Page 1

MGR20 / MGS20

Installation and Maintenance Instructions

CAUTION: Read installation and maintenance instructions thoroughly

before installing sensing edge.

MILLER EDGE, INC. • P.O. Box 159 • West Grove, PA 19390 • (610)869-4422 • Fax:(610)869-4423 • 800-220-3343 www.milleredge.com

MILLER EDGE, INC. • 6809 South Harl Avenue, Suite A, Tempe, AZ 85283 • (602)755-3565 • Fax (610)755-3558 • 800-887-3343

Wire the sensing edge into controls as specified by the control manufacturer. ALWAYS ADHERE TO THE LOCAL AND

NATIONAL ELECTRICAL CODE SPECIFICATIONS WHEN WIRING SENSING EDGE AND OTHER CONTROLS.

Adjust the equipment to which the sensing edge is attached so that the edge is never compressed more than 1/4”.

Test the edge with the gate closed.The edge should show an open circuit.If the circuit is closed, readjust close limit so the

edge circuit is open.

If no wiring directions exist, consult the Miller Edge Engineering Department at (800) 220-EDGE, for wiring directions and

assistance.

VER

Y IMPORTANT: After installation, check sensing edge and wiring to make sure the sensing circuit is working properly.

A

TTENTION INSTALLER

It is strongly recommended that you advise your customer to observe good maintenance practices by including a check of

the entire length of the sensing edge in their equipment maintenance manuals.The sensing edge should be checked periodically (at least once per month) for any signs of damage, cuts, loss of sensitivity or water damage. When the sensing edge is

compressed 1/2” along any portion of its length, star ting 2” in from the ends, it will send an electrical signal to controls.If this

does not occur, contact the equipment installer immediately for assistance. If the installer is not available, contact the Miller

Edge Customer Service Department at (800) 220-EDGE for assistance.

DO NO

T

operate equipment without a properly working and correctly wired sensing edge attached.

Rev 1-14-04

-Always Disconnect power to equipment before beginning work.

-Miller Sensing Edges operate on 24 volts AC/DC, 1/2 amp maximum. Overloading will

decrease the life of the product and could cause immediate failure of the edge or electrocution.

-The MG Series is designed to be used as an emergency stop and reverse signal attached to

the leading edge of power operated gates.Miller Edge strongly recommends hard wiring any

sensing edge to assure integrity of operation.

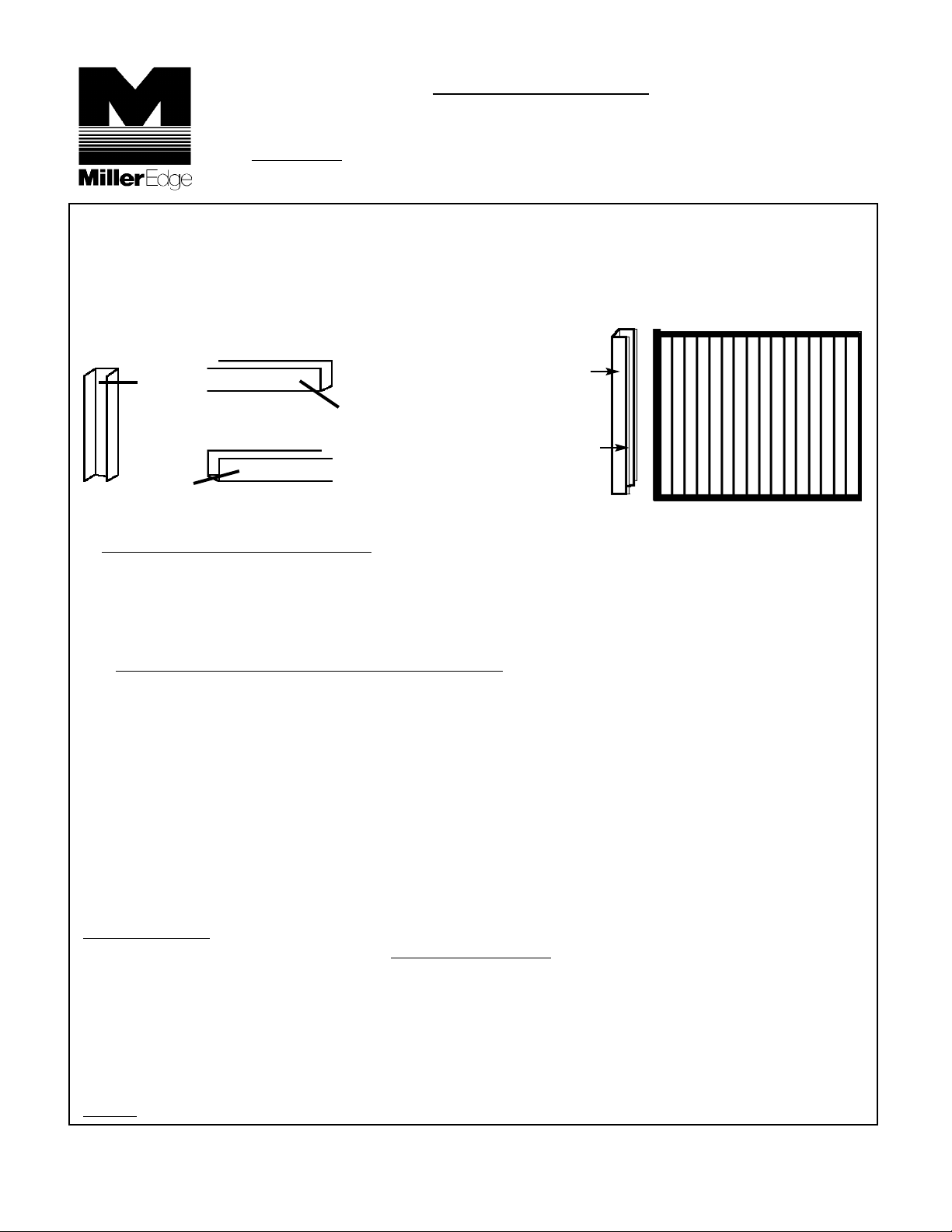

-Remove Sensing Edge from its box. Locate wire outlet.

RIGHT SIDE

1” from Right End of Edge

UNIVERSAL

1” from End of Edge

LEFT SIDE

1” from Left End of Edge

GATE

Sensing

Edge

Mounting Tab

For Universal Outlet Only-Begin Here

1. Measure distance from wire outlet to end of Sensing Edge.

2. Locate desired position of edge on gate post.

3. Drill 1/2” hole through gate post where wire will feed through post.

4. Lift Sensing Edge to post and feed wire through the drilled hole.

5. Continue as with side outlet.

For Side Outlet Location (and Univer

sal Outlet Continued)

6. Clip Sensing Edge onto post.

7. Use #10 screws (or smaller) to secure edge to post. Screw through

black mounting tab and

into gate post.

8.Wire to gate operator according to manufacturer’s instructions.

*DO NOT PLUG INTO ELECTRICAL OUTLET

UNTIL ALL CONNECTIONS ARE MADE*

NEVER PAINT Sensing Edge

NEVER CUT OR PUNCTURE Sensing Edge

NEVER PULL ON WIRES

NEVER operate unguarded equipment

Loading...

Loading...