Page 1

User's Guide

Portable Salinity Refractometer with ATC

Model RF20

Introduction

Congratulations on your purchase of the Extech RF20 Handheld Salinity Refractometer

with Automatic Temperature Compensation. This precision optical instrument should be

handled gently; avoid touching the optical surface. Careful use of this instrument will

provide years of reliable service.

Page 2

Warranty

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of defects in parts and

workmanship for one year from date of shipment (a six month limited warranty applies on sensors and

cables). If it should become necessary to return the instrument for service during or beyond the warranty

period, contact the Customer Service Department at (781) 890-7440 ext. 210 for authorization or visit our

website at www.extech.com (click on ‘Contact Extech’ and go to ‘Service Department’ to request an RA

number). A Return Authorization (RA) number must be issued before any product is returned to Extech. The

sender is responsible for shipping charges, freight, insurance and proper packaging to prevent damage in

transit. This warranty does not apply to defects resulting from action of the user such as misuse, improper

wiring, operation outside of specification, improper maintenance or repair, or unauthorized modification.

Extech specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and

will not be liable for any direct, indirect, incidental or consequential damages. Extech's total liability is limited

to repair or replacement of the product. The warranty set forth above is inclusive and no other warranty,

whether written or oral, is expressed or implied.

Specifications

Scale Range Resolution

Parts Per Thousand 0 to 100 0/00 1

Specific Gravity 1.000 to 1.070 d20/

Dimensions 7.6 x 1.5 x 1.5" (194 x 38 x 38mm)

Weight Approx. 8.0 oz. (227g)

0.001 d

20

0

/00

20

/

20

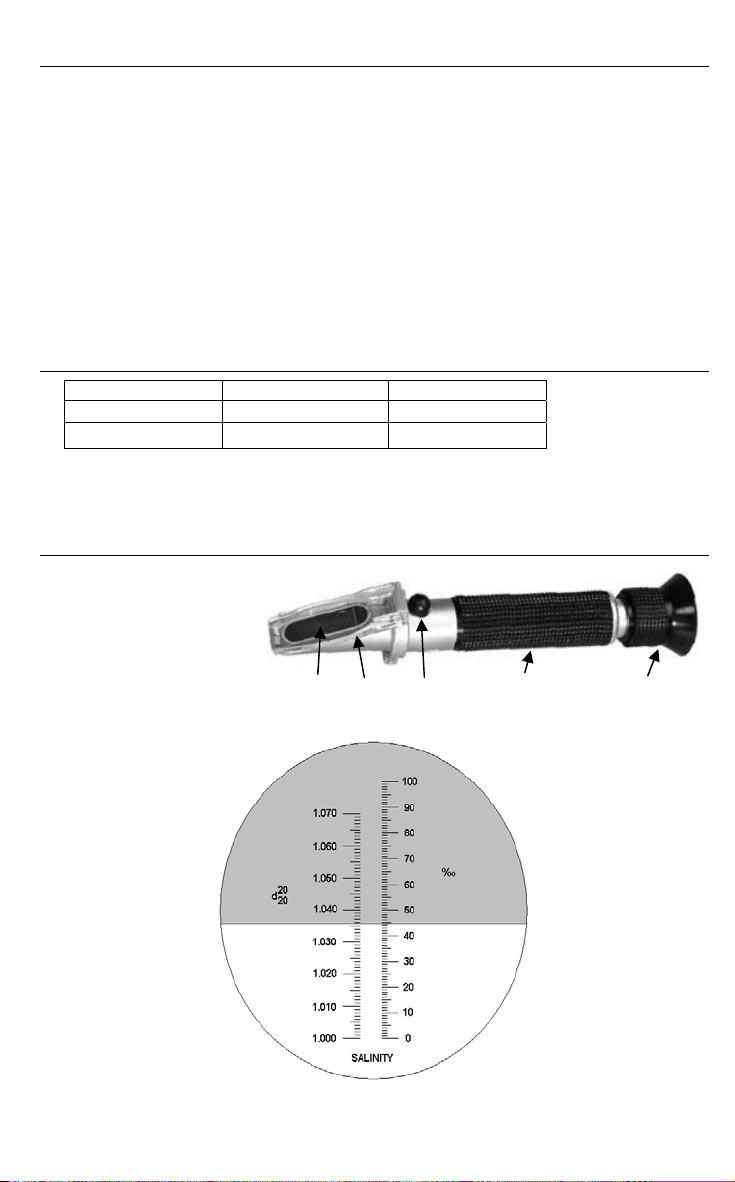

Description

1. Prism

2. Cover Plate

3. Adjustment Screw

4. Mirror Tube

5. Eyepiece

1 2 3 4 5

2

RF20 Version 1.1 September 2003

Page 3

Operation

The instrument measures the refractive index of the sample and displays the result in parts

per thousand (

1. Zero Adjustment

Put distilled water on the prism; enough to cover the entire prism. Close the cover plate

and rotate the adjusting screw so that the light/dark boundary line (known as the

shadow-line) evens up with the zero line. After the zero adjustment, clean the prism with

soft cloth.

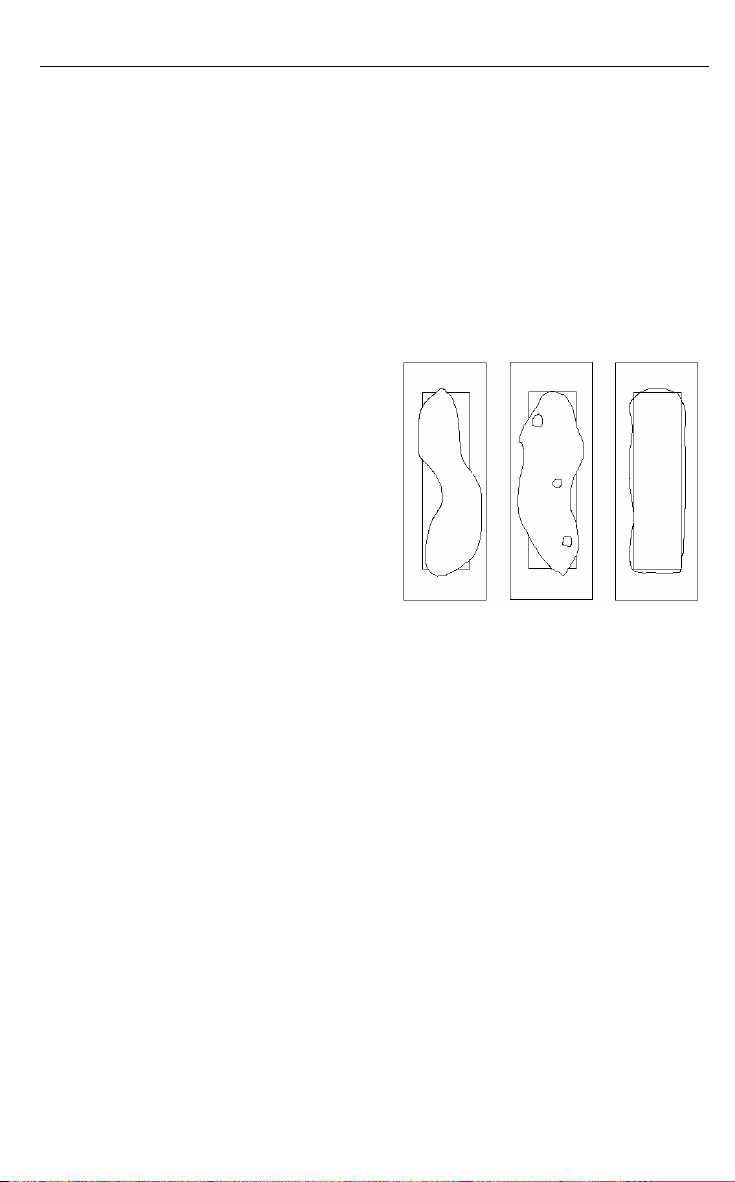

2. Sample Preparation and Reading

To take a reading, place a few drops of a sample liquid on the measurement prism.

Ensure that enough solution is added to the prism in order to cover the entire prism.

Close the prism so that the liquid spreads across the entire surface of the prism without

air bubbles or dry spots (see diagrams below). Allow the sample to remain on the prism

for approximately 30 seconds.

While holding the instrument under a light

source, look through the eyepiece. The

salinity concentration is determined by the

intersection of the boundary of the light

and dark fields (known as the shadowline) on the printed scale. The left side of

the scale indicates the specific gravity and

the right side parts per thousand. If the

scale appears out of focus, the eyepiece

may be adjusted by rotating the knurled

portion. The instrument also features an

eye guard to prevent stray light from

entering the eyepiece and causing

reflections.

It may be necessary to adjust the position of the light source to maximize the contrast of

the shadow-line. Under normal conditions, optimal contrast is obtained by holding the

instrument underneath and perpendicular to a light source.

Once a reading has been taken, wipe dry with a clean cloth (do not wash or rinse) and

place the instrument in the supplied plastic case. Store the instrument in a safe, dry

environment.

Temperature is the single most important factor influencing refractometer readings and

is one of the largest sources of measurement error. However, this device incorporates

automatic temperature compensation and the concern for temperature fluctuations in

sample liquids is alleviated. When ambient temperature varies from 68°F (20°C),

readings are automatically adjusted to compensate for temperature variance between

50°F to 86°F (10°C to 30°C).

0

/00 ) and specific gravity (d 20/20).

Bad Bad Good

3

RF20 Version 1.1 September 2003

Page 4

Calibration and Repair Services

Extech offers complete repair and calibration services for most of the products we sell.

For periodic calibration, NIST certification or repair on most Extech products, call customer

service for details on services available. Extech recommends that calibration be performed

on an annual basis to ensure calibration integrity.

Copyright ©

All rights reserved including the right of reproduction in whole or in part in any form.

Support Hotline (781) 890-7440

Tech support: Ext. 200; Email: support@extech.com

Repair/Returns: Ext. 210; Email: repair@extech.com

Website: www.extech.com

2003 Extech Instruments Corporation.

4

RF20 Version 1.1 September 2003

Loading...

Loading...