Page 1

OSICS Multifunction Platform

8-Channel Modular Platform

Programming Guide

www.EXFO.com

OSICS_PG_3v2.2

Page 2

Page 3

About This Manual

Subject This manual specifies the remote interfaces of the OSICS Mainframe and modules and

the corresponding remote commands.

Application Information in this document applies to the OSICS Mainframe version 3.06 and the

following versions of OSICS modules:

• OSICS ATN v. 1.07 and higher versions

• OSICS BKR v. 1.07 and higher versions

• OSICS DFB v. 2.38 and higher versions

• OSICS SLD v. 1.03 and higher versions

• OSICS SWT v. 1.07 and higher versions

• OSICS SWT-APC v. 1.13 and higher versions

• OSICS T100 v. 3.05 and higher versions

• OSICS TLS-AG v. 3.14 and higher versions

Intended Readers Users of this manual must be familiar with:

• Fiber optic technology

• The RS-232C and/or IEEE-488.1 interfaces used to operate the OSICS in remote

mode

• The use of the OSICS multifunction platform (see OSICS User Guide)

Date 17 September 2018

Manual Reference OSICS_PG_3v2.2

Typographical

Conventions

Command Syntax

Notation

Conventions

bold Identifies graphical interface objects such as menu names, labels,

italic Identifies references to other sections or other guides.

monospace Identifies portions of program codes, command lines, or messages

IMPORTANT Identifies important information to which you must pay particular

Notation Meaning

[...] The content between square brackets is optional.

<...> The content between angled brackets indicates the type of

| Indicates an alternative. Equivalent to "or".

buttons and icons.

displayed in command windows.

attention.

information that you must enter as parameter (command) or that is

received (response).

# Represents a numeric suffix, for example an OSICS slot number.

OSICS Programming Guide 3

Page 4

About This Manual

Symbols

Abbreviations

Used

Warning

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury. Do not proceed unless you understand and meet

the required conditions.

Caution

Indicates a potentially hazardous situation which, if not avoided, may result in

component damage. Do not proceed unless you understand and meet the

required conditions.

Abbreviation Meaning

GPIB General Purpose Interface Bus

LF line feed

CR carriage return

EOI End-Or-Identify

LSB Least Significant Bit

Copyright Copyright © 2012–2018 by EXFO. Published by EXFO. All rights reserved.

This documentation is provided as a user guide to EXFO customers and potential

customers only. The contents of this document may not be reproduced in any part or as

a whole, transcribed, stored in a retrieval system, translated into any language, or

transmitted in any form or by any means (electronic, mechanical, magnetic, optical,

chemical, photocopying, manual, or otherwise) without the prior written permission of

EXFO.

Product Warranty

and Limitation of

For detailed information about the sales terms and conditions, visit the EXFO web site at

www.exfo.com/how-to-buy/sales-terms-conditions

Warranty

Contact

Information

To obtain after-sales service or technical support for this product, contact EXFO at one of

the following numbers.

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

Tel. USA and Canada: 1 866 683-0155

Fax: 1 418 683-9224

E-mail: support@exfo.com

For detailed information about technical support and for a list of other worldwide

locations, visit the EXFO web site at

www.EXFO.com/support

To accelerate the process, please have information such as the name and the serial

number (see the product identification label), as well as a description of your problem,

close at hand.

4 OSICS Programming Guide

Page 5

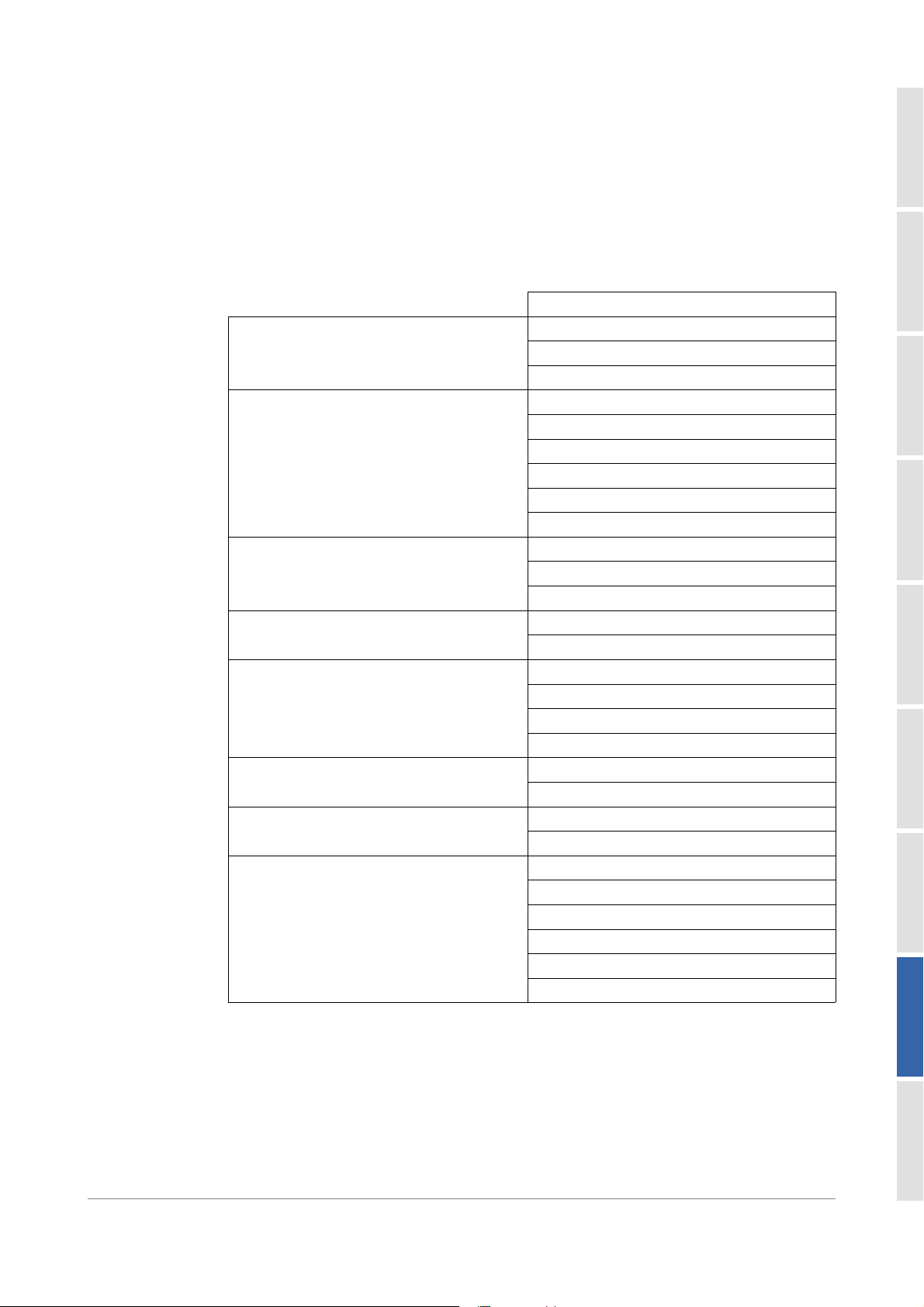

Table of Contents

About This Manual..................................................................................................................................... 3

Table of Contents ...................................................................................................................................... 5

1. Remotely Controlling the OSICS Multifunction Platform ...................................................................... 9

1.1 Switching Between Remote and Local Mode ...................................................................................... 9

1.2 Remotely Controlling the OSICS via IEEE 488.................................................................................... 10

1.3 Remotely Controlling the OSICS via USB-B (RS-232C Protocol)....................................................... 12

2. General System and Status Control ................................................................................................... 13

2.1 Communication Principles .................................................................................................................. 13

2.2 Standard IEEE Status Register Commands and Queries................................................................... 15

2.3 RS-232C Common Commands ........................................................................................................... 19

3. OSICS Mainframe Control ................................................................................................................. 21

3.1 Optical-Output Control......................................................................................................................... 22

3.2 Spectral Unit Selection ........................................................................................................................ 23

3.3 Output Power Control .......................................................................................................................... 24

3.4 Modulation Control .............................................................................................................................. 26

3.5 Working Configuration Control ........................................................................................................... 27

3.6 OSICS System Management Control.................................................................................................. 28

4. OSICS ATN Control ........................................................................................................................... 31

4.1 Unit Selection ....................................................................................................................................... 31

4.2 Attenuation Setting .............................................................................................................................. 33

4.3 Wavelength Setting .............................................................................................................................. 34

4.4 Offset Setting ....................................................................................................................................... 35

4.5 Module System-Version Information.................................................................................................. 36

5. OSICS BKR Control............................................................................................................................ 37

5.1 Unit Selection ....................................................................................................................................... 37

5.2 Reflectance Setting.............................................................................................................................. 39

5.3 Wavelength Setting .............................................................................................................................. 40

5.4 Offset Setting ....................................................................................................................................... 41

5.5 Module System-Version Information.................................................................................................. 42

6. OSICS DFB Control............................................................................................................................ 43

6.1 Optical-Output Control......................................................................................................................... 44

6.2 Unit Selection ....................................................................................................................................... 45

6.3 Output-Power Setting........................................................................................................................... 47

6.4 Diode-Current Setting .......................................................................................................................... 48

6.5 Optical Emission-Wavelength/Frequency Setting ............................................................................. 49

OSICS Programming Guide 5

Page 6

Table of Contents

6.6 Modulation Control .............................................................................................................................. 51

6.7 Calibration Control ............................................................................................................................... 55

6.8 Module Parameter-Monitoring with the OUT 1 Output...................................................................... 57

6.9 Module System-Version Information.................................................................................................. 58

7. OSICS SLD Control ............................................................................................................................ 59

7.1 Unit Selection ....................................................................................................................................... 59

7.2 Optical-Output Control......................................................................................................................... 61

7.3 Optical Output Settings........................................................................................................................ 62

7.4 Module System-Version Information.................................................................................................. 63

8. OSICS SWT Control........................................................................................................................... 65

8.1 Input/Output Selection ........................................................................................................................ 65

8.2 Module System-Version Information.................................................................................................. 69

9. OSICS SWT-APC Control................................................................................................................... 71

9.1 Operating-Mode Selection and Configuration.................................................................................... 72

9.2 Input/Output Channel Selection.......................................................................................................... 73

9.3 Unit Selection ....................................................................................................................................... 73

9.4 Optical-Output Control......................................................................................................................... 75

9.5 Output-Power Setting........................................................................................................................... 77

9.6 Optical Emission-Wavelength/Frequency Setting ............................................................................. 79

9.7 Coherence Control ............................................................................................................................... 80

9.8 Auto-peak Find Control........................................................................................................................ 81

9.9 Modulation Control .............................................................................................................................. 82

9.10 Module System-Version Information.................................................................................................. 84

10. OSICS T100 Control .......................................................................................................................... 85

10.1 Optical-Output Control......................................................................................................................... 86

10.2 Unit Selection ....................................................................................................................................... 87

10.3 Output-Power Setting........................................................................................................................... 89

10.4 Diode-Current Setting .......................................................................................................................... 90

10.5 Optical Emission-Wavelength/Frequency Setting ............................................................................. 91

10.6 Coherence Control ............................................................................................................................... 92

10.7 Auto-peak Find Control........................................................................................................................ 92

10.8 Modulation Control .............................................................................................................................. 94

10.9 Calibration Control............................................................................................................................... 96

10.10 Module Parameter-Monitoring with the OUT 1 Output...................................................................... 99

10.11 Module System-Version Information................................................................................................ 100

11. OSICS TLS-AG Control .................................................................................................................... 101

11.1 Optical-Output Control....................................................................................................................... 102

11.2 Unit Selection ..................................................................................................................................... 102

11.3 Operating-Mode Control .................................................................................................................... 105

11.4 Output-Power Setting......................................................................................................................... 107

6 OSICS Programming Guide

Page 7

Table of Contents

11.5 Optical Emission-Wavelength/Frequency Setting ........................................................................... 108

11.6 Module System-Version Information................................................................................................ 113

12. Error Codes ..................................................................................................................................... 115

13. Program Example and Library ......................................................................................................... 117

13.1 OSICS LabVIEW Library ..................................................................................................................... 117

13.2 OSICS LabVIEW Example .................................................................................................................. 118

Index...................................................................................................................................................... 121

OSICS Programming Guide 7

Page 8

Table of Contents

8 OSICS Programming Guide

Page 9

1. Remotely Controlling the OSICS Multifunction

You can remotely control the OSICS Mainframe through the following ports:

• IEEE-488.2 communication through the GPIB port

• RS-232C communication through the USB-B port

This section explains how to use these ports to remotely control the OSICS multifunction

platform.

1.1 Switching Between Remote and Local Mode

Procedures Entering the Remote Mode

• The OSICS multifunction platform automatically switches to remote mode if it

receives a command (via the USB or GPIB port).

When the OSICS multifunction platform enters into remote mode, the Mode area

displays Mode: REMOTE and the user interface control-panel is disabled.

Platform

The System Status screen remains active and displays the current module settings,

such as operating wavelength (or frequency) or output power.

Switching Back to Local Mode

• To go back to local mode, select LOCAL by pressing the right control button (see the

front panel description in the OSICS User Guide).

In GPIB, if the OSICS multifunction platform is set to local lockout condition, the

message LOCAL LOCKOUT is displayed. This means that the OSICS multifunction

platform is locked into GPIB remote-control operation: all OSICS front panel controls

are disabled and local operating mode can no longer be restored using the LOCAL

soft-key.

To restore the user interface control panel, send the "Go to local" instruction to the

OSICS multifunction platform from the computer or GPIB controller (refer to the

programming guide of your GPIB board to know the exact syntax for the "Go to local"

instruction).

OSICS Programming Guide 9

Page 10

Remotely Controlling the OSICS Multifunction Platform

Main 12 345678

Main Setup - GPIB Address

EXITESCAPE

▲

GPIB Address :

10

Modify the value.

ENTER

1.2 Remotely Controlling the OSICS via IEEE 488

Subject This section explains how to use the IEEE-488.2 GPIB interface to remotely operate the

OSICS multifunction platform.

The GPIB port is located on the rear panel and is labeled IEEE 488 (see OSICS User

Guide).

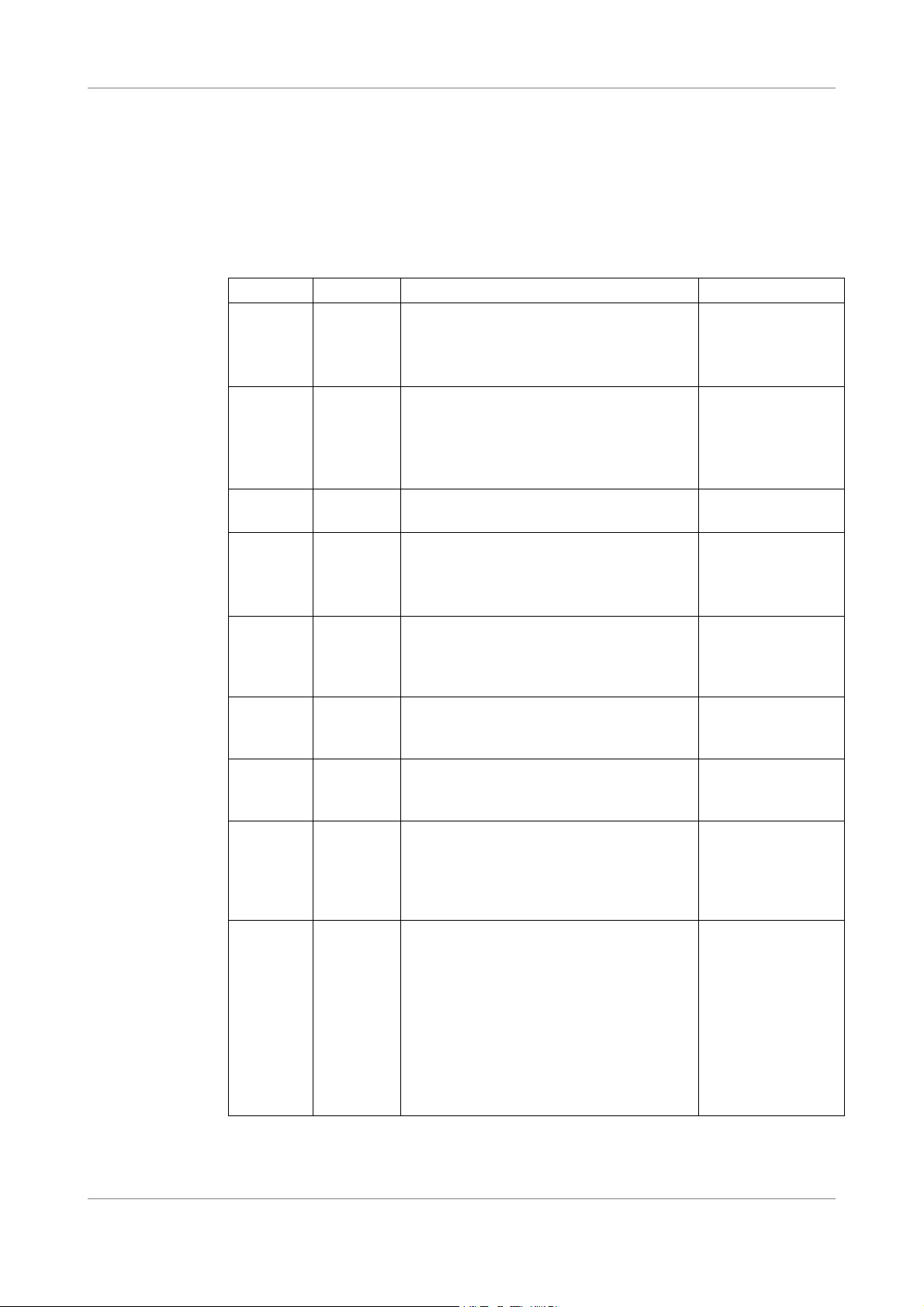

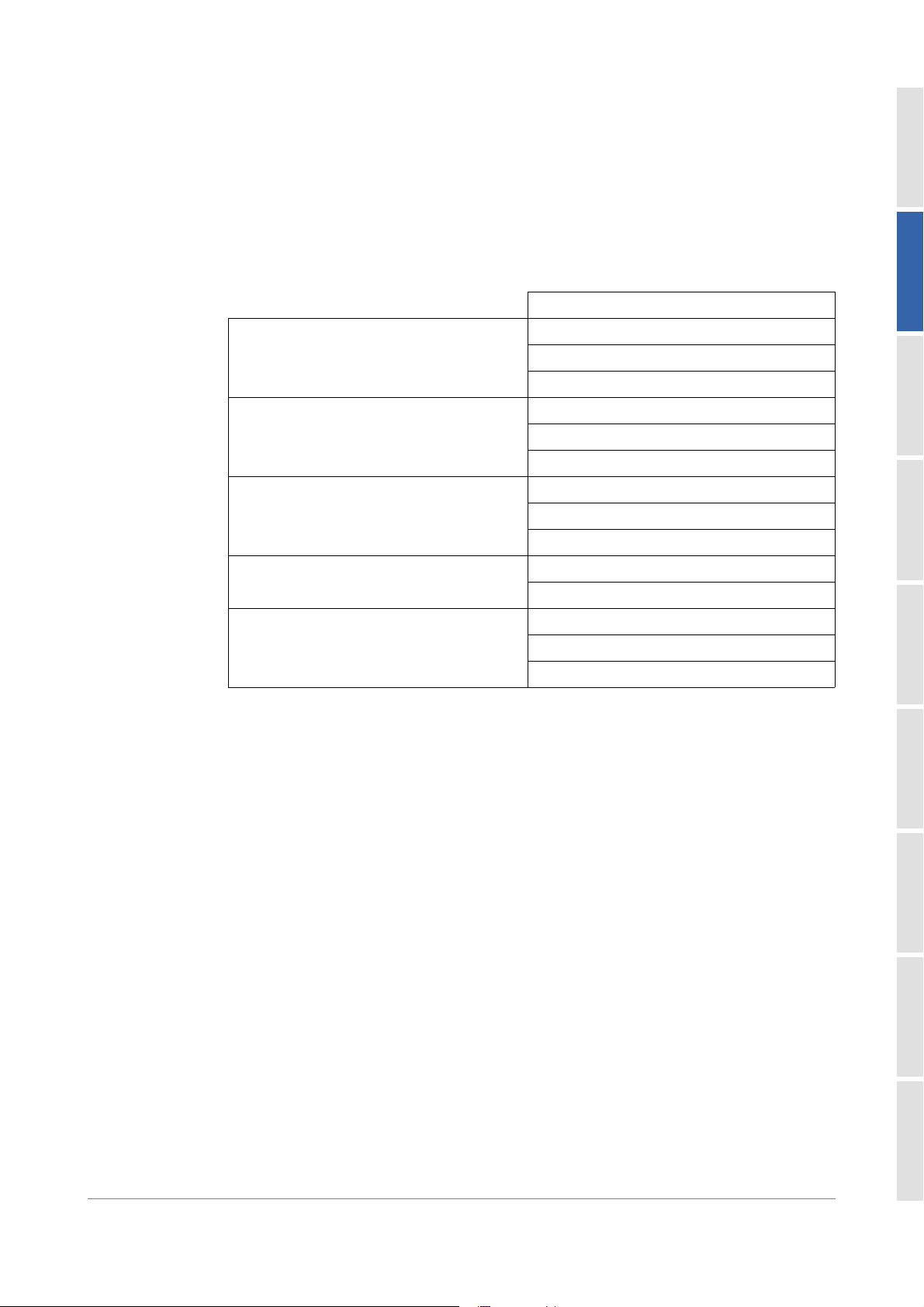

Capabilities The following table lists the OSICS GPIB capabilities.

Mnemonic Function

SH1 Complete source handshake

AH1 Complete acceptor handshake

T5 Complete talker

L3 Complete listener

SR1 Complete service request

RL1 Complete remote/local

PP0 No parallel poll

DC1 Complete device clear

DT0 No device trigger

C0 No controller

Table 1: GPIB Interface Capabilities

1.2.1 Setting the GPIB Address

Subject The default GPIB address of the OSICS is factory-set to 10. This section explains how to

modify it (possible values are 1 to 30).

Up to 15 devices may be connected on the same GPIB bus simultaneously. Each device

has its own GPIB address in the range of 0 to 30. To avoid address conflicts, you must

make sure that your OSICS GPIB address is different from the address of any other

device already connected to the GPIB port.

Procedure 1. Access the Main Setup menu (see OSICS User Guide).

2. Turn the rotary knob to put the cursor before the GPIB address menu and press the

knob to enter it.

The GPIB Address sub-menu appears and displays the current GPIB address.

10 OSICS Programming Guide

3. Enter the wanted address as follows:

Figure 1: Main Setup – GPIB Address

Page 11

Remotely Controlling the OSICS Multifunction Platform

a. Turn the rotary knob to put the cursor under the digit to modify and press the

knob to highlight it.

b. Turn the knob clockwise to increase the value or anticlockwise to decrease it and

press the knob to validate the selected digit.

c. Perform steps a. and b. for every digit you want to modify.

d. Turn the rotary knob clockwise to put the cursor under ENTER and press the

knob to validate the new address.

The new GPIB address is set and stored in memory. You do not need to restart the

OSICS Mainframe.

1.2.2 Connecting the OSICS to an IEEE 488 Controller

Subject The GPIB port enables you to connect the OSICS Mainframe to a computer and to control

it via remote commands.

Before Starting Make sure you have a GPIB cable to link the OSICS Mainframe to an IEEE-488.2 controller

(GPIB PCI card or GPIB-USB-HS module from National Instrument) connected to your

computer.

Procedure 1. Connect the GPIB port of the OSICS Mainframe to the IEEE-488.2 controller

connected to your computer via the GPIB cable.

2. Use the authorized remote GPIB commands detailed in the present guide to remotely

control the OSICS multifunction platform.

OSICS Programming Guide 11

Page 12

Remotely Controlling the OSICS Multifunction Platform

1.3 Remotely Controlling the OSICS via USB-B (RS-232C Protocol)

Subject The USB 2.0-B port is located on the on the rear panel and is labeled USB-B (see OSICS

User Guide).

The OSICS multifunction platform can receive RS-232C commands at the USB-B port

from a computer on which the appropriate USB driver is installed. To achieve this, you

must install the OSICS USB Driver on your computer in order to make the USB port appear

as an additional COM port available to the PC (see the following procedure).

Application software can then access the USB port in the same way as it would access a

standard COM port. Therefore, RS-232C commands can be sent to the OSICS using a

serial-communication terminal.

The OSICS USB Driver is available on the USB key provided with the OSICS, or from the

EXFO website.

This section explains how to connect your computer to the OSICS Mainframe and how to

install the OSICS USB driver.

Before Starting • Make sure your computer runs one of the following operating systems: Windows 10,

Windows 8, Windows 7.

If not, the OSICS USB driver is not supported by your computer.

• Make sure you have a USB-A to USB-B cable to link the OSICS Mainframe to your

computer.

Procedure 1. Do one of the following:

• Connect the OSICS USB key to the USB-A port of your computer.

• From the EXFO website (www.exfo.com/en/exfo-apps), download the OSICS

USB Driver (.zip file) and unzip it to a temporary folder on your computer.

2. In the USB Driver folder, double-click one of the following files, depending on you

Windows platform (if you select the wrong file, a message appears, prompting you to

select the other file):

• 32-bit system: OSICSUSBInstaller_x86.exe

• 64-bit system: OSICSUSBInstaller_x64.exe

The OSICS USB Driver installation wizard appears.

3. Follow the instructions displayed in the wizard window.

The OSICS USB Driver is now installed on your computer.

4. Connect the USB-B port of the OSICS to the USB-A port of your computer using a

USB-A to USB-B cable.

The OSICS USB-B port is recognized as a COM port by the computer.

5. Use the authorized remote RS-232C commands (detailed in the present guide) to

remotely control the OSICS multifunction platform.

Port Settings On your computer, make sure the port settings are configured with the following values:

• Baud rate (bits per second): 9600 bauds

• Data bits: 8

• Parity: none

• Stop bits: 1

• Flow control (handshaking): none

12 OSICS Programming Guide

Page 13

2. General System and Status Control

2.1 Communication Principles

2.1.1 Format of Messages

Message Endings Command Message Ending

A command message must end with one of the following:

• USB (RS-232C): CR (or ASCII code 13 character)

• GPIB: LF (or ASCII code 10 character) or EOI message

Response Message Ending

• All commands sent via RS-232C generate a response message from the OSICS

Mainframe to inform the computer whether the order was successfully performed

(OK) or that an error was produced (error messages are explained in the following

Error Handling section, p14).

A response message always ends with the end-of-message sequence composed of:

• the <CR> at the end of the message string

• a blank line

• the > sign placed on the next line followed by one white-space character, to

separate messages from one another along the vertical layout.

Example:

P=0.5 <CR>

P=? <CR>

will generate the following two response messages if operation is successful:

OK <CR>

>

P=0.5 DBM <CR>

>

• Commands sent via GPIB follow the standard status model, see section Standard

Status Model, p. 15.

Message Syntax

Rules

OSICS Programming Guide 13

Case

Commands are not case sensitive, you can type messages in upper-case or lower-case

characters.

White Space

White spaces are allowed only before or after a command string, but not within a

command mnemonic.

Multiple Commands

Compound commands are allowed and consist of a series of individual instructions

separated from one another by a semicolon ( ; ).

Page 14

General System and Status Control

The commands are processed by the OSICS Mainframe in the order received.

Command Length

A single command string can be up to 255 characters long. A longer command string

generates a command-error message and the buffer is cleared.

A new command cannot be sent until all the instructions of the command string already

in the buffer are completed. This will otherwise clear the buffer and generate a

command-error. Moreover all the previous commands will be lost.

Numeric Values

Numeric values are either integers or doubles depending on the definition of the

parameter.

• A numeric value can start with a leading 0

Example: P=01.2

• The = sign cannot be totally omitted but can be replaced by a white-space character.

Example: P 1.2

• White spaces are allowed before and after the = sign.

• Unit notation cannot be used after a numeric value.

• A comma cannot be used in a dot-decimal notation.

• White spaces are not allowed within a numerical value.

Error Handling The OSICS Mainframe performs error-checking on each command received and during

command execution. Errors fall into three categories and may generate one of the

following error messages:

• Execution Error

The command syntax is valid but the data contained in the command parameter is

out of valid range. The current parameter setting remains unchanged.

• Command Error

An unknown command is received or the command string has a syntax error in it.

• Device Dependent Error

Some condition due to instrument malfunction or overload has been detected.

2.1.2 Command Applicability

Commands are based on a simple two-level hierarchy:

• First-level commands affect the OSICS Mainframe only. To enter an OSICS

Mainframe command, simply type in the instruction string followed by the carriage

return character in RS-232C, as shown in the following example:

P=0.22 <CR>

This command sets the output power for all the modules installed in the OSICS

Mainframe to 0.22 mW (if mW is the selected power unit).

• Second-level commands are used to control the operation and setting parameters of

OSICS modules installed in the OSICS Mainframe.

14 OSICS Programming Guide

Page 15

General System and Status Control

Module commands require the CH#: specifier, where # is the slot number of the

module to which the command applies (ranging from 1 to 8), as shown in the

following example:

CH2:P=0.22 <CR>

This command sets the output power of the module installed in the channel-slot 2 to

0.22 mW (if mW is the selected power unit).

Similarly, the OSICS modules send a response statement to every command received

and executed. Response messages are similar in syntax to programming commands'

responses and feature the channel-specifier CH# in front of the message to differentiate

between channels.

2.2 Standard IEEE Status Register Commands and Queries

2.2.1 Standard Status Model

Status Model The status word is an 8-bit variable that relates to the status of the OSICS Mainframe and

error reporting as well. It contains a number of binary indicators which can be used by

the controller for an optimal synchronization between the OSICS Mainframe and the

controller. They indicate to the controller the nature of the current operation as well as

the errors encountered.

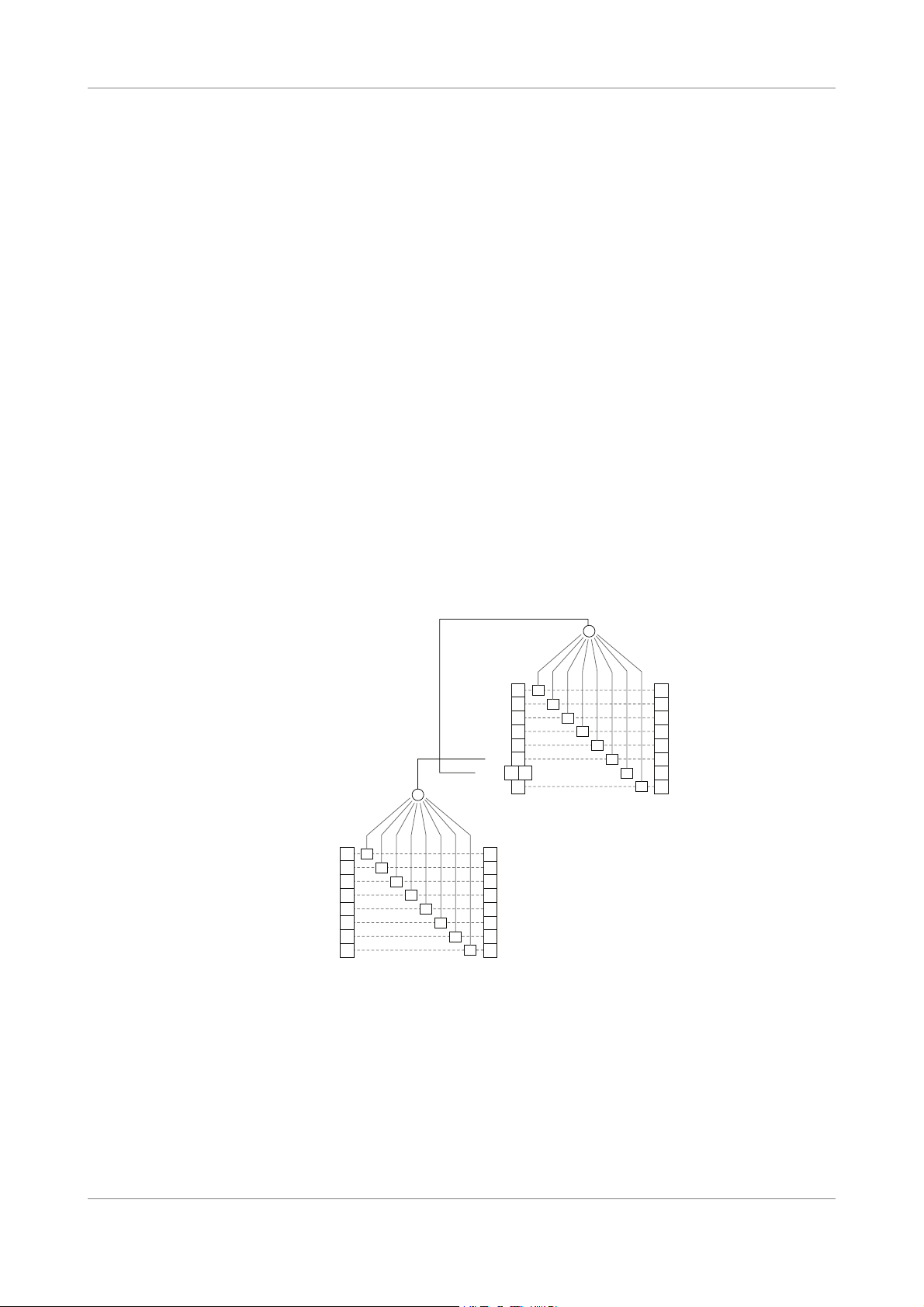

The following figure shows the standard IEEE status model.

7XEXYW&]XI

6IKMWXIV1EWO

34'

65'

5:)

(()

'1)

965

432

)<)

)ZIRX7XEXYW

6IKMWXIV)76

7XEXYW&]XI

6IKMWXIV78&

1%:

)7&

657

34'

177

)ZIRX7XEXYW

6IKMWXIV1EWO

Figure 2: Status Word Model

Two mask registers are associated with the Status Byte register (STB) and the standard

Event Status Register (ESR). These masks are used to control the service request

operation of the instrument.

In the status and standard event registers, individual bits are validated by setting to 1 the

corresponding bit in the mask register. Once the required bits have been set in each

OSICS Programming Guide 15

Page 16

General System and Status Control

mask register, the summary bit will be set to 1 when the corresponding status or event

register bits are set to 1.

The summary bit is obtained by performing a logical AND operation between each

register and the corresponding mask register, and then a logical OR operation between

all individual bits of the result.

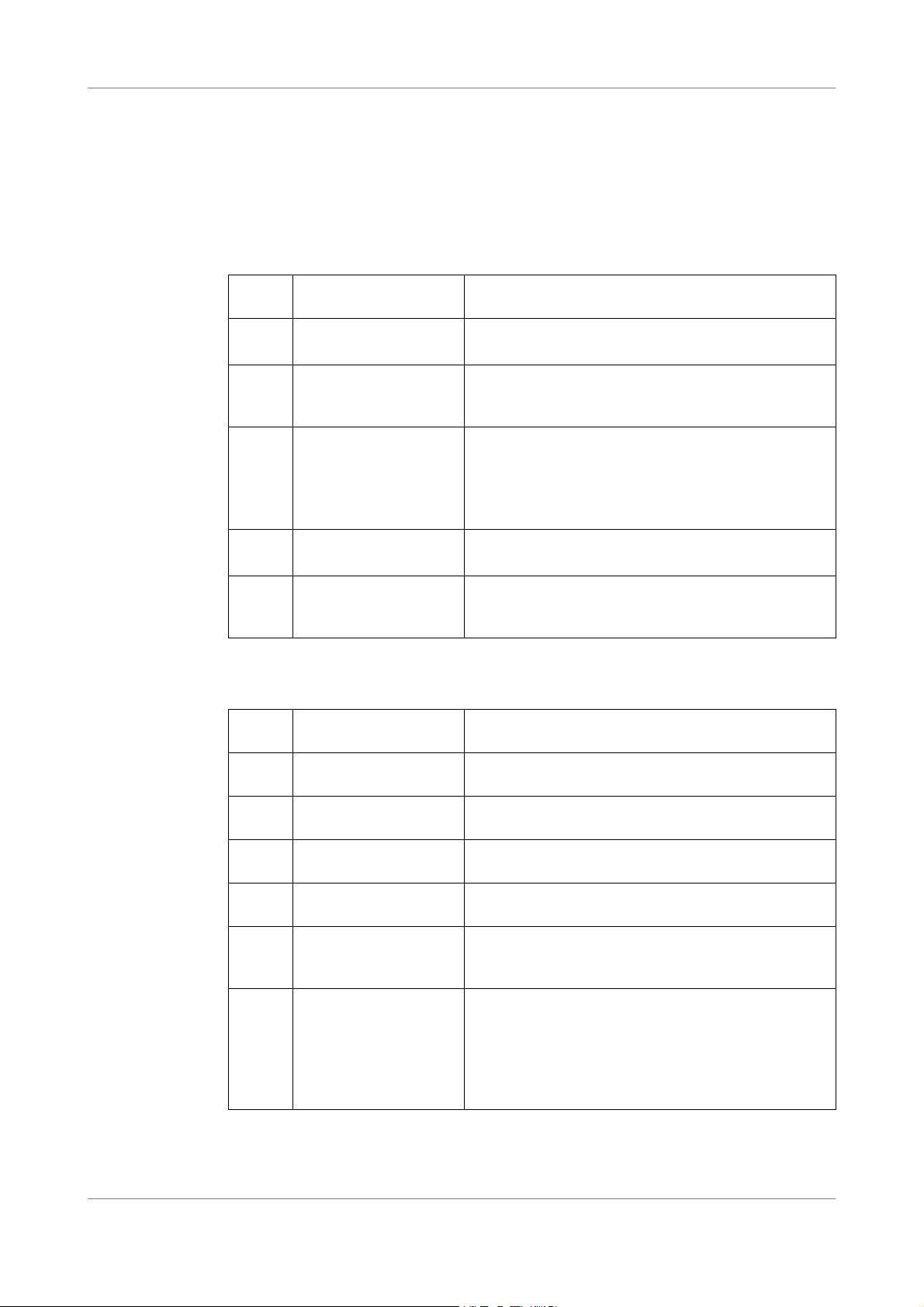

Status Byte Register

Bit

Name Meaning

Number

7OPC

(OPeration Complete)

6RQS

(ReQuest Service)

Set to 1 once the last command has been

completed.

Set to 1 if a service request has been generated by

the OSICS Mainframe. This bit remains activated

until a serial poll has been performed.

6MSS

(Master Summary

Status)

Set to 1 together with the RQS bit. This bit remains

activated as long as the condition that has lead to a

service request is high.

It is cleared as soon as this condition ceases. This

bit can be read by the *STB? command.

5ESB

(Event Status Bit)

4MAV

(Message AVailable)

Set to 1 as soon as one or more bits in the Event

Status Register (ESR) are activated.

Set to 1 if a message is available and ready to be

read in the output queue. This bit remains activated

as long as the output queue has not been emptied.

Event Status Register

The following table gives the meaning of each bit in the Event Status register (ESR).

Bit

Name Meaning

Number

7 PON (Power ON) Set to 1 once the instrument initialization routine has

been completed.

6 URQ (User ReQuest) Set to 1 to indicate that an instrument front-panel key

has been pressed.

5 CME (ComMand Error) Set to 1 to indicate a command syntax error or an

unknown command.

4 EXE (EXecution Error) Set to 1 when a parameter value is out of the valid

range or when a command cannot be executed.

3 DDE (Device Dependent

Error)

Set to 1 if a malfunction has occurred on the

instrument or an overload condition has been

reached.

2 QYE (QuerY Error) Set to 1 in either of those two cases:

• The GPIB controller has attempted to read from

the OSICS Mainframe while the output queue

was empty.

• The data in the GPIB output queue has been

overwritten and lost.

16 OSICS Programming Guide

Page 17

General System and Status Control

Task

Synchronization

Bit

Number

1 RQC (ReQuest Control) This bit may not be set to 1, since the OSICS

0 OPC (OPeration

The Event Status Register is cleared each time it is read by the controller. When the

execution of a command line begins, the OPC bit is cleared.

The GPIB interface of the OSICS Mainframe performs tasks sequentially in the order

received; it does not support overlapping tasks.

• The OPC (OPeration Complete) bit is cleared while the instruction is being processed

• The MAV (Message AVailable) bit indicates that messages are available in the

To ensure a proper sequence of events, it may be useful to combine the use of the

STatus Byte Register (STB) with the Event Status Register (ESR). The most relevant bit in

the STB byte is bit 4 (MAV). The STB byte can be read either through a serial poll or as a

response to the *STB? query.

Name Meaning

instrument does not work as an IEEE-488.2 bus

controller.

In most cases this bit is set to 1 as soon as a

Complete)

and set to 1 once it has been completed. This is particularly useful when setting a

channel to a new wavelength, as this operation may take a few seconds to complete.

The computer should verify this flag until it is set to 1 and then only proceed to the

next instruction. The status of the OPC flag is available through serial-polling the STB

byte register. The OPC flag is contained in bit 7 of the STB byte register.

output buffer and ready to be read. For instance, if a query command was sent, the

computer must wait until the response message is placed in the output queue before

reading it. If several queries were sent via a compound command, the MAV flag

remains activated until all response messages have polled by the computer. The

MAV flag is contained in bit 4 of the STB byte register.

command has been completely executed.

Error Handling If different types of errors occur, relevant bits in the Event Status Register (ESR) are set

to 1. The following diagram shows the ESR error model:

34'

(()

)<)

'1)

The ESR byte can be read via the *ESR? query.

The relevant bits in this control byte are the following bits:

• 0 (OPeration Complete: OPC)

• 3 (Device Dependent Error: DDE)

• 4 (EXecution Error: EXE)

• 5 (CoMmand Error: CME).

)ZIRX7XEXYW

6IKMWXIV)76

We recommend reading the ESR bit each time a command is sent to help trace errors

throughout programmed operation, identify possible causes for errors and make the

necessary programming adjustments.

Caution

Reading the ESR byte with the *ESR? query command clears all the bits in the

Event Status Register. Therefore, we recommend reading all significant bits

at the time of query to ensure no relevant information is left out or lost.

OSICS Programming Guide 17

Page 18

General System and Status Control

2.2.2 Common IEEE Commands and Queries

To accelerate and secure the exchange of information between the controller and the

OSICS Mainframe, we recommend checking the values of the Status Register and of the

standard Event Status Register using the IEEE-488.2 common commands presented in

the following table.

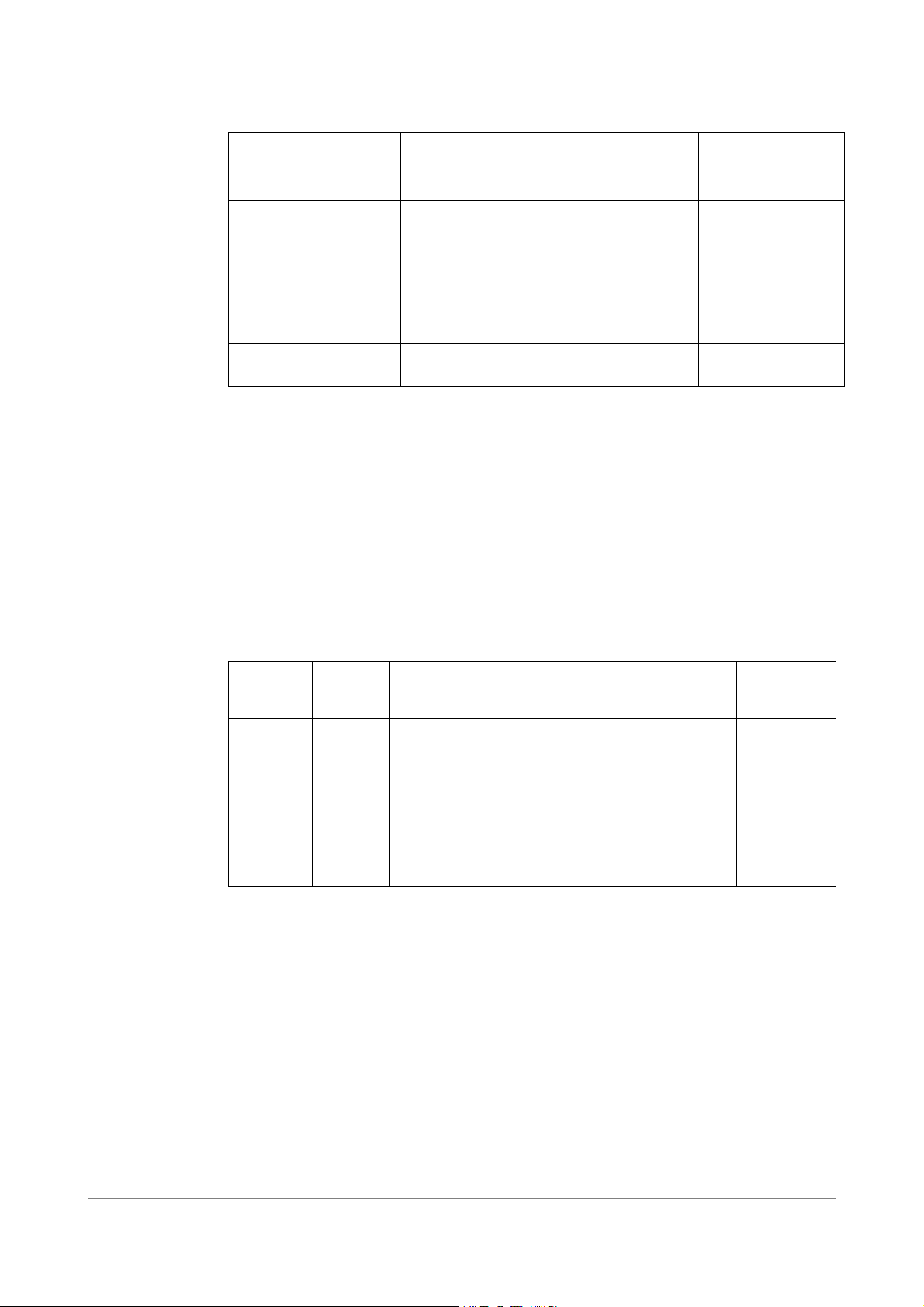

Command Parameter Action OSICS Response

*CLS none Clears the Event Status Register and the

output queue. Sets the OPC bit to 1.

The CLS instruction is automatically sent

to each module.

*ESE Integer

value

(0 to 255)

*ESE? none The value of ESE is placed in the output

*ESR? none Standard Event Status Register query.

*IDN? none IDeNtification query.

*OPC none Waits until the pending command is

*OPC? none Waits until OPC bit is true, then places “1”

*RST none The input buffer is cleared. The command

*SRE Integer

value

(0 to 255)

The standard event mask register is set to

a value equal to the parameter of ESE

command.

If the parameter is out of the range of 0 to

255, this triggers the “Execution Error”.

queue.

The value of the standard event register is

placed into the output queue and the

standard event register is cleared.

completed, then sets the OPC bit in the

Event Status Register.

in the output queue, followed by the LF

character.

interpreter is reset and a reset instruction

is sent to every module. The status and

event registers are cleared. Sets the OPC

bit to 1.

Sets the value of the Service Request

Enable Register. SRE determines which

event triggers a serial poll. SRE is

assigned the value of its parameter. For

example, if bit 4 is set, this means that a

service request will be generated when a

message becomes available in the output

queue.

If the parameter is out of the range from 0

to 255, this triggers the “Execution Error”.

Returns the value of

ESE (0 to 255).

Returns the value of

the ESR byte

(0 to 255).

EXFO,OSICS,

<serial number>,

<software version>

/<FPGA version>

This command

always returns 1.

OK

18 OSICS Programming Guide

Page 19

General System and Status Control

Command Parameter Action OSICS Response

*SRE? none Reads the value of the SRE register. Value of the SRE

register (0 to 255).

*STB? none STatus Byte query.

The value of the status byte register is

sent to the output queue. STB contains

Value of the STB

status byte (0 to

255).

the MAV flag that takes bit number 4.

In the STB? query, bit 6 is assigned the

MSS flag rather than the RQS flag, unlike

the standard STB.

*WAI none Does nothing but wait until the pending

command has been completed.

2.3 RS-232C Common Commands

Subject This section describes the ECHON command, which is useful for viewing the characters

keyed in at the terminal.

Setting the echo mode by using the ECHON command is needed for some terminals and

terminal emulation programs that do not feature local echo, otherwise typed characters

cannot be seen.

Before Starting Make sure that the "echo" feature is enabled on the terminal emulation program you use.

Commands

Command/

Query

ECHON none Sets the OSICS Mainframe to echo each typed

Parameter Description OSICS

Mainframe

Response

OK

character received back to the terminal.

ECHOFF none Default setting.

OK

Cancels the echo mode on the OSICS Mainframe.

If the local operating mode is restored using the

front-panel LOCAL button, the echo mode is

automatically switched off and restored to

default: ECHOFF.

OSICS Programming Guide 19

Page 20

General System and Status Control

20 OSICS Programming Guide

Page 21

3. OSICS Mainframe Control

The following table gives an overview of all available commands and queries for OSICS

Mainframe control.

Command/Query Corresponding Section

Optical-Output Control

Spectral Unit Selection

Output Power Control

Modulation Control

Working Configuration Control

OSICS System Management

Control

DISABLE DISABLE, p. 22

ENABLE ENABLE, p. 22

ENABLE? ENABLE?, p. 22

GHZ GHZ, p. 23

NM NM, p. 23

NM? NM?, p. 23

DBM Power Unit Selection, p. 24

MW

MW?

P= Power Setting, p. 25

P?

MOD_SRC MOD_SRC?, p. 26

MOD_SRC? MOD_SRC?, p. 26

MOD_F= MOD_F=, p. 26

MOD_F? MOD_F?, p. 27

SAVE SAVE, p. 27

RECALL RECALL, p. 27

*IDN? *IDN?, p. 28

*RST *RST, p. 28

INTERLOCK? INTERLOCK?, p. 28

PRESENT? PRESENT?, p. 29

BKRATNMAIN DFB T100SLD SWT TLS-AGSWT APC

OSICS Programming Guide 21

Page 22

OSICS Mainframe Control

3.1 Optical-Output Control

3.1.1 DISABLE

Syntax DISABLE

ATN MAINBKRDFBT100 SLDSWTTLS-AG SWT APC

Parameter None.

Description Default setting.

Disables the laser output on all installed OSICS modules.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.1.2 ENABLE

Syntax ENABLE

Parameter None.

Description Enables the laser output on all installed OSICS modules.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.1.3 ENABLE?

Syntax ENABLE?

Parameter None.

Description Returns the current state of the OSICS Mainframe laser output master control.

OSICS Response • ENABLED: the laser is set to ENABLE.

• DISABLED: the laser is set to DISABLE.

22 OSICS Programming Guide

Page 23

OSICS Mainframe Control

3.2 Spectral Unit Selection

3.2.1 GHZ

Syntax GHZ

Parameter None.

Description Sets the frequency in GHz as the spectral unit on all modules throughout the system.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.2.2 NM

Syntax NM

Parameter None.

Description Default setting.

Sets the wavelength in nm as the spectral unit on the OSICS Mainframe and all installed

OSICS modules.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.2.3 NM?

Syntax NM?

BKRATNMAIN DFB T100SLD SWT TLS-AGSWT APC

Parameter None.

Description Returns the current spectral unit used on the OSICS Mainframe and all installed OSICS

modules.

OSICS Response • 1: the current spectral unit used is nm.

• 0: the current spectral unit used is GHz.

OSICS Programming Guide 23

Page 24

OSICS Mainframe Control

3.3 Output Power Control

3.3.1 Power Unit Selection

ATN MAINBKRDFBT100 SLDSWTTLS-AG SWT APC

3.3.1.1 DBM

Syntax DBM

Parameter None.

Description Sets dBm as the power unit on all modules. All power-related functions throughout the

OSICS Mainframe now use dBm as power unit.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.3.1.2 MW

Syntax MW

Parameter None.

Description Default setting.

Sets mW as the power unit on all modules. All power-related functions throughout the

OSICS Mainframe now use mW as power unit.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.3.1.3 MW?

Syntax MW?

Parameter None.

Description Returns the current power unit used on the OSICS Mainframe and all installed OSICS

modules.

OSICS Response • 1: the current power unit used is mW.

• 0: the current power unit used is dBm.

24 OSICS Programming Guide

Page 25

OSICS Mainframe Control

3.3.2 Power Setting

3.3.2.1 P=

Syntax P=xx.xx|(±)xx.xx

Parameter • [±]xx.xx: optical output power in dBm, if the unit is set to dBm (see section DBM,

p. 24). Possible values are given in the Technical Specifications section

corresponding to the installed modules in the OSICS User Guide.

• xx.xx: optical output power in mW, if the unit is set to mW (see section MW, p. 24).

Possible values are given in the Technical Specifications section corresponding to

the installed modules in the OSICS User Guide.

Description Sets the optical output power of all modules to the same value, depending on the

selected power unit (see section Power Unit Selection, p. 24).

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

BKRATNMAIN DFB T100SLD SWT TLS-AGSWT APC

3.3.2.2 P?

Syntax P?

Parameter None.

Description Returns the optical output power value set for the modules, according to the selected

power unit. The format of the response depends on the power unit selected (see section

Power Unit Selection, p. 24).

The returned response is the value set using the P= command (see section P=, p. 25), it

does not give the power of the installed modules.

OSICS Response • P=xx.xx: output power value in mW.

• P=±xx.xx: output power value in dBm.

OSICS Programming Guide 25

Page 26

OSICS Mainframe Control

3.4 Modulation Control

3.4.1 MOD_SRC

Syntax MOD_SRC INT|EXT

ATN MAINBKRDFBT100 SLDSWTTLS-AG SWT APC

Parameters • INT: INTERNAL digital modulation signal. The internal source uses the OSICS

Mainframe on-board modulation signal generator. To set the frequency of the OSICS

internal TTL modulation, use the MOD_F command (see section MOD_F=, p. 26)

• EXT: EXTERNAL digital modulation signal. In this case, you must connect a TTL

signal generator to the Mod. In BNC connector located at the rear panel of the OSICS

Mainframe (see OSICS User Guide).

Description Sets the type of modulation source of the OSICS Mainframe.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.4.2 MOD_SRC?

Syntax MOD_SRC?

Parameter None.

Description Returns the type of digital (TTL) modulation source currently selected for the OSICS.

OSICS Response • MOD_SRC=INT: the modulation source is set to INTERNAL.

• MOD_SRC=EXT: the modulation source is set to EXTERNAL.

3.4.3 MOD_F=

Syntax MOD_F=xxxxxxx

Parameter • xxxxxxx: frequency in Hz, in the range 123 Hz to 1000000 Hz (1 MHz).

Default value: 200 Hz

Description Sets the frequency of the OSICS Mainframe internal digital (TTL) modulation source.

If the OSICS Mainframe is not able to generate the exact value of the frequency setting, it

applies the nearest available frequency value, right under the value of the setting.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

26 OSICS Programming Guide

Page 27

OSICS Mainframe Control

3.4.4 MOD_F?

Syntax MOD_F?

Parameter None.

Description Returns the frequency of the OSICS internal digital (TTL) modulation source in Hz.

OSICS Response MOD_F=xxxxxxx

3.5 Working Configuration Control

The commands detailed in this section enable you to load or save working

configurations. For more details on working configuration, see OSICS User Guide.

3.5.1 SAVE

Syntax SAVE STARTUP|A|B|C|D

Parameters • STARTUP: configuration loaded at OSICS startup.

• A: A configuration memory.

• B: B configuration memory.

• C: C configuration memory.

• D: D configuration memory.

Description Saves the current OSICS Mainframe and module configuration settings to the selected

configuration memory.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

BKRATNMAIN DFB T100SLD SWT TLS-AGSWT APC

3.5.2 RECALL

Syntax RECALL DEFAULT|STARTUP|A|B|C|D

Parameter • DEFAULT: factory-set DEFAULT configuration type.

• STARTUP: STARTUP configuration type.

• A: A configuration memory.

• B: B configuration memory.

• C: C configuration memory.

• D: D configuration memory.

OSICS Programming Guide 27

Page 28

ATN MAINBKRDFBT100 SLDSWTTLS-AG SWT APC

OSICS Mainframe Control

Description Loads the selected configuration type.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.6 OSICS System Management Control

3.6.1 *IDN?

Syntax *IDN?

Parameter None.

Description Returns information about the OSICS Mainframe.

OSICS Response EXFO,OSICS,<serial number>,<software version>/<FPGA version>

3.6.2 *RST

Syntax *RST

Parameter None.

Description • Resets the OSICS Mainframe and all modules to the same state as after system turn-

on and initialization.

• Clears the input queue.

• Sets the OPC bit to 1.

The command interpreter is reset and a reset instruction is sent to every module.

The status and event registers are cleared.

OSICS Response • RS-232C: OK

• GPIB: none, see section Standard Status Model, p. 15.

3.6.3 INTERLOCK?

Syntax INTERLOCK?

Parameter None.

Description Returns the current state of the remote interlock mode.

OSICS Response • 1: the remote interlock is on (laser switched off).

• 0: the remote interlock is off (laser switched on).

28 OSICS Programming Guide

Page 29

OSICS Mainframe Control

3.6.4 PRESENT?

Syntax PRESENT? #

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the type of OSICS module installed in channel-slot number #. Each type of OSICS

module has its own module code.

OSICS Response • -1: empty slot.

• 1: the module installed in the selected slot is a T100 module.

• 2: the module installed in the selected slot is a DFB or SLD module.

• 7: the module installed in the selected slot is an SWT module.

• 8: the module installed in the selected slot is an ATN or BKR module.

• 10: the module installed in the selected slot is a TLS module.

BKRATNMAIN DFB T100SLD SWT TLS-AGSWT APC

OSICS Programming Guide 29

Page 30

ATN MAINBKRDFBT100 SLDSWTTLS-AG SWT APC

OSICS Mainframe Control

30 OSICS Programming Guide

Page 31

4. OSICS ATN Control

The following table gives an overview of all available commands and queries for

OSICS ATN control.

Command/Query

Unit Selection (p. 31) CH#:GHZ

CH#:NM

CH#:NM?

Attenuation Setting (p. 33) CH#:ATN

CH#:ATN?

CH#:ATN_MIN_MAX?

Wavelength Setting (p. 34) CH#:L

CH#:L?

CH#:LREF?

Offset Setting (p. 35) CH#:OFFSET

CH#:OFFSET?

Module System-Version Information

(p. 36)

CH#:FIRM?

CH#:*IDN?

CH#:TYPE?

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

4.1 Unit Selection

4.1.1 CH#:GHZ

Syntax CH#:GHZ

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets GHz as the spectral unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

4.1.2 CH#:NM

Syntax CH#:NM

OSICS Programming Guide 31

Page 32

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS ATN Control

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets nm as the spectral unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

4.1.3 CH#:NM?

Syntax CH#:NM?

Parameter

Description Returns the actual spectral unit.

OSICS Response • CH#:NM=TRUE: the selected unit is nm.

• CH#:NM=FALSE: the selected unit is GHz.

32 OSICS Programming Guide

Page 33

4.2 Attenuation Setting

4.2.1 CH#:ATN

Syntax CH#:ATN xx.xx

Parameters • #: slot number of the module, in the range 1 to 8.

• xx.xx: total attenuation value, which must be set between minimum insertion loss

value and the attenuation range value indicated in the Technical Specifications

section of the module in the OSICS User Guide. To know the possible values, see

section CH#:ATN_MIN_MAX?, p. 33.

Description Set the total attenuation in dB.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

OSICS ATN Control

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

4.2.2 CH#:ATN?

Syntax CH#:ATN?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the value of the attenuation in dB.

OSICS Response CH#:ATN=xx.xx

4.2.3 CH#:ATN_MIN_MAX?

Syntax CH#:ATN_MIN_MAX? 1|2

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

Description Returns the minimum and maximum attenuation setting in dB for the given wavelength

number (1|2).

OSICS Response CH#:ATN_MIN_MAX=+<minimum value>+<maximum value>

OSICS Programming Guide 33

Page 34

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS ATN Control

4.3 Wavelength Setting

4.3.1 CH#:L

Syntax CH#:L 1|2

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

•

Description Sets the reference wavelength. Each module is factory-calibrated at different

wavelengths depending on the module version (SMF or PMF).

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

4.3.2 CH#:L?

Syntax CH#:L?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the number of the wavelength used (see section CH#:L, p. 34).

OSICS Response CH#:L=1|2

4.3.3 CH#:LREF?

Syntax CH#:LREF? 1|2

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

34 OSICS Programming Guide

Page 35

OSICS ATN Control

Description Returns the wavelength in nanometer corresponding to the given wavelength number

(1|2).

OSICS Response CH#:L(1|2)=<wavelength value>

4.4 Offset Setting

4.4.1 CH#:OFFSET

Syntax CH#:OFFSET 1|2 xx.xx

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

• xx.xx: offset value in dB, in the range -10 dB to +10 dB.

Description Sets the attenuation Offset for the given wavelength number (1|2).

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

4.4.2 CH#:OFFSET?

Syntax CH#:OFFSET? 1|2

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

Description Returns the Offset value in dB for the given wavelength number (1|2).

OSICS Response CH#:OFFSET(1|2)=+xx.xx

OSICS Programming Guide 35

Page 36

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS ATN Control

4.5 Module System-Version Information

4.5.1 CH#:FIRM?

Syntax CH#:FIRM=x.xx

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the software version of the module.

OSICS Response CH#:FIRM=x.xx

4.5.2 CH#:*IDN?

Syntax CH#:*idn?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns information about the ATN module as follows: company name, module name,

serial number, software version number (FPGA version).

OSICS Response CH#:EXFO,OSICS-<Module name>,<serial number>,

<software version>/<FPGA version>

4.5.3 CH#:TYPE?

Syntax CH#:TYPE?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the ATN module type version and options.

OSICS Response CH#:ATN

36 OSICS Programming Guide

Page 37

5. OSICS BKR Control

The following table gives an overview of all available commands and queries for

OSICS BKR control.

Command/Query

Unit Selection (p. 37) CH#:GHZ

CH#:NM

CH#:NM?

Reflectance Setting (p. 39) CH#:ATN

CH#:ATN?

CH#:ATN_MIN_MAX?

Wavelength Setting (p. 40) CH#:L

CH#:L?

CH#:LREF?

Offset Setting (p. 41) CH#:OFFSET

CH#:OFFSET?

Module System-Version Information

(p. 42)

CH#:FIRM?

CH#:*IDN?

CH#:TYPE?

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

5.1 Unit Selection

5.1.1 CH#:GHZ

Syntax CH#:GHZ

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets GHz as the spectral unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

5.1.2 CH#:NM

Syntax CH#:NM

OSICS Programming Guide 37

Page 38

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS BKR Control

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets nm as the spectral unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

5.1.3 CH#:NM?

Syntax CH#:NM?

Parameter

Description Returns the actual spectral unit.

OSICS Response • CH#:NM=TRUE: the selected unit is nm.

• CH#:NM=FALSE: the selected unit is GHz.

38 OSICS Programming Guide

Page 39

5.2 Reflectance Setting

5.2.1 CH#:ATN

Syntax CH#:ATN xx.xx

Parameters • #: slot number of the module, in the range 1 to 8.

• xx.xx: total reflectance value, which must be set between minimum insertion loss

value and the reflectance range value indicated in the Technical Specifications

section of the module in the OSICS User Guide. To know the possible values, see

section CH#:ATN_MIN_MAX?, p. 39.

Description Set the total reflectance in dB.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

OSICS BKR Control

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

5.2.2 CH#:ATN?

Syntax CH#:ATN?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the value of the reflectance in dB.

OSICS Response CH#:ATN=xx.xx

5.2.3 CH#:ATN_MIN_MAX?

Syntax CH#:ATN_MIN_MAX? 1|2

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

Description Returns the minimum and maximum reflectance setting in dB for the given wavelength

number (1|2).

OSICS Response CH#:ATN_MIN_MAX=+<minimum value>+<maximum value>

OSICS Programming Guide 39

Page 40

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS BKR Control

5.3 Wavelength Setting

5.3.1 CH#:L

Syntax CH#:L 1|2

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

•

Description Sets the reference wavelength. Each module is factory-calibrated at different

wavelengths depending on the module version (SMF or PMF).

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

5.3.2 CH#:L?

Syntax CH#:L?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the number of the wavelength used (see section CH#:L, p. 40).

OSICS Response CH#:L=1|2

5.3.3 CH#:LREF?

Syntax CH#:LREF? 1|2

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

40 OSICS Programming Guide

Page 41

OSICS BKR Control

Description Returns the wavelength in nanometer corresponding to the given wavelength number

(1|2).

OSICS Response CH#:L(1|2)=<wavelength value>

5.4 Offset Setting

5.4.1 CH#:OFFSET

Syntax CH#:OFFSET 1|2 xx.xx

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

• xx.xx: offset value in dB, in the range -10 dB to +10 dB.

Description Sets the attenuation Offset for the given wavelength number (1|2).

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

5.4.2 CH#:OFFSET?

Syntax CH#:OFFSET? 1|2

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

Parameters • #: slot number of the module, in the range 1 to 8.

• 1: first wavelength value of the factory calibration:

• on SMF: 1300 nm

• on PMF: 1550 nm

• 2: second wavelength value of the factory calibration:

• on SMF: 1550 nm

• on PMF: 1625 nm

Description Returns the Offset value in dB for the given wavelength number (1|2).

OSICS Response CH#:OFFSET(1|2)=+xx.xx

OSICS Programming Guide 41

Page 42

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS BKR Control

5.5 Module System-Version Information

5.5.1 CH#:FIRM?

Syntax CH#:FIRM=x.xx

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the software version of the module.

OSICS Response CH#:FIRM=x.xx

5.5.2 CH#:*IDN?

Syntax CH#:*idn?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns information about the BKR module as follows: company name, module name,

serial number, software version number (FPGA version).

OSICS Response CH#:EXFO,OSICS-<Module name>,<serial number>,

<software version>/<FPGA version>

5.5.3 CH#:TYPE?

Syntax CH#:TYPE?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the BKR module type version and options.

OSICS Response CH#:BKR

42 OSICS Programming Guide

Page 43

6. OSICS DFB Control

The following table gives an overview of all available commands and queries for

OSICS DFB control.

Command/Query

Optical-Output Control (p. 44) CH#:DISABLE

CH#:ENABLE

CH#:ENABLE?

Unit Selection (p. 45) CH#:GHZ

CH#:NM

CH#:NM?

CH#:DBM

CH#:MW

CH#:MW?

Output-Power Setting (p. 47) CH#:P=

CH#:P?

CH#:LIMIT?

Diode-Current Setting (p. 48) CH#:I?

CH#:IMAX?

Optical Emission-Wavelength/Frequency

Setting (p. 49)

Modulation Control (p. 51) CH#:MOD_CTRL

CH#:L=

CH#:L?

CH#:LMAX?

CH#:LMIN?

CH#:F=

CH#:F?

CH#:FMAX?

CH#:FMIN?

CH#:MOD_CTRL?

CH#:MOD_SRC

CH#:MOD_F=

CH#MOD_F?

CH#:MOD_SRC?

CH#:SIN_FREQ=

CH#:SIN_RATE=

CH#:SIN_OUT

CH#:SIN_FREQ?

CH#:SIN_RATE?

CH#:SIN_OUT?

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

OSICS Programming Guide 43

Page 44

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS DFB Control

Calibration Control (p. 55) CH#:PCAL=

Module Parameter-Monitoring with the

OUT 1 Output (p. 57)

Module System-Version Information

(p. 58)

6.1 Optical-Output Control

6.1.1 CH#:DISABLE

Command/Query

CH#:PCAL?

CH#:DL=

CH#:DL?

CH#:AOUT

CH#:AOUT?

CH#:FIRM?

CH#:*IDN?

CH#:TYPE?

CH#:ERRORT?

Syntax CH#:DISABLE

Parameter • #: slot number of the module, in the range 1 to 8.

Description Default setting.

Disables the laser output of the DFB module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.1.2 CH#:ENABLE

Syntax CH#:ENABLE

Parameter • #: slot number of the module, in the range 1 to 8.

Description Enables the laser output of the DFB module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.1.3 CH#:ENABLE?

Syntax CH#:ENABLE?

Parameter • #: slot number of the module, in the range 1 to 8.

44 OSICS Programming Guide

Page 45

Description Returns the state of the laser-output control on the DFB module.

OSICS Response • CH#:ENABLED: the laser output is set to ENABLE.

• CH#:DISABLED: the laser output is set to DISABLE.

6.2 Unit Selection

6.2.1 CH#:GHZ

Syntax CH#:GHZ

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets GHz as the spectral unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

OSICS DFB Control

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

6.2.2 CH#:NM

Syntax CH#:NM

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets nm as the spectral unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.2.3 CH#:NM?

Syntax CH#:NM?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the actual spectral unit.

OSICS Response • CH#:1: the selected unit is nm.

• CH#:0: the selected unit is GHz.

OSICS Programming Guide 45

Page 46

OSICS DFB Control

6.2.4 CH#:DBM

Syntax CH#:DBM

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets dBm as the power unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

6.2.5 CH#:MW

Syntax CH#:MW

Parameter • #: slot number of the module, in the range 1 to 8.

Description Sets mW as the power unit of the module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.2.6 CH#:MW?

Syntax CH#:MW?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the actual power unit.

OSICS Response • CH#:1: the selected unit is mW.

• CH#:0: the selected unit is dBm.

46 OSICS Programming Guide

Page 47

OSICS DFB Control

6.3 Output-Power Setting

6.3.1 CH#:P=

Syntax CH#:P=[±]xx.xx|xx.xx

Parameters • #: slot number of the module, in the range 1 to 8.

• [±]xx.xx: optical output power in dBm, if the unit is set to dBm (see section Unit

Selection, p. 45). Possible values are given in the module Technical Specifications

section in the OSICS User Guide.

• xx.xx: optical output power in mW, if the unit is set to mW (see section Unit

Selection, p. 45). Possible values are given in the module Technical Specifications

section in the OSICS User Guide.

Description Sets the optical output-power of the module depending on the selected power unit (see

section Unit Selection, p. 45).

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

6.3.2 CH#:P?

Syntax CH#:P?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the current value of the output power according to the selected power unit. The

format of the response depends on the power unit selected (see section Unit Selection,

p. 45).

The module optical-output must be enabled (see section Optical-Output Control, p. 44).

OSICS Response • CH#:P=xx.xx: output-power value in mW.

• CH#:P=±xx.xx: output-power value in dBm.

• CH#:Disabled: the optical output is disabled; the output-power value cannot be

returned.

6.3.3 CH#:LIMIT?

Syntax CH#:LIMIT?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the state of the output power.

OSICS Response • CH#:1: the selected output power is not reached.

• CH#:0: the selected output power is reached.

OSICS Programming Guide 47

Page 48

OSICS DFB Control

6.4 Diode-Current Setting

6.4.1 CH#:I?

Syntax CH#:I?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the present current level in mA.

The module optical output must be enabled (see section Optical-Output Control, p. 44).

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS Response • CH#:I=xxx.x

• CH#:Disabled: the optical output is disabled; the current level value cannot be

returned.

6.4.2 CH#:IMAX?

Syntax CH#:IMAX?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the diode maximum current in mA.

OSICS Response CH#:IMAX=xxx.x

48 OSICS Programming Guide

Page 49

6.5 Optical Emission-Wavelength/Frequency Setting

6.5.1 CH#:L=

Syntax CH#:L=xxxx.xxx

Parameters • #: slot number of the module, in the range 1 to 8.

• xxxx.xxx: the emission wavelength value in nm. The possible wavelength range is

available by using the CH#:LMIN? and CH#:LMAX? commands (see p. 49).

Description Sets the emission wavelength of the module in nm.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.5.2 CH#:L?

Syntax CH#:L?

OSICS DFB Control

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the emission wavelength of the module in nm.

OSICS Response CH#:L=xxxx.xxx

6.5.3 CH#:LMAX?

Syntax CH#:LMAX?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the highest possible wavelength of the DFB module wavelength range in nm.

OSICS Response CH#=xxxx.xxx

6.5.4 CH#:LMIN?

Syntax CH#:LMIN?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the lowest possible wavelength of the DFB module wavelength range in nm.

OSICS Response CH#=xxxx.xxx

OSICS Programming Guide 49

Page 50

OSICS DFB Control

6.5.5 CH#:F=

Syntax CH#:F=xxxxxx.x

Parameters • #: slot number of the module, in the range 1 to 8.

• xxxxxx.x: the emission frequency value in GHz. The possible frequency range is

available by using the CH#:FMIN? and CH#:FMAX? commands (see p. 50).

Description Sets the emission frequency of the module in GHz.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

6.5.6 CH#:F?

Syntax CH#:F?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the emission frequency of the module in GHz.

OSICS Response CH#:F=xxxxxx.x

6.5.7 CH#:FMAX?

Syntax CH#:FMAX?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the highest possible frequency of the DFB module frequency range in GHz.

OSICS Response CH#=xxxxxx.x

6.5.8 CH#:FMIN?

Syntax CH#:FMIN?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the lowest possible frequency of the DFB module frequency range in GHz.

OSICS Response CH#=xxxxxx.x

50 OSICS Programming Guide

Page 51

6.6 Modulation Control

6.6.1 CH#:MOD_CTRL

Syntax CH#:MOD_CTRL OFF|ON|ON_INV

Parameters • #: slot number of the module, in the range 1 to 8.

• OFF (default setting): the digital modulation is turned off.

• ON: the digital modulation is turned on.

• ON_INV: the reversed digital modulation is turned on.

Description Sets the digital (TTL) modulation of the DFB module optical signal.

If you apply analog modulation directly via the SMB subclic connector at the module

faceplate, you must set this function to disable all pending digital modulation.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

OSICS DFB Control

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

6.6.2 CH#:MOD_CTRL?

Syntax CH#:MOD_CTRL?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the selected modulation activation state.

OSICS Response • CH#:MOD_CTRL=OFF: the modulation signal is set to OFF.

• CH#:MOD_CTRL=ON: the modulation signal is set to ON.

• CH#:MOD_CTRL=ON_INV: the modulation signal is set to ON INVERTED.

6.6.3 CH#:MOD_SRC

Syntax CH#:MOD_SRC MAIN|INT

Parameters • #: slot number of the module, in the range 1 to 8.

• MAIN: the modulation source is set to MAINFRAME.

• INT (default setting): the modulation source is set to INTERNAL.

Description Sets the modulation source of the DFB module.

• The MAINFRAME modulation signal may be generated either by the OSICS

Mainframe's own source, or by an external function generator connected to the

Mainframe's Mod. In BNC connector. To set the frequency of the internal Mainframe

generator, see section MOD_F=, p. 26.

OSICS Programming Guide 51

Page 52

BKR ATNDFBT100 SLDSWTTLS-AG SWT APC MAIN

OSICS DFB Control

• The internal source uses the module's built-in modulation signal generator. To set

the frequency of the internal TTL modulation, see the CH#:MOD_F= section of the

module.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.6.4 CH#:MOD_F=

Syntax CH#:MOD_F=xxxxxx

Parameters • #: slot number of the module, in the range 1 to 8.

• xxxxxx: frequency of the modulation signal in Hz, in the range 1 to 555000

(555 kHz).

Description Sets the frequency of the DFB module INTERNAL digital (TTL) modulation source.

If the module is not able to generate the exact value of the frequency setting, it applies

the nearest available frequency-value right under the value of the original setting.

To check the actual frequency of the INTERNAL modulation source see section

CH#:MOD_F=, p. 52.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.6.5 CH#:MOD_F?

Syntax CH#:MOD_F?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the frequency selected for the internal modulation generator in Hz.

OSICS Response CH#:MOD_F=xxxxxx

6.6.6 CH#:MOD_SRC?

Syntax CH#:MOD_SRC?

Parameter • #: slot number of the module, in the range 1 to 8.

Description Returns the selected modulation source.

OSICS Response • CH#:MOD_SRC=INT: the modulation source is set to INTERNAL.

• CH#:MOD_SRC=MAIN: the modulation source is set to MAINFRAME.

52 OSICS Programming Guide

Page 53

6.6.7 CH#:SIN_FREQ=

Syntax CH#:SIN_FREQ=xxx.x

Parameter • #: slot number of the module, in the range 1 to 8.

• xx.x: frequency of the sinus modulation signal in kHz, in the range 10 kHz to

100 kHz.

Description Sets the frequency of the DFB module's internal sinus modulation signal.

OSICS DFB Control

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.6.8 CH#:SIN_RATE=

Syntax CH#:SIN_RATE=xx.x

Parameter • #: slot number of the module, in the range 1 to 8.

• xx.x: amplitude rate of the sinus modulation signal in %, in the range of 0 % to 15 %.

Description Sets the amplitude rate of the DFB module's internal sinus modulation signal as a

percentage of the diode bias-current. For more details, see OSICS User Guide.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

6.6.9 CH#:SIN_OUT

Syntax CH#:SIN_OUT ON|OFF

BKRATN DFB T100SLD SWT TLS-AGSWT APCMAIN

Parameter • #: slot number of the module, in the range 1 to 8.

• ON: the sinus modulation function is set to on.

• OFF: the sinus modulation function is set to off.

Description Turns on or off the sinus modulation function.

OSICS Response • RS-232C: CH#:OK

• GPIB: none, see section Standard Status Model, p. 15.

OSICS Programming Guide 53

Page 54

OSICS DFB Control

6.6.10 CH#:SIN_FREQ?

Syntax CH#:SIN_FREQ?

Parameter • #: slot number of the module, in the range 1 to 8.