Page 1

MGT

ATTACH EDGE

SENSOR CABLE

TO TERMINALS

TO SAFETY EDGE

GATE SAFETY EDGE

TRANSMITTER

Installation

Instructions

(760) 438-7000 • FAX (760) 438-7043

USA & Canada (800) 421-1587 & (800) 392-0123

Toll Free FAX (800) 468-1340

www.linearcorp.com

DESCRIPTION

The MGT is part of Linear’s Access Control product line and is the only fully

supervised gate edge safety transmitter on the market today. In a typical installation,

the MGT is mounted on a motorized gate, door or barrier arm and wired to a standard

exterior safety edge sensor which presents a closed circuit across the connecting

wires when an object is hit during the closing of a gate. To insure full compatibility

with all gate edge supervision features, Linear recommends Miller gate edge

sensors with an optional capacitor (.001 UF) installed. Please specify when ordering

sensor. If the edge sensor is pressed for 1/8 second, the MGT transmits a message

to the AccessMaster or AccessPro to reverse the movement of the gate. A status

message is sent to the receiver once every hour which indicates battery condition

and that the transmitter is operational. If the edge sensor becomes disconnected or

shorted, the status transmission informs the receiver that a trouble condition exists.

The MGT also features a tamper switch which will send a trouble transmission when

the cover is removed.

The MGT circuit board has been coated to prevent moisture damage and is mounted

inside a weather resistant fiberglass box. The mounting box attaches to the gate

through sealed interior mounting screws.

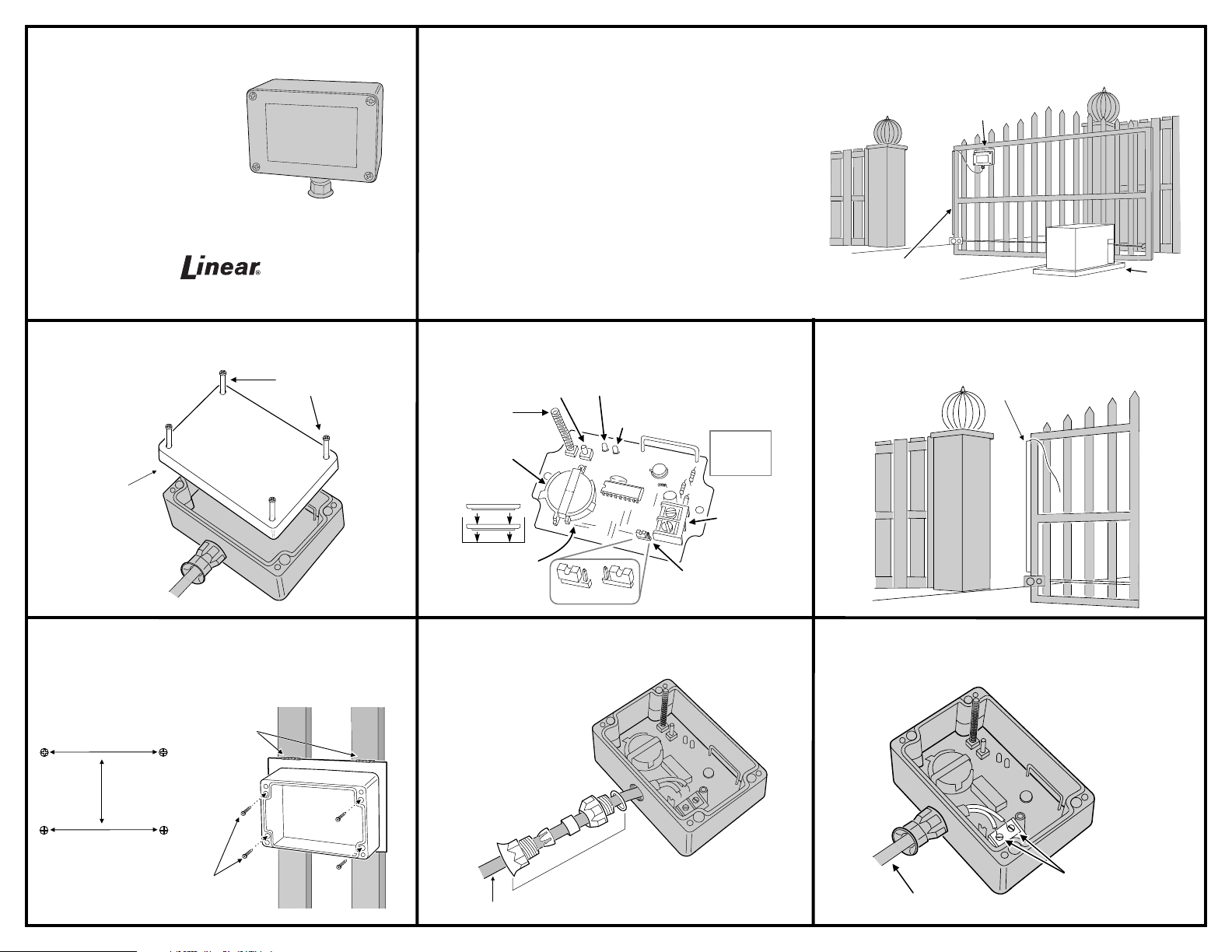

TYPICAL INSTALLATION

DTG

TRANSMITTER

SAFETY EDGE

SENSOR

GATE

OPERATOR

STEP 1 Remove Cover. Loosen the four screws on transmitter

top and remove cover.

LOOSEN

SCREWS

REMOVE

COVER

STEP 4 Mount MGT. Choose a location as high as possible on

gate in a secure position. Use the template attached to mark the

location for the transmitter. You may have to attach a metal or wood

plate to mount transmitter. Use a 3/32" bit and drill holes. Attach MGT

to gate using the four #6 self-tapping drill point screws.

WELD PLATE

TO GATE

STEP 2 Locate Parts. Refer to diagram below for transmitter

parts location and details.

POWER LIGHT, LIGHTS WHEN TRANSMITTING

(STEADY=NORMAL, FLASH=LOW BATTERY)

LOOP TROUBLE LIGHT

(ON WHEN SENSOR LOOP IS OPEN

OR SHORTED DURING TEST)

LOOP

TEST ON

LOOP

TEST OFF

LOOP TROUBLE TEST

OPTION JUMPER

NOTE:

LIGHTS ONLY

WORK WITH

COVER OFF

SAFETY

EDGE

INPUT

TERMINALS

TAMPER

SWITCH

BATTERY

HOLDER

+

-

+

-

INSTALL TWO

DURACELL

TYPE DL2450

BATTERIES (+)

SIDE UP

TEST

BUTTON

STEP 5 Assemble Cable Grip. Unscrew the cable grip about 3/4

of the way and thread the safety edge cable through the cable entry

on the transmitter.

STEP 3 Mount Safety Edge. Mount safety edge according to

manufacturer’s instructions included with the product.

INSTALL

SAFETY EDGE

STEP 6 Attach Cable. Attach safety edge cable to terminals as

shown. Tighten cable grip assembly using pliers to assure a water

tight seal.

3.88"

1.77"

ATTACH DTG

TO PLATE

A

C

TO SAFETY EDGE

Y

L

B

M

E

S

S

A

P

I

R

G

E

L

B

Page 2

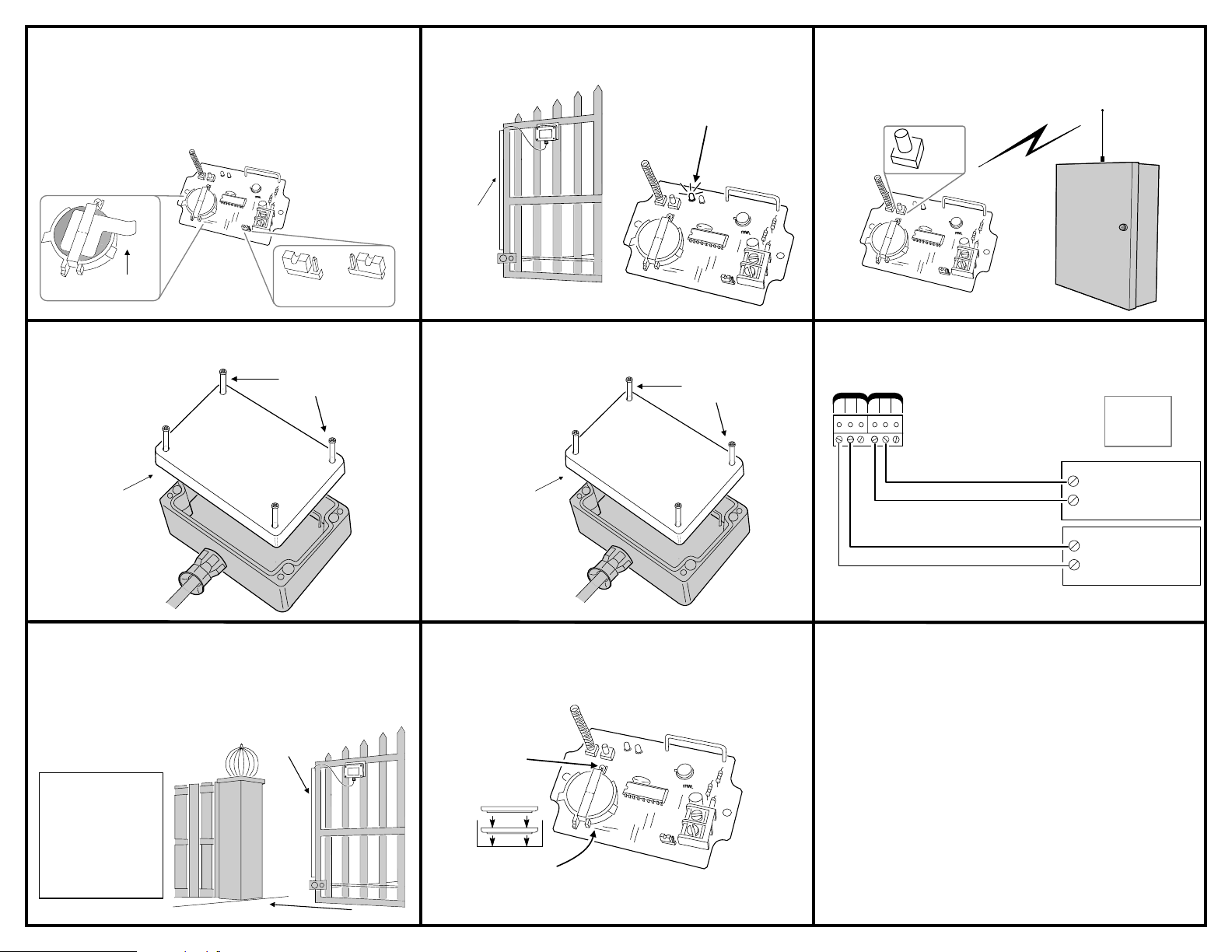

STEP 7 Set Jumper. Remove the battery protection strip. The

MGT monitors the edge sensor for short circuits and cut wiring by

measuring the edge sensor capacitance value. This function works

with edge sensors such as Miller Edge Models MGR20 and MGS20.

Some edge sensors may not present enough capacitance to pass

this test. If a constant loop trouble condition is being indicated the

test can be disabled by setting the Open Loop Test Option Jumper

to the OFF position.

STEP 8 Test Safety Edge. Test safety edge connection by

pressing the safety edge. The power light should come on.

POWER INDICATOR SHOULD

LIGHT WHEN SAFETY EDGE

IS PRESSED

PRESS

WITH

HAND

STEP 9 Program Transmitter. Refer to receiver programming

instructions to set the receiver into the program mode. Press the “test”

button to program the unit identification code into the receiver.

Facility/ID code is located on the inside of the unit, near the terminal

block.

TEST

BUTTON

REMOVE BATTERY

PROTECTION STRIP

TEST ON

OPEN LOOP

TEST OFF

STEP 10 Reset Trouble Indicator. Close transmitter cover and

reset any trouble indicators on receiver caused by the open cover.

TIGHTEN

SCREWS

REPLACE

COVER

STEP 13 Test System. Activate the gate to close. As the gate is

closing, press the safety edge with your hand. Gate should stop and

reverse

☞

CAUTION! DO not stand in the path of the closing gate.

PRESS

SAFETY EDGE

WARNING!

NO AUTOMATIC

SUPERVISION OF

A DAMAGED GATE

EDGE SENSOR IS

PROVIDED. USER IS

CAUTIONED TO TEST

THE TRANSMITTER

REGULARLY.

CLOSE GATE

STEP 11 Test Tamper. Open transmitter cover and check receiver

to see that a tamper is indicated. Replace cover when finished.

LOOSEN

SCREWS

REMOVE

COVER

STEP 14 Replacing Batteries. Remove the screw on the battery

clip to remove batteries. Place two Duracell Lithium 3V type DL 2450

batteries with the (+) side up in the battery compartment and replace

clip and screw.

REMOVE

SCREW

+

-

+

-

INSTALL TWO

DURACELL

TYPE DL2450

BATTERIES (+)

SIDE UP

STEP 12 Wire Receiver. Wire receiver obstacle output to obstacle

input on operator. Refer to operator and receiver wiring instructions.

CHANNEL C CHANNEL D

N.O. COM.

N.C.

N.O. COM.

N.C.

NOT USED

NOT USED

This Linear product is warranted against defects in material and workmanship for twelve (12) months. The

Warranty Expiration Date is labeled on the product. This warranty extends only to wholesale customers who

buy direct from Linear or through Linear’s normal distribution channels. Linear does not warrant this product to

consumers. Consumers should inquire from their selling dealer as to the nature of the dealer’s warranty, if any.

There are no obligations or liab ilities on the part of Linear Corporation for consequential damages arising

out of or in connection with use or performance of this product or other indirect damages with respect to

loss of property, revenue, or profit, or cost of removal, installation, or reinstallation. All implied warranties,

including implied warranties for merchantability and implied warranties for fitness, are valid only until Warranty

Expiration Date as labeled on the product. This Linear Corporation Warranty is in lieu of all other warranties

express or implied.

All products returned for warranty service require a Return Product Authorization Number (RPA#). Contact Linear

Technical Services at 1-800-421-1587 for an RPA# and other important details.

Important!!!

Linear radio controls provide a reliable communications link and fill an important need in portable wireless signaling.

However, there are some limitations which must be observed.

For U.S. installations only: The radios are required to comply with FCC Rules and Regulations as Part 15

1

devices. As such, they have limited transmitter power and therefore limited range.

1

A receiver cannot respond to more than one transmitted signal at a time and may be blocked by radio signals

that occur on or near their operating frequencies, regardless of code settings.

1

Changes or modifications to the device may void FCC compliance.

1

Infrequently used radio links should be tested regularly to protect against undetected interference or fault.

1

A general knowledge of radio and its vagaries should be gained prior to acting as a wholesale distributor or

dealer, and these facts should be communicated to the ultimate users.

Copyright 2002 Linear Corporation 210025 B

LIMITED WARRANTY

Typical

AccessMaster Hook-up

NOTE:

ONE OR TWO

OPERATORS

MAY BE USED

NORMALLY OPEN

OBSTACLE

INPUT

NORMALLY OPEN

OBSTACLE

INPUT

EXIT

GATE

OPERATOR

ENTRY

GATE

OPERATOR

Loading...

Loading...