCH SETTING

21

ON

1st 4 Address Switches

hown in the OFF position

s

.E. Termination:

S

OFF = 4-wire,

ON = 2-wire with 10KΩ

5

3

4

7

6

OFF

8

OFF(0)

FF = Normal Operation

O

afety Edge:

S

FF = N/C

O

ON = N/O

art # 400-MW-002

P

ev. 002 / 8-18-10

R

est Mode:

T

POWER INPUT

(Red & Black Wires)

24V AC/DC

(100mA min.)

RELAY OUTPUT

JUMPER/SHUNT

LEFT PAIR=N/C

RIGHT PAIR=N/O

SAFETY EDGE (1 Relay)

(YELLOW LED)

(OFF = FAULT)

POWER

(GREEN LED)

(Normal = ON)

FUTUREUSE

(Green LED)

SAFETYEDGE

ACTIVE

(Yellow LED)

MILLER EDGE, INC. • P.O. Box 159 • West Grove, PA 19390 • 610-869-4422 • Fax: 610-869-4423 • 1-800-220-3343 • www.milleredge.com

MILLER EDGE, INC. • 6809 South Harl Avenue • Suite A • Tempe, AZ 85283 • 480-755-3565 • Fax:480-755-3558 • 1-800-887-3343

Wireless Receiver Wiring Diagram

SAFETY EDGE (Relay1)

(White Wires)

SIGNAL ACQUIRED

(GREEN LED)

ON when receiving signal

from transmitter with

correct address

MAINTENANCE

REQUIRED

(Red LED)

1 RECEIVER W/ 1 TRANSMITTER

RECEIVER SWITCH SETTING

5

21

3

ON

1st 4 Address Switches

shown in the OFF position

4

OFF(0)

Always OFF

U.S.Patent # 7,123,144

Page 4

Part # 400-MW-002

Rev. 002 / 8-18-10

The Communicator II

Wireless Transmitter Wiring Diagram

IMPORTANT

Any user thatchanges or makes modifications not expressly approved by Miller EdgeInc.

could void theuser’sauthority to operate theequipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.These limits

are designed to provide reasonable protection against harmful interference in a residential installation.This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.If this equipment does cause harmful interference to radio or television reception,which may be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

1- Re-orient or relocate the receiving antenna

2- Increase the separation between the equipment and receiver

3- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

4- Consult the dealer or an experiencedradio/TV technician for help.

U.S.Patent # 7,123,144

MILLER EDGE, INC. • P.O. Box 159 • West Grove, PA 19390 • 610-869-4422 • Fax: 610-869-4423 • 1-800-220-3343 • www.milleredge.com

MILLER EDGE, INC. • 6809 South Harl Avenue • Suite A • Tempe, AZ 85283 • 480-755-3565 • Fax:480-755-3558 • 1-800-887-3343

Loading...

Loading...