Page 1

®

WWW.ALLOMATIC.NET

SL-90DC Installation Manual

Copyright © 2008 all-o-matic inc. www.allomatic.net

®

L

D

I

E

S

T

Pending

UL325

compliant

UL991

compliant

US

Page 2

TABLE OF CONTENTS

Important safety instructions ....

Different UL 325 class types........................................................

Concrete pad installation..................................................................

Different installation types (front & rear mounts)..............................

Gate travel adjustment.....................................................................

Directional settings...........................................................................

Electrical power connection..............................................................

Typical loop layout.....................................................................

Accessory connections...................................................................

Multiple safety device connection...................................................

Plugin loop detector installation......................................................

Three button station system installation..........................................

Leading edge installation................................................................

Master/Slave connection.................................................................

Magnetic/Solenoid lock installation.................................................

.........................................................

3&4

10&11

2

5

6

7

8

9

12

13

14

15

16

17

18

Radio receiver hookup....................................................................

Open and close electronic reversing sensor(ERDs) adjustment....

Timer adjustment............................................................................

Dip switch functions........................................................................

Solar panel installation...................................................................

Led diagnostics..............................................................................

Emergency release.........................................................................

19

20

21

22

23

24

25

1

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING

To reduce the risk of

READ THE FOLLOWING DIRECTIONS. DO NOT EVEN THINK OF STARTING UNTIL

YOU HAVE READ AND UNDERSTAND THESE DIRECTIONS. IF THERE IS

SOMETHING YOU DO NOT UNDERSTAND CALL US.

Never

children.

Always keep people and objects away from the gate. No one should cross the path of

the moving gate.

This operator must be tested monthly. The gate must reverse on contact with a ridged

object or stop when an object activates the non-contact sensors. After adjusting the

force or the limit travel, retest the gate operator. Failure to adjust and retest the gate

operator properly can increase the risk of injury.

Use the emergency release only when the gate is not moving.

let children operate or play with gate controls. Keep the remote control away from

injury:

Keep gates properly maintained. Have a qualified service person make repairs to gate

hardware. It takes many years of experience to make proper adjustments to gate

hardware or operators.

This entrance is for vehicles only. Pedestrian must use separate entrance.

There is nothing on a gate operator that is easily repaired without a great deal of

experience. Save yourself some time and call a qualified Gate Service Contractor who

knows your type of gate operator.

SAVE THESE INSTRUCTIONS

2

Page 4

INSTALL THE GATE OPERATOR ONLY WHEN

YOU HAVE READ THE FOLLOWING:

*Confirm that the gate operator being installed is appropriate for the application.

*Confirm that the gate is designed and built according to current published industry standards.

*Confirm that all appropriate safety features and safety accessory devices are being incorporated, including

both primary and secondary entrapment protection devices.

*Make sure that the gate works freely before installing the operator.

*Repair or service worn or damaged gate hardware before installation of the operator.

*Eliminate all gaps in a sliding gate below a 4 foot height that permits a 2 ¼ inch sphere to pass through

any location, including the area of the adjacent fence covered when the gate is in the open position.

*Eliminate all gaps in a swinging gate below a 4 foot height that permit a 4 inch sphere to pass through any

location, including the hinge area of the gate.

*Operator must be disconnected from the power source before attempting any installation of accessories.

*Install this gate operator according to our installation instructions.

*Adjust the operator clutch or load sensing device to the minimum force setting that will still allow for reliable

gate operation.

*Install the operator inside the fence line(do not install the operator on the public side of fence line).

*Install a proper electrical ground to a gate operator.

*Controls intended for user activation must be located at least six feet (6’) away from any moving part of the

gate and where the user is prevented from reaching over, under, around or through the gate to operate the

controls. Outdoor or easily accessible controls shall have a security feature to prevent unauthorized use.

The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control

shall not cause the operator to start.

*Install a minimum of two(2) WARNING SIGNS, one on each side of the gate where easily visible and take

pictures of the installation.

*Test all safety features for proper function before placing the automatic vehicular gate into service.

*Train owner/users about basic functions and safety features of the gate system, including how to turn off

the power and how to operate the manual disconnect feature.

*Leave safety instructions, product literature, installation manual and maintenance manual with end user.

*Explain to the owner/user the importance of routine service and retesting on a monthly basis.

3

Page 5

DIFFERENT UL 325 CLASS TYPES

Class one: Residential

A vehicle gate operator intended for use at a home of one to four single family dwellings,

garages or parking area.

Class Two: Commercial or General Public Access

A vehicular gate operator intended for use at a commercial location or building such as a

multi-family housing unit (five or more single family units), hotel, garages, retail stores,

other buildings servicing the general public.

Class three: Industrial or limited Access

A vehicular gate operator intended for use at an industrial location or building such as a

factory, loading dock area, or other locations not intended to service the general public.

Class Four: Restricted Access

A vehicular gate operator intended for use at a guarded industrial location or building

such as airport security areas or other restricted access locations not servicing the

general public where unauthorized access is prevented via supervision by security

personnel.

Other components required to satisfy UL 325

Each class must have a primary and secondary means to sense and react to

obstructions within two seconds.

The six types of obstruction sensing systems are:

Type A:

Inherent obstruction sensing system. This system must sense and initiate the reverse of

the gate within two seconds of contact with a solid object.

Type B 1:

Provision for connection of a non-contact device can be used, such as a secondary

protection.

Type B2:

Provision for connection of a contact sensor. Examples include an edge device or

equivalent. This can be used for secondary protection.

Type C:

Inherent adjustable clutch or pressure relief valve.

Type D:

Provision for connection of or provided with and actuation device requiring continuous

pressure.

4

Page 6

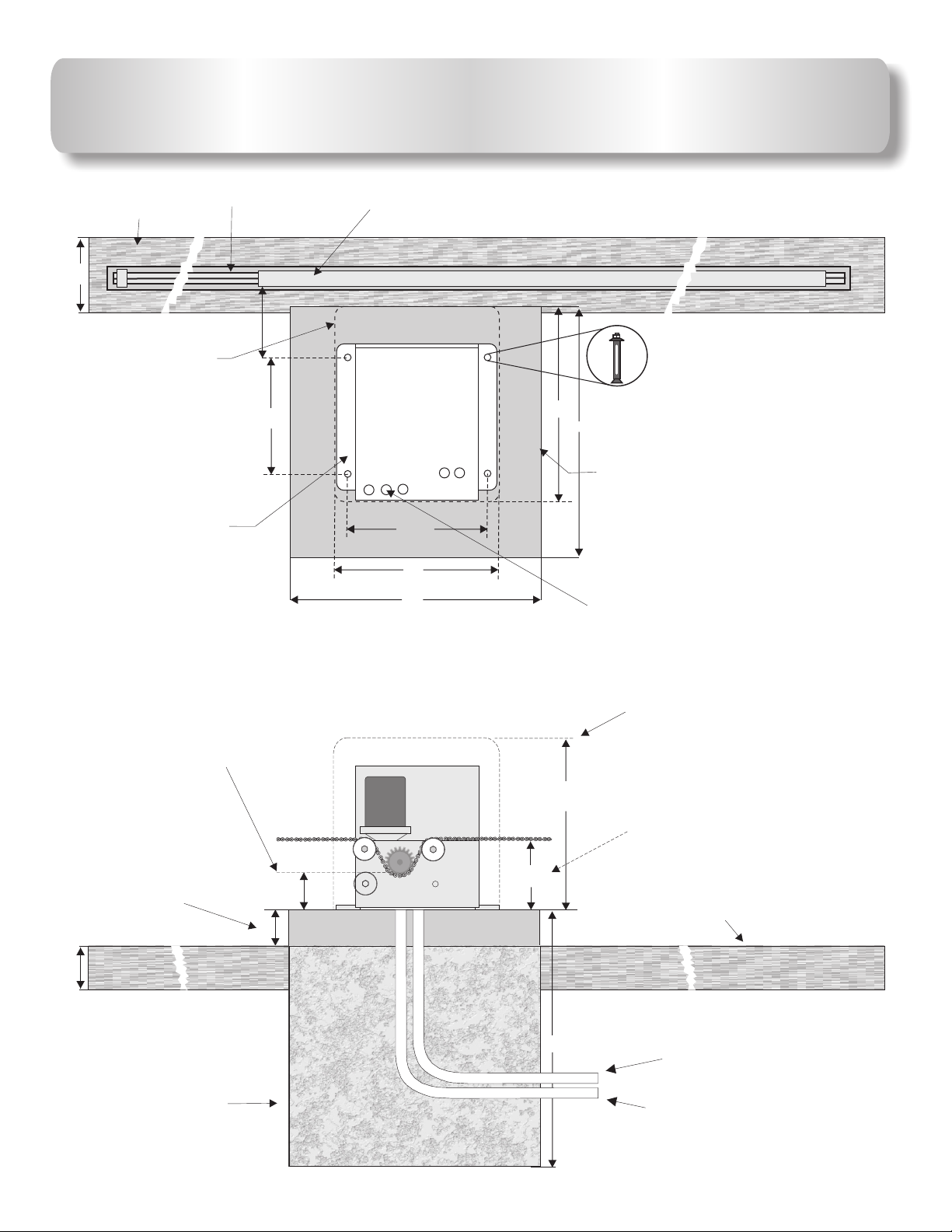

CONCRETE PAD PLACEMENT

FOR SL-90DC

GATE TRACK

FOOTING

10”

Minimum 5”

Operator plastic cover

Operator frame

GATE TRACK GATE

10

½”

13

15”

24”

RED HEAD BOLTS

FOUR PLACES ½”X 3 ½”

18”

24”

Operator concrete pad

½”

Area for conduit(s)

Drive chain level for rear

mount

When possible

Install 4” above

Ground

8”

Footing for

Gate operator

Total cover higth

16”

Drive chain level for front

mount

1

”

8

/

4

4”

GATE TRACK

FOOTING

4”

Low voltage single

24”

conduit for Master/Slave

High voltage

conduit

5

Page 7

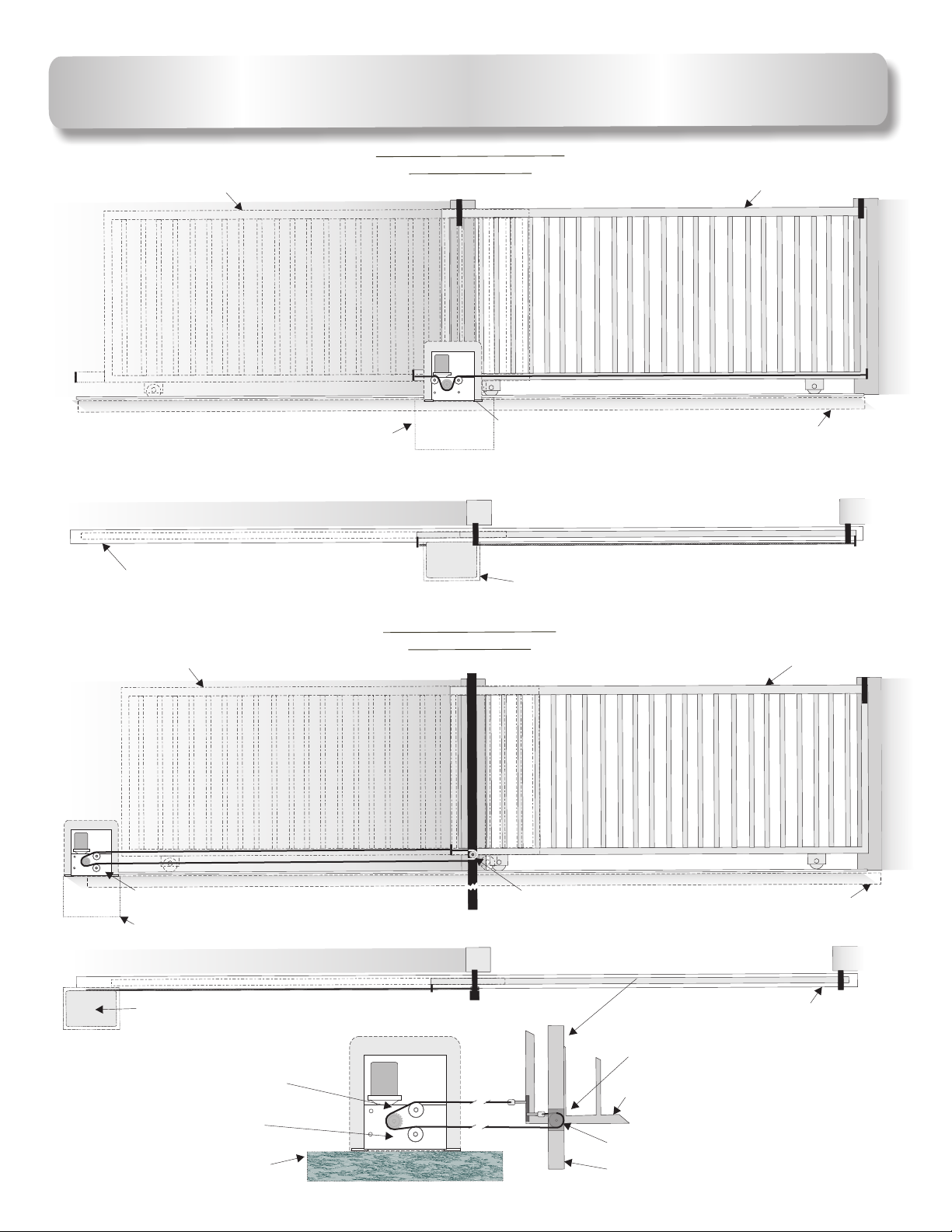

DIFFERENT INSTALL CONFIGURA

A front mount installation

Gate in open position

Operator footing

and chain layout

Gate operator

Overhead

View

TIONS

Gate closed

rack footing

T

rack footing

T

Gate in open position

Gate operator

Operator footing

Operator footing

Rear mount installation

and chain layout

See blow out below

DRIVEW

DRIVEW

A

Y

Gate closed

T

rack footing

A

Y

Operator footing

Move one idler to bottom

hole and follow

chain path as shown.

Gate operator footing

Chain path

Safety guard

Gate

Front idler

Gate post

Track footing

6

Page 8

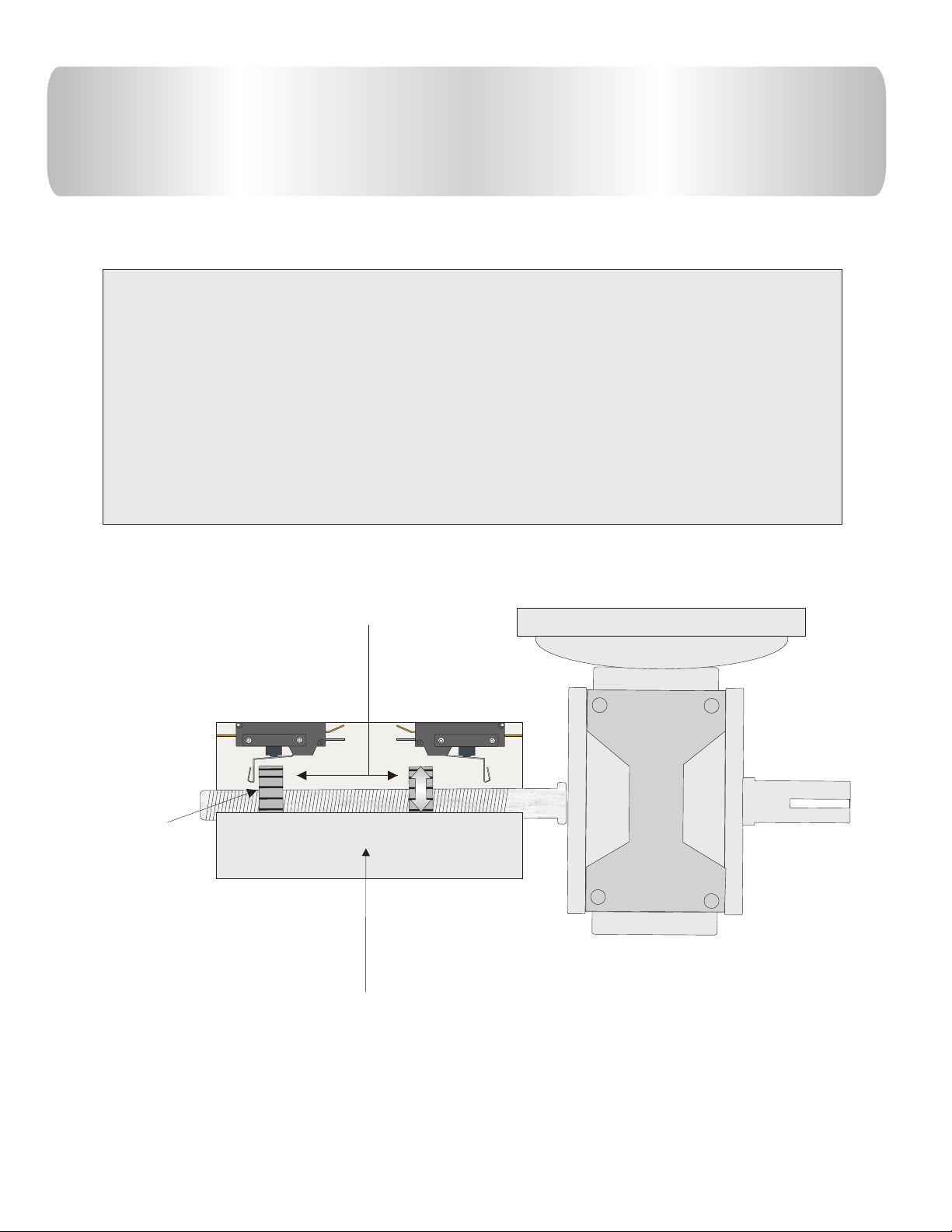

GATE TRAVEL ADJUSTMENT

FOR SL-90DC

Locate limit switches

Step 1: Stop the gate operator using the three button station on

the board.

Step 2: Push limit lock plate down. Turn limit nut in the desired

direction.

Step 3: Place limit plate to its locked position.

Step 4: Run gate operator.

Each notch equals

about

½” of travel.

Limit nuts

Gear box

Limit nut lock plate

7

Page 9

OPENING DIRECTION SETTINGS

Use dipswitch to change the opening direction on the operator.

OPEN L/R OFF

for left hand opening, for right hand opening.

LED’s will show opening or

closing directions when gate

is running.

ON

O

.01

/

O

I

5W

I0615

F260

S26

602

602

S

602

S26

535202

2001

1001

O

1

4750

1001

-----------------------OPEN------------------------

N

S

3

R

3

U

8

6

B

3

1 2 3 4 5 6 7 8

Coilcraft

104

F

1001

1001

1

PHILIPS

1001

S

N

S

3

R

3

U

8

O

6

B

PHILIPS

LMC64

82AIM

C8RB

1001

1210

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1002

1000

1001

R616

829B

14

SS

90R9

10R0

1000

710

KE.

1001

0618

IR21

IOR

0618

IOR

0618

IOR

G4

10S

IR21

10S

IR21

10S

Ls14

72CB74K

R616

829B

145

2001

1332

9

1AM

4750

2001

ATMEL

20AU 0743

ATMEGA168

LMC64

82AIM

C8RB

CMX-309FB C

72CB74K G4

Ls14

8.0000 M

1002

1001

1002

1001

1002

1001

1212

UC3906DW

1131

U 74ZF2CW

S26

S

9531

4750

360G

B

107A

911C0

802

ON

100

2491

HFK.

7J2

C8RB

LMC64

82AIM

2491

2262

476E

476E

900R3

900R3

72CB74K G4

N

S

3

1001

R

3

U

8

O

6

B

1001

3

1

3

58ADC1K G4

72CB74K

58ADC1K G4

MAGNECRAFT

1AM

9

W107DIP - 3

0022

1001

1002

KE.

KE.

710

710

6040

1001

1212

1001

3002

5GN

20M

HFK

2402

33

S21B

MAAF

1001

C8RB

LMC64

82AIM

DR127-330

43CL07 E

360G

802

B

ON

4021

683

Coilcraft

V

C8RB

LMC64

82AIM

ON

802

B

360G

1501

KE.

710

1002

Ls14

1501

KE.

710

1002

1501

KE.

710

1002

1501

Ls07

KE.

710

1002

1501

KE.

710

1002

1501

KE.

G4

710

Ls14

1002

1501

KE.

710

1002

1501

KE.

710

1002

Ls07

1501

KE.

710

1002

F

MOC8050

629Q

RS

1

2

3

RIGHT HAND

Opening

Right hand and left hand opening is from behind the operator.

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

LMC64

82AIM

C8RB

1001

1001

1002

KE.

710

1210

LEFT HAND

Opening

8

Page 10

GRD

ELECTRICAL CONNECTION

OPERATORS MUST BE PROPERLY GROUNDED!

120 Volt

230V

1

15V

LINE 1

LINE 2

Electrical

Plug.

Control Box

Power connection | 115VAC | 220VAC Single Phase

LINE 1 = 115V HOT 220V LINE 1

NOTE: When applying 230V to

operator make sure voltage

switch is flipped to 230V

position.

Power

LINE 2 = 115V N 220V LINE 2

Switch

For power, a minimum of a

20-Amp

breaker is needed.

dedicated circuit

GND

Connect to ground. Use a proper ground rod for a

ground reference.

Use the shortest and thickest wire possible for ground.

NOTE: To use the 120VAC

accessory outlet, connect white

wire from the outlet to neutral.

Only when using 120VAC as the

power source.

For power wire enclosure

use UL listed conduits.

All gate operators be properly grounded.

A proper ground in a gate operator installation minimizes or prevents damage from an electrical charge, such as a near

lightning strike or an electrical static discharge.

.

Use a single wire for the ground. DO NOT splice two wires for the ground. If the wire breaks or is cut, replace it with a

single length. NEVER use two wires for the ground.

MUST

Check with your City code for proper earth ground rod type and proper grounding procedures.

9

Page 11

TYPICAL LOOP LAYOUT

8 FT

OUT

WIRED IN SERIES

GATE

GATE OPERATOR

TWISTED 6 TURNS

PER FOOT

SAFETY LOOP

4 FT 4 FT

SAFETY LOOP

8 FT

EXIT LOOP

WHEN USED

4 FT4 FT

GATE TRACK

1/4 IN1/4 IN

1 1/2 IN

4 FT

This is a normal loop layout. Remember when connecting to an All-O-Matic

circuit board you use the normally closed contacts for your safety loop

detector and normally open contacts from the exit loop. You must twist

your wires from your exit point of the saw cut all the way to the circuit

board, no exceptions.

10

Page 12

GENERAL LOOP INSTALLATION GUIDELINES

The following loop installation guidelines are for installing typical driveway loops for access

control applications (i.e. parking gates, sliding gates, swing gates etc...) Always consult withl

loop detector manufacturers for specific equipment guidelines. This will confirm that the

proper configuration and installation techniques are properly applied for your application.

Useful information about inductive loops:

A. The typical sensing height is 2/3 of the shortest leg of loop (in feet)

Therefore a 4’ x 8’ loop typically has a detection height of 2.6’.

B. The inductance of a conventional four-slide loop can be estimated

using the formula:

L = P x (T + T) / 4 Where L = Loop Inductance in microHenries

P = Loop Perimeter in feet

T = Number of turns of wire in saw slot

2

Therefore a 4’ x 8’ loop with 3 turns would be:

L=(4 + 8 + 4 + 8) x (3 + 3) / 4

2

L=24 x (9 + 3) / 4

L=24 x 12 / 4

L=24 x 3

L=72 microHenries

Suggested guidelines for loop

installation:

Loop wires should be twisted 6 turns

per foot, and twisted from saw slot to

the detector. If possible start twisting

the wires from the edge of the loop.

All 90 degree corners should be

chamfered so that the course of the

wire does not change direction

sharply but rather at shallower angles

of 45 degrees or less. Core drilling of

the corners achieves the same effect

but can still lead to failure due to

sharp edges remaining in the corner

area.

Loop

Perimeter

6’ - 12’ 6

13’ - 20’ 5

21’ - 60’ 4

61’ - 240’’ 3

241 & Up 2

# of

Turns

45

Angles

Saw Slot

TWISTED 6

TURNS

PER FOOT

1/4’’ Feeder Slot

Driveway loop

1/4’’

Driveway

Sealant: 3/4’’ to 1’’ Min.

2’’

Backer Rod

Loop Wire: 3 Turns

}

11

Page 13

ACCESSORY CONNECTIONS

The circuit board output provides up to mAmps of power for accessories.

More than two or three accessories will require a separate power supply.

NOTE:

12 or 24VDC Accessories only.

12 or 24VDC 500

1002

1002

1002

1002

1501

1002

1501

1501

1501

1002

1002

1002

1002

1002

1002

1501

1501

1501

1501

1501

1501

1002

1501

360G

B

802

1501

U

V

V

ON

Remove wire jumper

from when

See page 14 for plugin loop

detector installation.

EXIT

Loop

Detector

Power

Detect

SENS.

LEVEL

BOOST ON

PULSE

FREQ.

Loop Fail

Reset

1 2 3 4 5 6

0

2

1

0

OFF

PRES

0

2

0

1

C

C

N/C

Power

Detect

SENS.

LEVEL

BOOST ON

PULSE

FREQ.

Loop Fail

Reset

1 2 3 4 5 6

0

2

1

0

SAFETY Loop

OFF

PRES

0

2

0

1

Detector

SAFETY

a safety device is

installed.

1501

1501

43CL07 E

LMC64

82AIM

C8RB

1001

1002

1002

DR127-330

MAAF

2402

1001

6040

1001

S21B

3002

1212

5GN

HFK

33

Keypad

or

Telephone

Push Button

or

Fire Box

Card Reader

or

Key Switch

ABC

DEF

1

2

3

GHI

JKL

MNO

4

5

6

PQRS

TUV

WXYZ

7

8

9

TONE

OPER

*

0

#

AB

PHOTO Beam

See page 13 for connection of

N/O

multiple safety device wiring

diagram.

= COMMON

C

N/O

= NORMALLY OPEN CONTACT

N/C

= NORMALLY CLOSED CONTACT

12

Page 14

MULTIPLE SAFETY DEVICES

CONNECTIONS

Multiple devices installed together must be connected in series .

SAFETY “ ”

Locate the white loop rack safety wire and connect with common wire of

second device. Dry contact (N.C.) from second device goes to on

the circuit board B

jumper from the position

. efore installing the accessory devices, remove the wire

SAFETY

on the control board.

SAFETY

Safety wire connections

From Loop rack to Second Accessory

White safety wire To Relay COM

1002

1002

1002

1002

1501

1002

1501

1501

1501

1002

1002

1002

1002

1501

1501

1501

1501

1002

1501

1501

From Second Accessory To Board pin

Relay N.C. To SAFETY

LMC64

82AIM

C8RB

360G

1002

1002

1501

1501

U

V

V

B

802

ON

1501

1501

1001

1002

1002

DR127-330

43CL07 E

MAAF

2402

S21B

33

HFK

5GN

1001

6040

1001

3002

1212

Loop Rack

Loop

Safety

Loop

Phantom

Loop

Exit

Loop Connections

Safety Loop

Phantom Loop

Exit Loop

safety wire

See side for

Jumper setting

Safety

Phantom

Exit

Ground

12VDC

AC/

24V

WHITE

Relay

(N.C.)

AB

PHOTO

Beam

Remove jumper

from when

a safety device is

wire

SAFETY

installed.

Relay (COM)

Wire nut

This diagram is for the relay wires of the safety devices, two wires to the board connections (one from

each device) and two wires to the orange wire nut.

13

Page 15

®

LPR-1 LOOP RACK INATALLATION

This is a loop configuration for a gated driveway. Remember when connecting to an

All-O-Matic circuit board the safety (reverse) uses from the loop

detector, the wire jumper from the safety connector needs to be removed when a safety loop

typical

normally closed contacts

is inatalled.

You must twist your wires from your exit point of the saw cut all the way to the loop

detectors, no exceptions.

Exit loop

WHEN USED

Inside Safety loop

24VAC/

12VDC

Ground

Exit

Phantom

Safety

Jumper setting

See side for

Exit Loop

Phantom Loop

Safety Loop

Loop Connections

Exit

Loop

Phantom

Loop

Safety

Loop

Only for

swing gates

NOTE:

To wire one or multiple safety devices in use

with loop rack safety device remove loop rack

safety white contact wire (N.C.) From safety

pin connector on circuit board and wire in

Series with added safety devices using the

(N.C.) Contact wire from your safety device in

the safety contact. (see page 13)

43CL07 E

DR127-330

1501

1002

33

HFK

5GN

1501

1212

6040

1001

1002

3002

MAAF

S21B

1001

1001

2402

C8RB

ON

802

B

360G

82AIM

LMC64

V

Compatible Detectors

Brand Model No.

Reno A&E

EDI

Diablo Controls

U

V

H2

LMA-1500-LP

DSP-40S

Outside Safety loop

1501

1501

1501

1501

1501

1501

1501

1501

1002

1002

1002

1002

1501

1002

1002

1002

1002

1501

1501

1002

1002

1501

1002

1002

Jumper setting

OFF

OFF

ON

14

Page 16

THREE BUTTON STATION

See push button connections below.

A three button station was integrated

on the board to make adjustments

easier when setting limit switches

and adjusting ERDs.

SYSTEM

LMC64

1210

C8RB

1002

710

KE.

710

KE.

MAGNECRAFT

W107DIP - 3

9

1AM

1001

0022

629Q

MOC8050

58ADC1K G4

Ls07

F

KE.

KE.

710

710

1002

1002

1002

1501

1501

710

KE.

1501

PHILIPS

72CB74K

Ls14

G4

KE.

710

1002

1501

1

O

U

B

R

N

S

3

3

6

8

3

1001

PHILIPS

Ls07

KE.

KE.

710

710

1002

1002

1501

1001

1

O

U

B

R

N

S

3

3

6

8

3

1001

1001

1

O

U

B

R

N

S

3

3

6

8

3

58ADC1K G4

1002

1501

72CB74K G4

Ls14

KE.

KE.

710

1501

KE.

710

710

1002

1002

1501

1501

360G

F

476E

900R3

476E

900R3

802

B

ON

Coilcraft

104

2262

2491

ON

B

802

360G

LMC64

82AIM

C8RB

HFK.

100

7J2

1C0

91

107A

2491

LMC64

82AIM

C8RB

4021

Coilcraft

683

V

Connect the from all the push buttons

COMMON

to input on the board.

Connect push button contact to

EXIT

input on the board.

Connect push button contact to

3BT

input on the board.

Connect push button Contact to

PED-SW

PED-SW

COMMON

OPEN N.O.

CLOSE N.O.

STOP N.C.

input on the board and remove

jumper.

N.O.

N.O.

N.C.

OPEN

CLOSE

STOP

V

V

U

PED-SW

Jumper

COM

15

Page 17

LEADING EDGE CONNECTION

LMC64

82AIM

C8RB

360G

1002

1002

1002

1002

1501

1002

1501

1501

1501

1002

1002

1002

1501

1501

1002

1501

1501

1501

wire to 12VDCRED

BLACK wire to COMMON

1002

1002

1501

1002

1501

1501

U

V

V

B

802

ON

1501

1501

43CL07 E

1001

1002

1002

DR127-330

MAAF

2402

1001

6040

1001

S21B

3002

1212

5GN

HFK

33

LEADING EDGE SENSOR

Wireless

edge

Receiver

A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate

operator for entrapment protection functions shall be located where the transmission of the

signals are not obstructed or impeded by building structures, natural landscaping or similar

obstruction. A wireless contact sensor shall function under the intended end-use conditions.

Connect one of the wires from leading edge and/or one of the grey

wires from a wireless edge receiver to connector on

COMMON

control board.

Connect the other wire from leading edge and/or the other wire from

a wireless edge receiver to connector on control board.

EDGE

16

Page 18

MASTER/SLAVE CONNECTION

Before connecting master/slave gate operators together, test and adjust limit switches and the ERDs

the

for each operator as “stand alone” machines. All accessories must be installed on the master board, no

exception.

See page 22 for dip switch settings.

Use a two wire shielded cable and run it through a UL listed conduit for master/slave connection.

Follow the wiring diagram as shown below.

Master Board Slave Board

+.....................Positive to Positive...................+

-...................Negative to Negative...................-

Use UL listed

conduit

Shielded

cable

Slave Board

Master Board

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

1210

1001

1001

710

KE.

710

KE.

82AIM

LMC64

C8RB

1002

Slave switch

ON

only on

slave board

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

1210

710

KE.

710

1001

1001

KE.

82AIM

LMC64

C8RB

1002

Connect shield to

slave metal frame

only.

17

Page 19

MAGNETIC/SOLENOID LOCK

CONNECTIONS

Magnetic lock installation requires a step down transformer with appropriate voltage for the

specific lock accessory. Operator will provide a 120VAC outlet for the step down transformer.

Connections: Plug the lock device transformer to the 120VAC outlet plug.

For Magnetic lock: Connect one wire from transformer directly to one wire of the magnetic lock,

the other wire from transformer will be connected to the relay plug input and the relay

output connects to the other wire of the magnetic lock. See illustration below.

For Solenoid lock: Connect one wire from transformer directly to one wire of the solenoid lock,

connect the other wire from transformer to the relay plug input and the relay output

COM SOL

connects to the other wire of the solenoid lock. See illustration below.

COM MAG

IOR

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

0618

90R9

10R0

1000

IR21

10S

IOR

SOLENOID

LOCK

1

3

1

3

1

3

1001

4750

ATMEL

20AU 0743

ATMEGA168

72CB74K

Ls14

1001

1002

1001

1002

1001

1002

2001

LMC64

82AIM

C8RB

CMX-309FB C

G4

8.0000 M

535202

1001

1001

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

PHILIPS

PHILIPS

LMC64

82AIM

C8RB

1001

1001

1210

G4

58ADC1K

Ls07

G4

72CB74K

Ls14

G4

58ADC1K

Ls07

MAGNECRAFT

W107DIP - 3

1002

KE.

KE.

710

710

F

MOC8050

1AM

9

0022

1001

629Q

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

Relay plug

120VAC

outlet plug

MAGNETIC

LOCK

Step Down

Transformer

18

Page 20

RADIO RECEIVER CONNECTIONS

4 wire receiver: connect the two relay wires to & terminals. Black

negative 1 positive 3

wire to terminal and Red wire to terminal on

1 2

receiver strip outside control box as shown below.

9

1AM

1001

0022

MOC8050

629Q

1000

10R0

F

KE.

710

1002

1501

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

1001

1001

82AIM

LMC64

C8RB

1210

1002

710

KE.

710

KE.

MAGNECRAFT

W107DIP - 3

9

1AM

1001

0022

MOC8050

629Q

F

KE.

710

1002

1501

1000

90R9

10R0

1001

90R9

SS

829B

R616

14

IOR

0618

IR2110S

1002

1002

1002

1001

1001

1001

58ADC1K G4

Ls07

KE.

KE.

710

710

1002

1002

1002

1501

1501

72CB74K

Ls14

G4

CMX-309FB C

8.0000 M

535202

PHILIPS

72CB74K

Ls14

G4

KE.

710

1501

SS

14

TMEL

A

ATMEGA168

20AU 0743

82AIM

LMC64

2001

C8RB

4750

1001

1

3

1001

PHILIPS

1

3

1001

1

3

58ADC1K G4

Ls07

KE.

KE.

KE.

710

710

710

1002

1002

1002

1501

1501

1501

1000

1001

829B

R616

IOR

0618

IR2110S

1001

O

U

B

R

S

3

3

6

8

1001

O

U

B

R

N

S

3

3

6

8

1001

O

U

B

R

N

S

3

3

6

8

KE.

710

1002

10R0

145

829B

R616

72CB74K G4

1332

2001

4750

1AM

9

2001

N

72CB74K G4

Ls14

360G

KE.

710

1002

1501

1501

1001

90R9

SS

829B

R616

14

IOR

0618

IR21

10S

1001

KE.

710

Ls14

Coilcraft

104

F

ON

802

LMC64

82AIM

C8RB

2262

2491

100

HFK.

7J2

900R3

476E

900R3

476E

2491

LMC64

82AIM

C8RB

4021

802

B

ON

Coilcraft

683

V

V

U

602

F260

S26

S

S

602

S26

602

S26

S

B

360G

U 74ZF2CW

1C0

91

107A

UC3906DW

9531

1

4750

1212

131

20M

LMC64

82AIM

C8RB

360G

2402

B

1001

802

ON

1001

1001

S21B

MAAF

5GN

HFK

33

1002

1501

V

43CL07 E

DR127-330

.01

I0615

5W

I

O

/

O

Receiver terminal strip

located outside control

box.

3

2

1

3 = 12V

2 = Relay

1 = Common

Pcb also provides

12VDC & 24VDC

Inputs.

4 wire 12VDC

Radio Receiver

19

Page 21

OPEN AND CLOSE ELECTRONIC

REVERSING SENSOR(ERDs)

ADJUSTMENT

O

O

/

I

.01

5W

I0615

F260

S26

S26

602

602

S

S

602

S26

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1000

710

1001

KE.

0618

IR2110S

IOR

0618

IR21

10S

IOR

0618

IR21

10S

IOR

G4

Ls14

72CB74K

R616

829B

2001

145

1332

9

1AM

4750

2001

ATMEL

20AU 0743

ATMEGA168

LMC64

82AIM

C8RB

CMX-309FB C

72CB74K G4

Ls14

8.0000 M

535202

1001

1002

1001

1002

1001

1002

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

S

104

Coilcraft

F

2001

N

N

S

S

3

3

R

R

1001

1001

3

3

U

U

8

8

O

O

6

6

B

B

1

3

1

3

1001

4750

1001

PHILIPS

PHILIPS

LMC64

1002

82AIM

C8RB

KE.

KE.

1001

1001

710

710

1210

1212

1131

UC3906DW

U 74ZF2CW

9531

4750

360G

B

107A

911C0

802

100

ON

HFK.

2491

7J2

C8RB

LMC64

82AIM

2491

2262

476E

476E

900R3

900R3

72CB74K G4

Ls14

N

S

3

1001

R

3

U

8

O

6

B

1

3

1001

58ADC1K

Ls07

72CB74K G4

Ls14

58ADC1K

Ls07

MAGNECRAFT

1AM

W107DIP - 3

9

0022

1001

6040

1212

1001

1001

3002

5GN

HFK

20M

2402

33

S21B

MAAF

1001

C8RB

LMC64

82AIM

DR127-330

43CL07 E

360G

802

B

ON

Open and Close ERD

SENSITIVITY

MAX MAXMIN MIN

4021

683

Coilcraft

V

C8RB

LMC64

82AIM

ON

802

B

360G

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

G4

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

G4

1501

KE.

710

1002

F

MOC8050

629Q

1001

1001

N

S

3

R

U

O

B

1

1001

3

8

6

3

1001

N

S

3

R

3

U

8

O

6

B

1

3

ERD’S must be adjusted

by qualified technician.

The gate operator ERDs must be

adjusted so that the gate provides

regular, reliable and safe cycles.

ERD must be checked every six

months.

Counter clockwise maximum

sensitivity

Clockwise minimum sensitivity

When gate stops and reverses by itself,

the ERD is .

too sensitive

The gate must stop and reverse when it

hits an obstruction or the ERD is

not sensitive enough.

20

Page 22

TIMER ADJUSTMENT

TIMER ON: Timer to close, can be set from 1 to 60 seconds.

TIMER OFF: Gate operation is push button to open, push button to close.

TO OVERRIDE THE TIMER: Turn the RADIO switch to the “ON” position.

This will allow the radio receiver to close the gate before the timer.

TIMER ADJUSTMENT

Turn potentiometer counter clockwise for more

60

Sec

0

Sec

time.

60

Sec

TIMER “ ” to activate

ON

0

Sec

1001

1

4750

1001

the timer

RADIO “ON” = Allows

the transmitter to close

the gate before the timer.

Turn potentiometer clockwise for less time.

N

S

3

R

3

U

8

O

6

B

3

TIMER

RADIO

OSC

FAIL SF/SC

1-PASS

SLAVE

AUTO OPEN

OPEN L/R

OFF ON

1001

1001

-----------------------OPEN------------------------

1 2 3 4 5 6 7 8

O

O

/

I

.01

5W

I0615

F260

S26

602

602

S

602

S26

2001

1001

1

4750

1001

535202

1 2 3 4 5 6 7 8

LMC64

82AIM

C8RB

1001

1001

1210

S

104

Coilcraft

F

N

N

S

S

3

3

R

R

1001

3

3

U

U

8

8

O

O

6

6

B

B

3

1

3

1001

PHILIPS

PHILIPS

1002

KE.

KE.

710

710

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1000

1001

710

KE.

0618

IR21

10S

IOR

0618

IR2110S

IOR

0618

IR21

10S

IOR

G4

Ls14

72CB74K

R616

829B

2001

1332

145

9

1AM

4750

2001

ATMEL

20AU 0743

ATMEGA168

LMC64

82AIM

C8RB

72CB74K G4

CMX-309FB C

Ls14

8.0000 M

1001

1002

1001

1002

1001

1002

-----------------------OPEN------------------------

1212

131

1

UC3906DW

U 74ZF2CW

9531

S26

S

4750

360G

B

107A

911C0

802

100

ON

HFK.

7J2

2491

C8RB

LMC64

82AIM

2491

2262

476E

476E

900R3

900R3

72CB74K G4

N

S

3

1001

R

3

U

8

O

6

B

1

3

1001

58ADC1K

72CB74K G4

58ADC1K G4

MAGNECRAFT

W107DIP - 3

1AM

9

0022

1001

6040

1212

1001

3002

1001

5GN

HFK

20M

2402

33

S21B

MAAF

1001

C8RB

LMC64

82AIM

DR127-330

43CL07 E

360G

802

B

ON

4021

683

Coilcraft

V

C8RB

LMC64

82AIM

ON

802

B

360G

1501

KE.

710

1002

Ls14

Ls07

Ls14

Ls07

1501

KE.

710

1002

1501

KE.

710

1002

G4

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

1501

KE.

710

1002

F

MOC8050

629Q

21

Page 23

DIP SWITCH FUNCTIONS

TIMER

TIMER

OFF ON

-----------------------OPEN------------------------

TIMER switch “ON” activates the TIMER. See page 21

1 2 3 4 5 6 7 8

for details

.

RADIO

RADIO

OSC

FAIL SF/SC

RADIO switch “ON” allows the radio receiver to override

the timer. See page 21 for details.

1-PASS

SLAVE

OSC switch “ON” allows the radio receiver to stop and

AUTO OPEN

OPEN L/R

This is to set the operator as fail-safe or fail secure. ON for Fail-safe: on power failure,

board will monitor battery voltage to make sure gate opens before battery drains out

completely. OFF for Fail-secure: on power failure gate will run until battery is low and

stay close.

reverse the gate in any direction. During a cycle the first

signal stops gate, a second signal reverses gate.

FAIL SF/SC

OSC

1-PASS

This is a true one pass, anti-tailgating feature. This feature may only be used with safety

loops. With this switch in the “ON” position, the gate will open until one car passes the

safety loops then it will stop and close. If a second car pulls on the loop the gate will stop

the car must then back off the loop before the gate will close.

SLAVE

This feature is used on master/slave setups. Set slave switch “ON” on slave machine, all

other switches “OFF”. Set slave switch to the “OFF” position on master machine. Set

other function switches on master machine as desired. See page 17 for more details on

master/slave connections and settings.

AUTO OPEN

This feature is to automatic open the gate on power interruption. It is a very particular

feature used in areas where the fire department requires the gate to open automatically

after a power outage. Set this dip switch “ON” when this feature is desire.

OPEN L/R

This feature is to set the direction the operator will open. See page 8 for details.

22

Page 24

SOLAR PANEL CONNECTION

The solar panel input will take a 12VDC panel or two 12VDC panels wired in sires to

make 24VDC . The charging circuit is limited by 1 Amp max.

NOTE:

For information on what solar panel to use on any other type of installation

call ALL O MATIC for Assistance.

360G

B

802

ON

20M

C8RB

LMC64

82AIM

1212

1001

1001

3002

6040

2402

S21B

MAAF

1001

DR127-330

43CL07 E

O

O

/

I

.01

5W

I0615

F260

S26

602

602

S

602

S26

2001

1001

4750

1001

535202

1 2 3 4 5 6 7 8

LMC64

82AIM

1001

1001

S

104

Coilcraft

F

N

N

S

S

3

3

R

R

1001

3

3

U

U

8

8

O

O

6

6

B

B

1

3

1

3

1001

PHILIPS

PHILIPS

1002

C8RB

KE.

KE.

710

710

1210

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1000

1001

R616

829B

14

SS

90R9

10R0

1000

710

1001

KE.

0618

IR2110S

IOR

0618

IR21

10S

IOR

0618

IR2110S

IOR

Ls14

72CB74K G4

R616

829B

2001

145

1332

9

1AM

4750

2001

ATMEL

20AU 0743

ATMEGA168

LMC64

82AIM

C8RB

CMX-309FB C

72CB74K G4

Ls14

8.0000 M

1001

1002

1001

1002

1001

1002

-----------------------OPEN------------------------

1212

1131

UC3906DW

U 74ZF2CW

S26

9531

S

4750

360G

B

107A

911C0

802

100

ON

C8RB

LMC64

82AIM

2262

1001

1

1001

2491

N

S

R

U

O

B

MAGNECRAFT

W107DIP - 3

4021

HFK.

2491

7J2

C8RB

LMC64

82AIM

ON

802

476E

476E

900R3

900R3

B

360G

G4

72CB74K

Ls14

3

3

8

6

3

58ADC1K G4

Ls07

G4

72CB74K

Ls14

58ADC1K G4

Ls07

F

MOC8050

1AM

9

0022

1001

629Q

360G

B

802

ON

20M

C8RB

LMC64

DR127-330

82AIM

1212

3002

6040

683

Coilcraft

V

KE.

710

KE.

710

KE.

710

KE.

710

KE.

710

KE.

710

KE.

710

KE.

710

KE.

710

43CL07 E

1001

1001

S21B

MAAF

1001

2402

1501

1002

1501

1002

1501

1002

1501

1002

1501

1002

1501

1002

1501

1002

1501

1002

1501

1002

23

Page 25

LED DIAGNOSTICS

AC/PWR ON: Will be lit when AC power is ON.

M/S LINK: Will be lit when master/slave communication is active.

ALARM: Two states.

1st state: LED will blink(horn will beep also) every 30 seconds when battery is low, bad or

disconnected.

2nd state: LED will turn on for 5 minutes when operator goes on shut down mode do to the

gate hitting an obstruction(E.R.D.). Also, the horn will go off for 5 minutes.

LOW BATTERY: Three states.

1st state: LED will be on solid when battery is low.

2nd state: LED will blink slow(about every 2 seconds) when an overload occurs(over

current).

3rd state: Will blink fast(abouty every ½ second) when gate is jammed or motor sensors

Are not responding or disconnected.

OPEN-LIMIT: LED will be on while limit nut is against open limit switch.

CLOSE-LIMIT: LED will be on while limit nut is against close limit switch.

OPENING: LED will be on while operator is in the open cycle(running open).

CLOSING: LED will be on while operator is in the close cycle(running close).

RADIO: LED will turn on while radio input is activated(closed circuit to COMMON).

EXIT: LED will turn on while EXIT input is activated(closed circuit to COMMON).

PHANTOM: LED will turn on while PHANTOM input is activated(closed circuit to COMMON).

SAFETY: LED will turn on while SAFETY input is activated(circuit is open from COMMON).

PED-SW: LED will turn on while PED-SW input is activated(circuit is open from COMMON).

3BT: LED will turn on while 3BT input is activated(closed circuit to COMMON).

EDGE: LED will turn on while EDGE input is activated(closed circuit to COMMON).

TIMER LED: LED will blink when timer is counting (on the open position only).

CHRG: LED turns on when battery is charging.

24

Page 26

EMERGENCY RELEASE

Procedures to open gate for .

SL-90DC

1. Turn power OFF.

2. Our gear box has a 15 to 1 ratio so it allows you to push gate

open when set in fail safe mode.

T

T

T

A

E

A

E

A

E

G

O

G

O

G

O

P

P

C

P

C

C

I

I

I

E

E

E

T

T

T

R

R

R

A

A

A

A

A

A

T

M

T

M

T

M

O

O

O

O

O

O

T

R

T

T

R

R

S

S

S

U

U

U

A

A

A

®

S

S

S

S

S

S

L

L

L

D

D

D

I

I

I

D

D

D

A

A

A

E

E

E

E

E

E

R

R

R

H

H

H

S

S

S

R

R

R

E

E

E

•

•

•

V

V

V

S

S

S

O

O

O

W

W

W

•

•

•

I

I

I

N

N

N

S

S

S

G

G

G

R

R

R

E

E

E

25

Loading...

Loading...