Page 1

OTDR

Optical Time Domain Reflectometer

User Guide

Page 2

Copyright © 2013–2014 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

Feature(s) of this product is/are protected by one or more of US

patents 6,612,750; and patent appl. US 2013/0088718 A1 and equivalents in

other countries. The design patent is pending for this product.

Version number: 4.0.1.1

ii OTDR

Page 3

Contents

Contents

Certification Information ......................................................................................................vii

1 Introducing the OTDR .................................................................................. 1

Main Window .........................................................................................................................5

Software Options ....................................................................................................................6

Data Post-Processing ..............................................................................................................6

OTDR Basic Principles ..............................................................................................................7

Conventions ............................................................................................................................9

2 Safety Information ..................................................................................... 11

General Safety Information ...................................................................................................11

Laser Safety Information for FTB-7000 Series (Models without VFL) .....................................12

Laser Safety Information for FTB-7000 Series (Models with VFL) ..........................................13

Laser Safety Information for MAX-700 Series ........................................................................14

3 Preparing Your OTDR for a Test ................................................................. 15

Installing the EXFO Universal Interface (EUI) .........................................................................15

Cleaning and Connecting Optical Fibers ...............................................................................16

Naming Trace Files Automatically .........................................................................................18

Setting the IOR, RBS Coefficient, and Helix Factor ................................................................24

Excluding and Including Span Start and Span End ...............................................................28

Setting the Analysis Detection Thresholds ............................................................................30

Setting Macrobend Parameters .............................................................................................35

Setting Pass/Fail Thresholds ..................................................................................................39

4 Testing Fibers .............................................................................................. 45

Setting the Automatic Acquisition Parameters ......................................................................51

Defining Launch and Receive Fiber Settings ..........................................................................54

Enabling or Disabling the First Connector Check ..................................................................57

Applying Acquisition Settings by Wavelength .......................................................................59

Setting Distance Range, Pulse Width, and Acquisition Time .................................................60

Enabling the High-Resolution Feature ...................................................................................62

Monitoring Fibers in Real-Time Mode ...................................................................................64

OTDR iii

Page 4

Contents

5 Customizing Your OTDR ..............................................................................67

Setting Event Table and Graph Display Parameters ...............................................................67

Selecting the Distance Units .................................................................................................69

Customizing the Acquisition Distance Range Values .............................................................71

Customizing the Acquisition Time Values .............................................................................73

Selecting a Trace Display Mode .............................................................................................75

Selecting the Default View ....................................................................................................76

Setting the Default Storage Folder ........................................................................................78

Selecting the Default File Format ..........................................................................................79

Enabling or Disabling Automated File Saving .......................................................................81

6 Analyzing the Results Manually .................................................................83

Using Markers .......................................................................................................................83

Getting Event Distances and Relative Powers ........................................................................85

Getting Event Loss and Maximum Reflectance .....................................................................87

Getting Section Loss and Attenuation ..................................................................................90

Getting Optical Return Loss (ORL) .........................................................................................92

7 Analyzing Traces and Events ......................................................................93

Graph ...................................................................................................................................94

Summary Tab ........................................................................................................................96

Events Tab .............................................................................................................................99

Measure Tab .......................................................................................................................102

Linear View .........................................................................................................................103

Displaying the Graph in Full Screen ....................................................................................107

Using Zoom Controls ..........................................................................................................109

Viewing Span Start and Span End in Events Table ..............................................................112

Customizing the Events Table Appearance ..........................................................................114

Selecting the Displayed Wavelength ...................................................................................115

Using a Reference Trace ......................................................................................................116

Viewing and Modifying Current Measurement Settings .....................................................119

Modifying Events ................................................................................................................124

Inserting Events ..................................................................................................................128

Deleting Events ...................................................................................................................131

Managing Comments .........................................................................................................132

Analyzing or Reanalyzing a Trace ........................................................................................134

Analyzing the Fiber on a Specific Fiber Span .......................................................................136

Enabling or Disabling the Detection of Reflective Ends of Fiber ..........................................139

Opening Measurement Files ...............................................................................................142

8 Managing Trace Files from the OTDR Test Application ...........................145

iv OTDR

Page 5

Contents

9 Creating and Generating Reports ........................................................... 147

Adding Information to the Test Results ...............................................................................147

Generating a Report ...........................................................................................................149

10 Using the OTDR as a Light Source ........................................................... 155

11 Maintenance ............................................................................................. 159

Cleaning EUI Connectors ....................................................................................................159

Recalibrating the Unit .........................................................................................................162

Recycling and Disposal (Applies to European Union Only) ..................................................163

12 Troubleshooting ....................................................................................... 165

Solving Common Problems .................................................................................................165

Contacting the Technical Support Group ............................................................................167

Transportation ....................................................................................................................167

13 Warranty ................................................................................................... 169

General Information ...........................................................................................................169

Liability ...............................................................................................................................170

Exclusions ...........................................................................................................................170

Certification ........................................................................................................................170

Service and Repairs .............................................................................................................171

EXFO Service Centers Worldwide ........................................................................................172

A Technical Specifications ........................................................................... 173

MAX-710B ..........................................................................................................................173

MAX-715B ..........................................................................................................................174

MAX-720B ..........................................................................................................................175

MAX-730B ..........................................................................................................................176

FTB-7200D ..........................................................................................................................177

FTB-7300E ..........................................................................................................................178

FTB-7400E ..........................................................................................................................179

FTB-7500E ..........................................................................................................................180

FTB-7600E ..........................................................................................................................181

FTB-720 ..............................................................................................................................182

FTB-730 ..............................................................................................................................183

FTB-700G Series ..................................................................................................................184

OTDR v

Page 6

Contents

B Description of Event Types ......................................................................185

Span Start ..........................................................................................................................186

Span End ...........................................................................................................................186

Short Fibers .......................................................................................................................186

Continuous Fiber ...............................................................................................................187

End of Analysis ..................................................................................................................188

Non-Reflective Event ..........................................................................................................189

Reflective Event .................................................................................................................190

Positive Event .....................................................................................................................191

Launch Level ......................................................................................................................192

Fiber Section ......................................................................................................................193

Merged Event ....................................................................................................................194

Echo ..................................................................................................................................200

Reflective Event (Possible Echo) .........................................................................................201

Index ...............................................................................................................203

vi OTDR

Page 7

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

European Community Declaration of Conformity

An electronic version of the declaration of conformity for your product is

available on our website at www.exfo.com. Refer to the product’s page on

the Web site for details.

OTDR vii

Page 8

Page 9

1 Introducing the OTDR

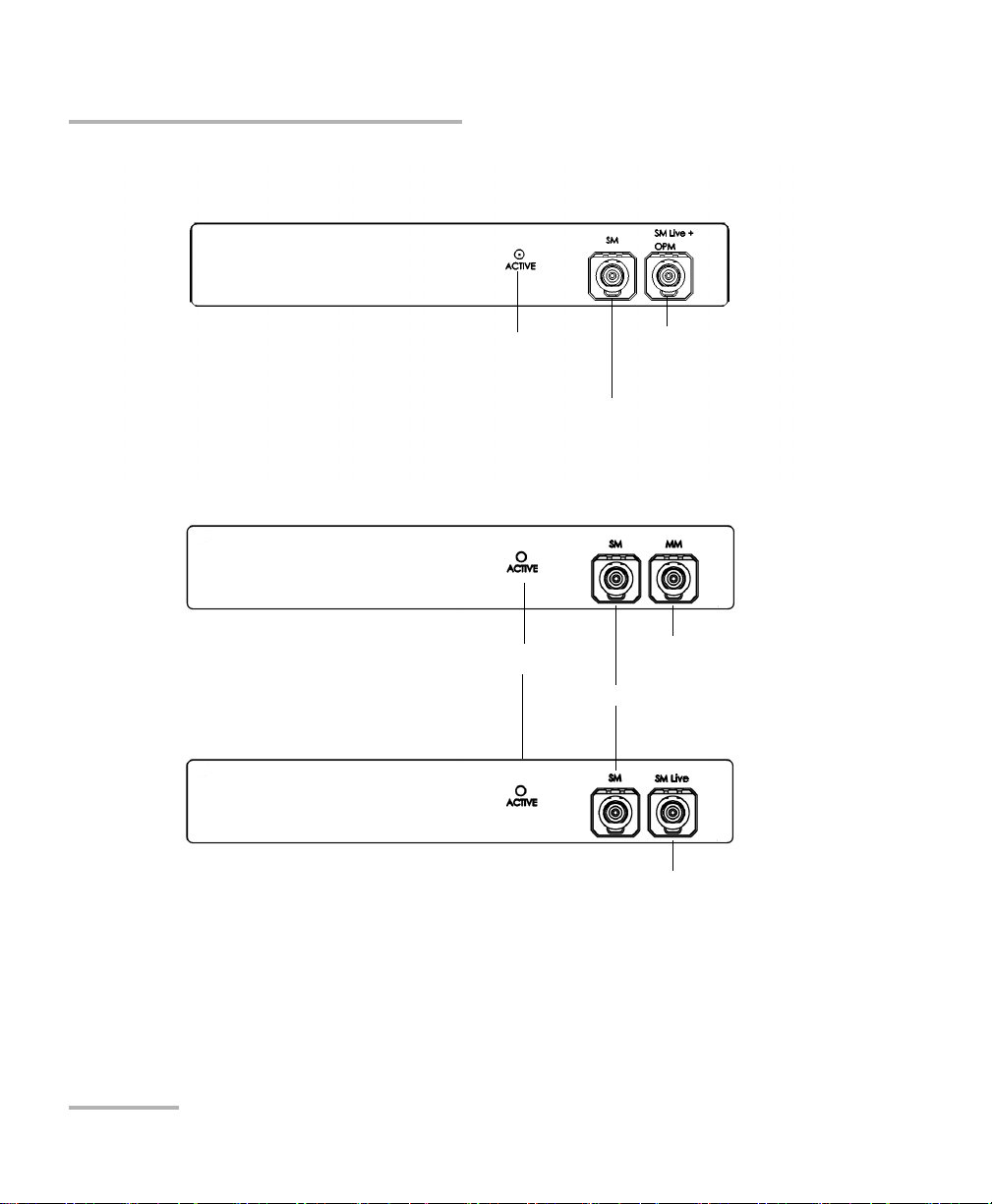

OTDR port (singlemode live)

OTDR port (singlemode)

Active LED

(on when laser is emitting)

MAX-700 Series

The OTDR allows you to characterize a fiber-optic span, usually optical

fiber sections joined by splices and connectors. The optical time domain

reflectometer (OTDR) provides an inside view of the fiber, and can

calculate fiber length, attenuation, breaks, total return loss as well as

splice, connector and total losses.

Note: In this documentation, the words “tap” and “double-tap” (related to the

use of a touchscreen) replace the words “click” and “double-click”.

OTDR 1

Page 10

Introducing the OTDR

SM / MM OTDR

FTB-7200D

SM

MM

LIVE

Handle

Visual fault locator (VFL) port

(optional)

OTDR port (singlemode)

OTDR port (multimode)

Singlemode and

multimode models

Singlemode and

singlemode live

models

SM OTDR

FTB-7300E

SM

SM

OTDR port (for live-fiber testing)

FTB-7000 Series for FTB-2 and FTB-2 Pro

2 OTDR

Page 11

Introducing the OTDR

OTDR

OTDR port

(singlemode or multimode)

Other models

Handle

Visual fault locator

(VFL) port (optional)

FTB-7000 Series for FTB-2 and FTB-2 Pro

OTDR 3

Page 12

Introducing the OTDR

OTDR port (singlemode)

OTDR port (singlemode

live and On-line power

meter)

Active LED

FTB-720 / FTB-720G / FTB-720G+

FTB-730 / FTB-730G / FTB-730G+

OTDR port (singlemode)

OTDR port (multimode)

Active LED

OTDR port

(singlemode live)

4 OTDR

Page 13

Main Window

Event

table

Button bar

Data

display

Graph

overview

window

Introducing the OTDR

Main Window

Note: Due to screen resolution, the appearance of your OTDR application may

vary slightly from the illustrations presented in this user guide.

OTDR 5

Page 14

Introducing the OTDR

Software Options

Software Options

Software options may be offered with your unit.

With the Source (SRC) software option, you can use your OTDR as a

source.

With the Real-Time (RT) software option, when working with the iOLM

application, you can also have access to the OTDR by pressing the

Launch OTDR button. In this case, the only button available to start an

acquisition is the Start Real Time button. Most of the standard OTDR

features, such as the Events tab, the Summary tab, the Identification,

and the Test Configuration button, are disabled.

The following table presents the software options available for your unit.

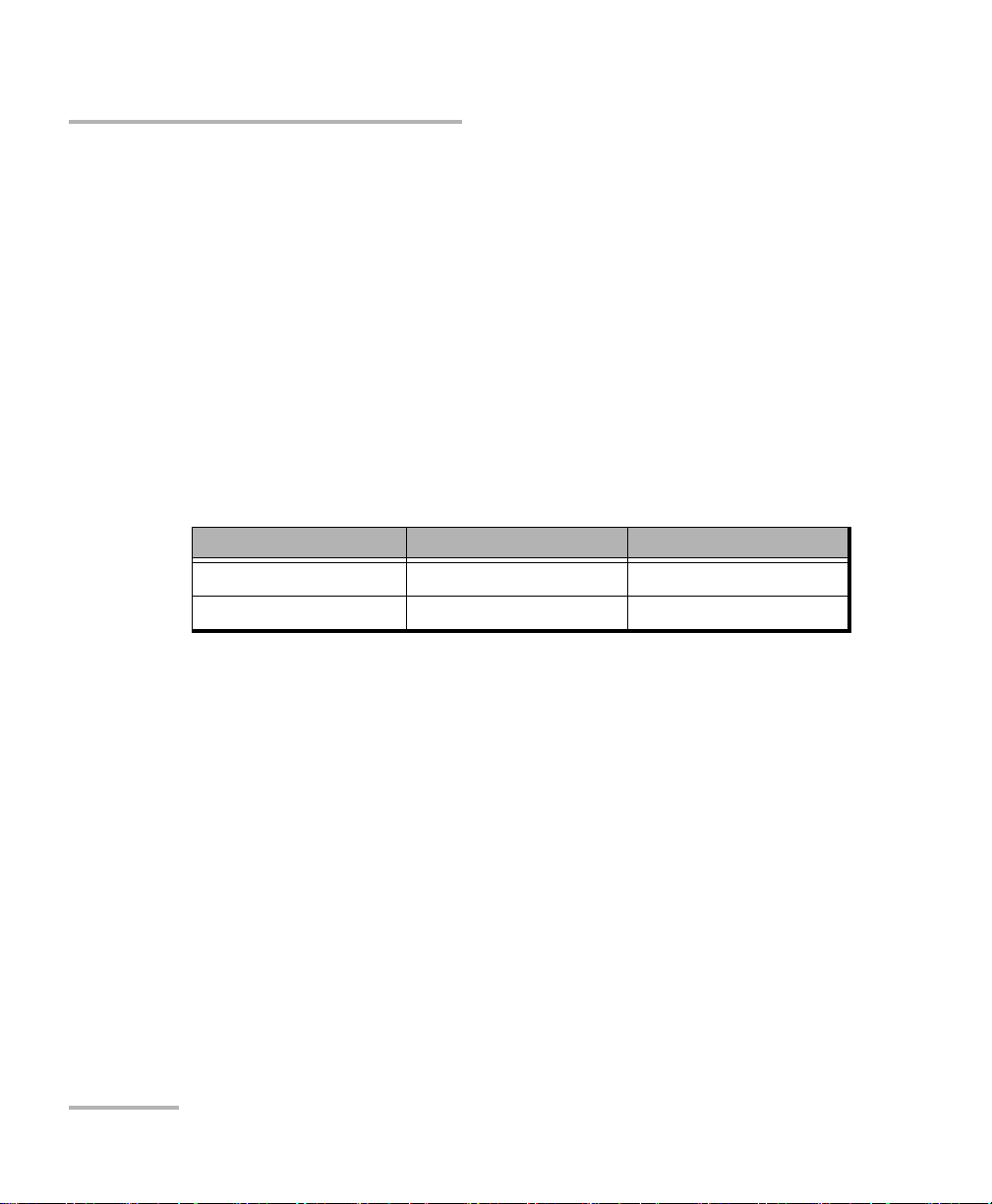

Software Options MAX-700B FTB-2 and FTB-2 Pro

Source (SRC) Available for purchase Already included

Real-Time (RT) Available for purchase Available for purchase

Data Post-Processing

To view and analyze traces without the OTDR application, use a computer

onto which FastReporter is already installed.

6 OTDR

Page 15

Introducing the OTDR

Distance

c

n

-- -

t

2

-- -

=

OTDR Basic Principles

OTDR Basic Principles

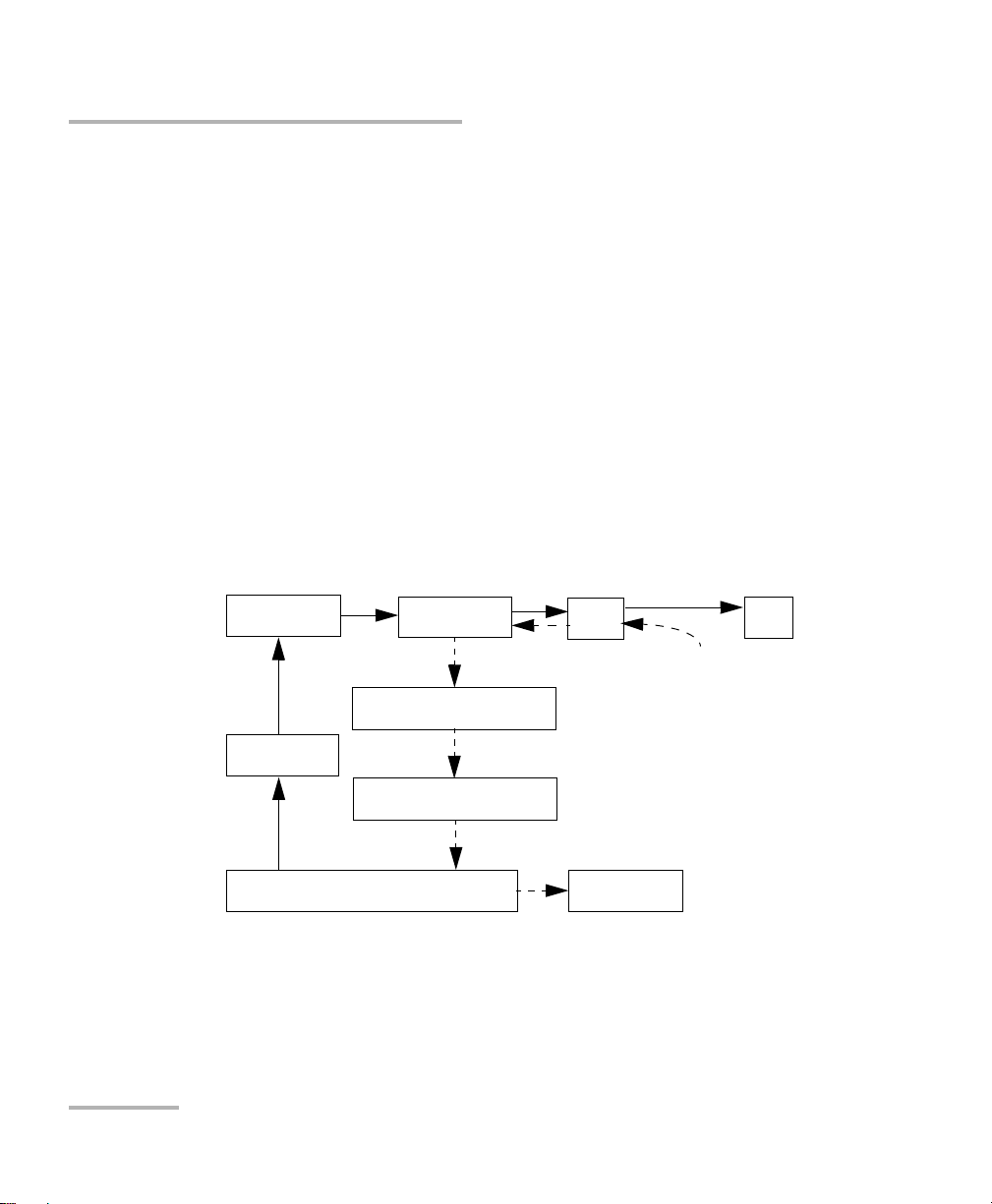

An OTDR sends short pulses of light into a fiber. Light scattering occurs in

the fiber due to discontinuities such as connectors, splices, bends, and

faults. The OTDR then detects and analyzes the backscattered signals. The

signal strength is measured for specific intervals of time and is used to

characterize events.

The OTDR calculates distances as follows:

where

c = speed of light in a vacuum (2.998 x 10

t = time delay from the launch of the pulse to the reception of the

pulse

n = index of refraction of the fiber under test (as specified by the

manufacturer)

8

m/s)

OTDR 7

Page 16

Introducing the OTDR

Microprocessor

Pulse

generator

Avalanche

photodetector (APD)

Display

Reflections come back

to the OTDR

Set of

instructions

Light pulses

Light pulses

Analog-to-digital

converter (A/D)

Returned signal

Analyzed signal

Laser

diode

Optical

coupler

OTDR

port

Fiber

OTDR Basic Principles

An OTDR uses the effects of Rayleigh scattering and Fresnel reflection to

measure the fiber’s condition, but the Fresnel reflection is tens of

thousands of times greater in power level than the backscatter.

Rayleigh scattering occurs when a pulse travels down the fiber and

small variations in the material, such as variations and discontinuities

in the index of refraction, cause light to be scattered in all directions.

However, the phenomenon of small amounts of light being reflected

directly back toward the transmitter is called backscattering.

Fresnel reflections occur when the light traveling down the fiber

encounters abrupt changes in material density that may occur at

connections or breaks where an air gap exists. A very large quantity of

light is reflected, as compared with the Rayleigh scattering. The

strength of the reflection depends on the degree of change in the index

of refraction.

When the full trace is displayed, each point represents an average of many

sampling points. You will have to zoom to see each point.

8 OTDR

Page 17

Introducing the OTDR

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

Conventions

IMPORTANT

Refers to information about this product you should not overlook.

OTDR 9

Page 18

Page 19

2 Safety Information

General Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

IMPORTANT

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

OTDR 11

Page 20

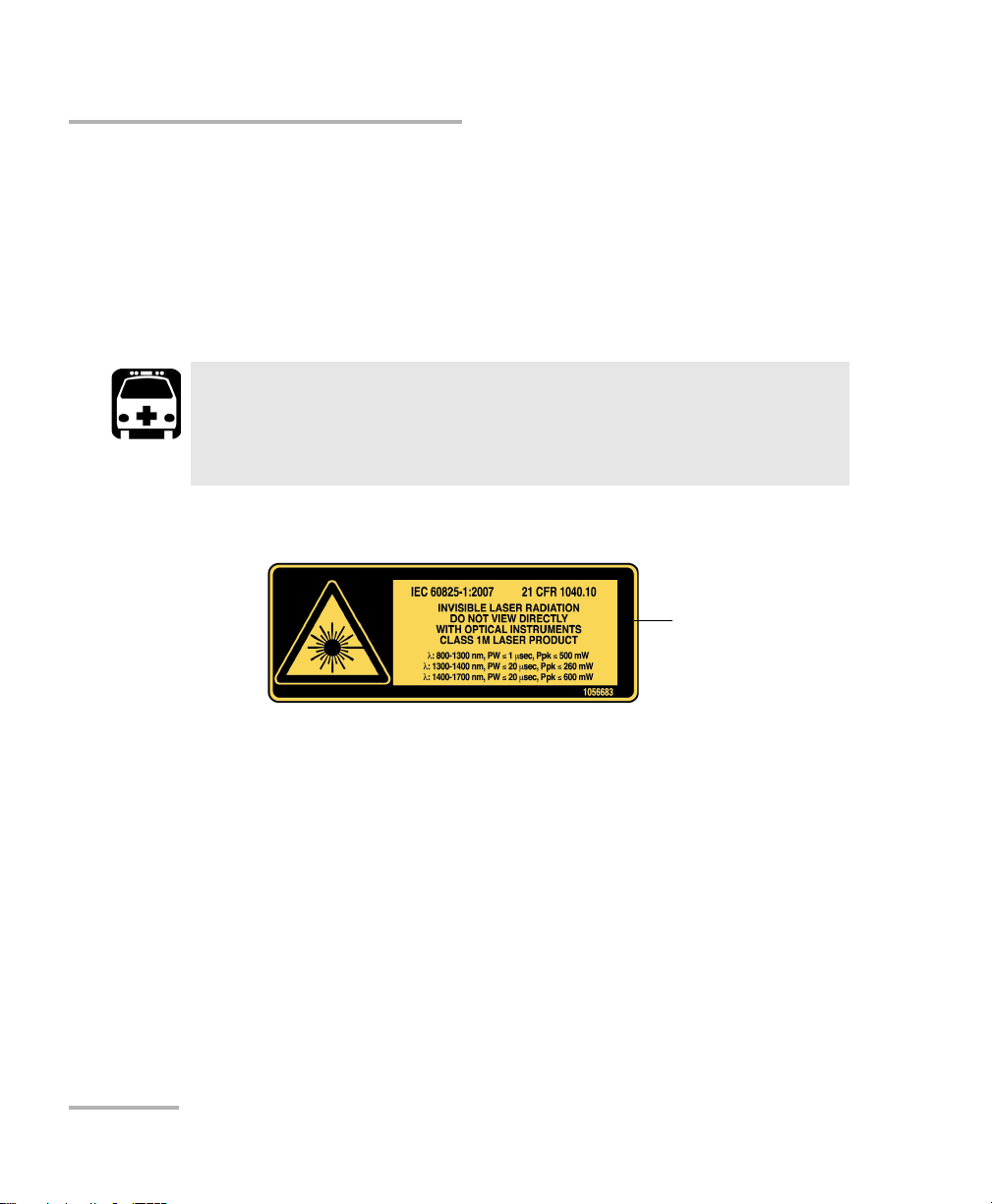

Safety Information

Affixed to module’s

side panel

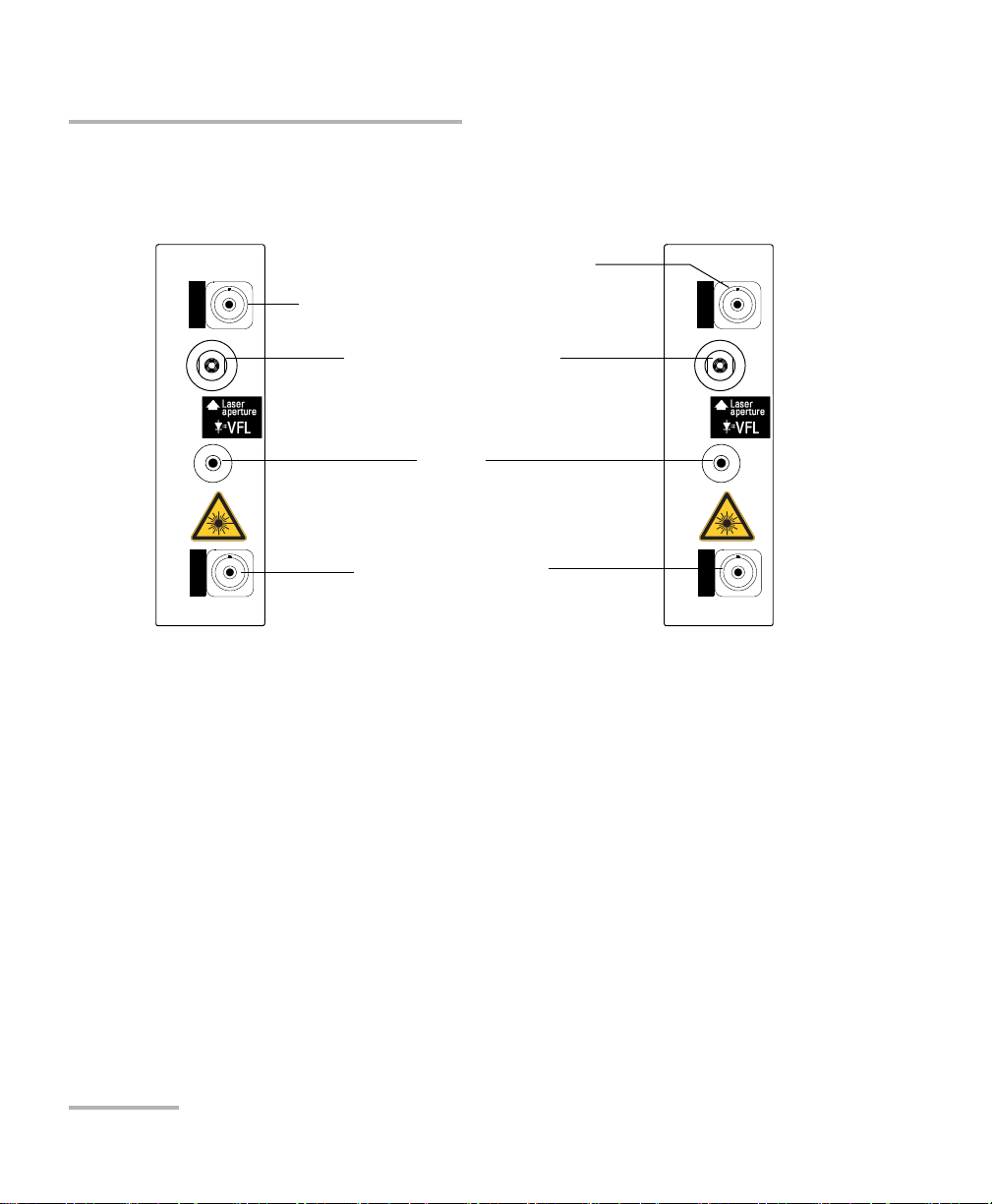

Laser Safety Information for FTB-7000 Series (Models without VFL)

Laser Safety Information for FTB-7000 Series

(Models without VFL)

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1: 2007 and 21 CFR 1040.10, except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. Invisible laser radiation may be

encountered at the output port.

WARNING

Viewing the laser output with certain optical instruments (for

example, eye loupes, magnifiers, and microscopes) within a

distance of 100 mm may pose an eye hazard.

The following label(s) indicate that the product contains a Class 1M source:

12 OTDR

Page 21

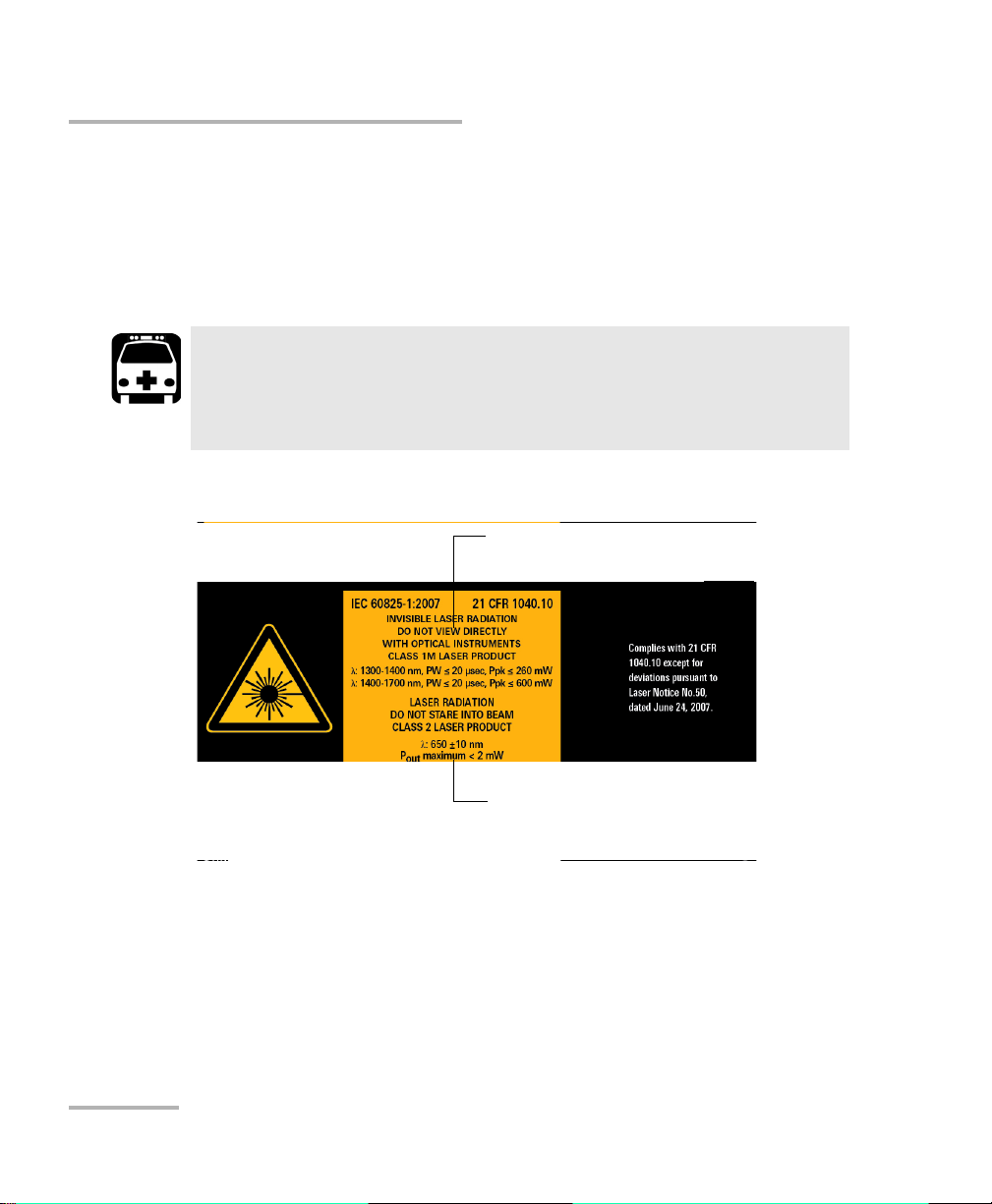

Safety Information

Affixed to module’s

side panel

Laser Safety Information for FTB-7000 Series (Models with VFL)

Laser Safety Information for FTB-7000 Series

(Models with VFL)

Your instrument is a Class 3R laser product in compliance with standards

IEC 60825-1: 2007 and 21 CFR 1040.10, except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. Laser radiation is emitted at the

output port. It is potentially harmful in direct intrabeam viewing.

The following label(s) indicate that the product contains a Class 3R source:

OTDR 13

Page 22

Safety Information

Laser information of the VFL. Always refer to

the user guide of the MaxTester Series for

the exact information.

Laser information of the test instrument

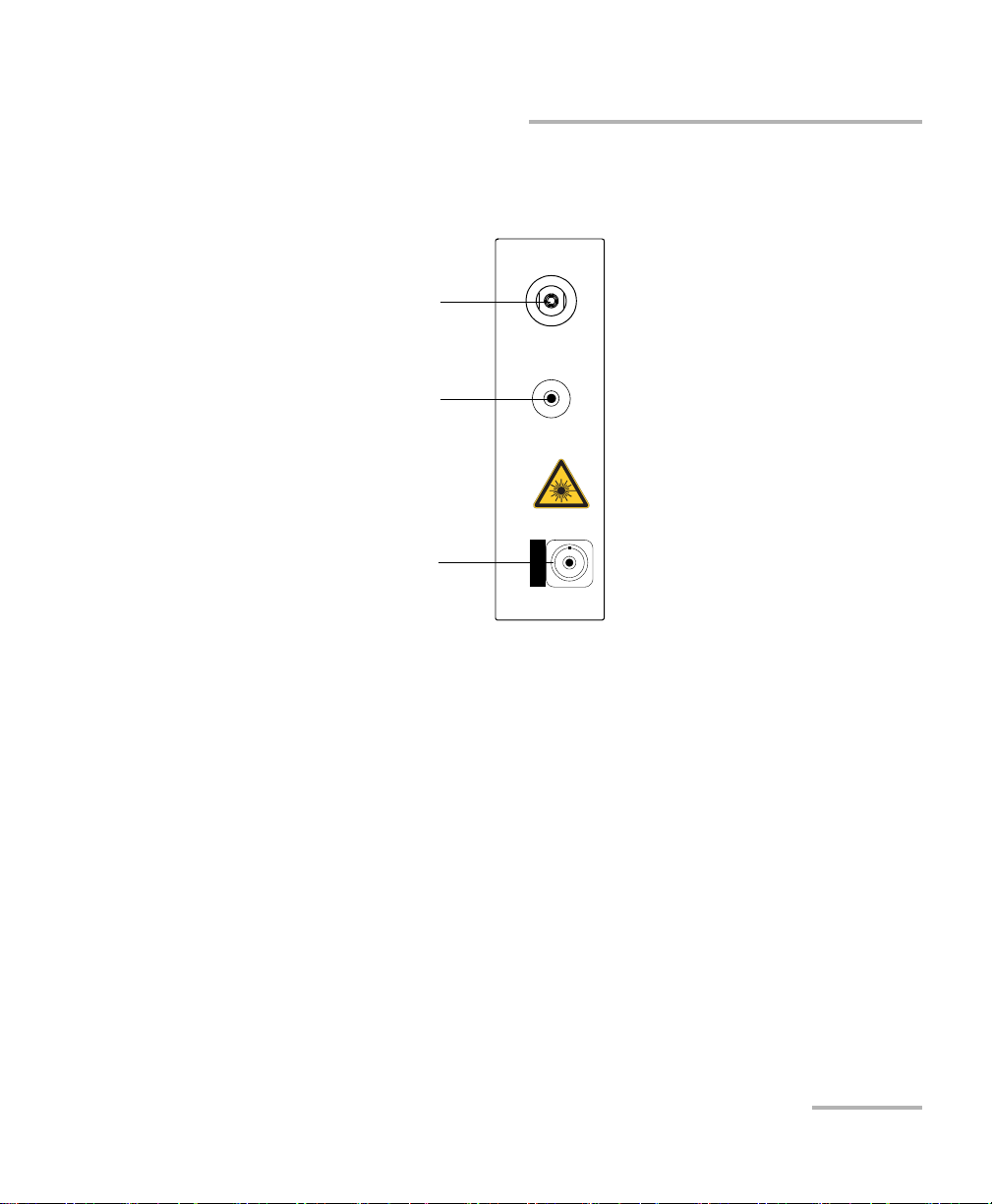

Laser Safety Information for MAX-700 Series

Laser Safety Information for MAX-700 Series

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1: 2007 and 21 CFR 1040.10, except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. Invisible laser radiation may be

encountered at the output port.

Viewing the laser output with certain optical instruments (for

example, eye loupes, magnifiers, and microscopes) within a

distance of 100 mm may pose an eye hazard.

The following label(s) indicate that the product contains a Class 1M source:

WARNING

Note: The label is affixed to the back panel of the unit.

For more information on product safety and equipment ratings, refer to the

user documentation of your platform.

All OTDR modules power consumption is below 10 W.

14 OTDR

Page 23

3 Preparing Your OTDR for a Test

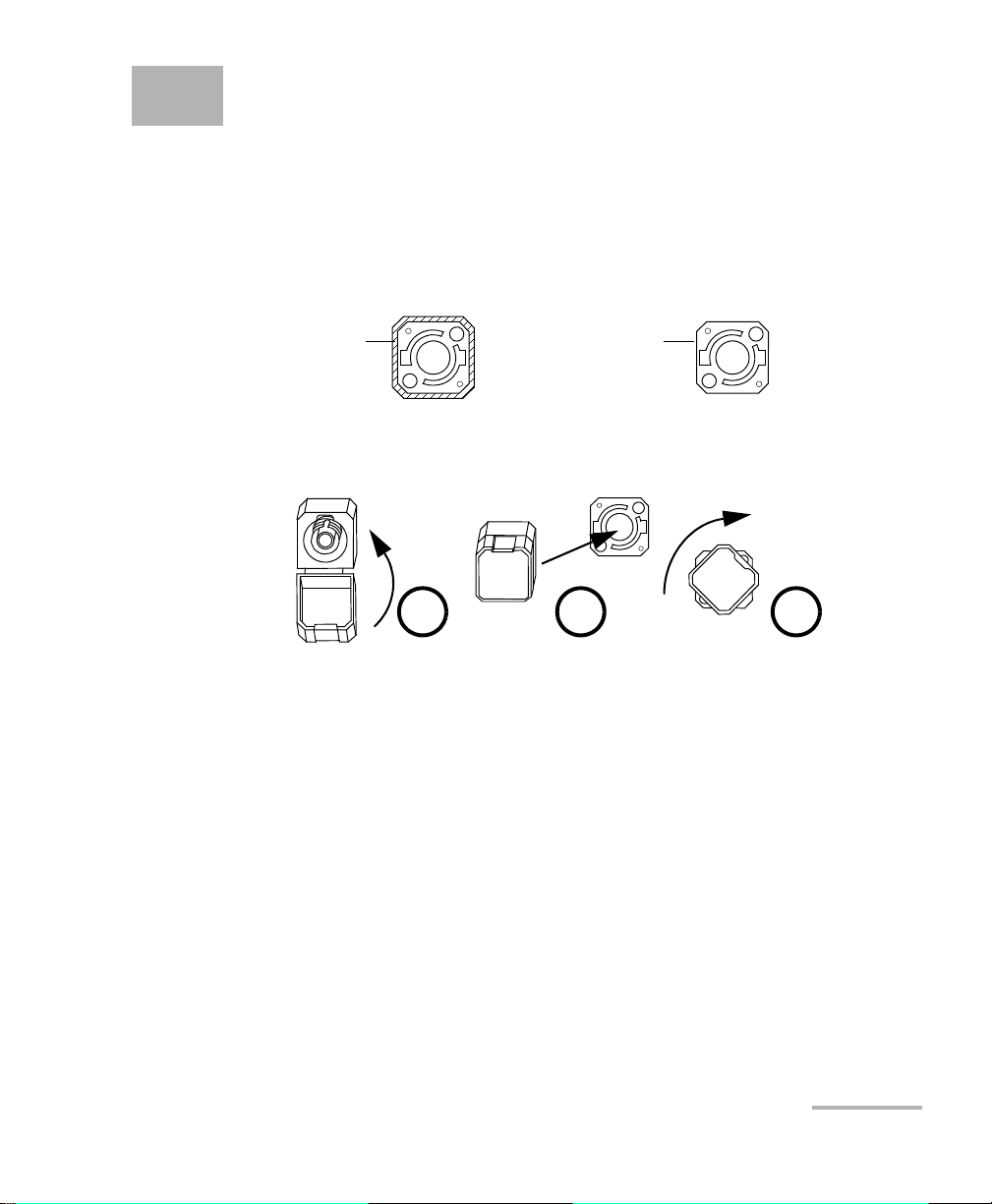

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

OTDR 15

Page 24

Preparing Your OTDR for a Test

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

To ensure maximum power and to avoid erroneous readings:

Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

IMPORTANT

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

16 OTDR

Page 25

Preparing Your OTDR for a Test

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

EXFO uses good quality connectors in compliance with EIA-455-21A

standards.

To keep connectors clean and in good condition, EXFO strongly

recommends inspecting them with a fiber inspection probe before

connecting them. Failure to do so will result in permanent damage to the

connectors and degradation in measurements.

OTDR 17

Page 26

Preparing Your OTDR for a Test

Naming Trace Files Automatically

Naming Trace Files Automatically

Each time you start an acquisition, the application suggests a file name

based on autonaming settings. This file name appears at the bottom of the

window.

The file name is made of one or more static parts (alphanumeric) and one

or more variable parts (numeric) that will be incremented or

decremented, according to your selection, as follows:

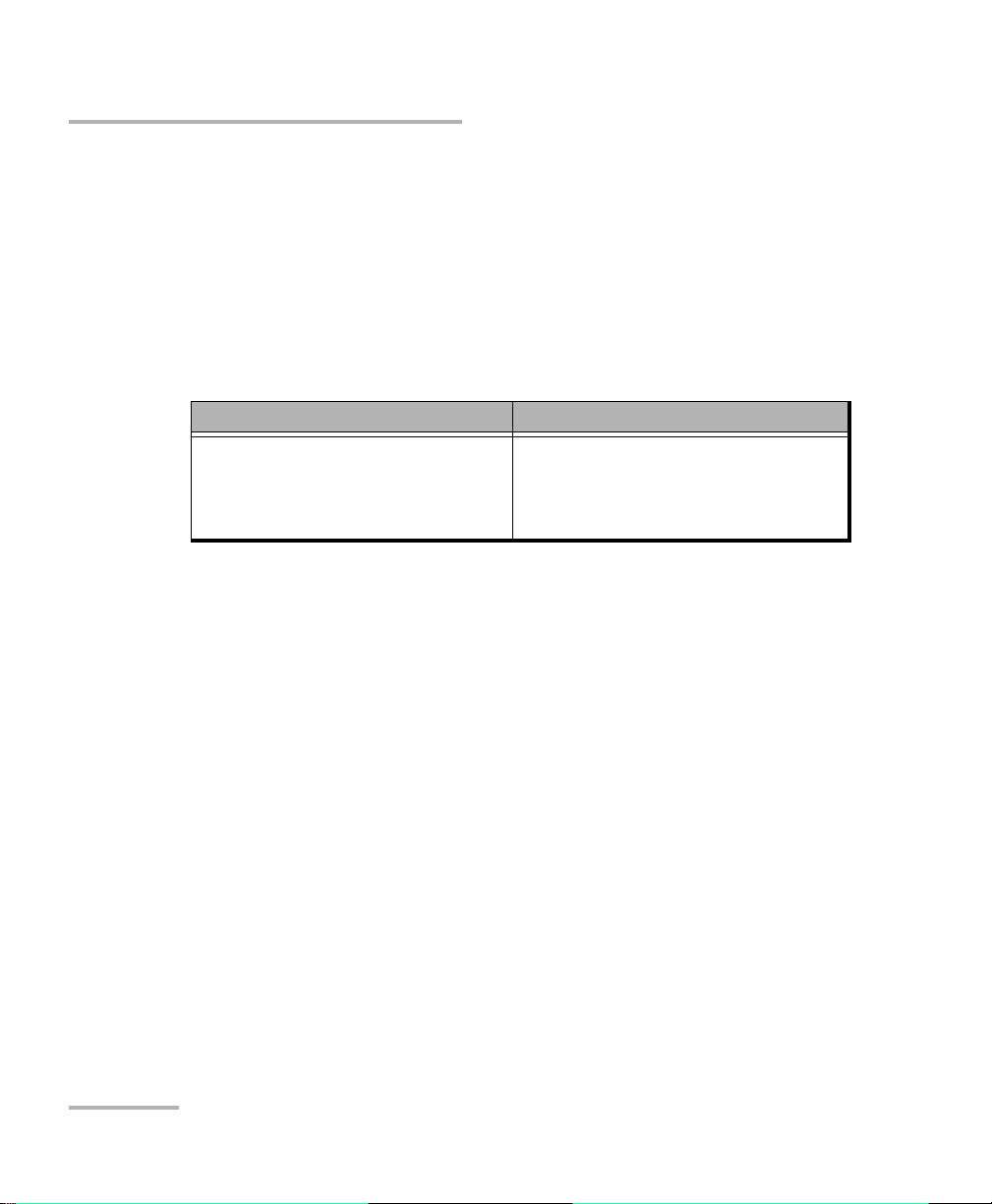

If you choose incrementation... If you choose decrementation...

Variable part increases until it

reaches the highest possible value

with the selected number of digits,

then restarts at 1.

Note: To decrement values, the start number must be higher than the stop

number.

After saving a result, the unit prepares the next file name by incrementing

(or decrementing) the suffix.

Variable part decreases until it

reaches 1, then restarts at the highest

possible value with the selected

number of digits.

18 OTDR

Page 27

Preparing Your OTDR for a Test

Naming Trace Files Automatically

You can select the number of digits displayed for the incremented or

decremented values.

Select "#" if you want to keep the value exactly in the same format as

defined in the start and stop values. If a value is to be incremented from 1

to 10, it becomes 1, 2, 3, ... 9, 10. One "#" is the default format.

Select two, three, or four "#" if you want all values to be expressed with the

same number of digits. The application fills the empty spaces with zeros

before the increment or decrement to ensure the appropriate format is

displayed. For example, if you select two "#" and the value is to be

incremented from 1 to 10, it becomes 01, 02, 03, ... 09, 10.

Note: If you choose not to save a particular trace file, the suggested file name

remains available for the next trace you acquire.

This function is particularly useful when testing multiple-fiber cables.

If you deactivate the automatic file naming function, the application will

use the default file name, which is Unnamed.trc.

By default, traces are saved in native (.trc) format, but you can configure

your unit to save them in Bellcore (.sor) format (see Selecting the Default

File Format on page 79).

Note: If you select the Bellcore (.sor) format, the unit creates one file per

wavelength (for example, TRACE001_1310.sor and TRACE001_1550.sor, if

you included both 1310 nm and 1550 nm in your test). The native (.trc)

format contains all wavelengths in a single file.

The autonaming parameters can be set only for files that have not been

saved yet. You will only see the parameters for the current and next

acquisition (when the test is done but not saved yet), or for the next

acquisition only (test is not done yet). Otherwise, the parameters will not

be displayed.

It is also possible to revert the settings to their default values.

OTDR 19

Page 28

Preparing Your OTDR for a Test

Naming Trace Files Automatically

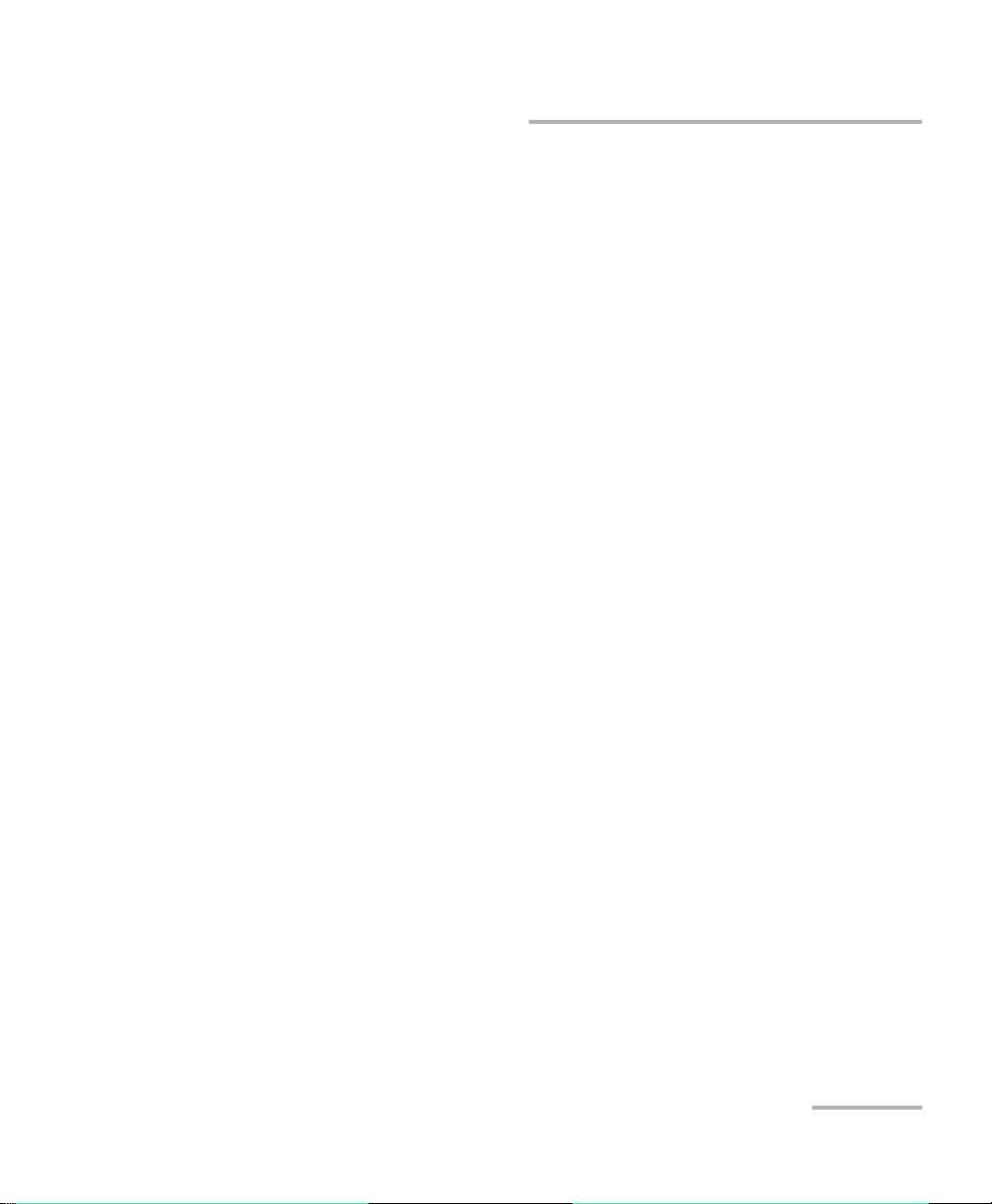

To configure the automatic file naming:

1. From the Main Menu, tap Identification.

2. From the Apply to list, ensure that Next Acquisition or Current and

Next Acquisition is selected.

3. Enter all the information as follows:

3a. Locate the row corresponding to the identifier that you want to

modify.

3b. Tap t he Value column corresponding to the desired identifier.

3c. Enter the information.

Note: You cannot edit the information in the dark gray boxes.

20 OTDR

Page 29

Preparing Your OTDR for a Test

Naming Trace Files Automatically

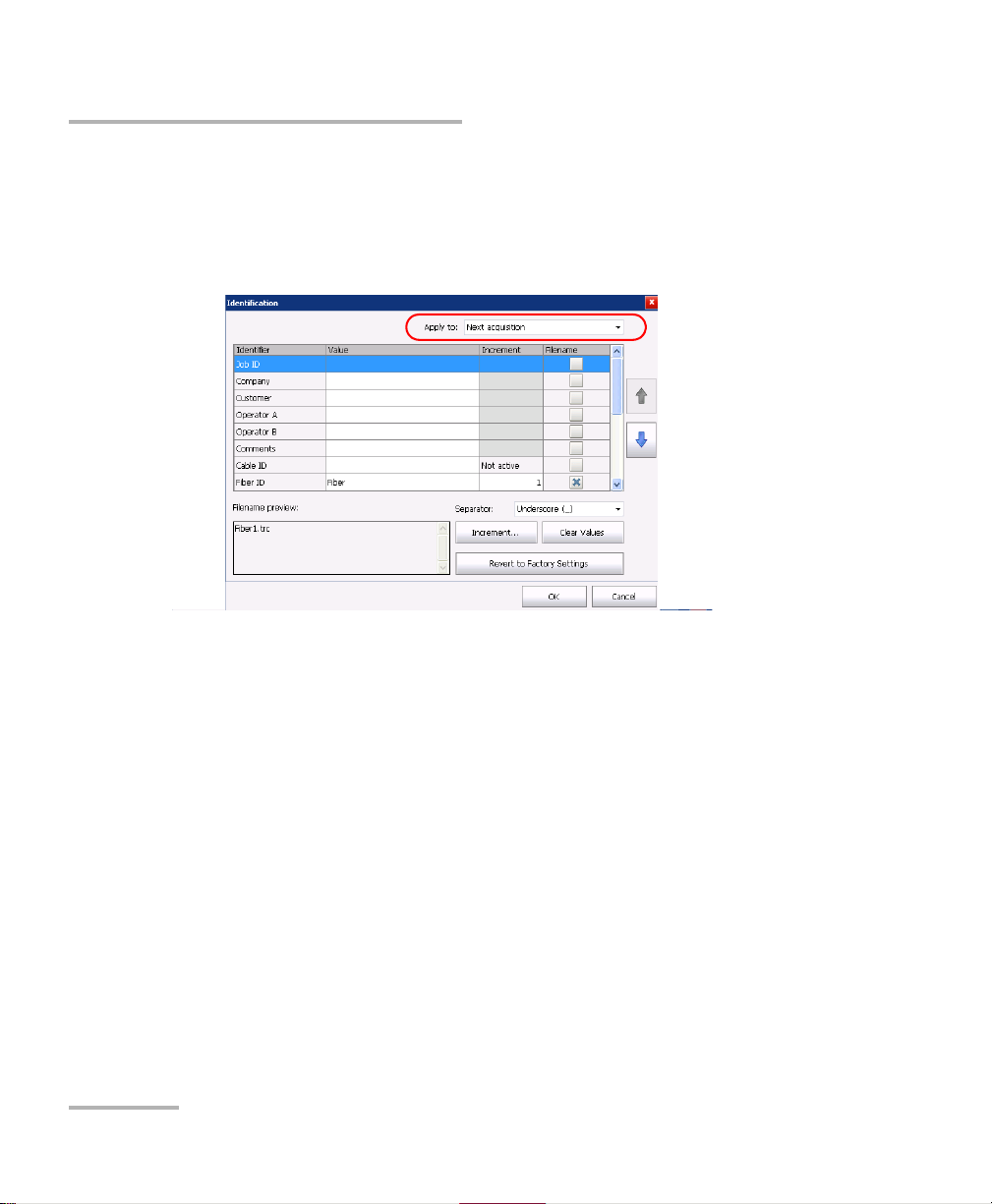

4. If you want to increment automatically the cable ID, the fiber ID or the

location (A and/or B), proceeds as follows:

4a. Tap the Increment button.

4b. In the Increment window, select the Auto Increment check box

corresponding to the identifier you want to increment.

4c. Enter the start, stop and increment values as desired.

Note: To decrement values, the start number must be higher than the stop

number.

4d. Choose the type of format in the list.

4e. Tap OK to return to the Identification window.

OTDR 21

Page 30

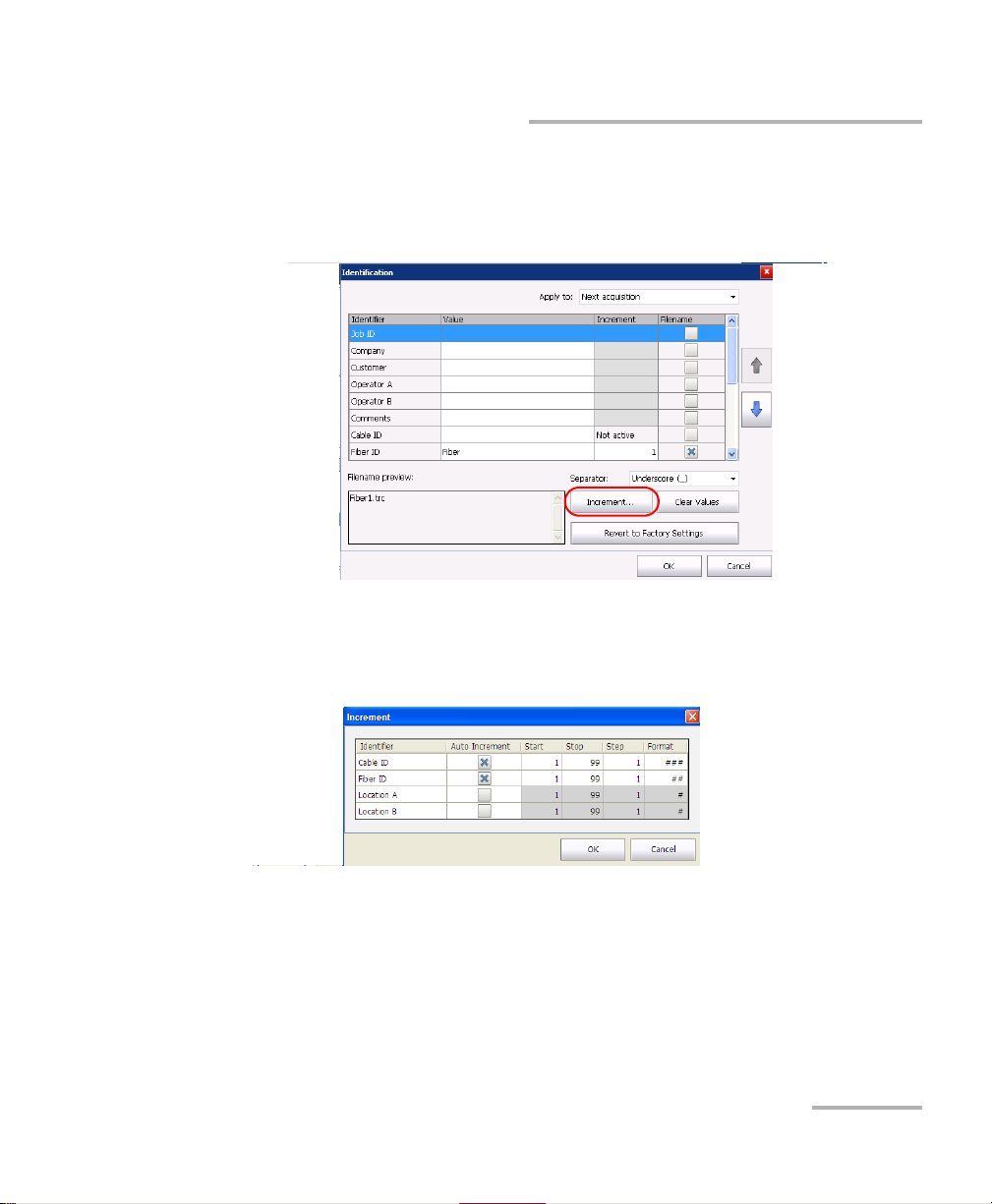

Preparing Your OTDR for a Test

Items that can be

included in the file

name

To modify the order

of appearance of

the selected

identifiers in the

file name

This preview is

updated

automatically as you

make your selections

To s e l e ct t h e

separator in the

automatic

numbering section

To revert to factory settings (not

available for the Current acquisition)

Naming Trace Files Automatically

5. Select the desired identifiers to include in the file name. You can

change the order of appearance of the highlighted component with the

up and down arrow buttons.

6. Ta p OK to confirm your new settings and to return to the main window.

22 OTDR

Page 31

Preparing Your OTDR for a Test

Naming Trace Files Automatically

To clear the values:

1. From the Main Menu, tap Identification.

2. In the Apply to list, select Next acquisition.

3. Ta p the Clear Values button.

4. Ta p OK to return to the main window.

All values in the Value column are erased from the white boxes.

OTDR 23

Page 32

Preparing Your OTDR for a Test

Setting the IOR, RBS Coefficient, and Helix Factor

Setting the IOR, RBS Coefficient, and Helix

Factor

You s hou ld s e t th e IO R (gr oup i nd e x ), backscatter coefficient and helix

factor before performing tests in order to apply them to all newly acquired

traces. However, you can also set them at a later time but in that case, you

have to reanalyze the trace if you change the backscatter coefficient (see

Viewing and Modifying Current Measurement Settings on page 119).

The index of refraction (IOR) value (also known as group index) is

used to convert time-of-flight to distance. Having the proper IOR is

crucial for all OTDR measurements associated with distance (event

position, attenuation, section length, total length, etc.). IOR is provided

by the cable or fiber manufacturer.

The test application determines a default value for each wavelength.

You can set the IOR value for each available wavelength. You should

verify this information before each test.

The Rayleigh backscatter (RBS) coefficient represents the amount of

backscatter in a particular fiber. The RBS coefficient is used in the

calculation of event loss and reflectance, and it can usually be

obtained from the cable manufacturer.

The test application determines a default value for each wavelength.

You can set the RBS coefficient for each available wavelength.

The helix factor represents the ratio between the length of the cable

and the length of the fiber inside the cable. Since fibers within a cable

are spiraling around the cable core, the fiber length is different from

the cable length.

By setting the helix factor, the length of the OTDR distance axis is

always equivalent to the physical length of the cable.

The helix factor is expressed as a percentage. For example, a helix

factor of 1 % implies that the fiber is 1 % longer than the cable. If you

specify a helix factor of 1 %, the displayed length would be reduced by

1 % according to the cable length.

24 OTDR

Page 33

Preparing Your OTDR for a Test

Setting the IOR, RBS Coefficient, and Helix Factor

Thresholds values are saved with the measurement. It is possible to view

these thresholds values even if you open the file on another unit.

You can revert the IOR, RBS Coefficient, and Helix factor to their default

values.

To set the IOR, RBS, and helix factor parameters:

1. From the Main Menu, tap Test Configuration.

2. From the Apply to list, select Next acquisition.

IMPORTANT

In the Apply to list, Next acquisition and Current file will be

displayed if an acquisition was made but was saved. The current

trace settings, as well as the future acquisitions, will be modified.

3. From the Test Configuration window, go to the Link Definition tab.

OTDR 25

Page 34

Preparing Your OTDR for a Test

Wavelength for which

RBS and IOR will be

defined

The Revert to Factory Settings

button resets all the values in

the Link Definition tab

Setting the IOR, RBS Coefficient, and Helix Factor

4. From the Wavelength list, select the desired wavelength.

IMPORTANT

Change the default RBS coefficient only if you have values provided

by the fiber manufacturer. If you set this parameter incorrectly, your

reflectance measurements will be inaccurate.

Note: The helix factor value takes into account the difference between the length

of the cable and the length of the fiber inside the cable; it does not vary with

wavelengths. For this reason, you cannot define a different helix factor for

each wavelength.

26 OTDR

Page 35

Preparing Your OTDR for a Test

Setting the IOR, RBS Coefficient, and Helix Factor

5. If you want to apply the test configuration information to the current

acquisition, proceed as follows:

5a. Tap the Copy to Current Acquisition button.

5b. When the application prompts you, select Yes .

Note: The information in the Link Definition and Pass/Fail Thresholds tabs will

be copied to the current acquisition.

6. Ta p OK to return to the main window.

OTDR 27

Page 36

Preparing Your OTDR for a Test

Excluding and Including Span Start and Span End

Excluding and Including Span Start and Span

End

When applicable, the application includes the losses caused by the span

start and span end events to the span loss value. The application also

includes the ORL caused by the span start and span end events to the span

ORL.

When the spans are included, the loss and reflectance values associated

with the events are taken into account to determine the pass/fail

thresholds.

To exclude or include span starts and span ends:

1. From the Main Menu, select the Test Configuration button.

2. Select the Link Definition tab.

3. Under Calculation and Pass/Fail thresholds, select the inclusion of

the span start and span end you want to display in the table.

OR

To exclude the span start and span end, clear the boxes.

28 OTDR

Page 37

Preparing Your OTDR for a Test

Excluding and Including Span Start and Span End

4. If you want to apply the test configuration information to the current

acquisition, proceed as follows:

4a. Tap the Copy to Current Acquisition button.

4b. When the application prompts you, select Yes .

Note: The information in the Link Definition and Pass/Fail Thresholds tabs will

be copied to the current acquisition.

5. Ta p OK to return to the main window.

OTDR 29

Page 38

Preparing Your OTDR for a Test

Setting the Analysis Detection Thresholds

Setting the Analysis Detection Thresholds

To optimize event detection, you can set the following analysis detection

thresholds:

Splice loss threshold: To display or hide small non-reflective events.

Reflectance threshold: To hide false reflective events generated by

noise, transform non-harmful reflective events into loss events, or

detect reflective events that could be harmful to network and other

fiber-optic equipment.

End-of-fiber threshold: To stop the analysis as soon as an important

event loss occurs; for example, an event that could compromise signal

transmission toward the end of a network.

When the end of fiber detection threshold is modified for an existing

measurement, the span end position at the new end of fiber position

can be automatically reset by the application.

Note: Changing detection thresholds on the current trace leads to a reanalysis. All

manual changes made will be lost.

IMPORTANT

The end-of-fiber (EoF) threshold that you define will be used if you

let the application evaluate the acquisition settings.

If you set this threshold, an EoF event will be inserted at the first

event for which the loss crosses the threshold. The application then

uses this EoF event to determine the acquisition settings.

Setting the thresholds allow you either to ignore events with known lower

values, or to ensure that all events are detected—even the ones for which

very small values are measured.

30 OTDR

Page 39

Preparing Your OTDR for a Test

Event location

Threshold

at 0.05 dB

Threshold

at 0.1 dB

Threshold

at 0.15 dB

Second spliceFirst splice

Not displayed

Not

displayed

Setting the Analysis Detection Thresholds

The following examples show how different splice-loss threshold levels

can affect the number of displayed events, especially small non-reflective

events such as those caused by two splices. Three traces are shown,

corresponding to three threshold level settings.

Threshold at 0.05 dB

With the threshold set to 0.05 dB, two events are displayed at distances

corresponding to the location of the first and second splices.

Threshold at 0.1 dB

Only the first splice is displayed, as the threshold is set to 0.1 dB and

the second splice loss is lower than 0.1 dB.

Threshold at 0.15 dB

The first two splices are not displayed, as the threshold is set to 0.15 dB

and the first and second splice losses are lower than 0.15 dB.

Thresholds values are saved with the measurement. It is possible to view

these thresholds values even if you open the file on another unit.

OTDR 31

Page 40

Preparing Your OTDR for a Test

Setting the Analysis Detection Thresholds

To set the analysis detection thresholds:

1. From the Main Menu, tap Test Configuration.

2. From the Apply to list, select Next acquisition.

3. From the Test Configuration window, go to the Link Definition tab.

32 OTDR

Page 41

Preparing Your OTDR for a Test

Setting the Analysis Detection Thresholds

IMPORTANT

The Revert to Factory Settings button resets all the values in the

Link Definition tab.

4. Under Detection Thresholds, enter the desired values in the

appropriate boxes.

OR

If you want to revert all settings to their default values, tap the Revert to

Factory Settings button.

OTDR 33

Page 42

Preparing Your OTDR for a Test

Setting the Analysis Detection Thresholds

5. If you want to apply the test configuration information to the current

acquisition, proceed as follows:

5a. Tap the Copy to Current Acquisition button.

5b. When the application prompts you, select Yes .

Note: The information in the Link Definition and Pass/Fail Thresholds tabs will

be copied to the current acquisition.

6. Ta p OK to return to the main window.

The analysis detection thresholds you have just set will be applied to future

traces.

34 OTDR

Page 43

Preparing Your OTDR for a Test

Setting Macrobend Parameters

Setting Macrobend Parameters

Your unit can locate macrobends by comparing the loss value of an event

at a given wavelength (for example, 1310 nm) with the loss value at the

same location with another wavelength (for example, 1550 nm).

The unit will identify a macrobend when comparing two loss values if:

Of the two loss values, the greater loss occurred at the greater

wavelength.

AND

The difference between the two loss values exceeds the defined delta

loss value. The default delta loss value is 0.5 dB (which is suitable for

most fibers), but you can modify it.

You can also disable macrobend detection.

Note: Macrobend detection is only possible with singlemode wavelengths.

Filtered wavelengths or port with only one wavelength are not available for

macrobend detection.

For information on how the information about macrobends is available

after an acquisition, see Summary Tab on page 96.

OTDR 35

Page 44

Preparing Your OTDR for a Test

Setting Macrobend Parameters

To set macrobend parameters:

1. From the Main Menu, tap Test Configuration.

2. From the Apply to list, select Next acquisition.

3. Select the Link Definition tab.

4. To enable the macrobend detection, select the Macrobend check box.

OR

To disable it, clear the check box.

36 OTDR

Page 45

Preparing Your OTDR for a Test

Setting Macrobend Parameters

5. If necessary, set the delta value as follows:

5a. From the Wavelengths list, select the pair of wavelengths for

which you want to define the delta value.

Note: Only the combinations of wavelengths your module can support will be

available for a next acquisition. For a current acquisition, the available

wavelength in the file will be used.

5b. In the Delta (loss) box, enter the desired value.

5c. Repeat steps 5a and 5b for all wavelength combinations.

OTDR 37

Page 46

Preparing Your OTDR for a Test

Setting Macrobend Parameters

6. If you want to apply the test configuration information to the current

acquisition, proceed as follows:

6a. Tap the Copy to Current Acquisition button.

6b. When the application prompts you, select Yes .

7. Ta p OK to return to the main window.

38 OTDR

Page 47

Preparing Your OTDR for a Test

Setting Pass/Fail Thresholds

Setting Pass/Fail Thresholds

You can activate and set Pass/Fail threshold parameters for your tests.

Thresholds values are saved with the measurement file. It is possible to

view these thresholds values even if you open the file on another unit.

You can set thresholds for splice loss, connector loss, reflectance, fiber

section attenuation, span loss, span length, and span ORL. You can apply

the same pass/fail thresholds to all test wavelengths or set different

thresholds for each available test wavelength.

These pass/fail thresholds will be applied to the analysis results of all newly

acquired traces as well as current traces with the corresponding

wavelength.

If you work with files containing other wavelengths, the application will

automatically add these wavelengths to the list of available wavelengths.

You will then be able to define thresholds for these new wavelengths. You

can revert all thresholds to their default values.

The loss, reflectance and attenuation thresholds that you set are applied to

all events where such values can be measured.

Once the thresholds are set, the application will be able to perform

Pass/Fail tests to determine the status of the results (pass or fail).

Values that are greater than the predefined thresholds are displayed in

white on a red background in the Events table. Span length, span loss and

span ORL values are displayed in the Summary table.

OTDR 39

Page 48

Preparing Your OTDR for a Test

Value and unit

associated with

the threshold to

set

Setting Pass/Fail Thresholds

To set pass/fail thresholds:

1. From the Main Menu, select Test Configuration.

2. From the Apply to list, select Next acquisition.

3. Select the Pass/Fail Thresholds tab.

In the Apply to list, Next acquisition and Current file will be

displayed if an acquisition was made but was saved. The current

trace settings, as well as the future acquisitions, will be modified.

4. From the Wavelength list, select the wavelength for which you want to

set thresholds.

IMPORTANT

40 OTDR

Page 49

Preparing Your OTDR for a Test

The Revert to Factory

Settings button resets

all the values in the

Pass/Fail Thresholds

tab

Setting Pass/Fail Thresholds

5. Select the boxes corresponding to the thresholds that you want to use,

and enter the desired values in the appropriate fields.

Note: If you no longer want the application to take into account a particular

threshold, simply clear the corresponding check box.

Note: Selecting or clearing a particular thresholds check box will affect all the

available wavelengths, not only the selected one.

OTDR 41

Page 50

Preparing Your OTDR for a Test

Setting Pass/Fail Thresholds

6. If you want to apply the thresholds you have just defined to one or

several other wavelengths, proceed as follows:

6a. Tap the Copy to Other Wavelengths button.

6b. Select the boxes corresponding to the wavelengths for which you

want to use the same thresholds.

Note: You can use the Select All button to quickly select all boxes at the same

time.

6c. Tap OK to confirm you selection.

42 OTDR

Page 51

Preparing Your OTDR for a Test

Setting Pass/Fail Thresholds

7. If you want to apply the test configuration information to the current

acquisition, proceed as follows:

7a. Tap the Copy to Current Acquisition button.

7b. When the application prompts you, select Yes .

Note: The information in the Link Definition and Pass/Fail Thresholds tabs will

be copied to the current acquisition.

8. Ta p OK to return to the main window.

OTDR 43

Page 52

Page 53

4Testing Fibers

Several tools are available to perform complete OTDR tests; you can also

control all test parameters.

By default, all available test wavelengths are selected.

You can either set the acquisition parameters yourself or let the application

determine the most appropriate values.

In the latter case, the application will automatically evaluate the best

settings according to the fiber link currently connected to the unit.

The pulse width will be determined using a factory-defined signal-to-noise

ratio (SNR) requirement specified where the End-of-Fiber (EoF) event has

been detected.

The EoF event detection algorithm uses the end-of-fiber threshold defined

in the Test Configuration window (for more information, see Setting the

Analysis Detection Thresholds on page 30). If you are not sure about which

value to choose, revert to the factory default value for this parameter.

Although the application sets the acquisition parameters, you can modify

these values as needed, even while the acquisition is in progress. The

OTDR simply restarts the averaging each time a modification is made.

Note: You can interrupt the acquisition at any time. The application will display

the information acquired to that point.

OTDR 45

Page 54

Testing Fibers

Event

table

Tra ce

display

After analysis, events appear in the events table. For more information,

see Analyzing Traces and Events on page 93.

You can save the measurement after analysis. If former results have not

been saved yet, the application prompts you to save them before starting a

new acquisition.

46 OTDR

Page 55

Testing Fibers

To acquire traces:

1. Clean the connectors properly (see Cleaning and Connecting Optical

Fibers on page 16).

2. Connect a fiber to the OTDR port.

If your unit is equipped with two OTDR ports, ensure that you connect

the fiber to the appropriate port (singlemode, singlemode live, or

multimode), depending on the wavelength you intend to use.

CAUTION

Never connect a live fiber to the OTDR port without a proper setup.

Any incoming optical power ranging from –65 dBm to –40 dBm will

affect the OTDR acquisition. The way the acquisition will be

affected depends on the selected pulse width.

Any incoming signal greater than 10 dBm could damage your OTDR

module permanently. For live-fiber testing, refer to the SM Live port

specifications for the characteristics of the built-in filter.

3. If you want to set your own IOR (group index), RBS coefficient or helix

factor, see Setting the IOR, RBS Coefficient, and Helix Factor on

page 24.

4. If you want to set the first connector check, see Enabling or Disabling

the First Connector Check on page 57.

OTDR 47

Page 56

Testing Fibers

5. Go to the OTDR tab.

6. If you want to test in high resolution, simply select the feature (see

7. If your OTDR supports singlemode, singlemode live, or multimode

Enabling the High-Resolution Feature on page 62)

wavelengths, from the Port list, select the desired fiber type (for

live-fiber testing, select SM Live; for C fiber, select 50 m and for D fiber,

select 62.5 m).

8. Select the boxes corresponding to the desired test wavelengths.

48 OTDR

Page 57

Testing Fibers

9. Select the desired distance range, pulse, and time values. For more

information, see Setting Distance Range, Pulse Width, and Acquisition

Time on page 60.

Note: To configure different parameters for each wavelength, see Applying

Acquisition Settings by Wavelength on page 59.

10. Tap Start. If the first connector check feature is enabled, a message

will appear if there is a problem with the injection level (see Enabling

or Disabling the First Connector Check on page 57).

Note: The acquisition starts with the selected wavelength. The following

wavelengths are tested in increasing order (smallest to largest).

You can modify the acquisition parameters as needed while the acquisition

is in progress. The OTDR simply restarts the averaging each time a

modification is made. This applies only to the wavelength currently under

test. Changing the time parameter does not restart the acquisition.

OTDR 49

Page 58

Testing Fibers

11. Once the analysis is complete, save the trace by tapping Save in the

button bar.

The application will use a file name based on the autonaming

parameters you defined (see Naming Trace Files Automatically on

page 18). This file name appears in the status bar.

The files that have to be saved are sent in the default file folder

(see Setting the Default Storage Folder on page 78).

Note: The application will only display the Save As dialog box if you have

activated the feature to always be prompted when you save a file. From

this dialog box, you can change the location, the file name and the file

format.

Even if you modify the name of the file, next time you save a trace, the unit

will prepare the next file name by incrementing or decrementing the suffix.

11a.If necessary, change the folder to which the file will be saved by

tapping the parent folder button until you reach the desired

location.

11b.If necessary, specify a file name.

12. Tap OK to confirm.

50 OTDR

Page 59

Testing Fibers

Setting the Automatic Acquisition Parameters

Setting the Automatic Acquisition Parameters

When the auto-settings parameters are activated, the application

calculates the distance and pulse for the first wavelength, then for the

second wavelength, and so on. You can also enable a feature that will let

you select the optimized range and pulse for the distance as determined by

the application when the auto-settings parameters are used at least once.

To set the automatic acquisition parameters:

1. From the main window, go to the OTDR tab.

2. Go to the Time (s) dial and select the appropriate time for your test.

The default value is 15 seconds.

3. Ta p AUTO.

OTDR 51

Page 60

Testing Fibers

Setting the Automatic Acquisition Parameters

4. If you want to keep the auto-settings activated once an acquisition is

done, proceed as follows:

4a. Tap the button.

4b. Under Advanced Parameters, select the Remain in

Auto-Settings box.

4c. Tap OK to return to the main window.

52 OTDR

Page 61

Testing Fibers

Setting the Automatic Acquisition Parameters

5. If you want to use the optimized range feature, proceed as follows:

5a. Tap the button.

5b. Under Advanced Parameters, select the Use optimized range

box.

5c. Tap OK to return to the main window.

6. Ta p Start to launch the acquisition.

OTDR 53

Page 62

Testing Fibers

Defining Launch and Receive Fiber Settings

Defining Launch and Receive Fiber Settings

To define the fiber span start, you can set the launch fiber length. If you do

not know the fiber length, it is also possible to define the launch/receive

fiber by event number.

When you perform tests with your unit, you connect a launch fiber

between your unit and the fiber under test. If the launch and receive fiber

are not defined, the fiber will appear as if it was part of the fiber under test.

When you define the length of the launch fiber, the application sets the

fiber span start at the beginning of the fiber under test. It allows to

characterize the first connector at the beginning of the fiber. Therefore,

only events related to the defined fiber span will be taken into account. The

application will include the loss caused by the span start event in the

displayed values. The span start event will also be taken into account when

determining the status (pass/fail) of connector loss and reflectance.

The span start becomes event 1 and its distance reference becomes 0.

Events excluded from the fiber span are shaded in the event table, and do

not appear in the trace display. The cumulative loss is calculated for the

defined fiber span only.

When you perform tests with your unit, you can connect a receive fiber to

the fiber under test. It allows to characterize the last connector at the end

of the fiber. By default, the fiber span also includes the receive fiber. When

the receive length is mentioned, the application finds the event which is

characterized as the end of fiber and moves the span end according to a

value corresponding to the specified receive fiber length (except for

continuous or end of analysis events).

When the span end is positioned, an event should be near the new

position of the span end. If no event is found, the application will

automatically add an event where there should be one.

The application can also set the span end according to a number of events

instead of using a distance.

54 OTDR

Page 63

Testing Fibers

Defining Launch and Receive Fiber Settings

The application allows you to manually set the lengths or the events of both

your launch and receive fibers.

To set the launch and receive settings for the next acquisition:

1. From the main window, go to the OTDR tab, then tap the button.

2. Under Launch and Receive Fiber, select if you want to apply settings

By fiber lengths or By event.

OTDR 55

Page 64

Testing Fibers

Defining Launch and Receive Fiber Settings

3. Select the check boxes corresponding to your needs and enter the

appropriate information in the boxes.

4. Ta p OK to return to the main window.

56 OTDR

Page 65

Testing Fibers

Enabling or Disabling the First Connector Check

Enabling or Disabling the First Connector

Check

The first connector check feature is used to verify that the fibers are

properly connected to the OTDR. It verifies the injection level and displays

a message when an unusually high loss occurs at the first connection,

which could indicate that no fiber is connected to the OTDR port. By

default, this feature is disabled.

To enable or disable the first connector check:

1. From the main window, tap the OTDR tab then tap the button.

OTDR 57

Page 66

Testing Fibers

Enabling or Disabling the First Connector Check

2. Under Advanced Parameters, to enable the first connector check,

select the First connector check box.

OR

To disable it, clear the box.

3. Ta p OK to return to the main window.

58 OTDR

Page 67

Testing Fibers

Applying Acquisition Settings by Wavelength

Applying Acquisition Settings by Wavelength

By default, the modifications made to the parameters (distance, pulse, and

time) are applied to all wavelengths. However, it is possible to modify the

acquisition parameters independently for each wavelength.

To apply acquisition settings by wavelength:

1. From the main window, select the OTDR tab then tap the button.

2. Under Advanced Parameters, select the Apply settings by

wavelength box.

3. Ta p OK to return to the main window.

You can now set the distance range, the pulse width, and the

acquisition time independently for each wavelength.

OTDR 59

Page 68

Testing Fibers

Setting Distance Range, Pulse Width, and Acquisition Time

Setting Distance Range, Pulse Width, and

Acquisition Time

The distance range, pulse width and acquisition time are set with the

controls in the OTDR main window.

Distance: corresponds to the distance range of the fiber under test

according to the selected measurement units (see Selecting the

Distance Units on page 69).

Changing the distance range modifies the available settings of the

pulse width and leaves only the settings available for the specified

range.

Pulse: corresponds to the pulse width for the test. A longer pulse

allows you to probe further along the fiber, but results in less

resolution. A shorter pulse width provides higher resolution, but less

distance range. The available distance ranges and pulse widths

depend on your OTDR model.

Note: Not all pulse widths are compatible with all distance ranges.

Time: corresponds to the acquisition duration (period during which

results will be averaged). Generally, longer acquisition times generate

cleaner traces (this is especially true with long-distance traces)

because as the acquisition time increases, more of the noise is

averaged out. This averaging increases the signal-to-noise ratio (SNR)

and the OTDR’s ability to detect small events.

The time settings will also determine how the timer (displayed in the

toolbar) counts time during testing.

60 OTDR

Page 69

Testing Fibers

Parameter-setting dials

Selection

marker

Setting Distance Range, Pulse Width, and Acquisition Time

You can use the same distance range, pulse width and acquisition time

parameters for testing at all wavelengths on a multiwavelength OTDR. For

more information, see Applying Acquisition Settings by Wavelength on

page 59.

IMPORTANT

To test the high-resolution feature, you must set a minimum

acquisition time of 15 seconds.

To set the parameters:

From the OTDR tab:

Tap the dial corresponding to the parameter you wish to set (the

selection marker will move clockwise).

OR

Tap directly the value to select it. The selection marker will go to that

value immediately.

Note: If your OTDR supports singlemode, singlemode live, or multimode

wavelengths, settings would be applied to either singlemode, singlemode

live, or multimode wavelengths, depending on the selected fiber type

(same settings for 50 m and 62.5 m).

OTDR 61

Page 70

Testing Fibers

Enabling the High-Resolution Feature

Enabling the High-Resolution Feature

Note: This feature applies only to the FTB-2 and FTB-2 Pro platforms.

You can select the high-resolution feature to obtain more data points per

acquisition. This way, the data points will be closer to each other, which

will result in a greater distance resolution for the trace.

Note: When you test with the high-resolution feature, you should use a longer

averaging time to maintain a signal-to-noise ratio (SNR) that will be

equivalent to the one you would have had with the standard resolution.

IMPORTANT

To test the high-resolution feature, you must set a minimum

acquisition time of 15 seconds.

62 OTDR

Page 71

Testing Fibers

Enabling the High-Resolution Feature

To enable the high-resolution feature:

1. From the main window, select the OTDR tab then tap the button.

2. Under Advanced Parameters, select the High-resolution acquisition

box.

Note: If your OTDR supports singlemode, singlemode live, or multimode

wavelengths, the high-resolution feature will be activated either for the

singlemode, singlemode live, or multimode wavelengths, depending on the

selected fiber type.

3. Ta p OK to return to the main window.

OTDR 63

Page 72

Testing Fibers

2

1

Monitoring Fibers in Real-Time Mode

Monitoring Fibers in Real-Time Mode

The application allows you to immediately view sudden changes in the

fiber link. In this mode, the trace is refreshed instead of averaged until you

switch to average mode or stop the acquisition.

Note: You cannot reanalyze a trace in real-time mode.

Note: In real-time mode, the trace is refreshed at a slower rate when the graph

overview window is displayed.

Note: You can only use one wavelength at a time to monitor your fiber.

You can switch from real-time mode to the averaging time interval mode at

any time. You can also switch between wavelengths during an acquisition

(all wavelengths must be selected before starting the test).

To activate the real-time mode:

1. If your module supports singlemode, singlemode live, or multimode

wavelengths, specify the desired fiber type (for live-fiber testing, select

SM Live; for C fiber, select 50 m and for D fiber, select 62.5 m).

2. From the wavelength list, ensure that all the desired wavelengths are

selected.

64 OTDR

Page 73

Testing Fibers

Monitoring Fibers in Real-Time Mode

3. If you have the full OTDR application, tap RT. The RT button turns

orange to show that the real-time mode is activated.

4. If you have the full OTDR application, tap Start RT.

OR

If you only have access to the OTDR in Real Time mode, tap Start Real

Time.

Note: The timer is not displayed during real-time acquisition.

5. From the wavelength list, tap the wavelength value (not the checkbox)

corresponding to the wavelength that you want to monitor.

Note: Ensure that the wavelength is highlighted.

OTDR 65

Page 74

Testing Fibers

Monitoring Fibers in Real-Time Mode

To deactivate the real-time mode:

If you have the full OTDR application, when you want to stop

monitoring, tap Stop RT.

OR

If you only have access to the OTDR in Real Time mode, tap Stop Real

Time.

If you have the full OTDR application, you can also stop the real-time

acquisition by starting an averaged acquisition. All the wavelengths for

which boxes are selected will be tested in averaging time interval

mode (not only the highlighted one).

66 OTDR

Page 75

5 Customizing Your OTDR

Graph

overview

window

You can customize the appearance and behavior of your OTDR application.

Setting Event Table and Graph Display Parameters

You can include or exclude items from the events table to better suit your

needs. You can also change several trace display parameters:

Note: Hiding the fiber sections will not delete these items.

Fiber sections: You can display or hide fiber sections in the events table,

depending on the types of values you want to display. When the fiber

sections are hidden, the Att. column is also hidden.

the gridlines: You can display or hide the grid appearing on the graph’s

background. By default, the grid is displayed.

the graph background: You can display the graph with a black (invert

color feature) or a white background. By default, the background is

white.

the graph overview: The graph overview window shows you which

portion of the graph is being magnified.

Note: The application always generates graphs with a white background in the

reports.

OTDR 67

Page 76

Customizing Your OTDR

The Revert to Factory Settings

button resets all the values in

the General tab

Setting Event Table and Graph Display Parameters

To set the event table and graph display parameters:

1. From the Main Menu, select the User Preferences button.

2. Select the General tab.

3. Under Display, select the boxes corresponding to the item you want to

display or include in the table.

OR

To hide them, clear the boxes.

4. Ta p OK to return to the main window.

68 OTDR

Page 77

Customizing Your OTDR

Distance units

Selecting the Distance Units

Selecting the Distance Units

You can select the measurement units that will be used throughout the

application.

The default distance units are the kilometers.

Note: The attenuation of fiber sections is always presented in dBs per kilometer

even if the distance units you selected are not the kilometers. This follows

the standards of the fiber-optic industry that provides the attenuation

values in dBs per kilometer.

OTDR 69

Page 78

Customizing Your OTDR

Selecting the Distance Units

To select the distance units for your display:

1. From the button bar, tap User Preferences.

2. From the User Preferences window, select the General tab.

3. From the Distance unit list, select the item corresponding to the

desired distance units.

4. Ta p OK to return to the main window.

You return to the main window and the newly selected distance unit

appears everywhere units are used.

70 OTDR

Page 79

Customizing Your OTDR

Customizing the Acquisition Distance Range Values

Customizing the Acquisition Distance Range

Values

You can customize the values associated with the Range dial. Once the

customization is complete, you are ready to set the distance range value

for your test. For more information, see Setting Distance Range, Pulse

Width, and Acquisition Time on page 60.

Note: The value found by an auto acquisition cannot be modified.

To customize the distance range values:

1. From the main window, select the OTDR tab then tap the button.

2. Under Custom Parameters, if your OTDR supports singlemode or

multimode, specify the desired fiber type.

Note: The fiber type list is not displayed if the module has only one fiber type.

OTDR 71

Page 80

Customizing Your OTDR

Customizing the Acquisition Distance Range Values

3. From the Range list, select the value you want to modify.

4. When the value becomes highlighted, enter the new value.

5. Ta p OK to return to the main window.

Note: You can revert to factory values by pressing the Revert to Factory Settings

button.

72 OTDR

Page 81

Customizing Your OTDR

Customizing the Acquisition Time Values

Customizing the Acquisition Time Values

You can customize the values associated with the Duration (s) dial. The

acquisition time values represent the time during which the OTDR will

average acquisitions.

You can customize the acquisition time to improve the signal-to-noise ratio

(SNR) of the trace and enhance the detection of low-level events. The SNR

improves by a factor of two (or 3 dB) each time the acquisition time is

increased by a factor of four.

To customize the acquisition time values:

1. From the main window, select the OTDR tab then tap the button.

2. Under Custom Parameters, from the Duration (s) list, select the value

you want to modify.

OTDR 73

Page 82

Customizing Your OTDR

Customizing the Acquisition Time Values

3. When the value becomes highlighted, enter the new value.

4. Ta p OK to return to the main window.

Note: You can revert to factory values by pressing the Revert to Factory Settings

button.

74 OTDR

Page 83

Customizing Your OTDR

Selecting a Trace Display Mode

Selecting a Trace Display Mode

You can choose the way the application will display traces on-screen and

in reports. The available choices are:

Complete trace: to display the whole trace and full acquisition

distance.

Span: to display the trace from the span start to the span end.

To select a trace display mode:

1. From the Main Menu, select the User Preferences button.

2. Select the General tab.

3. From the Trace display mode list, select a display mode.

4. Ta p OK to return to the main window.

OTDR 75

Page 84

Customizing Your OTDR

Selecting the Default View

Selecting the Default View

You can select which view will be displayed by default once all the

acquisitions are performed (at all the selected wavelengths) and the

analysis of the last wavelength is complete. The default view will also be

used when opening a measurement file.

The table below indicates the views that can be displayed.

View Remarks

Keep current The tab selected before the acquisition is

OTDR Displays the graph and the control dials (lists

Events Default view.

started remains the same once the acquisition

is complete.

when graph is in full view) for the OTDR

acquisitions.

For more information, see Graph on page 94.

Displays the results in the Events table after an

acquisition.

Measure Displays the results in the Measure table after

an acquisition. This view allows you to take

measurement with markers manually.

Summary table This table gives, for each wavelength,

information such as: the pass/fail status of the