Page 1

Installation Instructions

Patent Pending DO432

Page 2

Page 3

2

Measure the clear opening. Use the templates

provided to align conduit and determine placement

of the posts. Turn this page over to view Assemble and

Align and Mark instructions.

Minimum Clearance

for accessibility: 2 feet (61 cm)

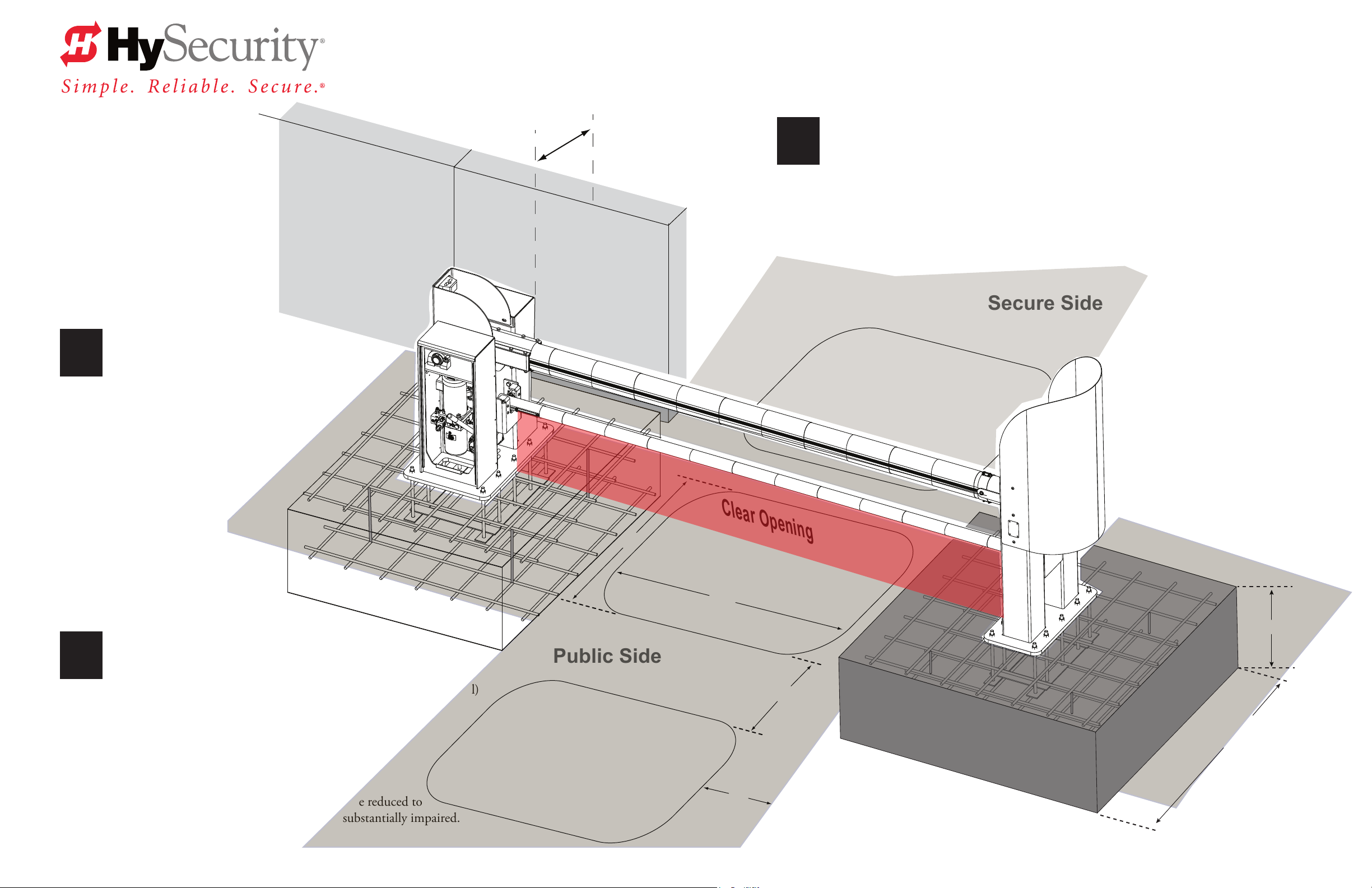

M30 PLAN SITE DESIGN

Read & Plan

Read and follow the Important Safety Information provided in the Programming and Operations

1

Roadway

Manual prior to installing the StrongArm M30™ Crash Rated Fortied Barrier Arm. Review these

installation instructions and make sure to conform to site specications and all local and federal

regulations and codes.

Secure Side

Inside

Obstruction

Loop (IOLD)

Design Vehicle Loops

If automatic close is desired, a RESET and one other loop

3

Dimensions:

A = 6 to 16 feet (183 to 488 cm) B = 6 to 8 feet (183 to 244 cm)

C = Maintain 4 feet (122 cm) between loop & edge of roadway

D = Maximum distance is 5 feet (152 cm). Vehicle must move

from one loop to the next without loss of detection.

NOTE: If tailgating is a concern, dimension “B” may be reduced to

3 ft (91 cm), but detecting high bed vehicles will be substantially impaired.

(IOLD or OOLD) is required.

ree loops are preferred: RESET, IOLD, OOLD (Free Exit, optional)

B

Public Side

Outside

Obstruction

Loop (OOLD)

Clear Opening

Centered under Barrier Arm

Reset Loop

A

D

C

2 ft*

(61 cm)

6 ft*

(183 cm)

* Concrete Dimensions

6 x 6 x 2 foot (183 x 183 x 61 cm)

Optional: 4 x 4 x 4 foot square (122 x 122 x 122 cm)

© 2013 www.hysecurity.com

StrongArm M30 Installation & Assembly - Plan Site Design

D0432 Rev D

Page 1

Page 4

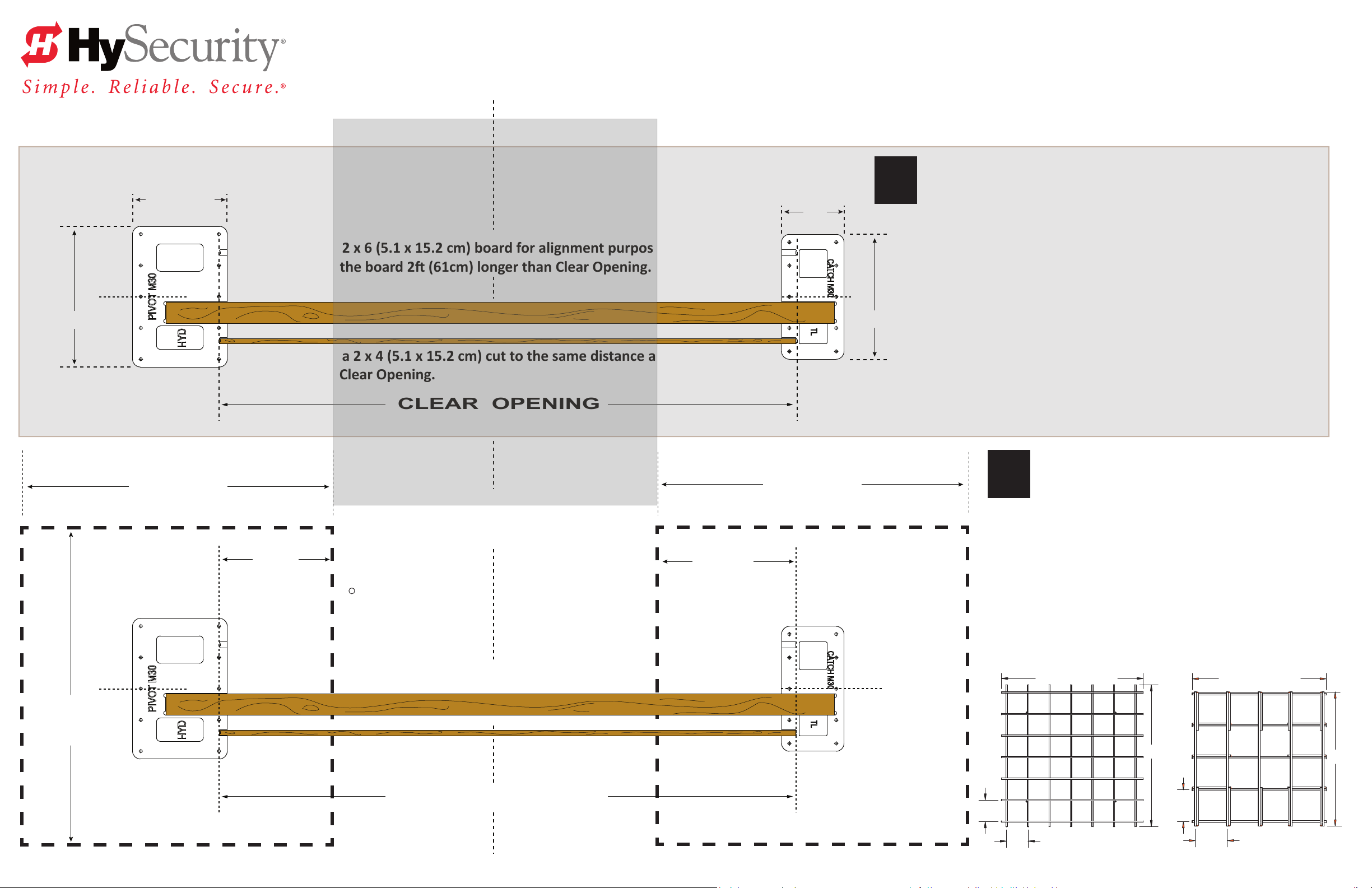

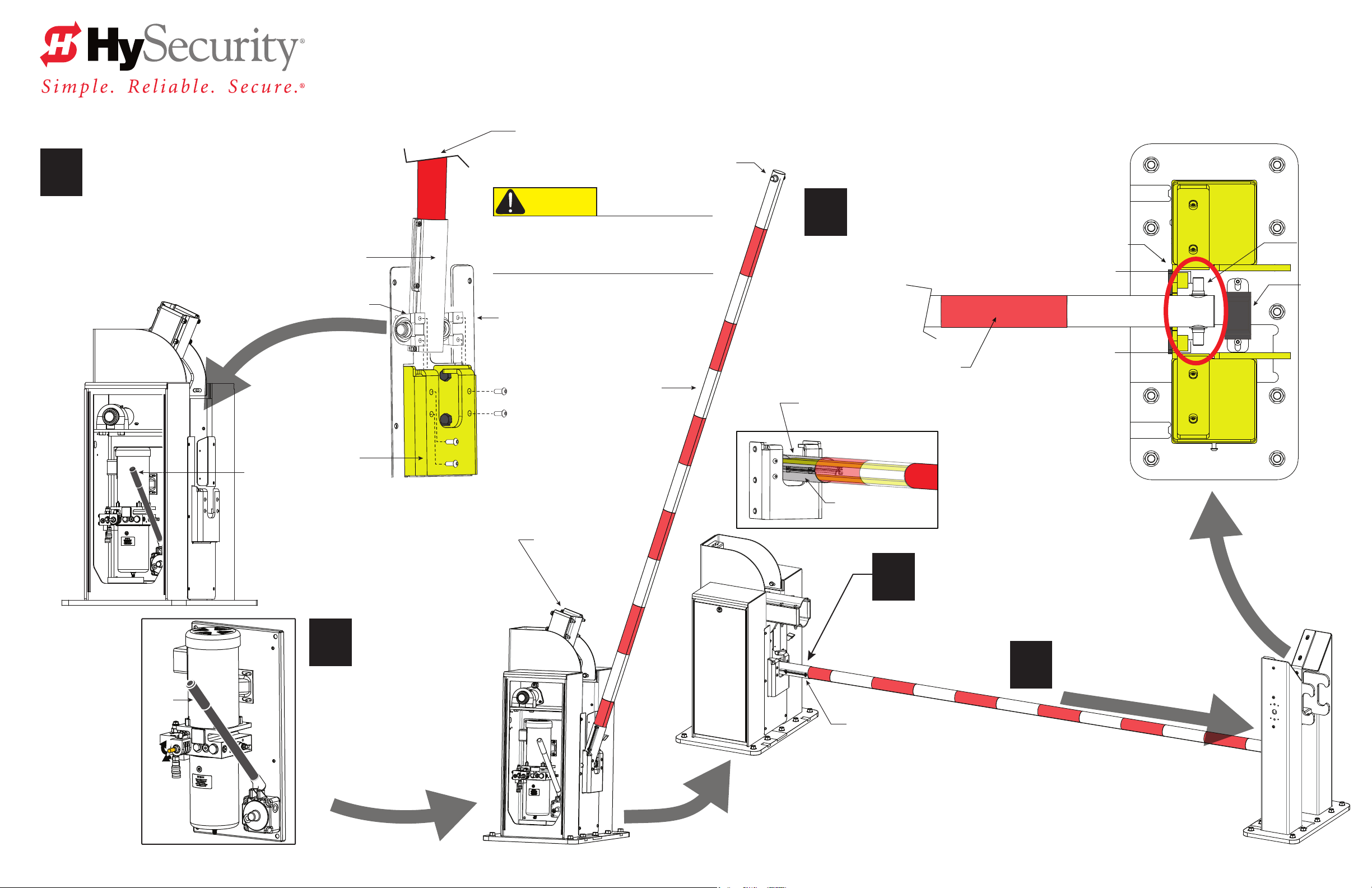

M30 ASSEMBLE & ALIGN & MARK

Roadway

C

/

L

24¼" (62 cm)

Use 2 x 6 (5.1 x 15.2 cm) board for alignment purposes.

Cut the board 2 (61cm) longer than Clear Opening.

C

/

L

Template Layout: 6 x 6 x 2 foot and 4 x 4 x 4 foot

Use Templates

To set the Pivot and Catch Posts in their respective locations, use the

16"

(41 cm)

1

C

/

L

anchor cage templates provided. Measure and cut one 2 x 6 (not provided)

exactly 2ft (61cm) longer than the Clear Opening and measure and cut

one 2 x 4 (not provided) equal to the Clear Opening. Secure both to the

anchor cage templates.

NOTE:

If standard lumber lengths are exceeded, two straight pieces may be

screwed together to reach the desired length.

36" (91 cm)

C

/

L

Pivot Post Template

72" (183 cm)

48" (122 cm)

25¾" to C.O.

(65 cm)

13¾" to C.O.

(35 cm) for 4 ft cage

Use a 2 x 4 (5.1 x 15.2 cm) cut to the same distance as

the Clear Opening.

CLEAR OPENING

Roadway

C

/

L

Catch Post Template

31⅝" to C.O.

(80 cm)

19⅝" to C.O.

(50 cm) for 4 ft cage

72" (183 cm)

48" (122 cm)

32" (81 cm)

C

/

L

IMPORTANT: Verify measurements.

Because of the nature of the StrongArm M30™, it is critical

to align the opening of the Catch Post with the center of the Pivot Post.

Measure and mark the excavation pit. Mark the

conduit openings and locate the conduit trenches

2

and rebar cages accordingly.

NOTE: e dashed square lines indicate excavation area

for concrete foundation.*

Sizes shown: 6 x 6 x 2 foot (183 x 183 x 61 cm)

Optional foundation size: 4 x 4 x 4 foot (122 x 122 x 122 cm)

(measurements shown in orange )

* Measurements based on centering templates on

concrete foundation.

REBAR CAGE: 6 x 6 x 2

Pivot & Catch post cages idencal.

Use #5 rebar, 5/8 in. (40 or beer).

66 inches (167 cm)

REBAR CAGE: 4 x 4 x 4

Pivot & Catch post cages idencal.

Use #5 rebar, 5/8 in. (60 or beer).

42 inches (107 cm)

72" (183 cm)

48" (122 cm)

66 in.

10 in.

10 in.

(25 cm)

O.C.

(25 cm)

O.C.

CLEAR OPENING

10 in.

O.C.

© 2013 www.hysecurity.com Page 2

StrongArm M30 Installation & Assembly - Assemble & Align Templates & Mark Openings D0432 Rev D

10.0

O.C.

42 in.

Page 5

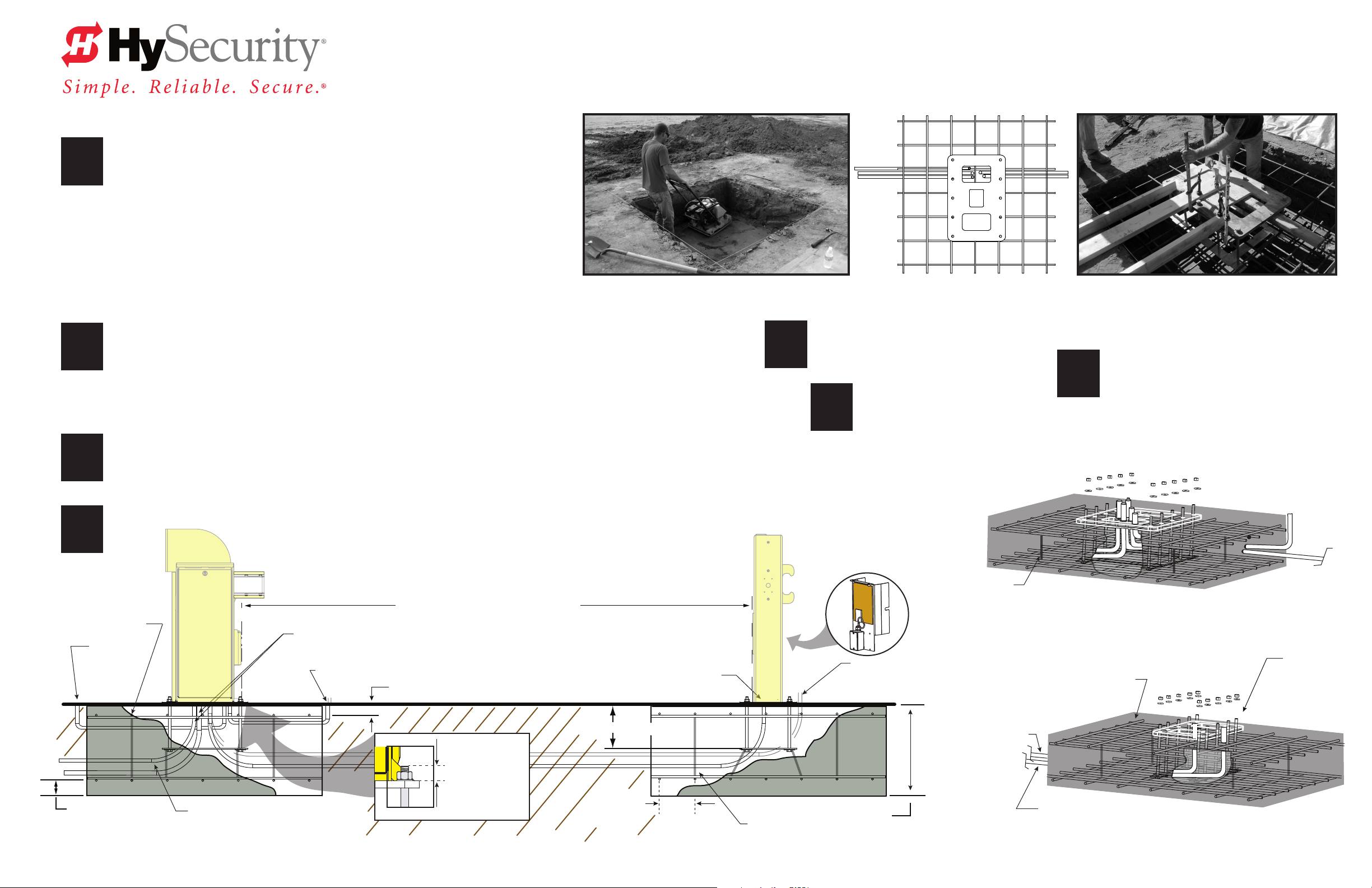

1

To make sure the stability of the StrongArm M30™ Crash Rated Fortied Barrier Arm,

the foundation must be constructed in accordance with the following guidelines:

• Excavate a hole for the foundation to house the rebar mats and anchor bolt assemblies.

Soil compression under and around the foundation shall be compacted to

a soil density of 95% of standard proctor (ASTM-698).

• Add gravel where necessary to ensure a solid soil base. Soil must be stable and

adequate to support the weight of the foundation.

IMPORTANT: Softer soils require a larger footing. Employ the services of a structural or

civil engineer for site specic considerations. In Northern latitudes, consider the frost line.

M30 INSTALL FOUNDATION

Soil Density compacted to 95% per ASTM-698 Aligning Rebar & Anchor CagePlan View: Pivot Post Template

Measure and lay conduit:

• Two separate 1-inch diameter conduits for the high voltage power and low voltage power controls.

2

3

• Conduit for vehicle loop wires. One separate conduit for each vehicle loop installed.

• Separate conduit for Earth ground.

• Appropriately-sized conduit between the operator Pivot Post and Catch Post for optional items such as:

thru beam photo eye, trac light, Mag Lock, or heater.

Lay rebar mat pattern 7 by 7 at 10-inch on center (OC).

Use #5 (⅝ inch) rebar: 10 lengths of 20 ft. (6m)

Cut 28 pieces of rebar 5½ ft long (168cm).

For the vertical pieces, cut 8 pieces of rebar 19 inches long (48cm).

Install the anchor bolt assemblies as shown.

4

Pivot Post

Rebar

verticals (4x)

Conduit

for Earth

Ground

3 inch (76 mm)

Bottom of rebar

CLEAR OPENING

Provide separate conduits for

High voltage & Low voltage power.

Conduit for Loops

2 inch Top of rebar (51 mm)

Correct

thread

height

extends approx.

1⅜ in. (35 mm)

Tip:

Tack weld base of anchor

cage to lower rebar (4x). Keeps the base of cage from oating when pouring the concrete.

above base

Conduit for optional items:

photo eye, traffic light

or Mag Lock

12 inch (30 cm)

Dim shown to bottom of plate

10 inch O.C.

(25 cm)

5

Heater

option

Rebar

verticals (4x)

Re-measure and adjust to

correct mis-alignment issues.

Ensure anchor cage location

6

is maintained while

pouring the concrete. See Tip.

Foundation dimensions:

Minimum 6 x 6 x 2 ft

(183 x 183 x 61 cm)

Catch Post

19 inch (48 cm)

Rebar verticals (4x)

Conduit for 240V

high voltage line.

Heater option.

Conduit for hard-wired

photo eye, Mag Lock, or

traffic light options

24 in. (61 cm)

e concrete properties must be, at minimum

7

3000psi. A smooth nish is required so the

Pivot & Catch posts sit at, level, & plumb.

Rebar mats:

#5 rebar (⅝ inch)

Length: 5½ ft (168cm)

Pivot Post

Anchor cages include 10 anchor bolts, washers, and nuts.

Rebar mats:

#5 rebar (⅝ inch)

Length: 5½ ft (168cm)

Conduit for 240V

high voltage line.

Heater option.

Catch Post

¾ in. bolts

15 in. length

(38 cm)

© 2013 www.hysecurity.com Page 3

StrongArm M30 Installation & Assembly - Foundation, Conduit, Anchor Cage D0432 Rev D

Page 6

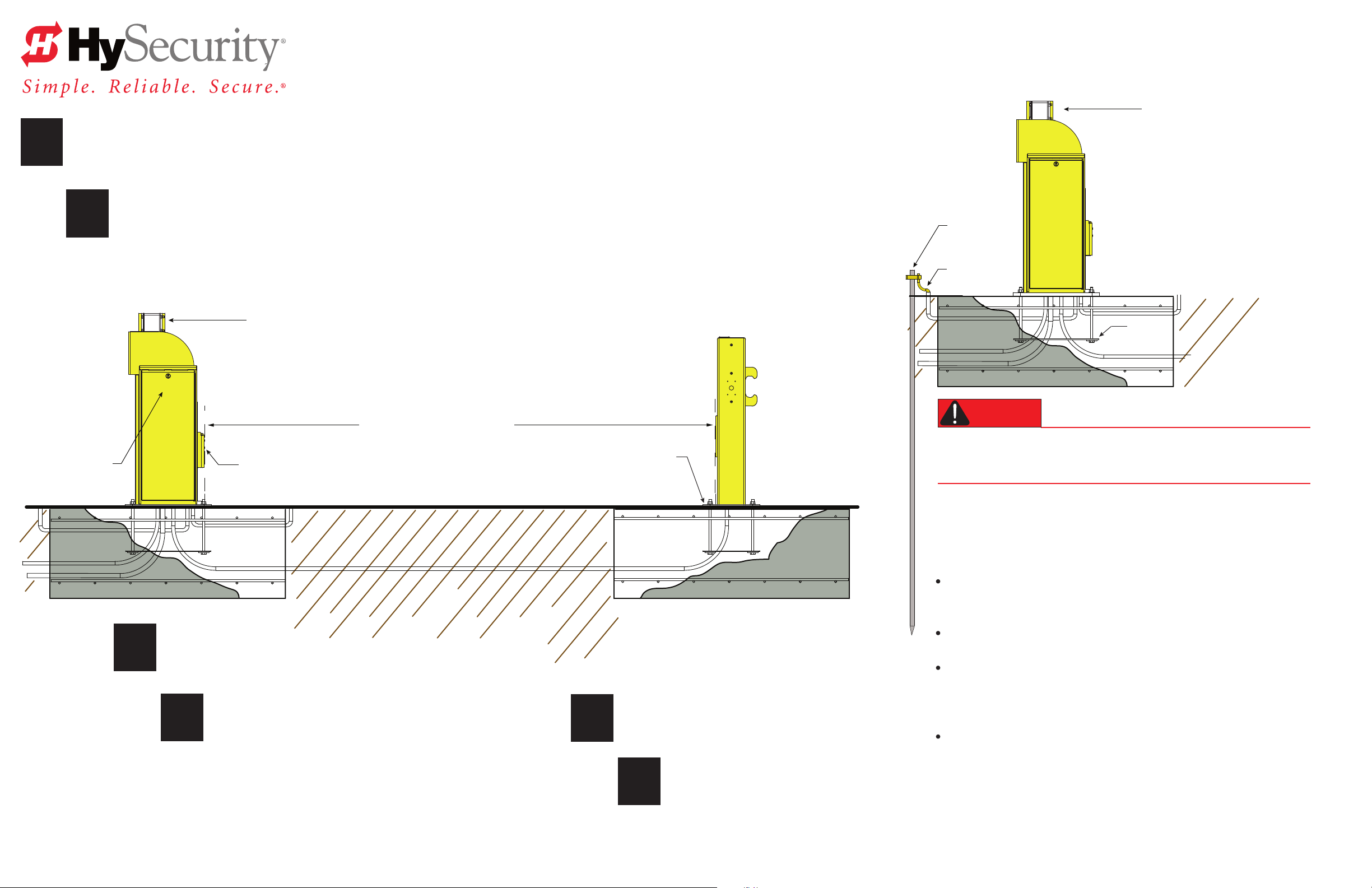

1

When the concrete has suciently hardened,

remove the templates.

M30 INSTALL POSTS & GROUND

M30 Arm Saddle

(Restraining strap - not shown)

Place the Pivot and Catch posts over their respective

2

Pivot Post Catch Post

Hydraulics cover

conduit and anchor bolt assemblies.

NOTE: Make sure to install the StrongArm M30 Crash Barrier Arm

on a level surface. Both pivot and catch posts must be plumb, level and

on grade with the roadway surface. Slope drainage ¼-inch per foot within 2 feet of the operator.

(2 cm per meter)

M30 Arm Saddle

(Restraining strap - not shown)

CLEAR OPENING

Lower Pivot Mount

Anchor plate

Pivot Post

Ground rod

6 AWG

Anchor

plate

DANGER

e potential for lightning discharge exists with all gates, barrier arms,

fences, and gate operators. National Electric Code (NEC) requires a

separate earth ground in addition to the required equipment ground.

For earth grounding requirements in the U.S.A., refer to the National

Fire Protection Association (NFPA) 780 - Standard for the Installation of

Lightning Protection Systems.

Highlights of the standard include:

e ground rod must be UL listed copper-clad steel, solid copper,

hot-dipped galvanized steel, or stainless steel. Minimum requirements:

½ inch (13 mm) diameter and 8 feet (244 cm) in length.

Ensure the posts are plumb.

3

© 2013 www.hysecurity.com Page 4

Shim or grout as required.

Secure each anchor plate using the

ten washers and nuts provided for

4

each post. Torque to 200 ft ∙ lb (271 N∙m)

Install the grounding rod per local building codes.

5

Attach a large earth ground wire (6AWG)

6

StrongArm M30 Installation & Assembly - Install Posts & Ground D0432 Rev C

from the grounding rod to the lug nut on

the chassis. Feed the 6AWG wire from the

chassis to the earth ground rod.

e ground rod is driven into the earth (refer to local codes for proper

depth requirements).

e ground rod is electrically bonded to the chassis with a single length

of un-spliced 6AWG copper wire less than 3 feet (91cm) long. Due to the

large concrete foundation, make the neccessary adjustments to accomodate

for earth ground requirements.

Local jurisdictions may impose additional or dierent requirements

above the NEC and NFPA 780. Consult the local codes and regulations

regarding requirements in your area.

IMPORTANT: Properly grounding the gate operator is critical to gate

operator performance and the life of its electrical components. Use sucient

wire size during installation. If you do not ground the operator with a separate

earth ground rod, you risk voiding the Limited Warranty.

Page 7

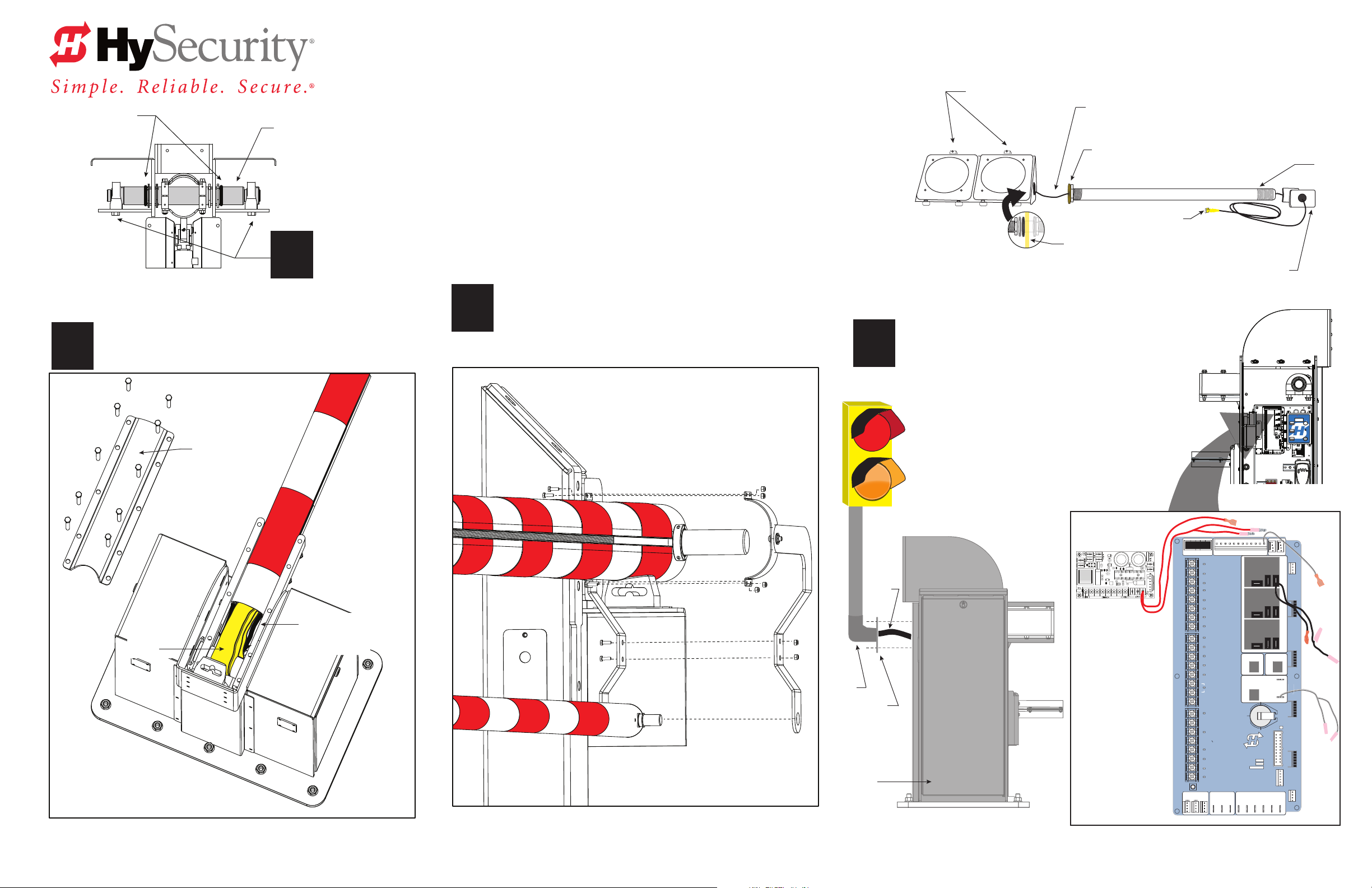

M30 ASSEMBLE BARRIER ARMS

Overhead View

Lower Arm

Lower Catch Pin

Mount the Lower Pivot Assembly (comprised of

the lower arm and bearings) into the Pivot Post

1

enclosure and secure the bearings to the Lower

Pivot Mount with the four buttonhead screws.

Pivot Post

Restraining strap

not shown

Hand Pump

Lower Pivot

Assembly

Bearings

Lower Pivot

Mount

Lower Catch Pin

CAUTION

Prevent potential injury! Remove the Lower Catch

Pin BEFORE installing the Lower Arm. If it is not

removed, it may slide out of the Lower Arm during

installation and drop onto personnel or equipment.

Loosen and remove the

four button head screws from the

bearings prior to installing the lower arm.

Lower Arm

5

Top Clamp

With the gap clearance set at

approximately ¾-inches between

the Lower Catch Pin and Post, securely

tighten the top clamp on the Lower Pivot Assembly.

¾-in. (2 cm) gap

¾-in. (2 cm) gap

Lower Arm

Lower

Catch Pin

Bumper

for M30

Arm

Pump

Handle

2

1

Open

Valve

2

Rest the Lower Arm on

the Catch Post, and then

use the manual pump

handle to lower the

M30 Arm saddle into a

horizontal position.

M30 Arm Saddle

Lower Pivot

Assembly

3

Lower Arm Saddle

Loosen, but DO NOT remove,

the six bolts and nuts on

the Lower Pivot Assembly.

Slide the Lower Arm to obtain

¾-inch clearance at the Catch Post.

4

Catch Post

© 2013 www.hysecurity.com Page 5

StrongArm M30 Installation & Assembly - Assemble Barrier Arms

D0432 Rev D

Page 8

INSTALL M30 ARM

1

Top clamp

Loosen and remove the ten top clamp

fasteners from the M30 Arm Saddle and

set the top clamp and nine fasteners aside.

Bottom clamp

(For clarity: Restraining

strap not shown)

Top clamp

M30 Arm Saddle

3

e M30 Arm is very heavy. Use proper lifting techniques

and obtain assistance to install the M30 Arm.

Rest the M30 Arm on the Catch Post’s bumper to

support its weight while you and your assistants

feed the restraining strap through the M30 Arm.

As you set the M30 Arm in its saddle, feed both sets of

the LED Arm Lights through the strain reliefs and into

the electronics side of the Pivot Post.

Strain relief holes in saddle for LED Arm Lights cable wiring

Double Restraining

Strap Loops

Shaft collar

End Cap

Shaft Collar

6

Front View

M30 End Cap

Adjust the Shaft Collars to hold the

pin in place and tighten the set screws

securely.

Position the End Cap and

secure it using four hex head

7

screws.

Upper Catch Pin

2

To stabilize the bottom clamp, return

one bolt and nut to the front edge of

the saddle. Keep the bolt loose while

installing the straps and aligning the

upper catch pin.

Bolt & washer

M30 Arm Saddle

Restraining strap

Bolt & nut

(Temporary

placement)

4

Bumper

Rest the M30 Arm

in its saddle and on

the Catch Post

bumper.

Double Restraining

Strap Loops

As you slide the Upper Catch Pin

through the end of the M30 Arm,

5

place both of the strap loops around

the Upper Catch Pin.

Tip:

Stretch the strap

using a 2 x 4

(100 x 50)

for leverage.

Upper

Catch

Pin

3/4 in.

(2 cm)

Side View

Restraining Straps

Cut away view

© 2013 www.hysecurity.com

Page 6StrongArm M30 Installation & Assembly - Link Arms and Install Trac Light D0432 Rev D

Page 9

Rubber bushings

SID

R

D

Replace the Top Clamp and ten fasteners.

Tighten securely to 75 ft∙lbs (102 N∙m).

2

Rear View

Upper Pivot Pin

Bearing screws (4x)

Torque to 150 ft∙lb. (203 N∙m)

1

M30 LINK ARMS & INSTALL LIGHT

Open Traffic Light

access panels

Wire (Tape the ends of the wire to feed

through the pipe and elbow.)

Lock nut and bronze toothed washer

Taped end

Traffic light chassis

C

Pipe

Threaded

Elbow

3

Assemble the Arm Linkage as shown in the illustration.

Tighten the fasteners securely using two box end wrenches.

Tip: Have an assistant, manually raise the M30 Arm so it clears

the Catch Post and provides easier access to the Arm Linkage fasteners.

4

A

Secure pipe

B

inside access panel

with 1 large rubber washer,

1 silver washer, and 1 nut.

Assemble the Trac Light:

A. Open the Trac Lights access panels and feed

the wire through the pipe (remove the threaded

elbow if necessary).

Top clamp

Restraining

strap

LED Cable Connections

LED Arm Light

cable wire

Arm Linkage

B. Secure the pipe inside the access panel with the

fasteners shown and tighten them securely.

C. Replace the threaded elbow.

D. Connect the trac and LED arm lights to the

Smart Touch Controller. Wires are color-coded.

Match spade and bullet connectors.

Traffic Light

D

Wire

Elbow

Bracket

Feed wires

through hole in

chassis & route

through conduit to the Smart Touch Controller.

Connect wires

(black to black,

white to white, &

red to red).

Bundle and tie

wrap all the wires

above the display

keypad’s white

box.

NOTE: The wiring

harness for

2 trac lights is

not shown.

DRIVE

STOP BUTTON

1

2

OPEN BUTTON

3

CLOSE BUTTON

REMOTE OPEN AND

4

RADIO CONTROL

5

OPEN/CLOSE

OPEN PARTIAL

6

INTERLOCK OPEN

7

TIME CLOCK OPEN

FREE EXIT DETECTOR

8

DISABLE EXIT DETECTOR

9

DISABLE CLOSE TIMER

INSIDE OBSTRUCTION

10

VEHICLE DETECTOR

OUTSIDE OBSTRUCTION

11

VEHICLE DETECTOR

SHADOW/RESET

12

VEHICLE DETECTOR

EDGE SENSOR

14

PHOTO EYE POWER

24 VOLTS COMMON

PHOTO EYE POWER

15

DO NOT USE

16

PHOTO EYE

17

OPEN DIRECTION

DO NOT USE

18

PHOTO EYE

19

CLOSE DIRECTION

20

DO NOT USE

CHARGER

21

AC LOSS

SPARE INPUT

22

EMERG CLOSE

23

FIRE DEPT OPEN

24

LED

LIMITDUAL GATE

RPM

COMCOMAB

POWER

USER 3

HySecurity

MX000585

VERSION

S/N

Smart Touch Controller

RADIO OPTIONS

Hy

Security

®

Smart Touch Controller

Open

Reset

Previous

Close

Next

Green = Operate

Yellow = Program

Red = Fault

Stop

Program

Select

I ON

RS485

STOP/BUZZER

MOTORUSER 1

FREE

EXIT

USER 2

INSIDE

OBSTR

OUTSIDE

OBSTR

COM

NO

VEHICLE DETECTORVEHICLE DETECTORVEHICLE DETECTOR

STATUS

SHADOW

RESET

DISPLAY

VEHICLE DETECTOR

RS232

WIEGAND

COMOPEN EDGE+24V +24V

© 2013 www.hysecurity.com

StrongArm M30 Installation & Assembly - Link Arms and Install Trac Light D0432 Rev D

Page 7

Page 10

DANGER

M30 COMPLETE THE INSTALLATION

Turn OFF AC power at the source (circuit breaker panel) before accessing the wires in the StrongArm M30

junction box. Follow facility Lock Out/Tag Out procedures. Make sure all power switches are in the OFF

position. Follow all electrical code standards and regulations.

Connect to Power: ree wires and a ground are available for connection to a 3 Phase power source (3Ø).

Loosen the screws on the power module to open the wire slots at the top and bottom.

1

3Ø supply power connection shown

NOTE: 1Ø optional: Omit wire (do not connect) to L2 wire if supply power is 1Ø.

L1 L2 L3

I ON

I ON

ON

OFF

Directional power switch

Top screws: Loosen and

open wire slots.

Disconnect Switch

(Not to scale)

3

Install entrapment shield: Remove the six hex head screws and fender washers

from the Catch posts and use them to secure the Entrapment Shield as shown.

Tighten all six screws using a 7/32 hex key.

Ground

T1 T3T2

Conduit

Connect AC Power:

2

NOTE: Wiring of gate operators must conform to NEC standards

and comply with all local codes. When the installation is compliant and

complete, turn on AC power at the source and power module.

Place the incoming power wires

into their appropriate slots.

Attach the ground wires to the chassis.

Loosen screws and

open wire slots.

Jacket to VFD wire connections

4

Vent Plug

Breather Cap

Remove the Vent Plug.

Replace it with

the Breather Cap.

5

Torque Requirements:

Bolt size

¼ - 20 10 13

⅜ – 16 28 28

½ - 13 75 102

⅝ – 11 & ⅝ – 18 150 203

¾ - 10 200 271

(inches) ft∙lbs N∙m

© 2013 www.hysecurity.com Page 8

StrongArm M30 Installation & Assembly - Complete the Installation D0432 Rev D

Page 11

Page 12

DO432

800-321-9947 www.hysecurity.com

Loading...

Loading...