Page 1

Ethernet and

User Guide

Fibre Channel Application

FTB-8500 Series and FTB-8120NGE/8130NGE for FTB-500

Page 2

Copyright © 2003–2012 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

January 23, 2012

Version number: 7.0.2

ii FTB-8500 Series and FTB-8120NGE/8130NGE

Page 3

Contents

Certification Information ....................................................................................................... ix

1 Introducing the Ethernet and Fibre Channel Application ......................... 1

Conventions ............................................................................................................................3

2 Safety Information ....................................................................................... 5

Laser Safety Warnings .............................................................................................................5

Installation Instruction Warnings ............................................................................................6

3 Getting Started ............................................................................................ 9

IQS Manager Installation ........................................................................................................9

Inserting and Removing Test Modules ....................................................................................9

Turning the Unit On ................................................................................................................9

4 Physical Interfaces and LEDs ..................................................................... 11

IQS-8510B Model ..................................................................................................................11

IQS-8510G Model .................................................................................................................15

IQS-8525 and IQS-8535 Models ............................................................................................18

IQS-8120NGE and IQS-8130NGE Models ..............................................................................26

5 Introducing the Smart User Interface ....................................................... 35

Starting the Module Application ...........................................................................................35

Main Window .......................................................................................................................37

Global Test Status and Controls ............................................................................................44

Favorites ...............................................................................................................................48

Test Report Generation .........................................................................................................50

Typical Tab Elements .............................................................................................................54

Tab Configuration .................................................................................................................57

Keyboard Usage ....................................................................................................................61

Ethernet and Fibre Channel Application iii

Page 4

6 Creating and Starting a Test Case ..............................................................67

Introducing the Test Setup ....................................................................................................68

Test Case Availability .............................................................................................................72

EtherSAM (Y.1564) Test Case .................................................................................................73

Ethernet EtherSAM (Y.1564) and RFC 2544 Dual Test Set Test Cases .....................................80

Ethernet RFC 2544 Test Case .................................................................................................89

Ethernet BERT Test Case ........................................................................................................95

Ethernet Frame Analyzer Test Case ......................................................................................102

Ethernet Smart Loopback Test Case ....................................................................................109

Ethernet TCP Throughput Test Case ....................................................................................113

Fibre Channel BERT Test Case ..............................................................................................116

7 Summary Tabs ...........................................................................................121

Test Summary .....................................................................................................................121

Alarm Summary ..................................................................................................................128

Test Logger .........................................................................................................................131

8 Port Tabs ....................................................................................................133

Electrical TX ........................................................................................................................134

Electrical RX ........................................................................................................................136

Optical TX ...........................................................................................................................138

Optical RX ...........................................................................................................................140

Interface Setup (Ethernet) ...................................................................................................142

Interface Setup (Fibre Channel) ..........................................................................................146

Network ..............................................................................................................................150

Advanced Auto-Neg. TX .....................................................................................................154

Advanced Auto-Neg. RX .....................................................................................................159

iv FTB-8500 Series and FTB-8120NGE/8130NGE

Page 5

9 Traffic Analyzer Tabs ................................................................................ 161

Ethernet TX .........................................................................................................................162

Ethernet RX ........................................................................................................................165

Ethernet Statistics ...............................................................................................................168

PBB-TE ................................................................................................................................170

Higher Layers ......................................................................................................................172

Flow Control .......................................................................................................................174

Traffic Filters .......................................................................................................................177

Traffic Filter Configuration ..................................................................................................182

Traffic Filter Stats ................................................................................................................184

Capture ...............................................................................................................................186

Graph .................................................................................................................................191

FC TX ..................................................................................................................................192

FC RX ..................................................................................................................................195

FC Latency ..........................................................................................................................197

FC Statistics ........................................................................................................................199

10 Stream Generation Tabs .......................................................................... 201

Overview .............................................................................................................................202

Stream Configuration .........................................................................................................209

PBB-TE ................................................................................................................................218

MAC ...................................................................................................................................220

MPLS ...................................................................................................................................223

IP/UDP/TCP ..........................................................................................................................225

Payload ...............................................................................................................................228

Frame Configuration (Fibre Channel) ..................................................................................229

11 Stream Analyzer Tabs ............................................................................... 239

Overview .............................................................................................................................239

Stream ................................................................................................................................241

12 WIS Tabs .................................................................................................... 243

WIS TX ................................................................................................................................243

WIS RX ................................................................................................................................247

WIS OH RX ..........................................................................................................................250

13 Pattern Tabs .............................................................................................. 253

Pattern TX ...........................................................................................................................254

Pattern RX ...........................................................................................................................257

Ethernet and Fibre Channel Application v

Page 6

14 IPTV Tabs ....................................................................................................259

IPTV Testing with the IQS-8510B .........................................................................................260

Discovery ............................................................................................................................262

Overview .............................................................................................................................266

MDI/TR 101 290 ..................................................................................................................281

IGMP ...................................................................................................................................288

Stream Information ............................................................................................................294

15 RFC 2544 Tabs ............................................................................................299

Global Configuration ..........................................................................................................300

Throughput ........................................................................................................................304

Back-to-Back .......................................................................................................................309

Frame Loss ..........................................................................................................................313

Latency ...............................................................................................................................317

Graph .................................................................................................................................322

16 EtherSAM Tabs ..........................................................................................325

Overview (Configuration) ....................................................................................................326

Services (Configuration) ......................................................................................................331

Ramp (Configuration) .........................................................................................................337

Burst (Configuration) ..........................................................................................................339

Overview (Results) ..............................................................................................................342

Service Configuration Test (Results) ....................................................................................347

Service Performance Test (Results) ......................................................................................350

17 TCP Throughput Tabs ................................................................................353

TCP Throughput Configuration ...........................................................................................353

TCP Throughput Analysis ....................................................................................................357

18 Advanced Tab ............................................................................................359

Service Disruption Time (SDT) .............................................................................................359

19 Common Tab .............................................................................................363

Performance Monitoring (PM) ............................................................................................363

20 System Tabs ...............................................................................................367

Preferences .........................................................................................................................368

Default/Ethernet Test Preferences .......................................................................................370

IPv6 Test Preferences ...........................................................................................................373

FC Test Preferences .............................................................................................................376

Module Information ...........................................................................................................378

Software Options ................................................................................................................380

Clock Synchronization ........................................................................................................385

Remote Control ..................................................................................................................390

vi FTB-8500 Series and FTB-8120NGE/8130NGE

Page 7

21 Tools Tabs .................................................................................................. 391

Script ..................................................................................................................................392

Ping Configuration .............................................................................................................396

Ping Results ........................................................................................................................398

Trace Route Configuration ..................................................................................................401

Trace Route Results .............................................................................................................402

ENIU Configuration .............................................................................................................405

ADC Configuration .............................................................................................................406

802.3ah Configuration .......................................................................................................410

802.3ah Statistics ...............................................................................................................412

802.3ah Events ...................................................................................................................415

Traffic Scan .........................................................................................................................417

22 Expert Mode Tabs ..................................................................................... 425

Expert Mode (RFC 2544) .....................................................................................................426

Throughput (RFC 2544) ......................................................................................................428

Back-to-Back (RFC 2544) .....................................................................................................430

Frame Loss (RFC 2544) ........................................................................................................432

Latency (RFC 2544) .............................................................................................................434

Expert Mode (BERT) ............................................................................................................436

Port (BERT) ..........................................................................................................................437

Ethernet (BERT) ...................................................................................................................439

Pattern (BERT) .....................................................................................................................441

23 Power Failure Recovery ............................................................................ 443

24 Maintenance ............................................................................................. 445

Recalibrating the Unit .........................................................................................................446

Recycling and Disposal (Applies to European Union Only) ..................................................446

25 Troubleshooting ....................................................................................... 447

Solving Common Problems .................................................................................................447

Contacting the Technical Support Group ............................................................................448

Transportation ....................................................................................................................448

26 Warranty ................................................................................................... 449

General Information ...........................................................................................................449

Liability ...............................................................................................................................450

Exclusions ...........................................................................................................................451

Certification ........................................................................................................................451

Service and Repairs .............................................................................................................452

EXFO Service Centers Worldwide ........................................................................................453

Ethernet and Fibre Channel Application vii

Page 8

A Specifications ............................................................................................455

Ethernet Optical Interfaces .................................................................................................455

Fibre Channel Interfaces .....................................................................................................458

Ethernet Electrical Interfaces ..............................................................................................460

Synchronization Interfaces ..................................................................................................463

B Glossary .....................................................................................................465

Acronym List .......................................................................................................................465

VLAN/B-VLAN ......................................................................................................................478

MPLS Labels ........................................................................................................................479

Path Signal Label (C2 byte) .................................................................................................480

C Pop-Up Windows .......................................................................................481

VLAN Configuration ............................................................................................................482

PBB-TE Interface configuration ...........................................................................................483

IPv4 Configuration ..............................................................................................................485

IPv6 Address Configuration ................................................................................................487

Copy Service Network Configuration ..................................................................................492

Service Profile Configuration ..............................................................................................493

Framing Configuration .......................................................................................................494

Frame Size Configuration ....................................................................................................495

Frame Format Configuration ...............................................................................................497

MAC Configuration .............................................................................................................498

MPLS Configuration ............................................................................................................499

UDP Configuration ..............................................................................................................501

TCP Configuration ..............................................................................................................501

Advanced TOS/DS ...............................................................................................................502

Ping ....................................................................................................................................504

Filter Selection ....................................................................................................................506

Truncation Calculator ..........................................................................................................507

Field Match Configuration ..................................................................................................508

Triggered Frame Details ......................................................................................................510

Data Capture Export ...........................................................................................................511

Index ...............................................................................................................513

viii FTB-8500 Series and FTB-8120NGE/8130NGE

Page 9

Certification Information

Certification Information

Federal Communications Commission (FCC) and Industry Canada (IC) Information

Electronic test and measurement equipment is exempt from FCC Part 15

compliance in the United States and from IC ICES 003 compliance in

Canada. However, EXFO Inc. (EXFO) makes reasonable efforts to ensure

compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

European Union (CE) Information

Electronic test and measurement equipment is subject to the EMC

Directive in the European Union. The EN61326 standard prescribes both

emission and immunity requirements for laboratory, measurement, and

control equipment. This unit has been tested and found to comply with the

limits for a Class A digital device. Please refer to the CE Declaration of

Conformity on page xi.

Ethernet and Fibre Channel Application ix

Page 10

Certification Information

For continued compliance to the requirements of the EMC

Directive:

For IQS-8510G, use only double-shielded cable, type Belden 9907 or

equivalent, with a maximum length of 3m for CLOCK OUT port.

1. For IQS-8535 and IQS-8130NGE, for the BNC/EXT CLK port(s) use

double-shielded coaxial cable, type 734A or equivalent.

2. For IQS-8535 and IQS-8130NGE, for the REF OUT port use double

shielded cable, type LMR-240 ULTRAFLEX or equivalent, with a

maximum length of 3m.

Note: If the equipment described herein bears the CE symbol, the said equipment

complies with the applicable European Union Directive and Standards

mentioned in the Declaration of Conformity.

Laser

This product complies with 21 CFR 1040.10 and with EN 60825-1.

This product may employ a Class 1 or Class 1M laser SFP or XFP. The laser

classification is reproduced on the SFP/XFP.

x FTB-8500 Series and FTB-8120NGE/8130NGE

Page 11

CE Declaration of Conformity

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: Ethernet Test Module /

FTB-8510/8510B/8510G

AND

IQS-8510/8510B/8510G Packet Blazer

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification and

requirements

EN 55022: 2006 + A1: 2007 Information technology equipment — Radio disturbance

characteristics — Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directives and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: February 1, 2009

DECLARATION OF CONFORMITY

Certification Information

Ethernet and Fibre Channel Application xi

Page 12

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: Fibre Channel and Ethernet Test Modules /

FTB-8525/8535 AND IQS-8525/8535

Packet Blazer

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification and

requirements

EN 55022: 2006 + A1: 2007 Information technology equipment — Radio disturbance

characteristics — Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directives and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: February 1, 2009

DECLARATION OF CONFORMITY

xii FTB-8500 Series and FTB-8120NGE/8130NGE

Page 13

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: Next-Generation Multiservice Test Modules /

FTB-8120NGE/8130NGE

AND

IQS-8120NGE/8130NGE Power Blazer

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification and

requirements

EN 55022: 2006 + A1: 2007 Information technology equipment — Radio disturbance

characteristics — Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directives and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: February 1, 2009

DECLARATION OF CONFORMITY

Certification Information

Ethernet and Fibre Channel Application xiii

Page 14

Page 15

1 Introducing the Ethernet and

Fibre Channel Application

Fully integrated test solution for performance assessment of Fibre Channel

and Ethernet transport networks.

Complete EtherSAM™ (ITU-T Y.1564) test suite. EtherSAM is the new

standard for testing Ethernet mobile backhaul and commercial

services

Throughput, back-to-back, latency and frame loss measurements as

per RFC 2544 (bidirectional)

EtherBERT™ test functionality for assessing the integrity of Ethernet

services running on WDM networks

Multiple-stream generation and analysis, allowing quality of service

(QoS) verification through VLAN and TOS/DSCP prioritization testing

MPLS and PBB-TE support for complete carrier Ethernet validation

Capability to perform BERT, RFC 2544, EtherSAM, Frame Analyzer, and

Smart Loopback tests over IPv6.

Remote control capability through the Visual Guardian Lite software

TCP throughput measurements for assessing application data

transmission over a TCP connection

IPTV testing and analysis

LAN and WAN PHY capability in a single module

Packet jitter measurement to qualify Ethernet transport networks for

transmission of delay-sensitive traffic such as video and voice-over-IP

(VoIP)

FC-0, FC-1, and FC-2 logical layer configuration for Fibre Channel port

definition, testing, and performance analysis

Round-trip latency measurement and buffer-to-buffer credit estimation

1x, 2x, 4x, and 10x Fibre Channel traffic generation and BER testing

Ethernet and Fibre Channel Application 1

Page 16

Introducing the Ethernet and Fibre Channel Application

Capability to perform full-line-rate data capture and decode.

Capability to scan incoming live traffic and auto-discover all

VLAN ID/Priority and MPLS ID/COS flows.

This user guide covers the Ethernet and Fibre Channel testing of the

following products:

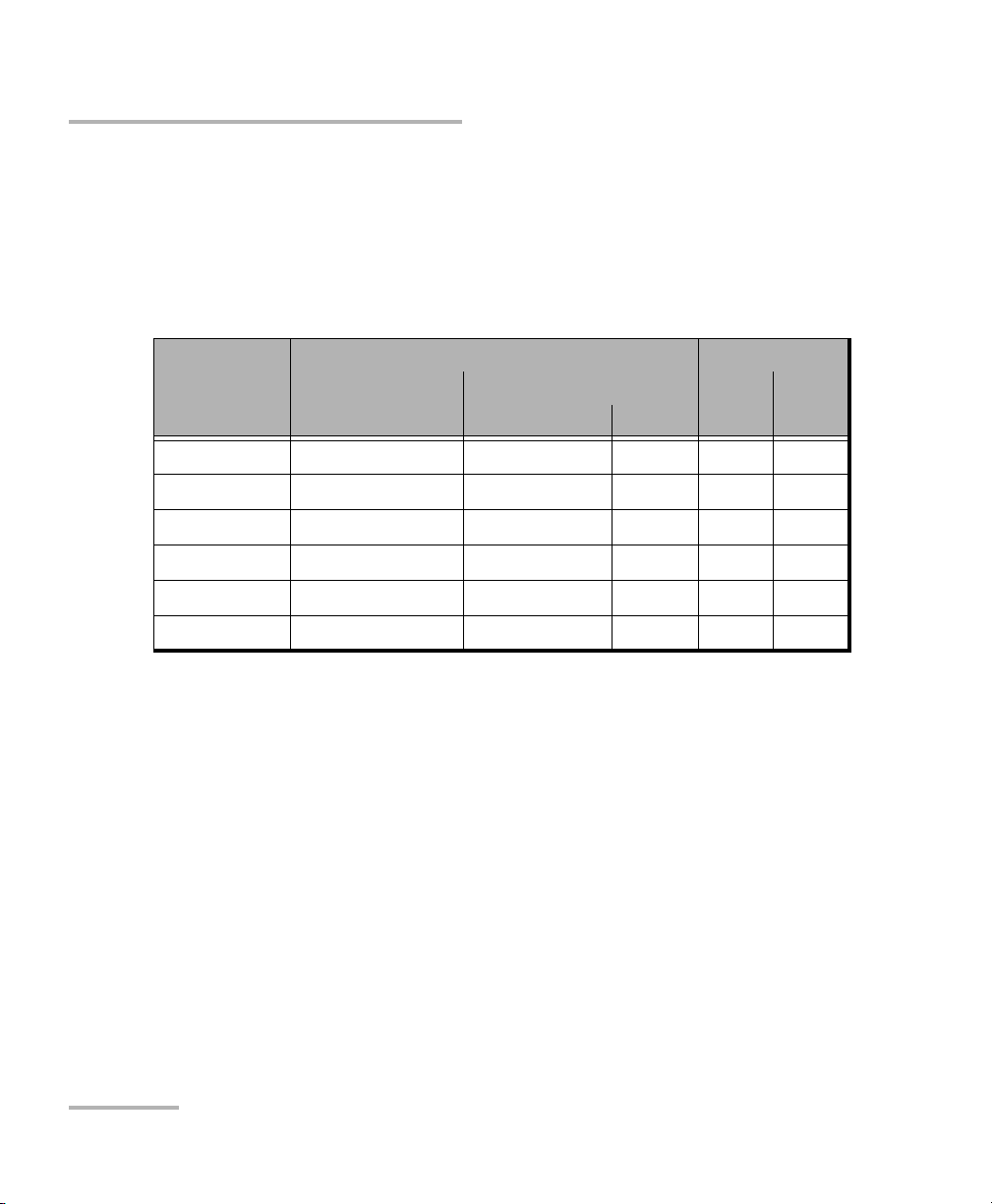

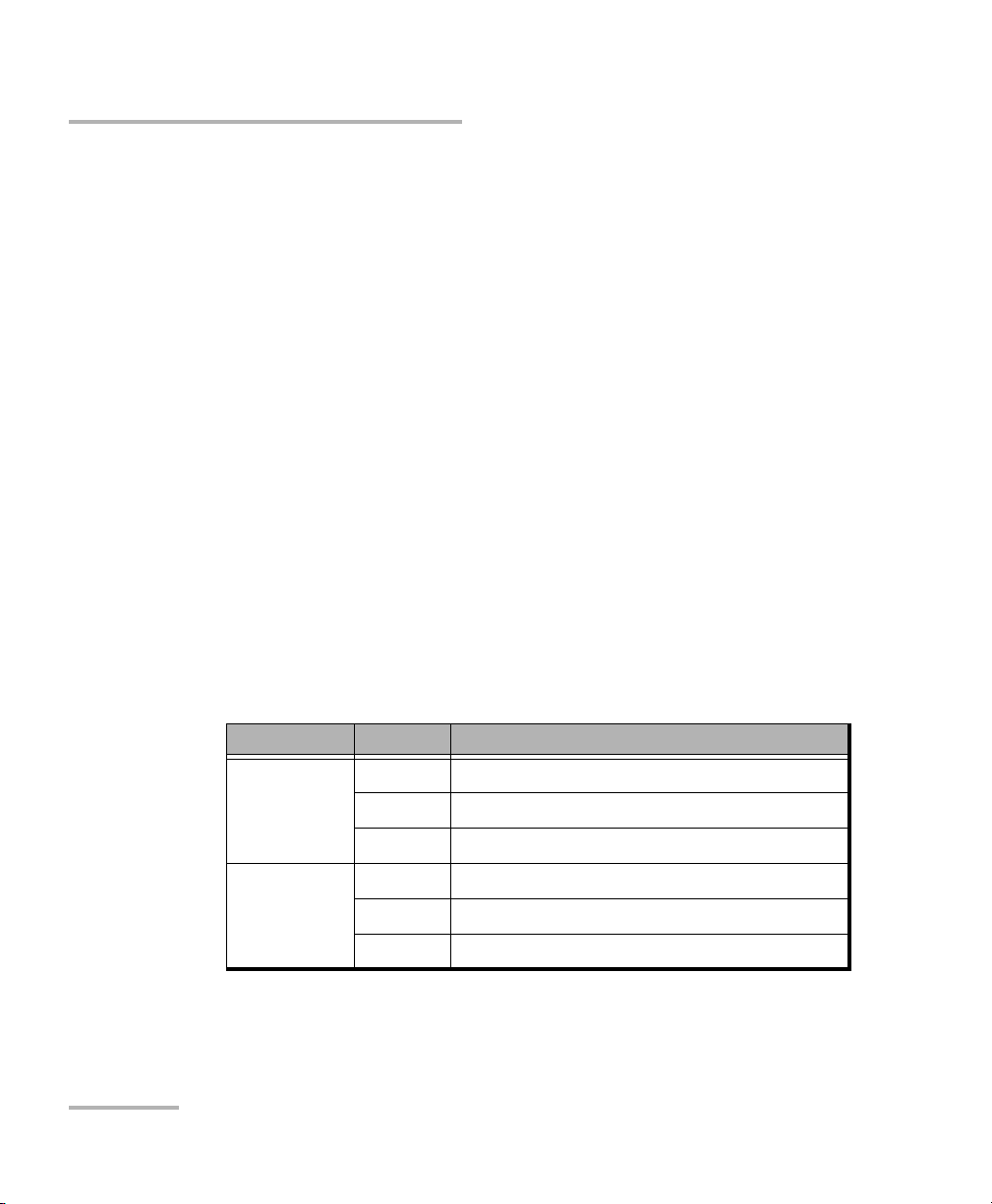

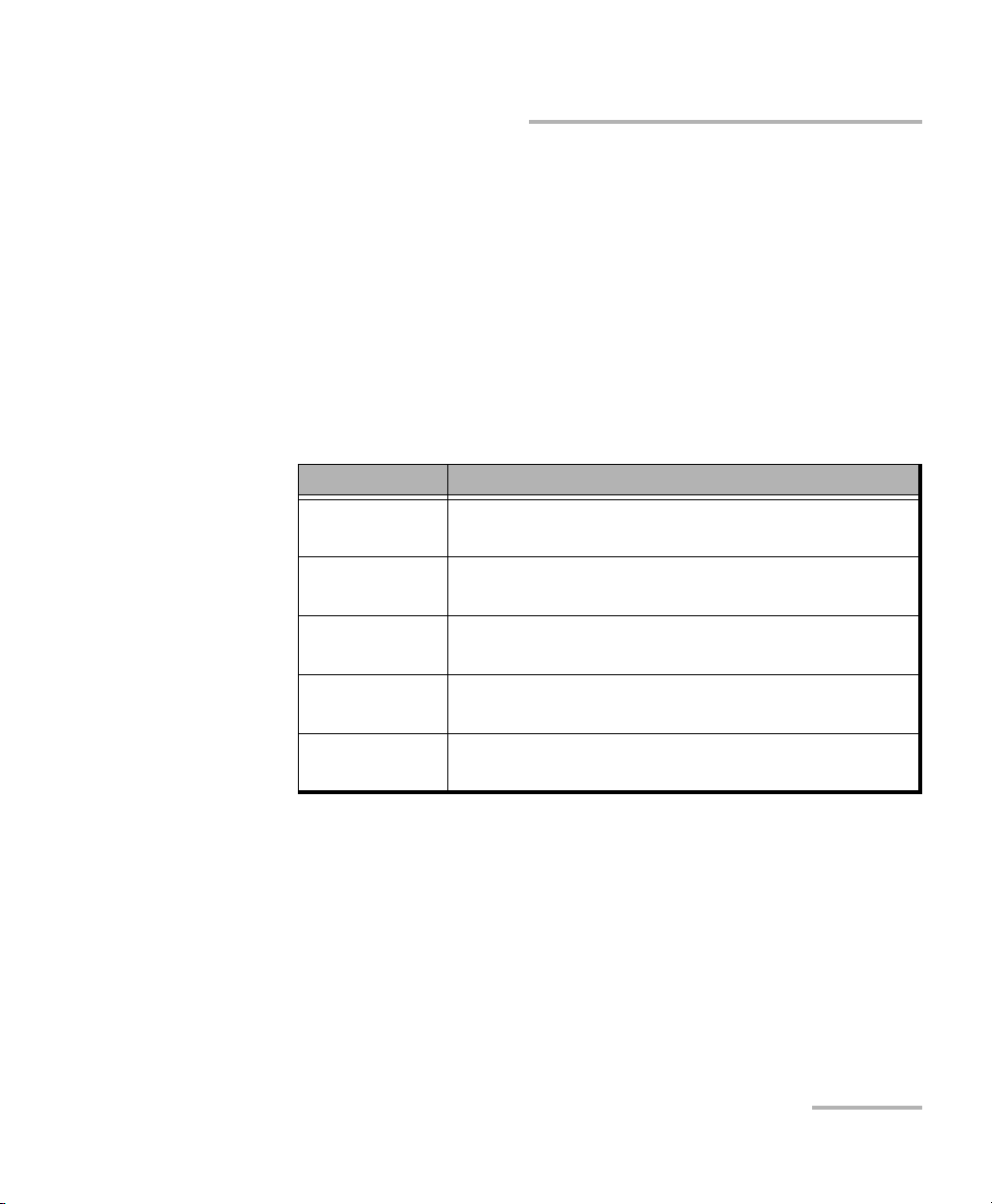

Ethernet (Electrical) Fibre Channel

Model Electrical Optical

10/100/1000 Mbps 100/1000 Mbps 10 Gbps 1x/2x 4x/10x

IQS-8510B X X X

IQS-8510G X

IQS-8525 X X X

IQS-8535 X X X X X

IQS-8120NGE X X X

IQS-8130NGE X X X X X

2 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 17

Introducing the Ethernet and Fibre Channel Application

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

Conventions

IMPORTANT

Refers to information about this product you should not overlook.

Ethernet and Fibre Channel Application 3

Page 18

Page 19

2 Safety Information

Laser Safety Warnings

WARNING

When the LASER LED is on, the IQS-8500 Series and

IQS-8120NGE/8130NGE is receiving/emitting an optical signal.

WARNING

Do not install or terminate fibers while a laser source is active.

Never look directly into a live fiber, and ensure that your eyes are

protected at all times.

WARNING

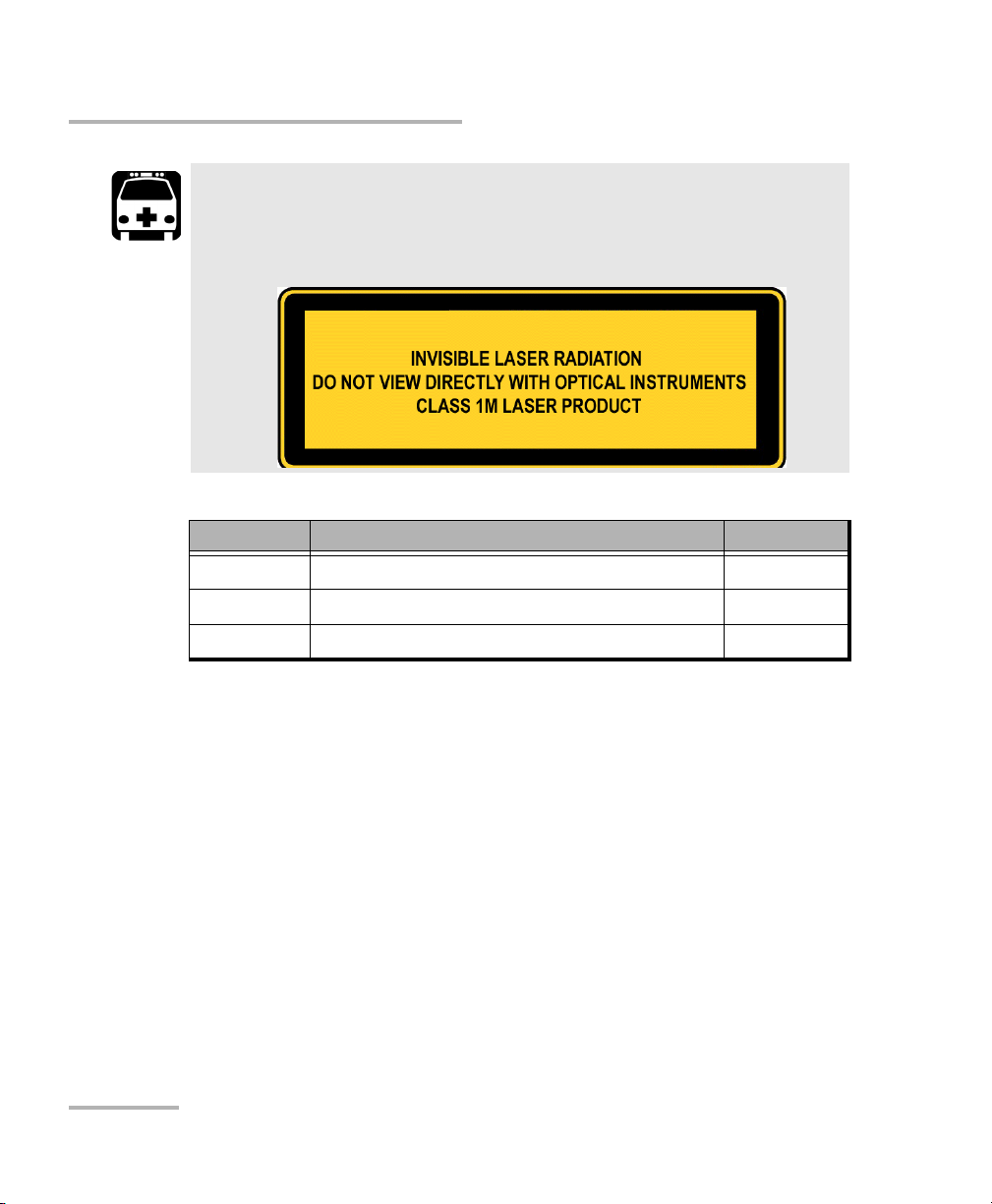

The IQS-8510B, IQS-8120NGE, and IQS-8525 may employ a Class 1M

SFP.

The IQS-8510G may employ a Class 1M laser XFP per IEC 60825-1.

The laser classification is reproduced on the XFP.

The IQS-8130NGE, and IQS-8535 may employ a Class 1M SFP and

XFP per IEC 60825-1. The laser classification is reproduced on the

XFP.

Ethernet and Fibre Channel Application 5

Page 20

Safety Information

Installation Instruction Warnings

Use of optical instruments with this product will increase eye

hazard.

Installation Instruction Warnings

This unit is for indoor use only.

All electrical interfaces are SELV (Safety Extra Low Voltage) circuitry

intended for intra-building use only.

To reduce the risk of fire, use only No. 26 AWG or larger

telecommunication line cord.

WARNING

CAUTION

CAUTION

CAUTION

No user serviceable parts are contained inside. Contact the

manufacturer regarding service of this equipment.

CAUTION

Keep all ventilation openings clear and unobstructed.

6 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 21

Safety Information

Installation Instruction Warnings

IMPORTANT

All wiring and installation must be in accordance with local building

and electrical codes acceptable to the authorities in the countries

where the equipment is installed and used.

CAUTION

Electrostatic Discharge (ESD) Sensitive Equipment:

Plug-in modules can be damaged by static electrical discharge. To

minimize the risk of damage, dissipate static electricity by touching

a grounded unpainted metal object

before removing, inserting, or handling the module.

before connecting or disconnecting cables to/from the module.

before inserting or removing SFP/XFPs to/from the module.

IMPORTANT

All telecom (electrical) interfaces are SELV (Safety Extra Low

Voltage) circuitry for intra-building use only.

Ethernet and Fibre Channel Application 7

Page 22

Page 23

3 Getting Started

If the Ethernet and Fibre Channel Application has been purchased at the

same time as the IQS-600, the Ethernet and Fibre Channel Application

module is pre-installed with the appropriate IQS Manager software version.

IQS Manager Installation

The IQS Manager is the baseline software and thus needs to be installed on

the IQS-600 before using the Ethernet and Fibre Channel Application

module.

Note: Refer to the IQS-600 platform user guide for more information on IQS

Manager installation procedure.

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the controller unit and its

expansion units are turned on. This will result in immediate and

irreparable damage to both the module and unit.

Note: Refer to the IQS-600 platform user guide for more information on how to

insert a module into the IQS-600 or to remove a module from the IQS-600.

Turning the Unit On

Turn on the IQS-600. Refer to the IQS-600 platform user guide for more

information.

Ethernet and Fibre Channel Application 9

Page 24

Page 25

4 Physical Interfaces and LEDs

Ethernet

10/100/1000 Mbps

Ethernet

100/1000 Mbps

This section describes all IQS-8500 Series and IQS-8120NGE/8130NGE

models, connectors (ports), and LEDs available on each module.

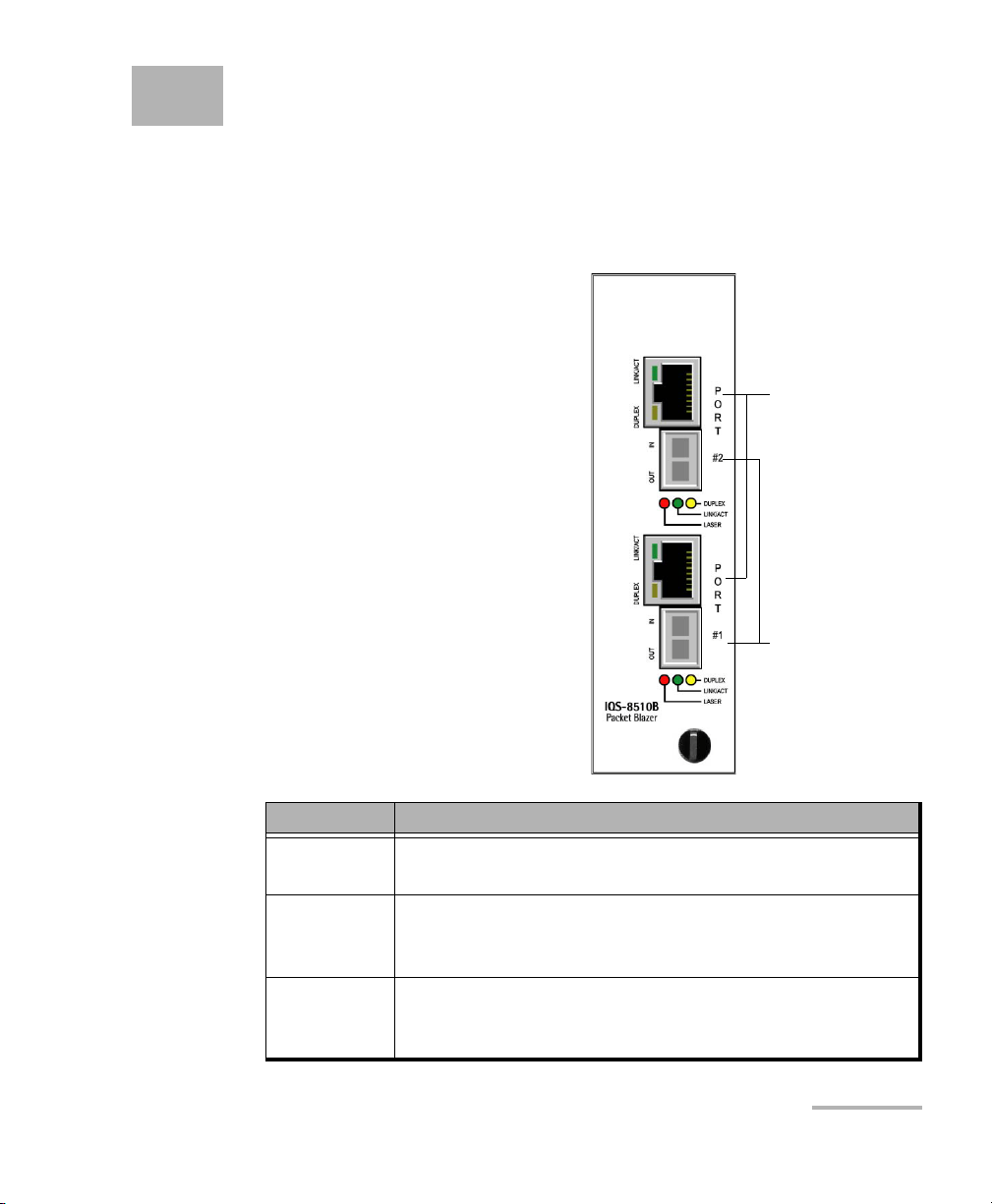

IQS-8510B Model

The IQS-8510B always comes with

two electrical 10/1000/1000 Mbps

Ethernet ports and two optical

ports that can be used either for

100/1000 Mbps Ethernet or 1x/2x

Fibre Channel, but only the

electrical 10/100 Mbps ports are

enabled on the basic model.

Ethernet and Fibre Channel Application 11

Model Description

IQS-8510B Ethernet and Fibre Channel Application with two electrical

10/100 Mbps Ethernet ports.

IQS-8510B-1 Ethernet and Fibre Channel Application with one electrical

10/100 Mbps Ethernet port, one electrical 10/100/1000 Mbps

Ethernet port and one 1000 Mbps Ethernet port.

IQS-8510B-2 Ethernet and Fibre Channel Application with two electrical

10/100/1000 Mbps Ethernet ports and two optical 1000

Mbps Ethernet ports.

Page 26

Physical Interfaces and LEDs

IQS-8510B Model

Note: The optical 100 Mbps Ethernet ports and Fibre Channel 1x and 2x ports are

available through software options. Refer to Software Options on page 380

for more information.

Electrical 10/100/1000 Mbps Ethernet

The IQS-8510B module provides two electrical ports for 10Base-T, or

100Base-TX. The IQS-8510B-1 and IQS-8510B-2 options add respectively

1000Base-T testing capability on one or both ports.

Port connector type is RJ-45 for category 5 unshielded twisted pair (UTP)

connection.

Note: Refer to Specifications on page 455 for cable specifications.

Connect the 10/100/1000 electrical signal to be tested to the port

10/100/1000 #1 or 10/100/1000 #2.

Note: Port #1 is the port enabled with the IQS-8510B-1 module for 1000Base-T

testing.

LEDs

LED Status Description

LINK/ACT

(Green)

On Ethernet link up.

Off Ethernet link down.

Flashing TX/RX activity.

DUPLEX

(Yellow)

On Full Duplex mode.

Off Half Duplex mode.

Flashing Collisions are detected.

12 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 27

Physical Interfaces and LEDs

IQS-8510B Model

Optical 100/1000 Mbps Ethernet or 1x/2x Fibre Channel

The IQS-8510B-1 and IQS-8510B-2 modules provide respectively one or

two optical ports for 1000Base-X Ethernet or Fibre Channel 1x/2x testing.

The optical 100Base-FX Ethernet and Fibre Channel 1x/2x are available

through software options.

The optical ports are Small Form Factor Pluggable (SFP) slot types (Dual or

Simplex LC connector).

Insert one of the following SFP modules into the optical #1/#2 slot.

Option Description

FTB-8590 1000Base-SX / FC 1x/2x (850nm) LC connectors

optical SFP transceiver module.

FTB-8591 1000Base-LX / FC 1x/2x (1300nm) LC connectors

optical SFP transceiver module.

FTB-8592 1000Base-ZX / FC 1x/2x (1550nm) LC connectors

optical SFP transceiver module.

FTB-85910 100Base-FX (1310nm, MMF, 2Km) LC connectors

optical SFP transceiver module.

FTB-85911 100Base-LX10 (1310nm, SMF, 15Km) LC connectors

optical SFP transceiver module.

Carefully connect optical fiber cables to the SFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fiber connector is

fully inserted into the optical connector port.

Note: Port #1 is the port enabled with the IQS-8510B-1 module for 1000Base-X

testing and when the optical 100M software option is enabled on one port

only.

Ethernet and Fibre Channel Application 13

Page 28

Physical Interfaces and LEDs

IQS-8510B Model

LEDs for Optical Ports

LED Status Description

LASER

(Red)

LINK/ACT

(Green)

DUPLEX

(Yellow)

Available

with Ethernet

interface only

On An optical signal is generated

Off No optical signal is generated

On Link up.

Off Link down.

Flashing TX/RX activity.

On Full Duplex mode.

Off Half Duplex mode, or when using

100Base-X or Fibre Channel interface.

Flashing Collisions are detected in half duplex mode.

14 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 29

Physical Interfaces and LEDs

IQS-8510G Model

IQS-8510G Model

IQS-8510G-LAN: One 10 Gigabit Ethernet LAN PHY (10.3125 Gbps) port

(LC connector type).

IQS-8510G-WAN: One 10 Gigabit Ethernet WAN PHY (9.953 Gbps) port (LC

connector type).

IQS-8510G-LAN/WAN: One 10 Gigabit Ethernet LAN/WAN PHY (10.3125 /

9.953 Gbps) port (LC connector type).

IQS-8585: Software option converting an IQS-8510G-LAN or

IQS-8510G-WAN model to an IQS-8510G-LAN/WAN model.

The IQS-8510G provides an optical

port labelled 10G ETHERNET, for

10 Gigabit Ethernet LAN/WAN testing

capability.

Insert one of the following XFP

optical transceiver into the 10G

ETHERNET slot.

Ethernet and Fibre Channel Application 15

Page 30

Physical Interfaces and LEDs

IQS-8510G Model

This product may employ a Class 1 or Class 1M laser XFP per IEC

60825-1. The laser classification is reproduced on the XFP.

Wavelength Description Part Number

850 nm Short-wave optics SR for LAN or SW for WAN FTB-85900

1310 nm Long-wave optics LR for LAN or LW for WAN FTB-85901

1550 nm Long-wave optics ER for LAN or EW for WAN FTB-85902

WARNING

Carefully connect optical fiber cables to the XFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

Note: Do not replace an XFP while the test is running to avoid distorting results.

First stop the test, replace the XFP, and then restart the test.

Note: Only use EXFO supported XFPs. Using non-supported XFPs can affect the

performance and accuracy of the optical port.

16 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 31

Physical Interfaces and LEDs

IQS-8510G Model

CAUTION

To prevent exceeding the maximum input power level, please use

an attenuator when a loopback configuration is used.

LEDs

LASER LED: The red LASER LED is on when the IQS-8500 Series and

IQS-8120NGE/8130NGE is emitting an optical laser signal.

LINK/ACT LED: The LINK/ACT LED is on when the link is up, off when

the link is down, and flashing when frames are transmitted and/or

received.

Ethernet and Fibre Channel Application 17

Page 32

Physical Interfaces and LEDs

External Clock

Ethernet 10/100/1000M

FC 1x/2x/4x

Ethernet 100/1000M

Clock (REF OUT)

FC 10x

Ethernet 10G

IQS-8525 and IQS-8535 Models

IQS-8525 and IQS-8535 Models

IQS-8525 Fibre Channel (1x/2x/4x) and Ethernet (10/100/1000M) analyzer.

IQS-8535 Fibre Channel (1x/2x/4x/10x) and Ethernet (10/100/1000M /

10Gig) analyzer.

18 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 33

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

The following table shows the list of available ports as well as a description

and signals supported for each model.

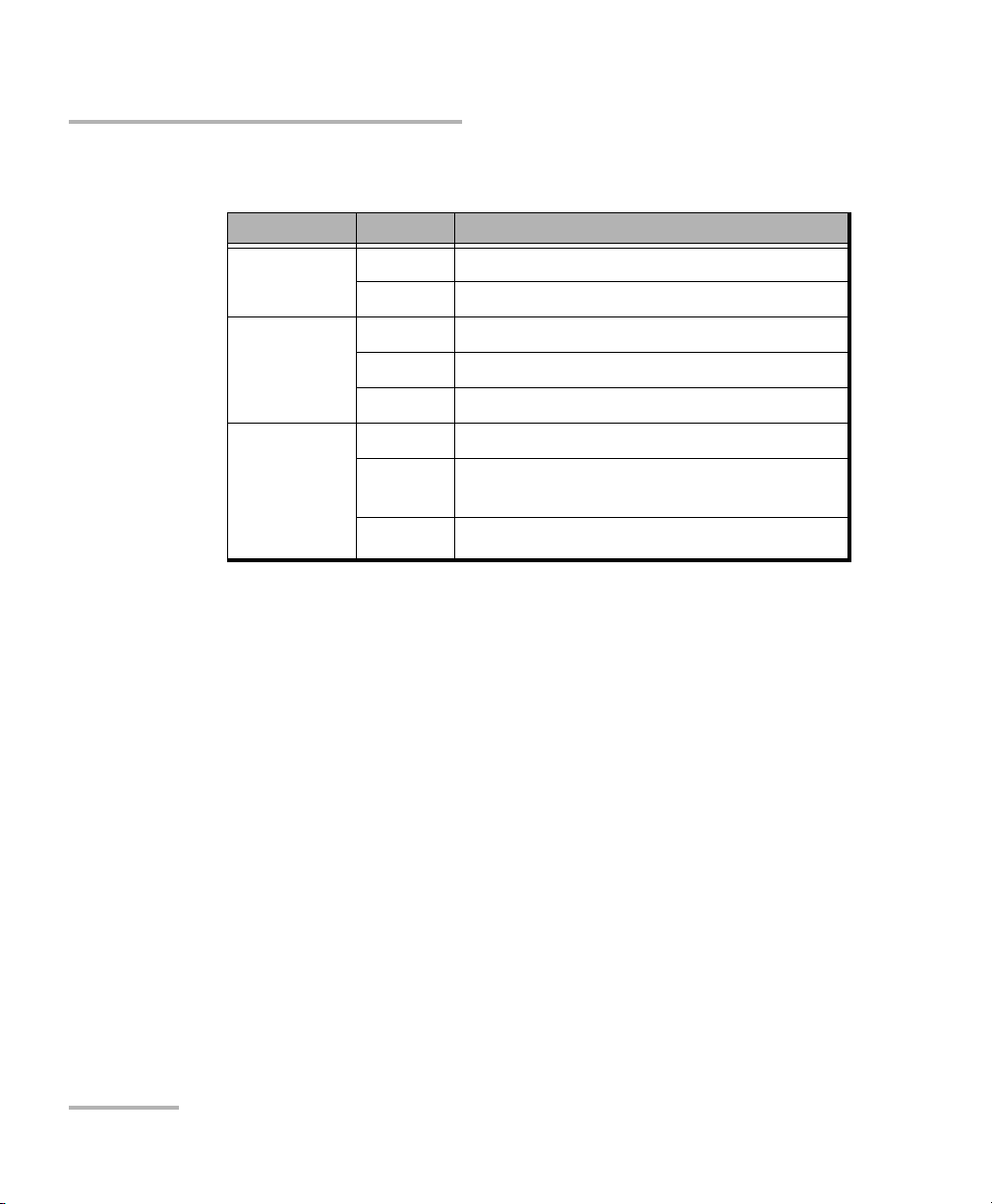

Port labelled Description Supported signal(s) Model

FC 1x/2x/4x

ETHERNET

Optical IN/OUT port small

form pluggable (SFP)

Fibre Channel 1x, 2x, and 4x

Ethernet 100 Mbps and 1 Gbps

IQS-8525

IQS-8535

100M/1G

FC 10x

ETHERNET 10G

Ethernet

10/100/1000M

EXT CLK Electrical port BNC DS1/1.5M/E1/2M signal for

Optical IN/OUT port small

form pluggable (XFP)

Electrical Ethernet port

RJ-45

Fibre Channel 10x

IQS-8535

Ethernet 10 Gbps

10/100/1000 Mbps (electrical) IQS-8525

IQS-8535

IQS-8535

external clock synchronization.

REF OUT Reference output port SMA IQS-8535

Electrical 10/100/1000 Mbps Ethernet

The IQS-8525/IQS-8535 module provides one electrical port for 10Base-T,

100Base-T, or 1000Base-T.

Port connector type is RJ-45 for category 5 unshielded twisted pair (UTP)

connection.

Note: Refer to Specifications on page 455 for cable specifications.

Connect the 10/100/1000 electrical signal to be tested to the port

ETHERNET 10/100/1000.

Ethernet and Fibre Channel Application 19

Page 34

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

LEDs

LED Status Description

LINK/ACT

(Green)

DUPLEX

(Yellow)

On Ethernet link up.

Off Ethernet link down.

Flashing TX/RX activity.

On Full Duplex mode.

Off Half Duplex mode.

Flashing Collisions are detected.

20 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 35

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

Optical Fibre Channel 1x/2x/4x or Ethernet 100/1000 Mbps

The IQS-8525 module provides one optical port for Fibre Channel 1x/2x/4x

testing. The optical Ethernet 100Base-FX and 1000Base-X are available

through software options. Fibre Channel 1x/2x/4x and Ethernet testing are

available through software options on the IQS-8535 model.

The optical ports are Small Form Factor Pluggable (SFP) slot types (Dual or

Simplex LC connector).

Insert one of the following SFP modules into the optical #1/#2 slot.

Description Wavelength Reach Part Number

Multirate (FC 1x/2x)

optical SFP transceiver

module with LC

connector

Ethernet 100 Mbps

optical SFP transceiver

module with LC

connector

Gig-E / FC 1x/2x optical

SFP transceiver module

with LC connector

Gig-E / FC 1x/2x/4x

optical SFP transceiver

module with LC

connector

1310 nm short (15 Km) FTB-8190

1310 nm intermediate (40 Km) FTB-8191

1550 nm intermediate (40 Km) FTB-8193

1550 nm long (80 Km) FTB-8192

1310 nm MM FTB-85910

1310 nm SM FTB-85911

850 nm MMF (<500 m) FTB-8590

1310 nm 10 Km FTB-8591

1550 nm 90 Km FTB-8592

850 nm MMF (<500 m) FTB-85912

1310 nm SMF (4 Km) FTB-85913

1310 nm SMF (30 Km) FTB-85914

1550 nm SMF (40 Km) FTB-85915

Ethernet and Fibre Channel Application 21

Page 36

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

Carefully connect optical fiber cables to the SFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fiber connector is

fully inserted into the optical connector port.

LEDs for Optical Ports

LED Status Description

LASER

(Red)

RX LED used

for Ethernet

and Fibre

Channel

Link/Activity

status

On An optical signal is generated

Off No optical signal is generated

On Link up

Off Link down

Flashing TX/RX activity

22 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 37

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

Fibre Channel 10x and 10G Ethernet

The IQS-8525/IQS-8535 provides an optical port for Fibre Channel 10x or

10 Gigabit Ethernet LAN/WAN testing capability.

Insert one of the following XFP optical transceiver into the

FC 10x - ETHERNET 10G slot.

WARNING

This product may employ a Class 1 or Class 1M laser XFP per IEC

60825-1. The laser classification is reproduced on the XFP.

Description Wavelength Reach Part Number

For Ethernet 10G:

10 Gbps optical XFP

transceiver module with LC

connector

For Ethernet 10G or

Fibre Channel 10x:

Multirate (10/10.7 Gbps)

optical transceiver module

with LC connector

Ethernet and Fibre Channel Application 23

850 nm Short-wave SR for LAN or

SW for WAN

1310 nm Long-wave

LR for LAN or LW for WAN

1550 nm Long-wave ER for LAN or

EW for WAN

1310 nm 10 Km FTB-81900

1310 nm 40 Km FTB-81901

1550 nm 80 Km FTB-81902

FTB-85900

FTB-85901

FTB-85902

Page 38

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

Carefully connect optical fiber cables to the XFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

Note: Do not replace an XFP while the test is running to avoid distorting results.

First stop the test, replace the XFP, and then restart the test.

Note: Only use EXFO supported XFPs. Using non-supported XFPs can affect the

performance and accuracy of the optical port.

CAUTION

To prevent exceeding the maximum input power level, please use

an attenuator when a loopback configuration is used.

Carefully connect optical fiber cables to the XFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

Note: Do not replace an XFP while the test is running to avoid distorting results.

First stop the test, replace the XFP, and then restart the test.

Note: Only use EXFO supported XFPs. Using non-supported XFPs can affect the

performance and accuracy of the optical port.

CAUTION

To prevent exceeding the maximum input power level, please use

an attenuator when a loopback configuration is used.

24 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 39

Physical Interfaces and LEDs

IQS-8525 and IQS-8535 Models

LEDs

LASER LED: The red LASER LED is on when the IQS-8500 Series and

IQS-8120NGE/8130NGE is emitting an optical laser signal.

LINK/ACT LED: The LINK/ACT LED is on when the link is up, off when

the link is down, and flashing when frames are transmitted and/or

received.

Ethernet and Fibre Channel Application 25

Page 40

Physical Interfaces and LEDs

External Clock

Ethernet 10/100/1000M

FC 1x/2x/4x

Ethernet 100/1000M

Clock (REF OUT)

FC 10x

Ethernet 10G

IQS-8120NGE and IQS-8130NGE Models

IQS-8120NGE and IQS-8130NGE Models

IQS-8120NGE Ethernet (10/100/1000M) and Fibre Channel (1x/2x/4x)

analyzer.

IQS-8130NGE Ethernet (10/100/1000M / 10Gig) and Fibre Channel

(1x/2x/4x/10x) analyzer.

Note: Only the ports related to the Ethernet and Fibre Channel application are

covered by this user guide; refer to the SONET/SDH user guide for more

information on the other ports.

26 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 41

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

The following table shows the list of available ports as well as a description

and signals supported for each model.

Port labelled Description Supported signal(s) Model

100M-4.25G Optical IN/OUT port small

form pluggable (SFP)

Fibre Channel 1x, 2x, and 4x

Ethernet 100 Mbps and 1

IQS-8120NGE

IQS-8130NGE

Gbps

10G-11.3G Optical IN/OUT port small

form pluggable (XFP)

Ethernet

10/100/1000M

Electrical Ethernet port

RJ-45

AUX Electrical port BNC DS1/1.5M/E1/2M or 1PPS

Fibre Channel 10x

Ethernet 10 Gbps

10/100/1000 Mbps

(electrical)

signal for external clock

IQS-8130NGE

IQS-8120NGE

IQS-8130NGE

IQS-8120NGE

IQS-8130NGE

synchronization.

REF OUT Reference output port SMA IQS-8130NGE

Electrical 10/100/1000 Mbps Ethernet

The IQS-8120NGE/IQS-8130NGE module provides one electrical port for

10Base-T, 100Base-TX, or 1000Base-T.

Port connector type is RJ-45 for category 5 unshielded twisted pair (UTP)

connection.

Note: Refer to section A for cable specifications.

Connect the 10/100/1000 electrical signal to be tested to the port

ETHERNET 10/100/1000 of the IQS-8500 Series and

IQS-8120NGE/8130NGE module.

Ethernet and Fibre Channel Application 27

Page 42

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

LEDs

LED Status Description

LINK/ACT

(Green)

DUPLEX

(Yellow)

On Ethernet link up.

Off Ethernet link down.

Flashing TX/RX activity.

On Full Duplex mode.

Off Half Duplex mode.

Flashing Collisions are detected.

28 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 43

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

Optical 100/1000 Mbps Ethernet or 1x/2x/4x Fibre Channel

The IQS-8500 Series and IQS-8120NGE/8130NGE module provides one

optical port for 1000Base-X Ethernet testing or Fibre Channel 1x/2x/4x

testing. The optical 100Base-FX Ethernet and Fibre Channel 1x/2x/4x are

available through software options.

The optical ports are Small Form Factor Pluggable (SFP) slot types (Dual or

Simplex LC connector).

Insert one of the following SFP modules into the optical #1/#2 slot.

Description Wavelength Reach Part Number

Multirate (FC 1x/2x) optical SFP

transceiver module with LC

connector

Ethernet 100 Mbps optical SFP

transceiver module with LC

connector

Gig-E / FC 1x/2x optical SFP

transceiver module with LC

connector

Gig-E / FC 1x/2x/4x optical SFP

transceiver module with LC

connector

1310 nm short (15 Km) FTB-8190

1310 nm intermediate (40 Km) FTB-8191

1550 nm intermediate (40 Km) FTB-8193

1550 nm long (80 Km) FTB-8192

1310 nm MM FTB-85910

1310 nm SM FTB-85911

850 nm MMF (<500 m) FTB-8590

1310 nm 10 Km FTB-8591

1550 nm 90 Km FTB-8592

850 nm MMF (<500 m) FTB-85912

1310 nm SMF (4 Km) FTB-85913

1310 nm SMF (30 Km) FTB-85914

1550 nm SMF (40 Km) FTB-85915

Ethernet and Fibre Channel Application 29

Page 44

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

Carefully connect optical fiber cables to the SFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fiber connector is

fully inserted into the optical connector port.

LEDs for Optical Ports

LED Status Description

LASER

(Red)

RX LED used

for Ethernet

and Fibre

Channel

Link/Activity

status

On An optical signal is generated

Off No optical signal is generated

On Link up

Off Link down

Flashing TX/RX activity

30 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 45

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

10G Ethernet and Fibre Channel 10x

The IQS-8525/IQS-8535 provides an optical port for 10 Gigabit Ethernet

LAN/WAN or Fibre Channel 10x testing capability.

Insert one of the following XFP optical transceiver into the 10-11.3G slot.

WARNING

This product may employ a Class 1 or Class 1M laser XFP per IEC

60825-1. The laser classification is reproduced on the XFP.

Description Wavelength Reach Part Number

For Ethernet 10G:

10 Gbps optical XFP

transceiver module with LC

connector

For Ethernet 10G or

Fibre Channel 10x:

Multirate (10/10.7 Gbps)

optical transceiver module

with LC connector

Ethernet and Fibre Channel Application 31

850 nm Short-wave SR for LAN or

SW for WAN

1310 nm Long-wave

LR for LAN or LW for WAN

1550 nm Long-wave ER for LAN or

EW for WAN

1310 nm 10 Km FTB-81900

1310 nm 40 Km FTB-81901

1550 nm 80 Km FTB-81902

FTB-85900

FTB-85901

FTB-85902

Page 46

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

Carefully connect optical fiber cables to the XFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

Note: Do not replace an XFP while the test is running to avoid distorting results.

First stop the test, replace the XFP, and then restart the test.

Note: Only use EXFO supported XFPs. Using non-supported XFPs can affect the

performance and accuracy of the optical port.

CAUTION

To prevent exceeding the maximum input power level, please use

an attenuator when a loopback configuration is used.

Carefully connect optical fiber cables to the XFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

Note: Do not replace an XFP while the test is running to avoid distorting results.

First stop the test, replace the XFP, and then restart the test.

Note: Only use EXFO supported XFPs. Using non-supported XFPs can affect the

performance and accuracy of the optical port.

CAUTION

To prevent exceeding the maximum input power level, please use

an attenuator when a loopback configuration is used.

32 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 47

Physical Interfaces and LEDs

IQS-8120NGE and IQS-8130NGE Models

LEDs

LASER LED: The red LASER LED is on when the IQS-8500 Series and

IQS-8120NGE/8130NGE is emitting an optical laser signal.

LINK/ACT LED: The LINK/ACT LED is on when the link is up, off when

the link is down, and flashing when frames are transmitted and/or

received.

Clock

Note: Clock Synchronization is only available for Ethernet 10G and Fibre

Channel 10x interfaces or for Dual Test Set in one-way latency

measurement mode.

Connect the signal clock to the AUX port.

Use a DS1 or E1 clock signal for Ethernet 10G and Fibre Channel 10x

tests.

Use an 1PPS signal for Dual Test Set in one-way latency measurement

mode. Only available with IQS-8120NGE and IQS-8130NGE in Dual Test

Set one-way latency measurement mode.

Ethernet and Fibre Channel Application 33

Page 48

Page 49

5 Introducing the Smart User

Interface

Starting the Module Application

To Start the IQS-8500 Series and IQS-8120NGE/8130NGE

Application:

1. Once your IQS-8500 Series and IQS-8120NGE/8130NGE module is

installed, turn on the IQS-600.

2. In the IQS Manager main window, under Modules, press IQS-8500

Series and IQS-8120NGE/8130NGE once to select the module.

3. Press Start Application to start the Smart User Interface (SUI) for

IQS-8510B/IQS-8510G/IQS-8525/IQS-8535 or the Network Analyzer for

IQS-8120NGE/IQS-8130NGE. The Network Analyzer application allows

to either run the SONET/SDH application or the Packet Analyzer

application. Both applications cannot run simultaneously.

Ethernet and Fibre Channel Application 35

Page 50

Introducing the Smart User Interface

Starting the Module Application

4. Fo r IQS-8120NGE/IQS-8130NGE only, on the Available Applications,

under the Applications tab, press Packet Analyzer to start the Smart

User Interface (SUI) for Ethernet and Fibre Channel test.

Refer to the SONET/SDH Application user guide for more information

on SONET/SDH.

The exit button ( X ) closes the Network Analyzer, SONET/SDH

Analyzer, and/or Ethernet Analyzer applications. If a test is created,

one of the following confirmation messages is displayed, based on the

standalone feature status (enabled or not). Refer to the IQS-600 user

guide for more information on the standalone feature.

Exiting the SUI while a test is created and standalone is disabled:

Are you sure you want to exit the Network Analyzer,

SONET/SDH Analyzer, and Ethernet Analyzer? Any unsaved

information will be lost.

Exiting the SUI while a test is created and standalone is enabled:

Exiting the application will maintain the module alive as the

Standalone mode is enabled. Are you sure you want to exit?

36 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 51

Main Window

Application name

Minimize

Help

Exit

Ta bs

Ta b( s )

Ta b’ s

Content

Remote

status

Date and time

Battery level /

AC power

Tes t c o ntro l s

Global test status

Introducing the Smart User Interface

Main Window

Ethernet and Fibre Channel Application 37

Page 52

Introducing the Smart User Interface

Main Window

Tabs

The SUI application contains the following four main application tabs that

contain other tabs.

TEST Tab

The TEST tab gives access to the test creation, configuration, and

results.

Note: Only the Setup tab is available when there is no test created.

Setup tab is part of the TEST tab and allows setting up the test. Refer to

page 68 for more information.

Once the test is created, other tabs containing one or two tabs are

enabled allowing configuration of test parameters and viewing of the

test status and results.

38 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 53

Introducing the Smart User Interface

Port 1

Port 2

Main Window

For Dual ports (IQS-8510B only), see the figure below for the

localization of the port number on each tabs.

Ethernet and Fibre Channel Application 39

Page 54

Introducing the Smart User Interface

Main Window

In this user guide, the tabs are grouped as shown below:

Summary Tabs on page 121

Port Tabs on page 133

Stream Generation Tabs on page 201

Stream Analyzer Tabs on page 239

Traffic Analyzer Tabs on page 161

IPTV Tabs on page 259 (IQS-8510B)

Patter n Tab s on page 253

RFC 2544 Tabs on page 299

EtherSAM Tabs on page 325

TCP Throughput Tabs on page 353 (not available on IQS-8510G)

Advanced Tab on page 359

WIS Tabs on page 243 (IQS-8510G, IQS-8535, and IQS-8130NGE)

Common Tab on page 363

Expert Mode Tabs on page 425

System tab; refer to page 367 for more information.

Tool s tab; refer to page 391 for more information.

About tab; gives information on EXFO company, contact, and product

software release version.

40 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 55

Introducing the Smart User Interface

Main Window

Application Title

Displays the software application title which is [x] - EXFO followed by the

application name. Where x is the slot ID in which the module is inserted.

A module description appears in front of the [x] slot ID when defined in

IQS Manager. Refer to Tool s, Remote Control Configuration and Module

Description field from the IQS-600 user guide for more information.

For Visual Guardian Lite, the IP address of the IQS-600 is inserted after the

[x] slot ID.

For example: Module #1 - [2] - 10.1.200.25 - EXFO Packet Blazer

Minimize

The minimize button ( _ ) allows minimization of a remote SUI application

(Visual Guardian Lite).

Ethernet and Fibre Channel Application 41

Page 56

Introducing the Smart User Interface

Main Window

Help

The help button ( ? ) displays the help

information on the current window. A

window pops up to select the area of the

application where help is required. Press

OK and the help information is

immediately displayed.

It is also possible to navigate through the

help information once the help window is open.

42 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 57

Introducing the Smart User Interface

Main Window

Exit

For IQS-8510B, IQS-8510G, IQS-8525, and IQS-8535:

The exit button ( X ) closes the current application. If a test is created,

one of the following confirmation messages is displayed, based on the

standalone feature status (enabled or not). Refer to the IQS-600 user

guide for more information on the standalone feature.

The following message is displayed when exiting the SUI while a

test is created and standalone is disabled:

Are you sure you want to exit the Ethernet and Fibre Channel

Application? Any unsaved information will be lost.

The following message is displayed when exiting the SUI while a

test is created and standalone is enabled:

Exiting the application will maintain the module alive as the

Standalone mode is enabled. Are you sure you want to exit?

For IQS-8120NGE, and IQS-8130NGE:

The exit button ( X ) switches from the current application to the

Network Analyzer application. If the test is running, a user

confirmation is required to stop the test before switching the

application. The switching puts the application in idle mode meaning

that the test case configuration is kept and will be recovered when

returning to that application.

Ethernet and Fibre Channel Application 43

Page 58

Introducing the Smart User Interface

Global Test Status and Controls

Global Test Status and Controls

Global Test Status

The global test status area displays the alarm, verdict, and test timer.

Clicking on this area maximizes the view of these status. The maximized

view is useful to facilitate distant viewing of these status.

To minimize the view, either click on the global test status area or click

anywhere on the maximized status area.

H (History): Indicates that alarms/errors occurred in the past. A grey

background indicates that the test did not run yet, a green background

indicates that no alarm/error has occurred, while a red background

indicates that at least one alarm/error has occurred.

44 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 59

Introducing the Smart User Interface

Global Test Status and Controls

Current status: Indicates the current alarm/error status of the test. A

grey background indicates that the test is not running (--), a green

background indicates that there is no alarm/error (NO ALARM), while

a red background indicates that at least one alarm/error condition has

occurred in the last second (ALARM).

Note: The history and current alarm/error status are monitored once the test is

started.

Verdict: Gives the verdict, PA SS (green background) or FAIL (red

background) of the test according to the defined threshold settings.

Verdict is only displayed with EtherSAM, RFC 2544, and BERT tests. For

RFC 2544 and BERT tests, at least one of the Enable criteria check

boxes must be selected. Refer to EtherSAM Tabs on page 325 or to

Expert Mode Tabs on page 425 (RFC 2544 and BERT tests) for more

information.

The test timer indicates the time elapsed since the beginning of the

test. The test timer format is day hour:minute:second.

Test Controls

Button Description

Start: Starts the test. Start is available when the test is created and not running.

a

: Stops the test.

Stop

a

H. Reset

Reset

(H) and current (C) LEDs for the entire test case. Also resets the logger.

Report

page 50 for more information.

New

the test.

Ethernet and Fibre Channel Application 45

: Resets the history (H) alarm and error LEDs.

a

: Resets counters (seconds, count, and rate), test timer and both history

b

: Generates a report of the current test. See Test Report Generation on

b

: Clears the current test. A user’s confirmation is required before clearing

Page 60

Introducing the Smart User Interface

Global Test Status and Controls

Button Description

Loadb: Loads a previously saved configuration. Select an existing file and press

Open to confirm. The default directory is

d:\IQSManager\User Files\PacketBlazerG2\Configuration. The configuration file

extension is cfg.

An error message is displayed and the configuration is not loaded when the file

is corrupted, the module is not properly installed, the hardware or software

options are not compatible, or when the resources or power are not sufficient.

b

: Saves the current test configuration. Select an existing file, or type a new

Save

name in the File name field, and press Save. The default directory is

d:\IQSManager\User Files\PacketBlazerG2\Configuration.

a

Send

: Generates pattern bit error according to the amount selected on the

Pattern TX tab. Refer to Pattern Error Injection on page 256. This button is only

available with BERT test.

a

Set

: Allows selecting the port that will be used for pattern bit error injection.

See Send button for error injection. This button is only available with BERT test

in Dual Ports topology. Available with IQS-8510B only.

Laser Off (grey): Indicates that the laser control is off. Pressing this button will

activate the laser immediately by emitting an optical laser signal. This button is

only available for optical interfaces. The laser is On by default when the test is

created unless otherwise set from the Default/Ethernet Test Preferences on

page 370.

Laser On (green): Indicates that the laser control is on. Pressing this button will

turn off the laser. This button is only available for optical interfaces. The laser is

On by default when the test is created unless otherwise set from the

Default/Ethernet Test Preferences on page 370. The laser control button is not

affected when turning off the laser by generating a LOS for example.

b

Favorites

: Provides access to 10 default or customer defined test case

configurations. See Favorites on page 48 for more information.

a. Only available when the test is running.

b. Only available when the test is not running (Stop).

46 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 61

Introducing the Smart User Interface

Global Test Status and Controls

Remote Status

Indicates whether the remote control feature is enabled/disabled and

indicates the number of connections established with the IQS-8500 Series

and IQS-8120NGE/8130NGE when enabled.

Indicates that the remote control feature is disabled. Refer to the

IQS-600 user guide for more information on how to enable it.

Indicates that a single connection is established with the IQS-8500

Series and IQS-8120NGE/8130NGE. The connection can be either

local (on the IQS-600) or remote (on a remote PC using Visual

Guardian Lite).

Indicates that at least two connections are established with the

IQS-8500 Series and IQS-8120NGE/8130NGE. Connections can be

a combination of one local (on the IQS-600) and at least one

remote connection (on a remote PC using Visual Guardian Lite),

two or more remote connections.

Date and Time

Indicates the date (YYYY-MM-DD) and time (HH:MM:SS).

Refer to Time Options on page 368 for more information on time format

and time zone.

AC Power

Indicates the presence of an AC power source.

Ethernet and Fibre Channel Application 47

Page 62

Introducing the Smart User Interface

Favorites

Favorites

Favorites gives access to 10 factory test case configurations. Favorites is

available when no test is running.

Press .

Favorites List

Allows to select a test case configuration. The test case configuration

selected by default is the first one in the list.

Note: Test cases not supported by the current IQS-8500 Series and

IQS-8120NGE/8130NGE model and its options will not be created.

Note: Favorites may or may not be compatible from one version of software to

another. They also may or may not be compatible from one module to

another depending on the hardware and software option installed.

48 FTB-8500 Series and FTB-8120NGE/8130NGE

Page 63

Introducing the Smart User Interface

Favorites

Overwrite Selected Favorite Content

The factory test case configurations can be modified as well as their

default names.

Favorite Name: Allows changing the name of the test case

configuration file. A maximum of 32 characters are allowed in the

name.

Save: Saves the current test case configuration using the specified

favorite name.

Load