Page 1

User Manual

Handheld Digital Storage

Oscilloscope & Multimeter

Model MS400

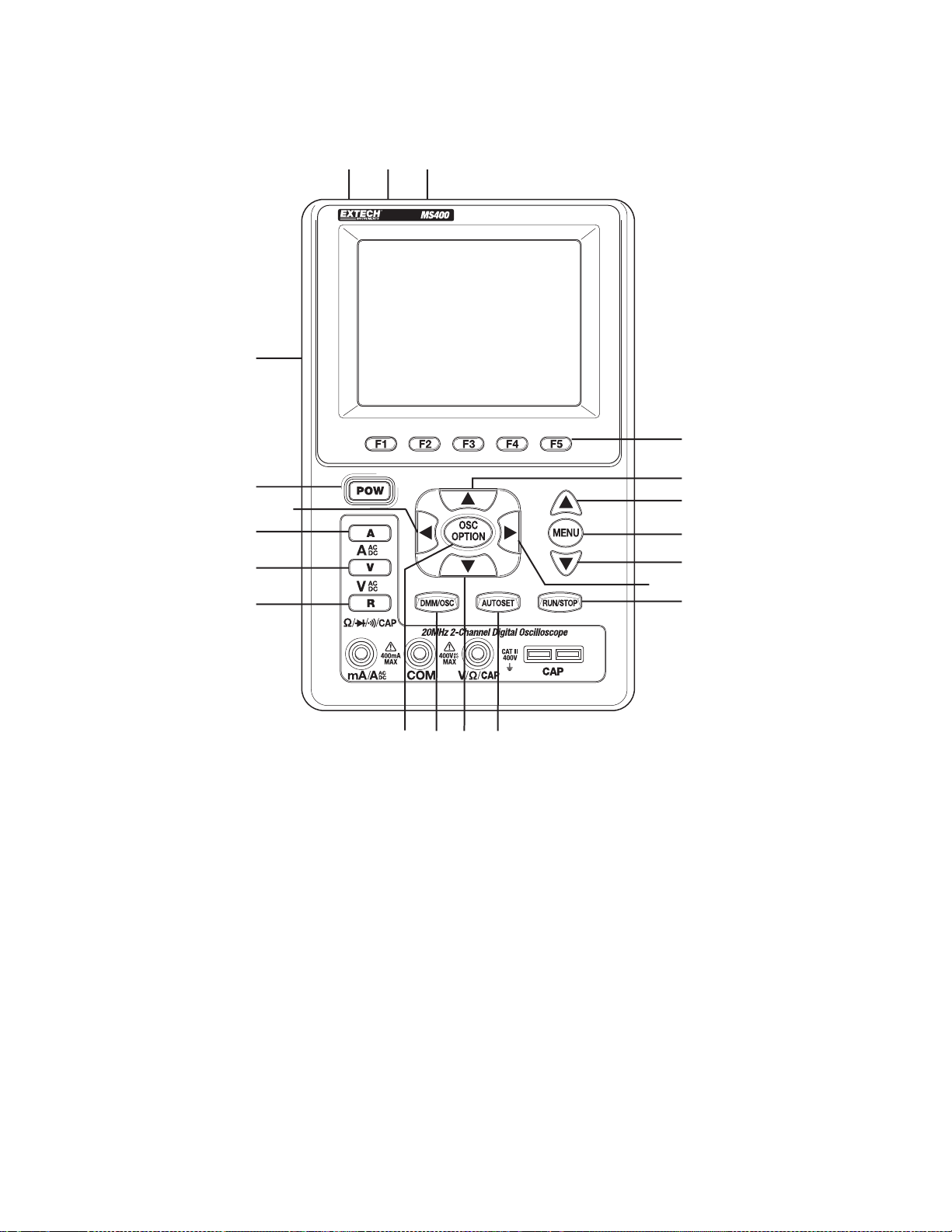

Figure 1 – Meter Faceplate

Page 2

Warranty

p

EXTECH INSTRUMENTS CORPORATION warrants this instrument to be free of

defects in parts and workmanship for one year from date of shipment (a six month

limited warr ant y a ppli es to s ens ors and cabl es ). I f it sho uld bec ome n ec ess ary to re tur n

the instrument for service during or beyond the warranty period, contact the Customer

Service Department at (781) 890-7440 ext. 210 for authorization or visit our website

www.extech.com for contact information. A Return Authorization (RA) number must be

issued before any product is returned to Extech. The sender is responsible for shipping

charges, freight, insurance and proper packaging to prevent damage in transit. This

warranty does not apply to defects resulting from action of the user such as misuse,

improper wiring, operation outside of specification, improper maintenance or repair, or

unauthorized modification. Extech specifically disclaims any implied warranties or

merchantability or fitness for a specific purpose and will not be liable for any direct,

indirect, incidental or consequential damages. Extech's total liability is limited to repair

or replacement of the product. The warranty set forth above is inclusive and no other

warranty, whether written or oral, i s expressed or implied.

Calibration and Repair Services

Extech offers repair and calibration services for the products we sell. Extech also

provides NIST certification for most products. Call the Customer Care Department for

information on calibration services available for this product. Extech recommends that

annual calibrations be performed to verify meter performance and accuracy.

Support line (781) 890-7440

Technical Support: Extension 200; E-mail: support@extech.com

Repair & Returns: Extension 210; E-mail: repair@extech.com

Product specifications subject to change without not ice

For the latest version of this User’s Guide, Software updates, and other

up-to-the-minute product information, visit our website: www.extech.com

Extech Instruments Cor

oration, 285 Bear Hill Rd., Waltham, MA 02451

2

MS400 Version 2.0 – December 2007

Page 3

Table of Contents

Chapter Page

Safety Information 5

Safety Terms and Symbols 5

Specific Warning and Caution Terms 5

Terms Used With This Product 5

Symbols Used With This Product 5

General Safety Information 5

General Inspection 7

Performing a General Inspection 7

Checking for Shipping Damage 7

Checking Accessories 7

Complete Instrument Check 7

Contents of the Meter Kit 7

Input Connections 8

Input Connections 8

Description of the Front Panel and Keys 8

Using the Scope 11

About this Chapter 11

Powering-Up the Oscilloscope 11

Oscilloscope Operation Window 11

Navigating a Menu 13

Manually Setting the Vertical System, Horizontal System and Trigger Position 14

Resetting the Oscilloscope 17

Input Connections 17

Displaying an Unknown Signal with Auto Set 18

Automatic Zero-ing of Trigger Horizontal Position and Trigger Level Position 18

Automatic Measurements 18

Freezing the Screen 19

Using Average for Smoothing Waveforms 19

Using ‘Persistence’ to Display Waveforms 20

Using Peak Detection to Display Glitches 20

Selecting AC-coupling 21

Reversing the Polarity of the Displayed Waveform 22

Using Waveform Math Functions 23

Using the Multimeter 24

About this Chapter 24

Meter Connections 24

Multimeter Operation Window 24

Multimeter Measurements 26

Measuring Resistance Values 26

Diode Measurement 26

Continuity Tests 26

Capacitance Measurement 27

DC Voltage Measurement 27

AC Voltage Measurement 27

DC Current Measurement 28

AC Current Measurement 28

Freezing the Readings 29

Taking a Relative Measurement 29

Selecting Automatic/Manual Range Adjustment 30

3

MS400 Version 2.0 – December 2007

Page 4

Advanced Oscilloscope FUNCTIONS 31

About this Chapter 31

Setting the Vertical CH1 and CH2 31

Setting the Channel Coupling 32

Enabling the Scope Channels 33

Adjusting the Probe Scale 33

Inverting a Waveform 33

Math Function Menu Settings 33

Setting the Trigger System 34

Triggering Control 35

Edge Triggering 35

Video Triggering 36

‘Acquire Mode’ Setting 37

Display Settings 37

Display Style 38

Persistence Mode 38

XY Mode 39

Saving Waveforms 39

Function Setting Menu 40

Automatic Measurements 40

Cursor Measurements 41

System State Menu 43

Setting Time Base Mode 44

Data Transmission – PC Interface 45

Trouble Shooting 46

Appendix 47

Appendix and Specifications 47

Oscilloscope 47

Meter 49

General Specifications 50

Appendix B: Maintenance and Cleaning 51

Common Maintenance 51

Storage of Oscilloscope 51

Replacing the Lithium Battery Unit 51

4

MS400 Version 2.0 – December 2007

Page 5

Safety Information

Note: Please read this user manual prior to operating the unit.

Safety Terms and Symbols

Specific Warning and Caution terms that appear throughout the manual

Warning: “Warning” identifies conditions and actions that pose hazards to users.

Caution: “Caution” identifies conditions and actions that may damage the product.

Terms printed on the meter and contained in this manual

The following terms may appear on the product or anywhere throughout the associated

manuals:

Danger: The term “Danger” is used in this manual to indicate that serious injury or

death may result if the safety instructions are not followed.

Warning: The term “Warning” is used in this manual to indicate that personal injury may

result if instructions are not followed.

Notice: The term “Notice” is used in this manual to indicate that damages to product,

other properties, or accessories may result if instructions are not followed.

Symbols Used on this Product and in the documentation

The following symbols may be found on the meter and in associated documentation:

High Voltage Refer to

User Manual

Protective

Ground

Measurement

Ground

Casing

Ground

General Safety Information

Carefully read the following safety information in order to avoid any personal injury and

damage to this product or to any products associated with its use. In order to lessen the

chances of any possible dangers that may occur in connection with the use of this

product, the product should only be used in the specified applications the product was

designed and intended for.

Warning:

To avoid fire or electrical shock please use the proper power adapter. Use only

the power adapter recommended by the manufacturer.

Warning:

If test tool inputs are connected to more than 42V peak (30Vrms) or used in

circuits of more than 4800VA, adhere to the following guidelines in order to

avoid fire or electrical shock:

● Use only insulated voltage probes, test leads and the adapter supplied with

the test tool, or indicated by Extech as suitable for the Oscilloscope &

Multimeter.

● Before use inspect voltage probes, test leads and accessories for

mechanical damage and replace when required.

● Remove all probes, test leads and accessories that are not in use.

5

MS400 Version 2.0 – December 2007

Page 6

● Always connect the power adapter first to the AC outlet before connecting

it to the Oscilloscope & Multimeter.

● Do not apply voltages that differ more than 400V from earth ground to any

input when measuring in a CAT III environment.

● Do not apply voltages that differ more than 400V from earth ground to any

input when measuring in a CAT II environment.

● Do not apply voltages that differ more than 400V from each other to the

isolated input when measuring in a CAT III environment.

● Do not apply voltages that differ more than 400V from each other to the

isolated inputs when measuring in a CAT II environment.

● Do not apply input voltages above the rating of the instrument. Use caution

when using 1:1 test leads because the probe tip voltage will be directly

transmitted to the Oscilloscope & Multimeter.

● Do not use exposed metal BNC or banana plug connectors. Do not insert

metal objects into connectors.

● Always use the Oscilloscope & Multimeter only in the manner specified.

● Voltage ratings that are mentioned in the warning are provided as limits for

“working voltage”. The representative Vac rms (50-60Hz) indicates AC sine

wave applications and as Vdc for DC applications. Overvoltage Category III

refers to distribution level and fixed installation circuits inside a building.

Overvoltage Category II refers to local levels, which are applicable for

appliances and portable equipment.

Only qualified technical personnel should perform maintenance.

Pay attention to the nominal values of all terminals: To avoid fire or electric

shock, please keep a watchful eye on all nominal values and marks specified on

this product. Before any connections are made, carefully read the user’s manual

of the product for further information of nominal values.

DO NOT operate this product without the instrument cover plate in place: If the

cover plate or panel has been removed, do not perform any operations with this

product.

DO NOT come into contact with bare conductors: When the product is powered

on, do not touch any bare joints or parts of the meter.

DO NOT operate this product in case of any undetermined failure: When in

doubt of the cause of any damage to this product, consult qualified technical

personnel.

Keep the product well ventilated: Refer to the user manual for detailed installation

instructions. Make sure the product is operated in a well ventilated area.

DO NOT operate this product in humid conditions.

DO NOT operate this product where explosives are handled or used.

Keep the product surface clean and dry.

6

MS400 Version 2.0 – December 2007

Page 7

General Inspection

After purchasing a new MS400 oscilloscope, it is suggested that a general inspection of

the instrument be performed according to the following steps:

Check whether there is any damage to the product caused by shipping

If the packing material, boxes or foam cushions are found in a damaged condition, keep

them in a proper place until the complete instrument and accessories have passed

electrical and mechanical tests.

Check the Accessori es

Double check the accessory list and pictures of the parts and accessories included with

your instrument. Check whether there is any accessory loss by referencing the Appendix.

In case of any accessory loss, damage or variation in specifications, contact the

organization where the product was purchased.

Check the Ins tru m e nt

If the instrument is apparently damaged, fails in normal operation or in a performance

test, consult the place of purchase.

If the instrument is damaged due to shipping, keep the packing material in a proper place

and contact the place of purchase.

Contents of the meter kit

Description Standard Optional

Meter ●

Adapter ●

Two (2) Oscilloscope Probes (grey) ●

Pair of Test Leads for Multimeter (black and red) ●

Measuring Extension Module for Low Current ●

Measuring Module for low range Capacitance ●

Adjustment Probe Tool ●

One (1) USB Data Transmission cable ●

User Manual ●

One (1) disk that includes the PC interface

software

Carrying Case ●

●

7

MS400 Version 2.0 – December 2007

Page 8

Input Connections

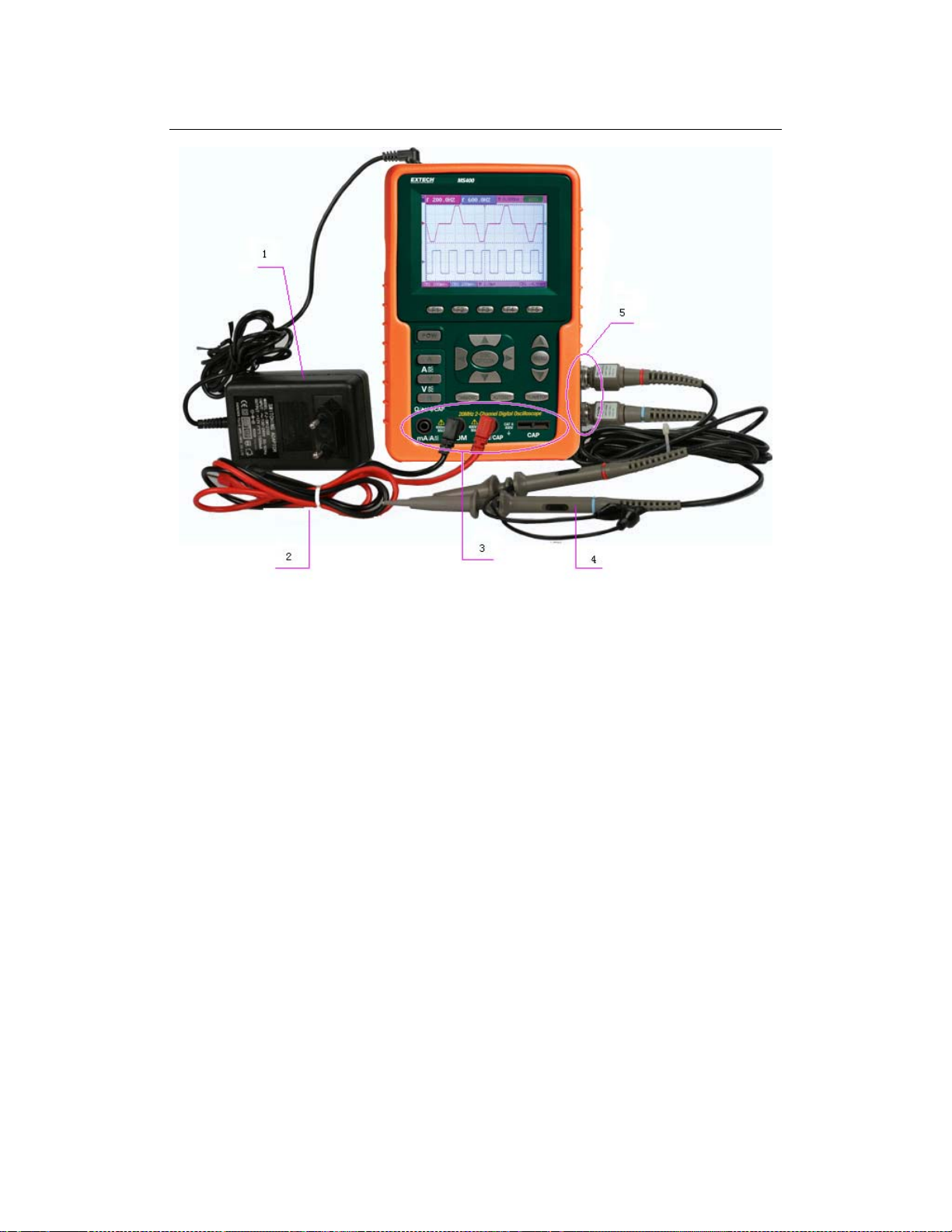

Figure 2

Description:

1. AC power adapter for AC power supply and battery recharging

2. Multimeter test leads

3. Multimeter input jacks, including three circular banana jacks and two square jacks.

The three circular jacks are used for voltage, current and resistance inputs, while the

two square jacks are used for capacitance inputs

4. Oscilloscope probes

5. Oscilloscope channel inputs: The upper one is for Channel 1 (CH1) while the lower

one is for Channel 2 (CH2)

8

MS400 Version 2.0 – December 2007

Page 9

Description of the Front Panel and the Keypad

132

4

20

5

9

6

7

8

Description:

1. Power adapter jack

2. Serial port

3. USB jack

4. Backlight switch

5. POWER: Power switch

14 12 15

11

13

19

18

17

10

16

Figure 3

6. A: Multimeter current measurement key

7. V: Multimeter voltage measurement key

8. R: Multimeter resistance, diode, On/Off and capacitance measurement key

9. OSC LEFT: Oscilloscope left-direction adjustment key

10. OSC RIGHT: Oscilloscope right-direction adjustment key

11. OSC OPTION: Oscilloscope setting key

9

MS400 Version 2.0 – December 2007

Page 10

Using the four keys OSC LEFT, OSC RIGHT, OSC UP and OSC DOWN, users

can make the following settings by pressing OSC OPTION. The settings include:

Voltage Unit Scale for Channel 1 (CH1 VOL); Voltage Unit Scale for Channel 2

(CH2 VOL); Primary Time base (TIME BASE), zero point position for Channel 1

(CH1 ZERO), zero point position for Channel 2 (CH2 ZERO), trigger horizontal

position (TIME) and trigger level position (TRIG).

When performing Waveform Calculations, users can also adjust and calculate the

Display Multiplying Factor of a Waveform (CHM VOL) and the vertical display

position (CHM ZERO).

In cursor measurement mode, users can adjust the positions of Cursor 1 (V1 or

T1) and Cursor 2 (V2 or T2).

12. OSC DOWN: Oscilloscope display downward adjustment key.

13. OSC UP: Oscilloscope display upward adjustment key.

14. OSC/DMM: Press to switch between oscilloscope and multimeter.

15. AUTO SET:

In the Multimeter Mode, when performing a current or voltage measurement, the

user can switch between AC and DC with this key; when performing a resistance

measurement, the user can select resistance, diode, On/Off or a capacitance

measurement with this key.

This key is used for auto setting in the oscilloscope operation mode.

16. RUN/STOP: key for starting or stopping an operation.

17. MENU DOWN: Move down the menu list.

18. MENU: Show / Hide the menu.

19. MENU UP: Move up the menu list.

20. F1~F5: Switch or Adjustment options for each menu

10

MS400 Version 2.0 – December 2007

Page 11

Using the Scope

About this Chapter

This chapter provides a step-by-step introduction to the oscilloscope’s functionality. The

introduction does not cover all of the capabilities of the scope functions but gives basic

examples to show how to use the menus and perform basic operations.

Power-Up the Oscilloscope

Connect the oscilloscope to AC power via the power adapter as shown in Figure 2

Turn the oscilloscope on by pressing the power on/off key POW.

The instrument then performs a self-check. A greeting window with “press any key to

continue.” displays after the self-check.

The user can press any key to enter the measurement functions.

The oscilloscope powers up in the last setup configuration.

Oscilloscope Operation Window

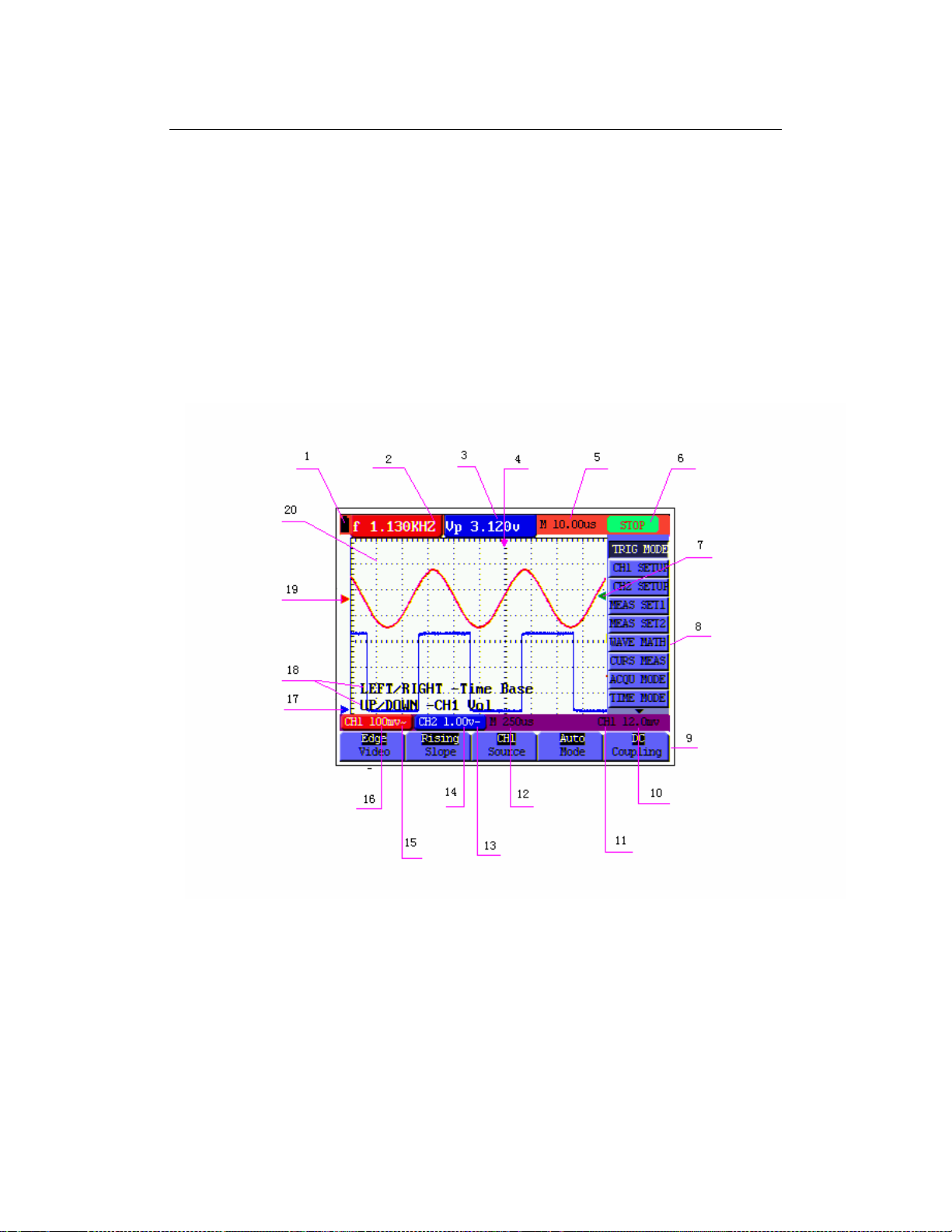

Figure 4: Oscilloscope Operation Window

11

MS400 Version 2.0 – December 2007

Page 12

1. Battery power level indicator symbols, including , , and .

2. Auto measurement window No. 1 where “f” is frequency, “T” is cycle, “V” is the

average value, “Vp” the peak-peak value and “Vk” the root-mean-square value.

3. Auto measurement window No. 2.

4. The pointer indicates the horizontal triggering position.

5. This reading gives the time difference between the horizontal triggering position and

the screen centerline. It reads zero when the pointer is in the center of the screen.

6. The trigger state indicates the following information:

Auto: The oscilloscope is in the automatic mode and displaying the waveform in the

non-trigger mode.

Trig’d: The oscilloscope has detected a trigger and is collecting the information

generated after the trigger.

Ready: All pre-triggered data have been captured and the oscilloscope is ready to

receive trigger signals.

Scan: The oscilloscope can gather/display the waveform data continuously in scan

mode.

Stop: The oscilloscope has stopped collecting the waveform data.

7. The green pointer shows the trigger voltage level.

8. A hidden-style menu: With the MENU key pressed, the user can view or hide the

menu.

9. Menu setting options: Various setting options for available menus.

10. The value of the trigger voltage level.

11. The display shows the trigger signal source.

12. The reading gives the value of the primary time base.

13. These graphics present the coupling modes of channel 2 (CH2). The graphic “~”

indicates AC, the graphic “-” indicates DC.

14. This reading shows the vertical Voltage Unit Scale of CH2.

15. These graphics show the coupling mode of CH1, the graphic “~” expresses and

indicates AC, the graphic “-” indicates DC.

16. This reading shows the vertical Voltage Unit Scale of CH1.

17. The blue pointer gives the grounding data point for the waveform on CH2, which is

the zero position of CH2. If this pointer does not display then the channel has not

been opened.

18. OSC OPTION operation prompt: There are various prompts for the available OSC

OPTION operations.

19. The red pointer gives the grounding data point for the waveform on CH1, which is the

zero position of CH1. No display of this pointer indicates that the channel has not

been opened.

20. Waveform display area. Red waveform represents CH1, blue waveform represents

CH2.

12

MS400 Version 2.0 – December 2007

Page 13

Navigating a Menu

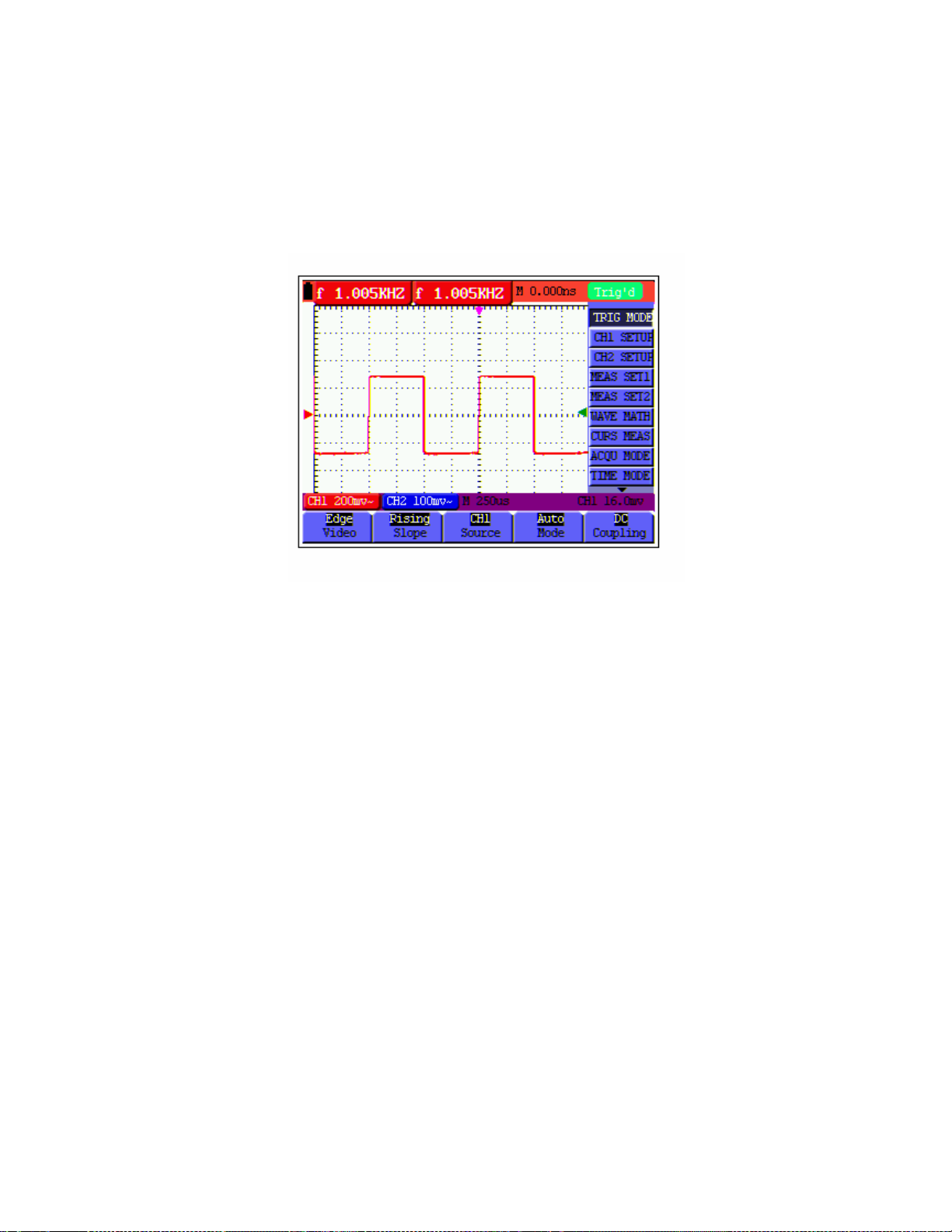

The following example shows how to use the tool’s menus to select a function, as shown

in figure 5:

1. Press the MENU key to display the Function Menu on the right of the screen and the

corresponding optional settings on the bottom. Press MENU again to hide the

Function Menu.

2. Press the MENU UP or MENU DOWN key to select various function menus.

3. Choose a key from F1 to F5 to change the function setting.

Figure 5: the Tool’s Menus

13

MS400 Version 2.0 – December 2007

Page 14

Manually Setting the Vertical System, Horizontal System and

Trigger Position

Using the four keys OSC LEFT, OSC RIGHT, OSC UP and OSC DOWN, the user can

make the following settings by pressing OSC OPTION. The settings include: Voltage Unit

Scale for Channel 1 (CH1 VOL), Voltage Unit Scale for Channel 2 (CH2 VOL), Primary

Time base (TIME BASE), zero point position for Channel 1 (CH1 ZERO), zero point

position of channel 2 (CH2 ZERO), trigger horizontal position (TIME) and trigger level

position (TRIG).

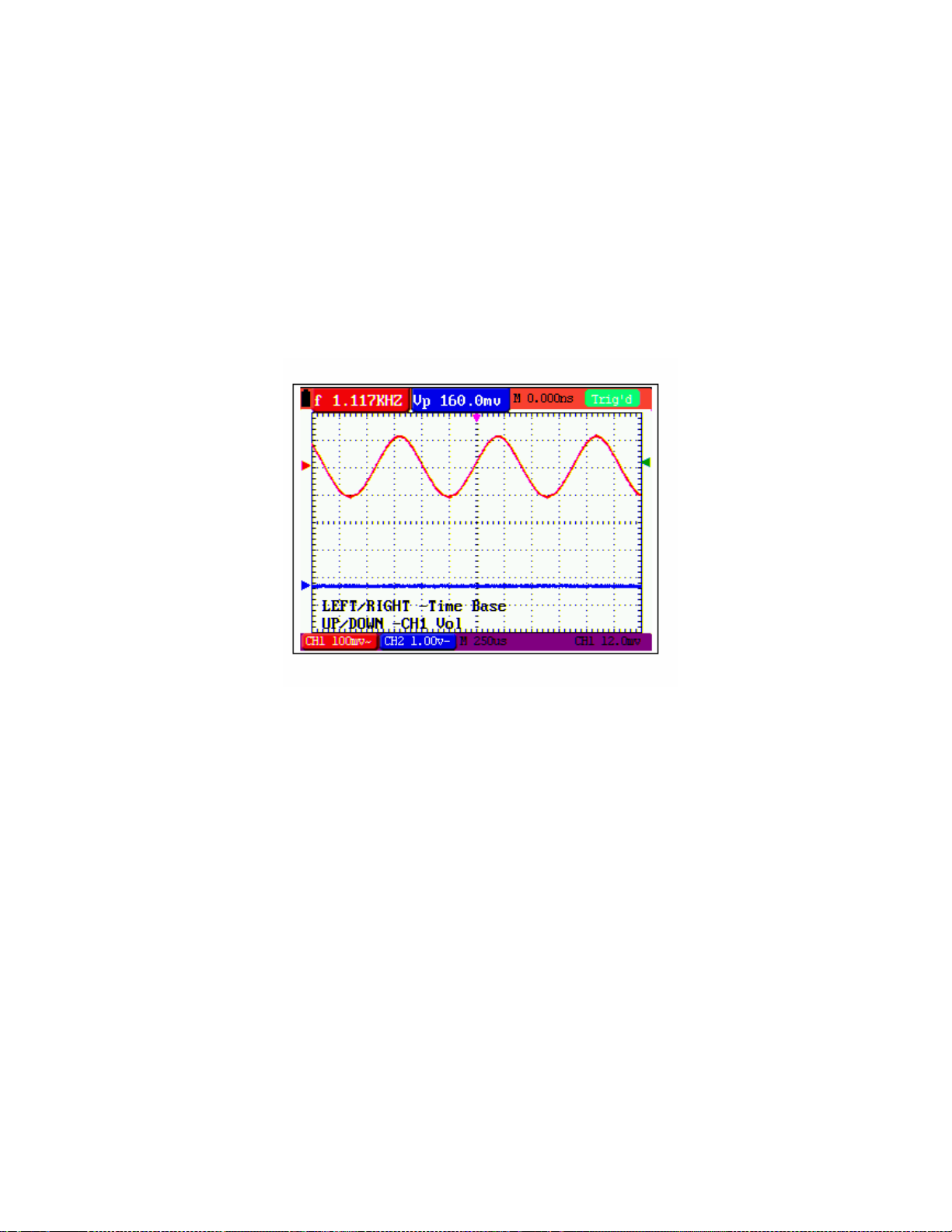

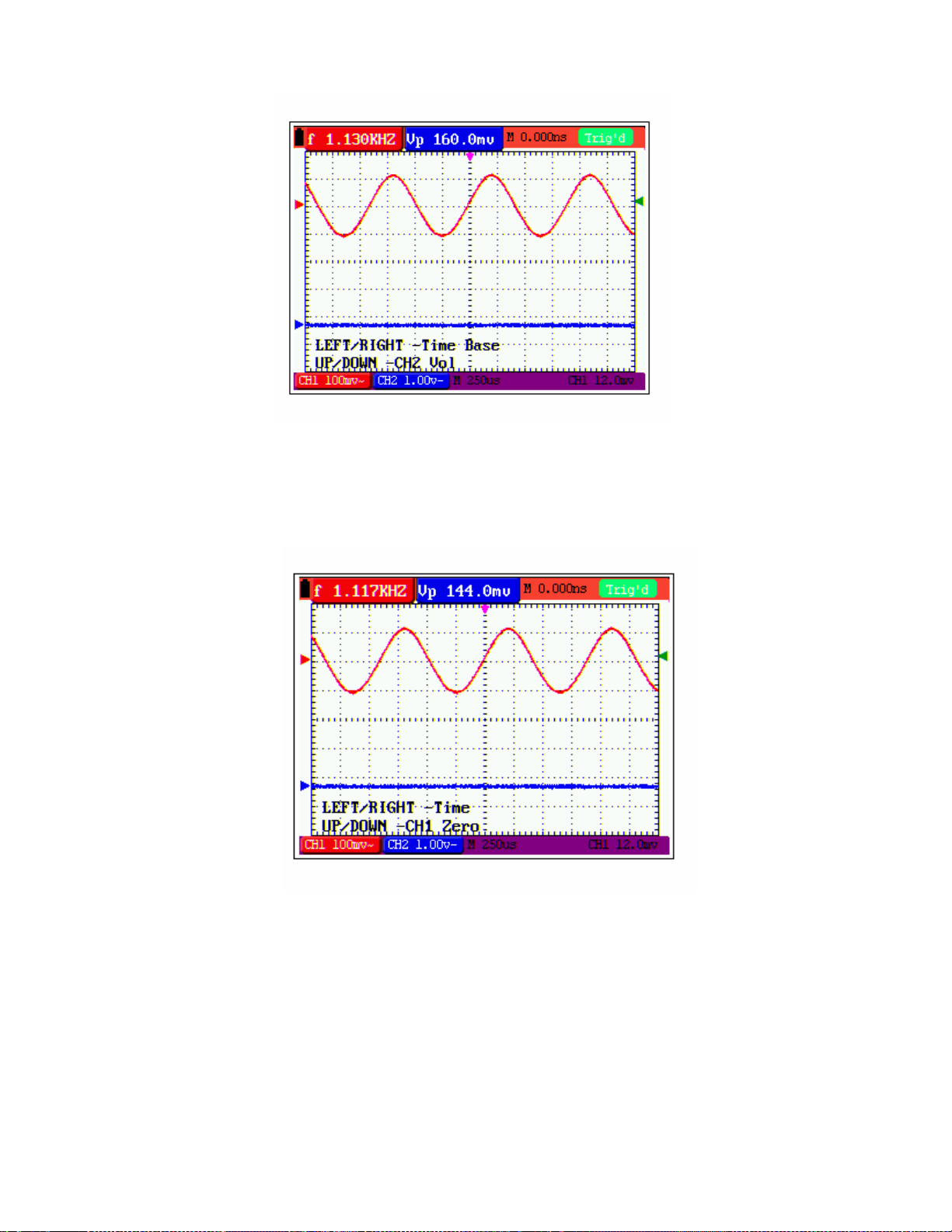

The following example shows how to use the OSC OPTION key:

1. Press the OSC OPTION key once; the following is displayed at the bottom left side of

the screen, as shown in figure 6:

LEFT/RIGHT – Time Base

UP/DOWN – CH1 Volts/Div

Figure 6: Voltage Unit Scale of Channel 1

2. Press the key OSC UP or OSC DOWN to adjust the vertical scale of Channel 1 and

press OSC LIFT or OSC RIGHT to adjust the horizontal time scale.

3. Press OSC OPTION once again, the following display is visible at bottom left side of

the screen as shown in figure 7:

LEFT/RIGHT – Time Base

UP/DOWN – CH2 Volts/Div

14

MS400 Version 2.0 – December 2007

Page 15

Figure 7: Voltage Unit Scale of Channel 2

4. Press the OSC UP or OSC DOWN key to adjust the vertical scale of Channel 2 and

press the OSC LIFT or OSC RIGHT key to adjust the horizontal time scale.

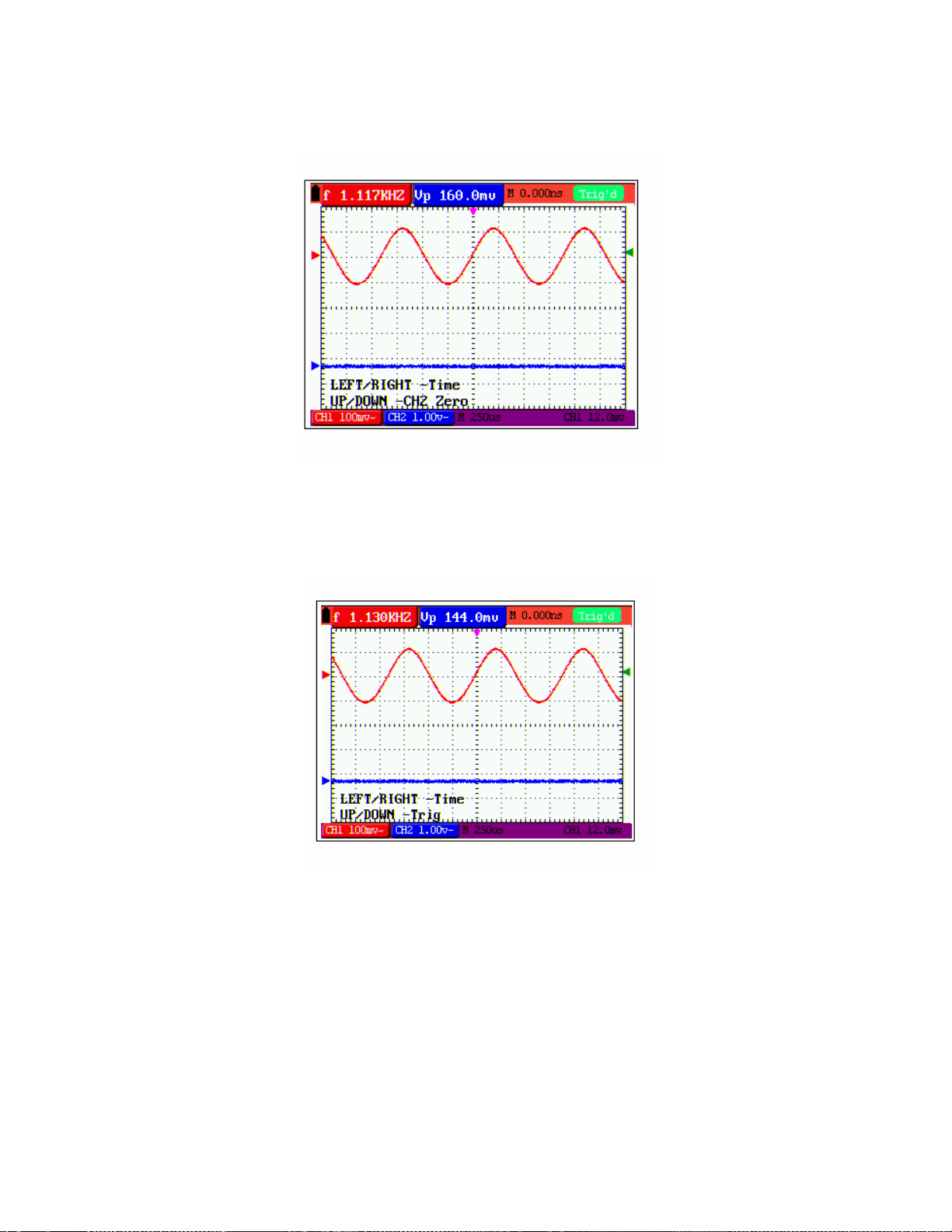

5. Press the OSC OPTION key one more time, and the following display is visible at the

bottom left side of the screen, shown in figure 8.

LEFT/RIGHT – Time

UP/DOWN – CH1 Zero

Figure 8: Zero Point Position of Channel 1

6. Press OSC UP or OS C DOWN key to adjust the zero position of Channel 1 in the

vertical direction and press OSC LIFT or OSC RIGHT key to adjust the horizontal

position.

15

MS400 Version 2.0 – December 2007

Page 16

7. Again, press O SC OPTION key and the following appears at the bottom left side of

the screen, shown as the following figure 9:

LEFT/RIGHT – Time

UP/DOWN – CH2 Zero

Figure 9: Zero Point Position of Channel 2

8. Press the OSC UP or OSC DOWN key to adjust the zero position of Channel 2 in the

vertical direction and press OSC LEFT or OSC RIGHT key to adjust the horizontal

position.

9. Press OSC OPTION key once more and the following appears at the bottom left of

the screen, shown as the following figure 10:

LEFT/RIGHT – Time

UP/DOWN – Trig

Figure 10: Trigger Level Position

10. Press the OSC UP or OSC DOWN key to adjust the trigger position of Channel 2 and

press OSC LIFT or OSC RIGHT key to adjust the horizontal position.

11. Press the OSC OPTION key again and return back to step 1.

16

MS400 Version 2.0 – December 2007

Page 17

Term Glossary

Vertical scale factor is the voltage amplitude represented by a division in the vertical

direction of the display area. The user can amplify or attenuate the signal with this

scale factor and thus regulate the signal amplitude for the expected range.

Vertical zero position is referred to as the grounding data point through the

adjustment of which one can regulate the display position of the waveform on the

screen.

Primary time base refers to the time values represented by a division in the

horizontal direction of the display area.

Trigger horizontal position is the time deviation between the actual trigger point

and the screen central line which will be displayed as 0 at the center point of the

screen.

Trigger level position represents the voltage deviation between the actual trigger

level and the zero position of the triggering signal source channel.

Resetting the Oscilloscope

To reset the Oscilloscope to the factory default settings:

1. Press the MENU key. The function menu appears on the right side of the screen

2. Press the MENU UP or MENU DOWN key to select FUNCTION. Three options

will be visible at the bottom of the screen.

3. Press F1 to select Factory Settings. The oscilloscope will revert to the factory

settings.

Figure 11: Reset the Oscilloscope

Input Connections

Examine the bottom and the right side of the Oscilloscope. The Oscilloscope has seven

signal inputs: two safety BNC jack inputs (CH1 and CH2) for scope measurements, three

safety 4-mm banana jack inputs for Multimeter R, V and A measurements, and two

square jack inputs for Multimeter capacitance measurements.

Isolated inputs allow independent floating measurements between Multimeter and Scope.

(fig. 2)

17

MS400 Version 2.0 – December 2007

Page 18

Displaying an Unknown Signal with Auto Set

The Auto-Set feature allows the Oscilloscope to display and measure unknown signals

automatically. This function optimizes the position, range, time-base, and triggering and

assures a stable display of virtually any waveform. This feature is especially useful for

quickly checking multiple signals.

To enable the Auto-Set feature:

1. Connect the test probe to the signals under test.

2. Press the AUTOSET key. The Oscilloscope is now in the automatic measurement

mode. The tested signals appear on the screen.

Automatic Zero-Returning of Trigger Horizontal Position and

Trigger Level Position

When the trigger horizontal position and trigger level position are adjusted to maximum,

they will become positioned off-screen. The following steps will allow the trigger horizontal

position and trigger level position to return to zero automatically:

1. Press the OSC LEFT key and the OSC RIGHT key simultaneously, the trigger

horizontal position automatically returns to zero.

2. Press the OSC UP and the OSC DOWN buttons simultaneously, the trigger level

position automatically returns to zero.

Automatic Measurements

The Oscilloscope offers 5 ranges of automatic scope measurements. Two numeric

readings can be displayed: measurement 1 and measurement 2. These readings are

selectable independently and the measurements can be performed on the input CH1 or

input CH2 waveform.

To choose a frequency for CHI1:

1. Press the MENU key. The function menu appears on the right side of the screen.

2. Press the MENU UP or the MENU DO WN key to select MEAS SET1. Five selectable

items are visible at the bottom of the screen.

3. Press the F1 key and select Freq CH1 from the mean square root value item. The

measuremen t 1 window turns red in color and shows the frequency for input CH1.

To choose a Peak-Peak measurement for Input CH2:

1. Press the MENU key. The function menu is displayed on the right side of the screen.

2. Press the MENU UP or the MENU DO WN key and select MEAS SET2, with 5

selectable items displayed at the bottom of the screen.

3. Press the F4 key to select PK-PK CH2 from Peak-Peak item. The measurement 2

window turns blue in color and shows the peak-peak value for input CH2.

Figure 12: Automatic Scope Measurements

18

MS400 Version 2.0 – December 2007

Page 19

Freezing the Screen

1. Press the RUN/STOP key to freeze the screen. STOP appears at top right side of the

screen.

2. Press the RUN/STOP key once more to resume measurement.

Figure 13: Freezing the Screen

Using Average for Smoothing Waveforms

To smooth the Waveform:

1. Press the MENU key and the function menu will appear on the right side of the

screen.

2. Press the MENU UP or the MENU DO WN key to select ACQU mode, with four

selectable items displayed at the bottom of the screen.

3. Press the F3 key to select Average Factors, then, press F4 to jump to Averages. This

averages the outcomes of 4, 16, 64, or 128 acquisitions and shows the final

averaging result on the screen, shown as in the following figures.

Figure 14: Average Factor Sampling Mode

19

MS400 Version 2.0 – December 2007

Page 20

Using Persistence to Display Waveforms

You can use Persistence to observe dynamic signals:

1. Press the MENU key and the function menu will appear on the right side of the

screen.

2. Press the MENU UP or the MENU DO WN key to select DISP SET. Four selectable

items are displayed at the bottom of the screen.

3. Press the F2 key to select Persist 1 sec, 2 sec, and 5 sec, Infinite or OFF. In this

case, jump to Infinite and the observed dynamic is kept on the screen continuously.

When the item OFF is selected, the Persistence function is switched off.

Figure 15: Using ‘Persistence’ to Observe Dynamic Signals

Using Peak Detection to Display Glitches

The user can use this function to display events (glitches or other asynchronous

waveforms) of 50 ns or wider:

1. Press the MENU key and the function menu will appear at the right side of the

screen.

2. Press the MENU UP or the MENU DOWN key to select the ACQU MODE. Four

selectable items are displayed at the bottom of the screen.

3. Press the F2 key and jump to Peak Detect.

Figure 16: Peak Detection

20

MS400 Version 2.0 – December 2007

Page 21

Term Glossary

Collecting mode: The oscilloscope transforms the collected analog data into a digital

form after it is gathered in the following three modes: sampling, peak value detection

and averaging values.

Sampling: The oscilloscope takes samples from the signal at equal time intervals to

reconstruct the waveform. In this mode, the analog signal can be expressed correctly

in most cases. However, rapid changes cannot be detected between two sampling

time intervals.

Peak value detection: The oscilloscope takes samples from the maximum and

minimum of signals in each sampling interval and shows the Waveform with the

sampled data. Thus, the oscilloscope may capture narrow pulses that could not be

detected in sampling mode.

Averaging values: The oscilloscope collects several Waveforms, averages them,

and displays the averaged Waveform. In this mode random noise can be reduced.

Duration time: When a new Waveform is displayed, the previous Waveform shown

on the screen does not disappear immediately but will continue to be displayed for a

period of time. This period of time is referred to as the duration time. Thus, a display

similar to that shown by an analog oscilloscope can be achieved.

Roll scan mode: The oscilloscope updates the Waveform sampling points by

scrolling through the screen from left to right (only applicable to the primary time base

setting above 50ms).

Selecting AC-Coupling

After a reset, the Oscilloscope is dc-coupled so that ac and dc voltages appear on the

screen. Use ac-coupling to observe small ac signals that ride on a dc signal. To select

ac-coupling:

1. Press the MENU key and the function menu will appear at the right side of the

screen.

2. Press the MENU UP or the MENU DO WN key to select the CH1 SETUP. Four

selectable items are visible at the bottom of the screen.

3. Press the F1 key and jump to AC. The bottom left side of the screen displays the ac-

coupling icon.

The user can view a screen that looks similar to the following Figure 17.

Figure 17: AC-Coupling

21

MS400 Version 2.0 – December 2007

Page 22

Reversing the Polarity of the Displayed Waveform

To invert the input CH1 waveform, do the following:

1. Press the MENU key and the function menu will appear at the right side of the

screen.

2. Press the MENU UP or MENU DOWN key to select CH1 SETUP. Four selectable

items are displayed at the bottom of the screen.

3. Press the F4 key to jump to Inverted. The inverted waveform of CH1 is displayed on

the screen.

Figure 18: Inverted

22

MS400 Version 2.0 – December 2007

Page 23

Using Waveform Mathematical Functions

When adding (CH1 + CH2), subtracting (CH1 – CH2, CH2 – CH1), multiplying (CH1 * CH2)

or dividing(CH1 / CH2 ) the input Waveforms of CHI and CH2, the Oscilloscope will

display the mathematical result Waveform M and the input Waveforms of CH1 and CH2 on

the screen. The Mathematical functions perform a point-to-point calculation on Waveforms

for CH1 and CH2.

To use a Mathematical function:

1. Press the MENU key and the function menu will display at the right side of the

screen.

2. Press the MENU UP or MENU DOWN key to select the WAVE MATH. Five

selectable items appear at the bottom of the screen.

3. Press F3 to select CH1+CH2 and the calculated waveform M (green) appears on the

screen. Press the F3 key to close the Waveform Calculation.

4. Press the OSC OPTION key and the following will be visible at the bottom left side of

the screen.

LEFT/RIGHT Time

UP/DOWN CHM Zero

Then press the OSC UP or the OSC DOWN key to adjust the vertical position of the

calculated waveform M displayed on the screen.

5. Press the OSC OPTION key and the following will appear at the bottom left side of

the screen.

LEFT/RIGHT Time Base

UP/DOWN CHM Vol

Press the OSC UP or OSC DOWN key to adjust the displayed amplitude of the

calculated waveform M.

Figure 19: Waveform Mathematics

23

MS400 Version 2.0 – December 2007

Page 24

Using the Multimeter

About this Chapter

This chapter provides step-by-step introductions for the multi-meter functions. The

introduction gives basic examples on how to use the menus and perform basic operations.

Meter Connections

Use the three 4-mm safety banana jack inputs for the Meter functions: COM, V/Ω, mA.

Two square capacitance jacks: CX

See Figure 2 for the proper connections.

Multimeter Operation Window

Figure 20: Multimeter Operation Window

Description:

1. Battery power level indictor.

2. Manual/Auto range indictors: Manual refers to the measuring range in manual

operation mode and Auto refers to the measuring range in automatic operation

mode.

3. Measurement mode indicators:

DCV: Direct voltage measurement

ACV: Alternating voltage measurement

DCA: Direct current measurement

ACA: Alternating current measurement

R: Resistance measurement

: Diode measurement

: Audible Continuity measurement

C: Capacitance measurement

24

MS400 Version 2.0 – December 2007

Page 25

4. The relative magnitude measurement indicator

5. Running state indicators, among which RUN expresses continuous update and

STOP represents the screen lock

6. The reference value of the relative magnitude measurement

7. The multiplying power of the dial indication. Multiplying the reading of the dial

pointer by the power will yield the measurement result

8. The measurement reading

9. Automatic control measuring range

10. Absolute / Relative magnitude measuring control: The sign “||” expresses the

absolute magnitude measuring control and “” represents the relative magnitude

measuring control

11. Manual measurement range control

12. Test lead indicates the scale of a reading; different test modes use various colors

25

MS400 Version 2.0 – December 2007

Page 26

Multimeter Measurements

By pressing the DMM/OSC key the oscilloscope will switch to the Multimeter mode.

The screen will display the multimeter windows, and, at the same time, prompt to

correctly insert the test leads. At this time press any key to enter the multimeter

measurement mode.

Measuring Resistance Values

To measure a resistance, do the following:

1. Press the R key and R appears at the top

of the screen.

2. Insert the black lead into the COM banana

jack input and the red lead into the V/Ω

banana jack input.

3. Connect the red and black test leads to the

resistor. The resistor value is displayed on

the screen in Ohms.

Figure 21: Resistance Measurement

Making a Diode Measurement

To make a diode measurement:

1. Press the R key and R appears at the top

of the screen.

2. Press the AUTO SET key until the

following is displayed

.

3. Insert the black lead into the COM banana

jack input and the red lead into the V/Ω

banana jack input.

4. Connect the red and black leads to the

diode and the reading is displayed on the

screen in V.

Figure 22: Diode measurement.

Making Continuity Tests

To perform a Continuity Test, do the following:

Press the R key and R appears on the top of

1.

the screen.

2. Press the AUTO SET key until the following is

shown on the screen.

3. Insert the black lead into the COM banana

jack input and the red lead into the V/Ω

banana jack input.

4. Connect the red and black test leads to the

test points. If the resistance value of the tested

point is less than 50Ω an audible beep will

sound.

Figure 23: Continuity.

26

MS400 Version 2.0 – December 2007

Page 27

Making a Capacitan ce Measurement

To measure a capacitance:

1. Press the R key and R appears on the top of

the screen

2. Press the AUTO SET key till C appears at the

top of the screen.

3. Insert the capacitor into the square jack and the

screen will show the capacitance reading.

Note: When the measured value is less than 5nF,

use the low capacitance mode of the multimeter

and the relative value measuring mode to

improve measurement precision. If the

capacitance measurement is larger than 40uF

the calculation will take about thirty seconds.

Making a DC Voltage Measurement

To measure a DC voltage, do the following:

1.

Press the V key and DCV appears at the top of

the screen.

2. Insert the black lead into the COM banana jack

input and the red lead into the V/Ω banana jack

input.

3. Connect the red and black test leads to the

measurement points and the measured voltage

value will display on the screen.

Making a AC Voltage Measurement

To measure AC voltage:

1. Press the V key and DCV appears at the top

of the screen.

2. Press the AUTO SET key and ACV appears at

the top of the screen.

3. Insert the black lead into the COM banana

jack input and the red lead into the V/Ω

banana jack input.

4. Connect the red and black test leads to the

measurement points and the AC voltage value

will be displayed on the screen.

Figure 24: Capacitance Measurement

Figure 25: DC Voltage Measurement

Figure 26: AC Voltage Measurement.

27

MS400 Version 2.0 – December 2007

Page 28

Making a DC Current Measurement

To measure DC current less than 400 mA:

1. Press the A key and DCA appears at the top

of the screen. The units on the main reading

screen are mA and 20A, press F4 or F5 to

switch the measurement between mA and

20A.

2. Insert the black lead into the COM banana

jack input and the red lead into the mA

banana jack input.

3. Connect the red and black test leads in

series to the measurement points and the

DC current value will be displayed on the

screen.

To measure DC current larger than 400mA:

1. Press the A key and DCA appears at the

top of the screen. The units on the main

reading screen will be mA.

2. Press F5 to change to the 20A

measurement mode, the units on the main

reading screen will be A.

3. Plug the 20A current shunt into the current

measure jack, and then plug the probe in

the module.

4. Connect the red and black test leads in

series to the measurement points and the

DC current value will be displayed on the

screen.

5. Press F4 to return to the 400mA

measurement mode.

Making an AC Current Measurement

To measure AC current less than 400mA:

1. Press the A key and DCA appears at the top

of the screen. The units on the main reading

screen are mA and 20A, press F4 or F5 to

switch the measurement between mA and

20A.

2. Press the AUTO SET key once and ACA will

be visible at the top of the screen.

3. Insert the black lead into the COM banana

jack input and the red lead into the mA

banana jack input.

4. Connect the red and black test leads to the

measurement point and the AC current value

will be displayed on the screen.

Figure 27: DC Current Measurement.

Figure 28: DC Current Measurement.

Figure 29: AC Current Measurement

28

MS400 Version 2.0 – December 2007

Page 29

To measure AC current larger than 400mA:

1. Press the AUTO SET key once and ACA

will be visible at the top of the screen.

2. Press F5 to select 20A, the units for the

main reading window will be A.

3. Press the AUTO SET key once and ACA

will be visible at the top of the screen.

4. Plug the current extended module into the

current measurement jack, and plug the test

leads into the shunt.

5. Connect the red and black test leads in

series to the measurement points and the

AC current value will be displayed on the

screen.

6. Press F4 to return to the 400mA

measurement mode.

Figure 30: AC Current Measurement for 20A

Freezing a Displayed Reading

Freeze the displayed readings at any time:

1. Press the RUN /STOP key to freeze the

screen, STOP will be displayed at the top right

of the screen.

2. Press the RUN /STOP key again to resume

measurements.

Figure 31: Freezing the Readings

Taking a Relative Measurement

A reading, relative to a reference value, is displayed in the relative measurement mode. The

following example shows how to take a relative measurement. First, the user must define a

reference value:

1. Press the R key and R will be displayed on the

top of the screen.

2. Press the AUTO SET key untill C appears at

the top of the screen.

3. Plug the capacitance extended module into the

capacitance measurement jack.

4. When the reading stabilizes, press F2 and the

triangle icon will be displayed on the top of the

screen. The saved reference value is

displayed below the triangle

5. All subsequent readings will be displayed

relative to the stored reference reading.

Figure 32: Relative Measurement.

29

MS400 Version 2.0 – December 2007

Page 30

Selecting Automatic/Manual Range

The default range mode is the automatic range mode. To switch to the manual range,

perform the following steps:

1. Press the F1 key and MANUAL is displayed

on the top left side of the screen.

2. In manual range mode, the measuring range is

increased each time F1 is pressed. After the

highest range is reached, the meter will return

to the lowest range. To return to automatic

mode, Press the F3 key and AUTO is

displayed on the top left side of the screen.

Figure 33: Automatic/Manual Range Adjustment

30

MS400 Version 2.0 – December 2007

Page 31

Advanced Oscilloscope Functions

About this Chapter

This chapter details the advanced oscilloscope functions.

Setting the Vertical CH1 and CH2

Each channel can be set independently.

To change vertical CH1 and CH2 settings:

1. Press the MENU key and the function menu will appear at the right of the screen.

2. Press the MENU UP or MENU DOWN key to jump to CH1 SETUP and four options

appear at the bottom of the screen.

3. Press any key from the F1 key through F4 to adjust the available settings.

The user can view a screen that looks similar to the following Figure 34.

Figure 34: Setting the Vertical

The following Table describes the Vertical Channel menu:

Function

menu

Coupling

Channel

Probe

Invert

Setting

AC

DC

Close

Open

1X

10X

100X

1000X

Close

Open

Description

The dc component in the input signal is blocked.

The ac and dc components of the input signal are

allowed

Close a channel

Open a channel

Select one setting according to the probe attenuation

factor to ensure a correct vertical scale reading.

Waveform is displayed normally.

Open the Invert function of the Waveform setting.

31

MS400 Version 2.0 – December 2007

Page 32

Setting the Channel Coupling

Example (CH1): Sine wave signal containing a dc offset.

Press F1 Coupling first and then press AC for an ac coupling setting. The dc component

contained in the tested signal is blocked.

Press F1 Coupling first and then press DC for a dc coupling setting. Both dc and ac

components contained in the tested signal are permitted.

The waveform is displayed as in Figures 35 and 36.

Figure 35: AC Coupling

Figure 36: DC Coupling

32

MS400 Version 2.0 – December 2007

Page 33

Enabling the Scope Channels

Example for CH1:

Set the F2 Channel key to OFF and CH1 will be turned off.

Set the F2 Channel key to ON and CH1 will be displayed.

Adjusting the Probe Scale

If a 10:1 probe is connected, the scale of the input channel on the oscilloscope should be

set to 10X to avoid any error occurring in the displayed scale factor information and tested

data.

Press F3 Probe to set the correct probe attenuation.

Table: Probe attenuation factors and the corresponding menu setting.

Probe Attenuation

Corresponding Menu Setting

Factor

1:1 1X

10:1 10X

100:1 100X

1000:1 1000X

Inverting a Waveform

The displayed signal reverses 180 degrees relative to ground.

Press F4 Invert to invert the waveform. Press F4 Invert once again to cancel the

Inversion.

Math Function Menu Settings

The MATH function provides the results for addition, subtraction, multiplication or division

calculations on CH1 and CH2 channel waveforms. The result can be shown in grid or

cursor modes. The amplitude of the calculated waveform can be adjusted with CHM VOL,

which is displayed in the scale factor form. The amplitude ranges are 0.001X, 0.002X,

0.005X and 10X. The position of the calculated waveform can be adjusted up and down

with the CHM Zero key.

Math Function Table

Setting Description

CH1-CH2 CH1 waveform minus CH2 waveform.

CH2-CH1 CH1 waveform minus CH2 waveform

CH1+CH2 Add CH1 waveform to CH2 waveform

CH1*CH2 Multiply CH1 waveform and CH2 waveform

CH1/CH2 Divide CH1 waveform by CH2 waveform

33

MS400 Version 2.0 – December 2007

Page 34

To perform a CH1+CH2 waveform calculation:

1. Press the MENU key and the function menu will appear at the right of the screen.

2. Press the MENU UP or MENU DOWN key to select WAVE MATH. Five options are

displayed at the bottom of the screen.

3. Press the F3 CH1+CH2 key and the obtained waveform M appears on the screen.

Press the F3 key again to close the waveform M.

4. Press the OSC OPTION key and the following will be displayed on the screen:

LEFT/RIGHT – Time Base

UP/DOWN – CH1 Volts/Div

5. Press the OSC UP or OSC DOWN key to adjust the amplitude of the waveform M.

6. Press the OSC OPTION key twice and the following will appear:

LEFT/RIGHT – Time

UP/DOWN – CHM Zero

7. Press the OSC UP or OSC DOWN key to adjust the position of waveform M.

Figure 37: Waveform Mathematics

Setting the Trigger

The trigger defines the start time for data acquisition and waveform display. When

beginning to acquire data, the oscilloscope collects sufficient data to draw the waveform at

the left side of the triggering point. After a trigger is detected, the oscilloscope gathers

enough data to draw the waveform at the right side of the triggering point.

To configure a trigger mode setting:

1. Press the MENU key and the function menu will appear at the right of the screen.

2. Press the MENU UP or MENU DOWN key to select TRIG MODE and five selectable

items will be displayed at the bottom of the screen.

3. Use the F1 through F5 keys to make selections.

4. Press the OSC OPTION key and the following will be shown on the screen:

LEFT/RIGHT – Time

UP/DOWN – Trig

5. Press the OSC UP or OSC DOWN key to adjust the trigger level positions.

34

MS400 Version 2.0 – December 2007

Page 35

Figure 38: Edge Trigger

Triggering Control

There are two triggering modes: Edge and Video. Each trigger mode is set by menu

functions:

Edge triggering occurs when the trigger input passes through a given level in the

specified direction.

Video triggering: Perform video field trigger or line trigger on standard video signals.

The following describes the Edge and Video triggering menus respectively.

Edge Triggering

With Edge triggering selected, the trigger occurs on the rising or falling edge of the

input signal, if the triggering threshold is met.

The Edge triggering menu:

Function

menu

Slope Rise

Signal

source

Trigger

mode

Coupling AC

Settings Description

Triggering on the rising edge of the signal.

Fall

CH1

CH2

Auto

Normal

Single Shot

Triggering on the falling edge of the signal.

CH1 is used as the trigger source.

CH2 is used as the trigger source.

Acquisition of waveforms is possible even if there is

no triggering condition detected.

Acquisition of waveforms can only be performed

when the triggering condition is satisfied.

The sampling is performed on a waveform when one

trigger is detected, then sampling ceases.

With this mode selected, the DC component is

DC

HF

suppression

LF

suppression

prevented from passing-through.

All dc components are allowed to pass.

The HF part of the signal is prohibited and only the LF

component is allowed.

The LF part of the signal is prohibited and only the HF

component is allowed to pass

35

MS400 Version 2.0 – December 2007

Page 36

Video Triggering

With Video triggering selected, the oscilloscope performs NTSC, PAL or SECAM

standard video signal field and line triggering.

The user can view a screen that looks similar to the following Figures 39 & 40.

Figure 39: Video Field Trigger

Figure 40: Video Line trigger

The Video triggering menu is described in the following table.

Function

Settings Description

menu

Polarity Normal

Invert

Applicable to the video signal in which the black level

is low level.

Applicable to the video signal of which the black level

is high level.

Signal source CH1

CH2

SYNC Line

Field

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Make a video line trigger synchronization setting

Make a video field trigger synchronization setting.

36

MS400 Version 2.0 – December 2007

Page 37

Term Glossary

Trigger modes: There are three kinds of trigger modes available for this oscilloscope-

auto, normal and single shot.

Automatic trigger mode: In this mode, the oscilloscope can acquire a Waveform

without any triggering condition detected. It will be triggered automatically after waiting a

specified period of time. When an invalid trigger is sensed the oscilloscope cannot keep

the Waveform in phase.

Normal trigger mode: In this mode the oscilloscope cannot acquire the Waveform until it

is triggered. If there is no trigger, the oscilloscope will display the original Waveform

without new Waveforms being captured and/or displayed.

Single shot mode: In this mode the oscilloscope will detect a trigger and capture a

Waveform each time the operator presses the RUN/STOP key.

Acquiring Mode Settings

The Acquiring Mode menu is described in the table shown below:

Function

menu

Sampling Normal sampling mode.

Peak Detection Used to detect a glitch.

Average Value Used to reduce random and unrelated noise.

Average Factor 4, 16, 64

Settings Description

Several average factors are available.

Select the average factor.

or 128

Display Settings

The Display Setting menu is described in the following table:

Function

menu

Type Vector

Persistence Close

Display format YT

Communication Bitmap

Settings Description

The vector fills the spaces between neighboring

Dot

1s

2s

5s

Infinite

XY

Vector

sampling points to form a line on the display.

Only the sample points are displayed.

Set ‘Persistence’ time for each sampling point.

Displays the relative relationship between vertical

voltage and horizontal time.

Display CH1 on the horizontal axis and CH2 on the

vertical axis.

The data is transmitted as a bitmap

The data is transmitted as a vector

37

MS400 Version 2.0 – December 2007

Page 38

Display Style

The display styles include Vector and Dot as shown in Figures 41 & 42.

Figure 41: Dot Style

Figure 42: Vector Style

Persistence Mode

With the Persistence function selected, the displayed data gradually decays in color

and the new data is shown bright in color. In the infinite persistence mode, the recorded

points will be kept on the screen until the controlled value is changed.

38

MS400 Version 2.0 – December 2007

Page 39

XY Mode

With the XY mode selected, CH1 is displayed on the horizontal axis and CH2

displayed on the vertical axis. When the oscilloscope is in a sampling mode in which

no trigger is found, the data appear as light spots.

Operation of various control keys:

■ CH1 Volts and CH1 Zero for CH1 are used to set the horizontal scale and

position.

■ CH2 Volts and CH2 Zer o for CH2 are used to set the vertical scale and position.

The following functions do not work in the XY display mode:

■ Reference or digital value waveform

■ Cursor

■ Auto Setting

■ Time base control

■ Trigger control

Waveform Saving Setup

The oscilloscope can save four (4) Waveforms all of which can be displayed on the

screen with the present Waveform. The recalled Waveform saved in the memory

cannot be adjusted.

The waveform saving /recalling menu is described in the following list.

Function

Setups Description

menu

Signal

source

CH1

CH2

Select the displayed Waveform to save.

MATH

Address A, B, C and D Select the address for saving or recalling a

Waveform.

Saving Store the Waveform of a selected signal source into

the selected address.

Addresses

A, B, C

Close

Start

Close or start displaying the Waveforms stored in

address A, B, C or D.

and D

To save a waveform on CH1 in address A:

1. Press the MENU key; the function menu will appear at the right of the screen.

2. Press the MENU UP or MENU DOWN key to select Wave Save. Four selectable

items are displayed at the bottom of the screen.

3. Press the F1 key to select the signal source CH1.

4. Press the F2 key to select the Address A.

5. Press the F3 key to save the CH1 Waveform in Address A.

To display the saved Waveform:

Press the F4 key to select Start for address A. The Waveform saved in address A will

be displayed on the screen in green and the zero point of Waveform k, voltage and

time, will be purple

39

MS400 Version 2.0 – December 2007

Page 40

The user can view a screen that looks similar to the following Figure 43.

Figure 43: Saving a Waveform

Function Setting Menu

The Function Setting Menu is described in the following list:

Function

Menu

Factory setting Return the instrument to its factory settings.

Self-correcting Perform a self-correcting procedure.

Language Chinese

Self-correcting:

The self-correcting program can improve the accuracy of the oscilloscope if the

ambient temperature variation is equal to or larger than 5 degrees Celsius.

Before the self-correcting program is performed, the probe or leads should be

disconnected; Press F2 “Self-correcting” to enter the self-correcting program.

Setting Description

Select the display language

English

Automatic Measurements

The oscilloscope can perform five (5) types of automatic measurements: Frequency,

Cycle, Average value, Peak-to-peak value and Root mean square. Two types of

measurements can be displayed on the screen simultaneously.

The function menu for automatic measurements is described in the following table:

Function

menu

Frequency CH1

Cycle CH1

Average value CH1

Peak-to-Peak

value

RMS value CH1

Settings Description

Measures the frequency of CH1

CH2

CH2

CH2

CH1

CH2

CH2

Measures the frequency of CH2

Measures the cycle of CH1

Measures the cycle of CH1

Measures the average value of CH1

Measures the average value of CH2

Measures the peak-to-peak value of CH1

Measures the peak-to-peak value of CH2

Measures root mean square (RMS) value of CH1

Measures root mean square (RMS) value of CH2

40

MS400 Version 2.0 – December 2007

Page 41

To measure the frequency of CH1 with Measurement 1 and the frequency of CH2 with

Measurement 2, perform the following:

1. Press the MENU key; the function menu will be shown at the right of the screen.

2. Press the MENU UP or MENU DOWN key to select MEAS SET1. Five options

appear at the bottom of the screen.

3. Press the F1 key to select the frequency measurement as CH1. The

measurement window 1 on the screen turns red in color and shows the frequency

of CH1.

4. Press the MENU UP or MENU DOWN key to select MEAS SET2 . Five options

appear at the bottom of the screen.

5. Press the F4 key to jump to the peak-to-peak measurement symbolized as CH2.

The measurement window on the screen turns blue in color and shows the peakto-peak value of CH2.

The user can view a screen that looks similar to the following Figure 44.

Figure 44: Automatic Measurements

Cursor Measurements

This oscilloscope allows the user to make manual cursor measurements of time and

voltage. The signal sources include Channel 1 (CH1), Channel 2 (CH2), MATH,

storage Address A and storage Address B.

The cursor measurement menus are listed and described in the following table:

Function

Settings Description

menus

Type Close

Voltage

Time

Signal

sources

CH1, CH2, ATH,

address A and

Closes the cursor measurement

Displays the voltage cursor and menu

Displays the time cursor and menu

Selects the Waveform channel on which the

cursor measurement will be performed

address B.

41

MS400 Version 2.0 – December 2007

Page 42

To make a voltage measurement on CH1, perform the following:

1. Press the MENU key: the function menu will appear at the right of the screen.

2. Press the MENU UP or MENU DOWN key to select CURS MEAS. Two options

are shown at the bottom of the screen.

3. Press the F1 key to select the measurement type Voltage. Two purple crossing

dashed lines V1 and V2 are shown on the screen.

4. Press the F2 key to select the measured channel CH1.

5. Press and hold the OSC OPTION key till the UP/DOWN CURSOR 1 is visible on

the screen. At this time, adjust OSC UP or OSC DOWN and the dashed line V1 is

shown moving up and down while the measured voltage value of V1 relative to

the zero position of CH1 appears on the screen.

6. Press and hold the OSC OPTION key until the UP/DOWN CURSOR 2 appears

on the screen. Now, adjust OSC UP or OSC DOWN and the dashed line V2 will

appear moving up and down while the measured voltage value of V2 relative to

the zero position of CH1 is displayed on the screen. Also, the absolute values of

V1 and V2 can be shown on the screen.

The user can view a screen that looks similar to the following Figure 45.

Figure 45: Use the Cursor for a Voltage Measurement

To use the cursor for a time measurement on CH1, perform the following:

1. Press the MENU key; the function menu will appear at the right of the screen.

2. Press the MENU UP or MENU DOWN key to select Cursor Measurement. Two

key labels are shown at the bottom of the screen.

3. Press the F1 key for measurement type Time. Two vertical dashed lines T1 and

T2 appear on the screen.

4. Press the F2 key to jump to the measured channel CH1.

5. Press and hold the OSC OPTION key until the UP/DOWN CURSOR 1 appears

on the screen. Then adjust OSC UP or OSC DOWN to observe the dashed line

moving left and right. At the same time, the time value of T1 relative to the

screen middle point position will be displayed on the screen.

6. Keep pressing the OSC OPTION key until UP/DOWN CURSOR 2 is displayed on

the screen. Then adjust OSC UP or OSC DOWN so that the dashed line T2 is

moving right and left while the time value of T1, relative to the screen middle

point position, appears on the screen. Observe the absolute time values and

frequencies for T1 and T2.

42

MS400 Version 2.0 – December 2007

Page 43

The user can view a screen that looks similar to the following Figure 46.

Figure 46: Use the Cursor for Time Measurement

System State Menu

The system state menu is used to display information about the present horizontal

system, vertical system, trigger system and others. The operational steps are listed

below:

1. Press the MENU key; the function menu will appear at the right side of the

screen.

2. Press the MENU UP or MENU DOWN key to select SYS STAT. Four options

appear at the bottom of the screen.

3. Sequentially press F1 through F4 and the corresponding status information will

display.

The following Figure 47 will be displayed.

Figure 47: System State

43

MS400 Version 2.0 – December 2007

Page 44

Setting the Time Base Mode

The time base mode menu is detailed in the following table:

Function menu Explanation

Main time base Horizontal main time base is used for waveform

display

Window setting Use two cursors to define a window area

Window extension Expand the defined window to full-screen display

For a Window Extension, use the following steps:

1. Press the MENU key; the function menu will appear on the right side of the

screen.

2. Press the MENU UP or MENU DOWN key to select TIME MODE (three options

appear at the bottom of the display).

3. Press the F2 key to select the window setting.

4. Press the OSC OPTION key to view TIME BASE, then use the OSC LEFT and

OSC RIGHT keys to adjust the time base window area defined by two cursors,

the window size will vary.

5. Press the OSC OPTION key to view the TIME, use the OSC LEFT and OSC

RIGHT keys to adjust the window position defined by two cursors, the window

position is the time difference of the window center to the main time base’s

horizontal pointer.

6. Press F3, select window extension, the defined window extends to a full-screen

display.

Figure 48: Window Setting

44

MS400 Version 2.0 – December 2007

Page 45

Figure 49: Window Extension

Data Transmission

1. Press the MENU key to display the function menu on the right side of the screen.

2. Press the MENU UP or the MENU DOWN key to select the DISP SET mode; four

options appear at the bottom of the display.

3. Press the F4 key and select Bitmap or Vectors for data transmission.

4. Use the supplied cable to connect the meter to the PC.

5. Open the supplied software program on the PC.

6. Set the parameters according to the Software User Guide or from the Help Utility

available inside the software program to start data transmission.

45

MS400 Version 2.0 – December 2007

Page 46

Troubleshooting

1. The oscilloscope will not Power ON

The battery may need recharging. The oscilloscope will not start even if it is powered

by the battery charger. First, charge the battery completely and then supply the

oscilloscope with power through the battery charger. However, do not switch on the

oscilloscope’s power for fifteen minutes. If the oscilloscope still will not start, please

contact Extech Instruments.

2. The oscilloscope shuts OFF after operating for only several seconds

The battery may need recharging. Check the battery symbol at the upper right of the

screen. The

charged.

3. The measurement displays ERR when in the multimeter mode

Make sure the instrument is switched to the measuring mode. Depress any of the

three keys V, A or R. The relative measuring mode will then be shown on the screen.

If ERR is still displayed, restart the meter.

4. The measured voltage amplitude value is 10 times larger or smaller

while in the oscilloscope mode

Check whether the channel attenuation factor matches the actual probe ratio.

5. In the Oscilloscope mode, the Waveform is displayed but is not

stable

symbol indicates that the battery has run out of power and must be

Check whether the setting in the trigger mode menu matches the signal channel

indicated.

Check the trigger mode: The edge trigger mode is applicable to normal

waveforms and the video trigger mode is applicable to video signals. Only when

the proper trigger mode is applied can the Waveform stabilize.

Change the trigger coupling to HF repression and LF repression in order to filter

the HF or LF noise.

6. There is no display on the screen when the RUN/STOP key is pressed

while in the oscilloscope mode

Check whether the trigger mode in the trigger mode menu is in the Normal or the

Single-Shot mode and whether the trigger level is out of the Waveform range. In

such a condition, adjust the middle trigger level or select the non-auto trigger mode.

Additionally, press the AUTO SET key.

7. The display speed is unusually slow when attempting to select the

average sampling in the sampling mode or while selecting a longer

display time in the display mode for the oscilloscope

This is normal.

46

MS400 Version 2.0 – December 2007

Page 47

Appendix

Appendix A: Specifications

Oscilloscope

All technical specifications are applicable with the probe set to the 10X attenuation switch

setting (unless otherwise noted). In order for the instrument to maintain these specifications

the oscilloscope should meet the following requirements:

■ The instrument should operate continuously for more than 30 minutes under specified

operating environmental temperatures.

■ If the variation in ambient temperature is equal to or greater than 5 degrees Celsius,

open the system function menu and perform a “self- calibration”

Sampling:

Sampling modes Normal sampling

Peak detection

Average value

Sampling rate 100 MS/s

Input:

Input coupling DC, AC

Input impedance 1MΩ ±2% connected in parallel with 20pF ±3pF

Probe attenuation coefficient 1X, 10X, 100X, 1000X

Max. Input voltage 400V (peak)

Channel delay time (typical) 150ps

Horizontal:

Sampling rate range 10S/s 100MS/s

Waveform interpolation (sin x)/x

Record length 6K points on each channel

Scanning speed range (S/div) 5ns/div 5s/div, stepping in the “1-2.5-5” mode

Sampling rate and relay time

accuracy

Time interval

(T)measurement

accuracy(full bandwidth)

±100ppm(any time interval which is equal to or larger

than 1ms)

Single: ±(1 sampling interval

time+100ppm×reading+0.6ns)

>average 16 : ±(1 sampling interval time

+100ppm×reading+0.4ns)

47

MS400 Version 2.0 – December 2007

Page 48

Vertical:

Analog digital converter(A/D)

With a resolution of 8 bits, sampling is performed on

both channels synchronously.

Sensitivity range (V/div) 5mV/div~5V/div(at the input BNC)

Displacement range ±50V(500mV~5V),±1V(5mV~200mV)

Analog bandwidth 20M

Single bandwidth Full bandwidth

Low frequency response (AD

≥5Hz (at the BNC)

coupling, -3dB)

Rise time (typical one at the

≤17.5ns

BNC)

DC gain accuracy ±5%

DC measurement accuracy

(average value sampling mode)

The voltage difference (V) between any two points

on the Waveform after averaging the captured

waveforms more than16: ±(5% reading + 0.05

divisions).

Trigger:

Trigger sensitivity (Edge

triggering)

DC

coupling

AC

coupling

CH1 and CH2: 1div(DC~full bandwidth)

Same as the DC coupling when it is equal to

or larger than 50Hz.

Triggering level range ±6 divisions from the screen center

Triggering level accuracy

(typical) which is applicable

to the signal with rise and

fall time equal to or longer

than 20ns

Trigger displacement

Make a 50% level setting

(Typical).

Trigger sensitivity (Video

triggering and typical mode)

Signal system and line/field

frequency (Video triggering

mode)

Measurement:

Cursor

Voltage difference (V) and time difference (T) between cursors

measurement

Auto

measurement

Peak-to-peak value, average value, root mean square value,

frequency and cycle.

±0.3 divisions

655 divisions for pre-triggering and 4 divisions for posttriggering

Operation with the input signal frequency equal to or

larger than 50Hz.

2 divisions of peak-to-peak value

Supports the NTSC, PAL and SECAM broadcasting

systems of any field or line frequency.

48

MS400 Version 2.0 – December 2007

Page 49

Probe:

1X position 10X position

Bandwidth Up to 6 MHz (DC) Up to full bandwidth (DC)

Attenuation rate 1: 1 10: 1

Compensation

10pf~35pf

range

Input resistance 1MΩ±2% 10MΩ±2%

Input impendence 85pf~115pf 14.5pf~17.5pf

Input voltage 150 V DC 300 V DC

Meter

Voltage (VDC)

Input Impedance: 10MΩ.

Max. Input Voltage: 1000V (DC or AC peak-to-peak value)

Range Accuracy Resolution

400.0mv 100uV

±1%±1 digit

4.000V 1mV

40.00V 10mV

400.0V

100mV

Voltage (VAC)

Input Impedance: 10MΩ.

Max. Input Voltage: 750V (AC, virtual value)

Frequency range: from 40Hz to 400Hz.

Display: Virtual value of the sine wave

Range Accuracy Resolution

4.000V 1mV

±1%±3 digits

40.00V 10mV

400.0V

100mV

Direct Current (DC):

Range Accuracy Resolution

40.00mA ±1%±1 digit 10uA

300.0mA ±1.5%±1 digit 100uA

20A (with adaptor) ±3%±3 digits 10mA

Alternating Current (AC):

Range

Accuracy Resolution

40.00mA ±1.5%±3 digits 10uA

300.0mA ±2%±1 digit 100uA

20A (with adaptor) ±5%±3 digits 10mA

49

MS400 Version 2.0 – December 2007

Page 50

Resistance

Range Accuracy Resolution

400.0 Ω ±1%±3 digits 0.1Ω

4.000KΩ 1Ω

±1%±1 digit

40.00KΩ 10Ω

400.0KΩ 100Ω

4.000MΩ

1KΩ

40.00MΩ ±1.5%±1 digit 10KΩ

Capacitance

Range Accuracy Resolution

51.20nF 10pF

±3%±3 digits

512.0nF 100pF

5.120uF 1nF

51.20uF 10nF

100uF

100nF

Diode

Voltage reading: 0 V ~1.5 V.

Continuity Test

A beep will sound when the resistance is less than 30Ω

General Specifications

Mechanical dimension 18 cm×11.5cm×4cm

Weight 645 g

Power consumption <6 W

Display type 3.8" color liquid crystal display

Display resolution 320 (horizontal) ×240 (vertical) pixels

Display color 4096 colors

Power Adapter:

Power supply 100-240 V AC (50/60Hz)

Power output 8.5 VDC

Current output 1500 mA

Ambient Temperature and Relative Humidity:

Temperature (Operational) and Relative Humidity %:

0 to 10°C (32 to 50°F) no condensation

10 to 30°C (50 to 86°F) 95 %

30 to 40°C (86 to 104°F) 75 %

40 to 50 °C (104 to 122°F) 45 %

Temperature (storage) and Relative Humidity %:

-20 to +60°C (-4 to +140°F) no condensation

50

MS400 Version 2.0 – December 2007

Page 51

Appendix B: Maintenance and Cleaning

Common Maintenance

Do not store or place the instrument in locations where the liquid crystal display (LCD)

may be exposed to direct sunlight for long periods of time.

In order to avoid damaging the instrument or the probe, do not expose to liquids or

solvent agents.

Cleaning:

Inspect the instrument and the probe frequently in accordance with the product’s

operating manual. Clean the outer surface of the instrument according to the following

steps:

1. Wipe off obvious dust on the outside of the instrument and on the probe with a soft,

clean cloth. When cleaning the LCD do not scuff the transparent LCD protective

screen.

2. Wipe the instrument clean while it is in its power off status. Use a soft cloth that is

moistened but not dripping wet. The instrument may be cleaned with mild detergent

and fresh water. To prevent damage to the instrument or to the probe do not use

abrasive chemicals, strong detergents or cleansers to clean the product.

Warning: Before powering and starting the product, please confirm that the

instrument has completely dried so as to avoid electrical short circuit and personal injury.

Storing the Oscilloscope

If the oscilloscope is to be stored for a long time, the lithium battery must be fully charged

before storage.

Charging the Oscilloscope

The lithium battery may not arrive fully charged when it is first received by the customer.

To properly charge the battery, it must be charged for 4 hours (the oscilloscope must be

turned off during charging). The battery can supply power for 4 hours after being charged

completely. When utilizing battery power, a battery charge indicator is displayed on the

top of the screen to show the battery’s remaining power level. The symbols that may

appear include

minutes. To charge the battery and power the instrument, connect the oscilloscope using

a power adapter according to Figure 2 to charge the battery. The charging speed can be

increased by turning off the oscilloscope.

Notice: To avoid overheating the battery during charging, the environmental temperature

should not exceed the temperatures listed in the technical Specifications section.

Note: Once the battery is fully charged, the charger will automatically switch itself to a

slower charging rate, thus eliminating the need to turn off the charger at the time the

battery is fully charged.

, , and , where shows that the battery can only be used for about 5

Replacing the Lithium Battery Unit

It is usually not required to replace the battery unit. But when it is required to be replaced

only qualified personnel should carry out this operation and the battery should be

replaced with the same specified lithium battery.

51

MS400 Version 2.0 – December 2007

Loading...

Loading...